Patents

Literature

224results about How to "Flexible lifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lifting platform for electric power overhaul

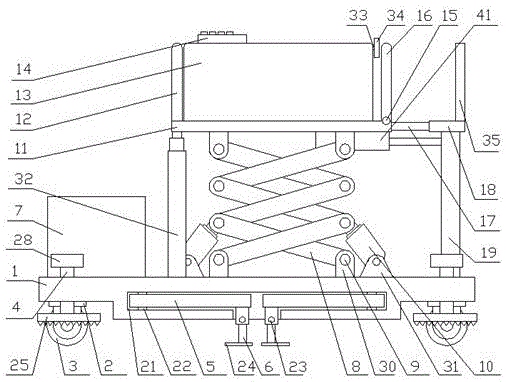

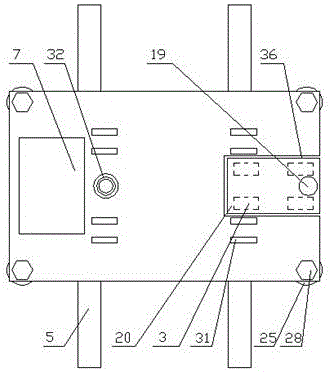

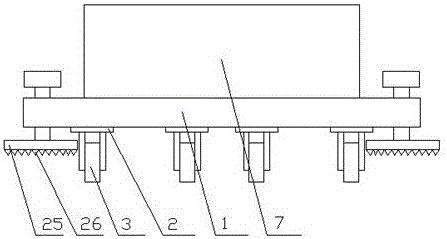

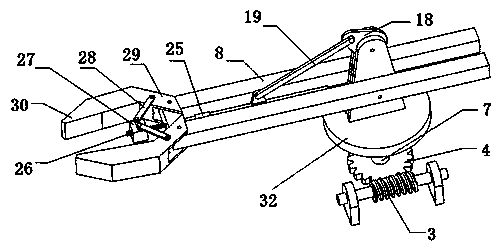

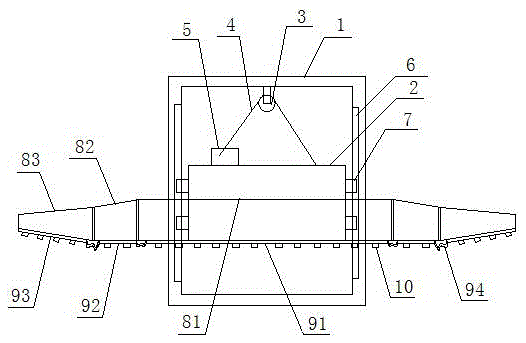

The invention discloses a lifting platform for electric power overhaul. The lifting platform comprises a device base. Support arms are hinged to the two sides of the device base. A lifting rack is arranged in the middle of the device base and matched with a set of lifting oil cylinders arranged on the device base. A lifting platform body is arranged on the lifting rack. Side guard bars are arranged at the two sides of the lifting platform body correspondingly. A controller is arranged on one of the side guard bars. The other end of the lifting platform body is hinged to a step plate guard bar through a pin shaft. The lifting platform body is connected with an extension rack through an extending-and-contracting rod and an extending-and-contracting oil cylinder. The lower portion of the extension rack is connected with a movable vehicle through a support pillar. The lifting platform for electric power overhaul can ascend and descend flexibly; the lifting platform body can be extended, the working area of the lifting platform body is expanded, and overhaul personnel can obtain a larger activity space; much convenience is provided for electric power overhaul; and meanwhile, the device base can be in stable contact with the ground without sliding, so that safety is high.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

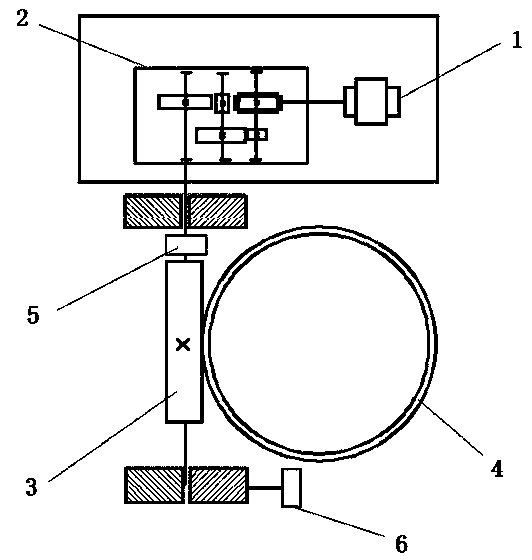

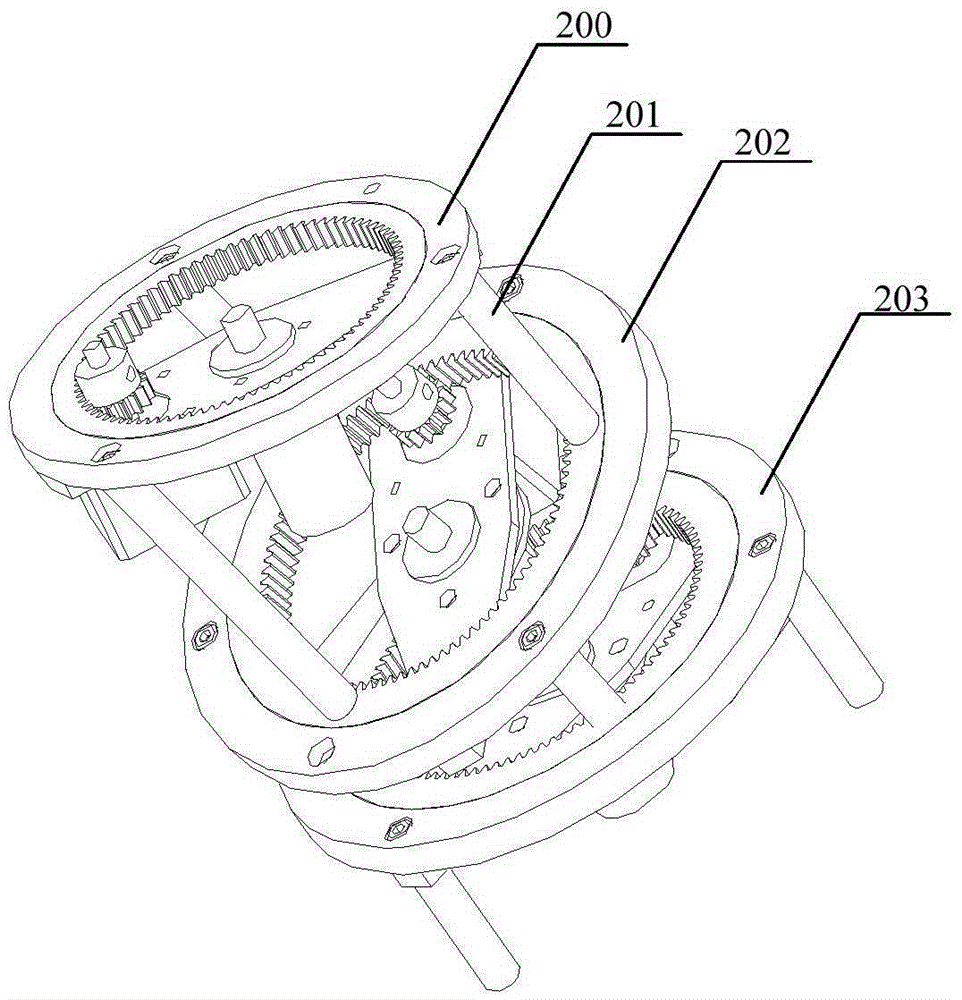

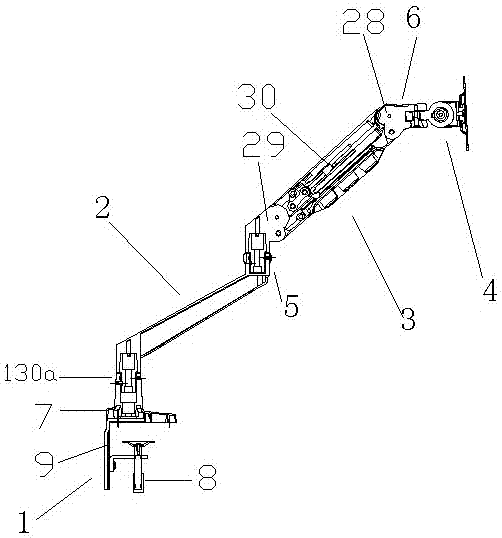

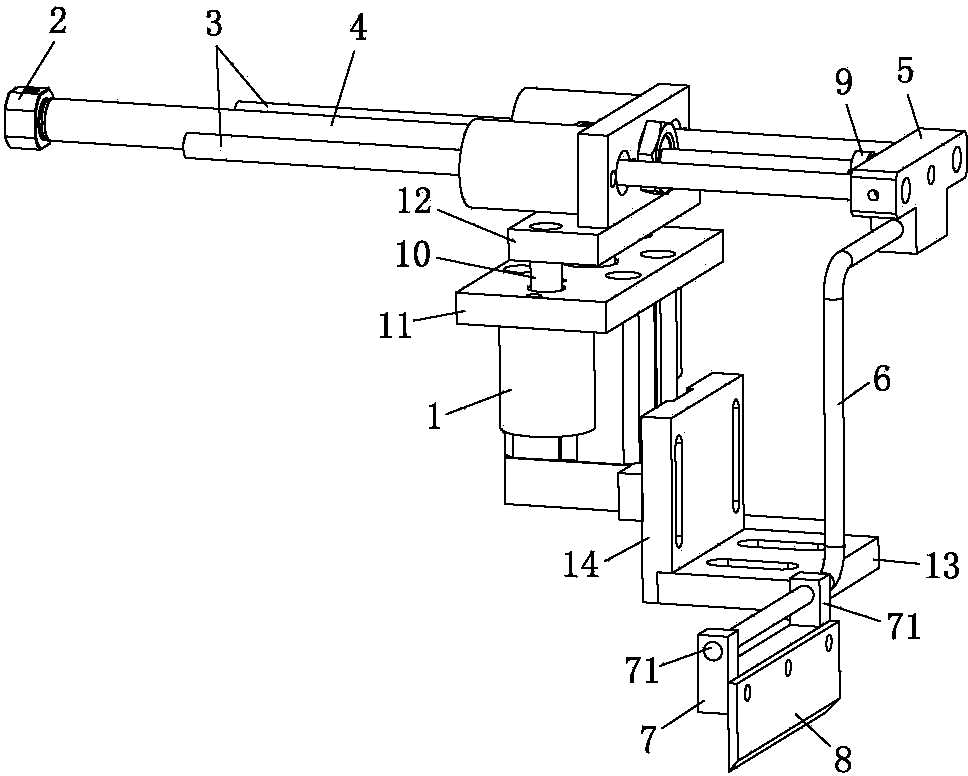

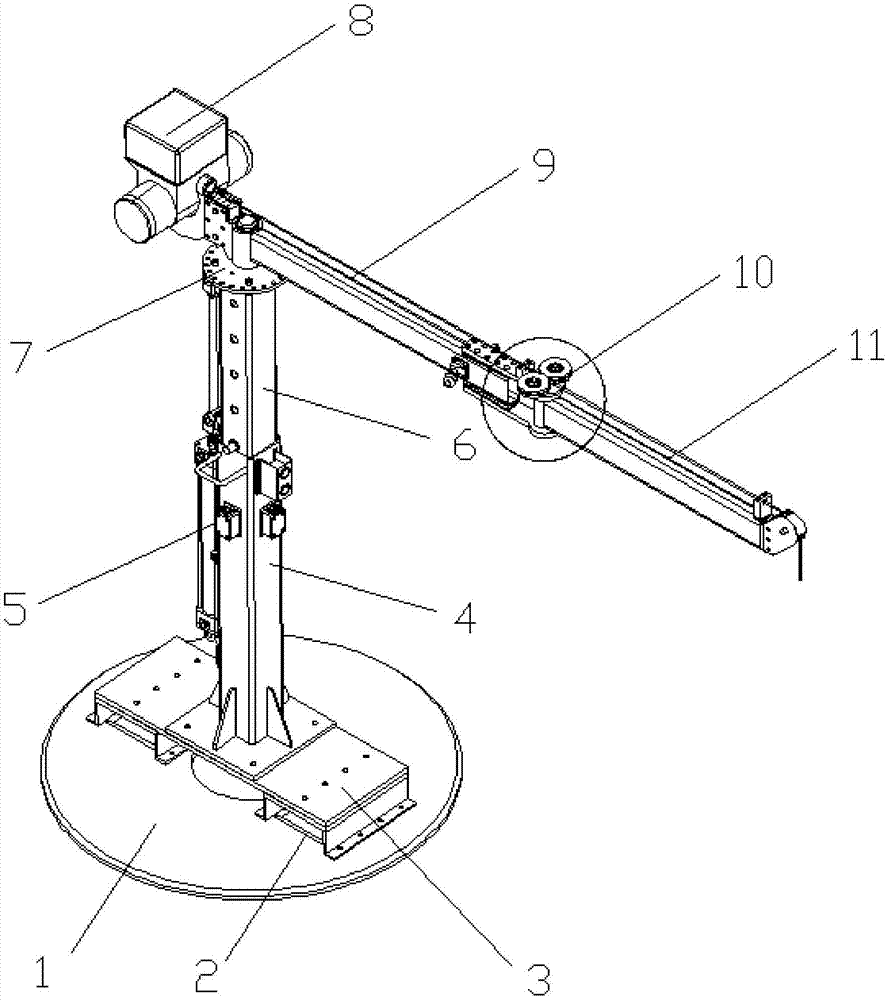

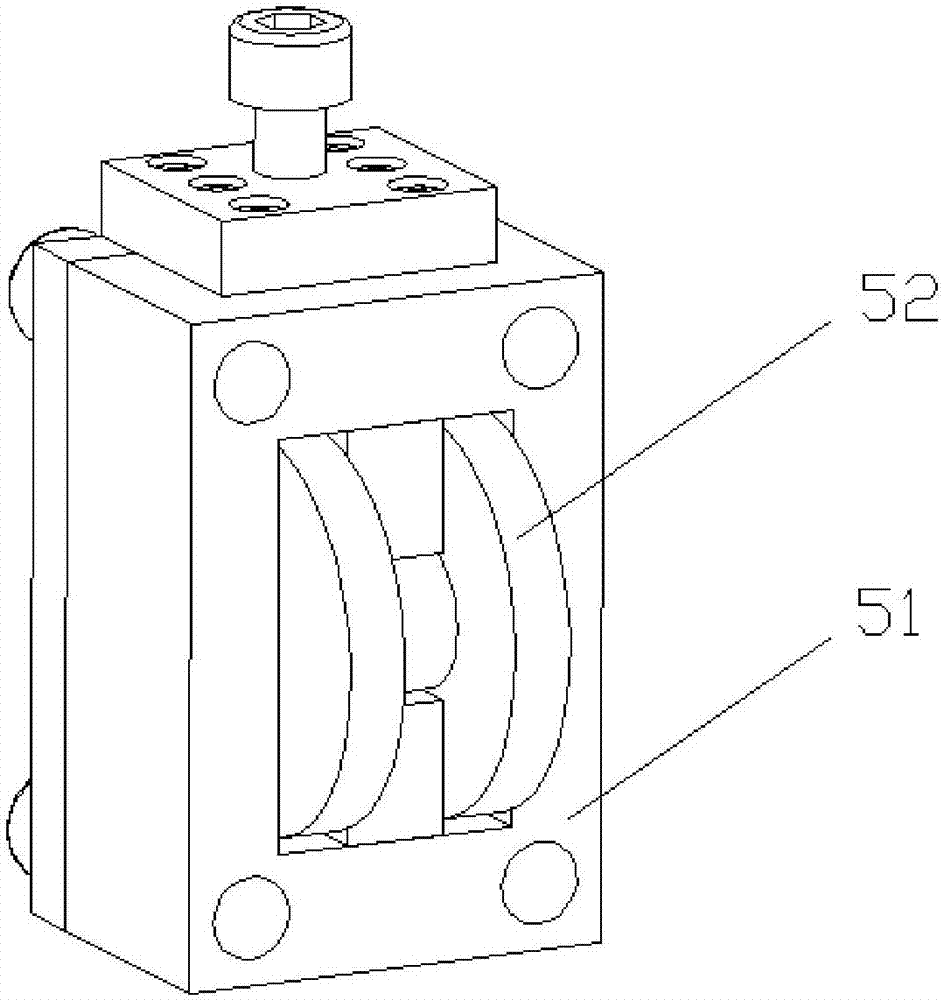

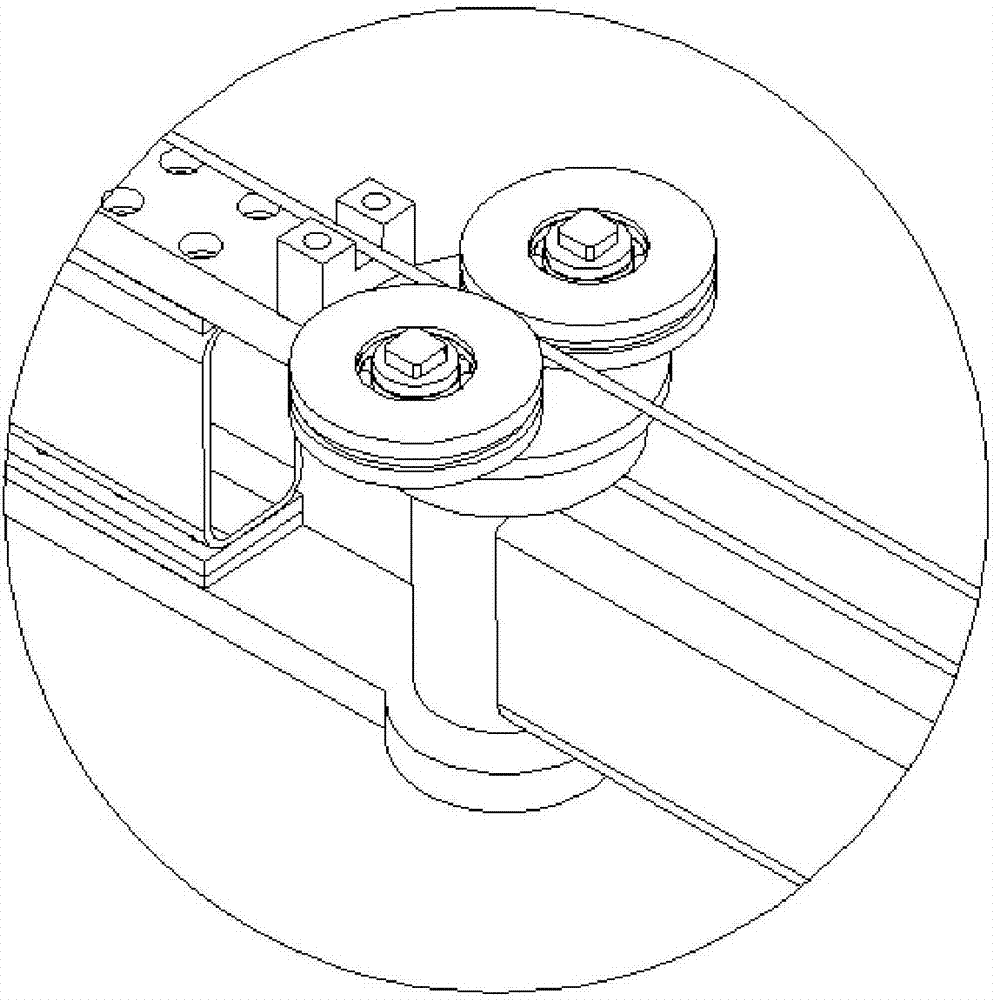

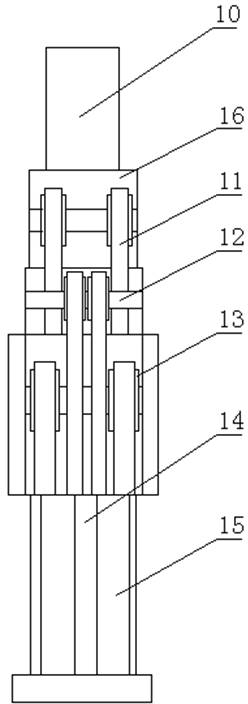

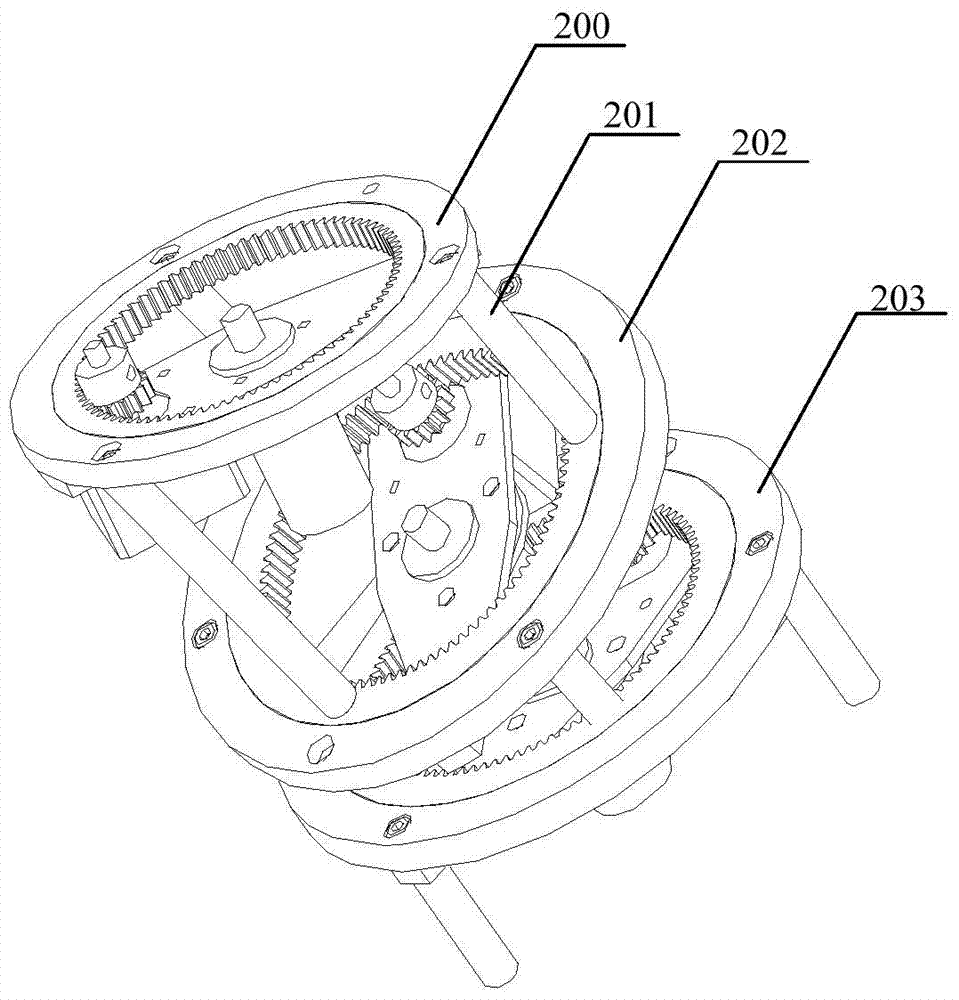

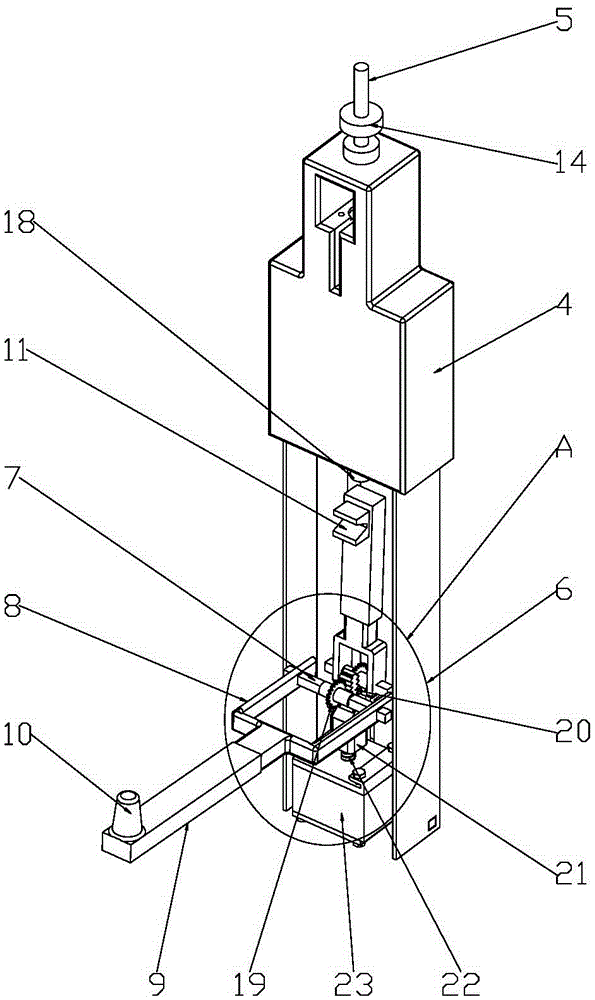

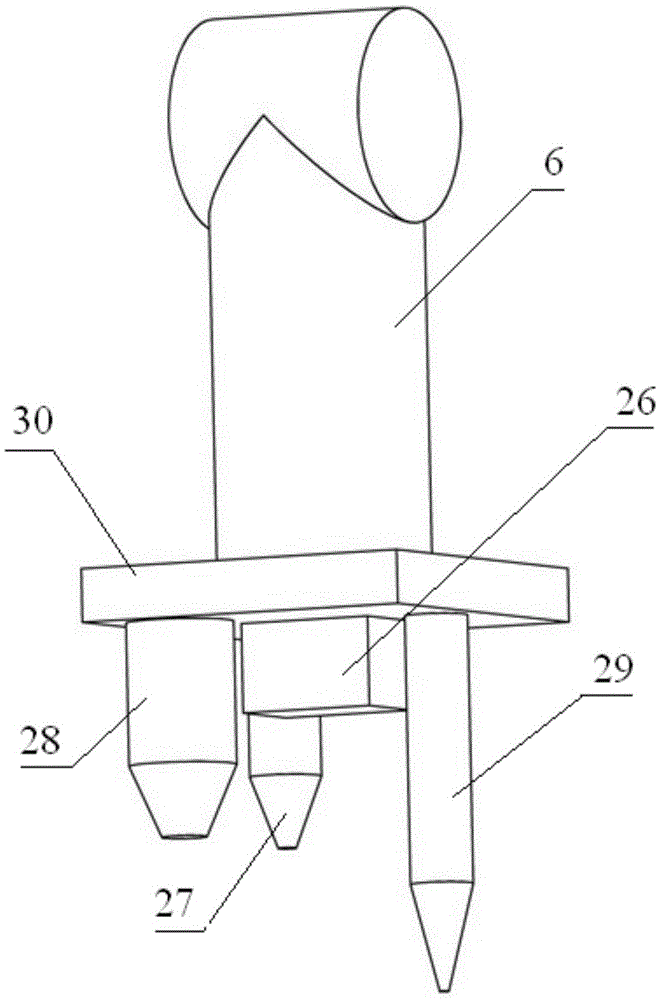

Three-freedom degree manipulator

InactiveCN103878763AStrong wear resistanceFlexible liftingProgramme-controlled manipulatorGripping headsDegrees of freedomEngineering

The invention relates to the technical field of mechanical automation, in particular to a three-freedom degree manipulator which is formed by a base assembly, an arm assembly and a gripper assembly. The arm assembly is arranged on the base assembly, and the gripper assembly is arranged at the end of the arm assembly. The three-freedom degree manipulator has the advantages that a three-freedom degree manipulator work station can be applied to automatic meal delivery of the catering industry and mechanical principle and designed experiment practical teaching of colleges and universities, and the automation degree reaches the international advanced level; the base assembly, the arm assembly and the gripper assembly are installed as a set, a mechanical structure is high in abrasion resistance, and the manipulator is safer and more reliable in operation.

Owner:JIANGSU UNIV

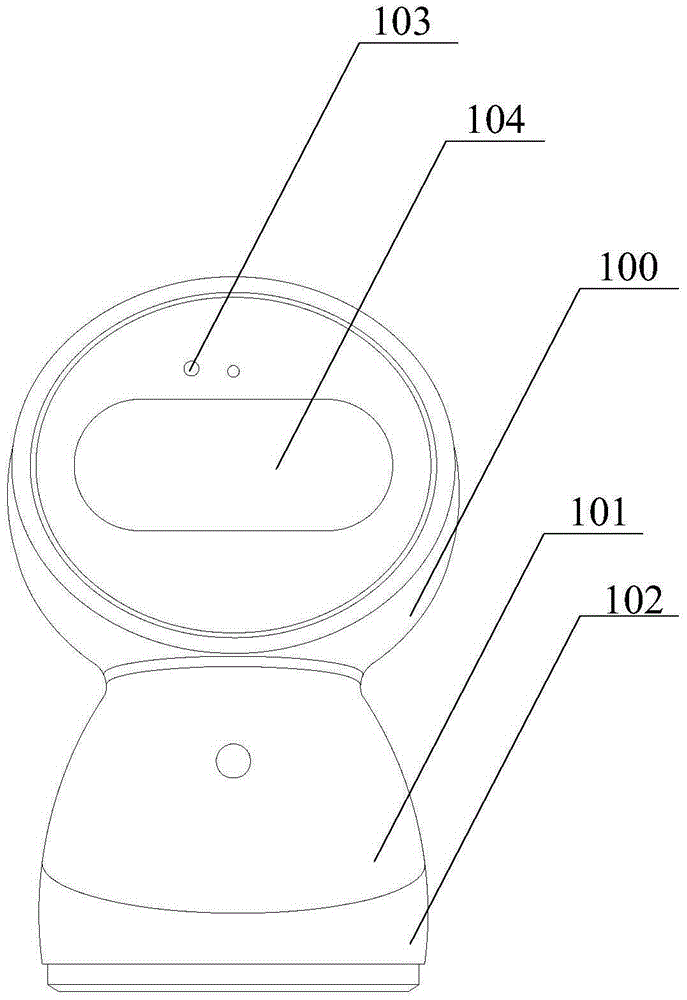

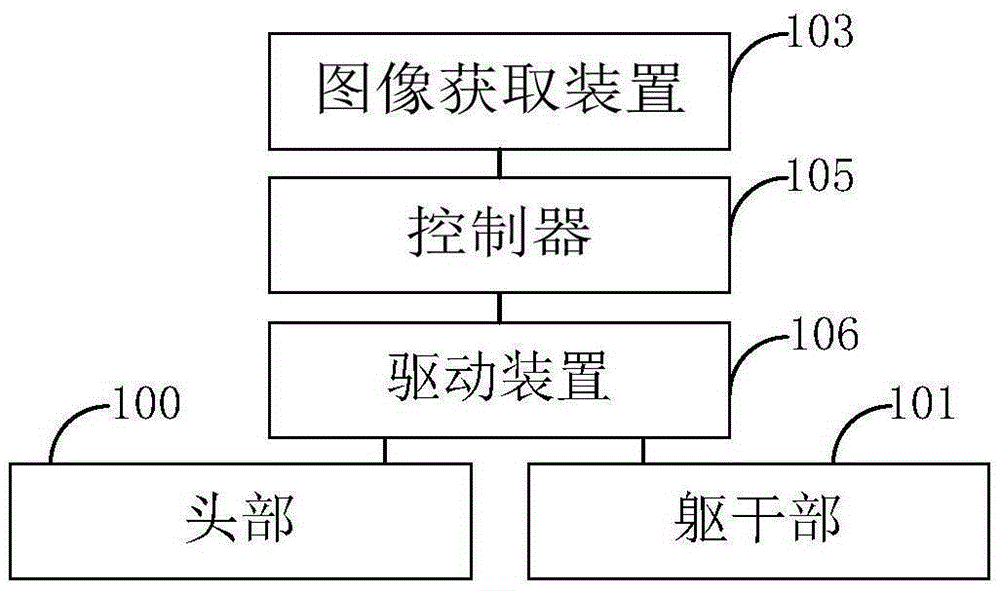

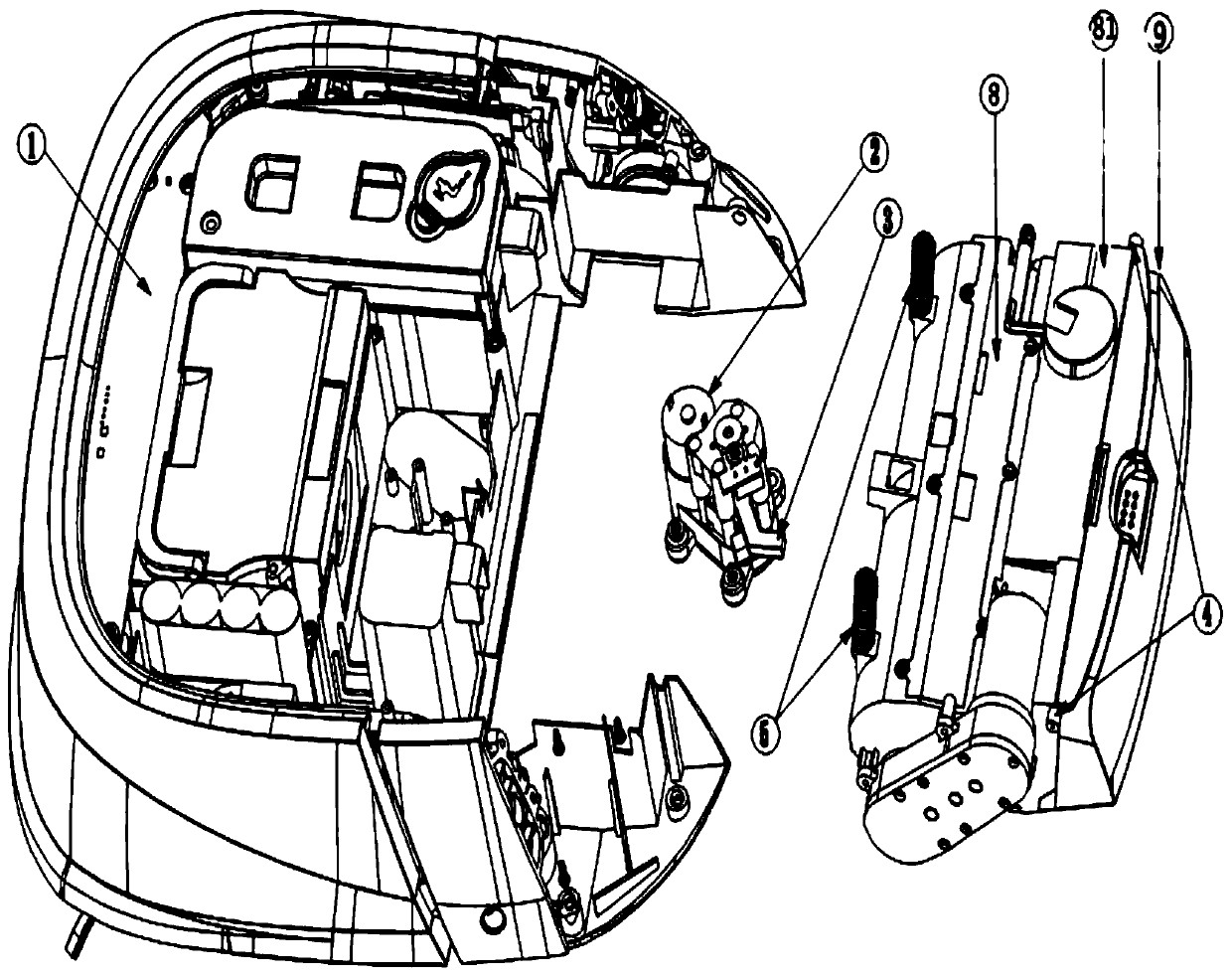

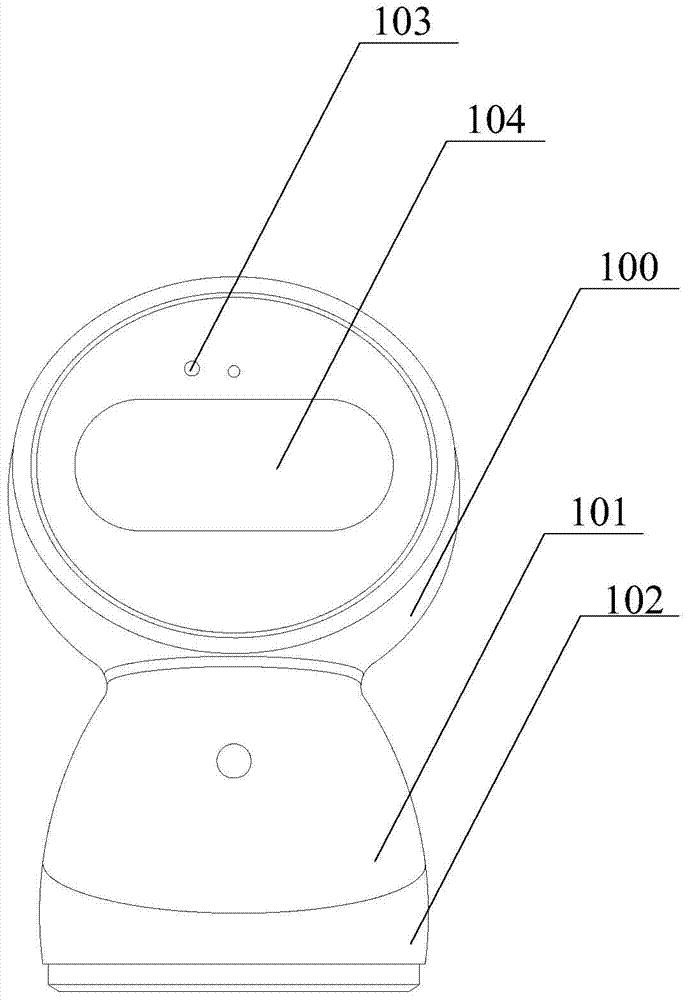

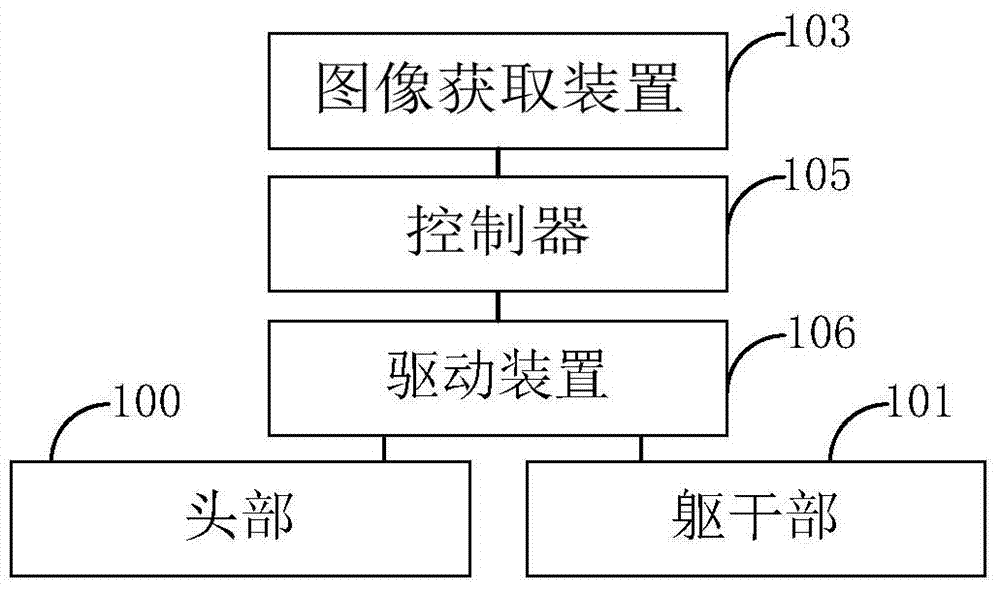

Intelligent robot

The embodiment of the invention provides an intelligent robot for solving the problem that in the prior art, the intelligent degree of an intelligent robot needs to be improved. The intelligent robot comprises a head, a body connected with the head, a base connected with the body, an image obtaining device for obtaining image data, a controller for analyzing the image data obtained by the image obtaining device to obtain analysis data, matching the analysis data with at least one preset datum and sending a corresponding movement instruction to a driving device when the analysis data are matched with at least one of the preset data, and the driving device for controlling at least one of the head and the body to rise and fall or rotate according to the movement instruction sent by the controller. By means of the intelligent robot, the intelligence degree of the intelligent robot can be increased, implementation is convenient, and application and popularization are easy.

Owner:成都英博格科技有限公司

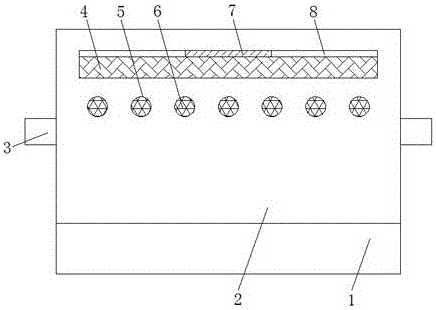

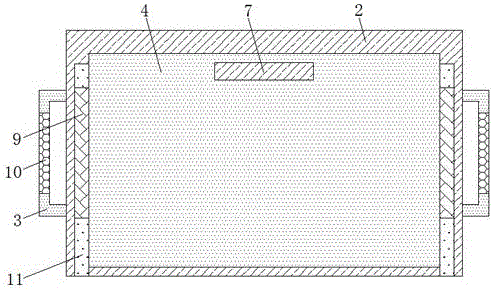

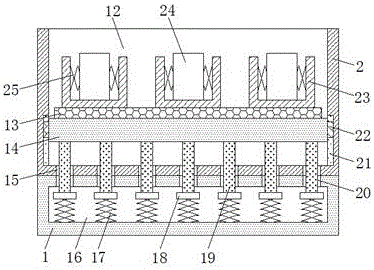

Battery holder for new energy automobile with damping function

InactiveCN106784506AWith shock absorption functionGuaranteed service lifeSecondary cellsCell component detailsDamping functionNew energy

The invention discloses a battery holder for a new energy automobile with a damping function. The battery holder comprises a battery holder body, wherein a through groove is formed in the front surface of the battery holder body; an accommodating groove is formed in the top of the battery holder body; the through groove communicates with the accommodating groove; two symmetrical first sliding grooves are formed in the inner side wall of the accommodating groove and communicate with the first sliding groove and the through groove; a baffle plate matched with the accommodating groove is put into the accommodating groove and one side surface of the baffle plate is put into the through groove; the outer side surface of the baffle plate is fixedly connected with a first sliding block matched with the first sliding groove; and the first sliding block is clamped into the first sliding groove. According to the battery holder for the new energy automobile with the damping function, shaking force can be effectively buffered, the damping property is high, effective emission of internal heat of the battery holder body is ensured, dust can be effectively blocked, the protection effect is relatively good, bruise of a battery part is effectively avoided and the service life of a battery element is effectively ensured.

Owner:SHENGZHOU YIYUAN INVESTMENT MANAGEMENT

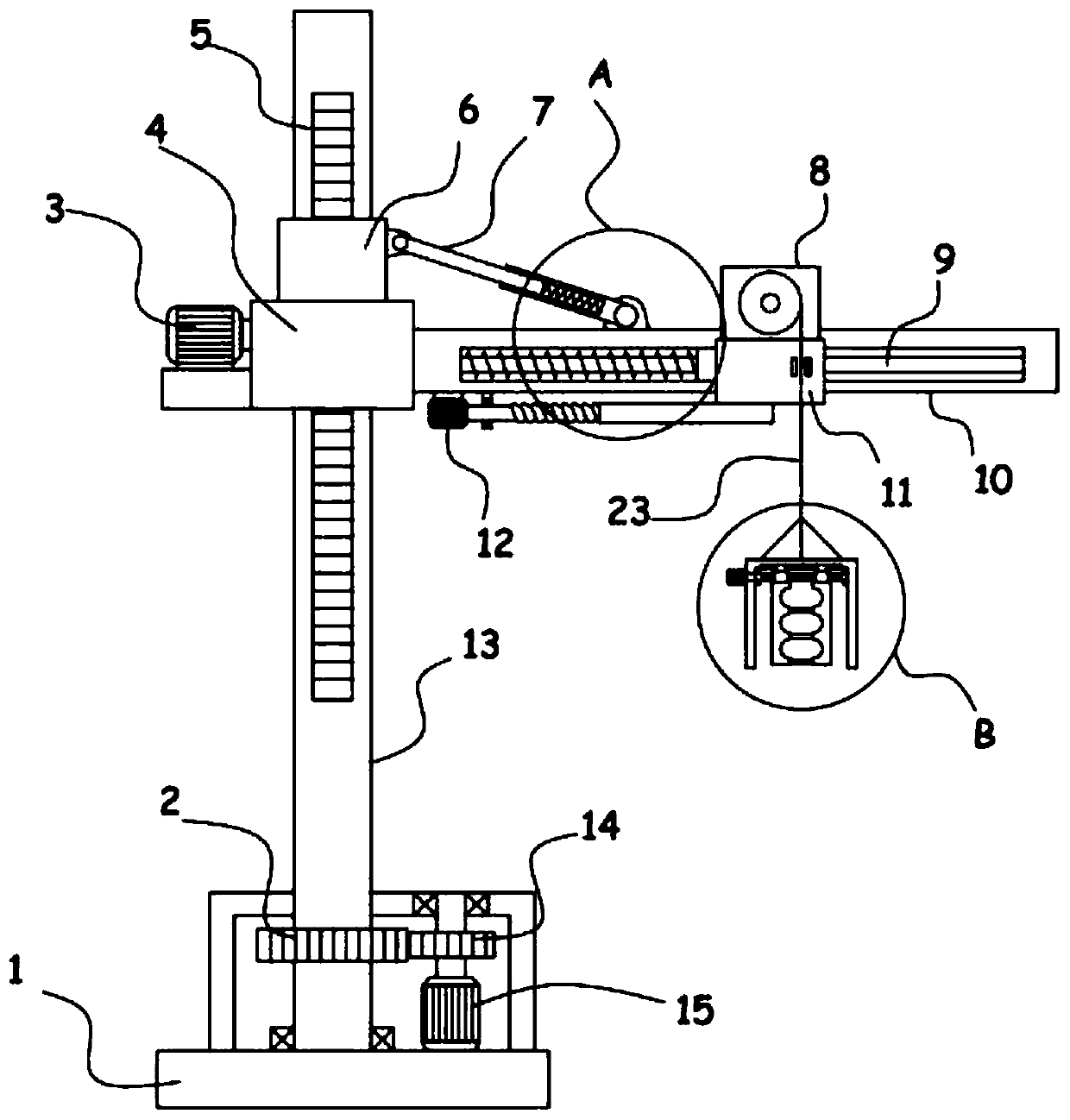

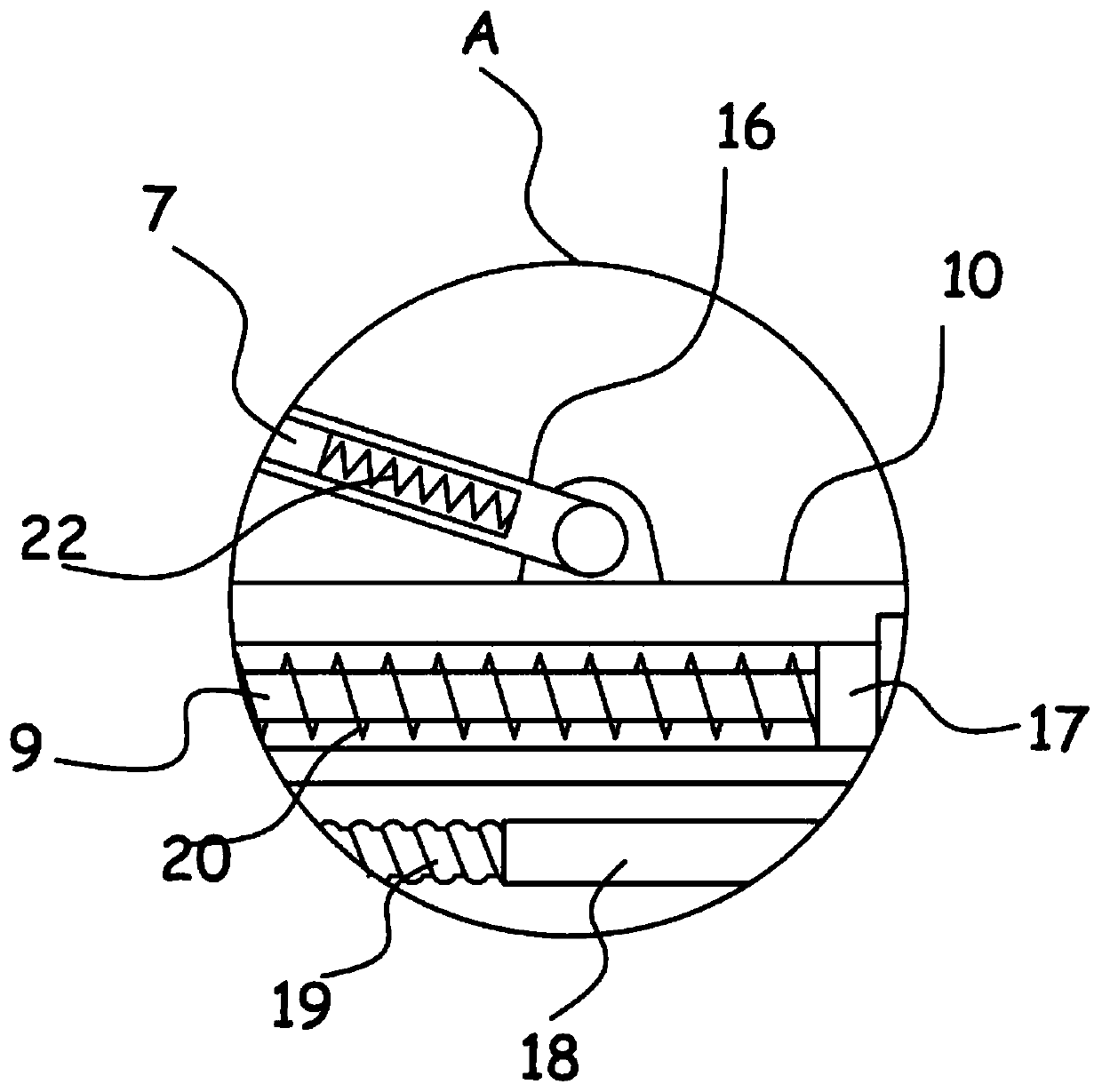

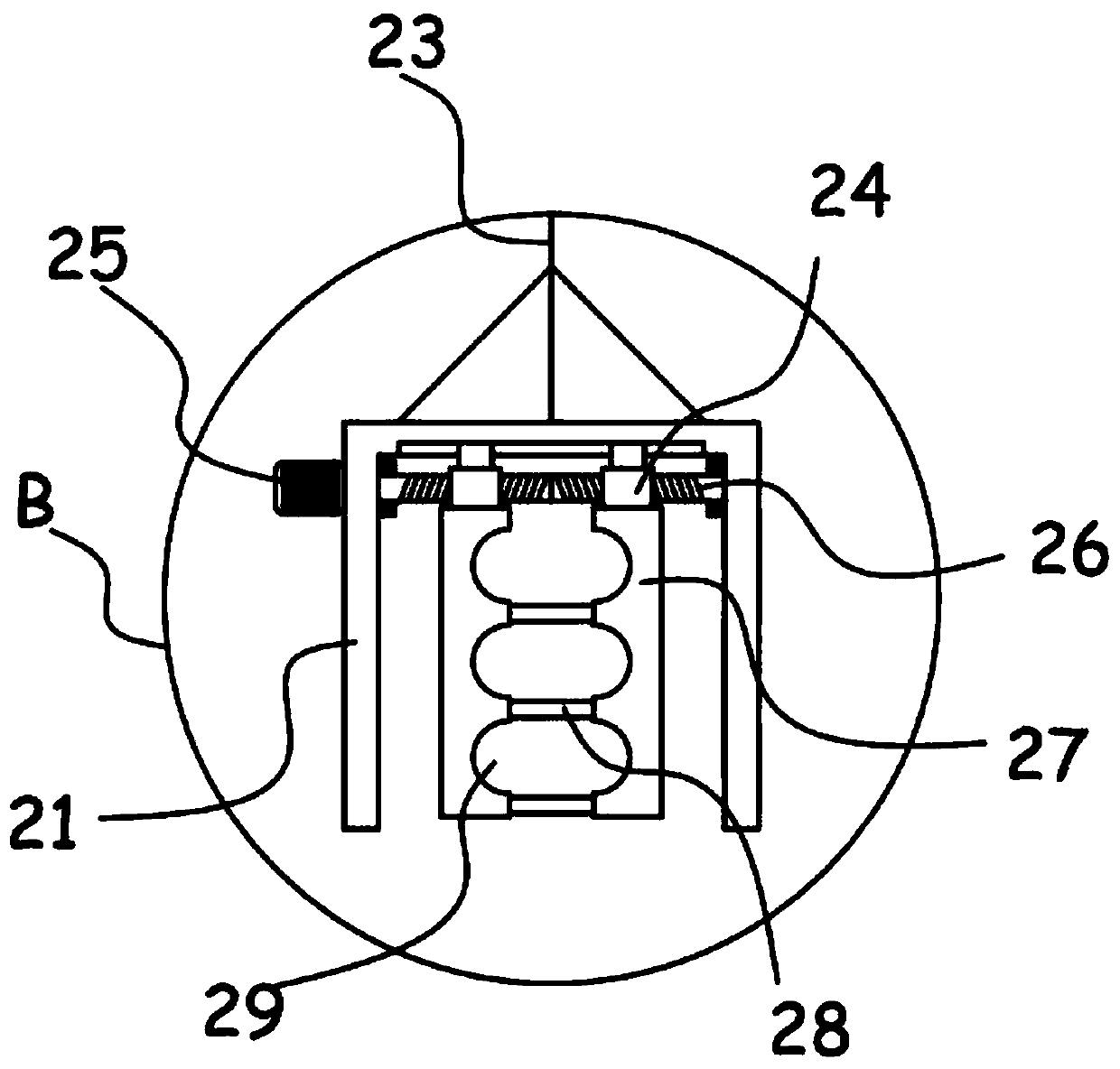

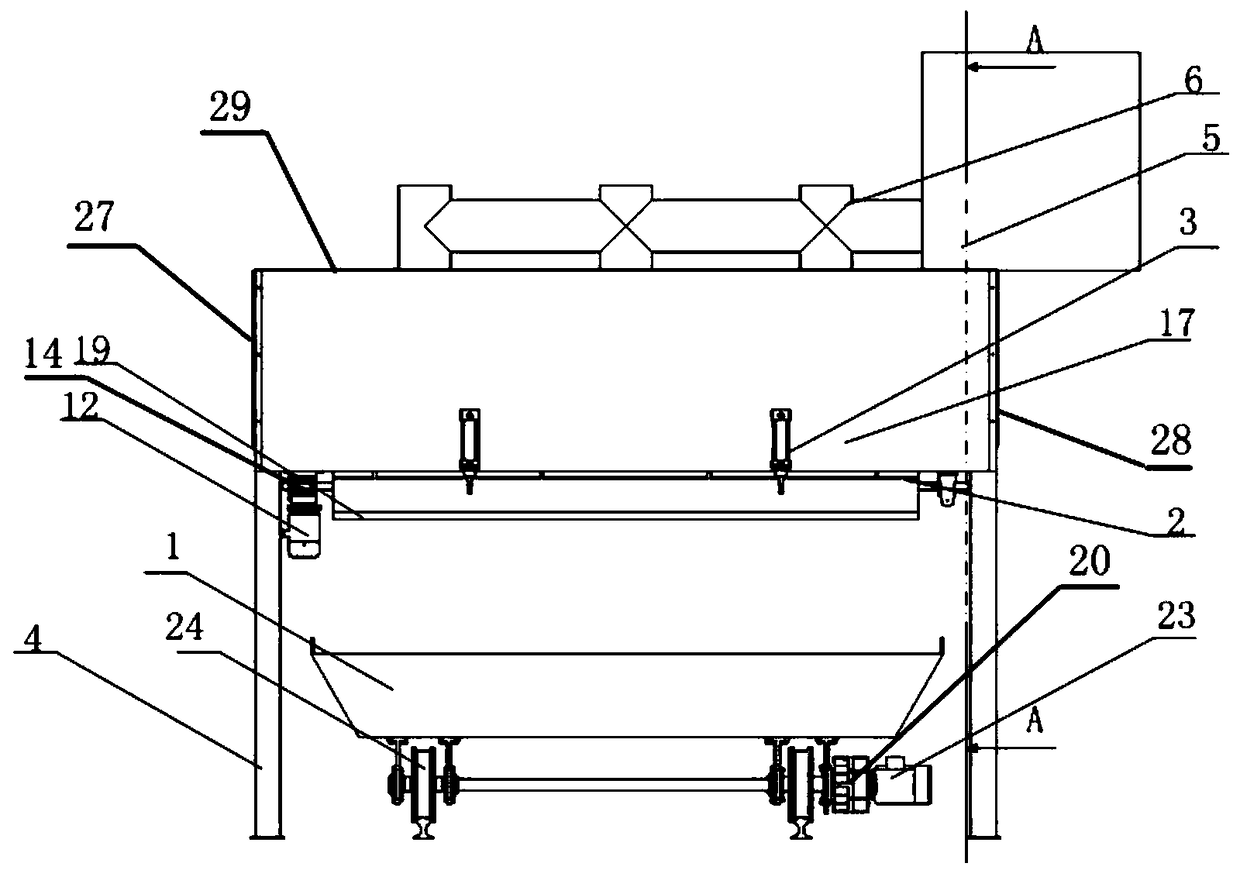

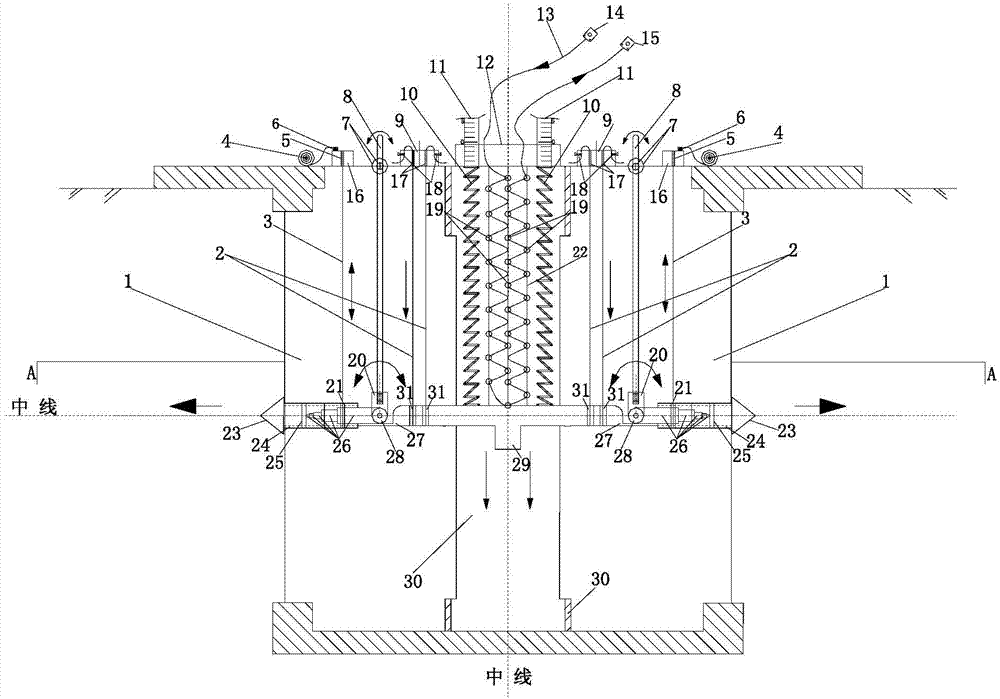

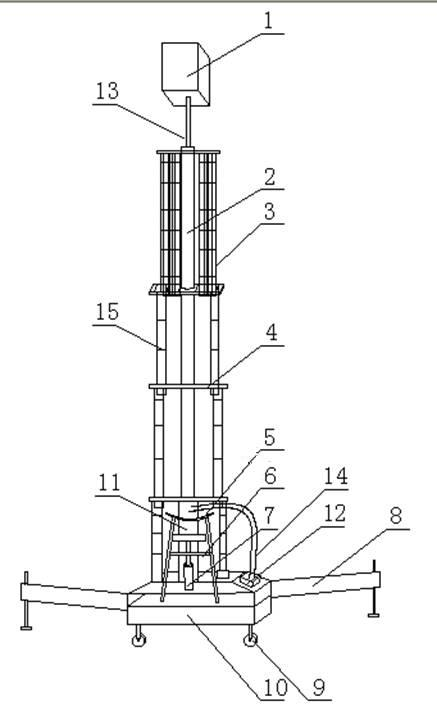

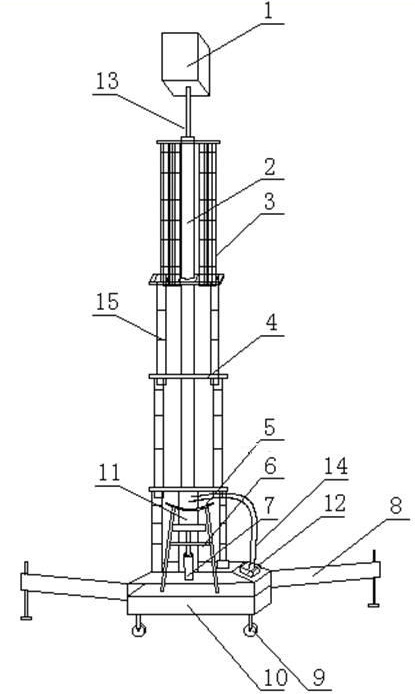

High-stability tower crane for pipes

InactiveCN111268557AFlexible liftingImprove work efficiencyTravelling gearCranesWire ropeMarine engineering

The invention discloses a high-stability tower crane for pipes, and relates to the technical field of pipe hoisting. The high-stability tower crane for the pipes comprises a bottom plate, a sliding frame driven by a translation mechanism is slidably mounted on a supporting plate, a damping guide mechanism is mounted between the sliding frame and the supporting plate, a machine frame is fixed at the lower end of a steel wire rope, and the machine frame is provided with a fixing mechanism used for clamping the pipes. According to the high-stability tower crane for the pipes, the pipes can be clamped and fixed through the arranged fixing mechanism, the stability of the hoisting process is guaranteed, an arranged lifting mechanism can drive the supporting plate to achieve flexible lifting at the vertical height, hoisting and carrying of the pipes are guaranteed, through an arranged stand column, the effect of turning the supporting plate to drive the fixing mechanism for circumferential position adjustment can be achieved, the translation mechanism can drive the fixing mechanism for transverse translation, efficient and flexible hoisting of the pipes is achieved, the working efficiencyis effectively improved, an elastic traction mechanism and the damping guide mechanism which are arranged can achieve an elastic damping effect in the hoisting process, and the hoisting stability ofthe pipes is remarkably improved.

Owner:徐州国联建机有限公司

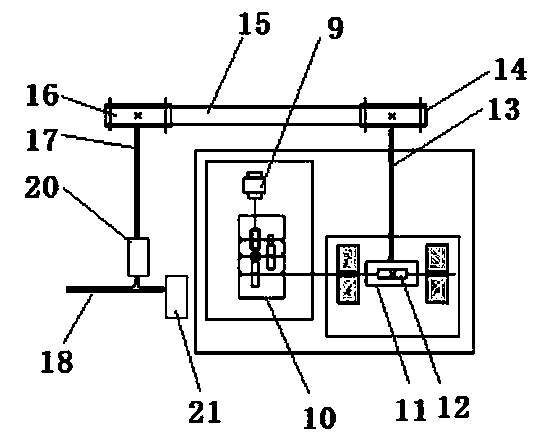

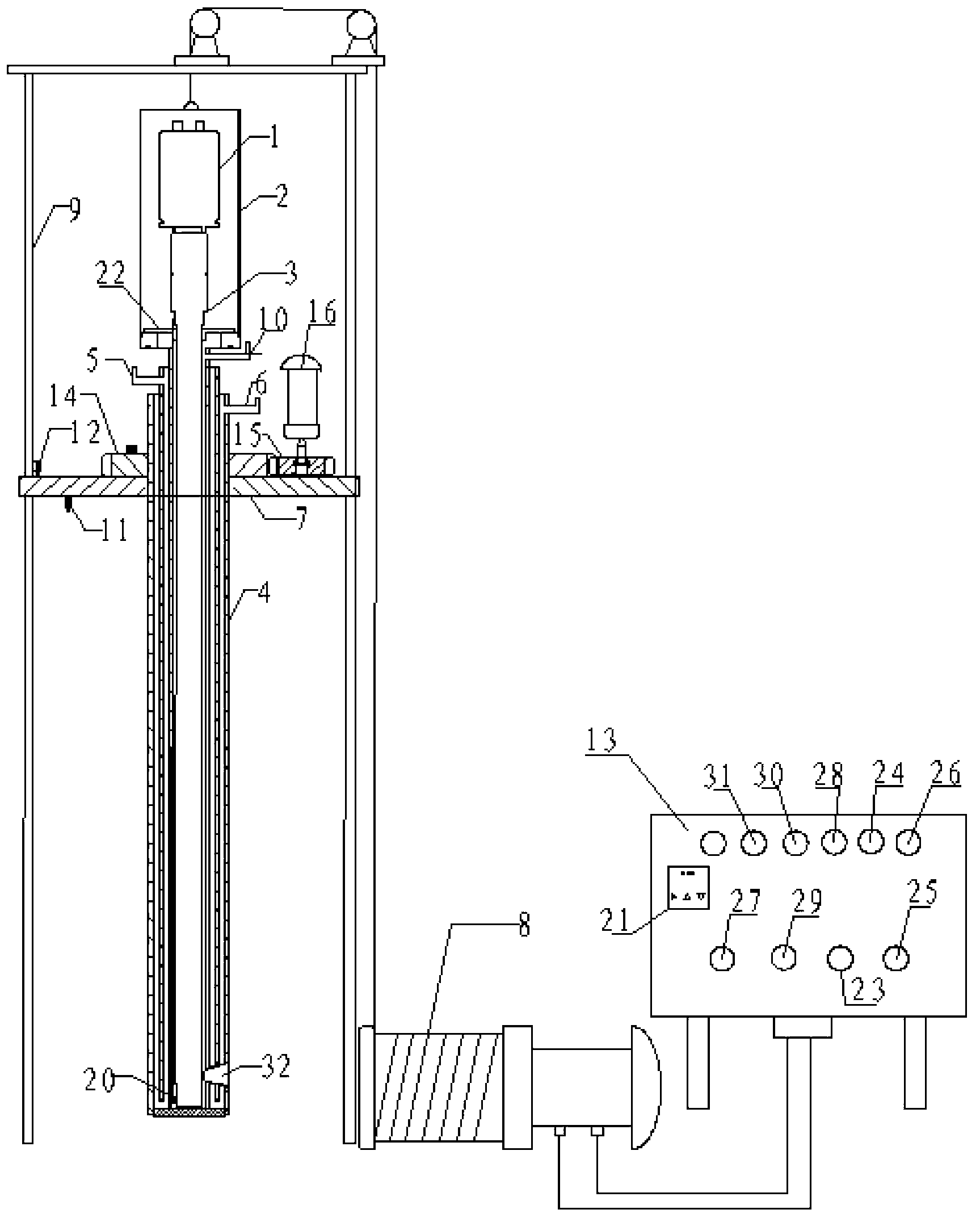

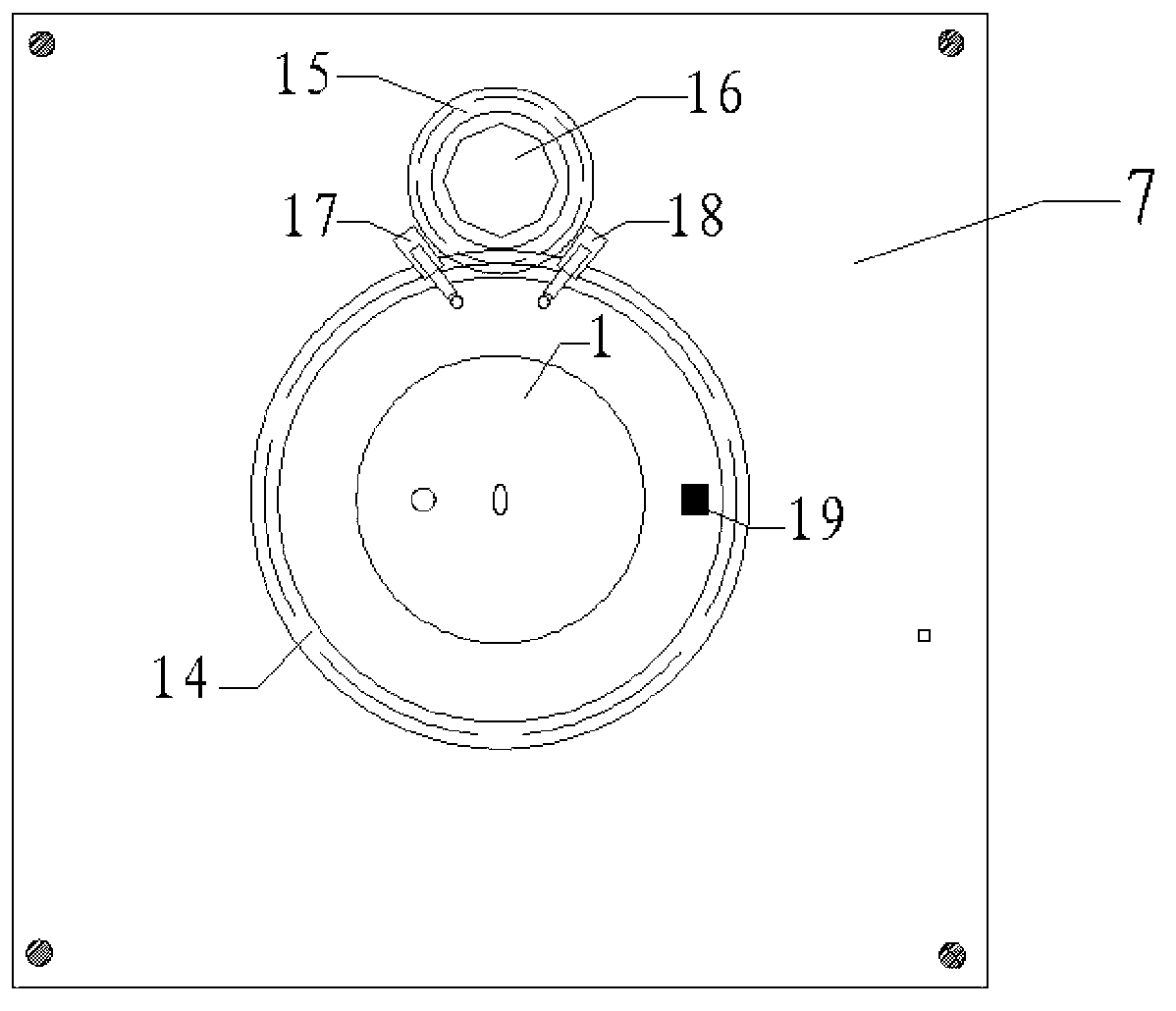

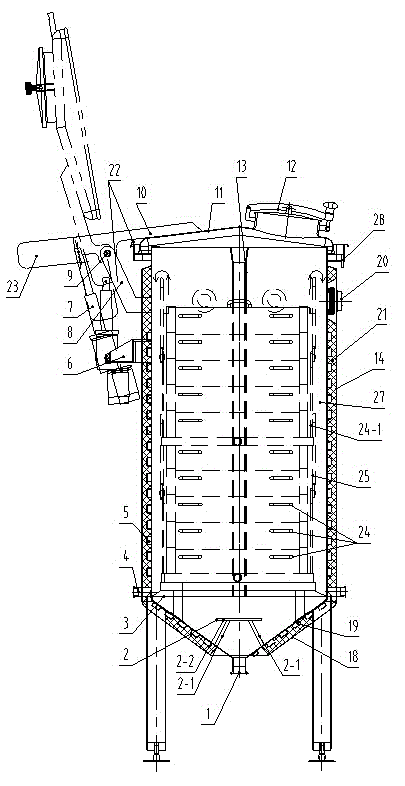

Automatic rotational lifting monitoring system for fouling and slagging of boiler furnace of coal-fired power plant

ActiveCN103024357AEasy to useFlexible liftingTelevision system detailsColor television detailsDisplay deviceEngineering

The invention discloses an automatic rotational lifting monitoring system for fouling and slagging of a boiler furnace of a coal-fired power plant. The system comprises a fixing support, a lifting platform, an imaging system, a cooling device, a driving mechanism and a displayer, wherein the lifting platform is matched with the fixing support in a sliding mode, the imaging system is installed on the lifting platform and comprises a charge coupled device (CCD) camera and an optical lens, the cooling device is fixedly sleeved outside the optical lens, an observation port which is matched with the optical lens is arranged at the bottom of the cooling device, the driving mechanism is used for driving the imaging system to rotate, and the displayer is connected with the imaging system. The system is convenient to use, flexible to lift and rotate, safe, reliable, high in economical efficiency and capable of integrating visualization, rotating and lifting functions and achieving the effect that the condition of the heating surface of the furnace can be monitored in a multi-angle and all-round mode through a single camera.

Owner:ZHEJIANG UNIV

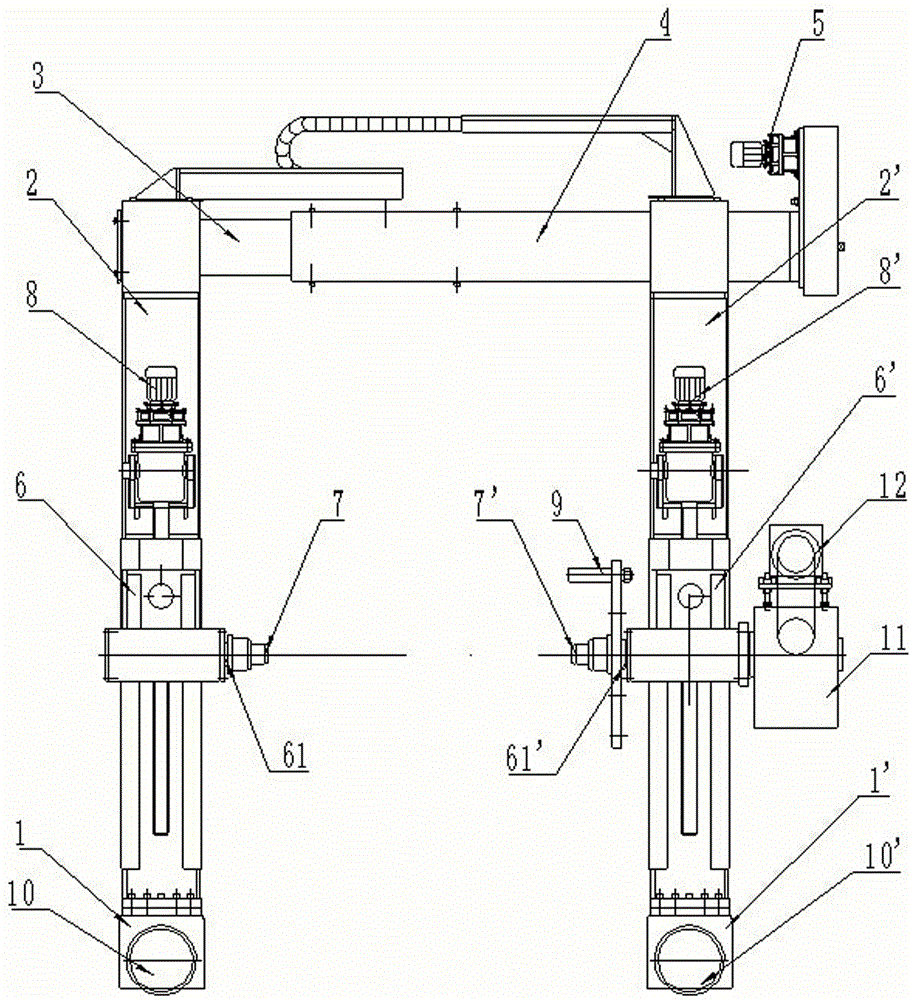

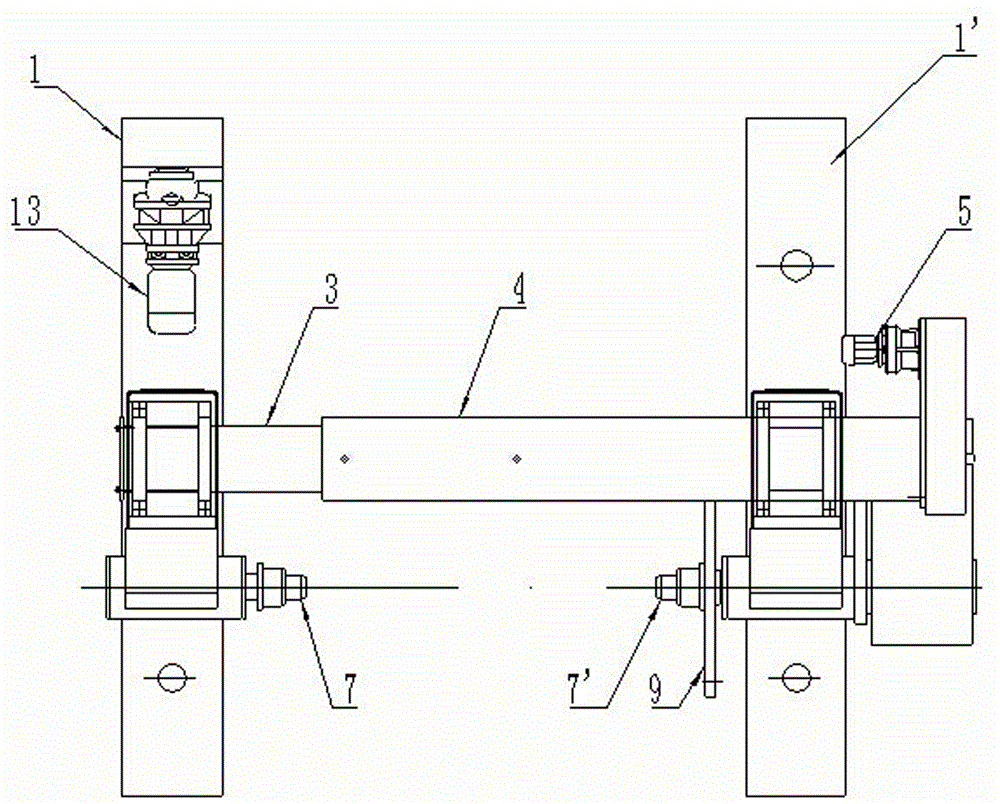

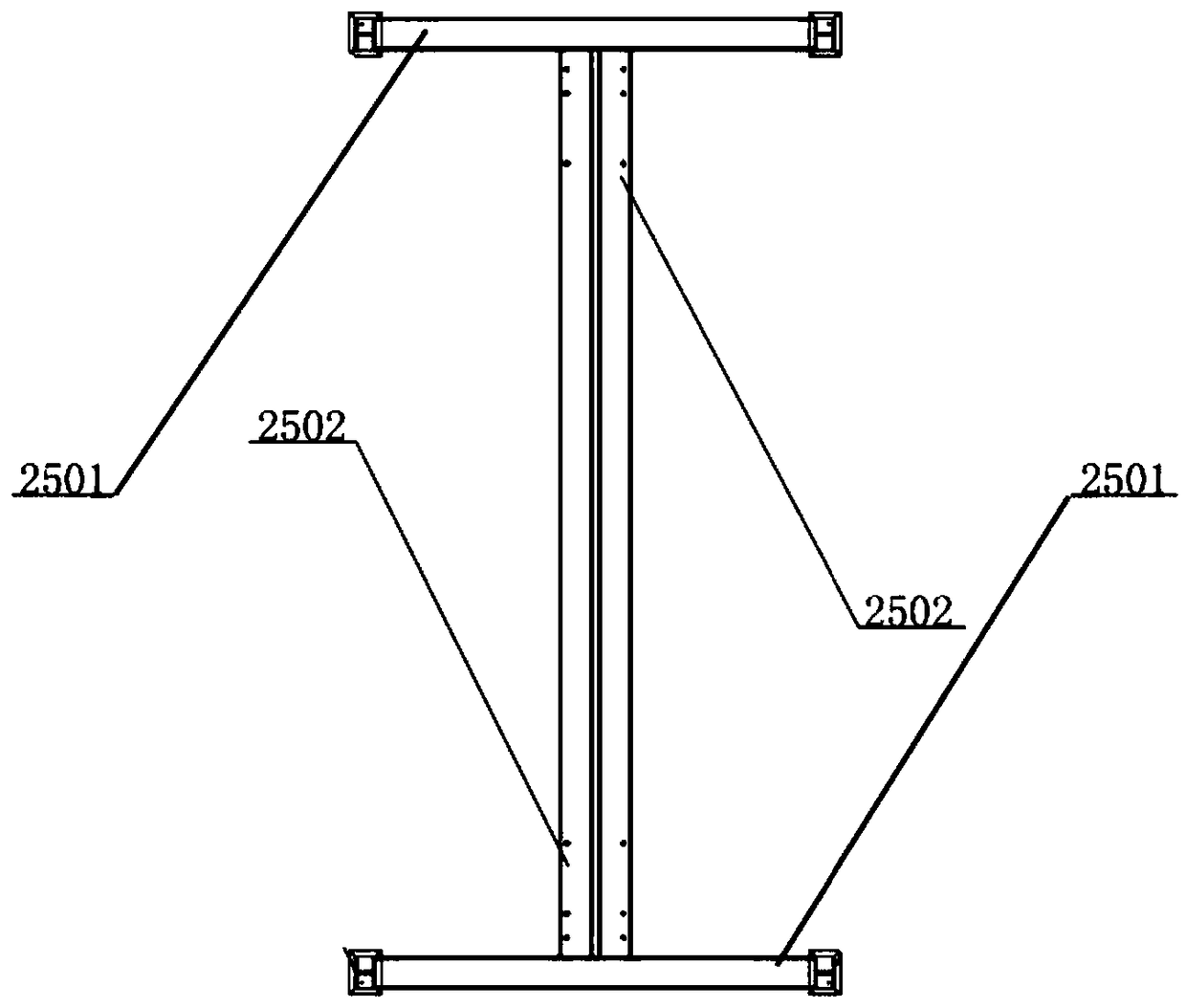

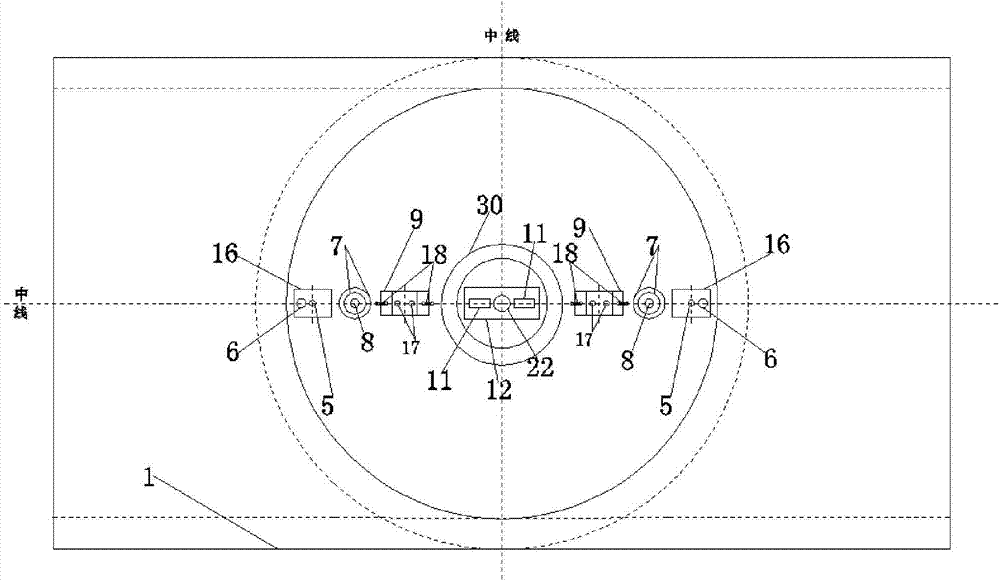

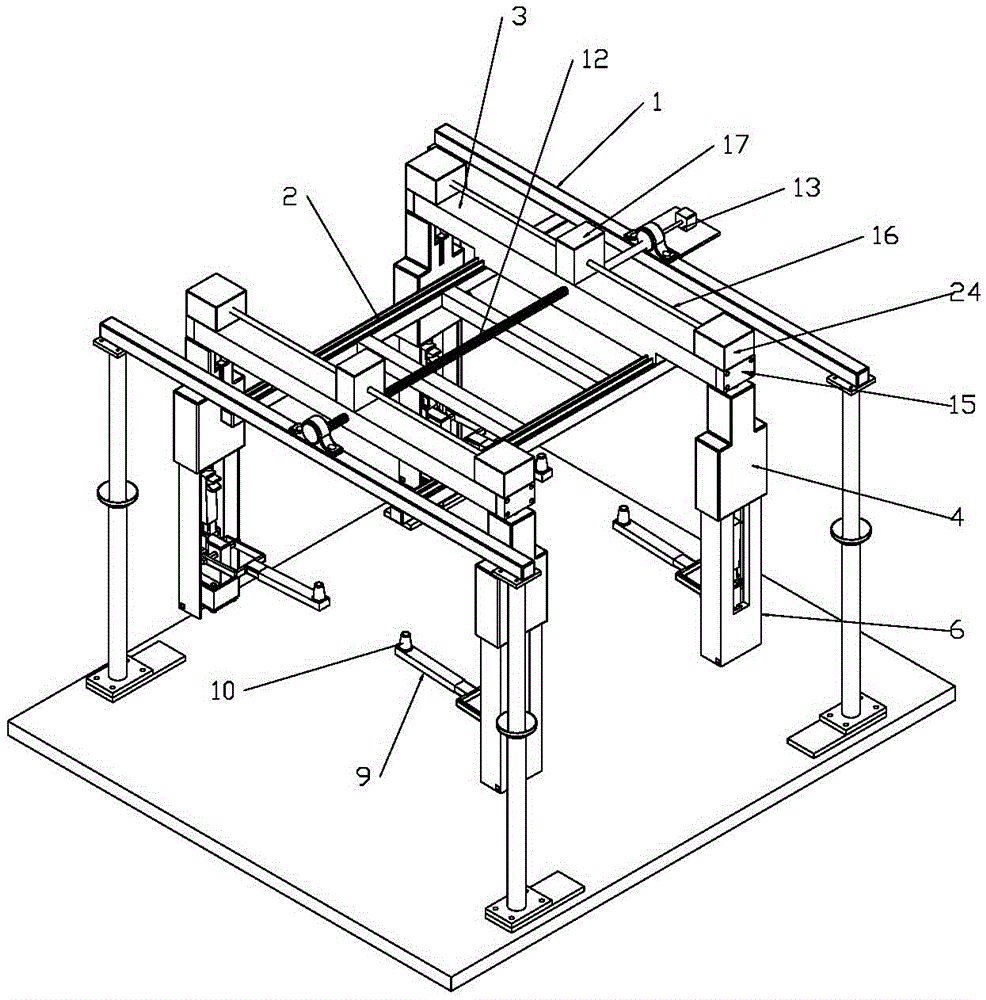

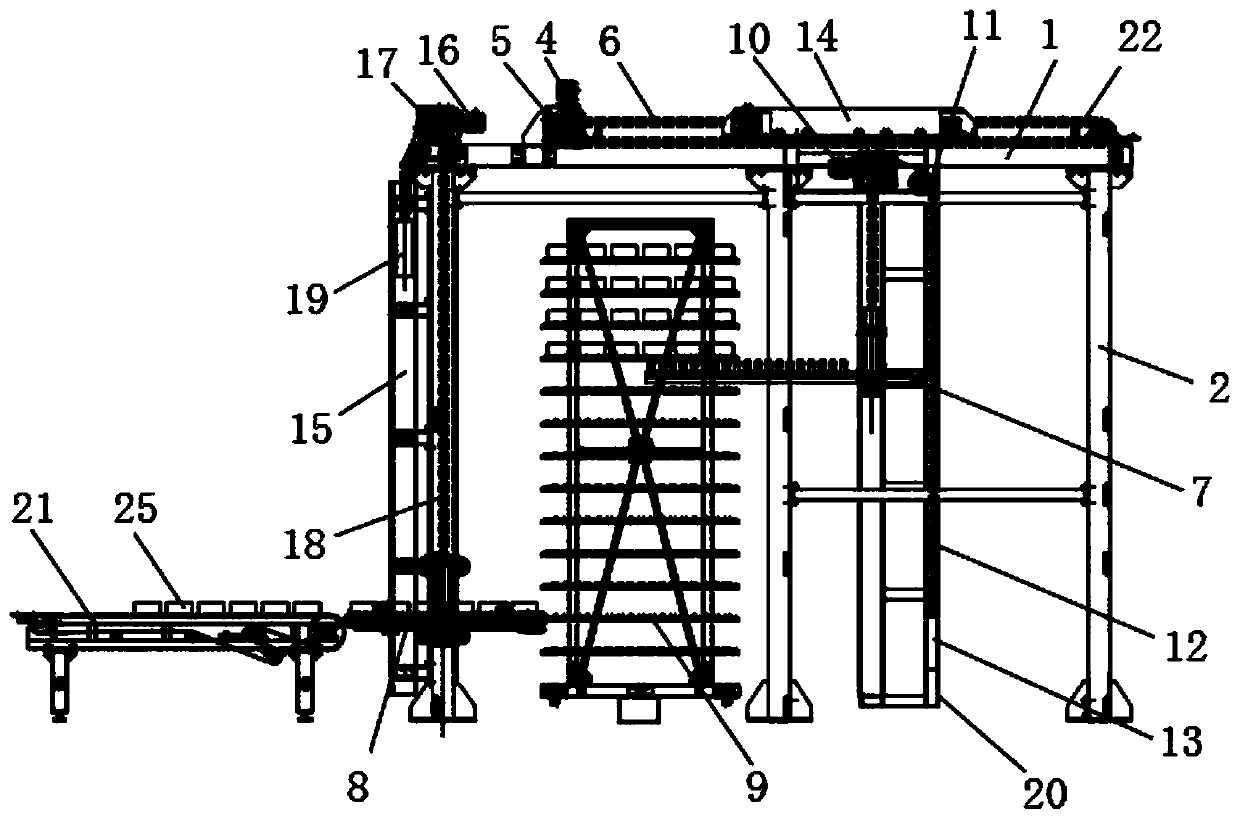

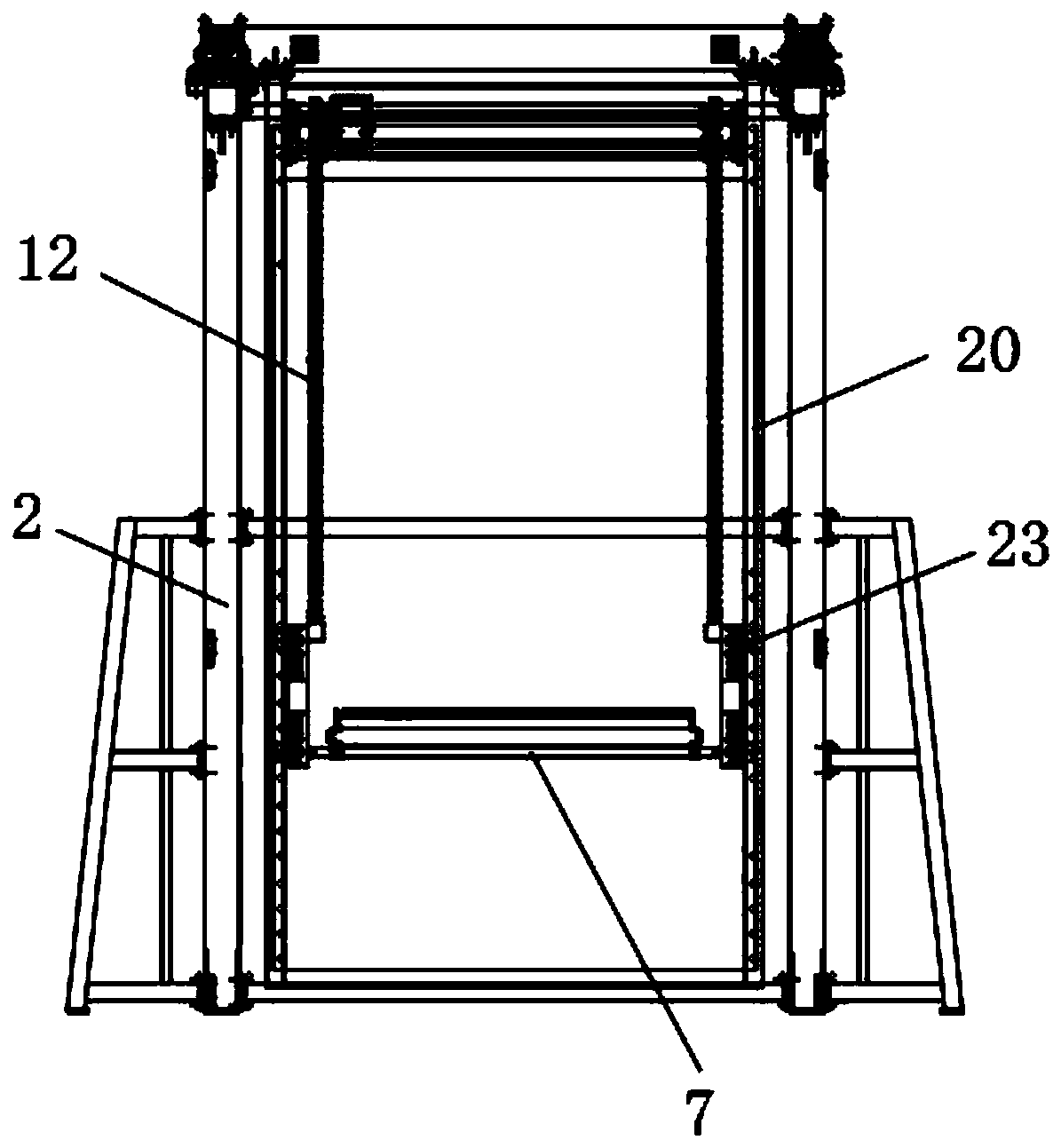

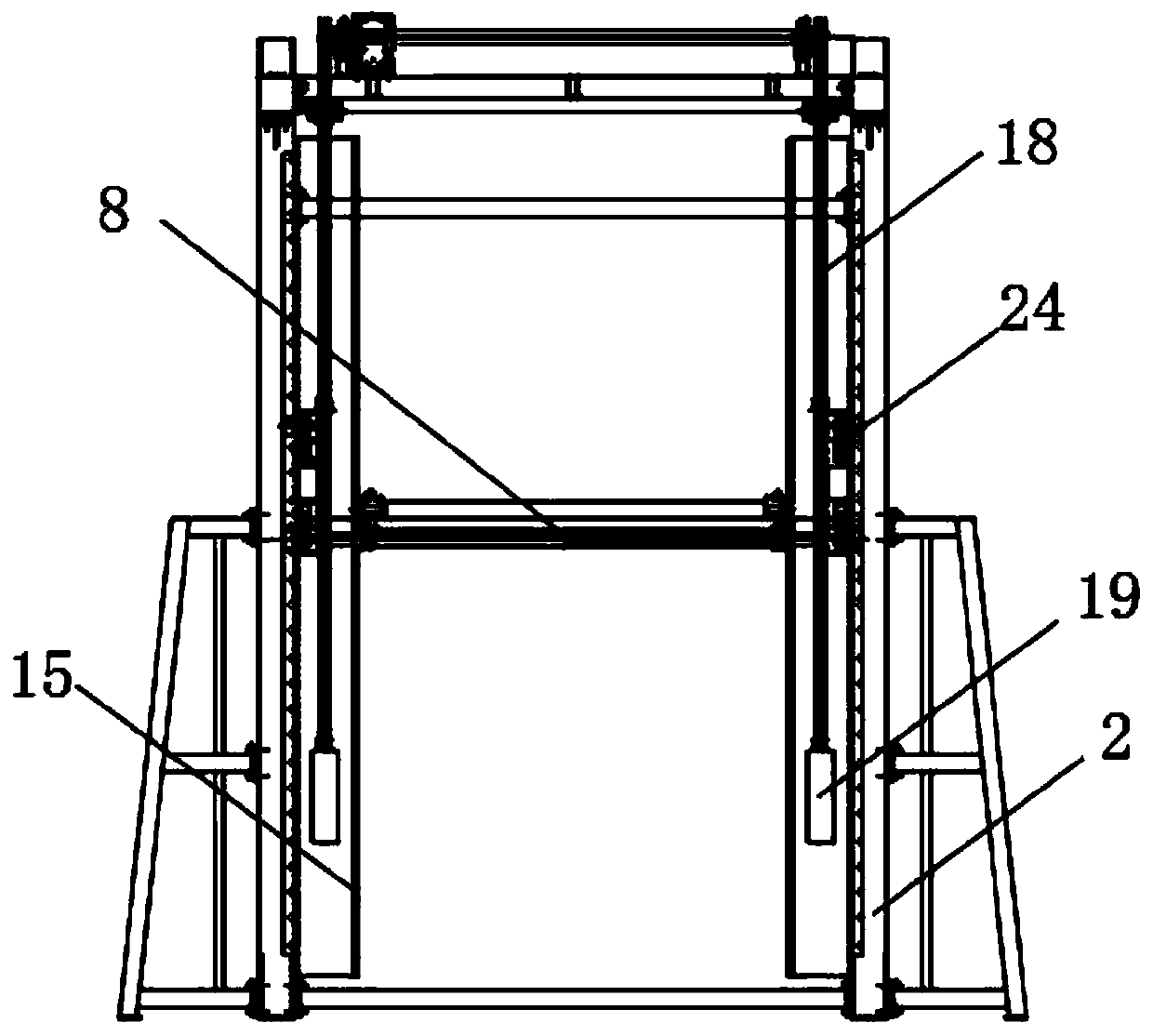

Walking type cable winding and arranging device for gantry ground rail

InactiveCN104609256AClamping freedomReasonable structural designFilament handlingCable trayElectric machine

The invention discloses a walking type cable winding and arranging device for a gantry ground rail. The walking type cable winding and arranging device comprises a left ground beam, a right ground beam, a left vertical column and a right vertical column, wherein the left vertical column and the right vertical column are arranged on the left ground beam and the right ground beam. A left idler wheel and a right idler wheel are arranged on the left ground beam and the right ground beam. An inner sleeve is arranged at the top of the left vertical column. An outer sleeve is arranged at the top of the right vertical column. The inner sleeve is sleeved with the outer sleeve. A gear motor is arranged at the upper portion of the outer sleeve. A left bracket and a right bracket are installed on the left vertical column and the right vertical column. A left bracket shaft and a right bracket shaft are arranged on the left bracket and the right bracket. A left tip cone and a right tip cone are arranged at one end of the left bracket shaft and one end of the right bracket shaft. A left motor and a right motor are arranged on the left vertical column and the right vertical column. A pulling pin is arranged at one end of the right bracket shaft, and a gearbox is arranged at the other end of the right bracket shaft and connected with a direct current motor. The walking type cable winding and arranging device has the advantages of being reasonable in structural design, free in cable tray clamping, convenient to use and large in application range, and is widely applied to winding, arrangement, cable defense and equipment matching for a crosslinking unit, an extrusion unit, a continuous curing unit, a cabling unit, an armoring unit, a tray dumping unit and other units of manufacturers for various cables such as wires, electric cables, optical cables and communication cables.

Owner:安徽普瑞斯电工机械有限公司

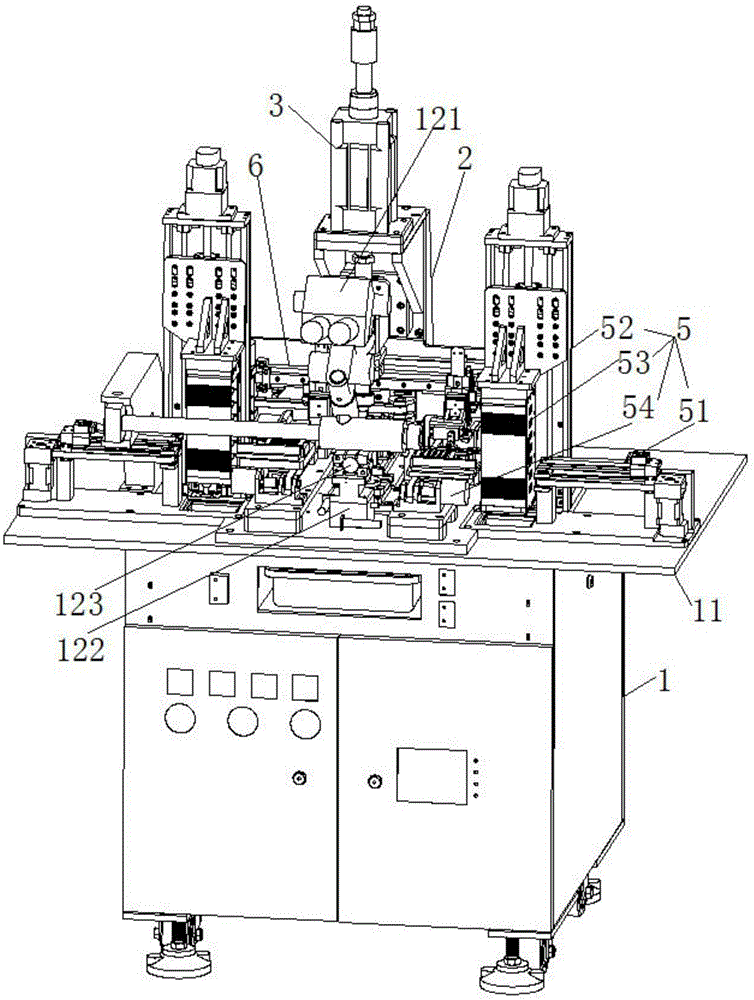

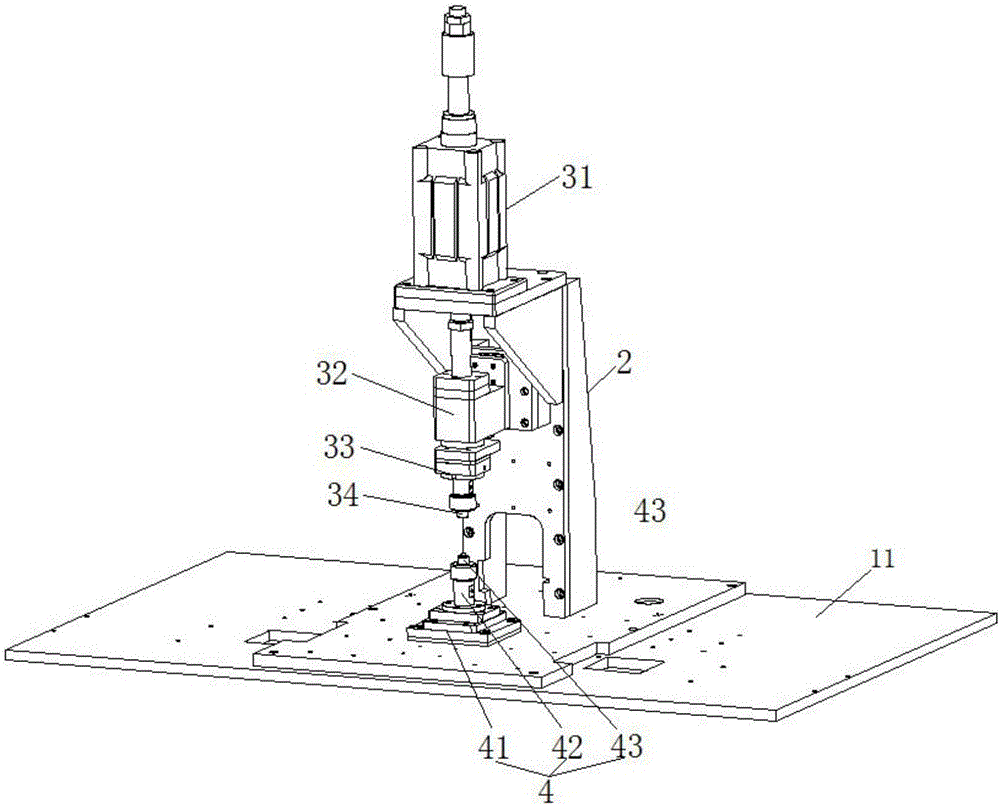

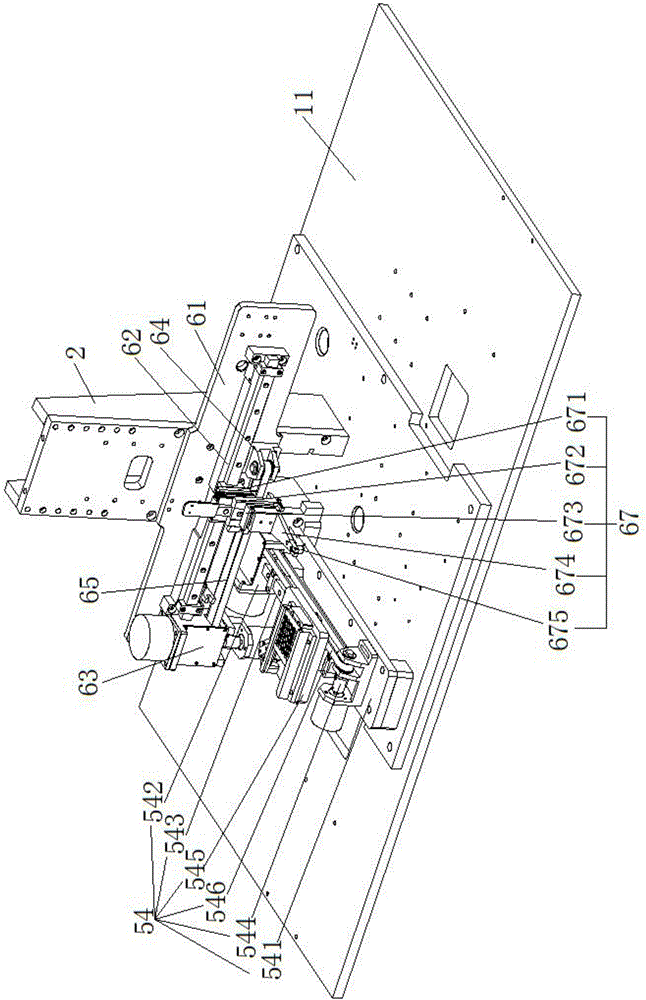

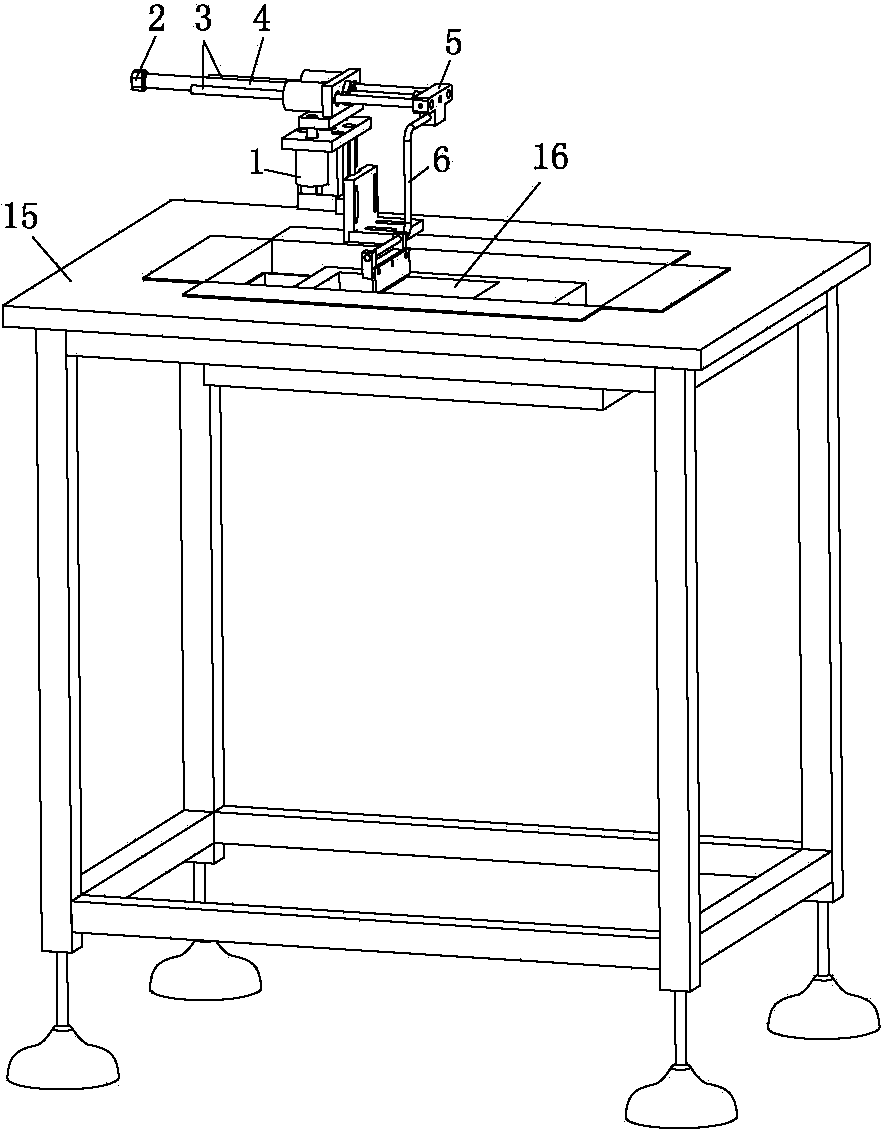

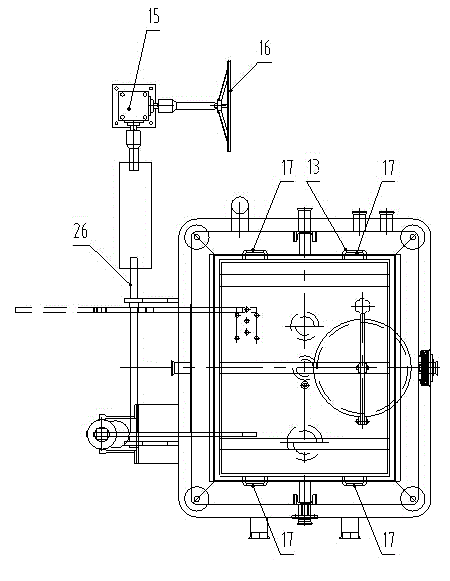

High-precision and full-automatic sealing equipment of metal tube shells

ActiveCN106270993AEnsure safetyImprove efficiencyResistance electrode holdersPressure electrodesAutomatic test equipmentEngineering

The invention relates to high-precision and full-automatic sealing equipment of metal tube shells. The equipment comprises a machine case, a supporting base body, a stamping and welding mechanism, a welding base mechanism, two feeding and conveying modules and a linear moving mechanism; a work table plate is arranged on the top of the machine case, the supporting base body is installed on the work table plate, the stamping and welding mechanism is installed at the upper end of the front side of the supporting base body, the welding base mechanism is installed on the work table plate and is located right below the stamping and welding end, and the feeding and conveying modules are symmetrically installed at the parts, located on two sides of the welding base mechanism, of the work table plate; the linear moving mechanism is installed on the supporting base body and is provided with a tube cap clamping and placing mechanism and a semi-finished tube base clamping and placing mechanism; and the semi-finished tube base clamping and placing mechanism can clamp semi-finished tube bases, can move to the position corresponding to the welding base mechanism under the drive effect of the linear moving mechanism and can place the semi-finished tube bases into the welding base mechanism. The equipment has the advantages that the machining precision is high, operation is simple, time and labor are saved, the efficiency is high, and the safety is high.

Owner:武汉威科赛尔光电技术有限公司

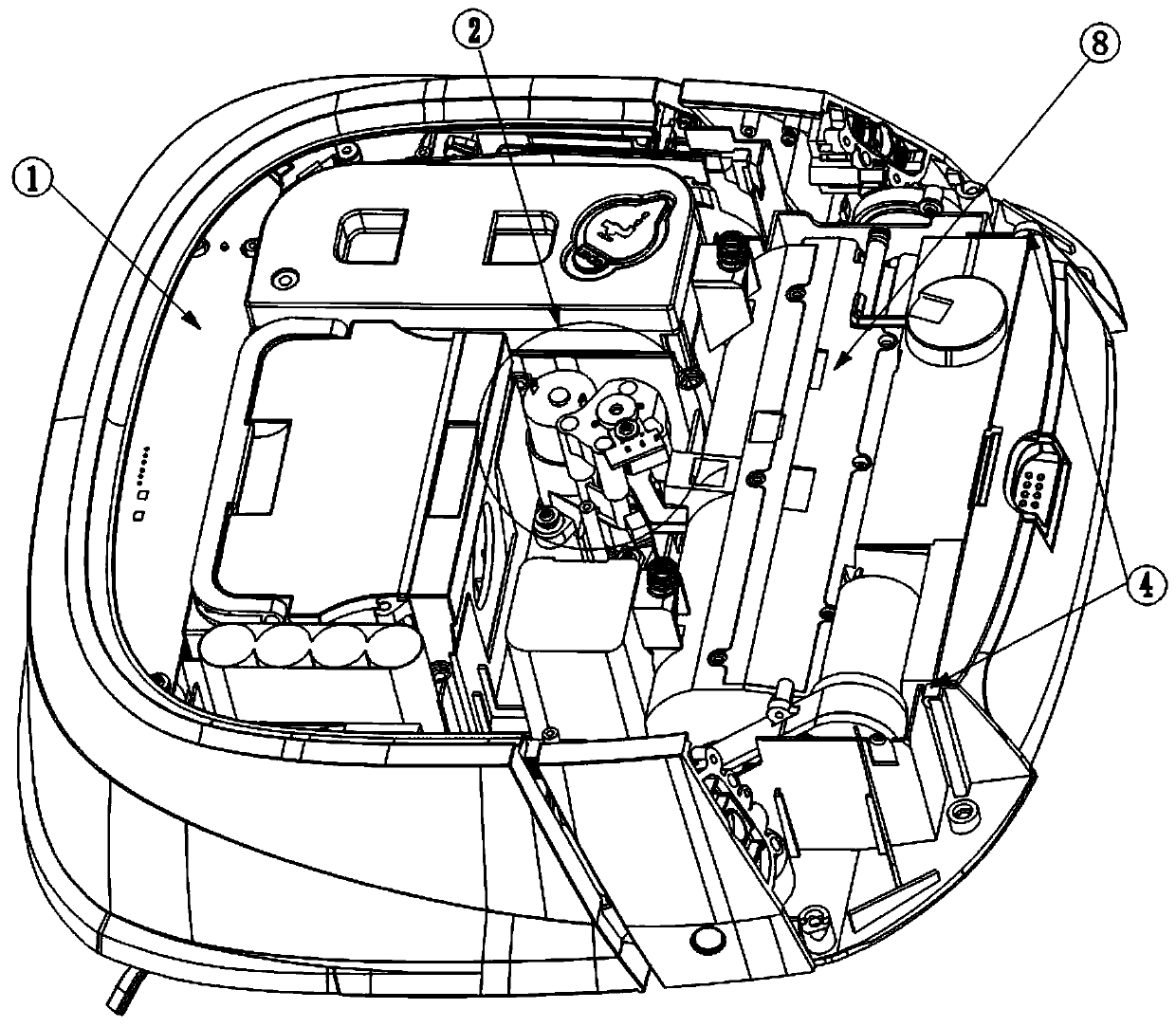

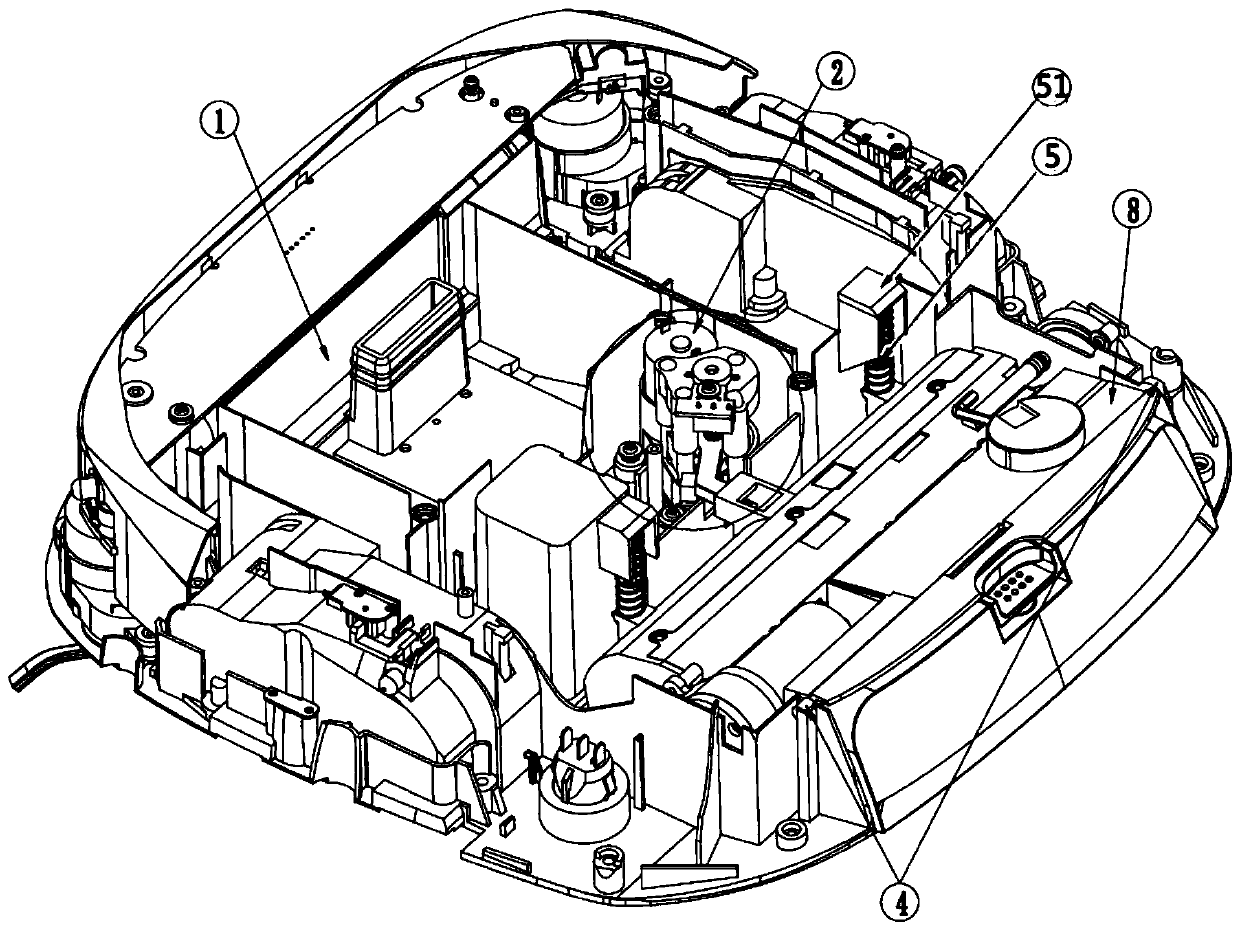

Lifting device for mopping roller of sweeping robot

PendingCN111568326AEffective beyondLightweight and fast operationCarpet cleanersCleaning action controlEngineeringMechanical engineering

The invention discloses a lifting device for a floor mopping roller of a sweeping robot, which comprises a body, a cleaning device is arranged on the body, the cleaning device comprises the floor mopping roller, floor mopping rag is arranged on the floor mopping roller, a lifting device is arranged in the body, the lifting device comprises a driving device, and the driving device is connected withthe cleaning device; a roller support is arranged on the body, and the cleaning device is arranged on the roller support. The lifting device for the mopping roller of the sweeping robot is simple instructure, flexible to use, accurate in lifting control and high in automation degree.

Owner:SHENZHEN TECBOT INTELLIGENT ROBOT CO LTD

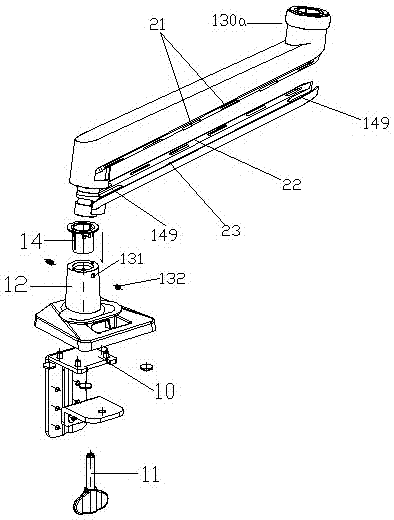

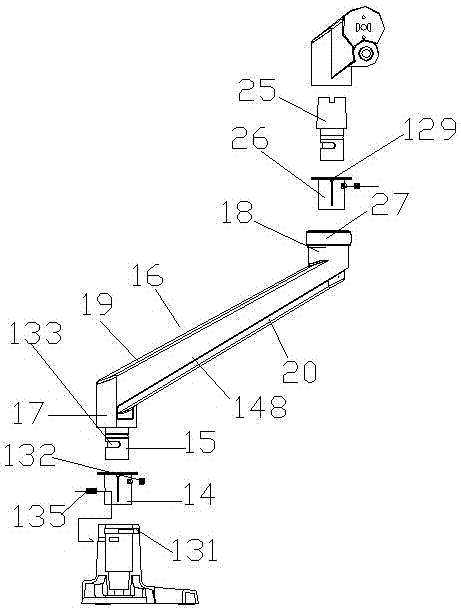

Novel telescopic spring supporting frame

The invention relates to the field of display screen supporting frames, in particular to a novel telescopic spring supporting frame. The novel telescopic spring supporting frame comprises a base, an extension arm, a lifting supporting arm and a display screen hanging tool. The base is provided with the extension arm. An extension arm connecting joint is arranged at the top end of the extension arm and provided with the lifting supporting arm. A swinging head is arranged at the head end of the lifting supporting arm. The display screen hanging tool is arranged at the top end of the swinging head. The extension arm, the lifting supporting arm and the display screen hanging tool are upwards arranged in an oblique angle manner (the display screen hanging tool can be adjusted in a pitching manner), the lifting supporting arm conducts universal rotation with the extension arm connecting joint as the axis, and the lifting supporting arm conducts universal rotation with the swinging head as the axis.

Owner:徐和云

Automatic tin scraping machine and tin soldering device

InactiveCN104191062AScraping action standardReduce labor intensityMetal working apparatusSolder feeding devicesSolderingEngineering

The invention relates to the technical field of transformer production, in particular to an automatic tin scraping machine and a tin soldering device. The automatic tin scraping machine structurally comprises a time relay, a first air cylinder, a second air cylinder and a tin scraping mechanism, wherein the first air cylinder and the second air cylinder are controlled by the time relay, and the tin scraping mechanism is connected with the second air cylinder in a driving mode. The first air cylinder is connected with the second air cylinder in a driving mode and enables the second air cylinder to do lifting motion to drive the tin scraping mechanism to do lifting motion. The second air cylinder is provided with a second air cylinder rod and a second air cylinder plain shaft, and the second air cylinder rod and the second air cylinder plain shaft are connected with the tin scraping mechanism and enable the tin scraping mechanism to do horizontal motion. The tin soldering device comprises a machine frame, a tin smelting furnace arranged on the machine frame and the automatic tin scraping machine. The automatic tin scraping machine has the advantages that the tin scrapping movement is standard, the labor intensity is low, the tin scrapping effect is ideal and the production efficiency is high. The tin soldering device has the advantages that the tin soldering time and the tin soldering height are standard and the tin scrapping effect is good.

Owner:DONGGUAN DAZHONG ELECTRONICS

PC component die table cleaning device and working method thereof

ActiveCN109396088AAvoid pollutionSimple structureCleaning using toolsCleaning using gasesBaghouseEngineering

The invention provides a PC component die table cleaning device. The PC component die table cleaning device comprises a main frame, a scraper plate is hinged to one side of the main frame, a scraper air cylinder is arranged between the scraper plate and the main frame, a distance measuring sensor is arranged in the part, on the side of the scraper air cylinder, of the main frame, and the device further comprises a lifting mechanism, a sweeping structure, a dust removal mechanism and a die table transportation mechanism. According to the PC component die table cleaning device, the defects of anexisting die table cleaning device can be effectively overcome, for the lifting mechanism of a brush roller, a lead screw is driven by adopting a servo motor, so that the ascending and descending movement of the brush roller is realized, and the sweeping action force can be controlled; the structure is simple, the control is easy to realize, and a cloth bag dust remover for dust is arranged, so that the pollution to the environment caused by sweeping is reduced; and therefore, the device has the advantages of being simple in structure, easy to control, high in sweeping efficiency and the like.

Owner:JIANGSU UNIV OF SCI & TECH

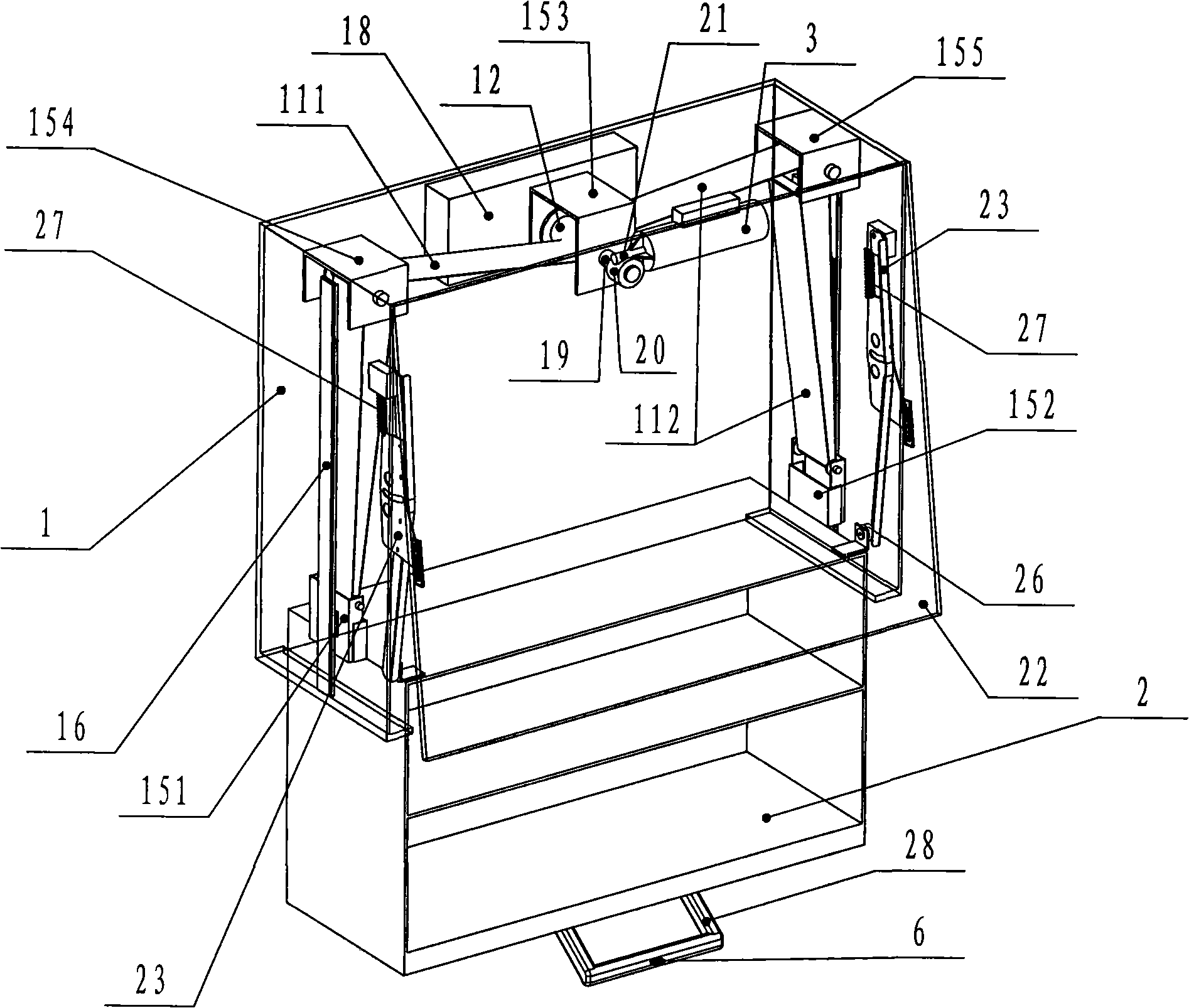

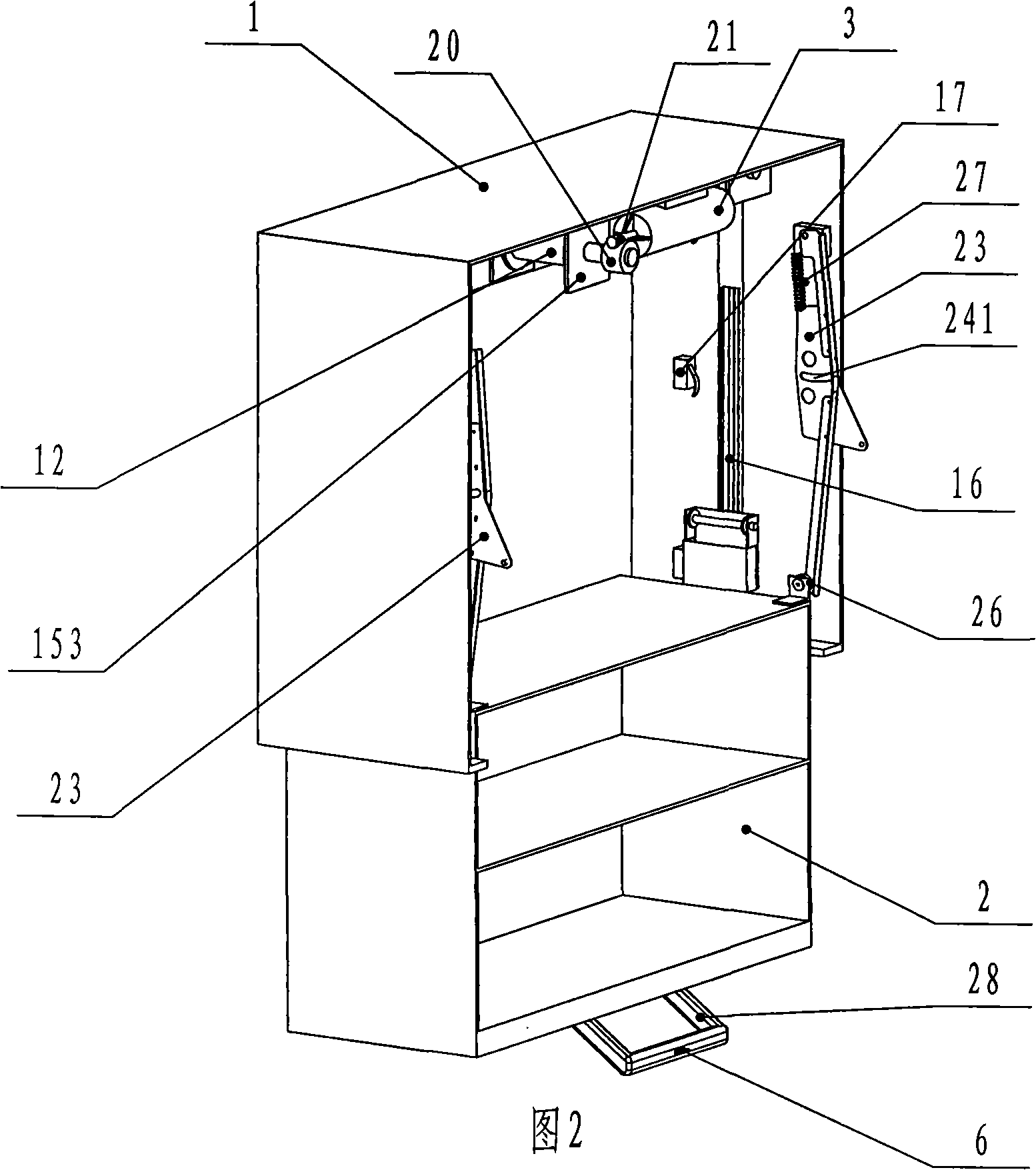

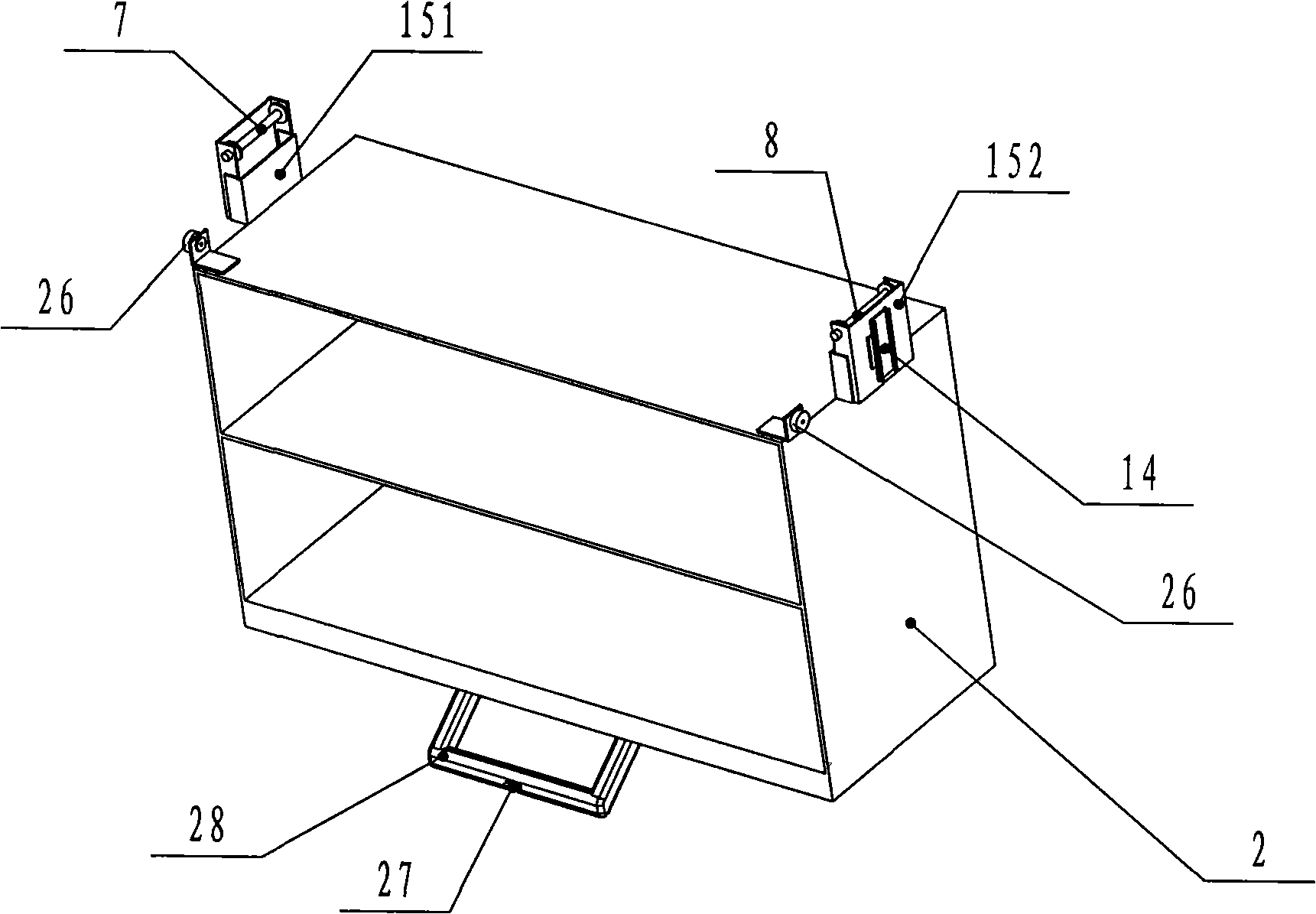

Electric up-down kitchen cabinet

The invention discloses an electric lifting cupboard which comprises a bottomless cupboard body (1), a cupboard tray (2), a motor (3), a lifting mechanism, an upper limit switch, a lower limit switch and a lifting switch (6); the lifting mechanism comprises a right movable pulley and a left movable pulley, a right static pulley, a left static pulley, a left leather belt (111), a right leather belt (112) and a driving pulley (12) that is arranged in the middle of the top of the bottomless cupboard body (1) and connected with the motor (3), wherein, the right movable pulley and the left movable pulley are respectively arranged at the two sides of the top of the cupboard tray (2); the right static pulley, the left static pulley, the left leather belt (111) and the right leather belt (112) are arranged at the two sides of the top of the bottomless cupboard body (1); one end of the left leather belt (111) and the right leather belt (112) is fixed on the driving pulley (12) at the same time, while the other end thereof respectively passes the right static pulley, the left static pulley, the right movable pulley and the left movable pulley and is fixedly arranged on a left fixing bar and a right fixing bar arranged beside the right static pulley and the left static pulley; the right movable pulley and the left movable pulley are movably matched with the inner wall of the bottomless cupboard body (1). The electric lifting cupboard has the advantages of flexible lifting and no dithering phenomenon happening during the processes of rising and falling.

Owner:徐剑光 +1

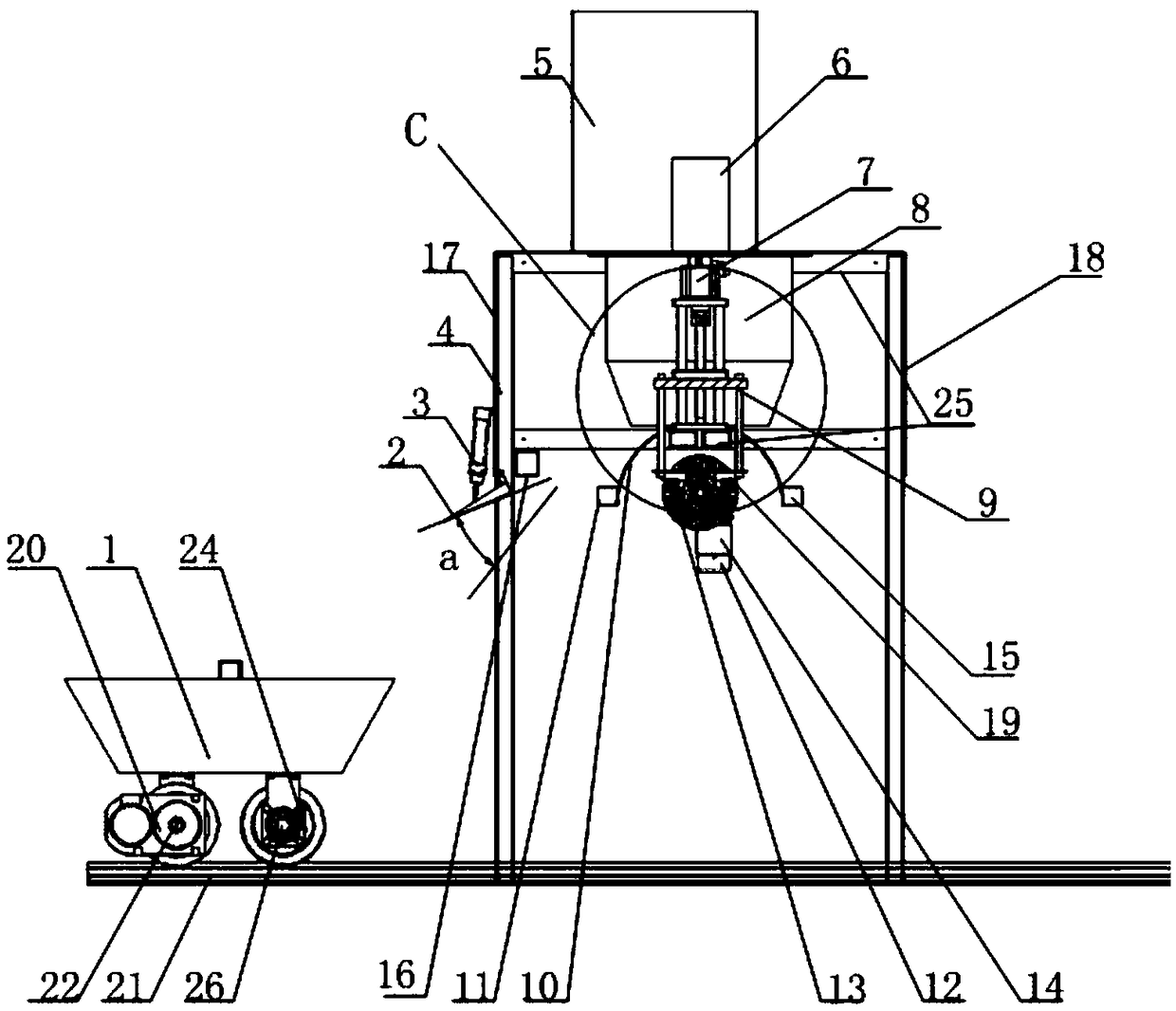

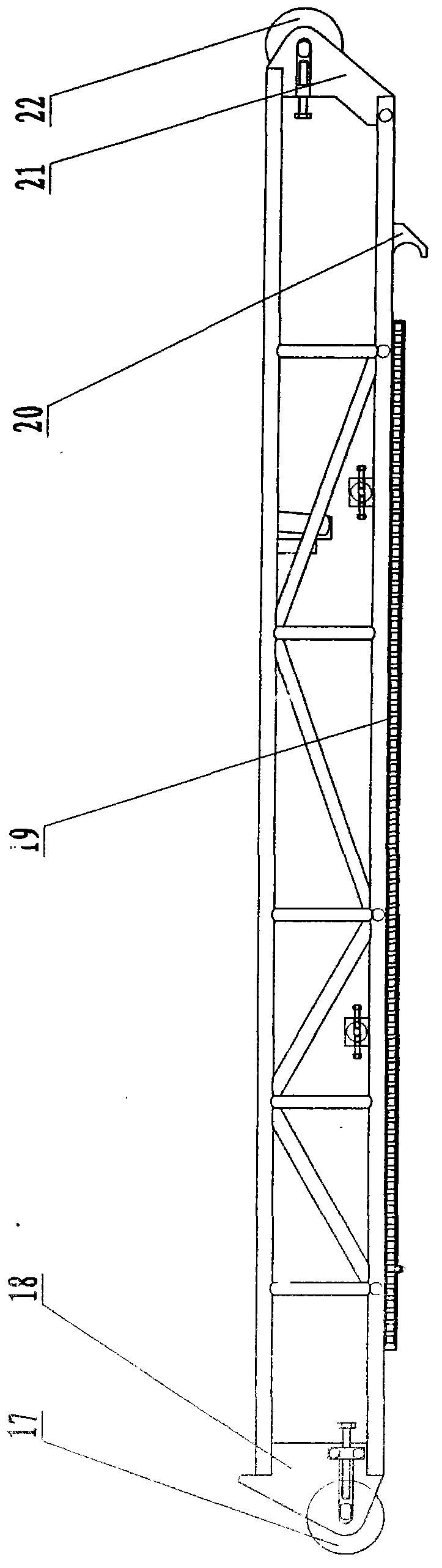

Self-traveling lifting type sprayer spraying rod device

InactiveCN105052877AFlexible liftingEasy to operateInsect catchers and killersWinchIndustrial engineering

The invention discloses a self-traveling lifting type sprayer spraying rod device. The self-traveling lifting type sprayer spraying rod device comprises a rack, a lifting frame, a fixed pulley, a mooring rope, a winch, a spraying pipe and a spraying rod assembly. Guide rails are arranged on the inner side of the rack. Pulleys matched with the guide rails are arranged on the lifting frame, and the guide rails and the pulleys form a vertical movement pair. The spraying rod assembly is fixedly connected to the lifting frame. The fixed pulley is arranged at the upper end of the rack. The winch is fixedly installed at the upper end of the lifting frame. The mooring rope is arranged in the winch in a surrounding mode, and one end of the mooring rope penetrates out of the fixed pulley to be fixed to the lifting frame. The self-traveling lifting type sprayer spraying rod device is flexible in lifting and convenient to operate, the height of the lifting frame can be freely adjusted so that the self-traveling lifting type sprayer spraying rod device can adapt to the height of a work face, the spraying rod assembly can be folded so that the width of the spraying rod assembly can adapt to the width of the work face, energy is saved, and efficiency is improved.

Owner:董刚

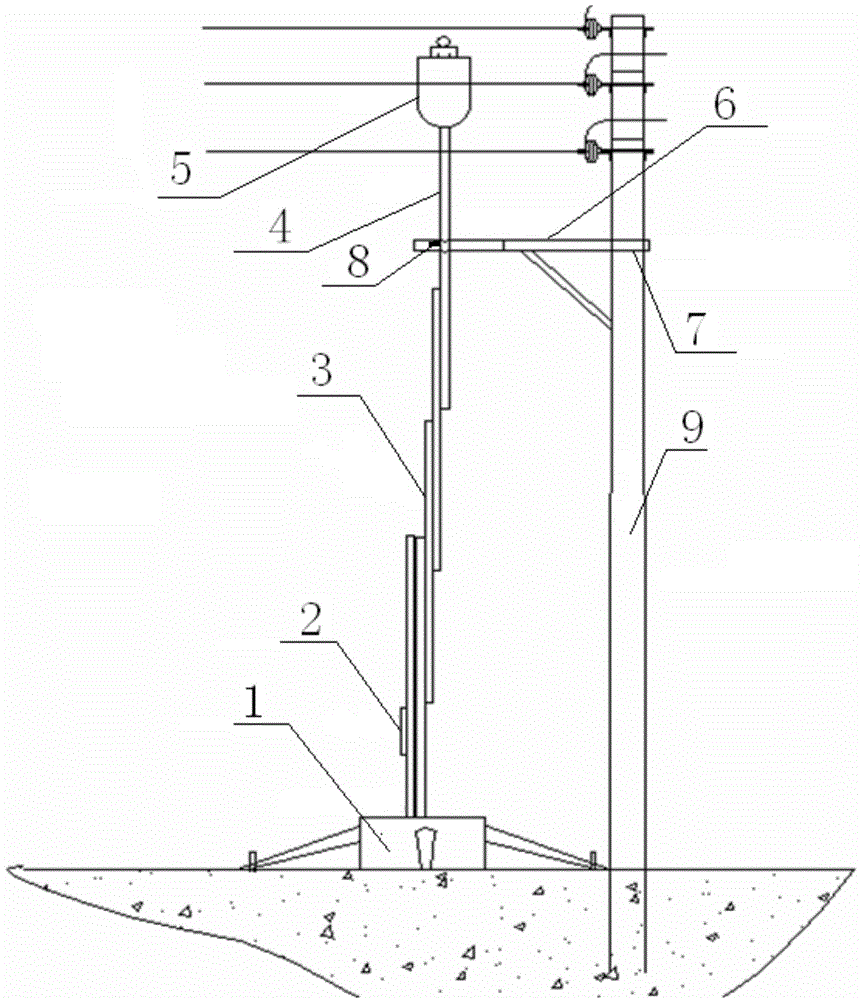

Liftable auxiliary apparatus for power system

InactiveCN104925711ALight in massSmall footprintLifting devicesApparatus for overhead lines/cablesElectric power systemEngineering

The present invention discloses a liftable auxiliary apparatus for a power system, being composed of a drive device, a processor, an execution unit, an insulation rod body, an insulation workbench, an insulation telescopic guide rail and a connection device, wherein the drive device is disposed on the ground and is connected to the processor which is further connected to the execution unit, and the execution unit is connected to the insulation rod body which is connected to the insulation workbench, and the connection device is disposed on a tower rod and is connected to the insulation rod body via the insulation telescopic guide rail. The present invention in particular provides the liftable auxiliary apparatus for the power system, having the characteristics of simple structure, easy handling and applicability to hot-line work. The whole apparatus herein is liftable, translatable, and rotatble, and has a high work efficiency and the capability of guaranteeing personnel safety, is in substantial economic and social values. The assembled workbench is rotatable around a main rod, which facilitates personnel on the rod to choose work position, thus addressing the inability of self-rotation of imported platforms; the assembly work bench is agile in lifting.

Owner:STATE GRID CORP OF CHINA +1

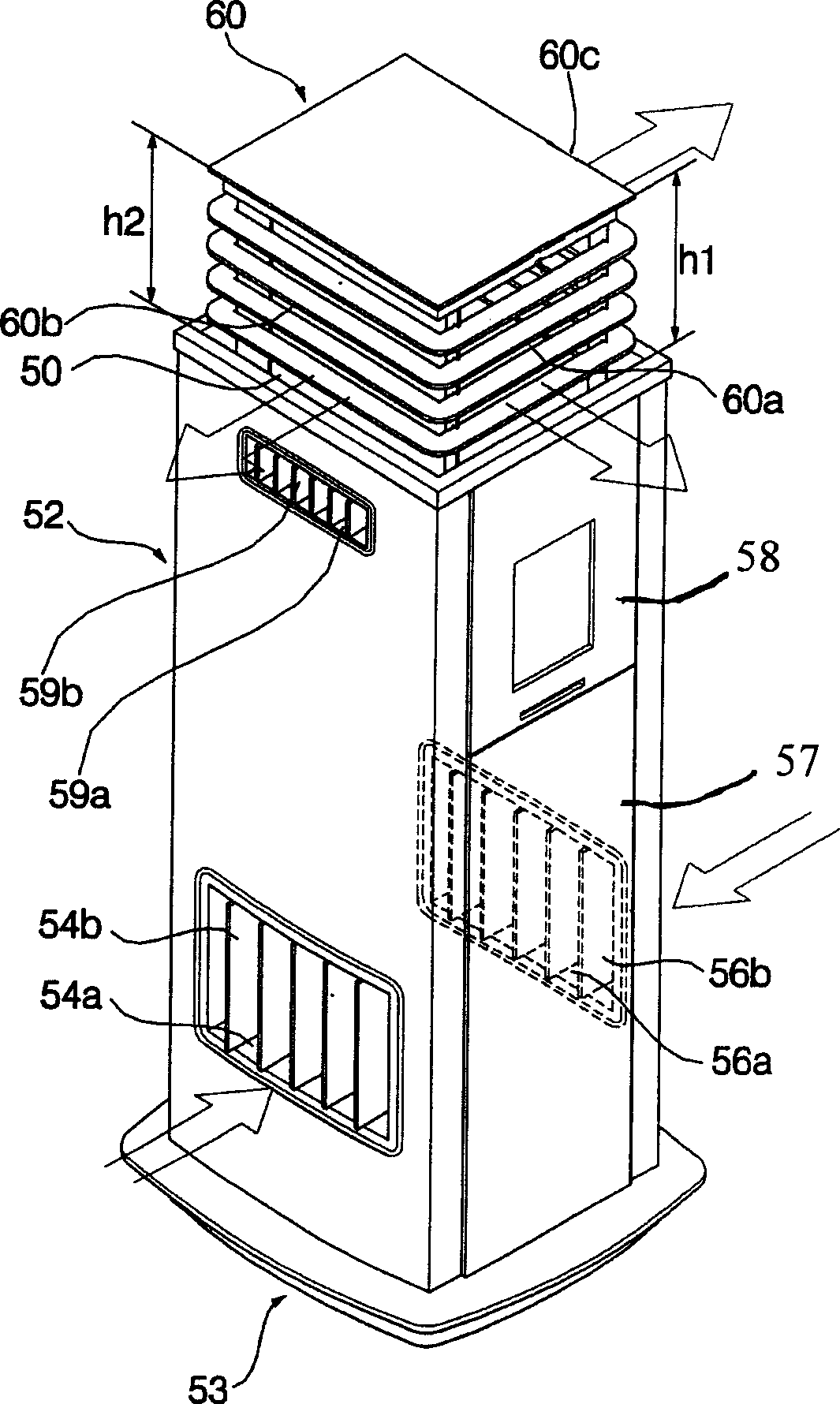

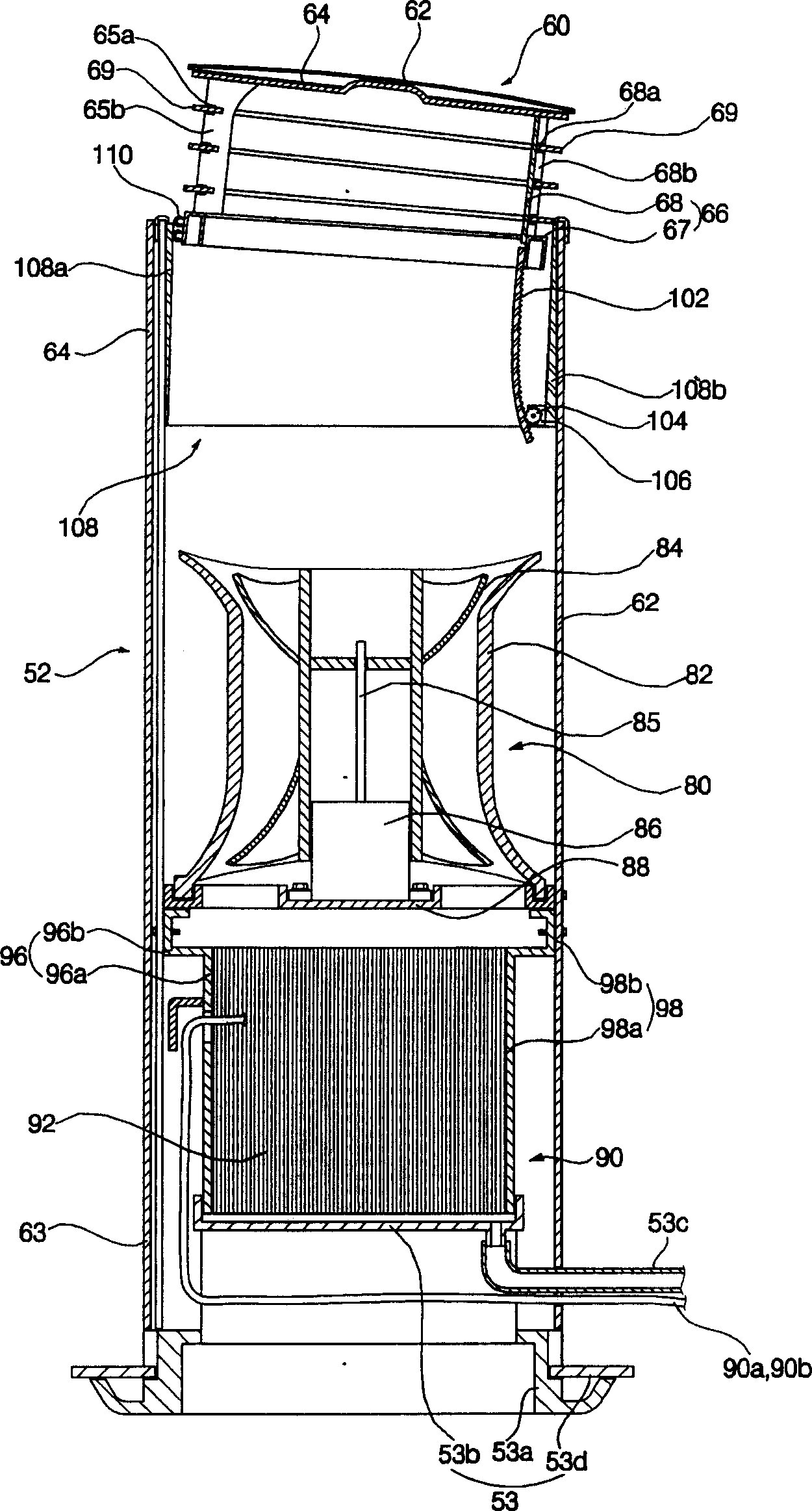

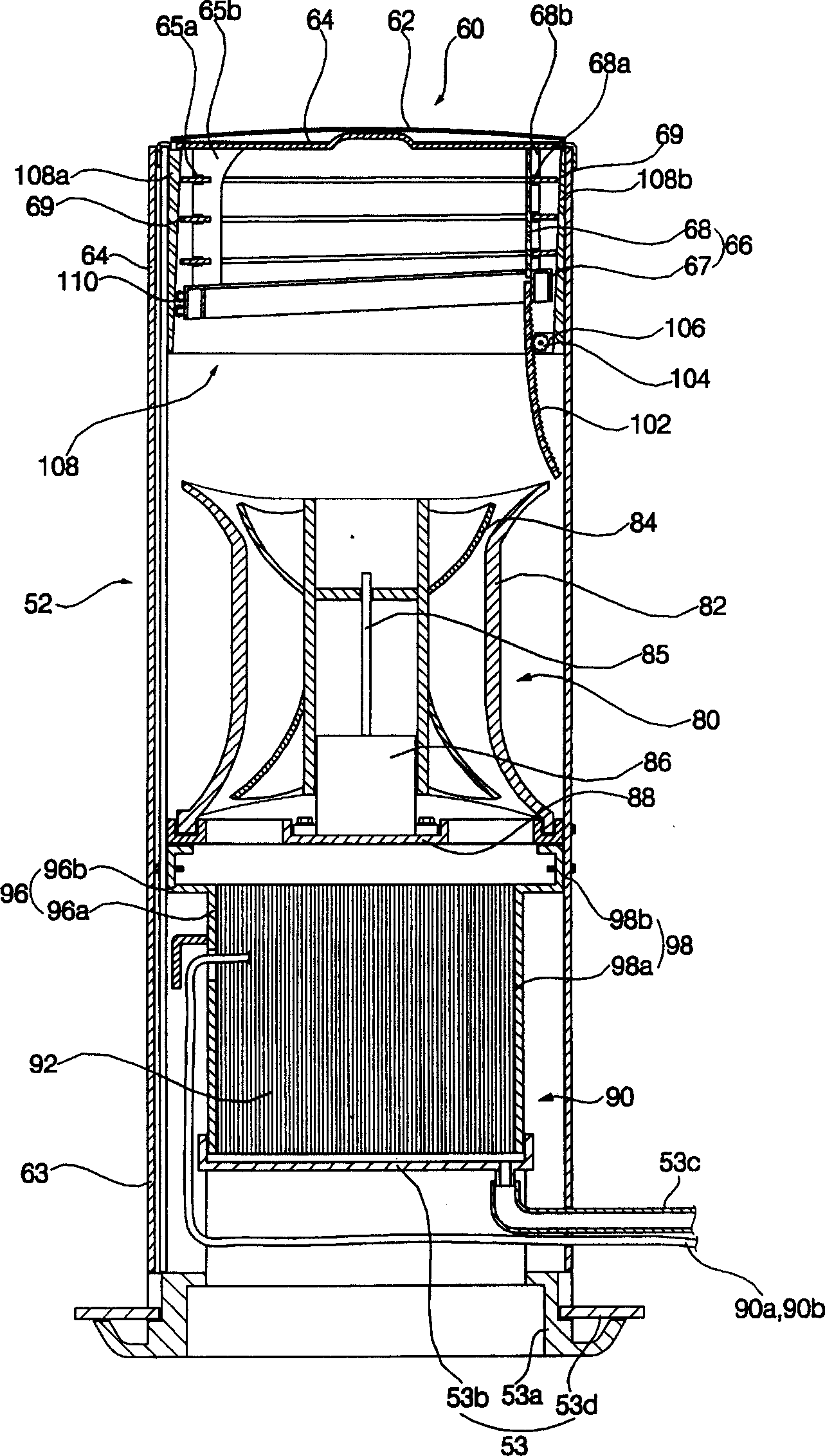

Indoor unit for air conditioner

InactiveCN1752600AQuick three-dimensional adjustmentReduce the overall heightDucting arrangementsLighting and heating apparatusAir conditioningWaste management

The indoor machine of air conditioner includes external shell whose upper portion is formed into discharge outlet, discharge outlet component which can be up-down movably mounted on the external shell and can be lifted toward upper side of discharge outlet and lifting and falling device which can make the lifting amplitude of front face portion of discharge outlet component be relatively larger than that of its back face portion when the discharge outlet component is lifted and fallen.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

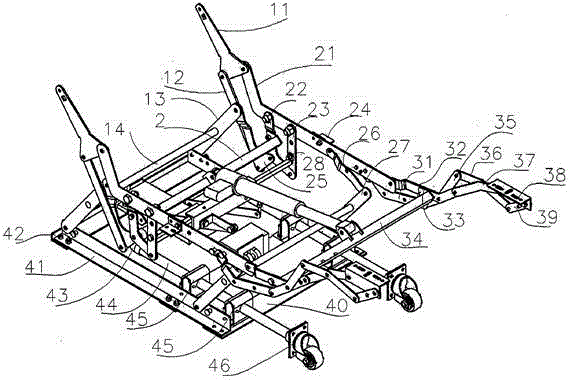

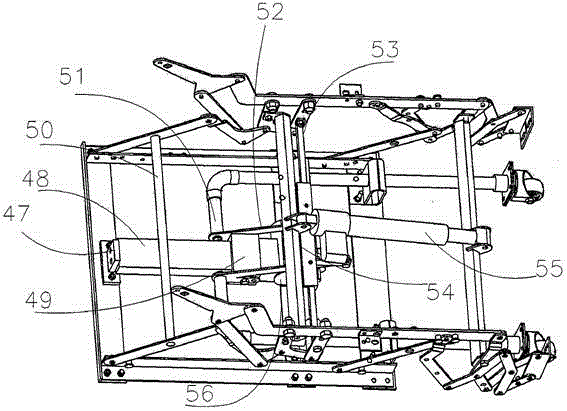

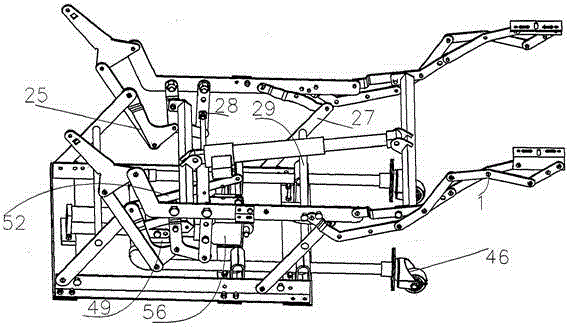

Anti-falling dual-motor functional sofa

Owner:HENGLIN HOME FURNISHINGS CO LTD

Flexibility pneumatic elevation-type transfer machine and using method thereof

The invention discloses a flexible pneumatic lift-type transfer machine and a use method thereof, which belong to the technical field of mobile handling equipment and solve the problem that the lifting coverage area of the existing transfer equipment is small. The transfer machine of the present invention includes a base, a column and a cantilever, and the column is fixed on the base; the cantilever is rotatably arranged on the top of the column, and also includes a pneumatic balance hoist; the The cantilever includes a long section and a short section; the division point of the long section and the short section is the point where the cantilever is rotatably connected to the column; the pneumatic balance hoist is set on the short section At the end, the steel wire rope in the pneumatic balance hoist protrudes toward the end of the long section along the upper surface of the cantilever. The invention can be easily moved and transported, has high stability, and has the effect of increasing the hoisting coverage area compared with the prior art.

Owner:铮孚智能工程(上海)有限公司

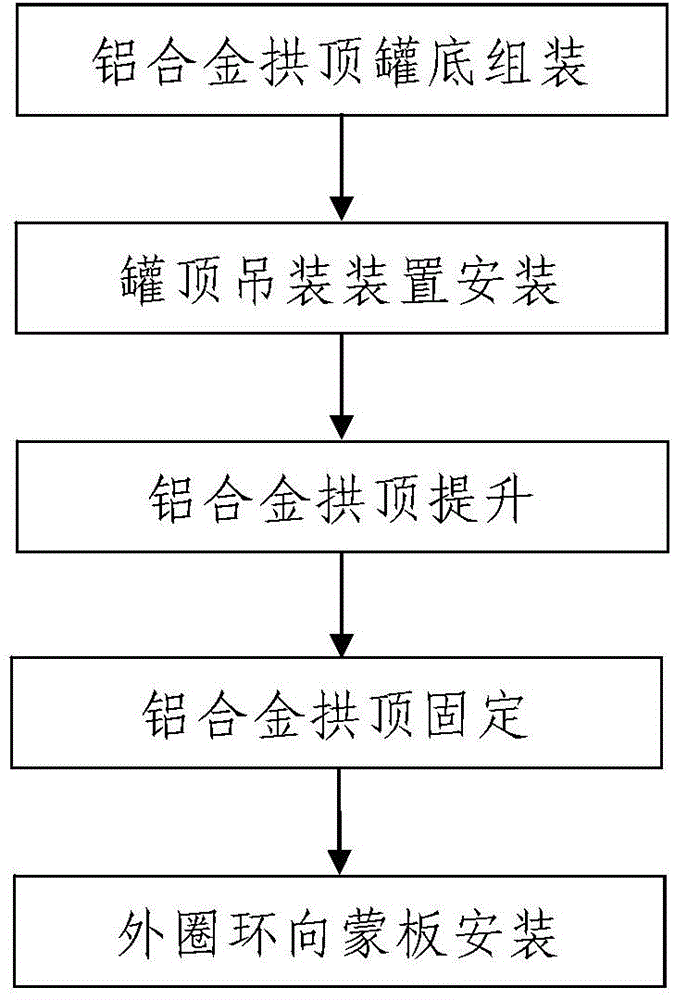

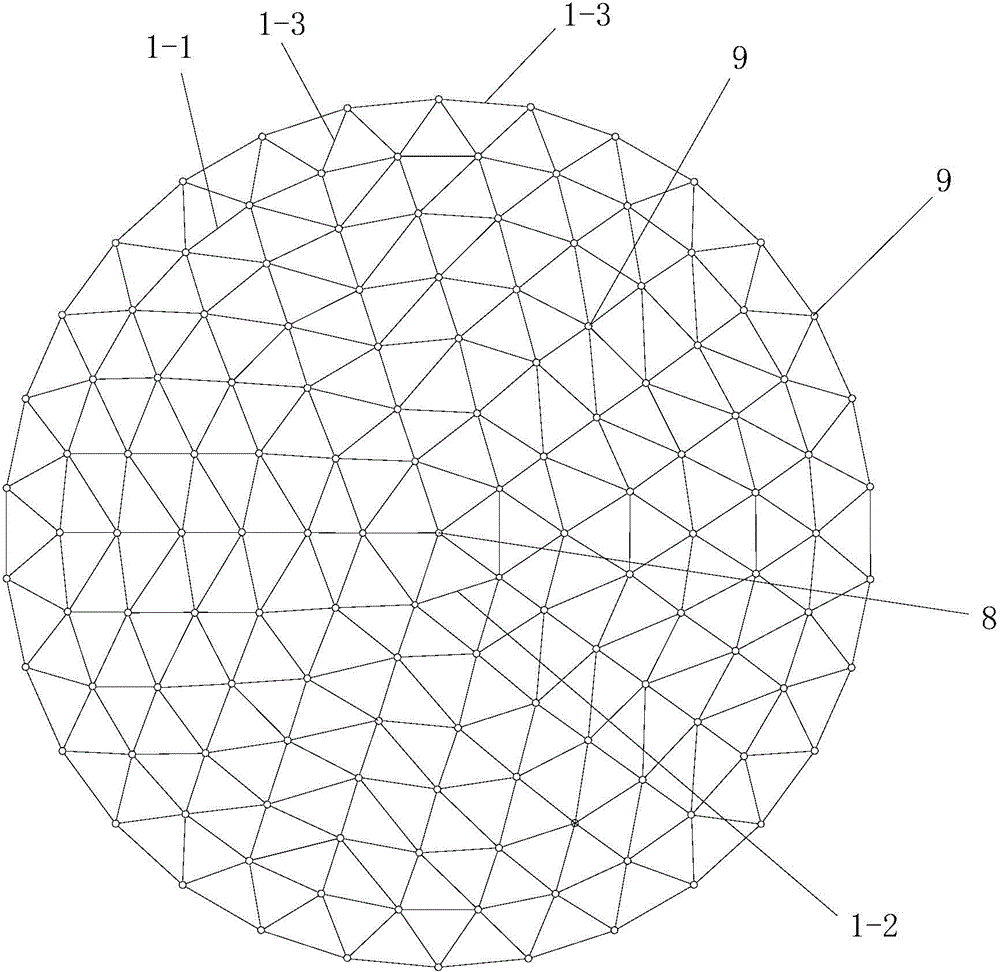

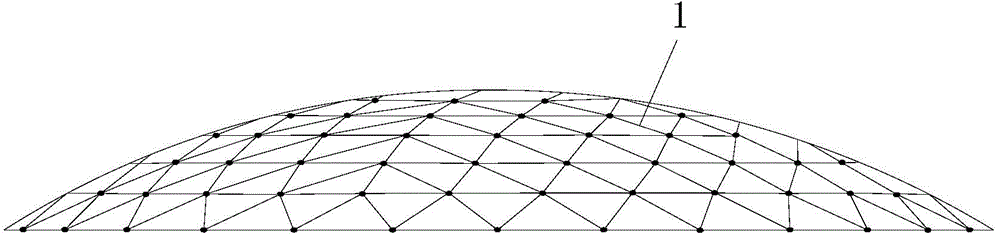

Construction method for single-piece hoisting of aluminum alloy vault of large vertical storage tank

InactiveCN104675171AThe method steps are simpleReasonable designBulk storage containerClerestoryMaterials science

The invention discloses a construction method for single-piece hoisting of an aluminum alloy vault of a large vertical storage tank. The aluminum alloy vault is fitted to the top of the large vertical storage tank in a covering manner; the aluminum alloy vault comprises a support frame and an outer mask covering the support frame; the support frame comprises a central connector and a plurality of ring beams distributed outside the central connector from inside to outside; the outer mask comprises a middle mask and a plurality of circumferential masks; the outermost one of the circumferential masks is an outer circular mask. The construction method includes: 1, assembling the aluminum alloy vault and a tank bottom; 2, mounting a tank top lift, namely, mounting the lift used for hoisting the required vault, outside the upper portion of the tank which is cylindrical; 3, hoisting the aluminum alloy vault; 4, fixing the aluminum alloy vault; 5, mounting the outer circular mask. The construction method has the advantages that steps are simple, the design is reasonable, construction is easier, construction is efficient, construction effect is good and the aluminum alloy vault can be hoisted to the large vertical storage tank simply and quickly.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Novel Chinese stewing pot device

A novel Chinese stewing pot device comprises a stewing pot body. The stewing pot body comprises a drum body at the upper portion and a pot bottom connected with the bottom of the drum body, an upper interlayer and a lower interlayer are arranged in the drum body and the pot bottom respectively, an upper interlayer cover is arranged in the upper interlayer, a lower interlayer cover is arranged in the lower interlayer, and steam pipelines are arranged in the upper interlayer cover and the lower interlayer cover. An upper circulating port is formed in the upper portion of the drum body, a stewing tray support is arranged on the inner side of the bottom of the drum body in the annular direction, and a plurality of layers of stewing trays are arranged on the stewing tray support. Stacked-up stewing tray frames form a drum shape from top to bottom, namely a stewing tray vertical drum. The stewing tray support seals the position between the bottom of the outer wall of the stewing tray vertical drum and the bottom of the inner wall of the drum body, and an annular cavity with the upper side open is formed by the outer wall of the stewing tray vertical drum, the inner wall of the drum body and the stewing tray support located at the bottom. The novel Chinese stewing pot device can ensure that materials stewed and boiled in the drum body are heated uniformly and the cooking degree and taste of the stewed and boiled materials are identical, control stewing temperature and progress accurately, and utilize internal space to increase the processing amount to the maximum extent.

Owner:CHUYING AGRO PASTORAL GRP

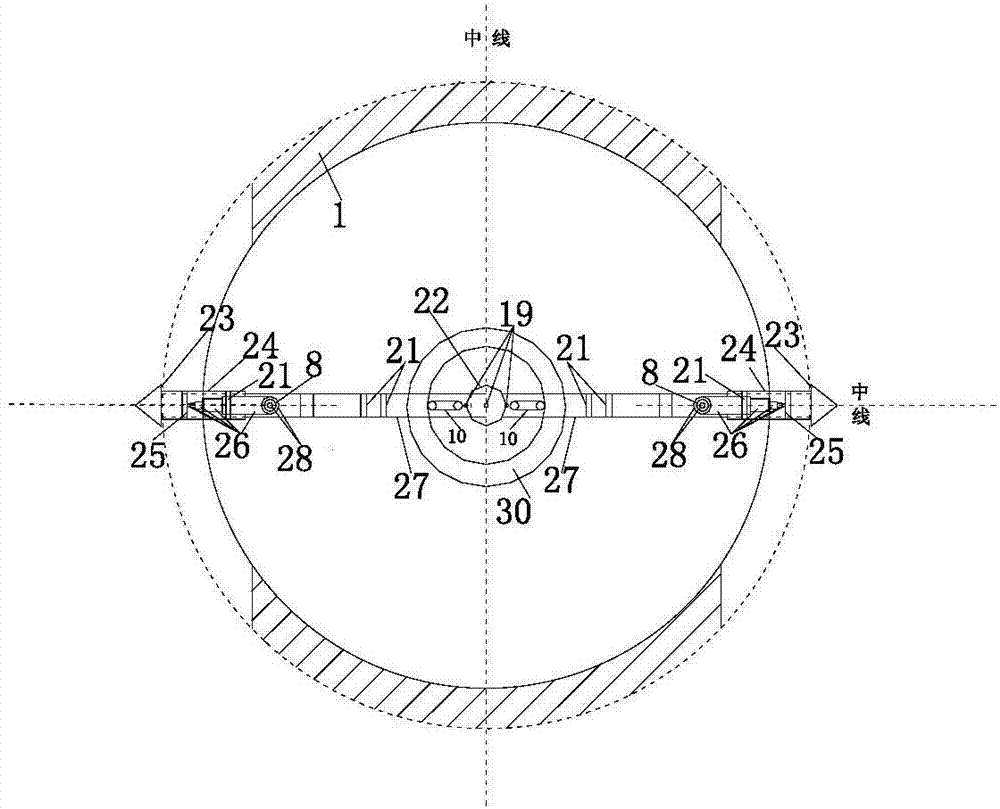

Device and method for monitoring differential settlement in portfolio for soil-stone combined region with hydraulic structure

ActiveCN104501772AEasy to disassembleFlexible liftingHeight/levelling measurementHydraulic structureRepeatability

The invention discloses a device and a method for monitoring differential settlement in portfolio for a soil-stone combined region with a hydraulic structure. The device comprises a bottom-through shaft and an inner carrying tube positioned inside the bottom-through shaft, wherein a displacement station is arranged in the inner carrying tube; drill driving devices are symmetrically arranged on two sides of the displacement station, and are connected with conical drills; the drill driving devices on two sides are respectively connected with lifting devices which are used for promoting motion of the drill driving devices; correcting devices which are used for correcting level of the displacement station are symmetrically arranged at two ends of the displacement station; the middle part of the displacement station is connected with one end of a group of symmetrically arranged springs, and the other end of each spring is hinged with a vertical measuring tape; an optical fiber hanging drum is arranged between two springs, and is filled with a corrugated loop optical fiber; and an optical fiber buckle is arranged on the corrugated loop optical fiber. The device has the advantages of use repeatability, convenience in assembly, real-time detection and maintenance and the like, and has the characteristics of distribution type, micro-macro structure, real-time performance, high adaptability to complex environment and the like.

Owner:HOHAI UNIV

Aluminum alloy lift

The invention discloses an aluminum alloy lift. The aluminum alloy lift also comprises a tilt supporting mechanism used for controlling a lifting body to tilt a certain angle; the lifting body comprises more than one mast groups and a supporting frame; each mast group comprises a tail mast, an upper mast, a plurality of middle masts, and a hydraulic cylinder; the masts are arranged from top to bottom, and upper masts can slide vertically along the lower masts; the upper end of each middle mast is provided with a driving sprocket and a sprocket frame; the driving sprocket is fixed on the sprocket frame; one end of a transmission chain is matched with the sprocket, and the other end of the transmission chain is arranged on the next mast; hydraulic cylinders are arranged on a base plate; the heads of the hydraulic cylinders are hinged with a lowermost pair of sprocket frames; the tilt supporting mechanism comprises a power cylinder; a cylinder body of the power cylinder is arranged on the base; and the top of a cylinder rod is connected with the supporting frame. By the structure, the aluminum alloy lift lifts flexibly and can be operated by one person; and the tilt supporting mechanism is arranged, so that the whole lift can tilt a moving angle, and can enter a narrow space for operation.

Owner:济南华北升降平台制造有限公司

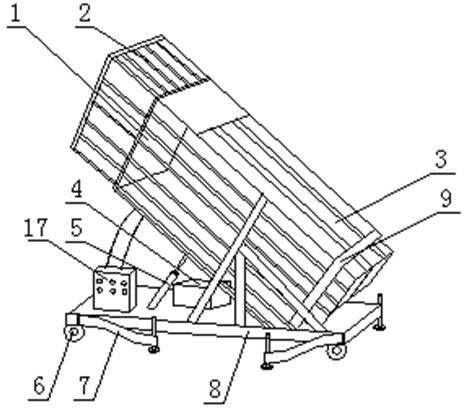

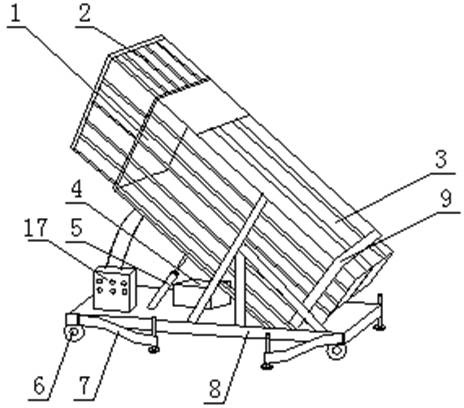

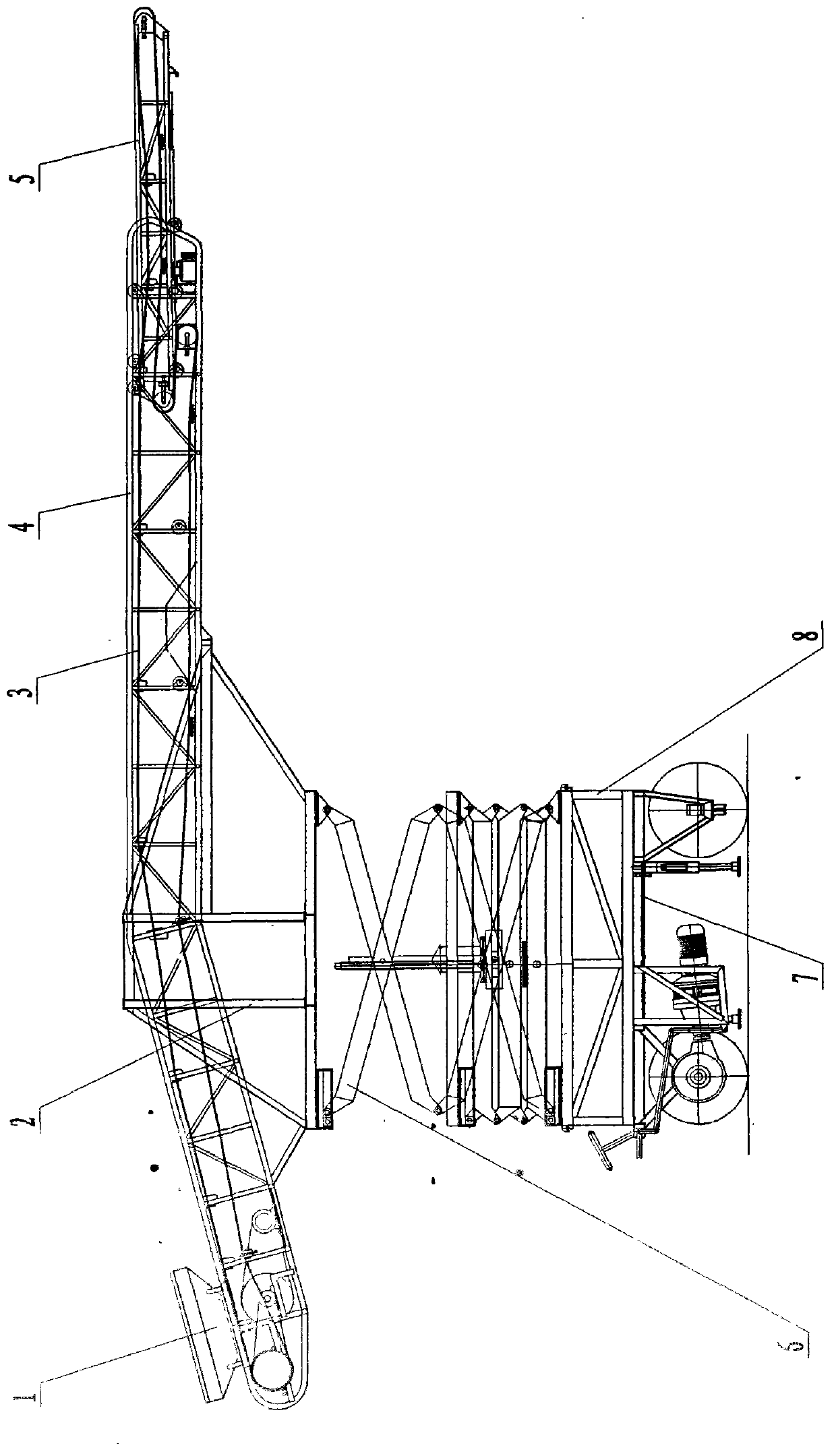

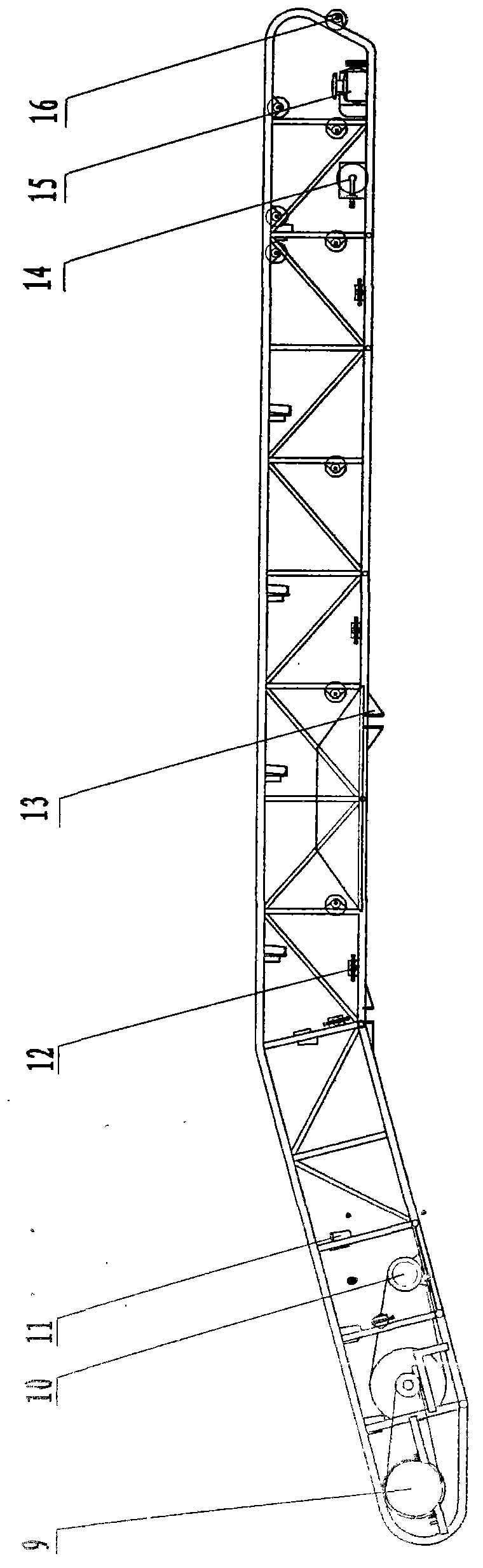

Movable and retractable type elevated grain binning machine

InactiveCN103863836AAdjustable conveying distanceExtend the entry distanceLoading/unloadingAutomatic controlElectric machinery

The invention discloses a movable and retractable type elevated grain binning machine, which is characterized in that an automobile chassis is adopted; an electric transmission mode is provided; the flexible variability of use conditions is improved; a lifting mechanism adopts a fork lever mechanism and an electric rectangular screw lifting mechanism, so that equipment is flexibly controlled to lift; as a retractable type framework structure is adopted for warehousing, the conveying distance of conveying equipment entering a grain bin can be adjusted; a main conveying rack is internally provided with a retractable sub-rack; after a conveying base rack is inserted into a window of the grain bin, the grain warehousing distance can be prolonged by stretching out the sub-rack; a lifting rack adopts a simple-structure fork lever combination and a rectangular screw combination with chain driving and automatic locking; the effect of automatic control on lifting is realized through motor control. According to the movable and retractable type elevated grain binning machine, as the automatic chassis is simultaneously adopted, and a driving mode of a motor and a cycloidal pinwheel speed reducer is also provided, the performances of free movement for workplace change, free retraction, simple operation and the like are realized; the effects of high efficiency and energy conservation are realized as well.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

smart robot

The embodiment of the invention provides an intelligent robot for solving the problem that in the prior art, the intelligent degree of an intelligent robot needs to be improved. The intelligent robot comprises a head, a body connected with the head, a base connected with the body, an image obtaining device for obtaining image data, a controller for analyzing the image data obtained by the image obtaining device to obtain analysis data, matching the analysis data with at least one preset datum and sending a corresponding movement instruction to a driving device when the analysis data are matched with at least one of the preset data, and the driving device for controlling at least one of the head and the body to rise and fall or rotate according to the movement instruction sent by the controller. By means of the intelligent robot, the intelligence degree of the intelligent robot can be increased, implementation is convenient, and application and popularization are easy.

Owner:成都英博格科技有限公司

Traction type anti-kidnapping device for automobile

InactiveCN103303243AReasonable forceEasy to liftPedestrian/occupant safety arrangementElectric machineryEngineering

A traction type anti-kidnapping device for an automobile solves the problems that in the conventional transmission mechanism, unbalanced loading is easily caused, an upper beam assembly unbalances to cause unstable lift, and the restriction on attacking people in the automobile is failed, and comprises an upper beam assembly, a lower beam assembly and a transmission mechanism assembly which are assembled at the bottom of a seat in the automobile. The technical key points of the traction type anti-kidnapping device are as follows: the transmission mechanism assembly adopts two groups of transmission mechanisms which are symmetrically arranged; two symmetrically arranged motors in each group of transmission mechanism respectively drive respective driving wheels to rotate and draw transmission ropes to drive sliding blocks to move towards sleeve guide sliding grooves, as a result, two upper supporting rods and two lower supporting rods which are symmetrically distributed on the upper beam assembly and the lower beam assembly synchronously extend and drive the upper beam assembly to be lift in a balanced way, and a seat cushion and the backrest of the seat form an oblique included angle. The stress of components is reasonable in distribution; limited space in the bottom of the seat in the automobile is fully utilized; the lift is light, convenient, flexible and stable; the use is safer and more reliable; the anti-kidnapping performance is further improved; and a driver is effectively protected from being attacked by people in the automobile.

Owner:李尚贤

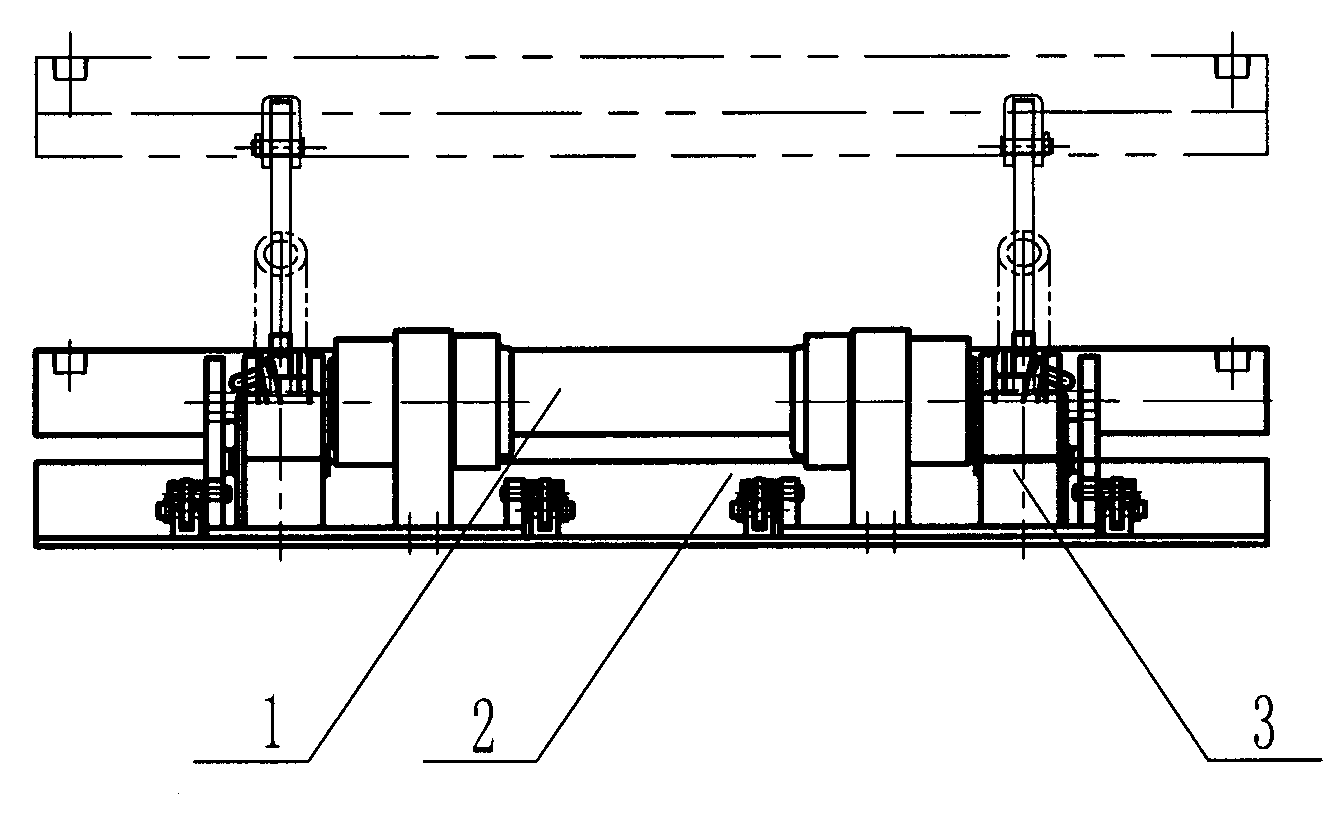

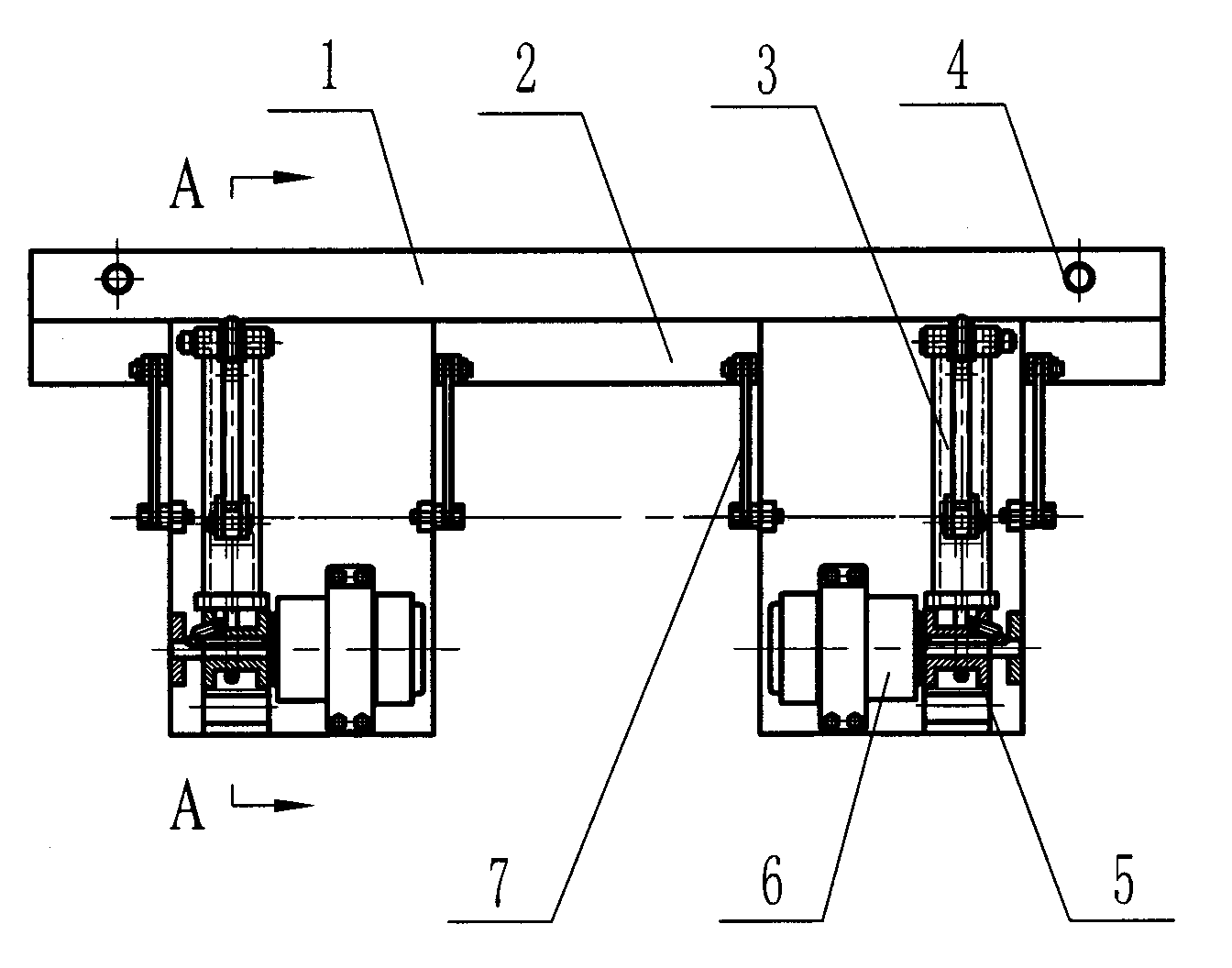

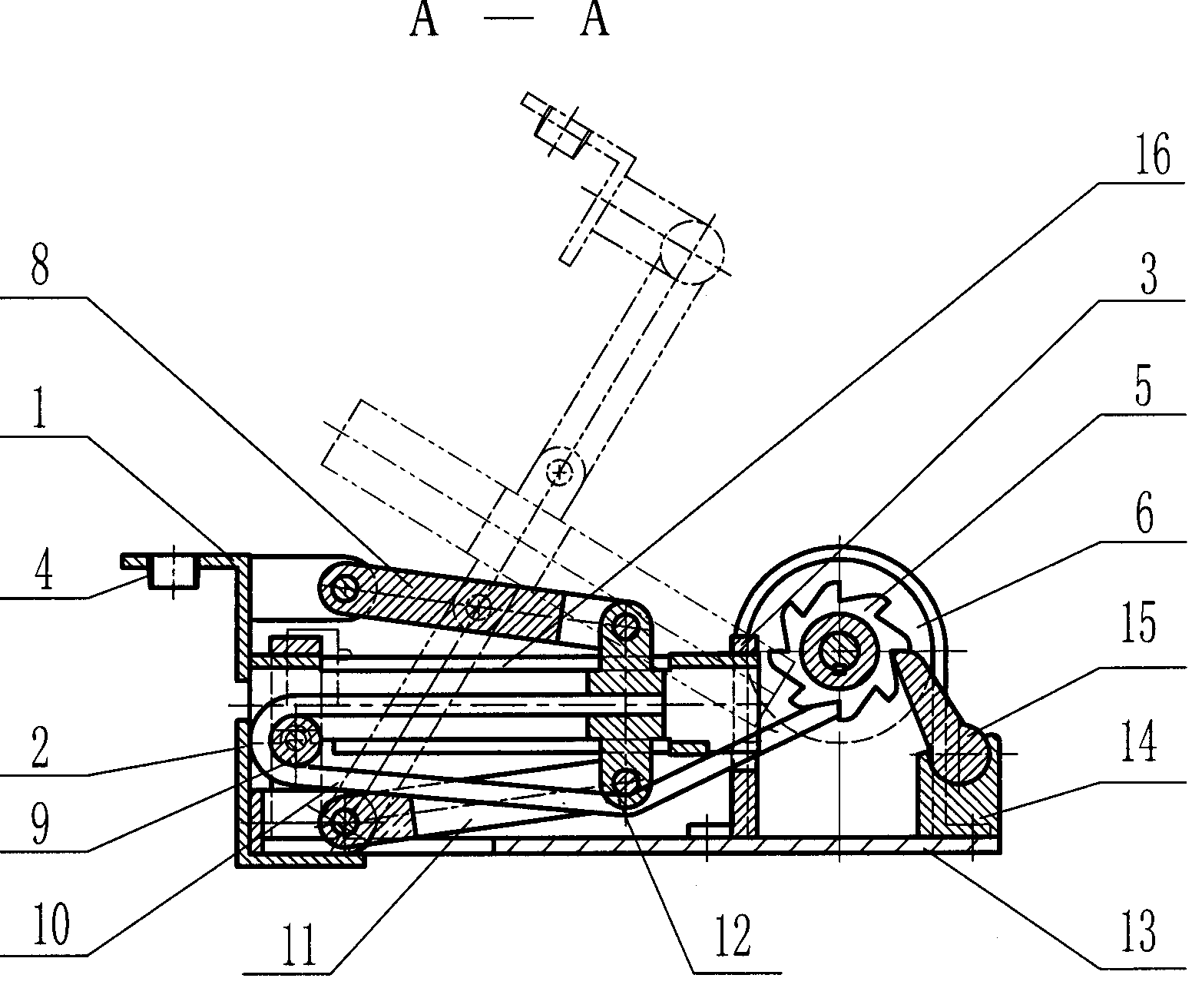

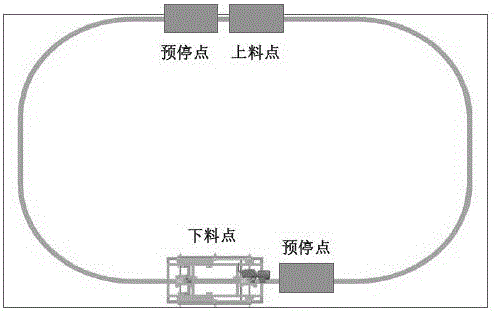

Flexible clamp apparatus for automobile assembly parts conveying system

The invention discloses a flexible clamp apparatus for an automobile assembly parts conveying system, comprising two bearing beams parallel to each other; a slide rail is provided between the two bearing beams, at least two clamp units are disposed on the slide rail, a spacing adjustment is arranged between the two bearing beams, each clamp unit comprises a support frame slidably and fitly mounted on the slide rail, two ends of the support frame are provided with clamp mechanisms respectively, each clamp mechanism comprises a connecting sleeve, the upper end of each connecting sleeve is provided with a connecting shaft that is rotationally fitly connected with the corresponding support frame, a rotational drive mechanism is arranged on each support frame, the lower end of each connecting sleeve is provided with a clamp support that is provided with a switching support mechanism, each switching support mechanism comprises two rotary shafts arranged horizontally and parallel to each other with the two rotary shafts being rotationally fitly mounted to the corresponding clamp supports respectively, a connecting fork is connected to each rotary shaft, a support rod is releasably mounted on each connecting fork, each support rod is provided with a positioning pin or a V-shaped block, and each clamp support is provided with a switching drive mechanism.

Owner:CHONGQING UNIV

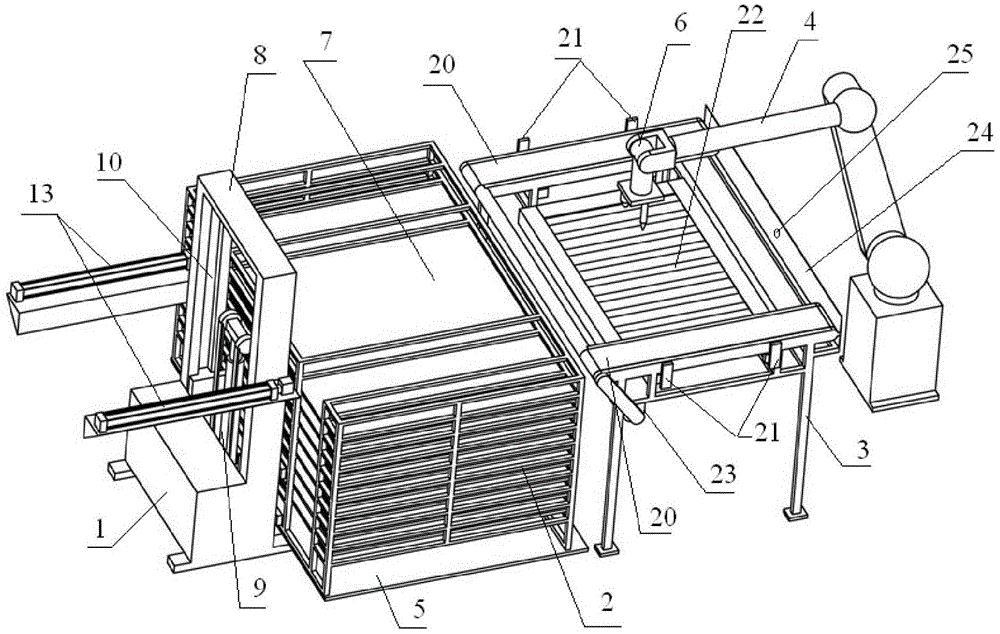

Horizontal intelligent detection and repair machine for screen printing templates

InactiveCN105628713AImprove accuracyIncrease productivityOptically investigating flaws/contaminationConveyor partsAutomotive engineeringWater source

The invention discloses a horizontal intelligent detection and repair machine for screen printing templates. The horizontal intelligent detection and repair machine comprises a lifting conveying mechanism, a template box, a detection and repair rack and a mechanical arm. The lifting conveying mechanism is arranged at the front end of the template box, a lifting table is arranged on the lower portion of the lifting conveying mechanism, and the template box is placed on a bottom plate of the lifting table. The detection and repair rack is arranged at the rear end of the template box, and the templates in the template box can be conveyed onto the detection and repair rack by the lifting conveying mechanism. The mechanical arm is arranged behind the detection and repair rack, a detection and repair device is connected to the mechanical arm in a pivoted mode, and the templates on the detection and repair rack can be detected and repaired through the detection and repair device on the mechanical arm. The horizontal intelligent detection and repair machine has the advantages of improving production efficiency and relieving the labor intensity of workers; the horizontal intelligent detection and repair machine is simple and improves the stability and reliability in the loading and unloading process; flexible lifting of the template box can be completed in the template detection process; meanwhile, real-time feedback can be achieved to improve repair precision; water sources can be saved; the horizontal intelligent detection and repair machine is convenient and flexible to use and compact in structure.

Owner:JILIN UNIV

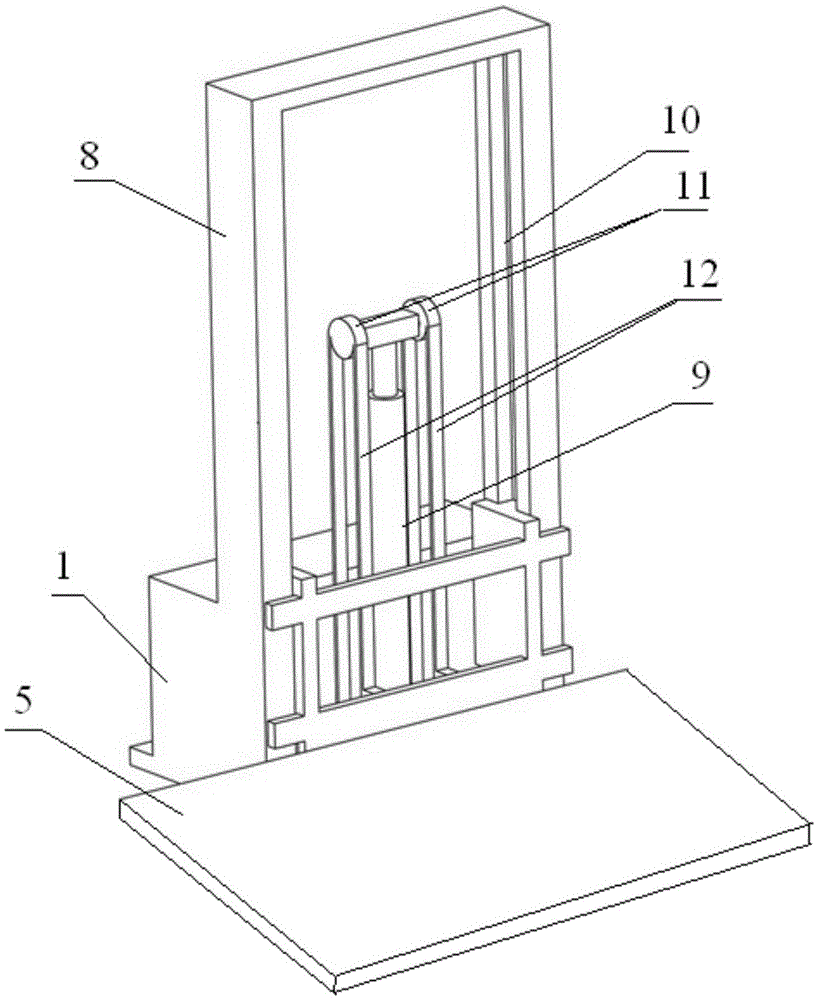

Bearing loading and unloading system of tray-free drying vehicle

The invention discloses a bearing loading and unloading system of a tray-free drying vehicle. The system comprises a top frame; a moving trolley is slidably arranged on the top frame; a guide frame ismounted at the bottom of the moving trolley; a second motor is fixedly mounted on the guide frame; the second motor is connected with a bracket through a second gear and a second chain; a third motoris further fixedly installed on the guide frame, and connected with a belt conveyor through a third gear and a third chain; a belt conveying device used for conveying green bricks is arranged at oneside of the belt conveyor; and the drying vehicle is arranged under the top frame, and located between the bracket and the belt conveyor. The bracket and the belt conveyor in the loading and unloadingsystem can be accurately butted and flexibly lifted, the green bricks can be quickly transferred, and the working efficiency is high; the green bricks can be conveniently arranged on different layersof the drying vehicle by means of the bracket; and the drying vehicle is simple in structure, convenient to produce, light, convenient and fast and convenient to move.

Owner:安徽兴林机械集团有限公司 +1

Telescopic cylindrical lift

The invention discloses a telescopic cylindrical lift, which comprises an operating platform, a base arranged below the operating platform, a telescopic cylindrical cylinder, and a tilt supporting mechanism used for controlling the telescopic cylindrical cylinder to tilt a certain angle, wherein more than two telescopic cylinders are arranged in the telescopic cylindrical cylinder, and are sleeved with one another; the innermost telescopic cylinder is provided with a plunger rod; the top of the plunger rod is connected with the bottom of the operating platform; an oil pump station is connected with the telescopic cylindrical cylinder through a pipeline; the tilt supporting mechanism comprises a power cylinder; a cylinder body of the power cylinder is obliquely arranged on the base; and the top of a cylinder rod of the power cylinder is connected with the telescopic cylindrical cylinder. The invention has the advantages that: the telescopic cylindrical lift is provided with the plurality of telescopic cylinders sleeved, lifts flexibly, can be regulated as required and has high safety; and the tilt supporting mechanism is arranged, so that the whole lift can tilt a moving angle.

Owner:济南华北升降平台制造有限公司

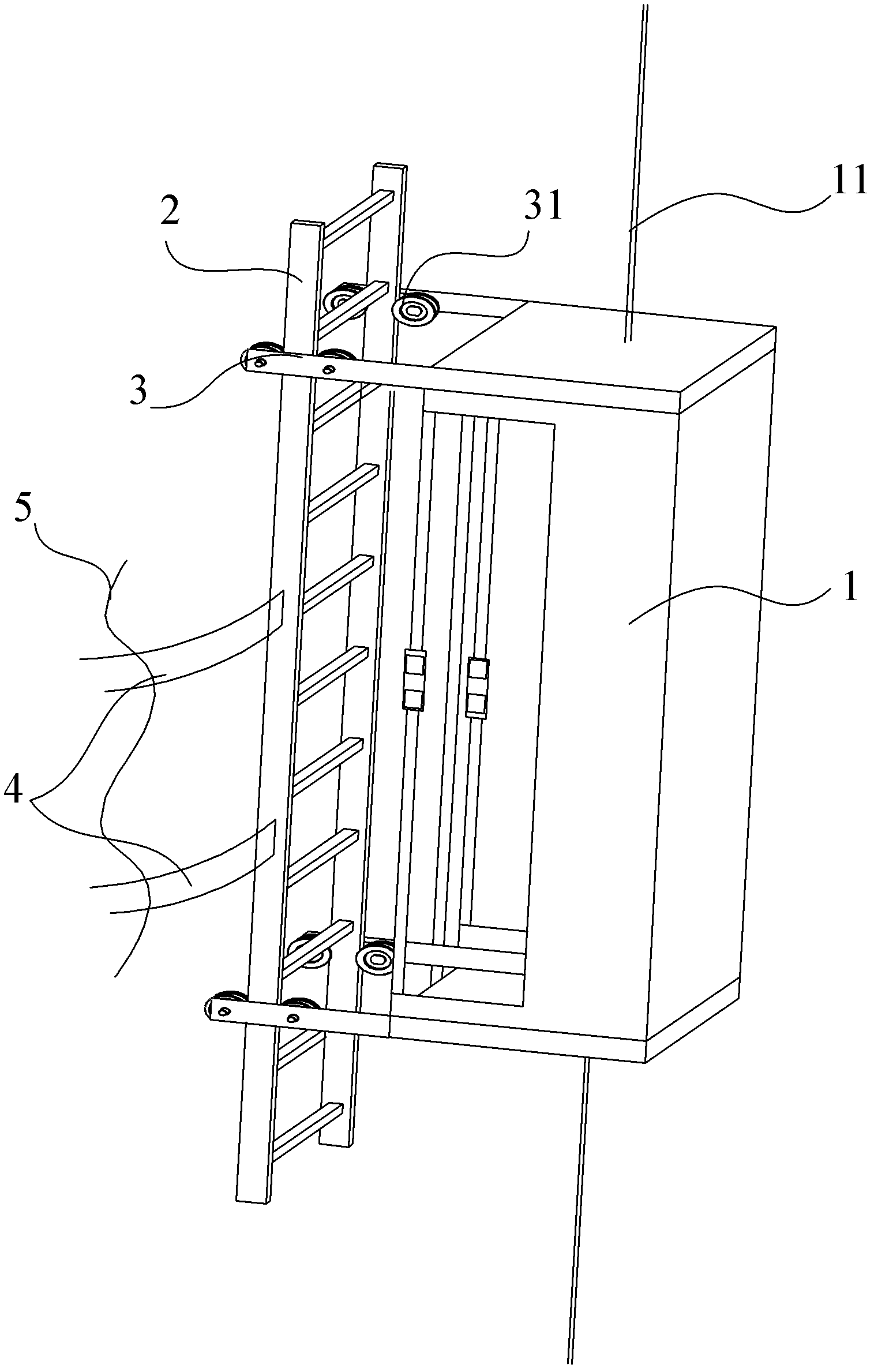

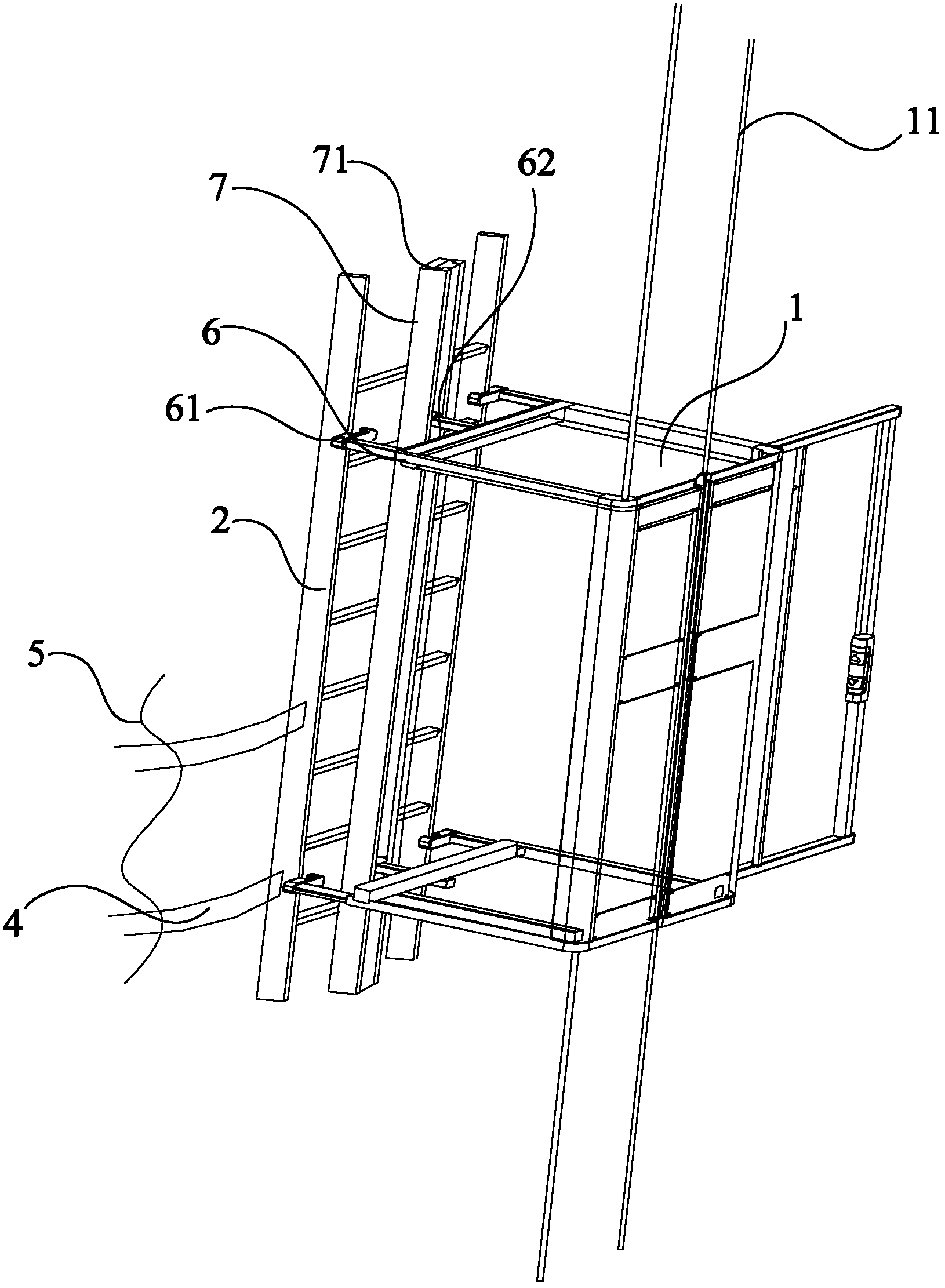

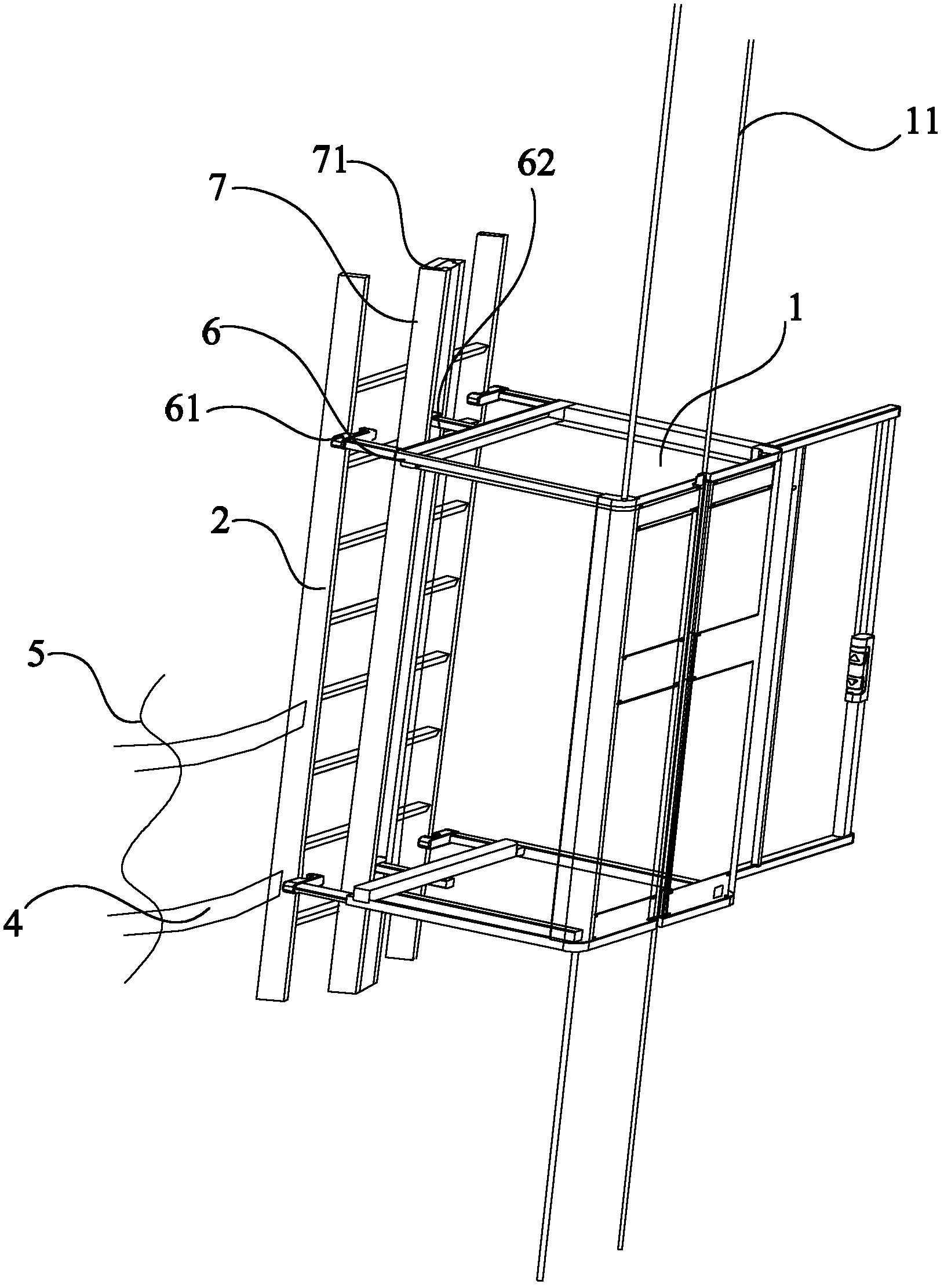

Miniature manned elevator for tower of wind turbine

The invention discloses a miniature manned elevator for a tower of a wind turbine. The miniature manned elevator comprises an elevator car, a straight ladder, a support frame and a sliding mechanism, the support frame is used for supporting the straight ladder, the sliding mechanism is used for leading the elevator car to vertically slide along the straight ladder and consists of at least two guiding supports, the guiding supports are mutually parallelly fixed onto a side surface, opposite to the straight ladder, of the elevator car, a clamp block clamped with a corresponding armrest of the straight ladder is disposed at the end of each guide support, and the clamp blocks are separated from the support frame when close to the support frame. The elevator car is connected with the armrests of the straight ladder in an adjacently clamped manner, so that the manned elevator ascends and descends in the tower of the wind turbine flexibly. In addition, the elevator car and the straight ladders are relatively fixed, so that stability is improved, and safety of personnel is guaranteed.

Owner:SHANGHAI AUSTRI WIND POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com