PC component die table cleaning device and working method thereof

A technology for cleaning device and mold table, which is applied to cleaning methods and utensils, cleaning method using tools, cleaning method using gas flow, etc. , difficult to clean concrete chips, etc., to prevent pollution of the working environment, simple and convenient structure, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

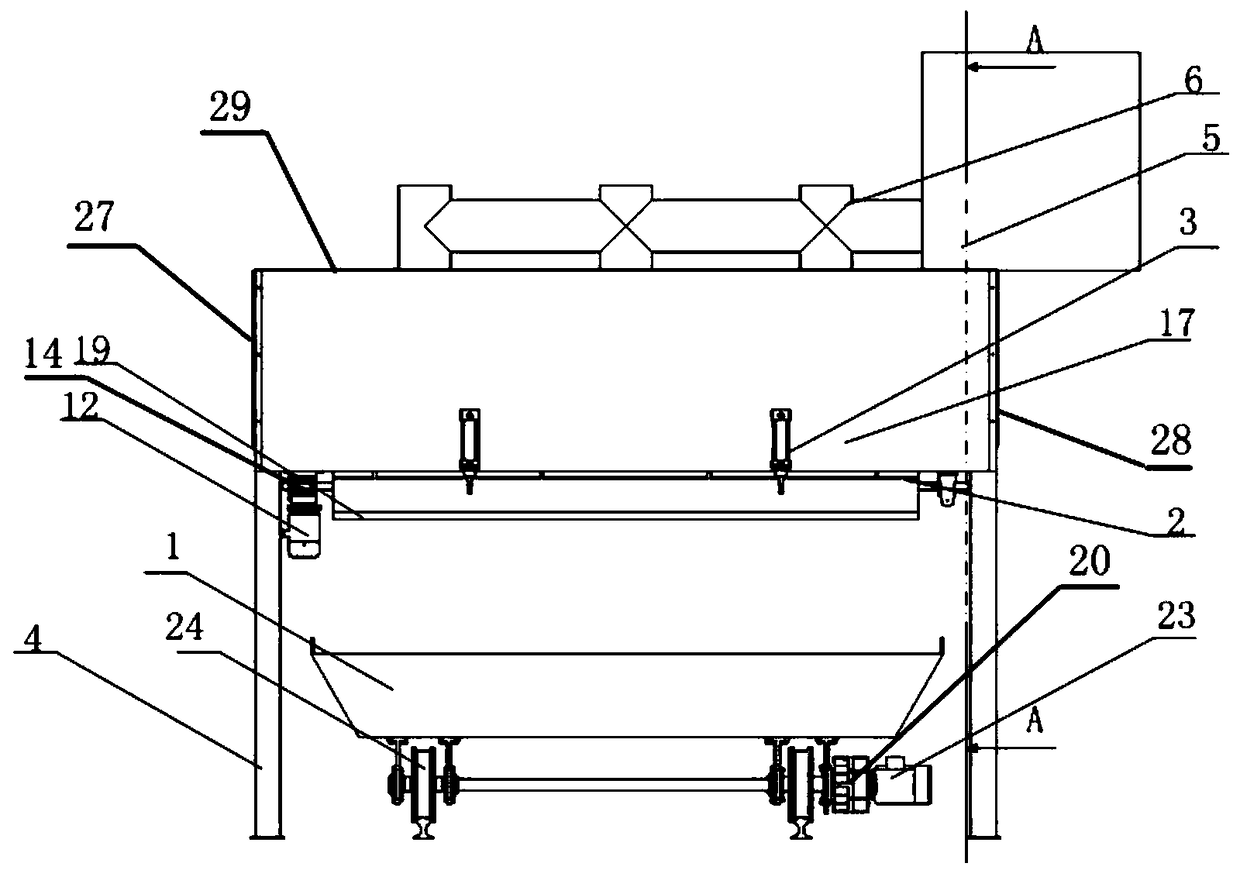

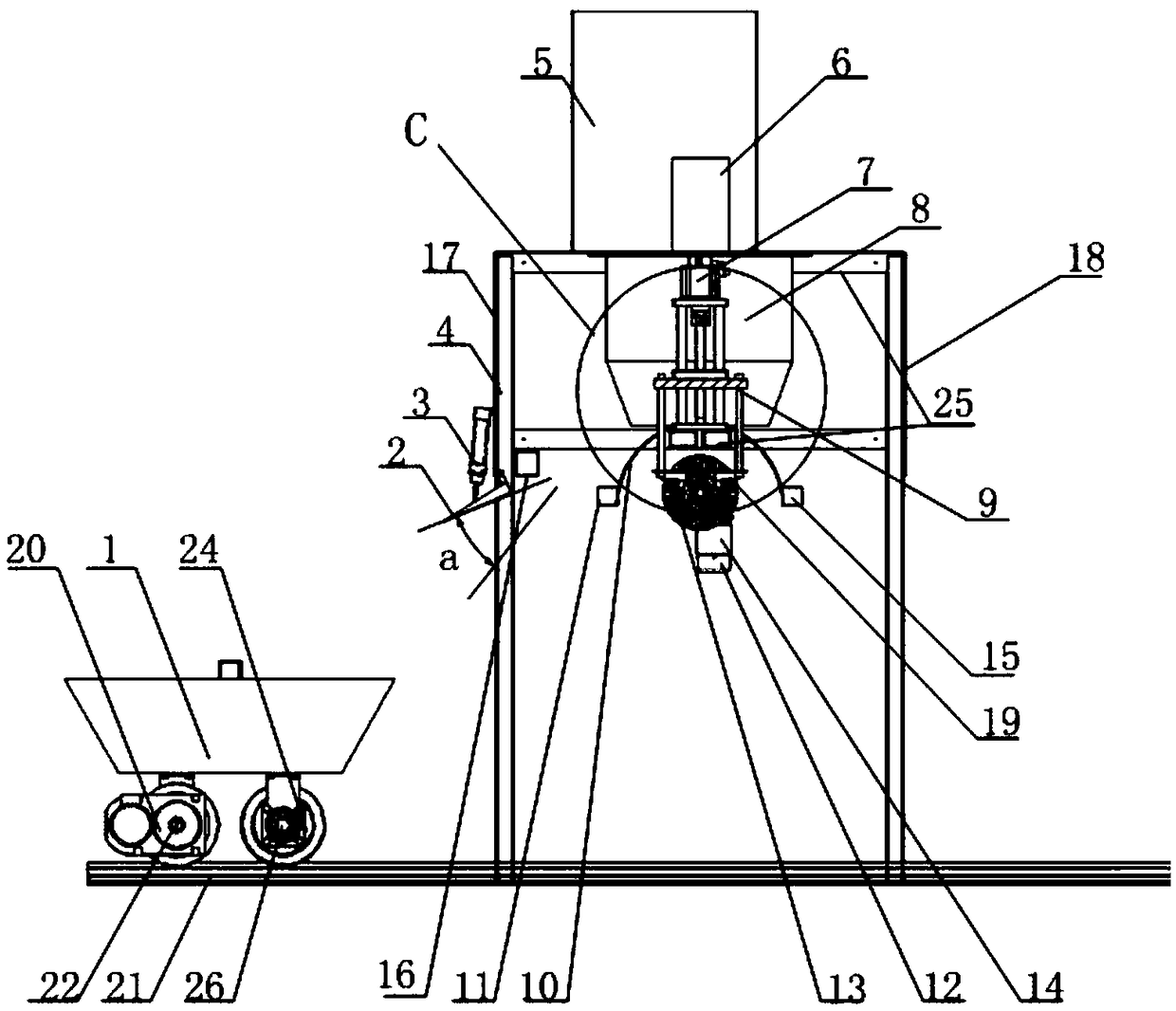

[0033] Such as figure 1 , figure 2 with image 3 Shown: a PC component mold table cleaning device, including a main frame 4, a scraper 2 is hinged on one side of the main frame 4, a scraper cylinder 3 is arranged between the scraper 2 and the main frame 4 , The side of the main frame 4 where the scraper cylinder 3 is provided with a distance measuring sensor 16, which also includes a lifting mechanism, a cleaning structure, a dust removal mechanism, and a mold platform transport mechanism;

[0034] The cleaning mechanism is set up and down in the main frame 4 through the lifting mechanism, and the mold table transport mechanism is set below the cleaning mechanism;

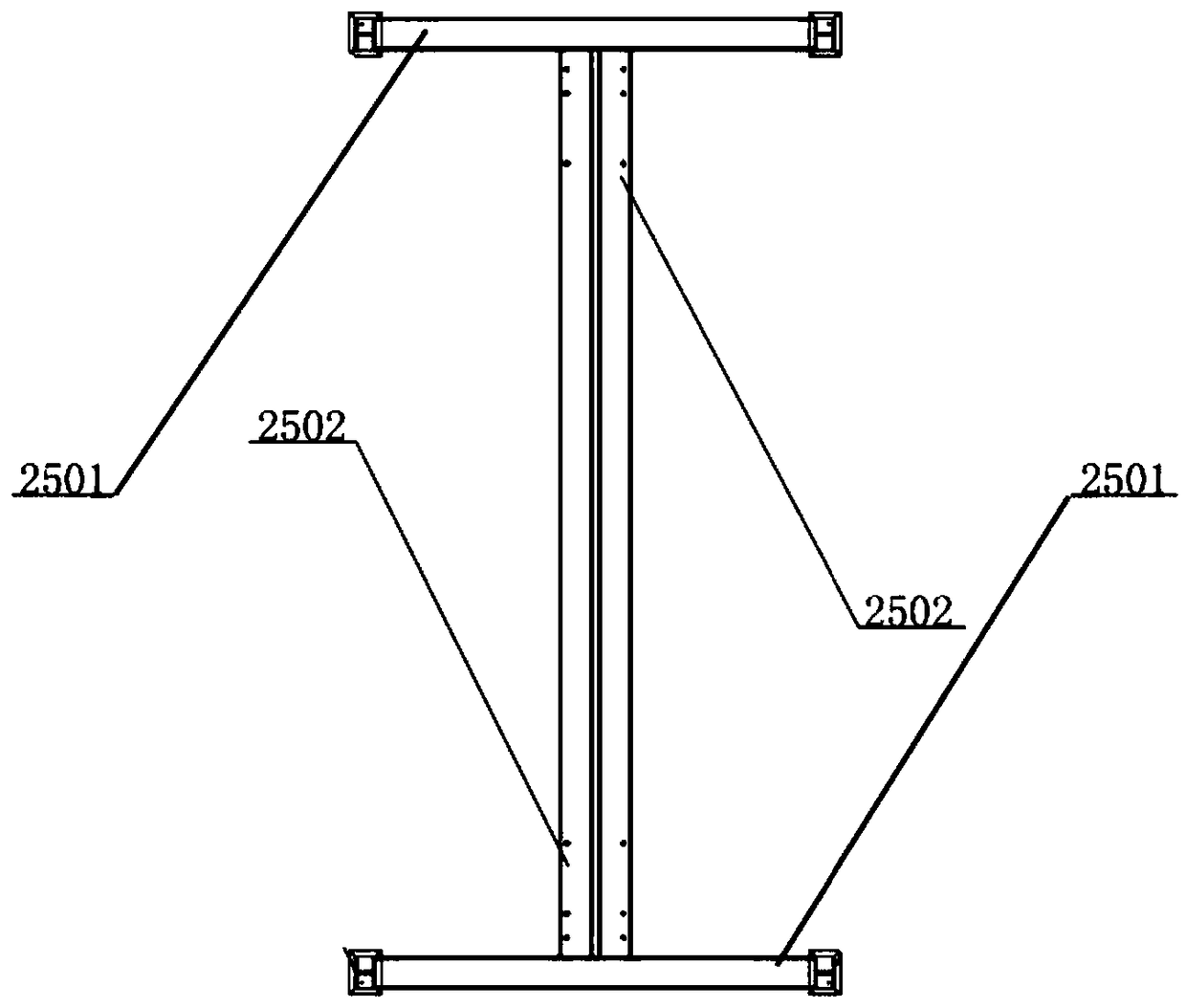

[0035] The lifting mechanism mainly includes a servo motor 7, a screw rod 902, a screw nut 906, and a lifting frame 9. One end of the servo motor 7 is equipped with a connecting plate 908, and the output shaft of the servo motor 7 is connected to the shaft through a coupling 905 The screw rod 902 is in transmission con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com