Lithium battery cap linear laser welding device and welding method thereof

A linear laser and welding device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, high labor cost, and many manual work procedures, so as to improve efficiency, reduce labor cost, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

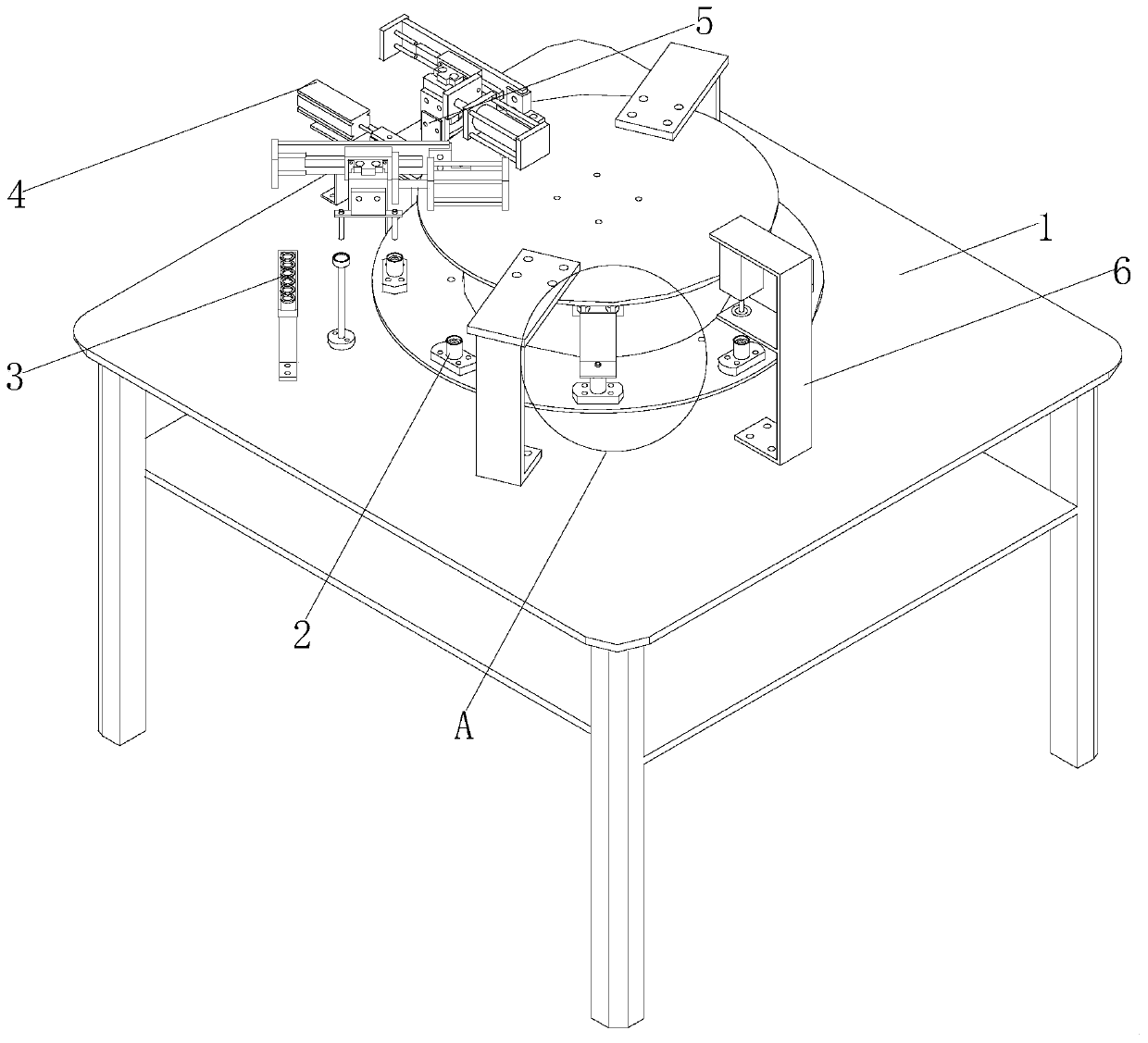

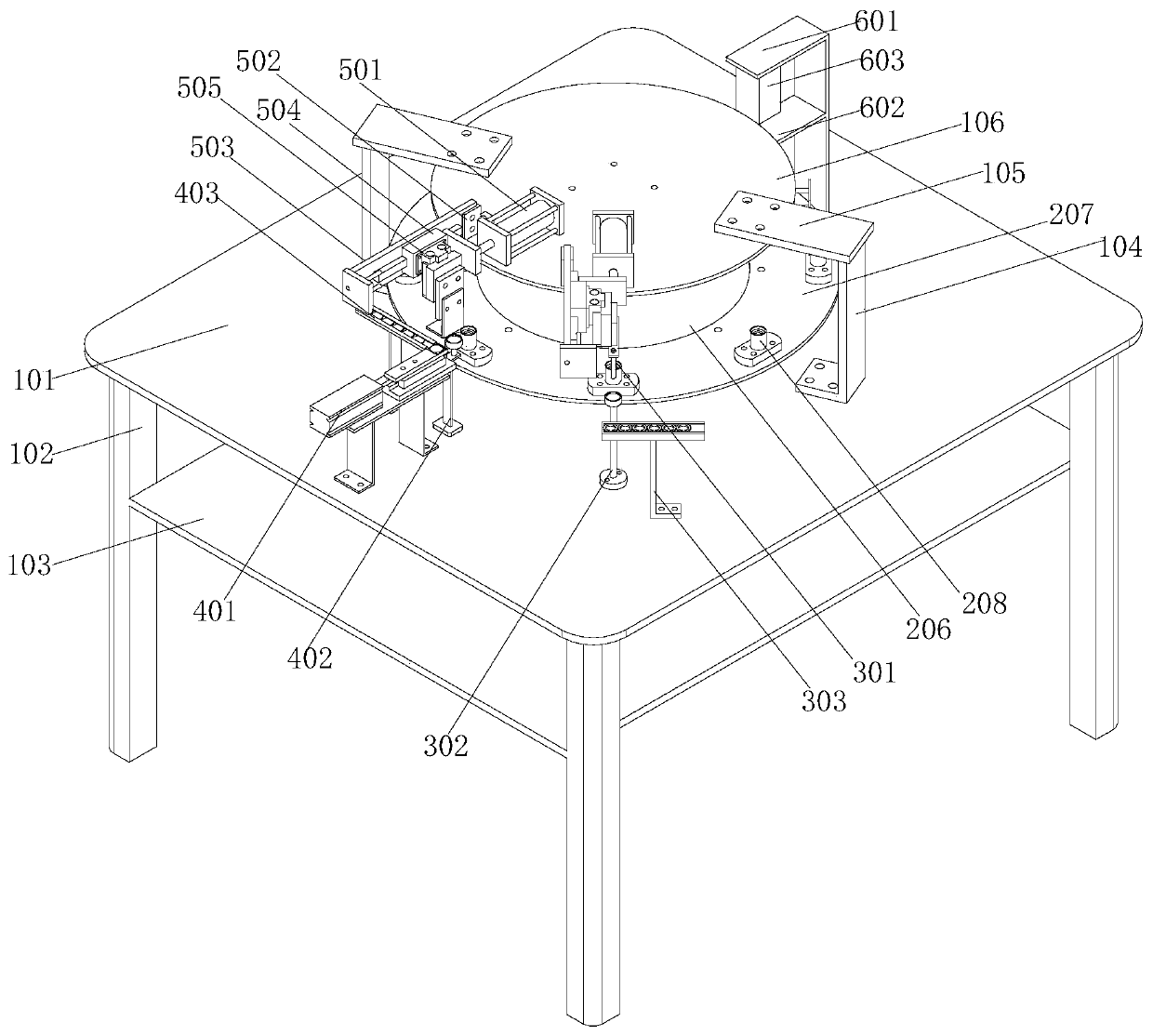

[0043] see Figure 1-7 , the present invention provides the following technical solutions: a linear laser welding device for lithium battery caps, comprising:

[0044] Frame 1, the frame 1 includes a workbench 101, four support legs 102 are fixedly installed on the bottom of the workbench 101, support plates 103 are fixedly installed on the inside of the four support legs 102, and two support plates 103 are fixedly installed on the top of the workbench 101 Upright blocks 104, fixed blocks 105 are fixedly installed on the tops of the two upright blocks 104, and top plates 106 are fixedly installed on the bottoms of the two fixed blocks 105.

[0045] The turntable mechanism 2, the turntable mechanism 2 is fixed on the frame 1, and is used to drive the finished cap and parts thereof to rotate.

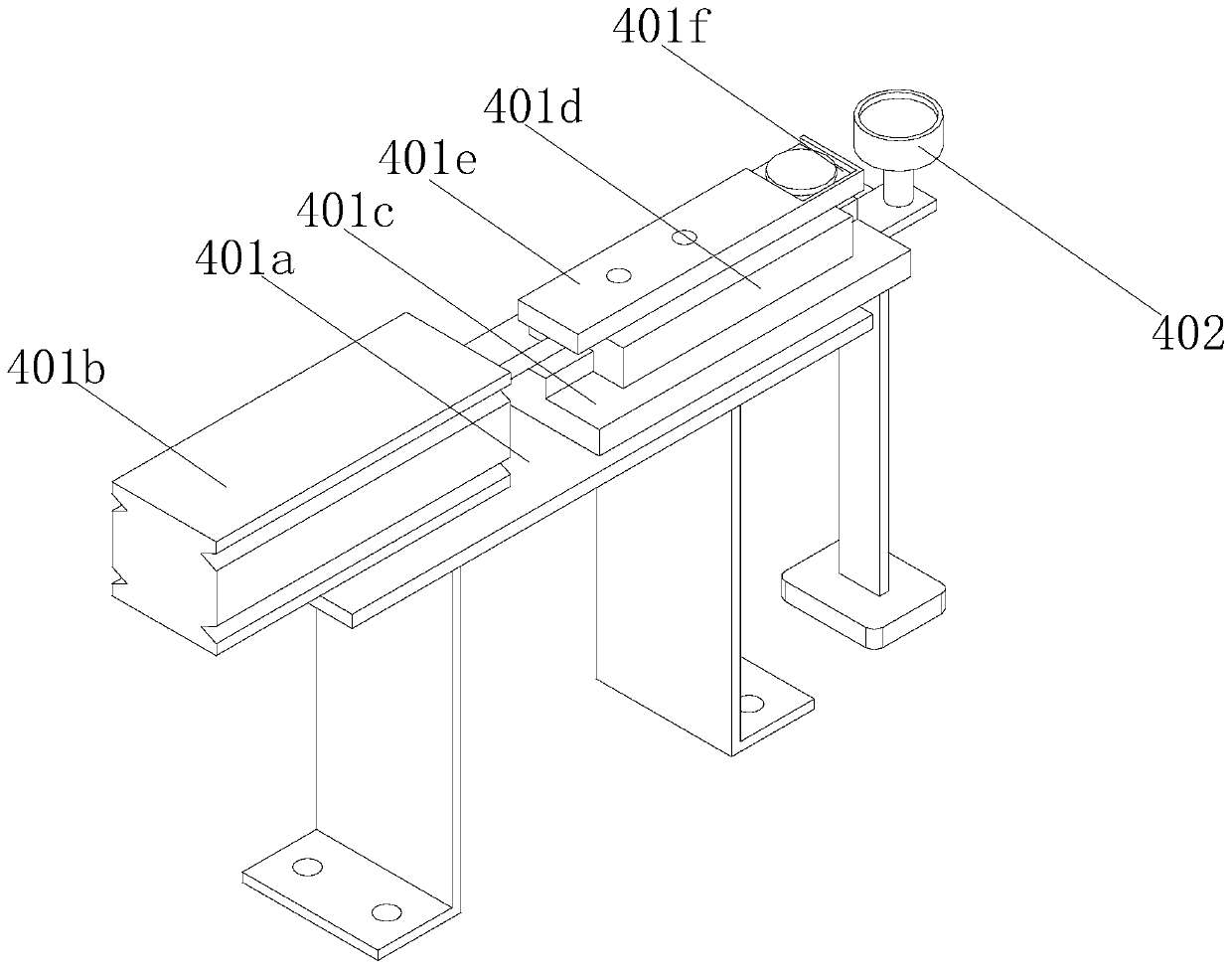

[0046] Orifice plate feeding mechanism 3, orifice plate feeding mechanism 3 is made up of orifice plate adsorption mechanism 301, orifice plate transfer mechanism 302 and orifice plate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com