Movable and retractable type elevated grain binning machine

A mobile telescopic and grain technology, applied in the field of warehouse grain loading and unloading, can solve the problems of restricting implementation, low degree of automation, and lack of special equipment for grain bulk loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

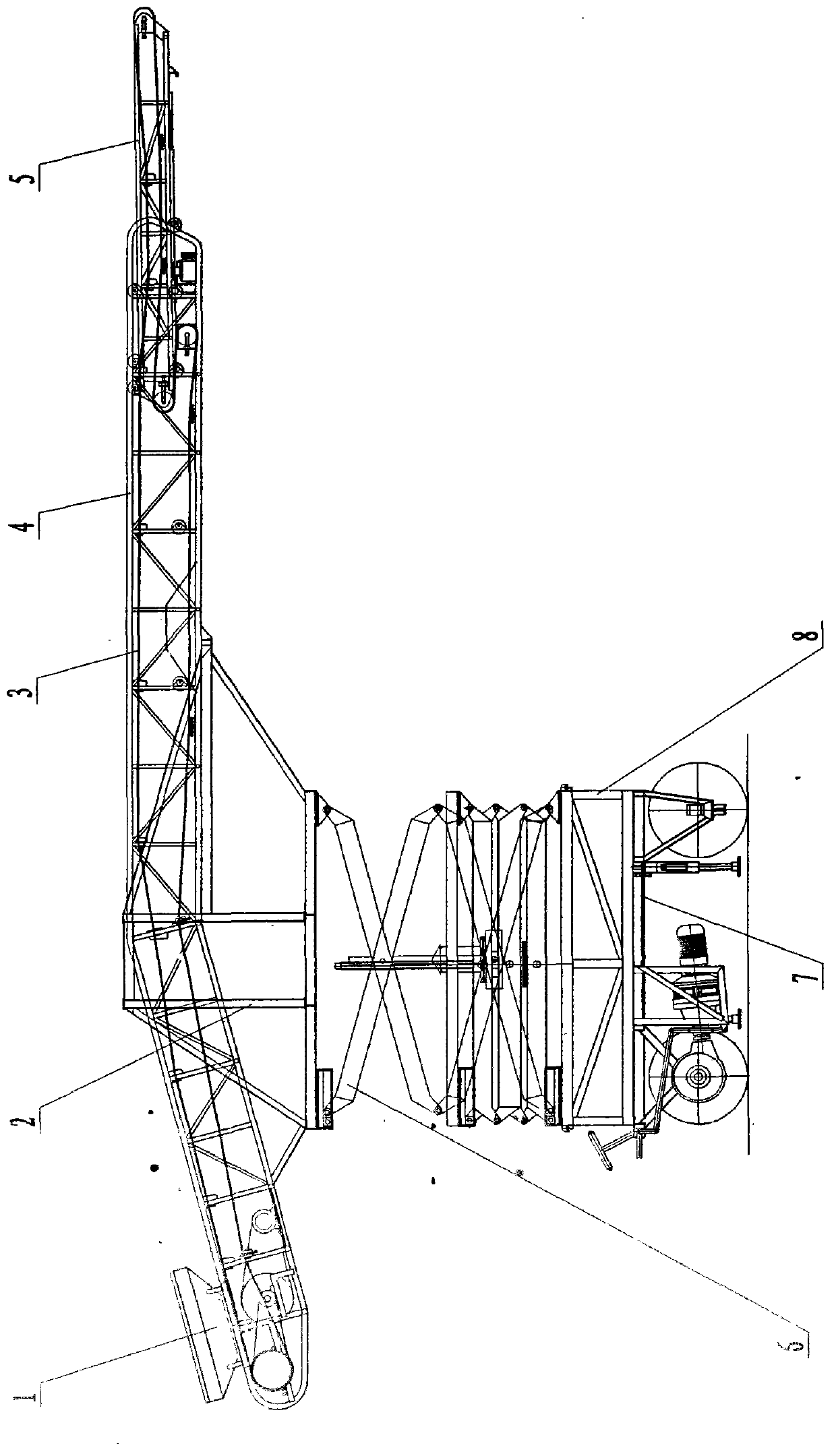

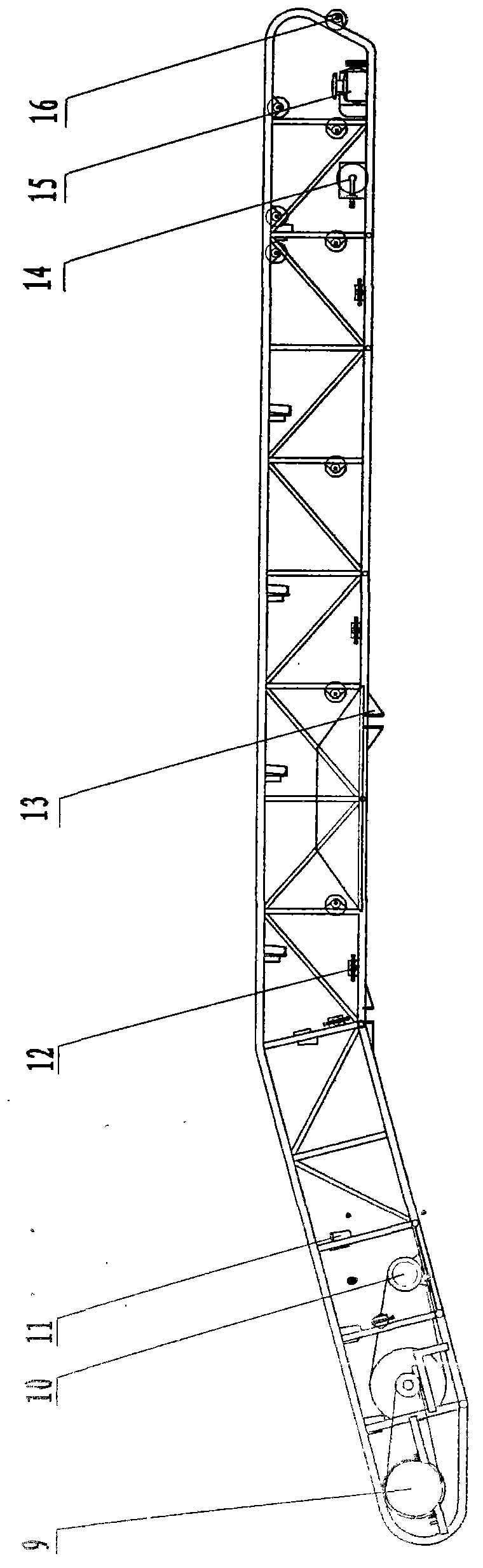

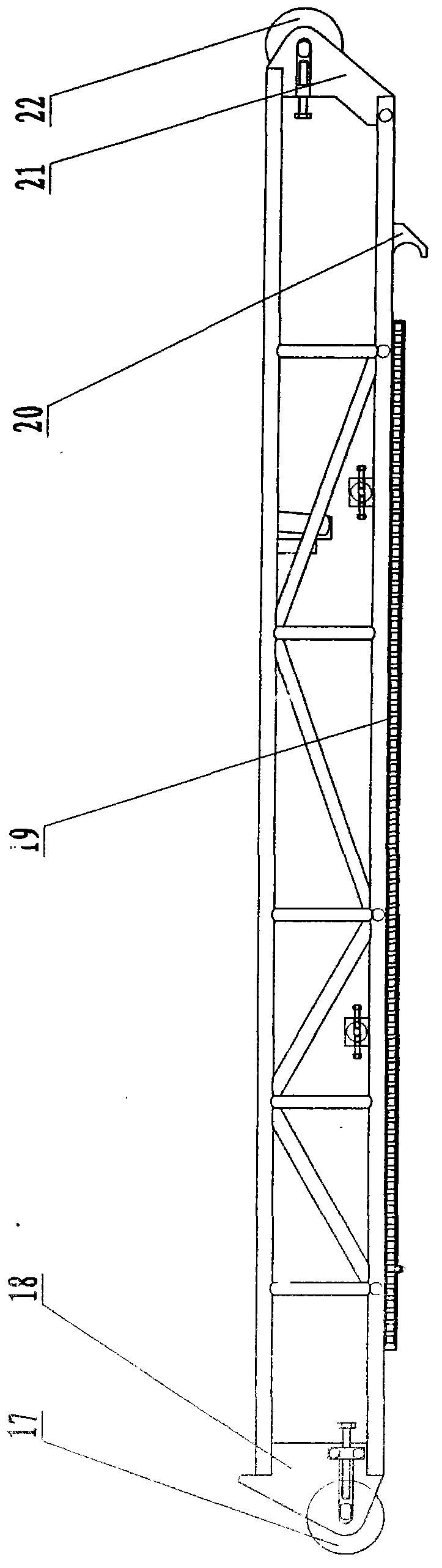

[0007] The products involved in this project are as follows: figure 1 As shown, the main conveyor frame mother frame 4 is welded on the support frame 2 through the fixed connecting plate 13; The main conveyor frame mother frame 4 is provided with an upper roller 11 and a lower flat roller 12 for supporting the rubber conveyor belt 3; the rubber conveyor belt 3 passes through the driving roller 9, the first diversion roller 14, the second diversion roller 17 No. 3 reversing drum 22 is connected into a curved ring; power is provided through the motor 10 to make the rubber conveyor belt 3 complete the motion cycle, so that the grain reaches the effect of entering the warehouse. The tail end of the main conveyor frame mother frame 4 is provided with a feed hopper 1, and the grain is transported to the feed hopper 1 by conveying equipment when entering the warehouse; then the function of entering the warehouse is completed. Such as figure 2 As shown, the main conveyor frame moth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com