Fire-fighting telescopic belt conveyor

A telescopic belt conveyor and belt conveyor technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of inability to flexibly adjust the conveying distance, and achieve the effect of good applicability and adjustable conveying distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

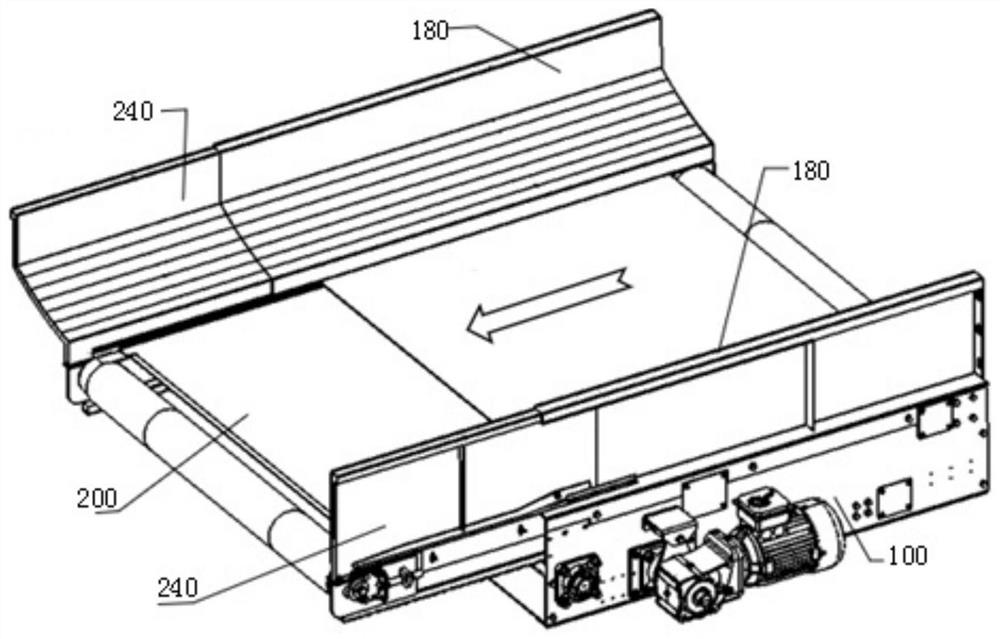

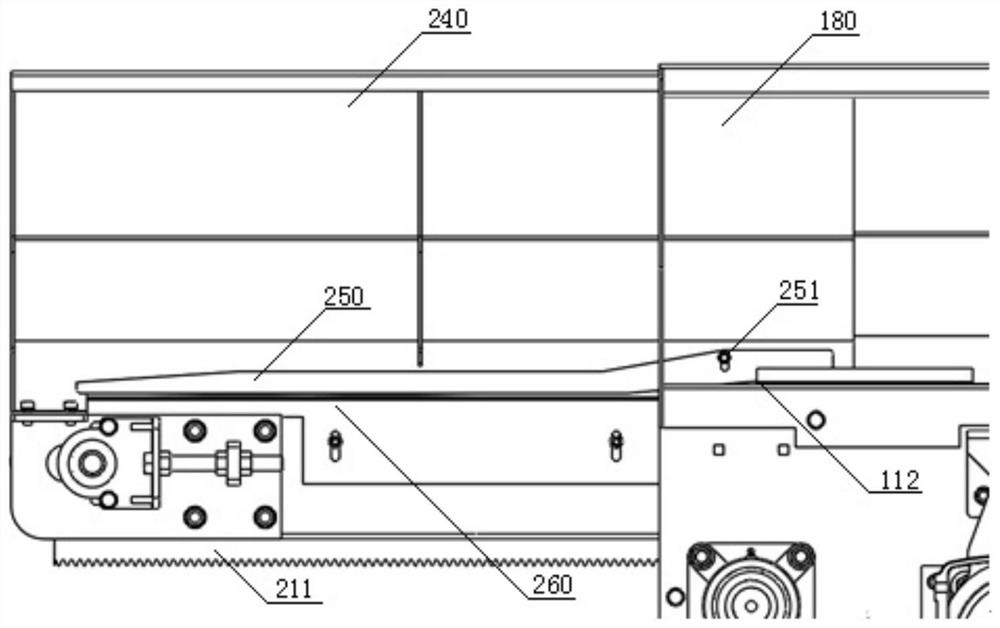

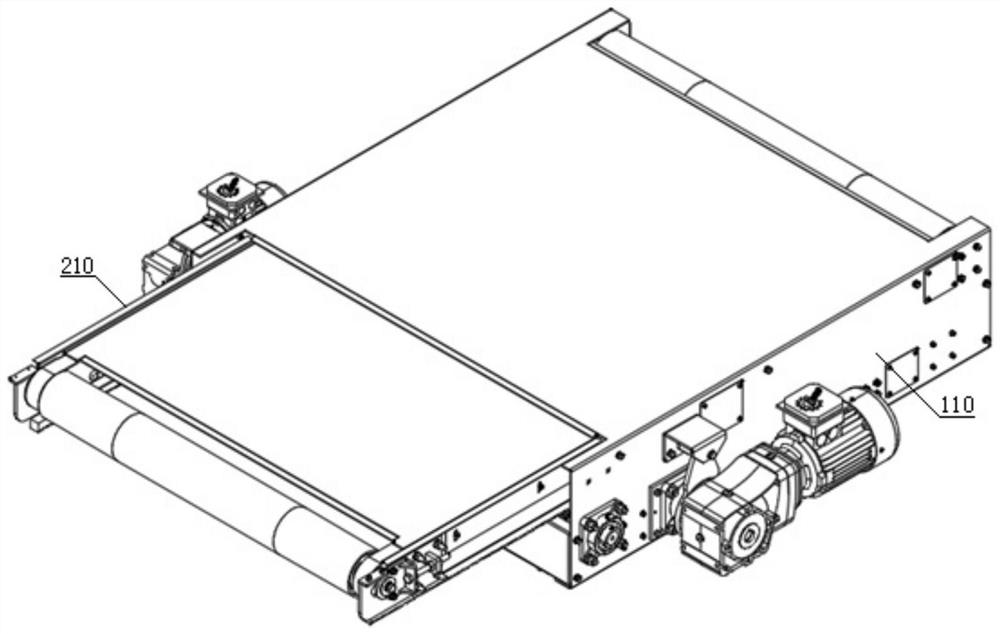

[0026] like figure 1 , 3 , 4, 5, 6, and 7, the fire-fighting telescopic belt conveyor of the present invention includes a belt conveyor fixed section, a belt conveyor telescopic section, and the belt conveyor fixed section includes a fixed section frame, and the lower floor head end of the fixed section frame is provided with a driving drum, The upper end of the fixed section frame is provided with a fixed section tail roller, and the telescopic section of the belt conveyor includes a telescopic section frame. roller. The first drum of the telescopic section and the tail drum of the fixed section are equipped with conveyor belts, and the conveyor belt passing through the tail drum of the telescopic section and the driving drum is wound on the tail drum of the telescopic section and the driving drum. The belt motor drives the driving drum to rotate, and the driving drum Drive the conveyor belt to run. The telescopic section frame and the inner side of the upper layer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com