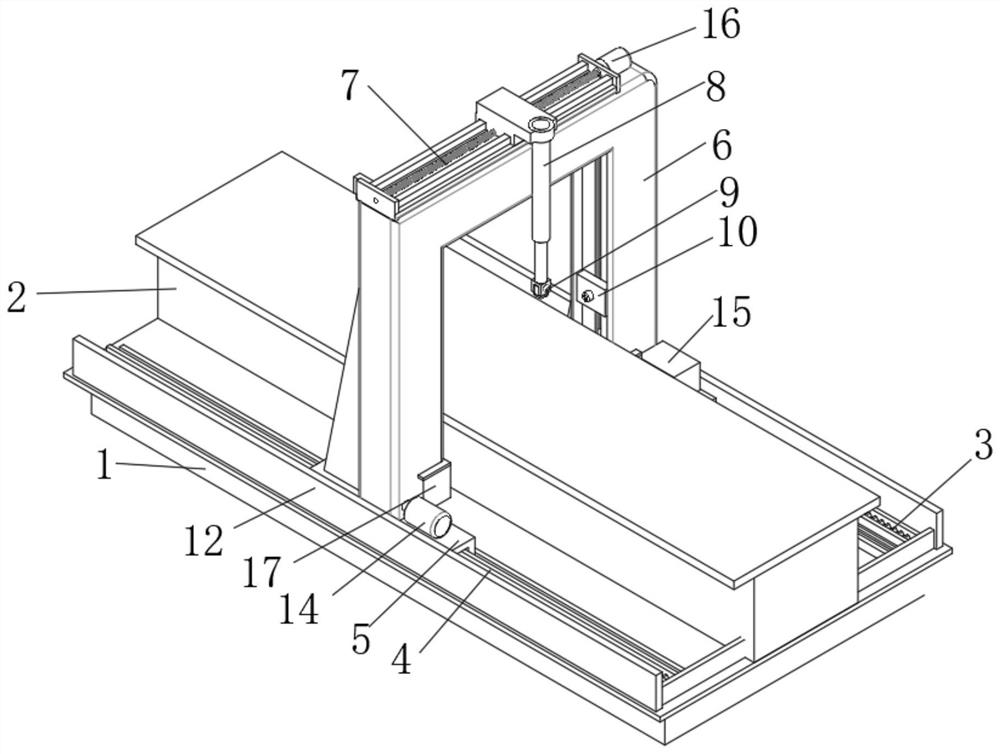

Portal type intelligent welding robot based on visual and three-dimensional model recognition

A welding robot, three-dimensional model technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor application effect, and achieve the effect of improving stability, enhancing practicability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

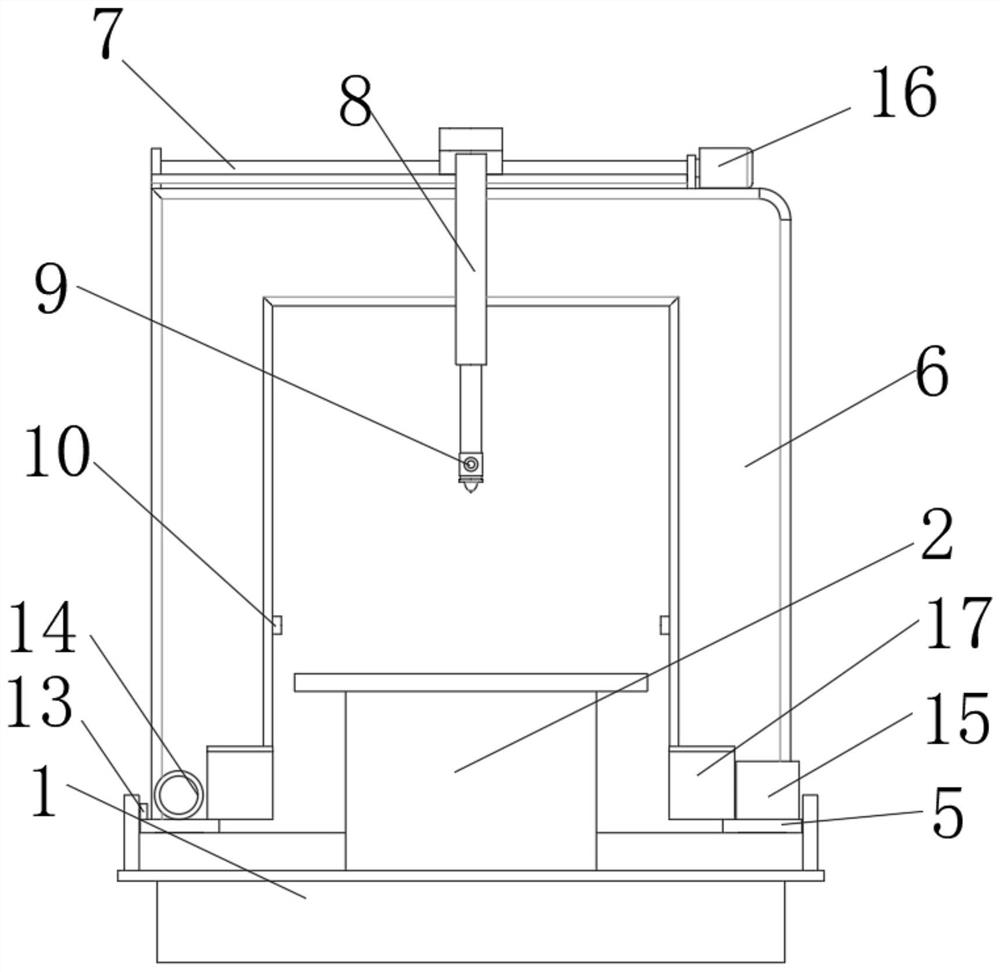

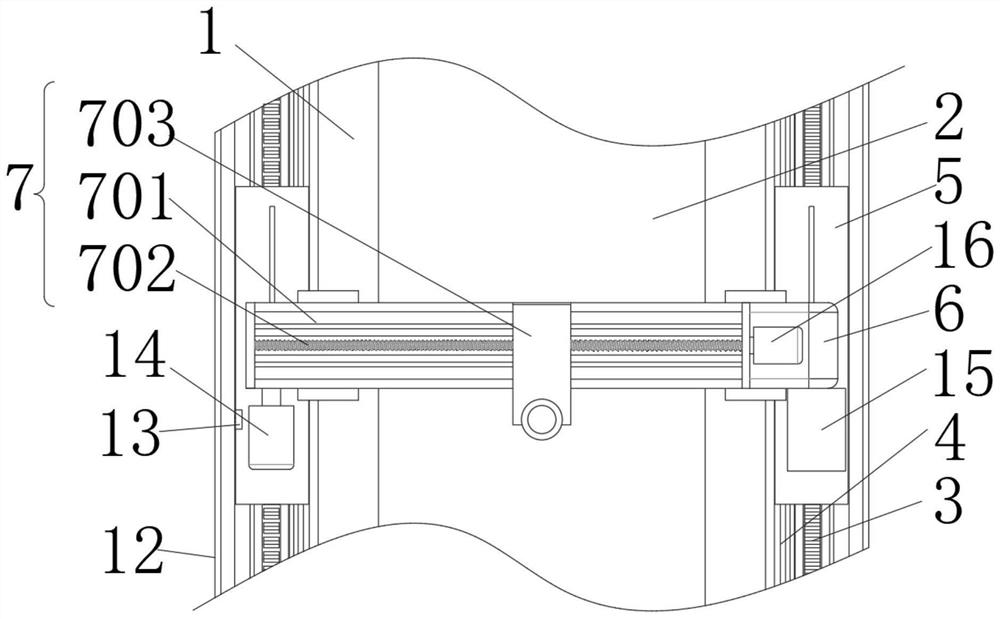

[0041] Such as Figure 1-7 As shown, the embodiment of the present invention provides a gantry-type intelligent welding robot based on vision and three-dimensional model recognition, including a base 1, a welding table 2 and a working method, and is characterized in that: the upper middle part of the base 1 is fixedly connected with a welding table 2, Both sides of the top of the base 1 are fixedly connected with fixed slide rails 3, the top of the base 1 is fixedly connected with a rack 4 in the middle of the two fixed slide rails 3, and the top of the two fixed slide rails 3 is slidably connected with a sliding seat 5. The upper middle of the two slides 5 is fixedly connected with the gantry 6, and the upper end of the gantry 6 is fixedly connected with the horizontal axis drive motor 16, and the upper end of the two slides 5 close to the end of the horizontal axis drive motor 16 is above the slide 5 The central part is fixedly connected with a server 15;

[0042] A positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com