Stainless steel thin-wall pore-free laser welding method

A technology of laser welding and stainless steel, which is applied in the direction of laser welding equipment, welding equipment, workpiece edge, etc., can solve the problems of easy access to the melting zone, formation of pores, poor casting performance, etc., and achieve good manufacturability, convenient processing, and welding process high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Stainless steel thin-walled non-porous laser welding method;

[0027] 1, Stainless steel Wall thickness 3mm≥δ≥0.5mm, no filler material in the weld;

[0028] 2. Welding process parameters: pulse width 1~3ms, frequency 40~50Hz, single point energy 5~7J, power 2.5~3.5kW, Speed 5~12mm / s ;

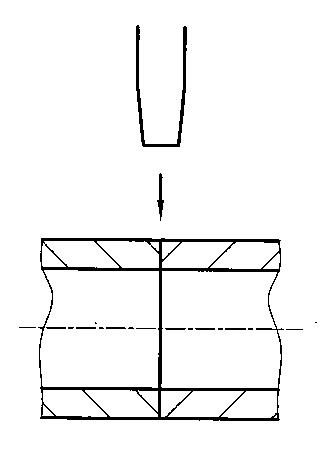

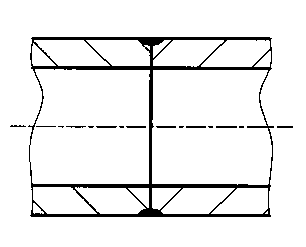

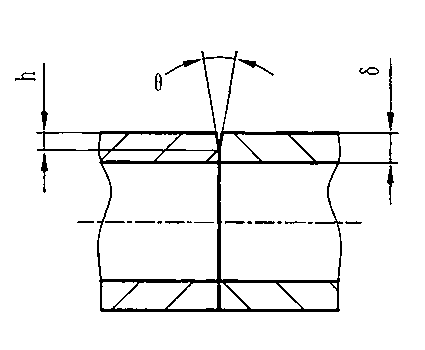

[0029] 3. Groove opening: outer ring butt weld or plane butt weld, groove opening is attached image 3 V-shape shown, or bevel opening as Figure 4 The inter-trough shape shown;

[0030] Groove angle θ=15°~20° or groove width between grooves a=0.1~0.2mm, depth h=0.5~2mm.

[0031] See attached table 2 and 3 for specific examples.

[0032] Schedule 1

[0033]

[0034] Schedule 2

[0035]

[0036] Schedule 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com