Patents

Literature

235results about How to "Consistent taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

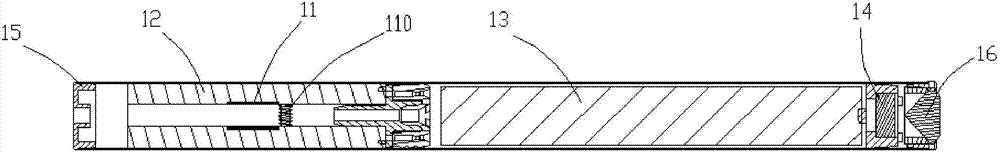

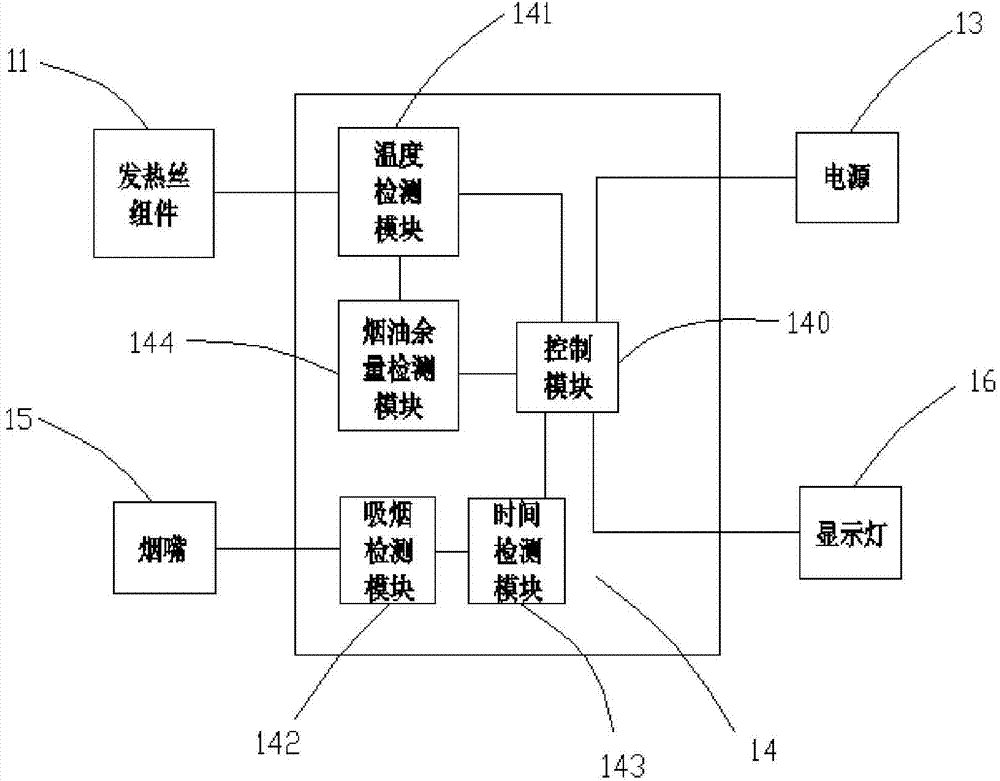

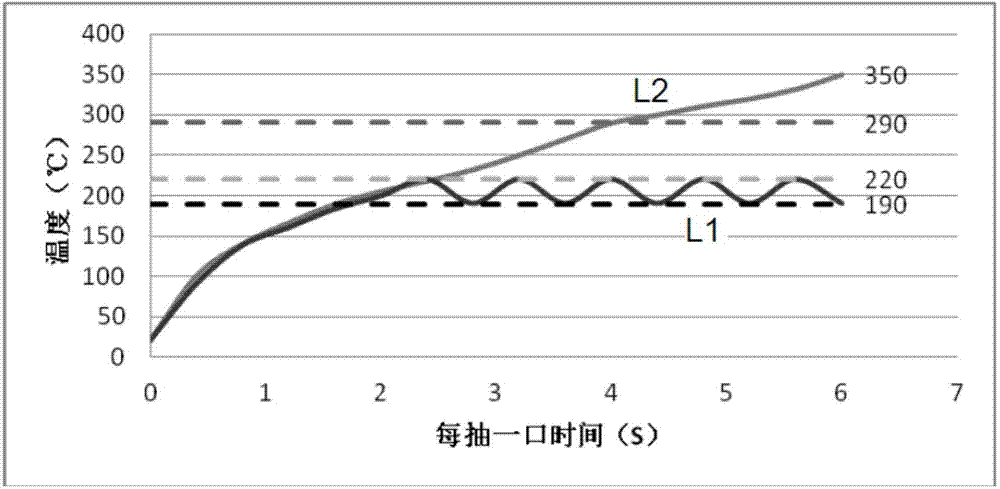

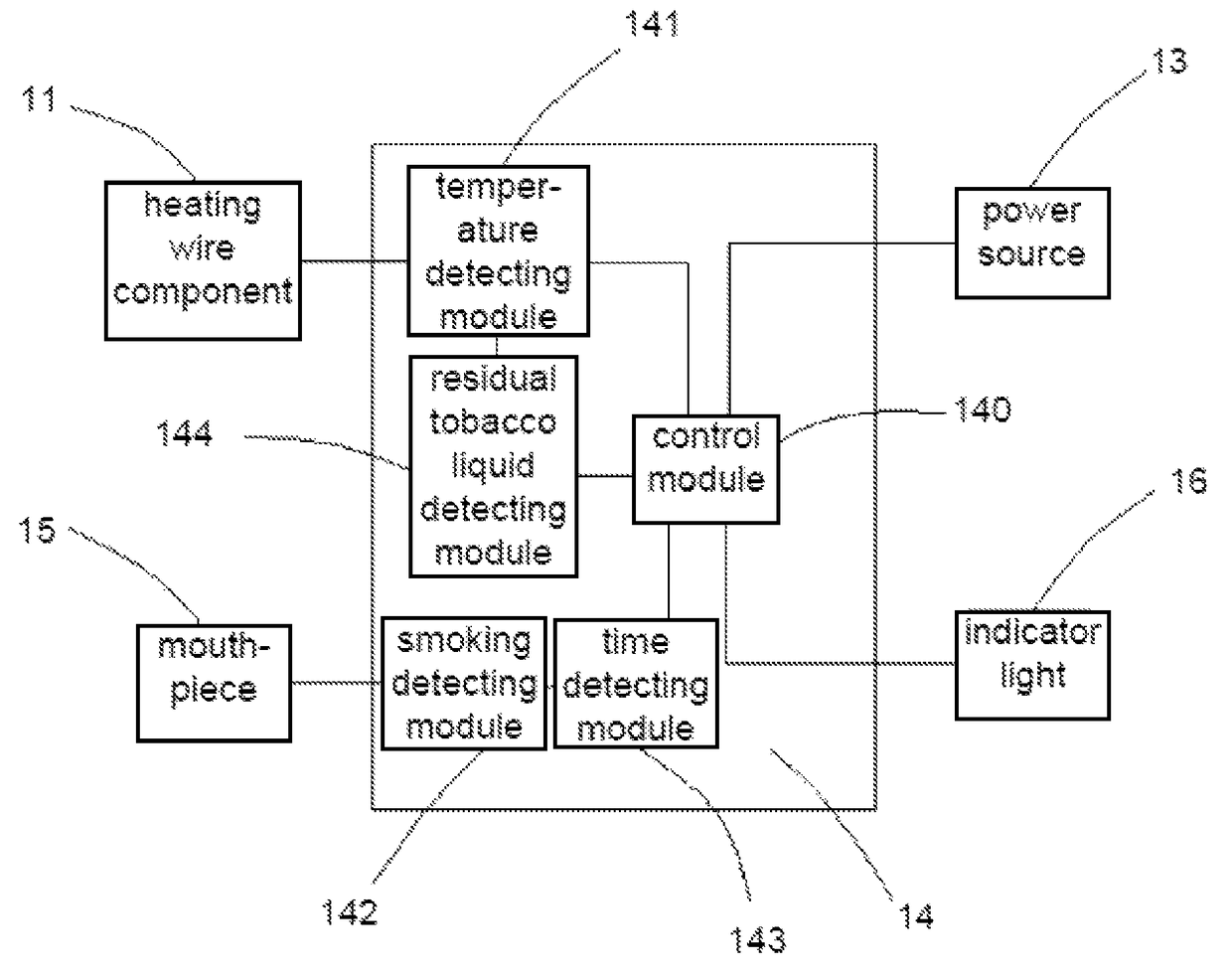

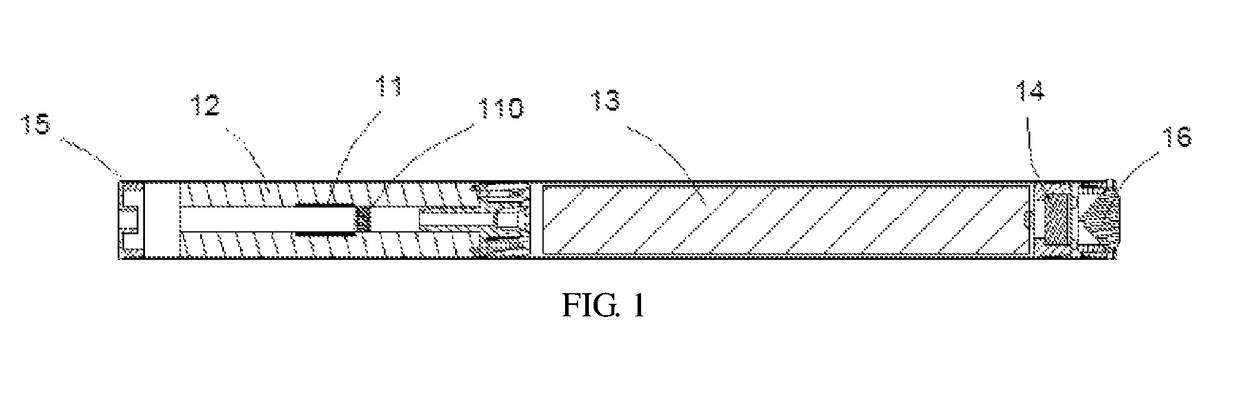

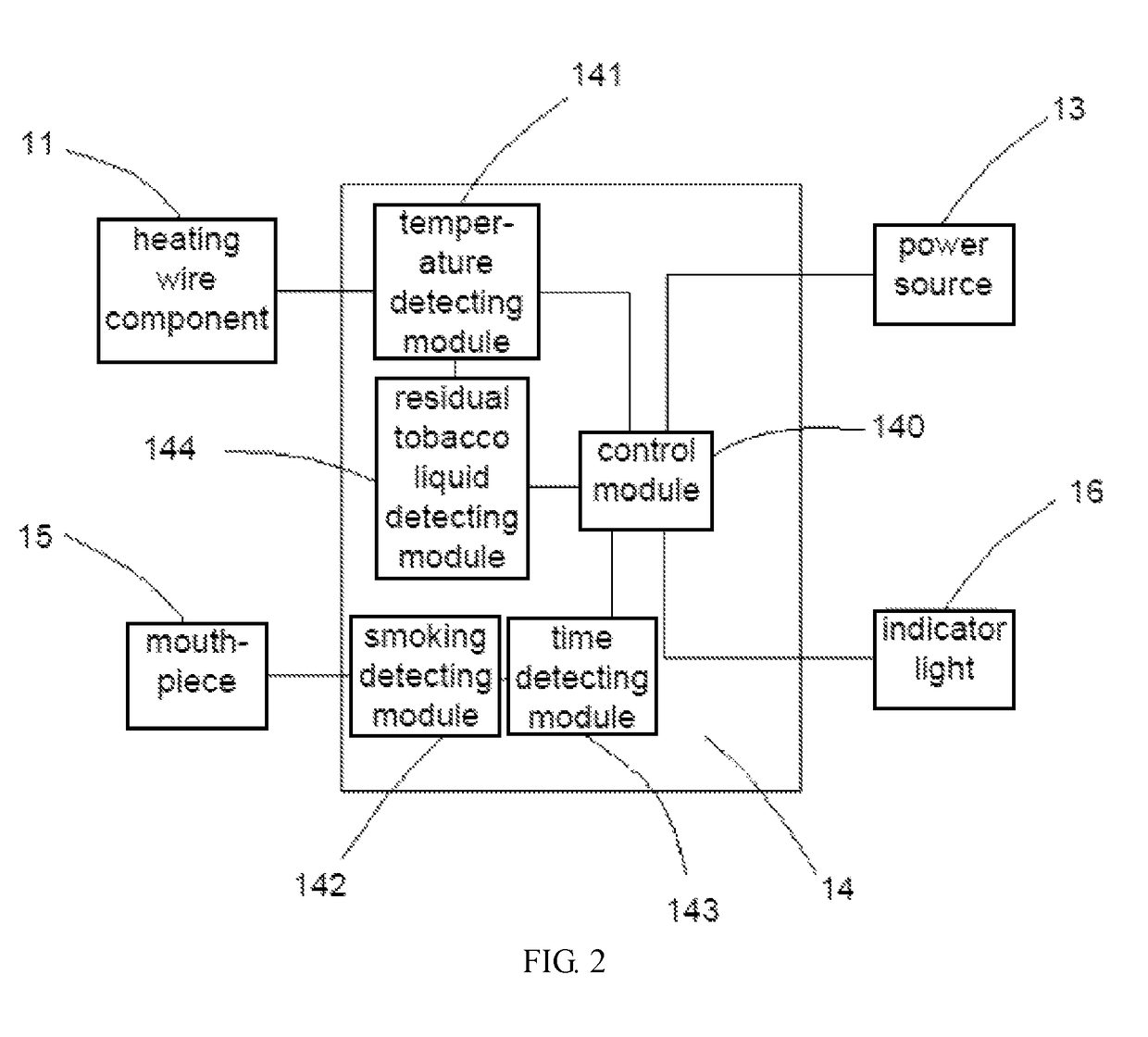

Electronic cigarette and control method thereof

ActiveCN104116138AAvoid burnt smellSave powerTobacco devicesOhmic-resistance heating detailsLower limitCurrent voltage

The invention provides an electronic cigarette and a control method thereof. The electronic cigarette comprises a heating wire assembly, a power source and a controller. The heating wire assembly is used for generating heat and comprises heating wires, wherein the resistance value of the heating wires changes along with the changes of temperatures. The power source is used for providing voltages for the heating wire assembly. The controller is electrically connected with the heating wire assembly and the power source and used for controlling the power source to output the voltages. The controller comprises a temperature detecting module which is used for detecting the resistance value of the heating wires to obtain the real-time temperature of the heating wire assembly, an upper limit heating temperature and a lower limit heating temperature are set in the temperature detecting module, the controller controls the power source to output a first voltage when the real-time temperature is smaller than or equal to the lower limit heating temperature and controls the power source to output a second voltage when the real-time temperature is larger than or equal to the upper limit heating temperature, the second voltage is smaller than the first voltage, and the controller controls the power source to keep outputting the current voltage when the real-time temperature is larger than the lower limit heating temperature and smaller than the upper limit heating temperature. The electronic cigarette and the control method thereof can ensure the taste consistency of the smoke of all times and save electric quantity.

Owner:SHENZHEN SMOORE TECH LTD

Fermented grains-fruit juice wine and its brewing process

InactiveCN1363652AConsistent qualityConsistent tasteAlcoholic beverage preparationFruit wineFruit juice

A fermented wine is prepared from grains and fruit juice (grape juice) through proportioning, mixing, fermenting and distillation. Its advantages include both grain wine smell and fruit wine smell ,unique taste and rich nutrients.

Owner:马兴宝

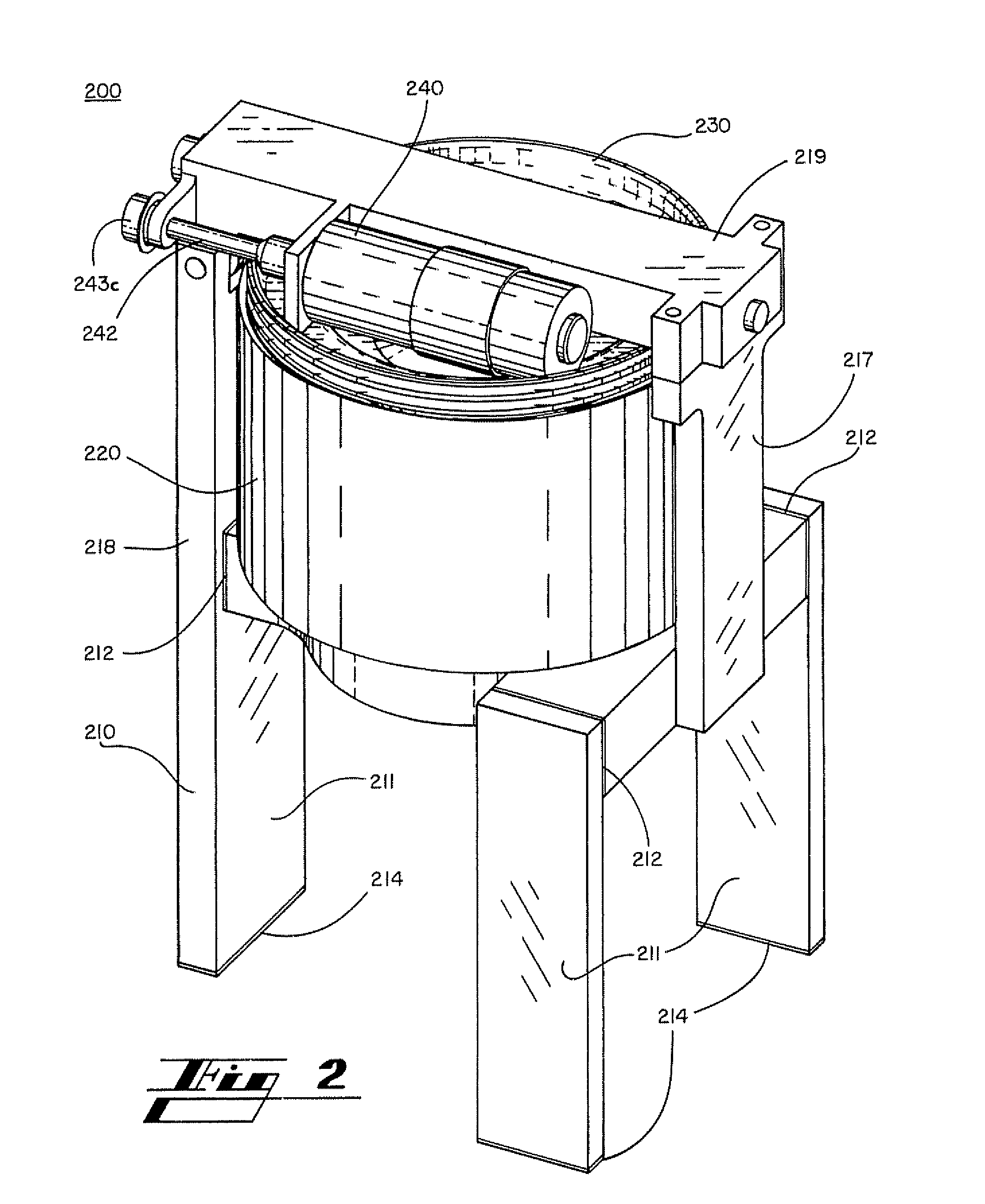

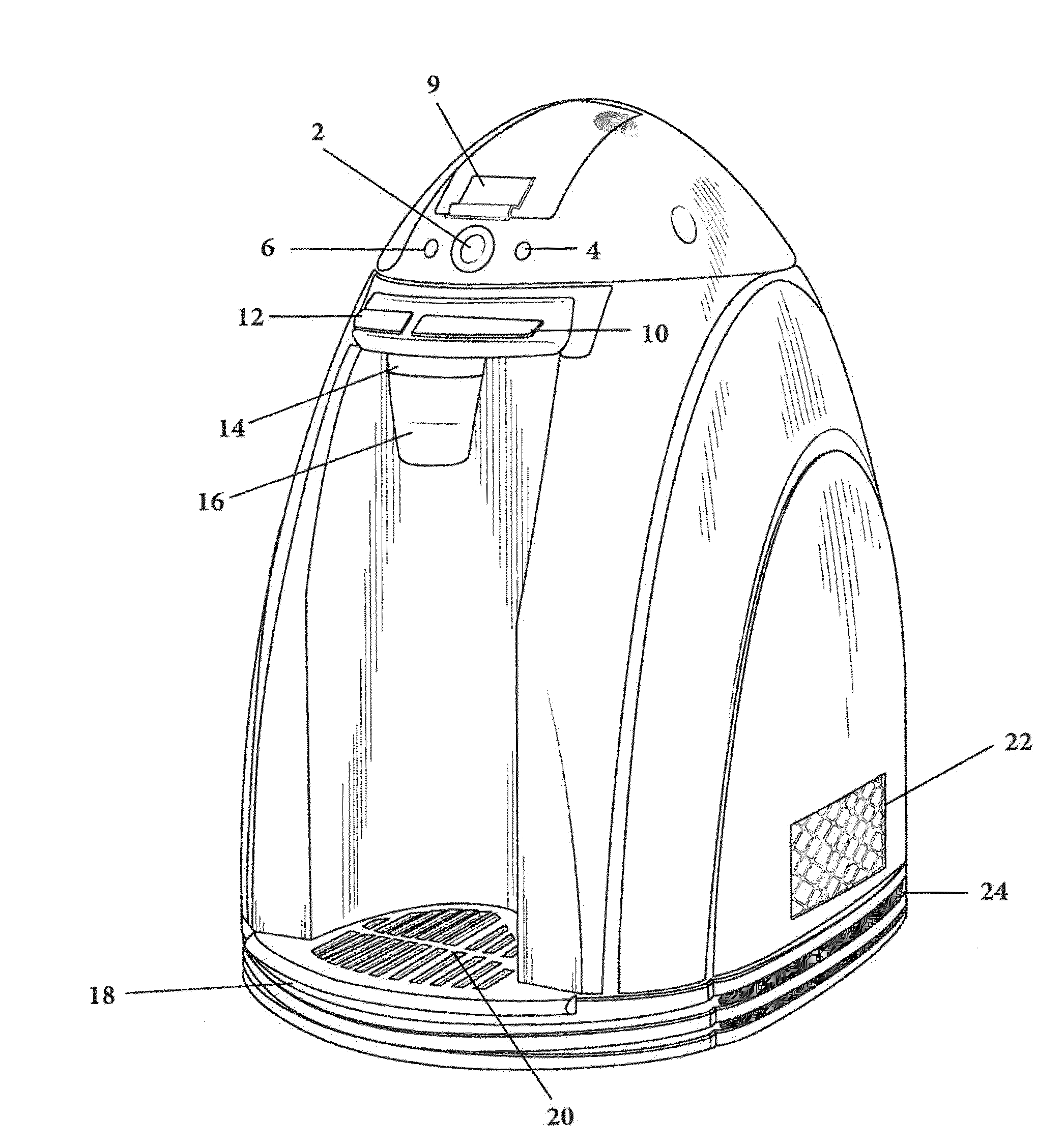

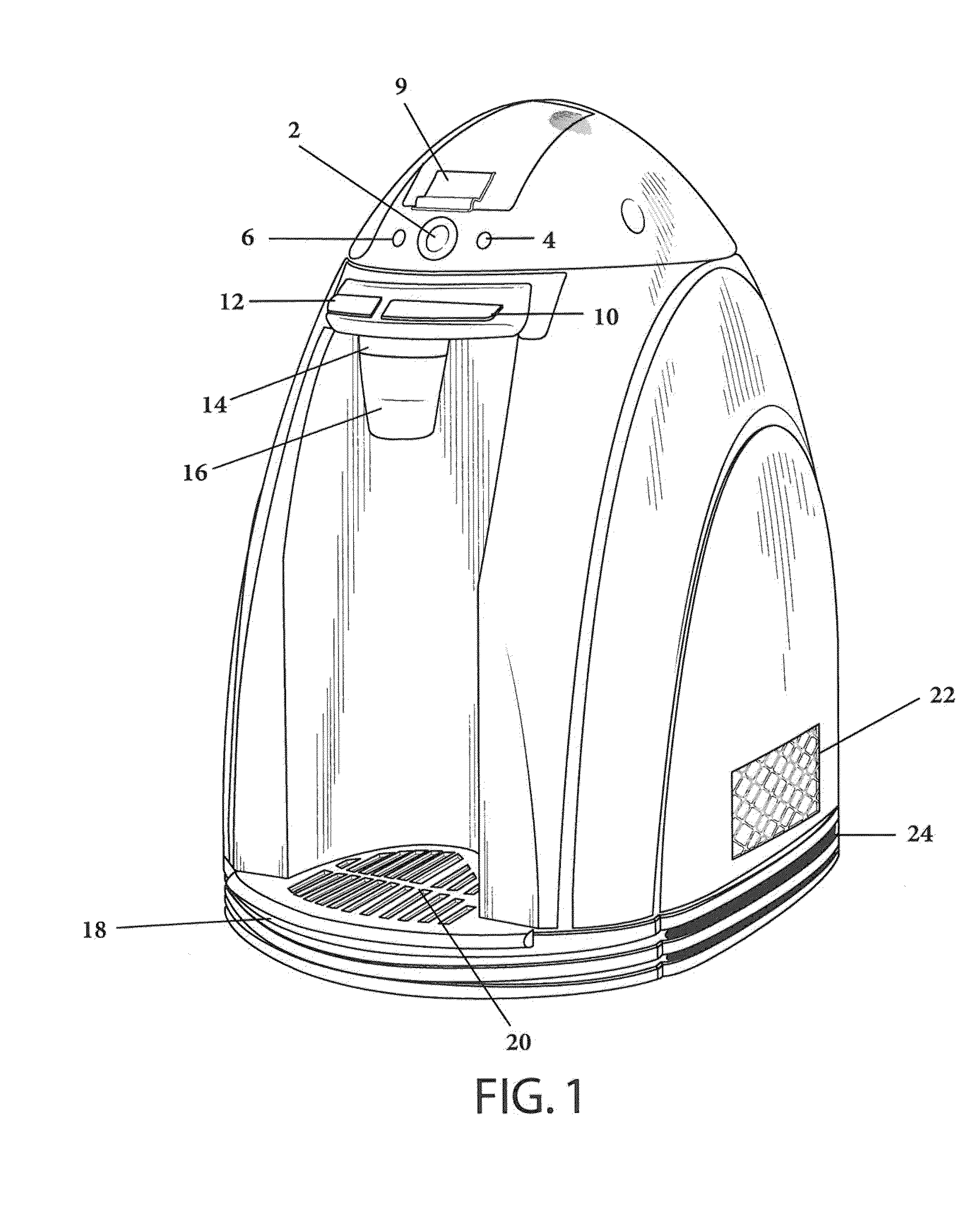

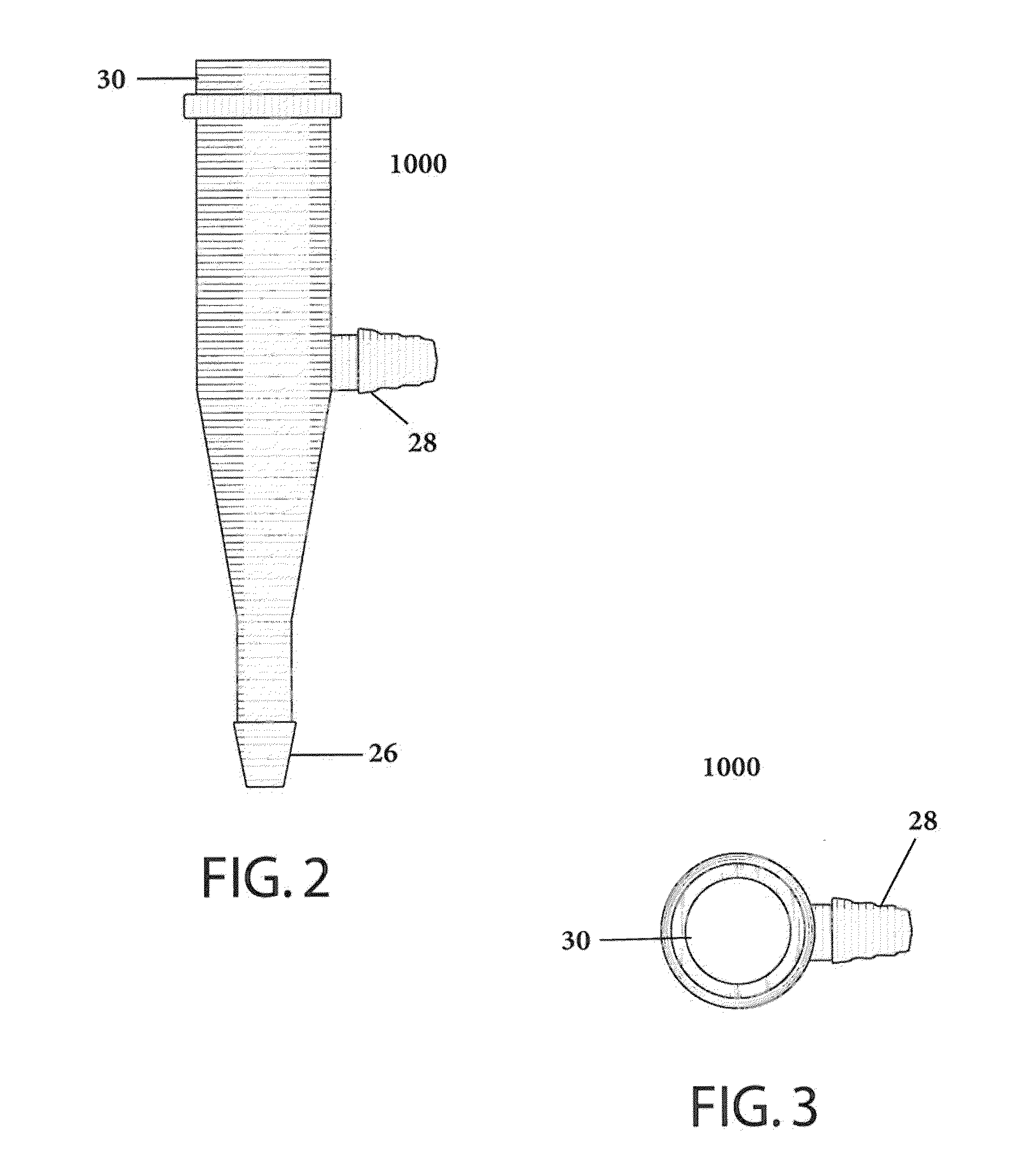

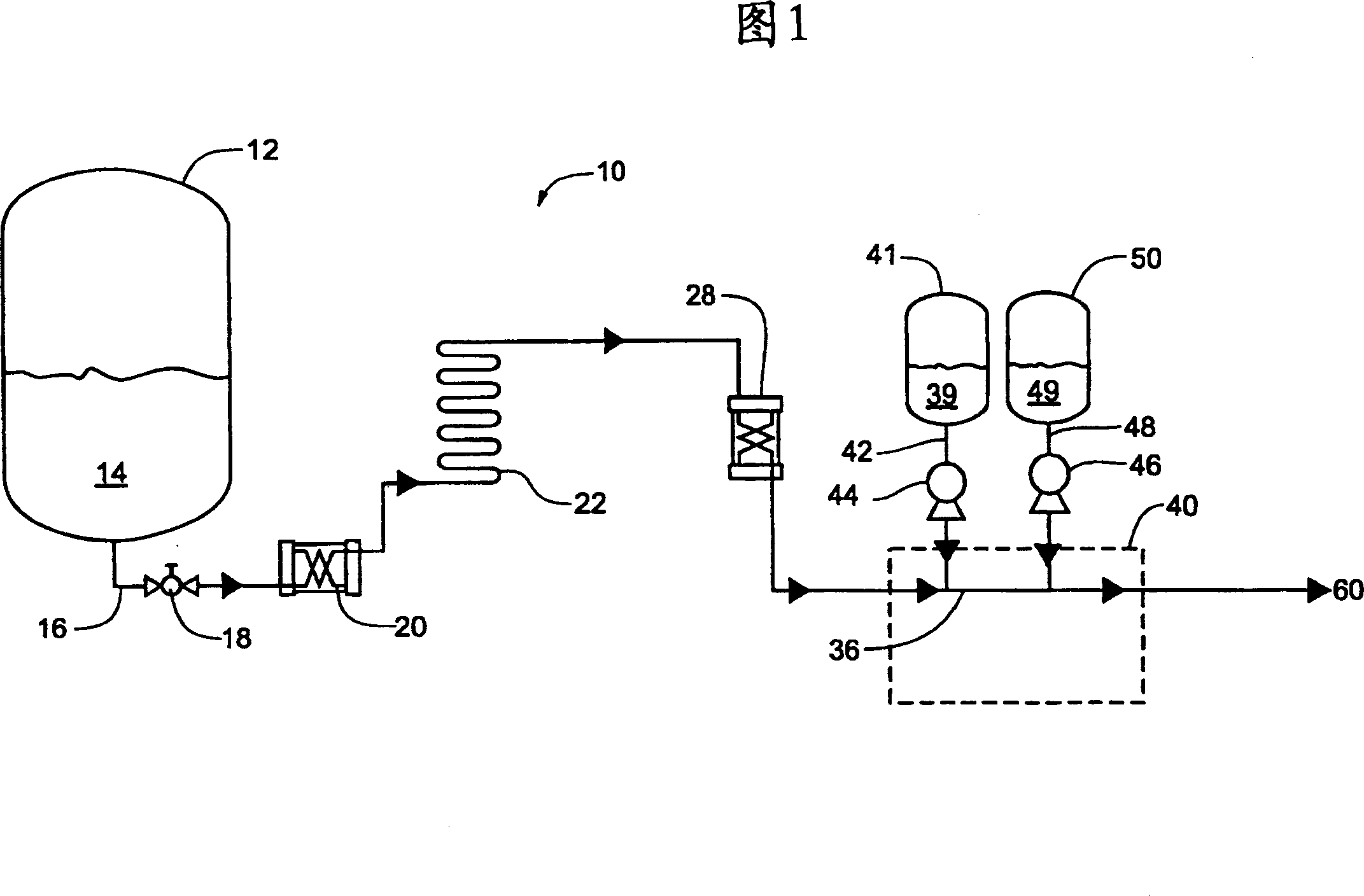

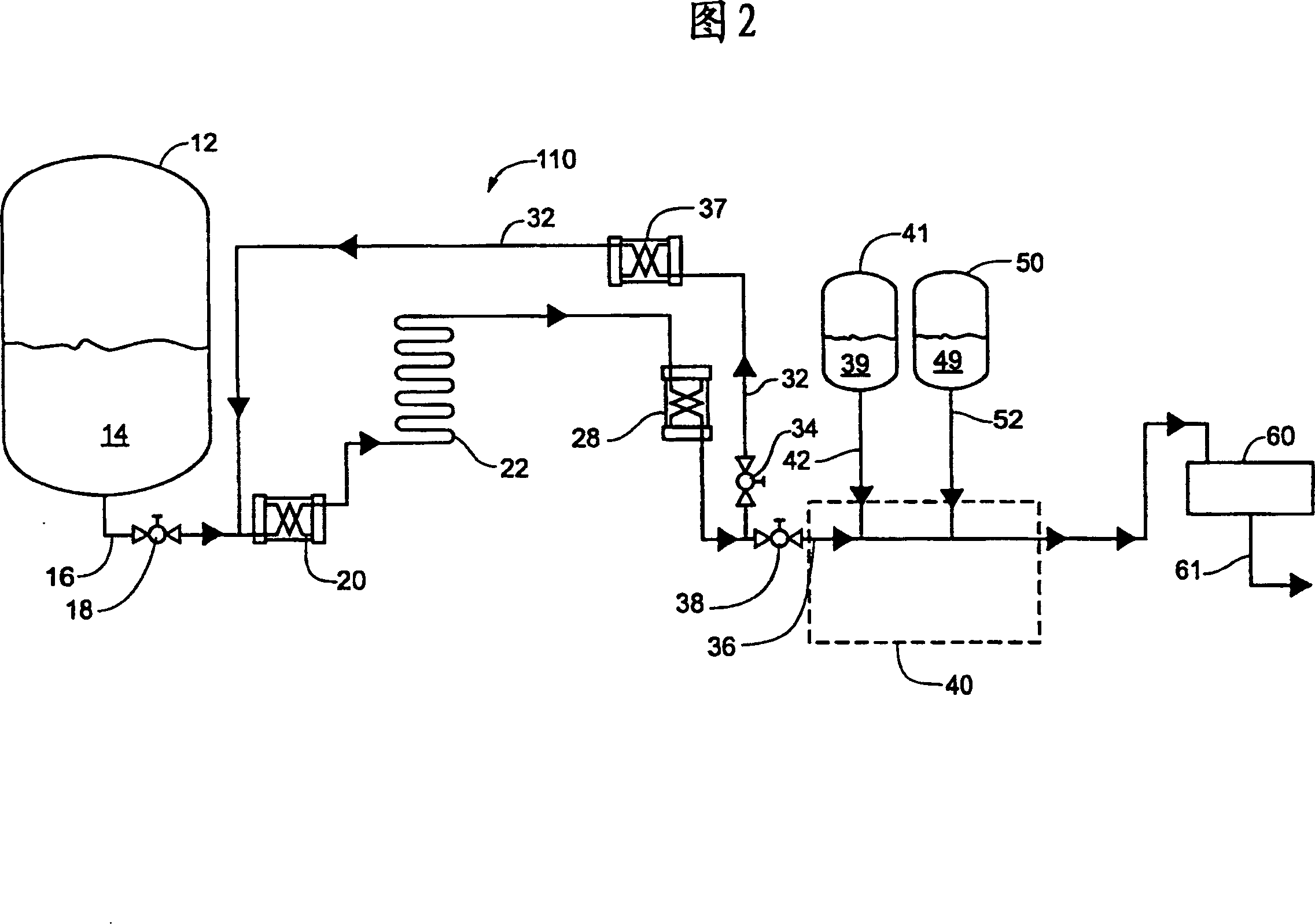

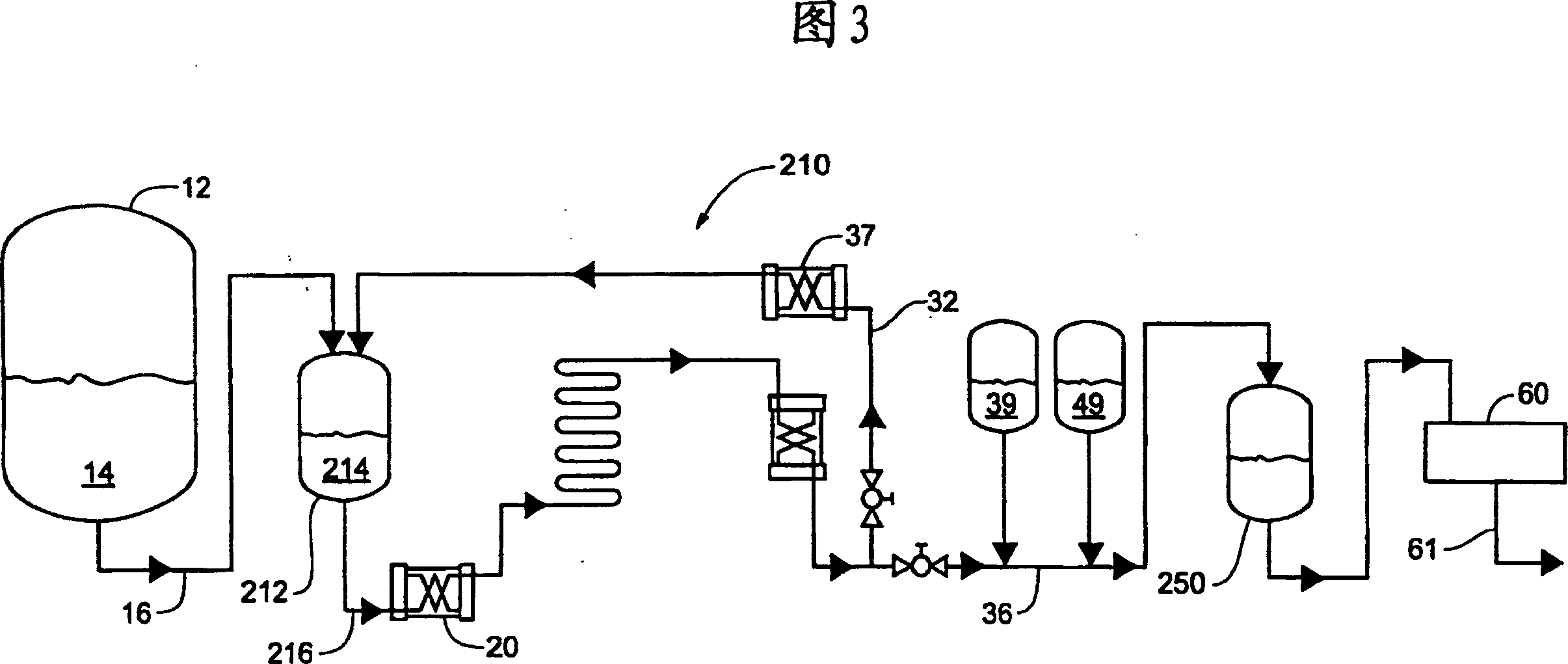

System and method for brewing beverages

A system and method for brewing beverages utilizing inertial separation and an adjustable-volume brewing chamber to selectively retain or release particulate matter, oils, and / or other components of the brewed beverage, whereby mechanical filtration may be avoided and smaller particulates may be separated from the beverage. Thus, less material is needed to achieve similar levels of infusion and brewing time may be reduced.

Owner:DUVALL GIDEON

Production method and application of non-continuous temperature-dependent phase change gel incense-carrying filter stick

The invention relates to a production method and application of a non-continuous temperature-dependent phase change gel incense-carrying filter stick. The production method comprises the steps of preparation of temperature-dependent phase change gel colloid and production of a non-continuous temperature-dependent phase change gel incense-carrying filter stick. The non-continuous temperature-dependent phase change gel incense-carrying filter stick is large in incense carrying amount, stable in incense carrying amount, long in incense holding time and less in volatilized flavor substances, whena cigarette is smoked, the heating effect of the smoke heat converts solid state gel into liquid gel, aroma components loaded in the gel are slowly and uniformly released, and the tastes of the frontsection and the rear section of the cigarette are kept consistent. By means of the cigarette which is prepared from the non-continuous gel filter stick, the oral cavity cannot be in direct contact with the gel when a consumer smokes the cigarette, and the discomfort and the psychological antipathy caused when the oral cavity of the consumer is in contact with the gel are avoided; meanwhile, duringsmoking, the fragrance concentration and the flavor of the front section and the rear section are stable, and the cigarette smoking quality is effectively improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL +1

Beverage dispenser and related methods

InactiveUS20140175125A1Variable quantityConsistent tasteLiquid transferring devicesLiquid dispensingServing sizeEngineering

The present invention relates to a beverage dispenser configured to dispense variable serving sizes of cold beverages. The present invention uses the Venturi effect in order to mix the syrup and water at a constant ratio.

Owner:BREAULT MICHAEL JOHN

Preparation method of dreg-free hot pot stock

The invention provides a preparation method of a dreg-free hot pot stock. The method comprises the following steps: preparing materials, namely processing chili powder, spice and Chinese prickly ash for later use; extracting, namely heating mixed vegetable oil, and respectively adding the chilli powder, bitter spice, fragrant spice and the Chinese prickly ash step by step, removing dregs and reserving oil; frying, namely heating the oil, sequentially adding green onion, ginger, garlic, hot and spicy sauce, thick broad-bean sauce, fermented soya beans, Chinese white spirit and rock candy, finally separating out oil to form dreg-free hot pot red oil, and reserving dreg-free hot pot condiments; decocting, namely decocting a soup-stock, boiling, adding the dreg-free hot pot condiments, adding salt, chicken essence and Chinese white spirit, removing the turbid part on a bottom layer, and reserving the dreg-free hot pot stock; and finally preparing the hot pot condiments. By virtue of the mode of the dreg-free hot pot red oil and the dreg-free hot pot stock, the more and more fragrant effect is fully finished by pungent, spicy and fragrant tastes of the dreg-free hot pot red oil, comprehensive fragrances of the green onion, ginger and garlic in the dreg-free hot pot stock, and the sauce flavors of thick broad-bean sauce and fermented soya beans.

Owner:杨文平

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

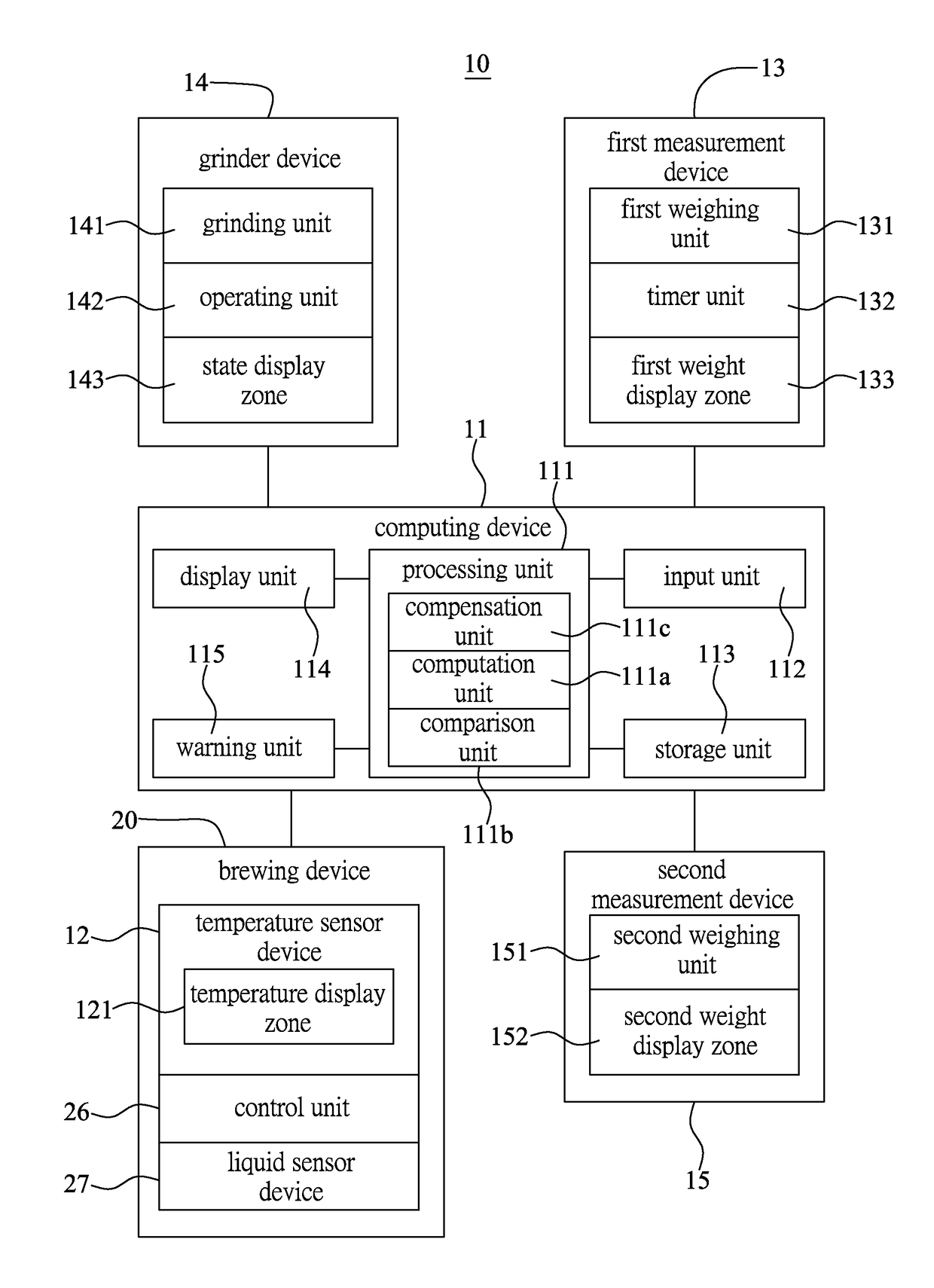

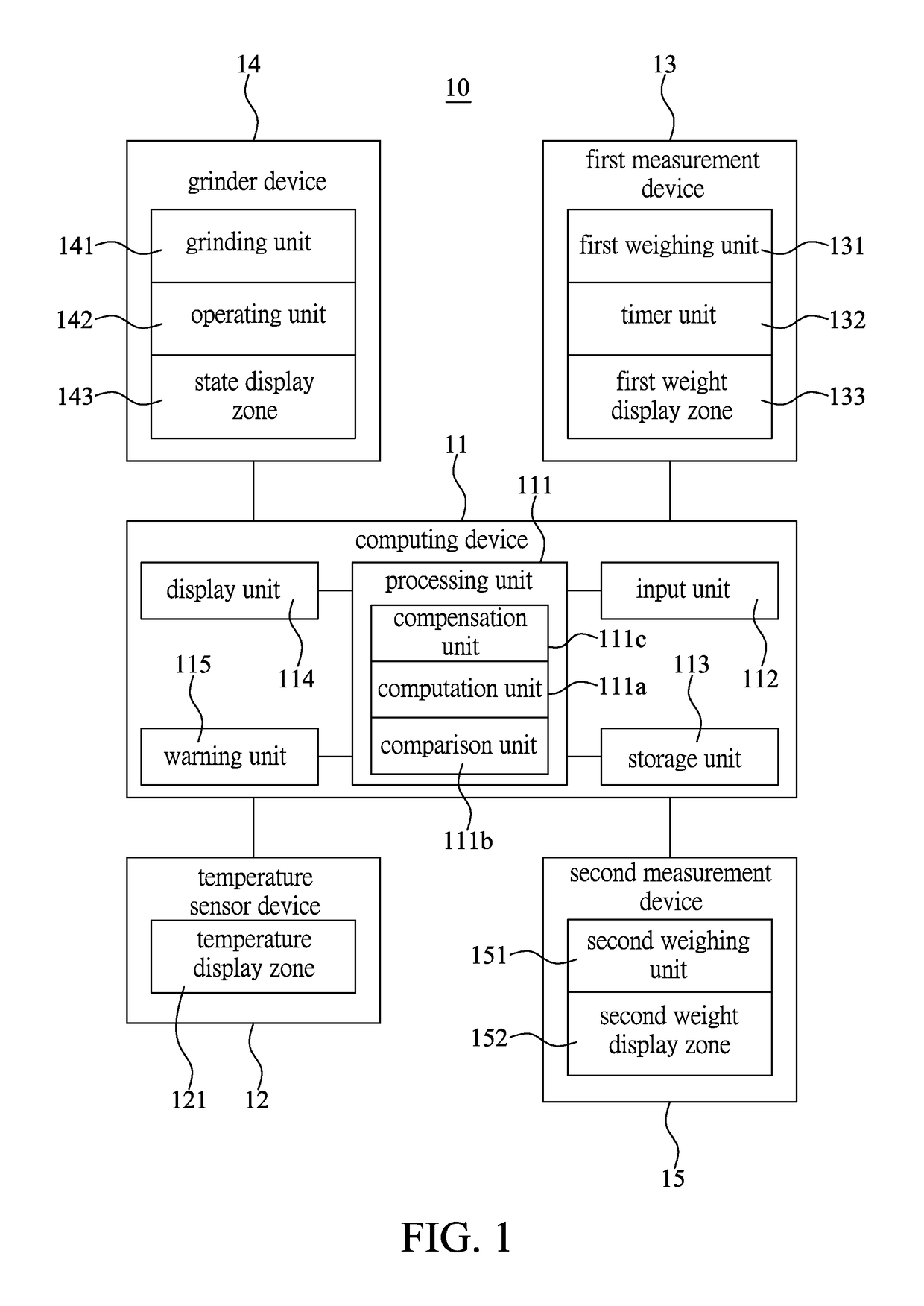

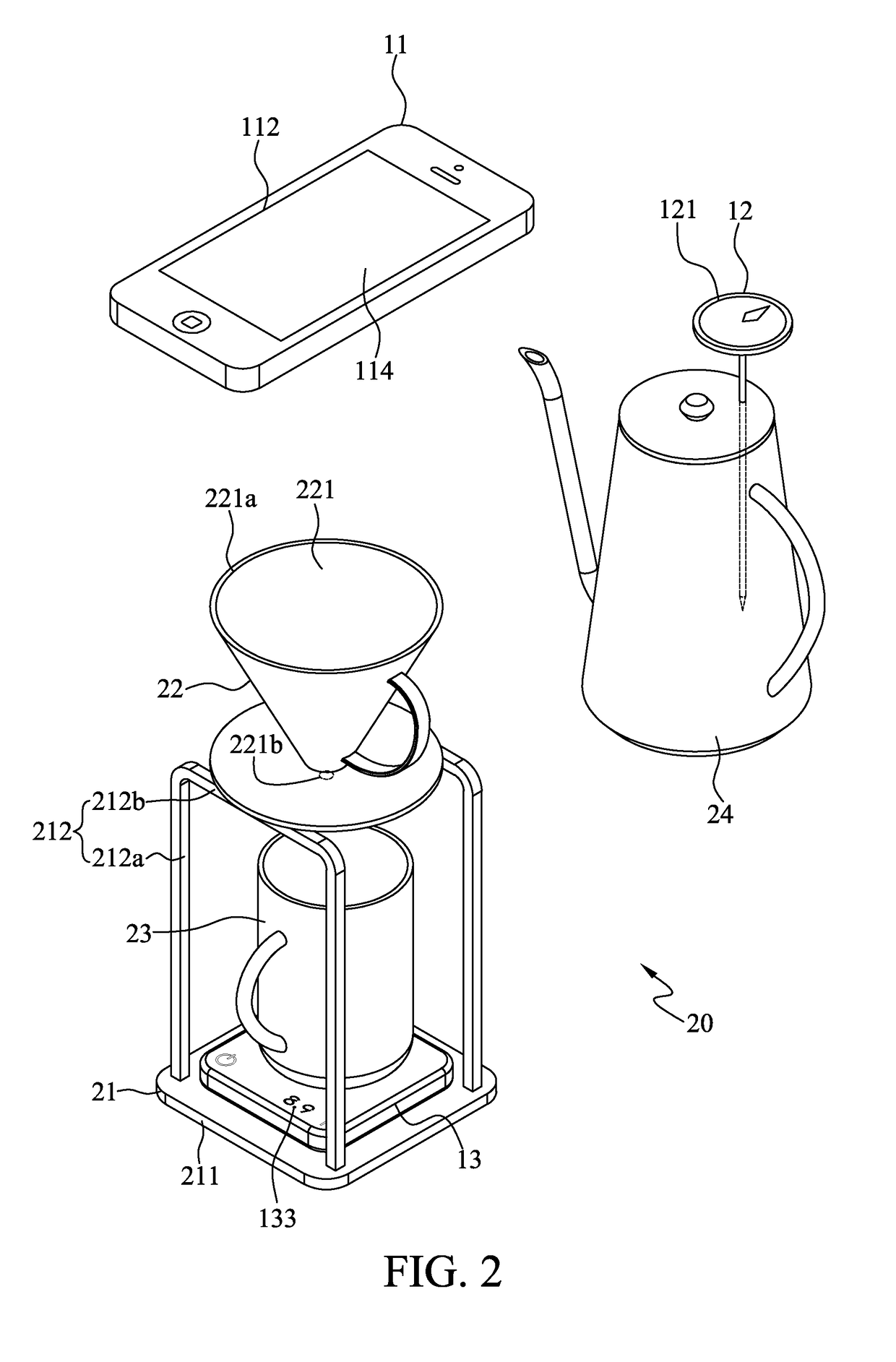

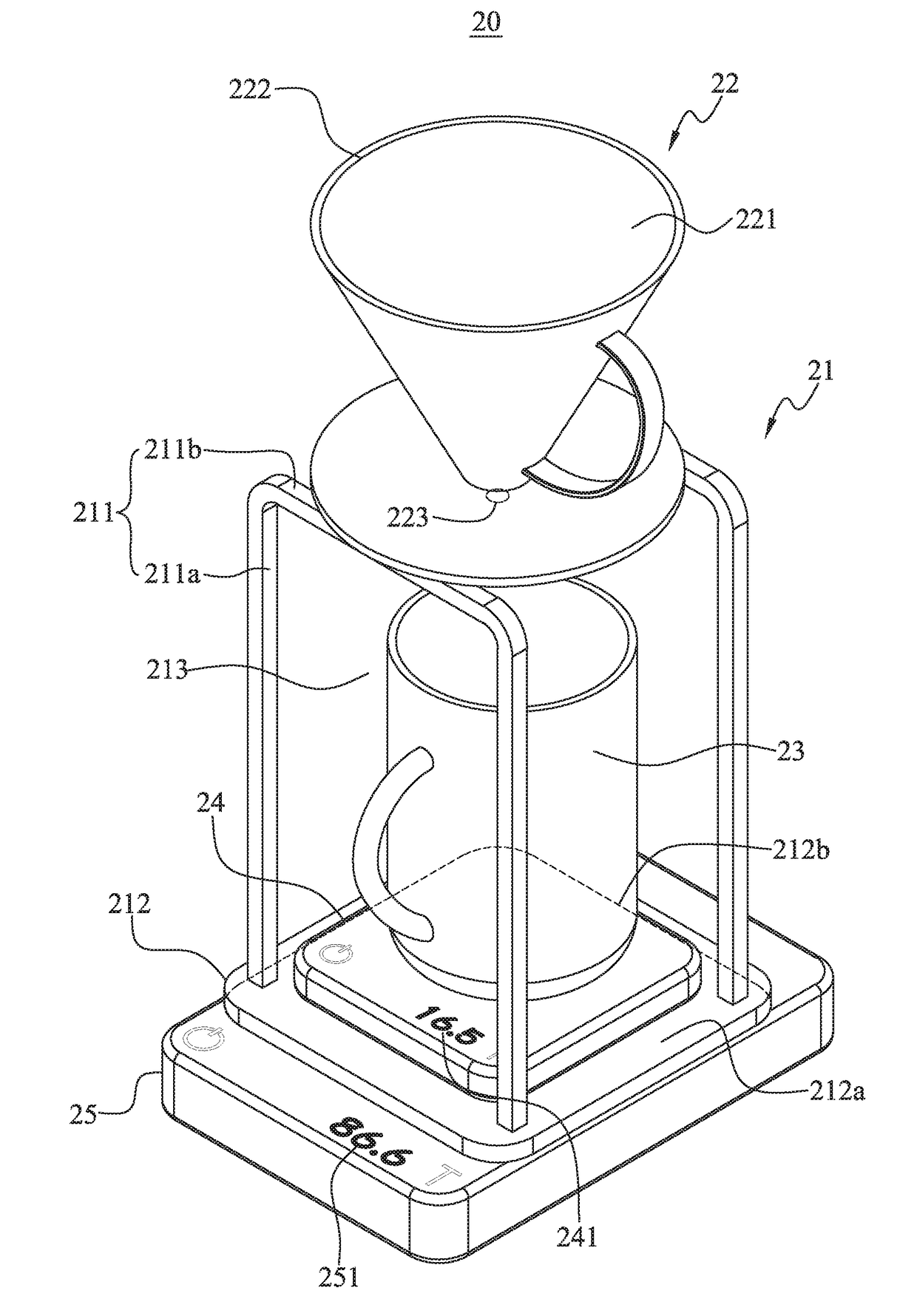

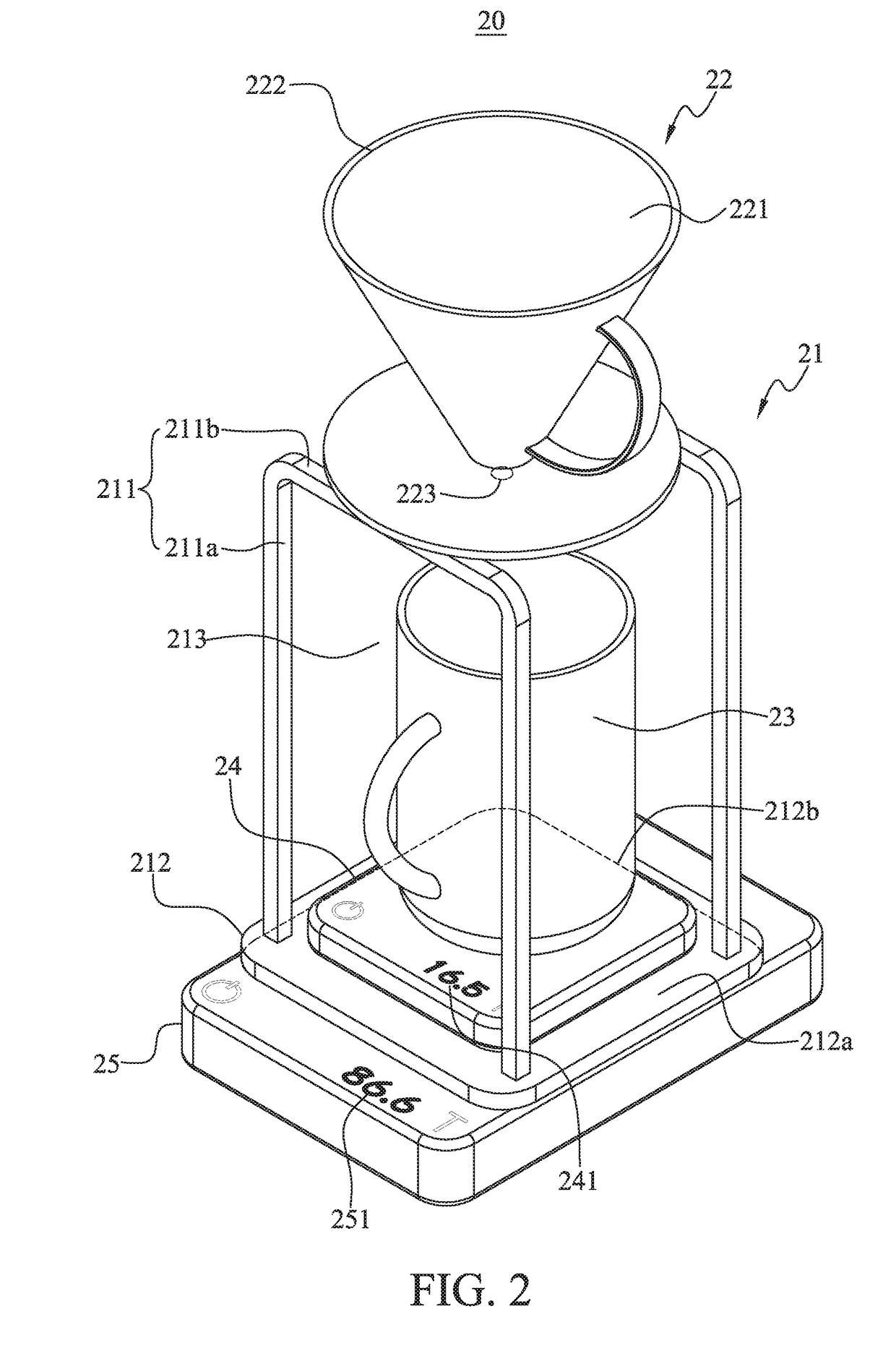

Method and system for beverage brewing management

InactiveUS20170295983A1Reduce lossesConsistent tasteBeverage vesselsStandard stateMeasurement device

A method and a system are disclosed for managing a brewing process in which a solution is produced by mixing a solvent with a solute and a beverage is extracted from the solution. The system includes a temperature sensor device for sensing a temperature change per unit time of the solvent to create temperature information; a first measurement device for sensing a weight increase per unit time of the beverage to create first weight information while counting the time elapsed in the brewing process to create timing information; and a computing device comparing preset standard-state information with the temperature, first weight and timing information. A warning message is displayed on the computing device to remind a brewing operator to stop brewing the beverage when any of the temperature, first weight and timing information created at a specific unit time does not match the standard-state information of the same unit time.

Owner:ACAIA

Processing method of peanuts with shells

The invention relates to a processing method of peanuts with shells, which is characterized in that peanuts with shells are used as raw materials, garlic, ginger, aginomoto, table salt, sodium cyclamate, AK (Acesulfame-K) sugar, and water are used as auxiliary materials to form ingredients, and the processing method comprises the steps of: washing, punching, flavoring, drying, baking, cooling and packaging. since a punch press is used for punching on the peanuts with the shells before flavoring, a vacuum kettle is used for vacuum flavoring and antioxidant is added in the processing process, the invention ensures that the made peanuts with the shells has consistent taste, long quality guarantee period, strong fragrant and crisp flavor and favorable mouthfeel while preserving the nutrients of the peanuts. The invention has reasonable and practical processing method, simple operation and good effect and is beneficial to wide popularization.

Owner:CHACHA FOOD CO LTD

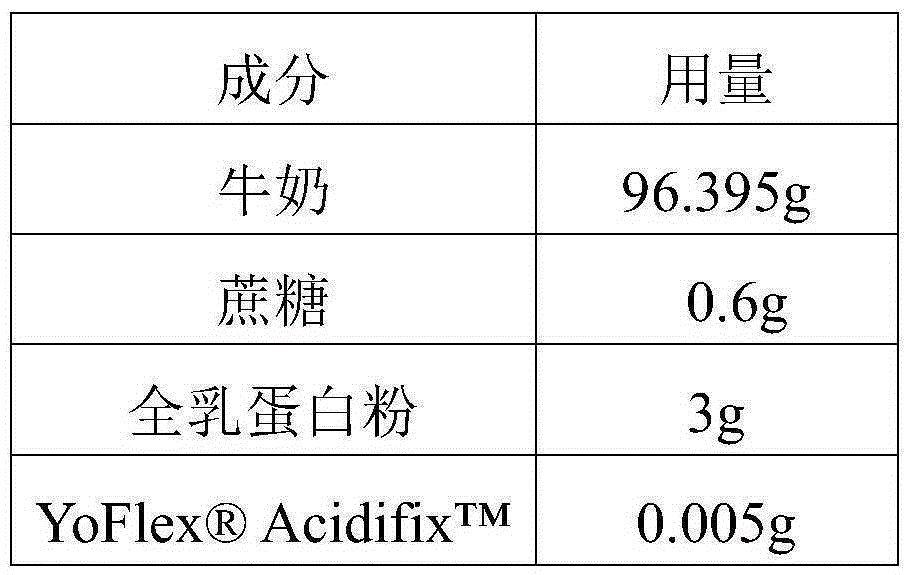

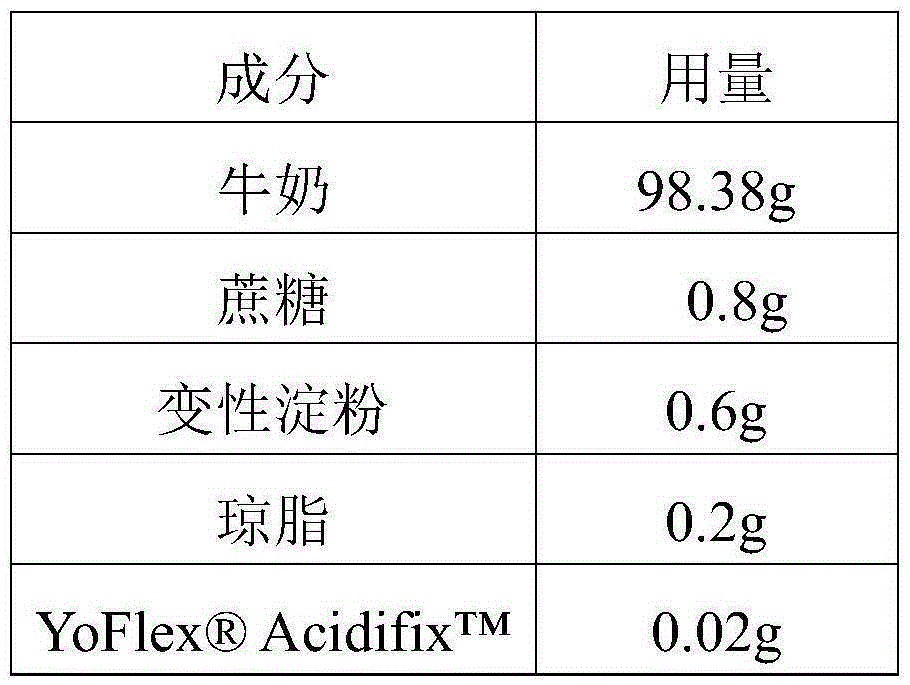

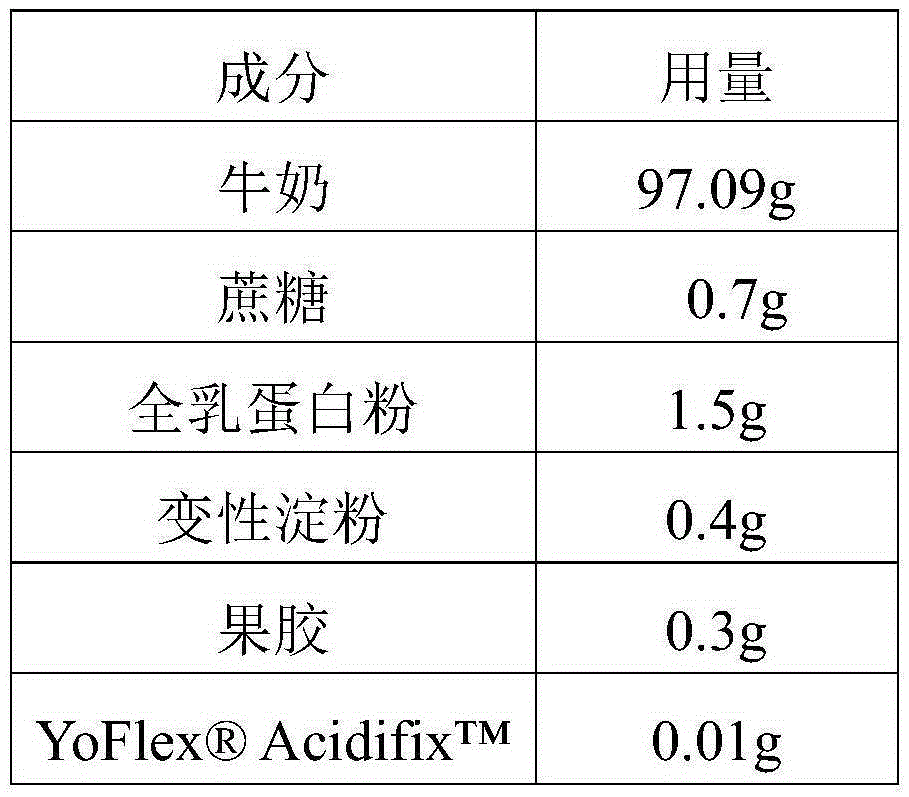

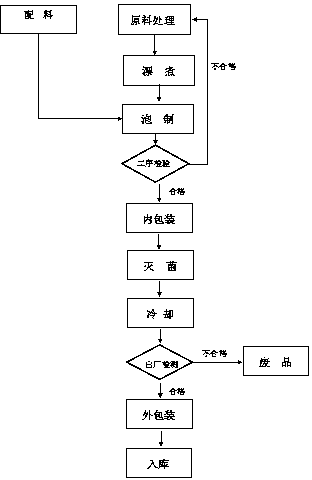

Living bacterium type room temperature yoghurt and making method thereof

ActiveCN105325541AViable count is stableConsistent tasteMilk preparationLactic acid bacteriumRoom temperature

The invention discloses living bacterium type room temperature yoghurt and a making method thereof. Raw materials of the living bacterium type room temperature yoghurt comprise conventional raw materials of yoghurt, wherein the content of saccharose accounts for 0.6%-0.8% of the total mass of the raw materials, the content of protein in the raw materials accounts for 2.95%-4.69% of the total mass of the raw materials, and a fermenting agent with the shop sign of YoFLex<R> Acidifix<TM> is adopted as a fermenting agent of the yoghurt. The making method specifically comprises the steps that 1, the raw materials except the fermenting agent are mixed; 2, the materials obtained in the step 1 are homogenized and sterilized to obtain a fermenting matrix; 3, the fermenting matrix obtained in the step 2 is cooled, and the fermenting agent is added for fermentation; 4, sweet substances which do not contain the saccharose are added in the fermented matrix obtained in the step 3, the mixture is stirred evenly, filling is performed, and then the living bacterium type room temperature yoghurt is obtained. The yoghurt breaks through the technical barrier that room temperature yoghurt has no living bacterium, and the acidity, the state, the mouthfeel and the lactic acid bacterium number are kept stable when the yoghurt is placed at the room temperature within the quality guarantee period.

Owner:BRIGHT DAIRY & FOOD CO LTD

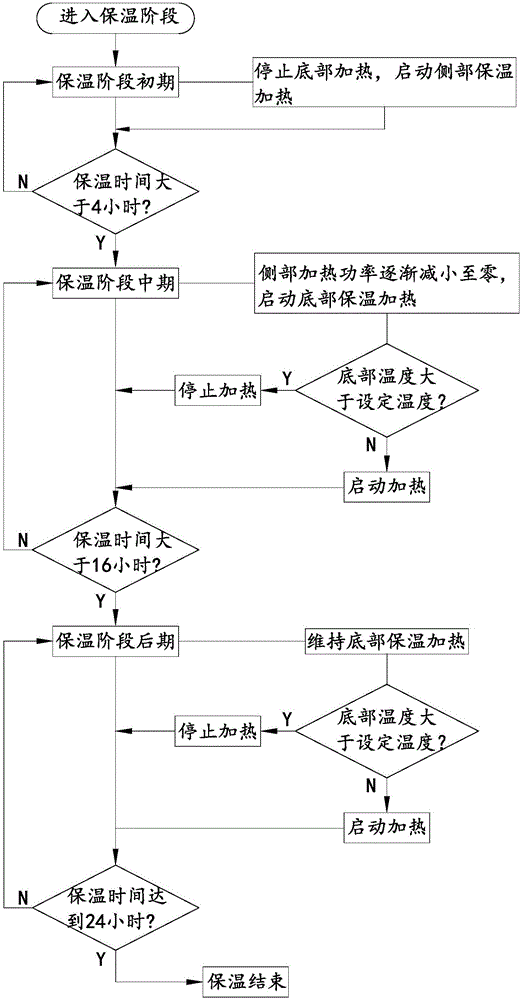

Heat preservation control method for electric rice cooker

ActiveCN106510481AAvoid hardening and yellowingConsistent tasteTemperature control using electric meansWarming devicesEngineeringCooker

The invention discloses a heat preservation control method for an electric rice cooker, belongs to the technical field of kitchen cooking, and solves the problem of food hardening and yellowing caused by long-time heat preservation of an existing electric rice cooker. The electric rice cooker comprises a control unit, a heating apparatus and an inner pot, wherein the heating apparatus comprises a bottom heater for heating the bottom of the inner pot and a side heater for heating the side part of the inner pot. According to the heat preservation control method, the control unit controls the bottom heater and the side heater to alternately perform heat-preservation heating according to a set heat preservation temperature after the electric rice cooker enters a heat preservation stage. The heat preservation control method is used for the electric rice cooker to perform food cooking such as rice cooking, congee cooking and the like.

Owner:JOYOUNG CO LTD

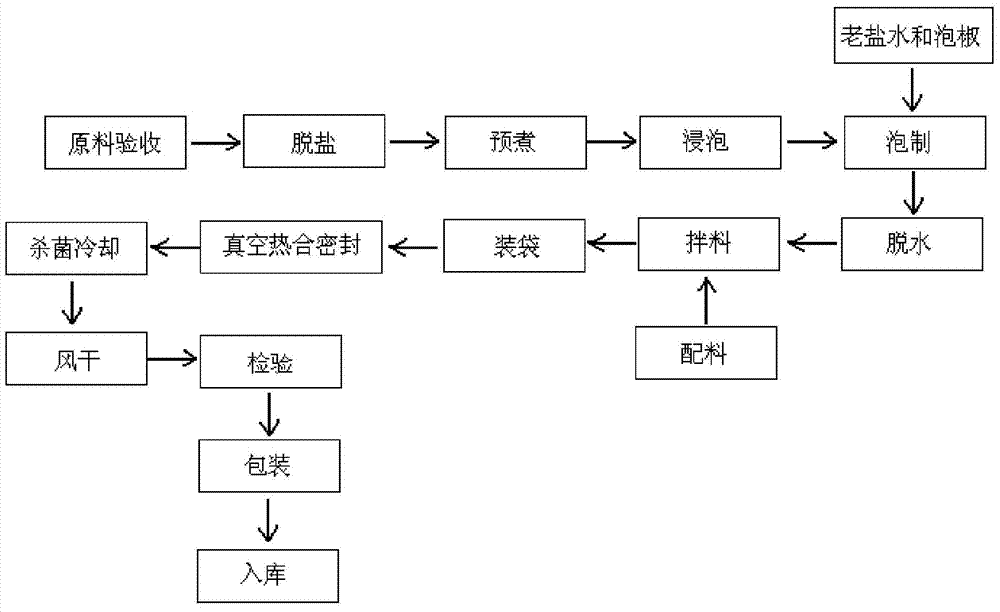

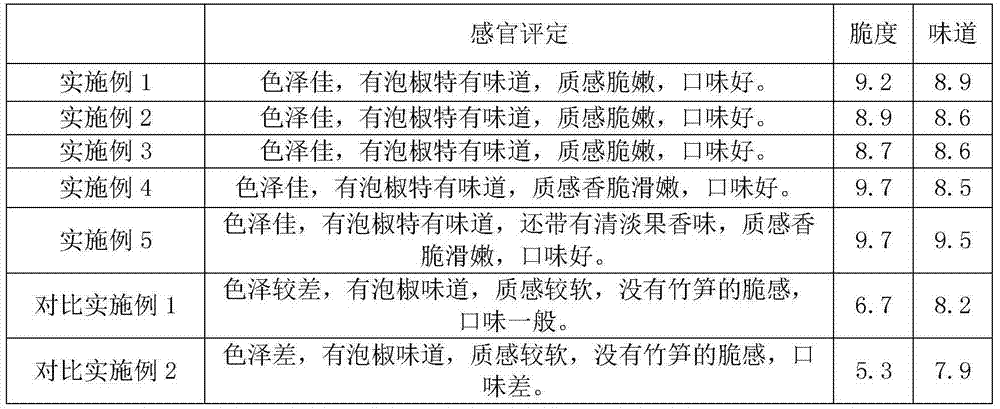

Preparation method of pickled bamboo shoots with pickled peppers

The invention relates to the field of foods and particularly relates to a preparation method of picked bamboo shoots with pickled peppers. The preparation method comprises the following steps: immersing pre-boiled bamboo shoots at a temperature from -5 DEG C to 0 DEG C for 1-3 hours; adjusting the acidity and the salinity of pickled mountain peppers and aged salt water so as to balance the salinity and the acidity; pre-boiling the balanced mountain peppers at 98-100 DEG C for 15-20 minutes to obtain pre-boiled mountain peppers; putting the balanced aged salt water, the pre-boiled mountain peppers and the immersed bamboo shoots into a pickling container according to the weight ratio of 100 to (90-120) to (10-15) and pickling at room temperature for 15-30 hours; and uniformly mixing the pickled bamboo shoots with the auxiliary materials to obtain the pickled bamboo shoots with the pickled peppers. Before pickling, the immersing procedure is added, and thus the obtained bamboo shoots have crispy texture and good mouth feel. Furthermore, a food brittleness increasing agent is added to improve the brittleness of the bamboo shoots. Furthermore, with an auxiliary material prepared from olive oil and / or loquat juice / jam and / or apple juice / jam, the pickled bamboo shoots with the pickled peppers also have a fruit flavor, the improved flavor is unique and novel and the pickled bamboo shoots with the pickled peppers is endowed with innovativeness.

Owner:CHONGQING XINRUN AGRI DEV

Processing method of beggar's chicken

The invention relates to a processing method of a beggar's chicken. The processing method comprises nine steps of: preparing flavoring liquid; preparing fillers; preparing paste; preparing auxiliary materials; preparing main materials; pickling; charging; wrapping paste and baking. The processing method of the beggar's chicken has the beneficial effects that the auxiliary materials are decocted; then chicken meals are pickled; and finally kaolin is used as the paste; and therefore, the delicious taste permeates into the inside of the beggar's chicken meat, the inside and outside of the beggar's chicken meat are ensured to be the same, the beggar's chicken meat is crisp and spicy and is purplish red and bright in color and fragrant.

Owner:CHONGQING HONGJIANG WINE IND

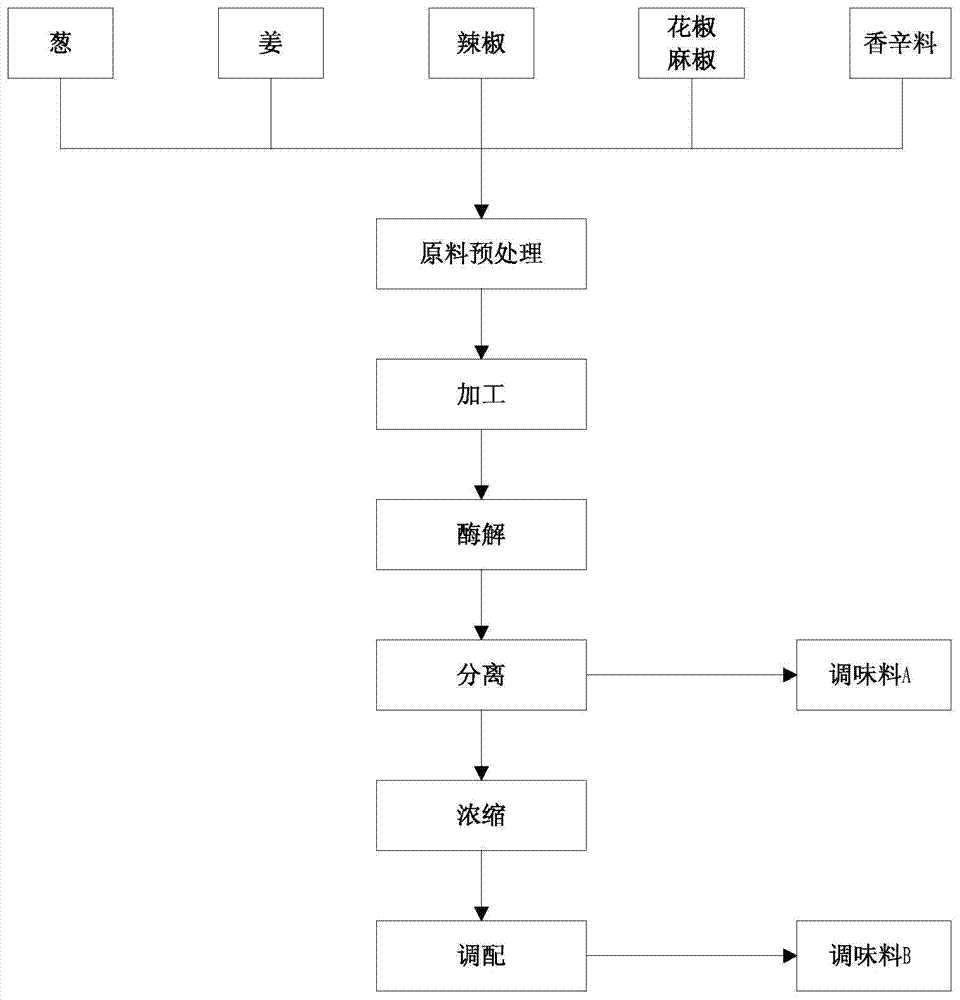

Method for preparing seasoning special for quantitative marinating

The invention discloses a method for preparing seasoning special for quantitative marinating. The method for preparing the seasoning special for quantitative marinating comprises the steps of pretreatment of raw materials, processing, enzymolysis, separation, concentration and blending. The seasoning prepared with the method can be spicy and hot or spiced and is compound seasoning. The seasoning prepared with the method contains seasoning A and seasoning B, the seasoning A and seasoning B are added independently in use according to the quantitative marinating technique, the seasoning B is added in a weight part proportion of 100:20 during kneading of quantitative marinating, and the seasoning A is added in a weight part proportion of 100:2 after food is prepared and before the food is packaged. According to the seasoning prepared with the method, the utilization rate of spice is high, the product yield is high, full utilization of the seasoning is achieved, waste of materials is avoided, no production liquid waste is discharged, and the comprehensive production effectiveness of traditional sauce braised pork products is improved. Quantitative marinating of the sauce braised pork products is achieved through the cooperation between the prepared seasoning special for quantitative marinating and the quantitative marinating technique, and the flavor and taste of the products can be kept uniform.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

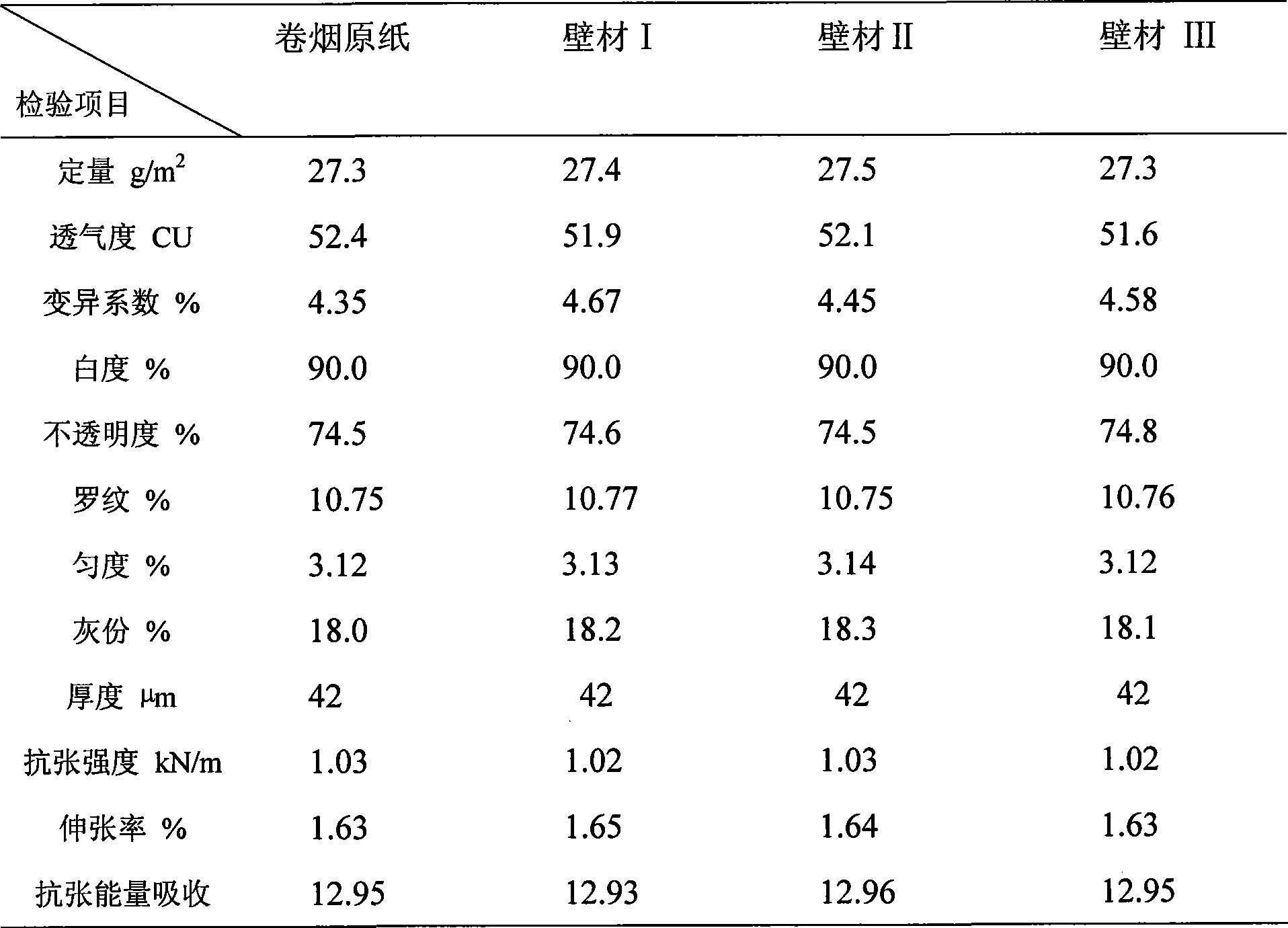

Preparation of peppermint type cigarette tissue

ActiveCN101487203AMeet the requirements of dryingReduce volatilityNon-fibrous pulp additionPaper coatingMentholAlcohol

The invention discloses a method for preparing mint-typed cigarette paper. A new material: functional molecule encapsulation menthol is selected; the performances of the molecule encapsulation menthol such as low volatility, low transitivity and thermal stability are utilized and alcohol is used as a solvent; furthermore, new technologies such as internal machine coating or external machine coating, low-temperature drying of a baking cylinder and the like are utilized during the production of the cigarette paper, therefore, the adding uniformity and remaining performance of the menthol on the cigarette paper are ensured, the shortages that the mint ingredients in the original mint cigarette are easy to be volatilized, have unstable effect and the like are overcome, and the mint cooling feeling of the cigarette is always kept during smoking process. The mint-typed cigarette paper greatly improves the quality of the mint-typed special cigarette and the good running performance of the production process, becomes one highlight for the special cigarette paper and is expected to be a new economic growing point for the cigarette paper products.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Processing technology of bamboo shoots with pickled peppers

InactiveCN103404815AEasy to packIncrease the scouring processFood preparationSalinityFood processing

The invention discloses a processing technology of bamboo shoots with pickled peppers, and relates to a food processing technology. The processing technology comprises the concrete steps of processing materials, boiling, distributing and pickling, wherein in the distributing step, mountain pepper water is prepared; and the preparation method comprises the steps of strictly putting various materials into a pot according to the ratio; and evenly stirring for 3-5 minutes to take out from the pot. According to the processing technology, the fading effect is even, and consistent in salinity control; water consumption is saved; the ratio of pickling liquid to fed materials is strictly controlled; the pickling temperature and the pickling time are controlled; the streamline operation is carried out; consistent mouthfeel of the product is ensured; the processing technology has good practicability.

Owner:CHONGQING XUANRUI FOOD

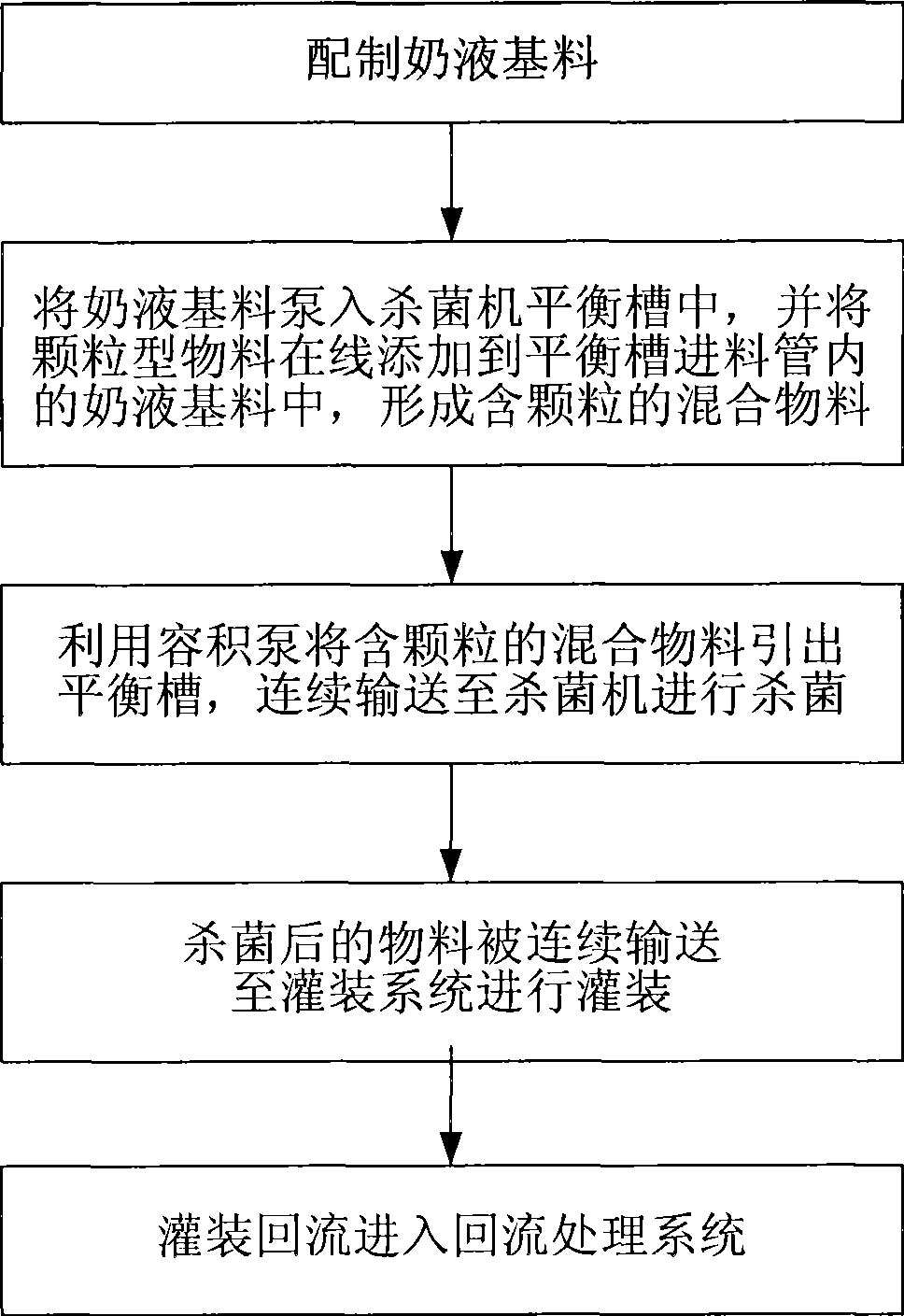

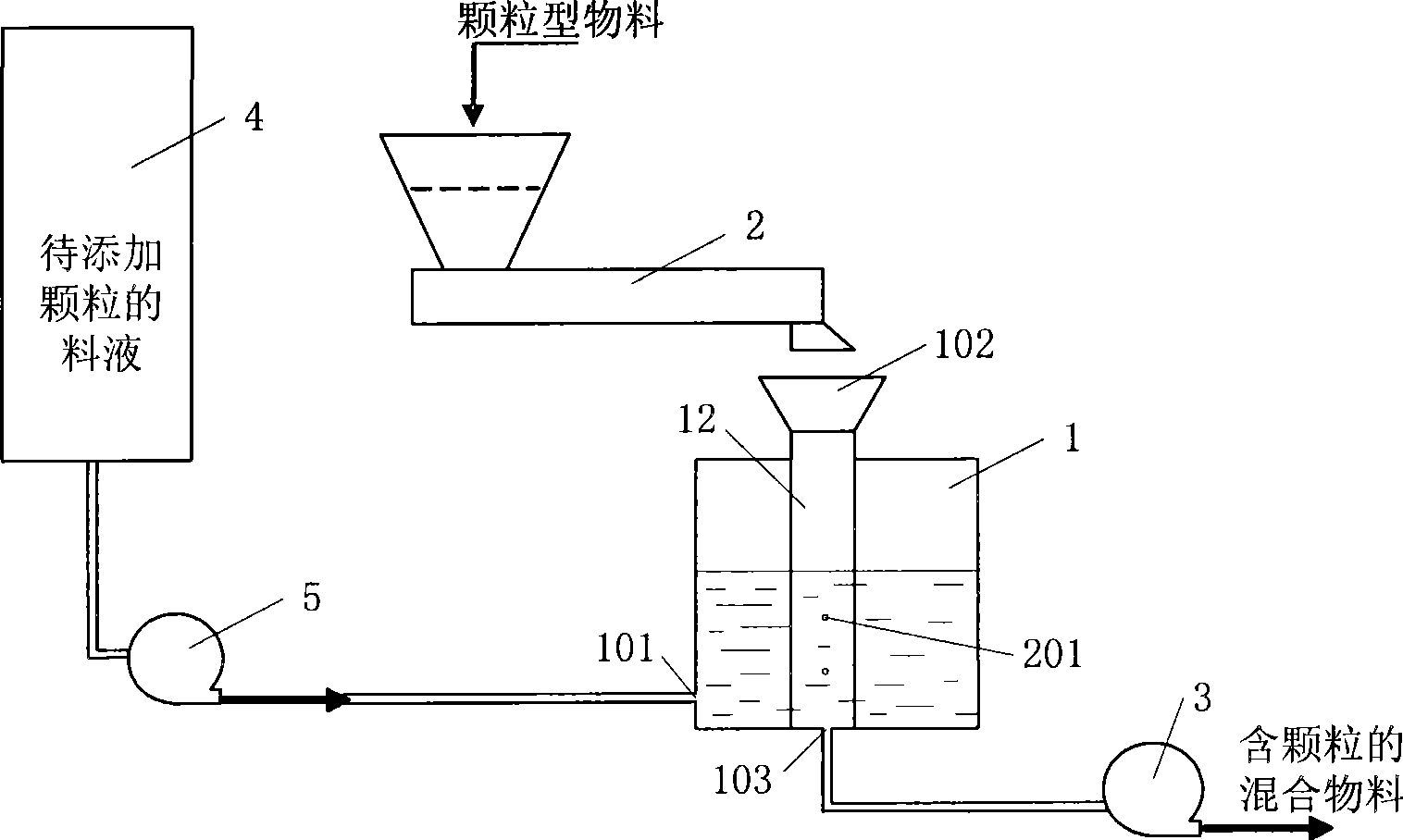

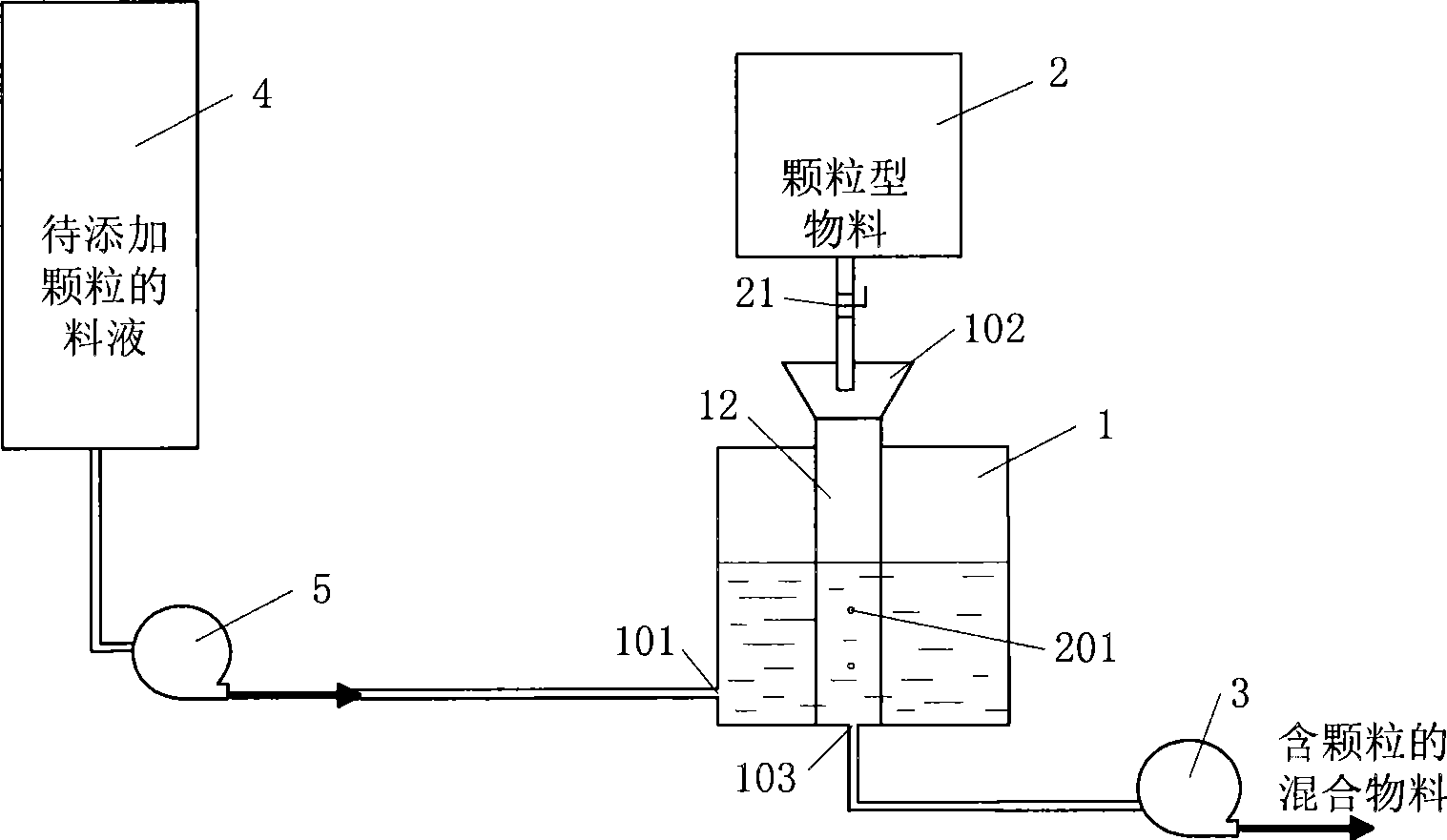

Method for producing granule-containing liquid drink

ActiveCN101480267AIntegrity guaranteedGuaranteed stabilityMilk preparationFood scienceLiquid stateAdditive ingredient

The invention provides a producing method of inclusion granule liquid drink, which comprises the following steps: feed liquid to be added with granules is prepared: other raw materials except granular materials are uniformly mixed according to the prescription of the liquid drink and are treated full-homogeneously so as to obtain the feed liquid to be added with granules, and the feed liquid to be added with granules is arranged in an ingredient keeping tank for standby; the feed liquid to be added with granules is pumped in a compensating groove, and the granular materials are quantitatively added into the flowing feed liquid to be added with granules in the compensating groove on line according to the prescription quantity so as to form inclusion granule mixed materials; the inclusion granule mixed materials in the compensating groove are led out of the compensating groove by a positive-displacement pump and are continuously conveyed to a sterilizer for being sterilized, and the sterilized materials are continuously conveyed to a filling system for being filled so that the inclusion granule liquid drink can be obtained. The method can realize the continuous manufacturing production of the inclusion granule liquid drink.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

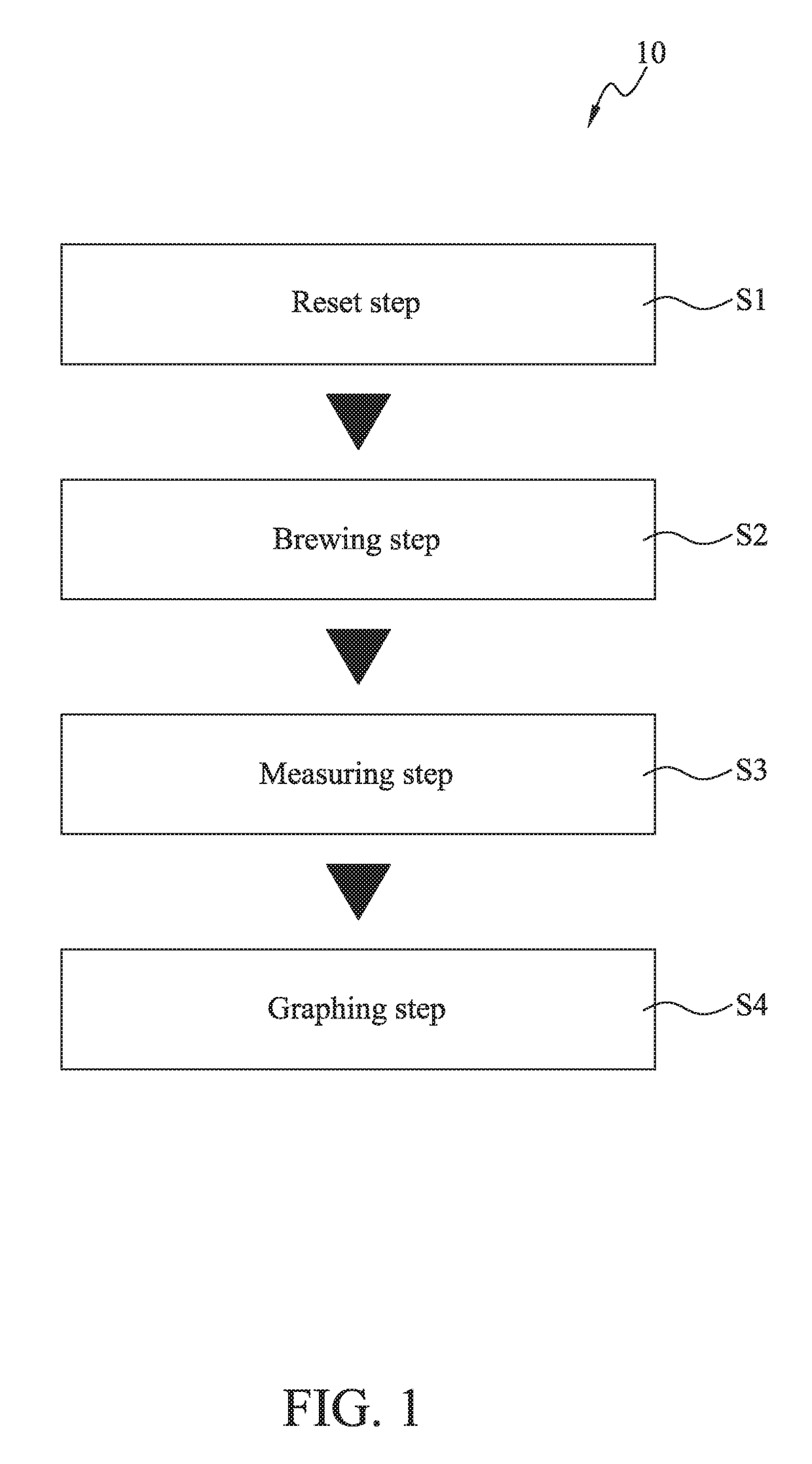

Method and device for examining beverage brewing and extracting process

A method for examining beverage brewing and extracting process includes the steps of adding a solvent to a solute, mixing the solvent and the solute together to produce a solution, and subjecting the solution to an extraction process to output an extract liquid; measuring a solvent weight increase per unit time of the added solvent and measuring an extract liquid weight increase per unit time of the output extract liquid at the same time during the step of adding the solvent to the solute; and performing a calculation on the solvent weight increase and the extract liquid weight increase to output a graphic data to represent the extraction process. By referring to the graphic data, even an inexperienced brewing operator can always ensure a consistent taste for the brewed solution.

Owner:ACAIA

Production method of fried bean sauce with mushroom and beef

The invention provides a production method of fried bean sauce with mushroom and beef, wherein the main ingredients include beef stuffing or shredded beef, minced mushroom, flour paste and fermented soya paste, the beef stuffing or shredded beef are refrigerated and defreezed under atmospheric temperature, water-loss reducer and anti-oxidizing agent are charged into laminated pan to be boiled, at last soup stock and thickening agent are also charged.

Owner:杨秀敏

Preparation method of five-spice multi-layer dried bean curd mock meat

InactiveCN103859056AGreat tasteUniform colorCheese manufactureFood scienceDry beanProcess conditions

The invention discloses a preparation method of five-spice multi-layer dried bean curd mock meat and relates to the technical field of bean product production. The preparation method comprises the following steps: screening raw materials, soaking, grinding and separation, boiling, coagulating, watering, pressing, stripping cloth, soaking, pressing for the second time, and airing for storage. The process is different from a conventional marinating method; dried bean curd is relatively tasty through the process of two-time pressing, watering and soaking; the process conditions are strictly controlled, so that the finished dried bean curd is uniform in color and taste; the multi-layer dried bean curd mock meat prepared by adopting the method is good in color, aroma and taste, and is popular in masses of consumers.

Owner:DEZHOU DOULAISHUN FOOD

Heated pour-in beverage production with flavouring inpouring

The present invention is flavored beverage producing process and system. The flavoring agent is added into the base beverage through pasteurization and other treatment in an alone step. After the base beverage is produced in a stable process, the flavoring agent is added in the downstream flavoring agent adding part. The present invention makes it easy for the beverage producing line to convert from producing the beverage with one first flavoring agent to producing the beverage with one second flavoring agent.

Owner:THE QUAKER OATS CO

Five-spice dried bean curd flavoring processing process

InactiveCN103404605AIncrease flexibilityGreat tasteCheese manufactureFood scienceTemperature controlRoom temperature

The invention discloses a five-spice dried bean curd flavoring processing process. The process comprises the steps that: alkali quick-boiling is carried out, wherein sliced and shaped dried bean curds are added into an alkali solution and steaming is carried out for 4min, wherein the alkali solution is an edible alkali solution, and the dried bean curds are added when the alkali solution is heated to 90 DEG C; marinating is carried out, wherein the dried bean curds processed with the alkali quick-boiling step is marinated in a marinating soup for 52-56min under a temperature controlled at 84-88 DEG C; drying is carried out, wherein the marinated and flavored dried bean curds are dried by using a drier; water content in the dried bean curds is 55%, and the dried bean curds is cooled to room temperature; and blending is carried out, wherein the dried bean curds are added into a blending machine; blending materials are added, and mechanical blending is carried out. According to the invention, through the alkali quick-boiling step, dried bean curd properties are changed. Toughness is enhanced, and bean odor is removed, such that the dried bean curds are easier to flavor during the subsequent marinating step. Conditions of various processes are strictly controlled, such that finished dried bean curd products has uniform color and consistent taste. With a unique formula, the finished dried bean curd product has good color, good fragrance, and good taste. The dried bean curds are popular among consumers.

Owner:CHENGDU XIANGXIANGZUI FOOD

Method for preparing black tea drink

InactiveCN101589746AConsistent tasteMellow tastePre-extraction tea treatmentTea extractionBlack teaDigestion

The invention provides a method for preparing a tea drink, and particularly relates to a method for preparing a black tea drink. The method is characterized in that: the method adopts the drink preparing steps of preparation of original tea, washing of original tea, taste burning, baking, warm soaking, low-fire cooking, steaming, cooling, stirring, filtering, temperature adjusting, filtering, degassing, sterilization, re-cooling, refiltering, heating and canning, quality inspection and the like; by the method, the original healthcare functions of degreasing, reducing fat, aiding digestion and benefiting intestines and stomach of the black tea are maintained, and no chemical additive is added; moreover, the black tea drink prepared by the method is red-yellow, has concentrated fragrance and tastes fresh and good, and the method provides a black tea original juice drink conveniently drunk by people.

Owner:ANHUA GOAM ERXI TEA DEV

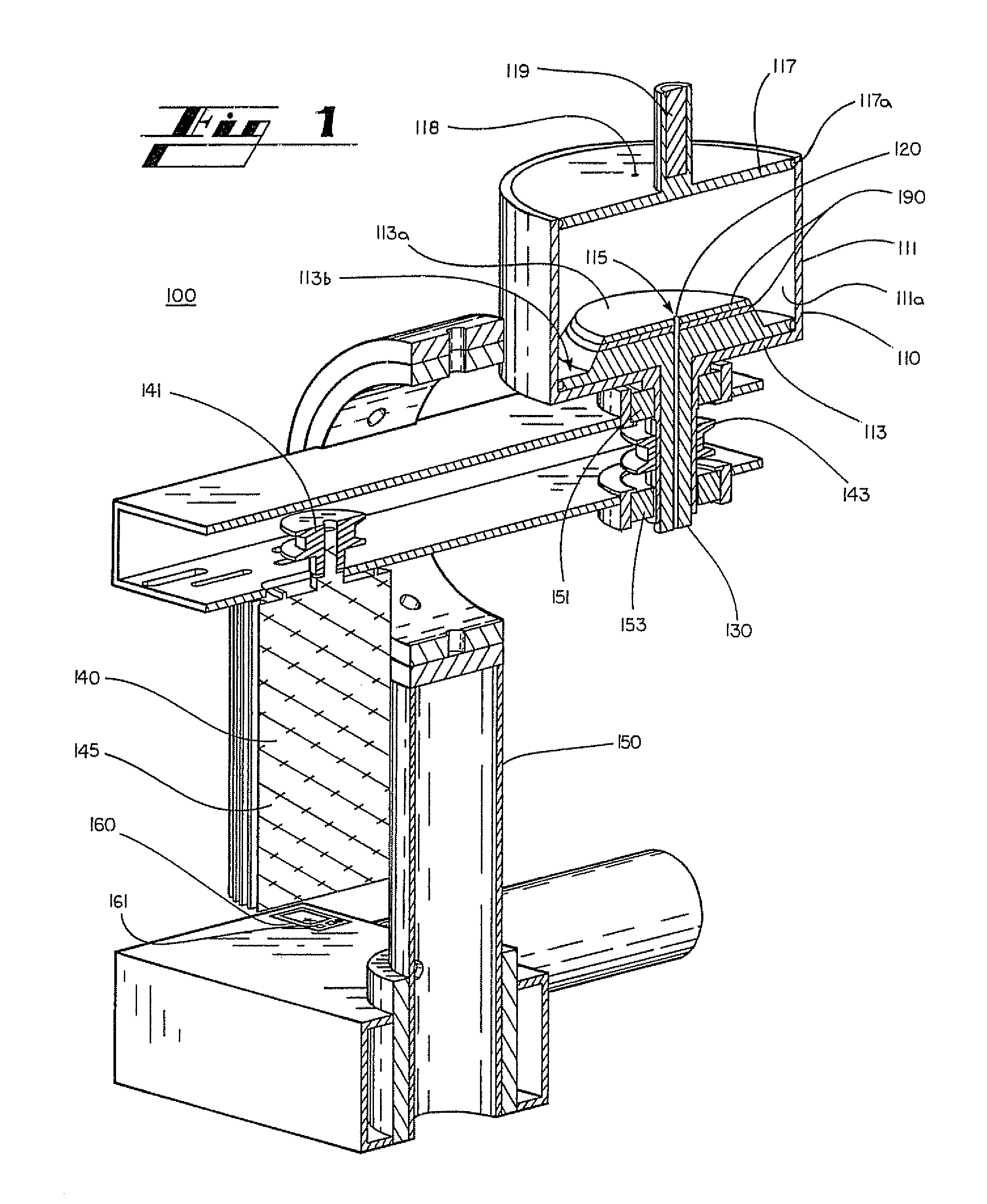

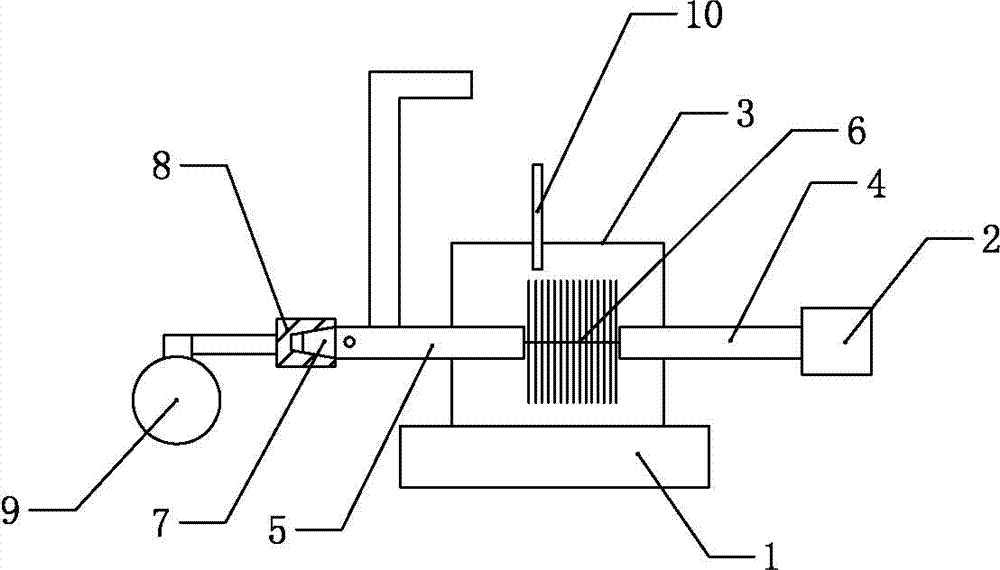

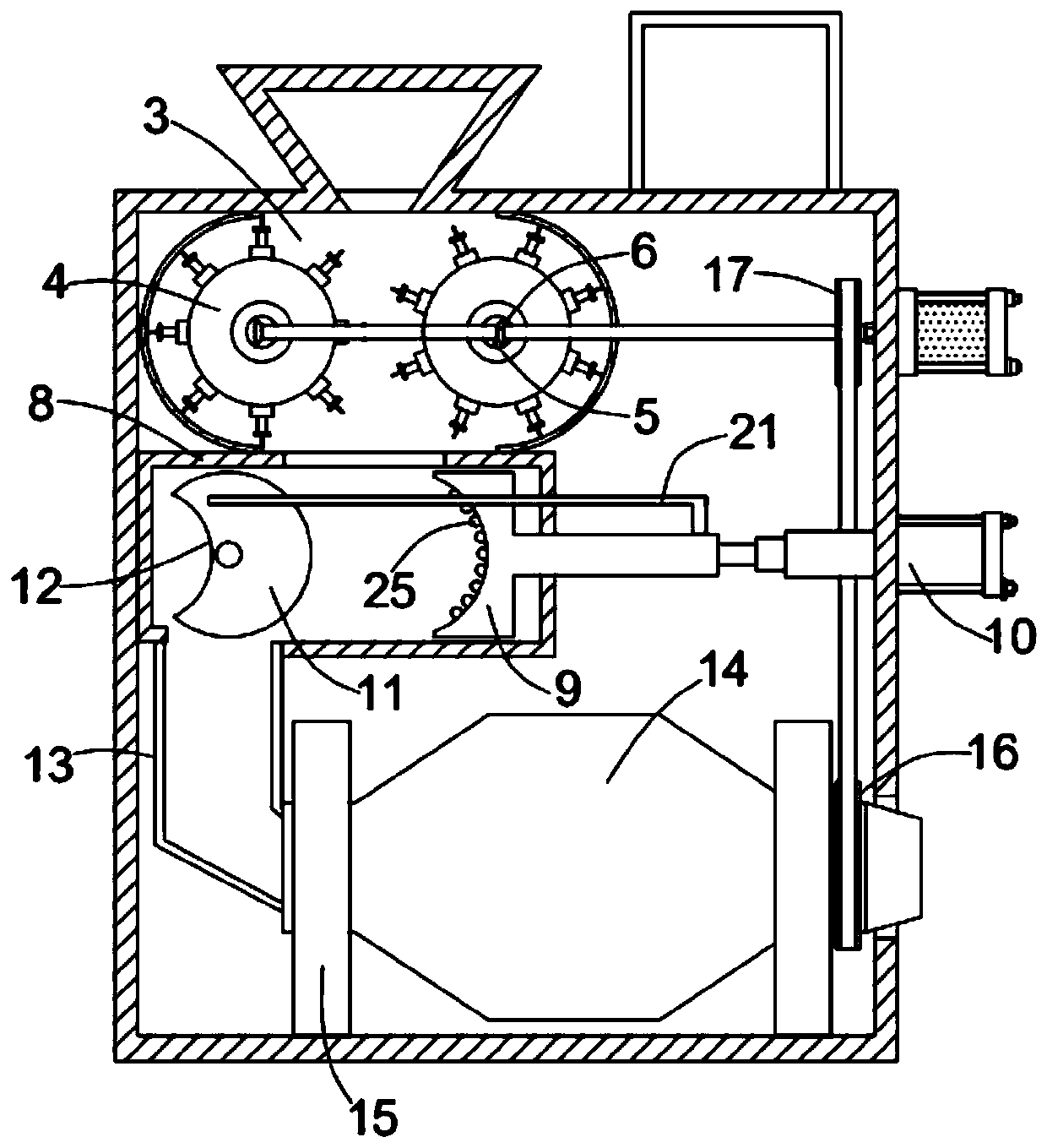

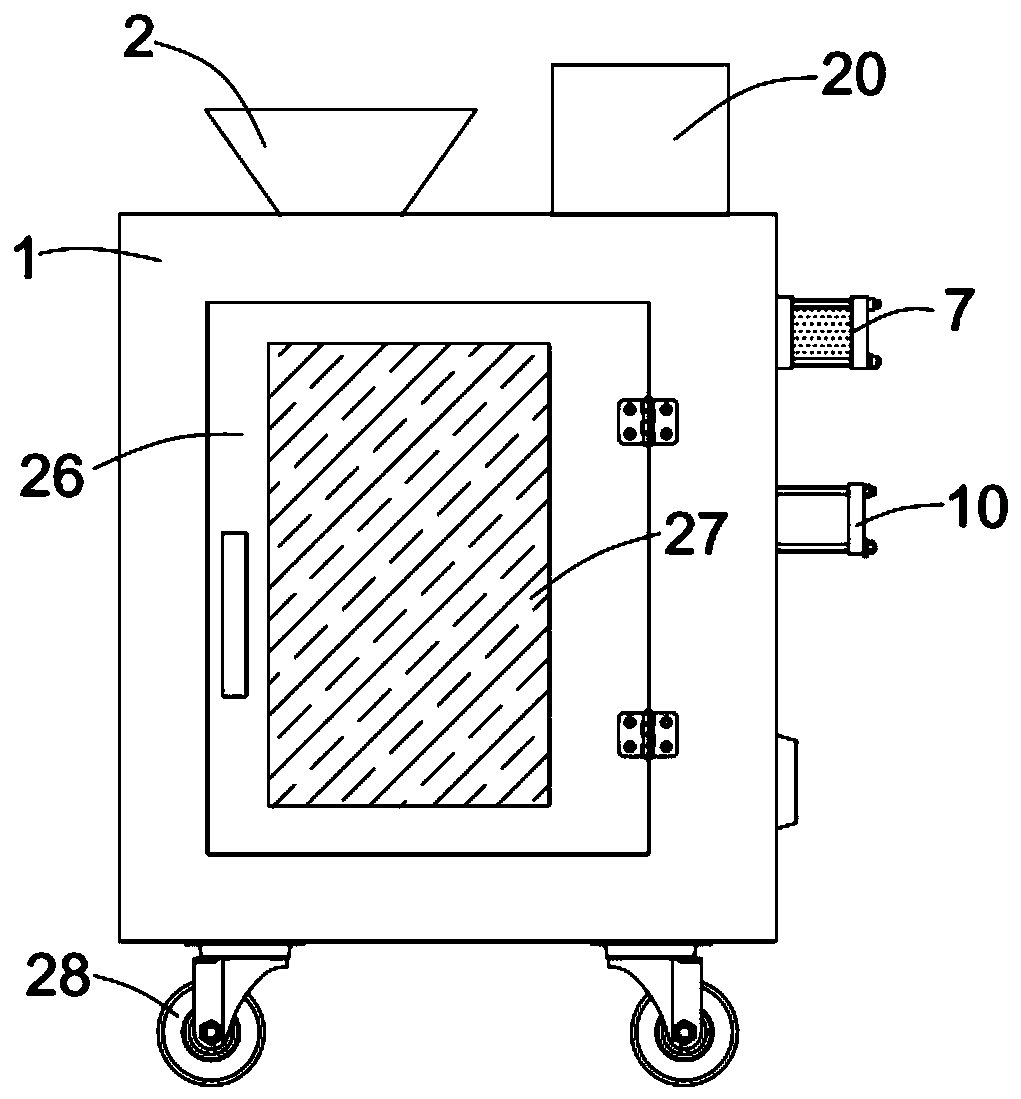

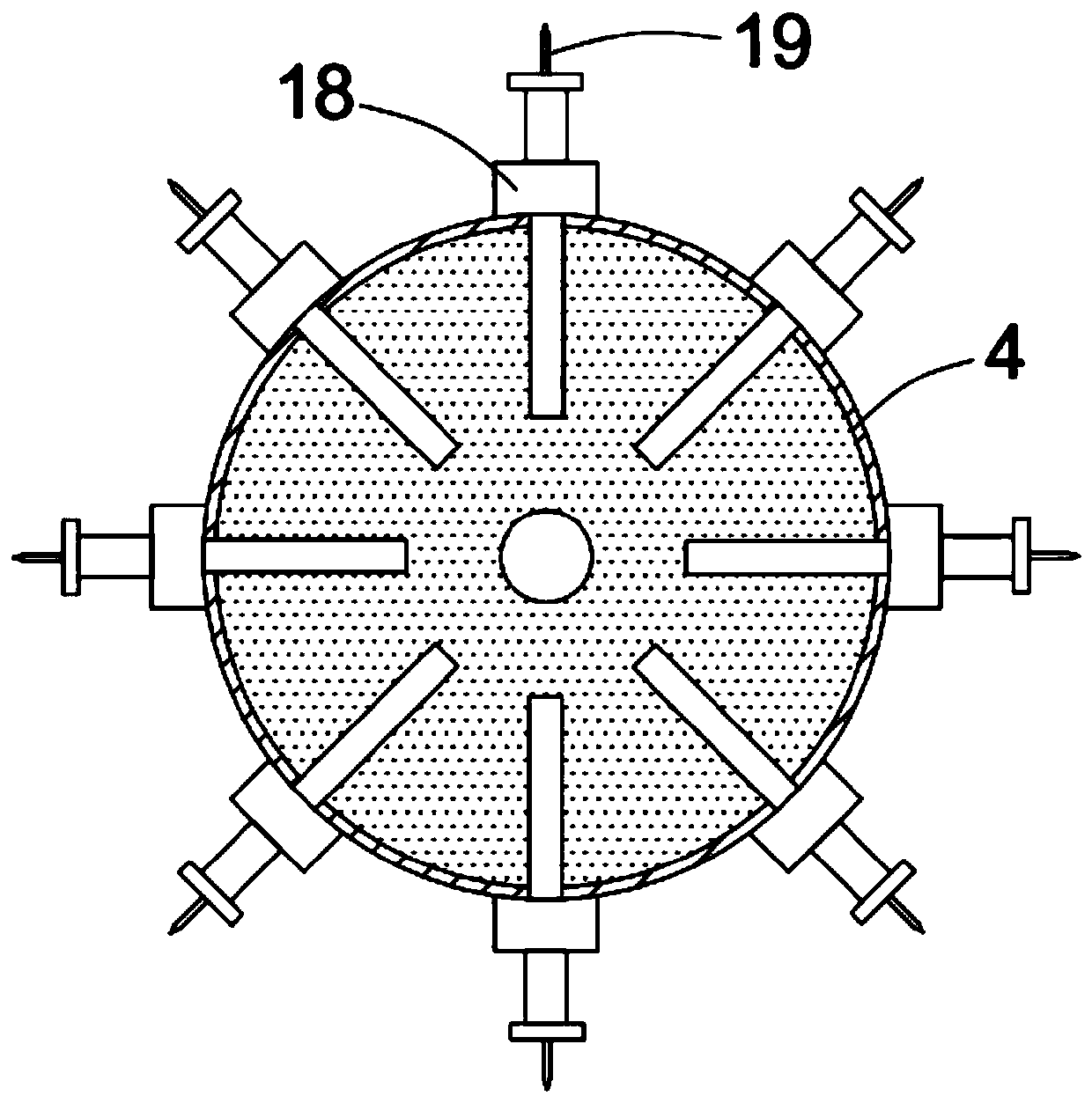

Beating device used for meat product

InactiveCN104489042AConsistent hammering effectConsistent tasteBeating-based meat tenderisingEngineeringMechanical engineering

Owner:重庆市合川区麒麟畜产品有限责任公司

Process for preparing rice matter of instant rice porridge and cooked rice

InactiveCN1653940AFully preserve the effective nutrientsPreserve effective nutrientsFood preparationBiotechnologyForeign matter

The present invention is the treating process of rice for compounding instant cooked rice and instant rice gruel. The rice for compounding instant cooked rice and instant rice gruel is produced with rice and through the steps of eliminating foreign matter, soaking, steaming, cooling, freezing and drying. The rice for compounding instant cooked rice and instant rice gruel is easy to maintain and eat, delicious and rich in nutritious matter.

Owner:肖兆泉

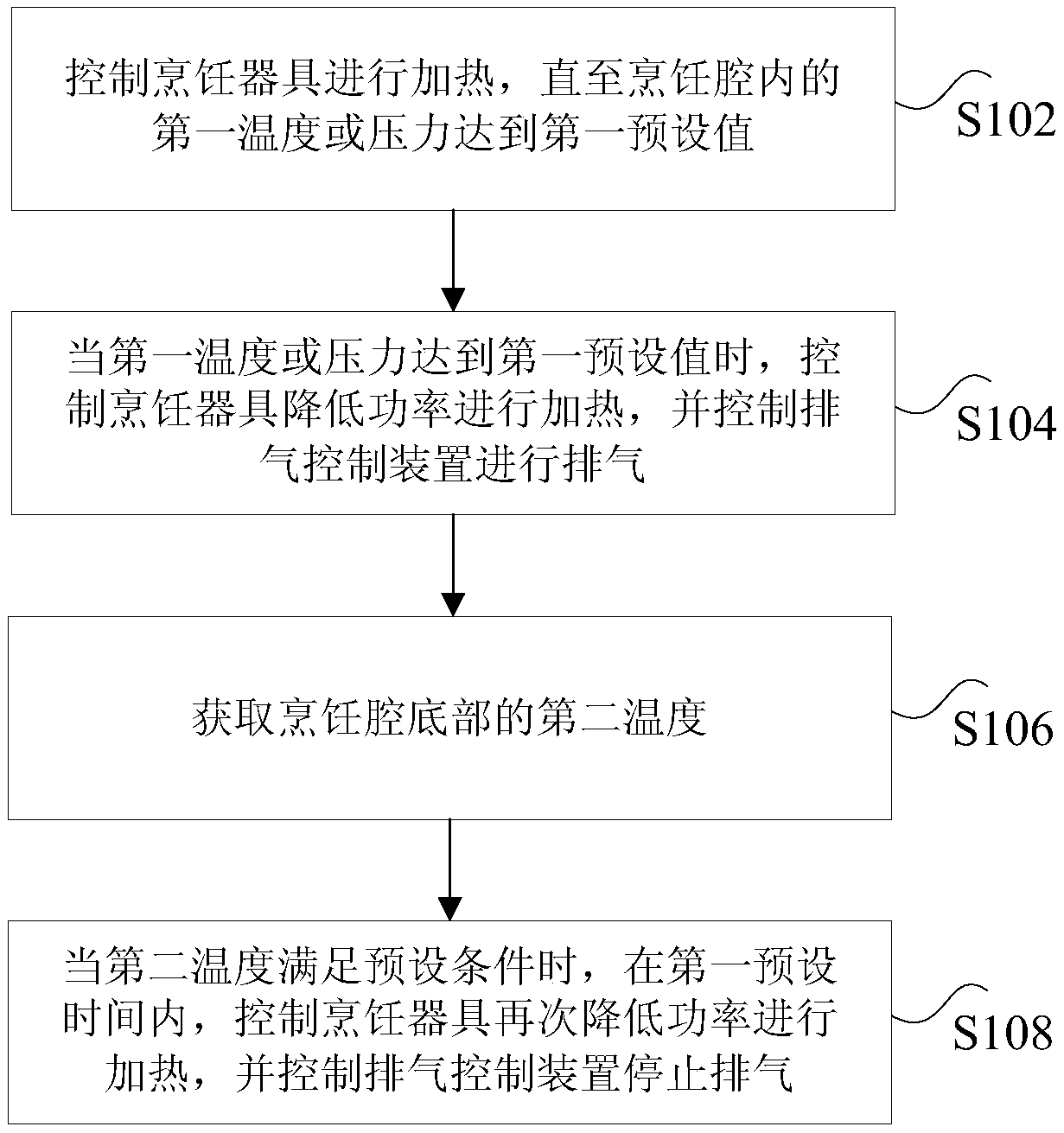

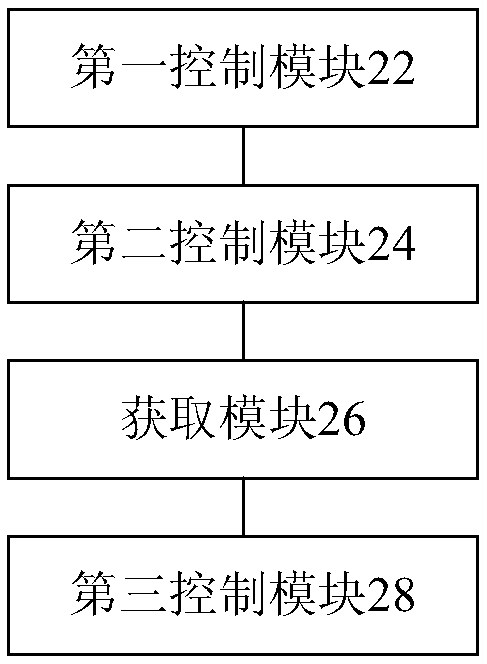

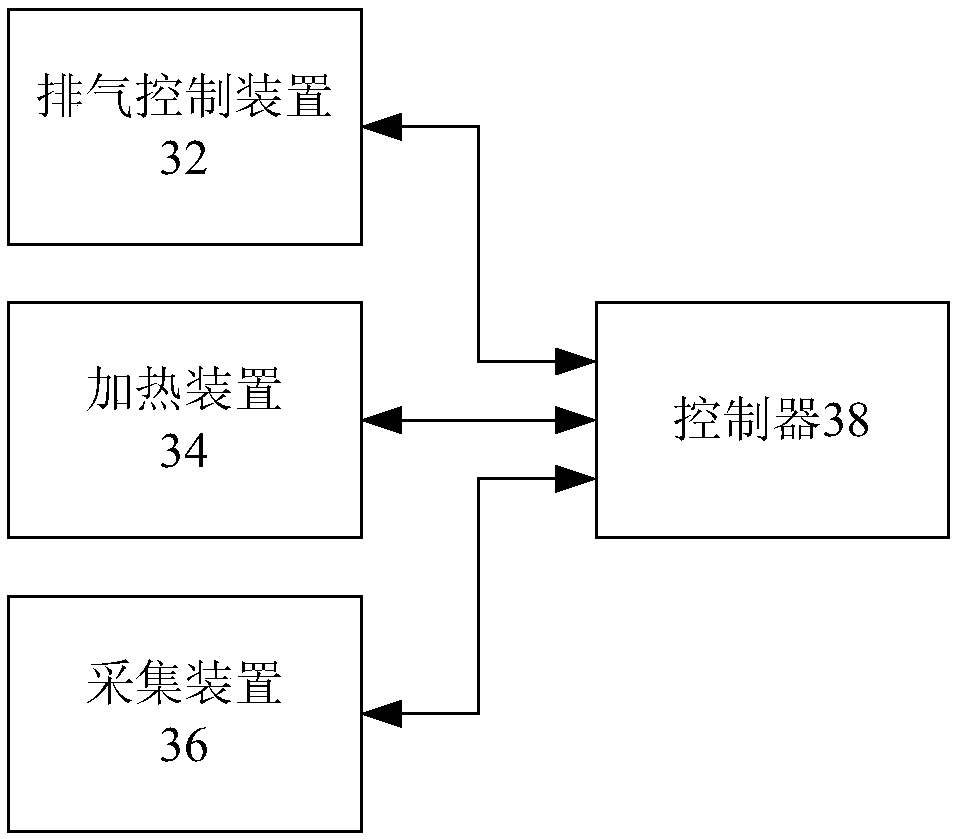

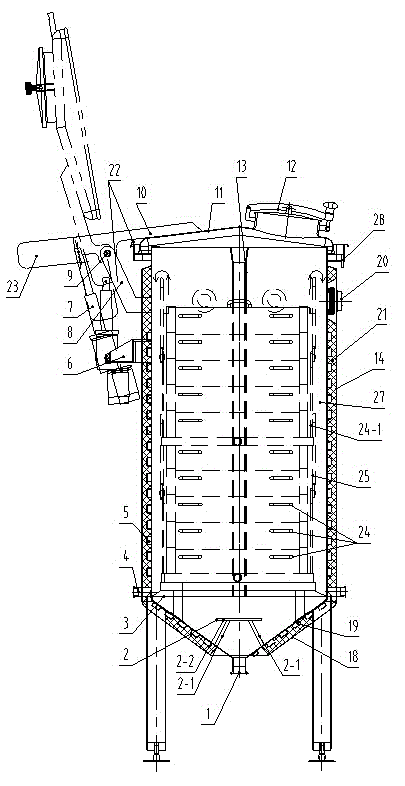

Cooking utensil as well as control method and control device for same

The invention discloses a cooking utensil as well as a control method and a control device for the cooking utensil. The cooking utensil comprises a cooking cavity with an air outlet, and an air exhaust control device used for plugging the air outlet. The control method comprises the following steps: controlling the cooking utensil to carry out heating till first temperature or pressure in the cooking cavity achieves a first preset value; when the first temperature or pressure achieves the first preset value, controlling the cooking utensil to carry out heating with the reduced power, and controlling the air exhaust control device to carry out air exhaust; acquiring second temperature at the bottom of the cooking cavity; and when the second temperature satisfies the preset condition, withinfirst preset time, controlling the cooking utensil to carry out heating at the reduced power again, and controlling the air exhaust control device to stop air exhaust. With the technical scheme provided by the invention, the technical problem that the existing cooking utensil carries out rice cooking according to the preset cooking process, so that the cooked rice is poor in effect is solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Making method of pot-falling chick

The invention discloses a making method of a pot-falling chick, which comprises the following steps of: selecting an underyear normally-slaughtering chick, slaughtering, dropping blood, drawing thorax out, and cleaning; soaking with clear water for 3-5h, placing in a salting chamber; injecting spice water in the chick according to the additive amount of 10-13 percent by weight of the chick by using an injecting machine under a working environment of 0-8 DEG C, rolling and kneading for 3-5h; after rolling and kneading are finished, placing in a container, salting for 12-24h with the spice water, stacking the chick fished from soup stock in a smoking furnace, and fuming with sugar for smoking for 5-10min until the surface of the chick is yellow in color. The chick made by using the making method has the advantages of thorough taste, good mouthfeel, uniform flavor, and tender, fresh and delicious meat, is easier to accept by a user, and is complete in appearance; and the appearance and the color of the traditional smoked chick can be kept.

Owner:BEIZHEN GOUBANGZI FOOD

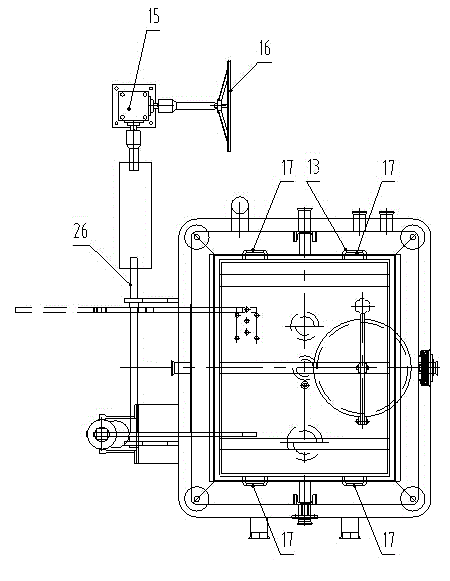

Novel Chinese stewing pot device

A novel Chinese stewing pot device comprises a stewing pot body. The stewing pot body comprises a drum body at the upper portion and a pot bottom connected with the bottom of the drum body, an upper interlayer and a lower interlayer are arranged in the drum body and the pot bottom respectively, an upper interlayer cover is arranged in the upper interlayer, a lower interlayer cover is arranged in the lower interlayer, and steam pipelines are arranged in the upper interlayer cover and the lower interlayer cover. An upper circulating port is formed in the upper portion of the drum body, a stewing tray support is arranged on the inner side of the bottom of the drum body in the annular direction, and a plurality of layers of stewing trays are arranged on the stewing tray support. Stacked-up stewing tray frames form a drum shape from top to bottom, namely a stewing tray vertical drum. The stewing tray support seals the position between the bottom of the outer wall of the stewing tray vertical drum and the bottom of the inner wall of the drum body, and an annular cavity with the upper side open is formed by the outer wall of the stewing tray vertical drum, the inner wall of the drum body and the stewing tray support located at the bottom. The novel Chinese stewing pot device can ensure that materials stewed and boiled in the drum body are heated uniformly and the cooking degree and taste of the stewed and boiled materials are identical, control stewing temperature and progress accurately, and utilize internal space to increase the processing amount to the maximum extent.

Owner:CHUYING AGRO PASTORAL GRP

Electronic cigarette and control method therefor

ActiveUS9949511B2Obstruction is producedSave powerTobacco devicesHeating element shapesElectricityElectrical resistance and conductance

An electronic cigarette and a control method thereof are provided. An electronic cigarette with a heating wire component used for producing heat, where the heating wire component comprises a heating wire having a resistance that varies with temperature; a power source used for providing the heating component with a voltage; and, a controller electrically coupled to the heating wire component and the power source and used for controlling the voltage outputted by the power source. The controller comprises a temperature detection module used for detecting the resistance of the heating wire and thus acquiring the actual temperature of the heating wire component. The temperature detection module presets an upper limit heating temperature and a lower limit heating temperature.

Owner:SHENZHEN SMOORE TECH LTD

Pork kneading-salting device

The invention discloses a pork kneading-salting device. The device comprises a box body, a pair of injection rollers are movably arranged in an injection chamber, a kneading pressing plate is movablyarranged in a kneading pressing chamber, the kneading pressing plate and a kneading pressing rotating plate are cooperatively connected, the two injection rollers are of hollow structures, the top endof a pressing pump is fixedly provided with an injection needle, one end, away from the kneading pressing plate, of a telescopic connecting rod is fixedly provided with a rack, the rack and a drivingwheel of an irregular gear mechanism are engaged, a driven shaft of the irregular gear mechanism is also fixedly connected with a driving wheel of an intermittent moving mechanism, and a wheel shaftof a driven wheel of the intermittent moving mechanism is fixedly connected with the kneading pressing rotating plate; the device can not only make fresh meat be turned over during the salting process, but also knead and press a meat product, make the taste of a salted product uniform inside and outside by injectingsalting liquid into the meat product in cooperation with an external salting material which is smeared in advance, and make the salting even, thereby ensuring the taste of the salted meat product.

Owner:BENGBU COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com