Novel Chinese stewing pot device

A Chinese-style, new type of technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of hidden product quality, easy damage of materials, large heat loss, etc., and achieve stable product quality, reduced labor, and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

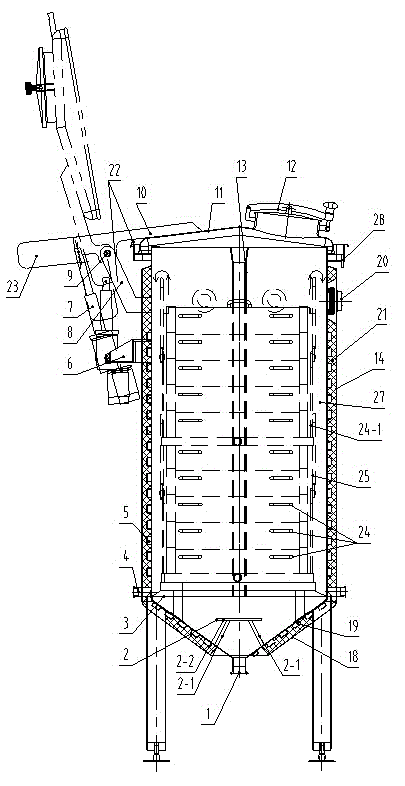

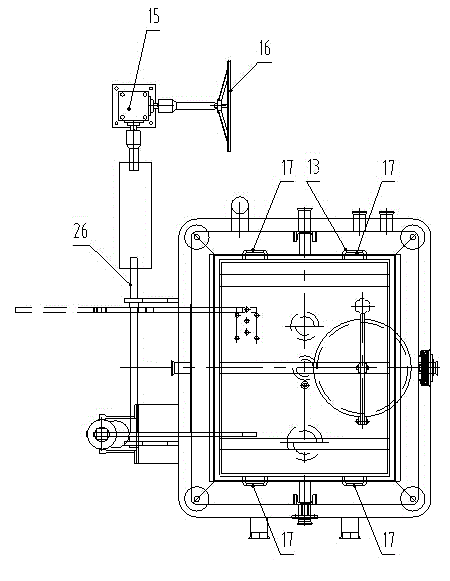

[0044] Such as figure 1 , 2 As shown, the present invention includes a stewed pot body 14, and the stewed pot body 14 includes an upper cylinder body 21 and a tank bottom 18 connected with the bottom of the cylinder body 21, and the cylinder body 21 is a square cylinder with a large opening (the cylinder body 21 can be It is made into a cylindrical shape according to the actual situation), the tank bottom 18 is located at the bottom of the stewed pot body 14, and the cylinder body 21 is integrally connected with the tank bottom 18.

[0045] The vertical section of the tank bottom 18 is conical. The inner side of the cylinder body 21 is provided with an upper interlayer (also referred to as a square liner), the upper interlayer is provided with an upper jacket 5, the inner side of the tank bottom 18 is provided with a lower interlayer, and the lower interlayer is provided with a lower jacket 19, and the upper jacket 5 and the lower jacket 19 all adopt honeycomb panels. Steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com