Patents

Literature

614results about How to "Consistent quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

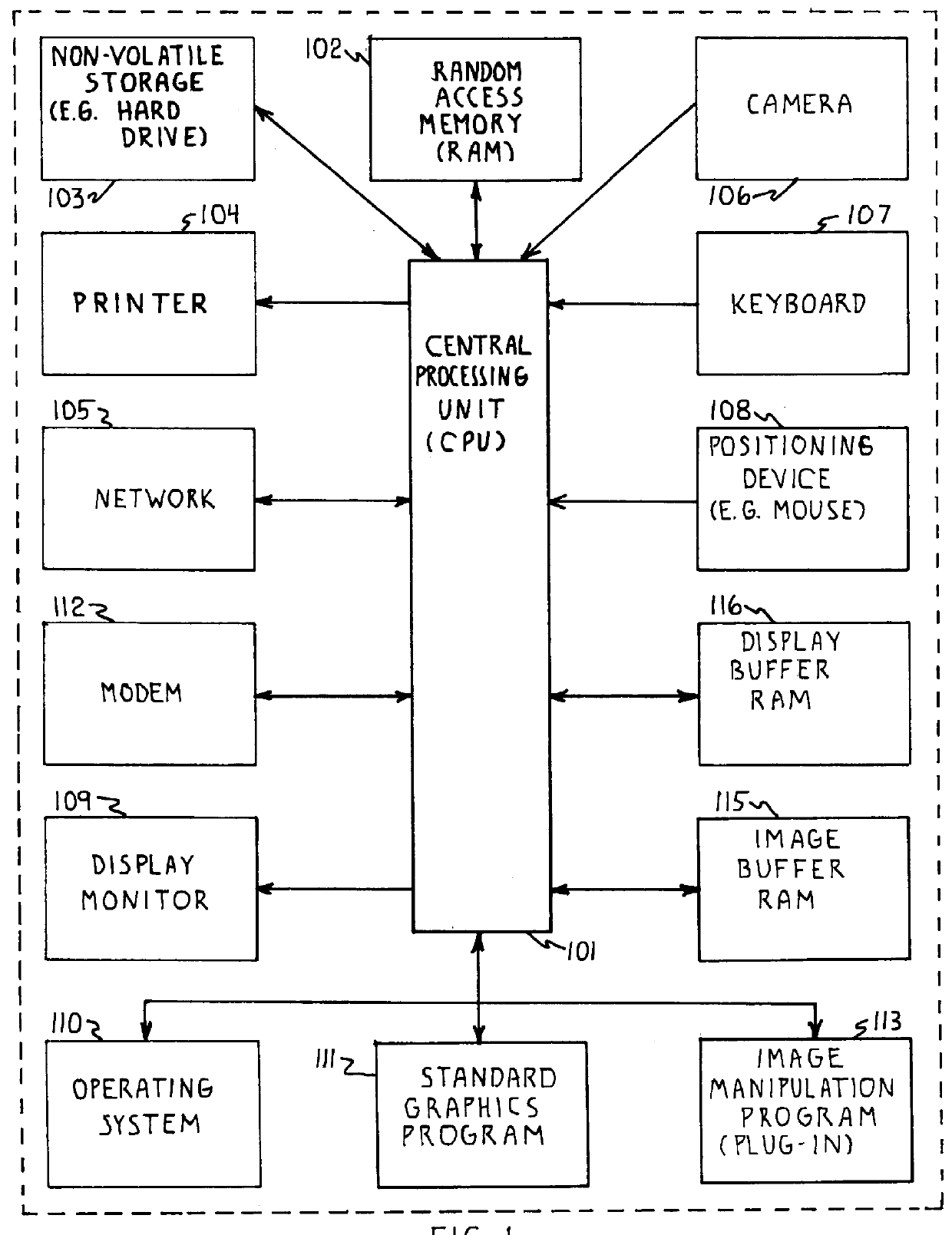

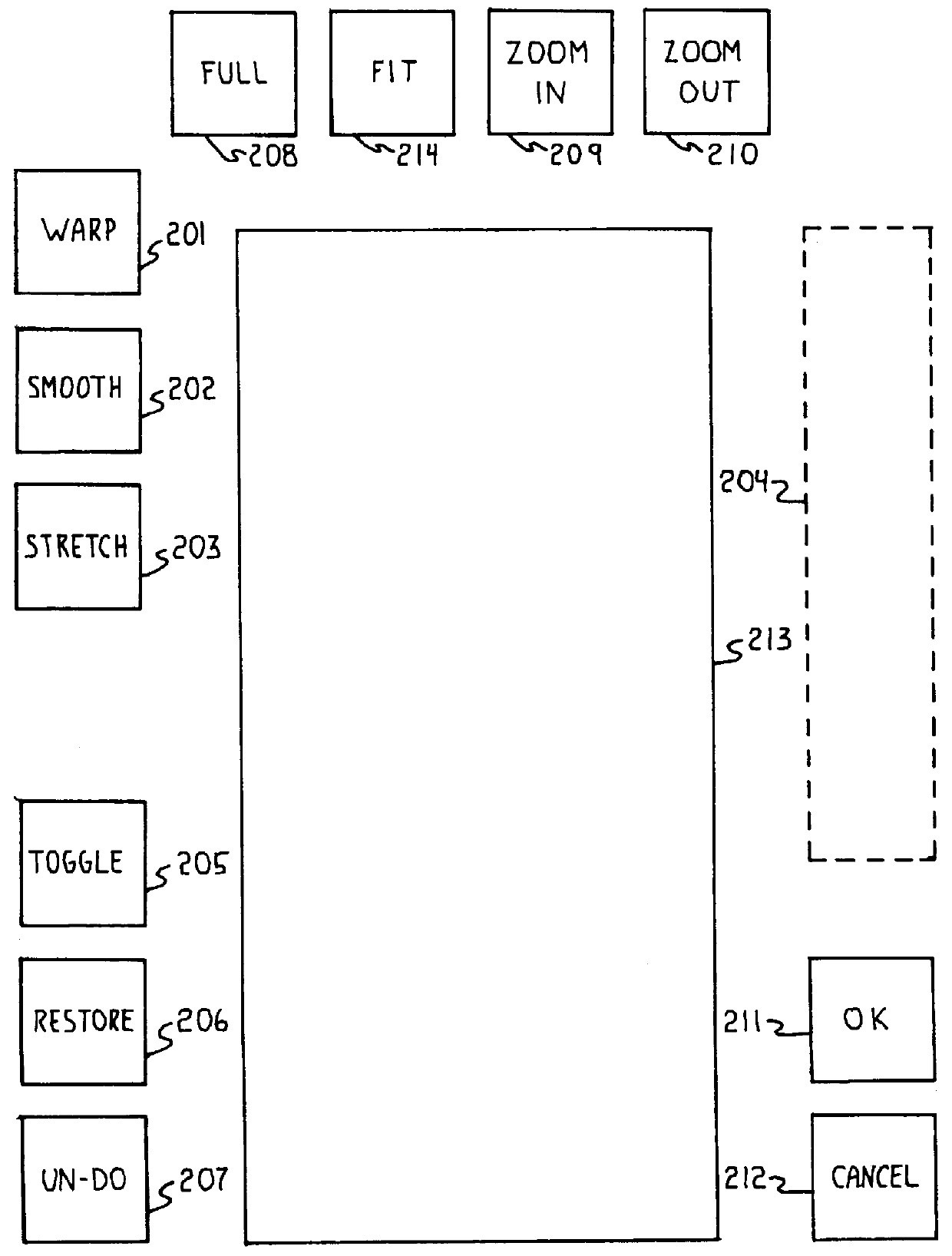

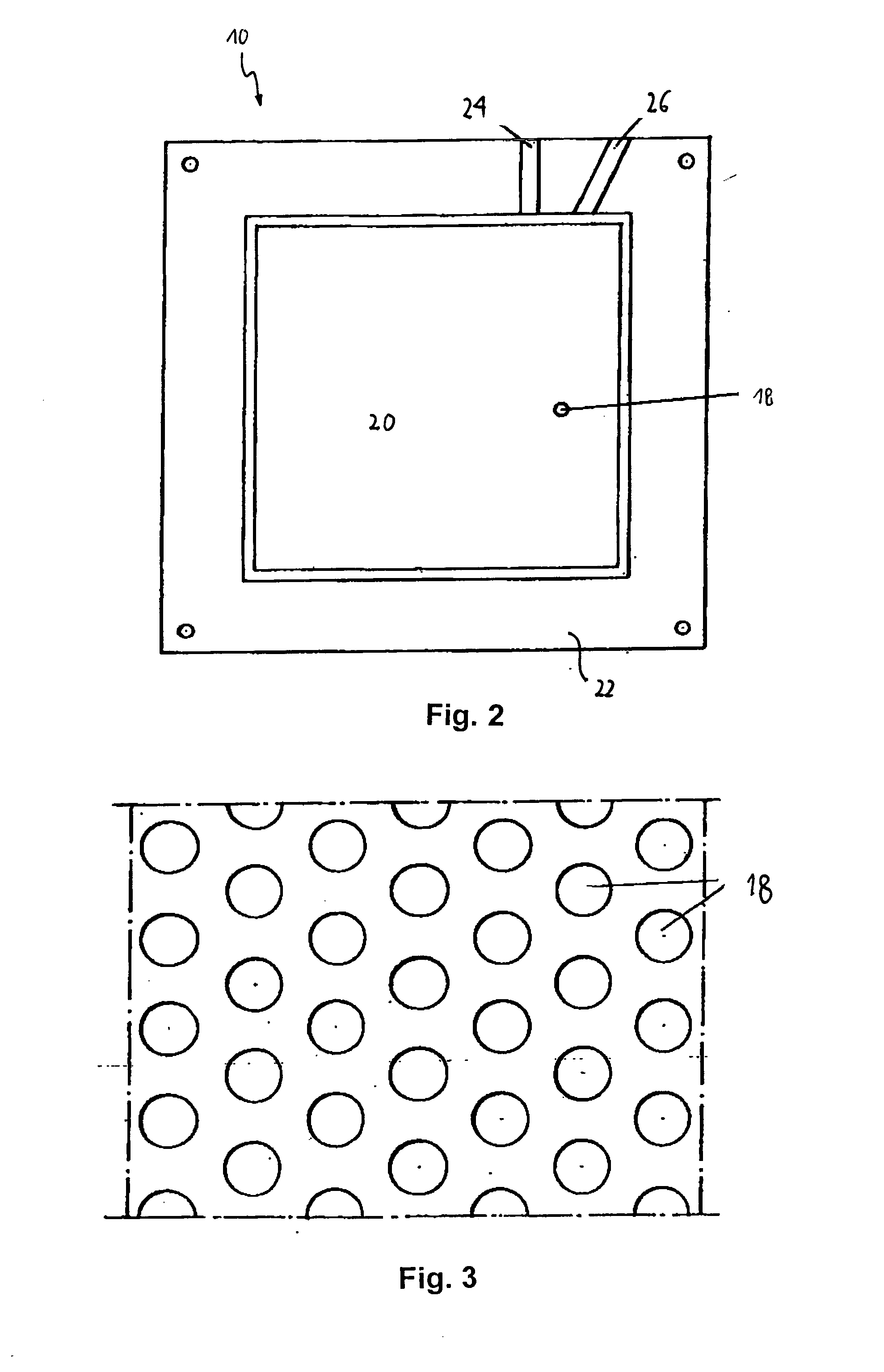

Apparatus for modifying graphic images

InactiveUS6084598AIncrease speedConsistent qualityDrawing from basic elementsGeometric image transformationChange managementShape change

A computer system modifies digital images of the human form as well as other objects. The computer system provides intuitive means for accessing warp, smooth, stretch, copy, and paste tools for image modification; undo, toggle and restore tools for change management; and zoom, fit, and full tools for image display sizing. The computer system is controlled by a program that uses a combination of novel approaches to make image manipulation fast and easy. Buttons are displayed only when they are actually available for use, based on the current system operating mode. The image sizing tools enable an image size change to accomodate the tool size without a required change to the cursor state or to the edit mode state. When regions are defined by the user, the cursor shape changes to indicate whether the cursor is located inside a region, outside the region, and on the region bounding box; allowing a user to perform different operations depending upon cursor location rather than depending upon, and requiring, user executed button pushing as a specific operation. The computer system uses display contexts and bitmap masks that enhance operation speed. Operations are always performed on the full image resolution rather than a displayed image resolution.

Owner:CHEKERYLLA JAMES

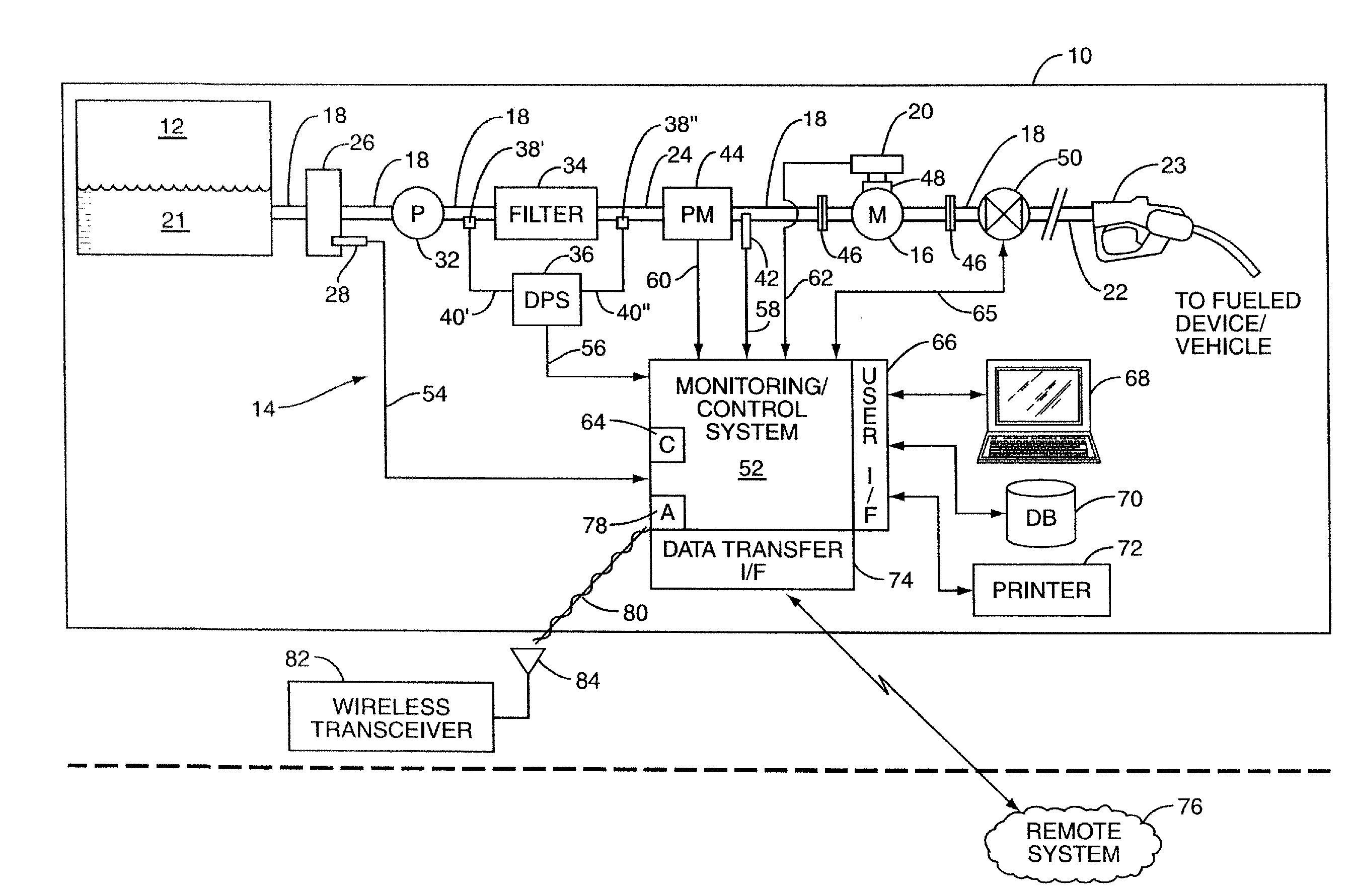

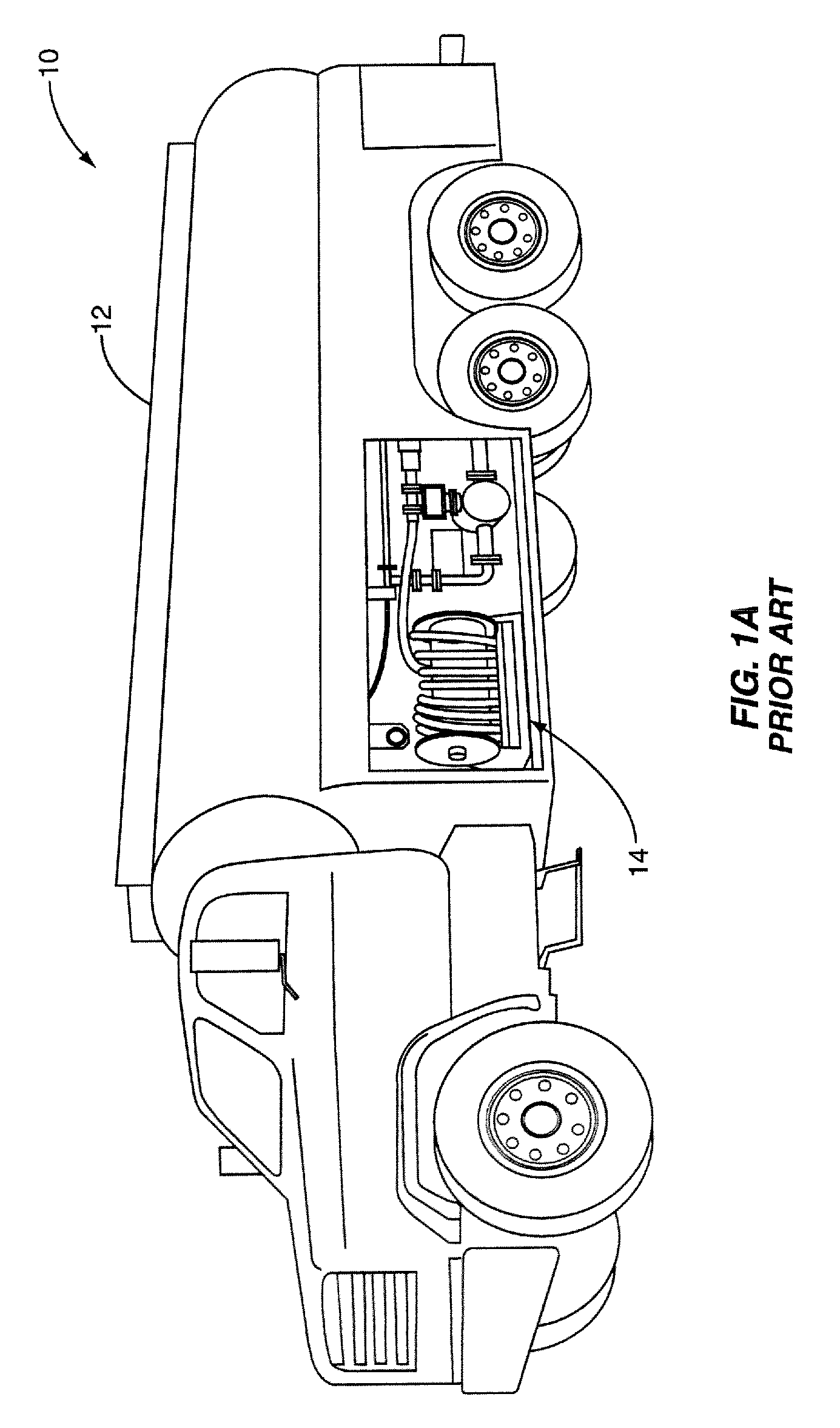

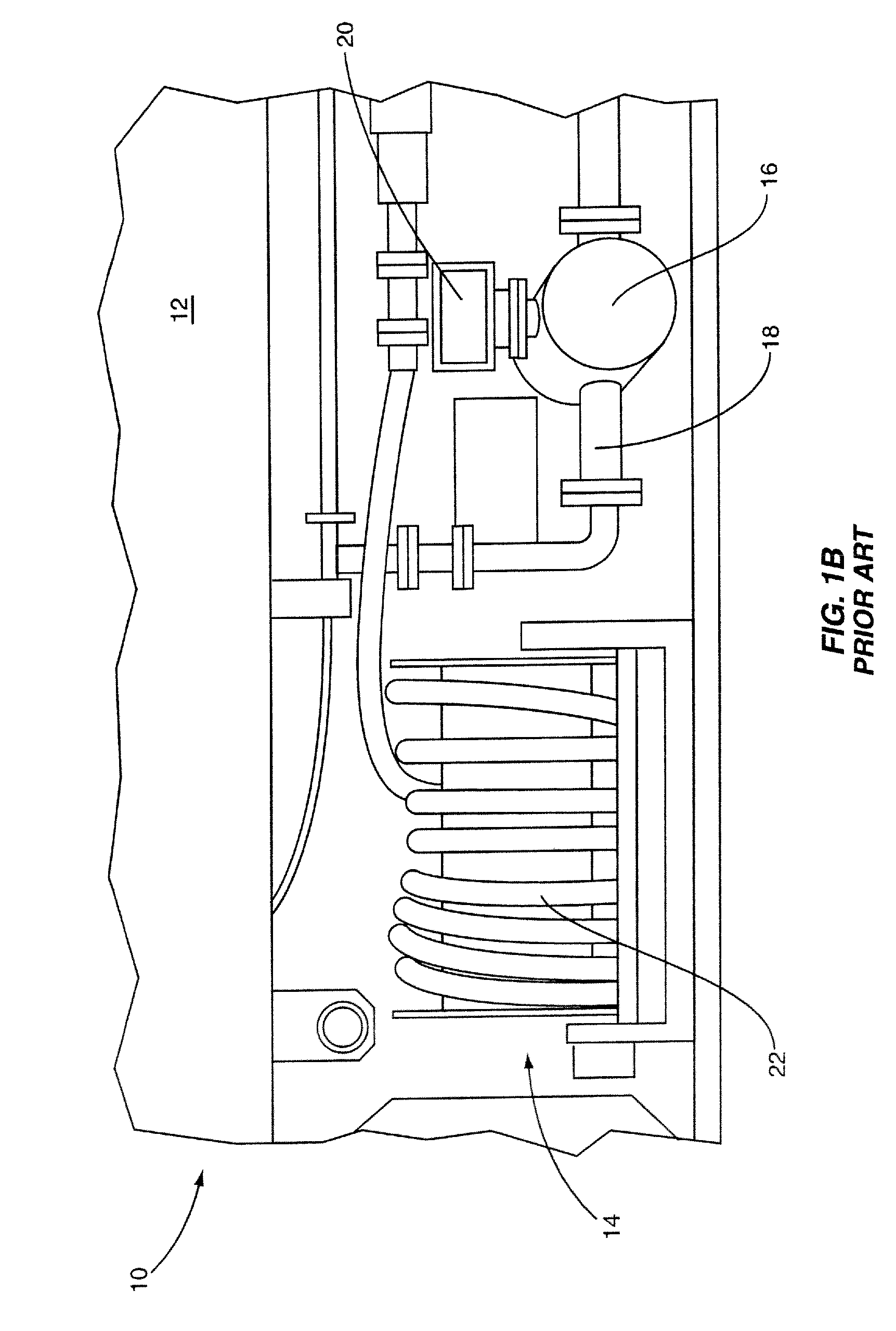

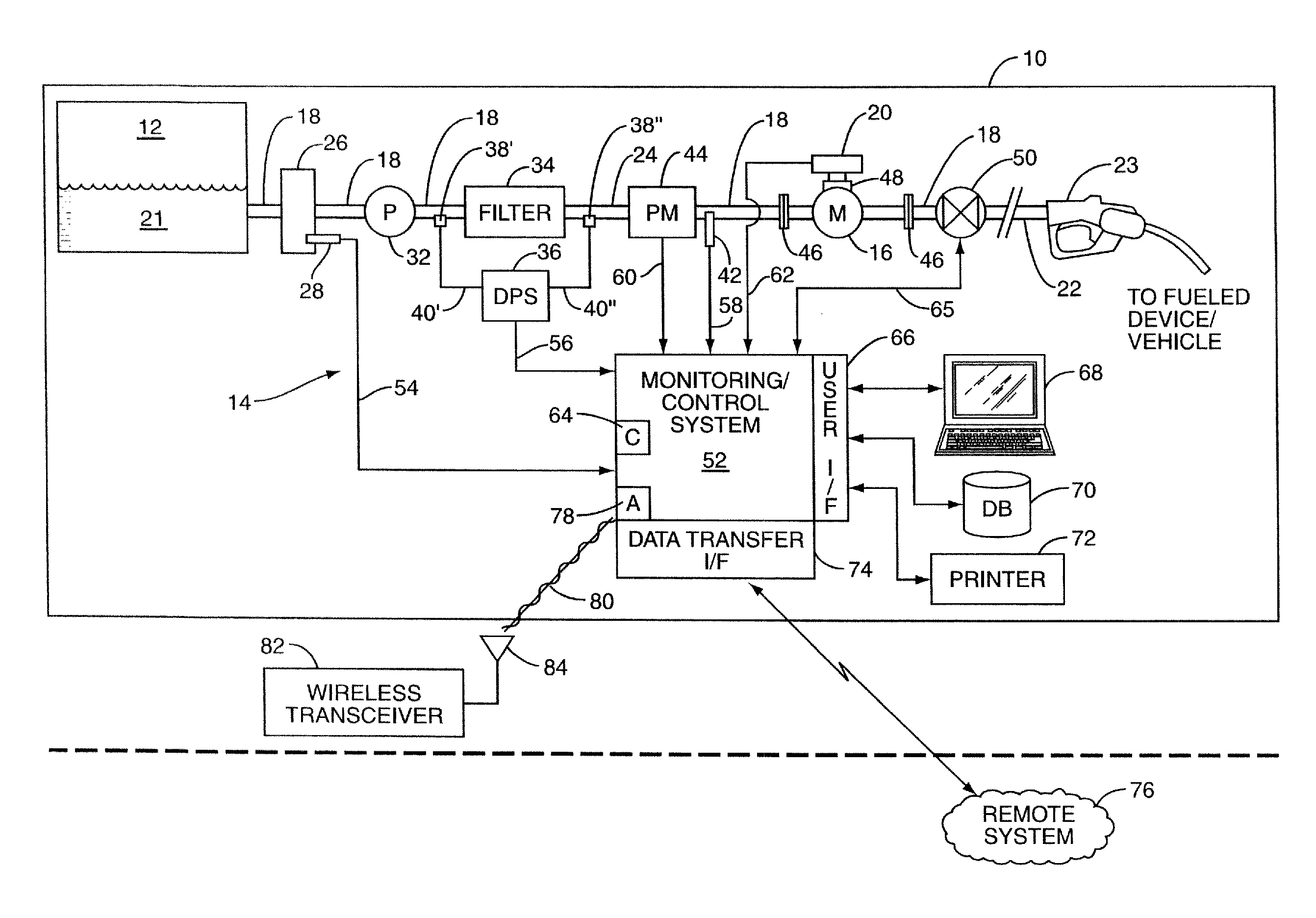

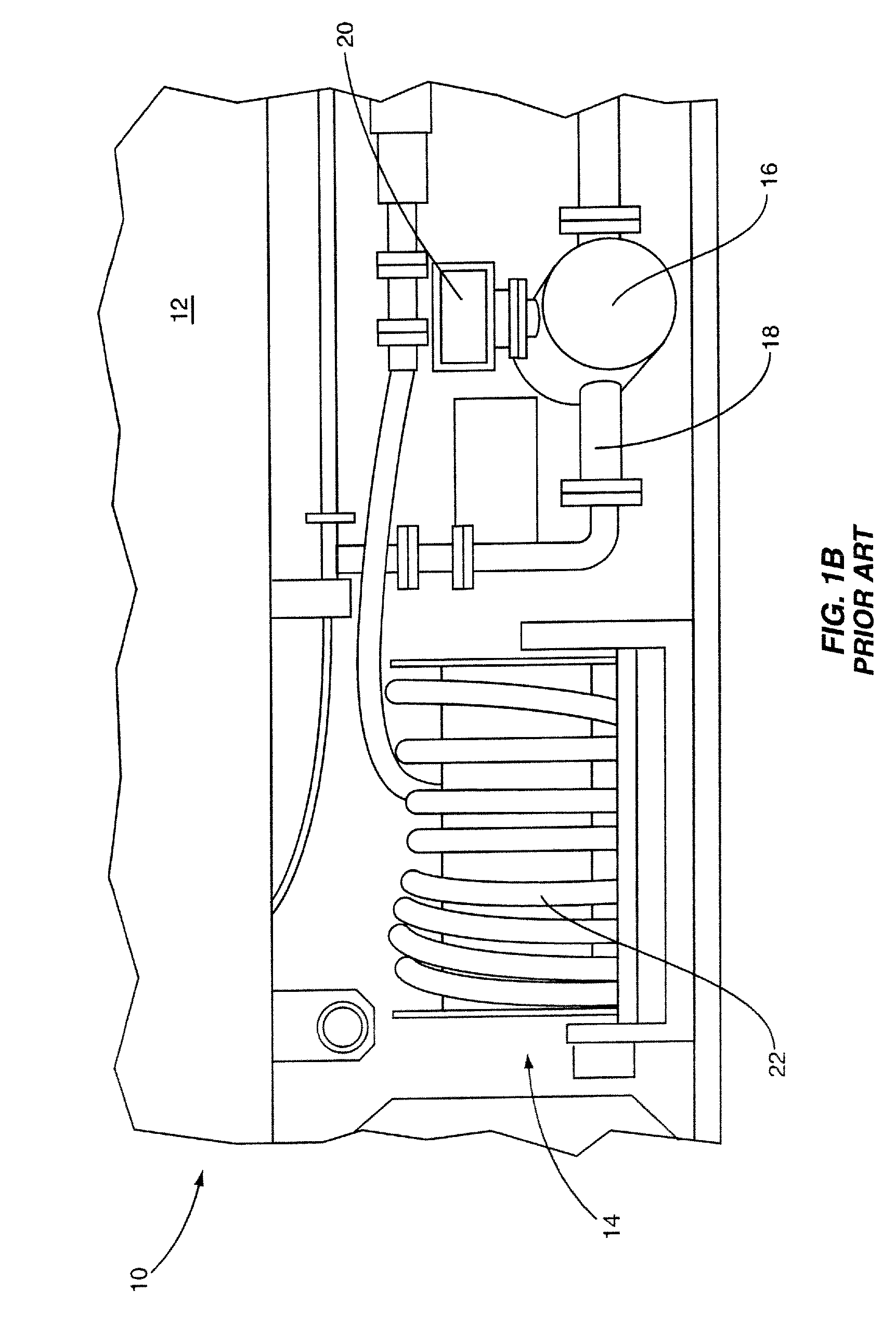

Automated Fuel Quality Detection and Dispenser Control System and Method, Particularly for Aviation Fueling Applications

ActiveUS20080230146A1Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

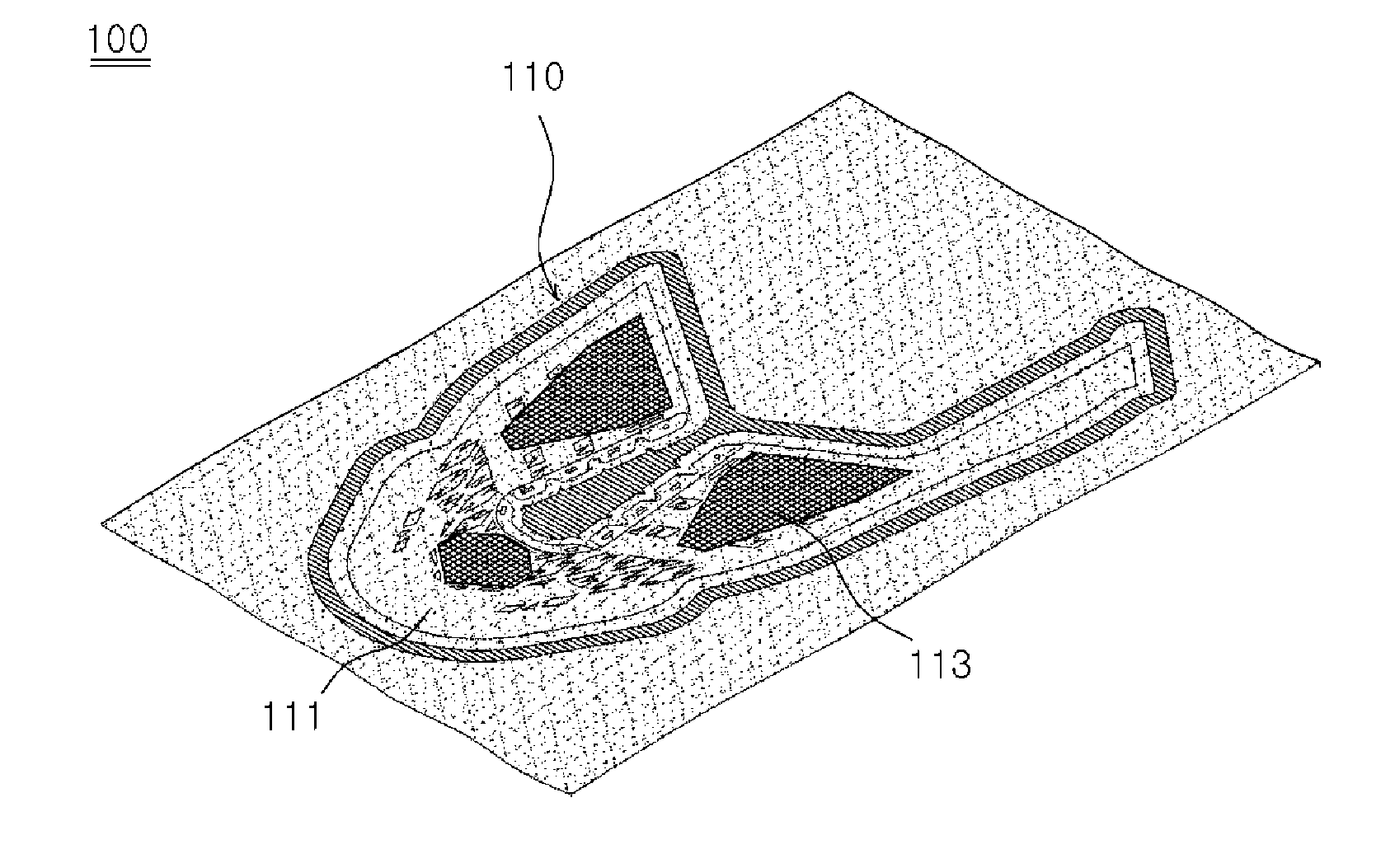

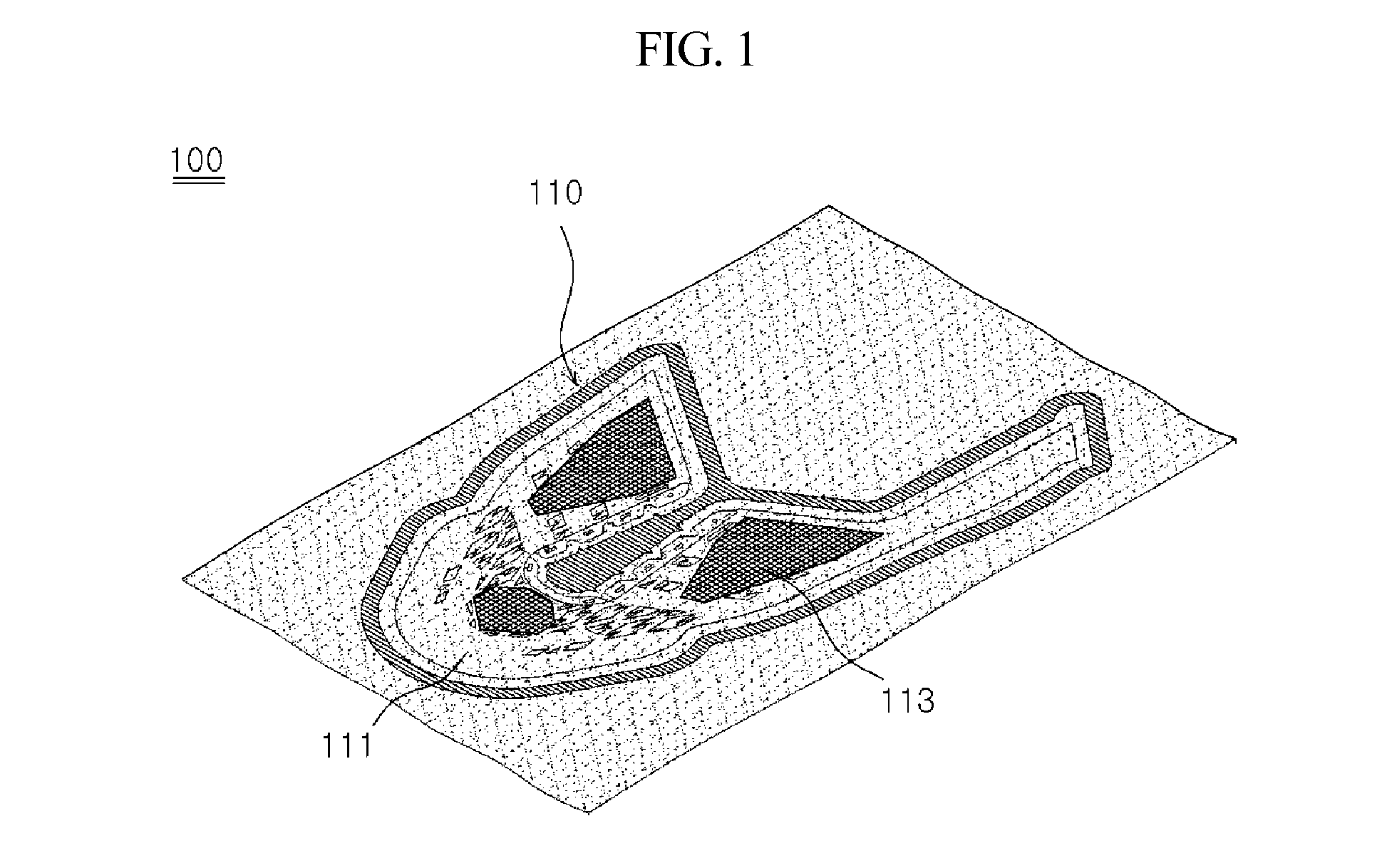

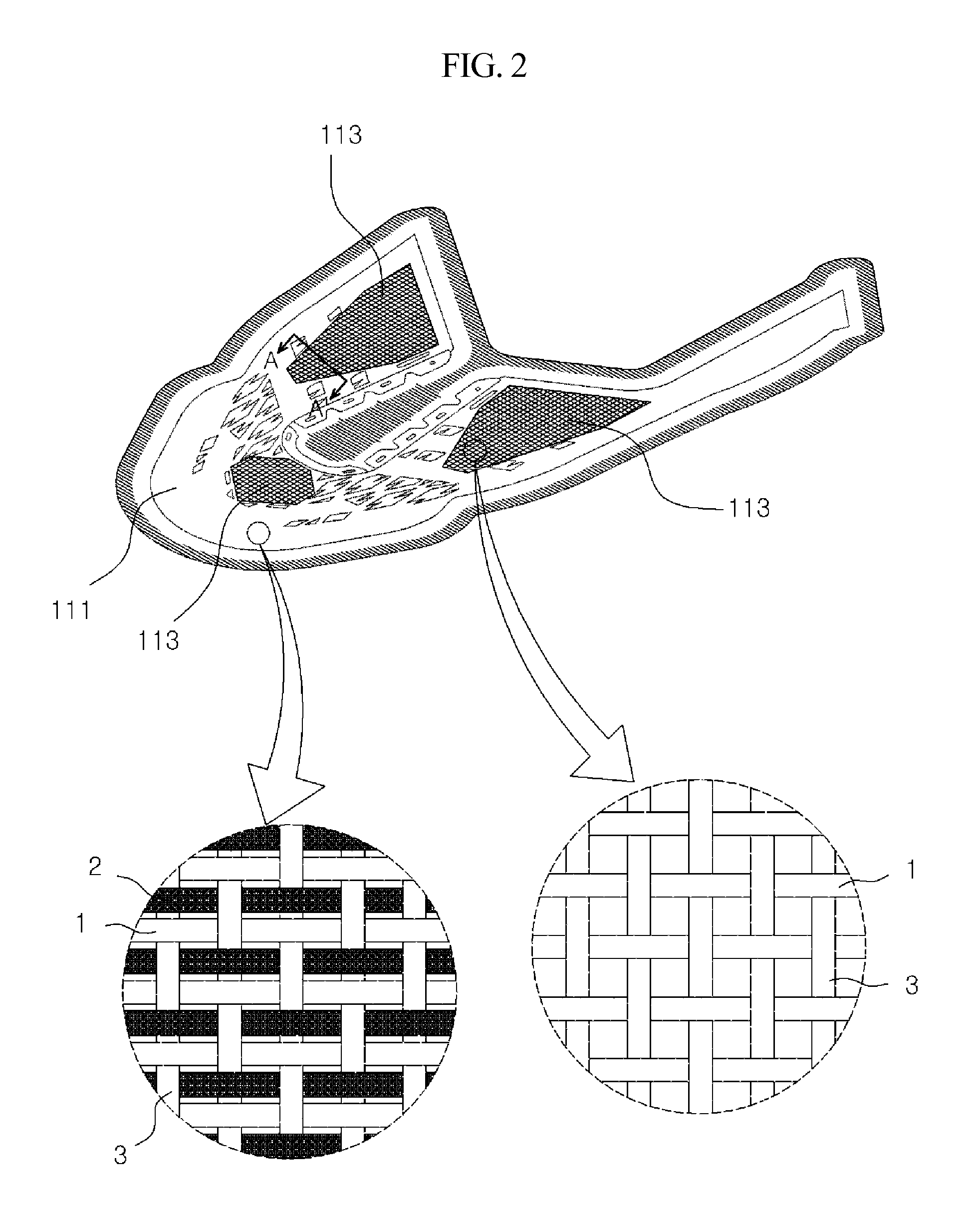

Upper of footwear and manufacturing method thereof

InactiveUS20140338222A1Improve productivityKeeping quality consistentInsolesUpperProduction rateEngineering

Owner:SONG SOO BOK

Fermented grains-fruit juice wine and its brewing process

InactiveCN1363652AConsistent qualityConsistent tasteAlcoholic beverage preparationFruit wineFruit juice

A fermented wine is prepared from grains and fruit juice (grape juice) through proportioning, mixing, fermenting and distillation. Its advantages include both grain wine smell and fruit wine smell ,unique taste and rich nutrients.

Owner:马兴宝

Polyamide powder with long-lasting, consistently good flowability

A composition containing from 88 to 99.99% by weight of a polyamide, a compound of a polyamide and mixtures of these, and from 0.01 to 0.25% by weight of a flow aid where the drying loss from the flow aid after 5 days of conditioning at a relative humidity of 95% is less than or equal to 1%, determined by ISO 787 / 2.

Owner:EVONIK OPERATIONS GMBH

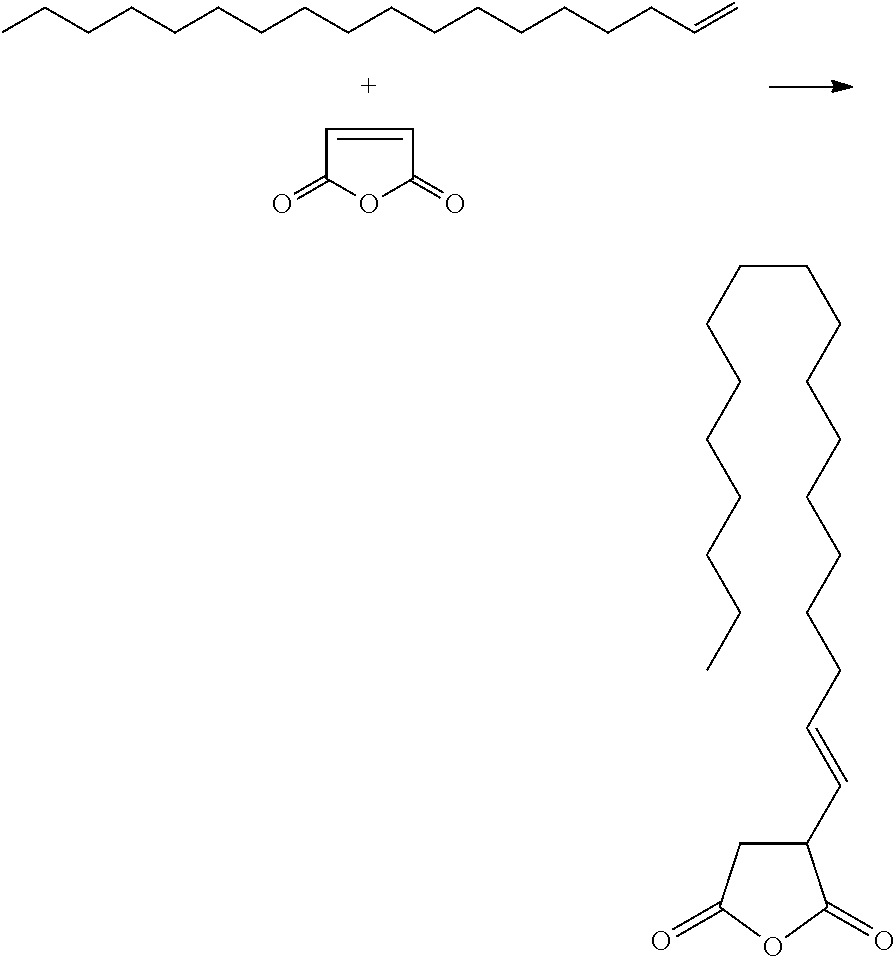

Maturation or ripening inhibitor release from polymer, fiber, film, sheet or packaging

ActiveUS20110143004A1Extend useful lifetime of dressingConsistent qualityBiocideLiving organism packagingMaturation inhibitorThermoplastic

Thermoplastic polyolefin polymer compositions, polymer chips, fibers, woven or nonwoven fabrics, films, closures, and laminates include a polymer and cyclodextrin compound with a volatile maturation inhibitor or an olefinic ethylene receptor antagonist in respiring produce materials. The polymer composition can also include a cyclodextrin-modified polymer or a substituted cyclodextrin. Olefinic ethylene inhibitors can be formed in the cyclodextrin composition, wherein the cyclodextrin releases the olefinic inhibitor composition when used in produce packaging materials. Coating compositions can also be made. The inhibitor is introduced into the materials and is released under controlled conditions of humidity. Upon release, the olefinic inhibitor blocks ethylene receptor sites on proteins that control maturation and can produce an extended period during which the produce does not substantially complete maturation or ripening to a degree leading to spoilage.

Owner:VERDANT TECH LLC

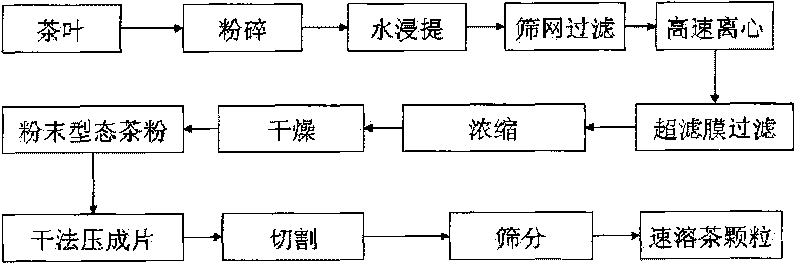

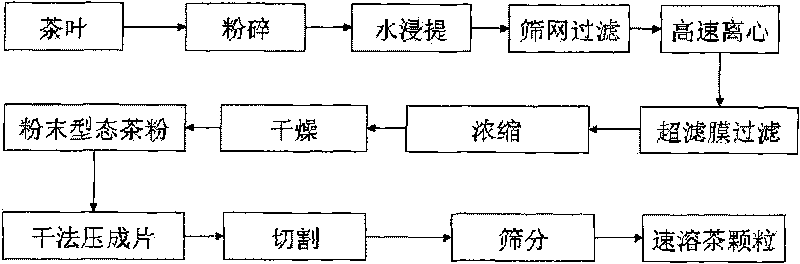

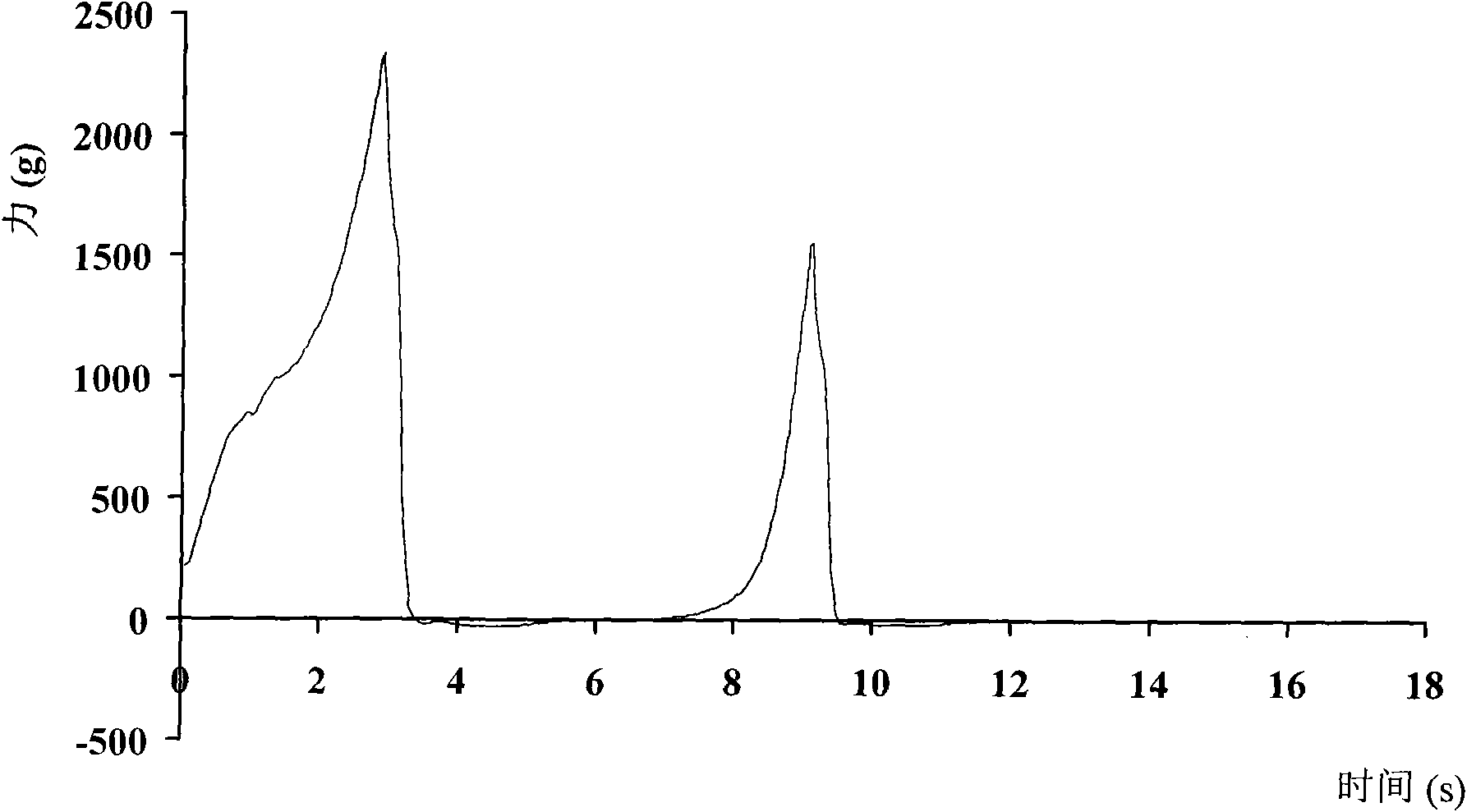

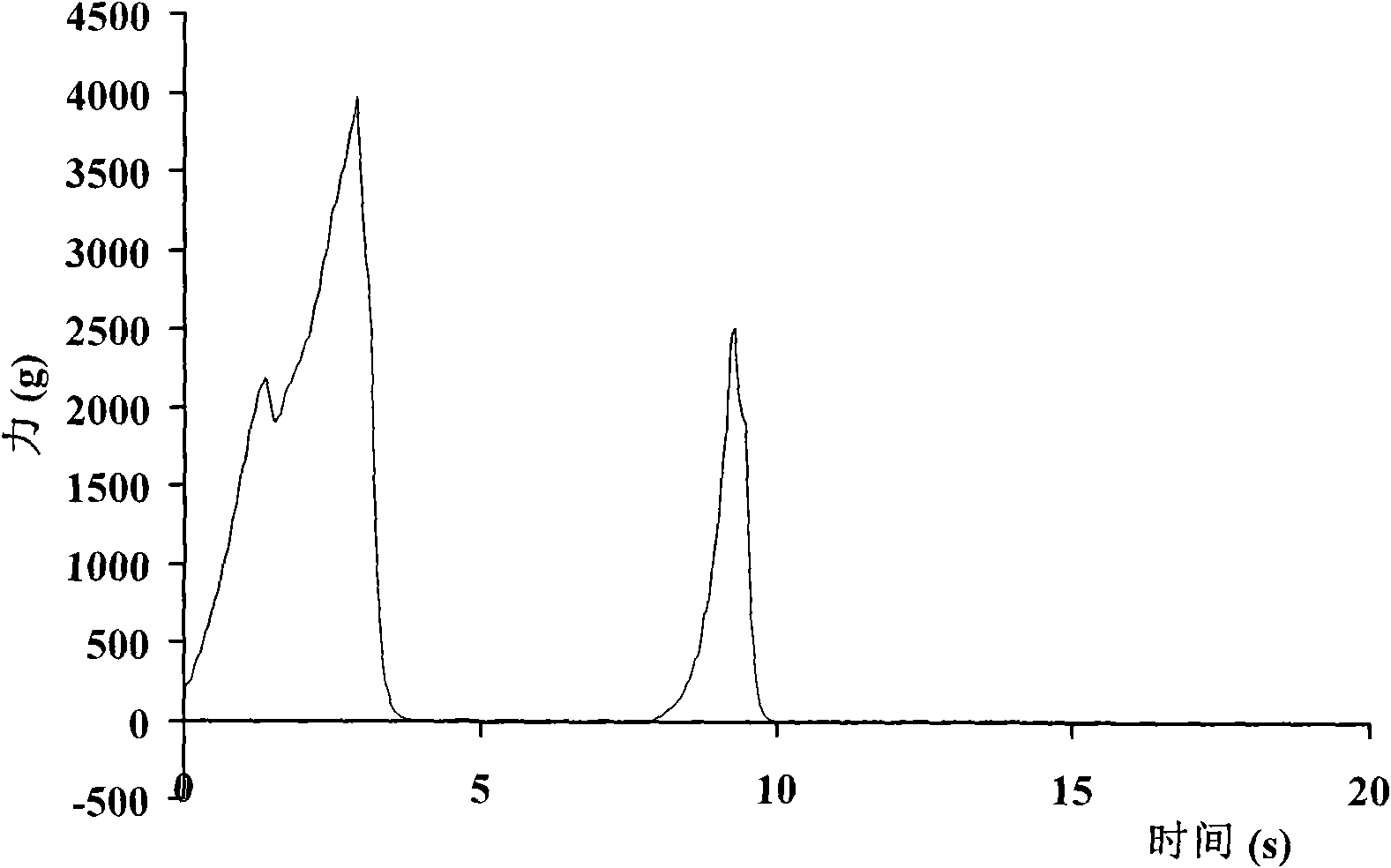

Preparation method for instant tea solid particle beverage

The invention discloses a preparation method for an instant tea solid particle beverage. The preparation method comprises the following steps of: carrying out water extraction, filtration, centrifugation, ultrafiltration membrane filtration, concentration and drying on a tea to obtain a powdered tea extract; and carrying out compressing dry granulation, cutting and sieving to obtain instant tea particles. The instant tea solid particle beverage prepared by the preparation method can be directly dissolved and brewed by cold water and hot water, has no residues and precipitates, has clear and lucent tea water, and keeps the original flavor, mouthfeel, taste and functional components of the conventional tea. The beverage is trendy, fashionable, convenient and instant and is suitable for drinking in places such as homes, offices, coffee houses, tours, hotels and the like.

Owner:黄山天健农业科技有限公司

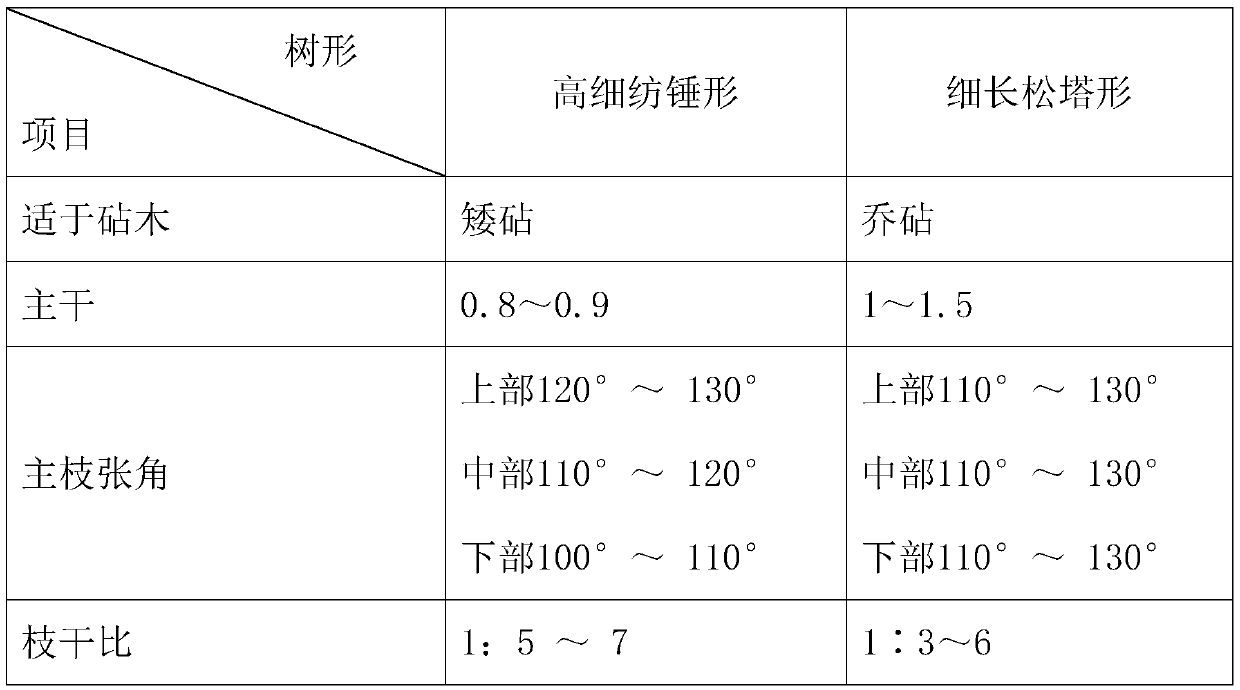

High slender spindle-shaped apple tree form and trimming method thereof

InactiveCN101755655ACrown small and tallStrong result abilityCultivating equipmentsDecapitationUltimate tensile strength

The invention discloses a high slender spindle-shaped apple tree form and a trimming method thereof. As a whole, the tree form is of high slender spindle shape. After an apple tree is formed, the crown diameter of the apple tree is small, slender and high. The apple tree is 3.5-4.0m high and the trunk of the apple tree is 0.8-0.9m high. Thirty to fifty spirally arranged small boughs are grown on the central leading trunk of the apple tree. The average length of the small boughs is 1m. The average angle between the central trunk and the small bough is 115 degrees. The top-to-bottom spacing among the small boughs on the same side is 0.25m. The trimming method of the high slender spindle-shaped tree form is simple. Other boughs require no decapitation but branch drawing except that the central trunk requires short-cutting in winters in 1-2 years. Thereby, the trimming method can be popularized in tree forms of simplified trimming and low labor strength.

Owner:NORTHWEST A & F UNIV

Integrally formed 3D flyknitted vamp and making method thereof

The invention discloses an integrally formed 3D flyknitted vamp and a making method thereof.Low-melting yarn and dyed yarn are adopted as raw materials, an upper layer of double-faced jacquard vamp body and a lower layer of double-faced jacquard vamp body with the edges interwoven together are woven on a bidirectional jacquard double-faced loop transfer computer flat knitting machine, openwork figured texture weave is primary weave, different weave structures are adopted in functional zones of the vamp, and then the integrally formed 3D flyknitted vamp is made through hot pressing shaping.The temperature of hot pressing shaping ranges from 170 DEG C to 200 DEG C, and the time of hot pressing shaping ranges from 20 s to 80 s.Each double-faced jacquard vamp body comprises a dyed yarn layer and a low-smelting yarn layer which are interwoven together through yarn coils, and the integrally formed 3D flyknitted vamp is formed by bonding and combining the two layers of double-faced jacquard vamp bodies according to the wave structure of one dyed yarn layer, one low-melting yarn layer, the other low-melting yarn and the other dyed yarn layer through the upper low-melting yarn layer and the lower low-melting yarn layer in a hot pressing and melting mode.The integrally formed 3D flyknitted vamp has the advantages of being soft, comfortable, durable, colorful, attractive, low in cost and the like.

Owner:厦门翔鹭化纤股份有限公司

Production process of instant Chinese chestnut kernels and product

The invention relates to a production process of instant Chinese chestnut kernels and a product, which belong to the field of the deep processing of agricultural products. The production process comprises the following main technological processes: taking Chinese chestnuts with high water content, low reducing sugar, low starch and low fruit breaking rate as a raw material, processing instant Chinese chestnut kernels, sieving the raw material, classifying, removing outer peels, blanching, removing inner peels, quick-freezing, unfreezing, saccharifying, steaming, pasting, packaging and sterilizing. The instant Chinese chestnut kernels produced by the method have golden color, low fruit breaking rate and proper sweetness, are fragrant, glutinous and delicious and can be used as leisure foods for eating.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

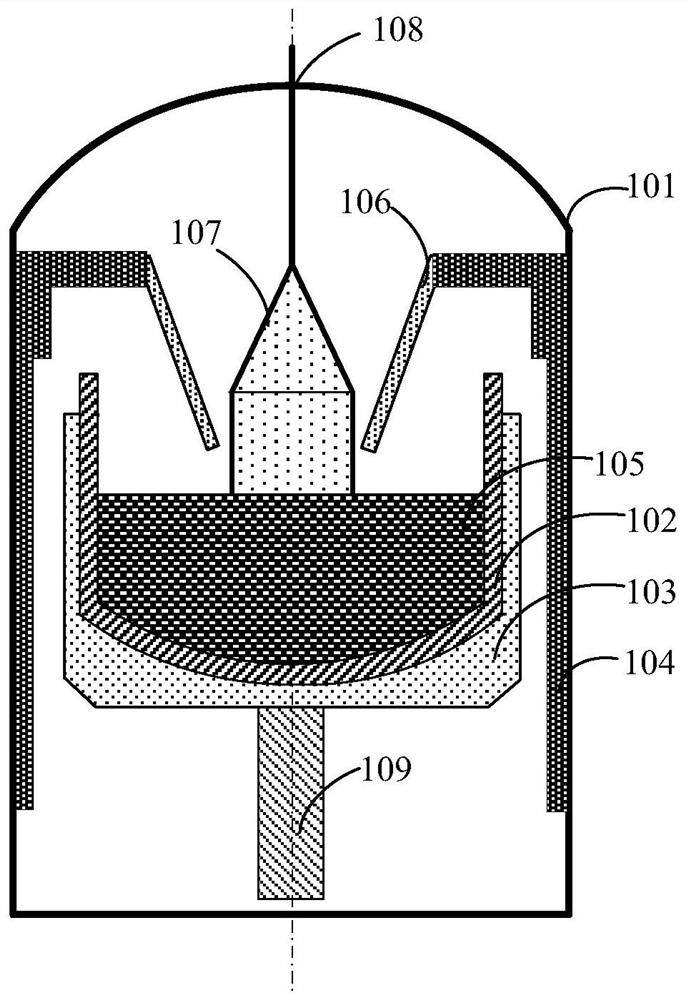

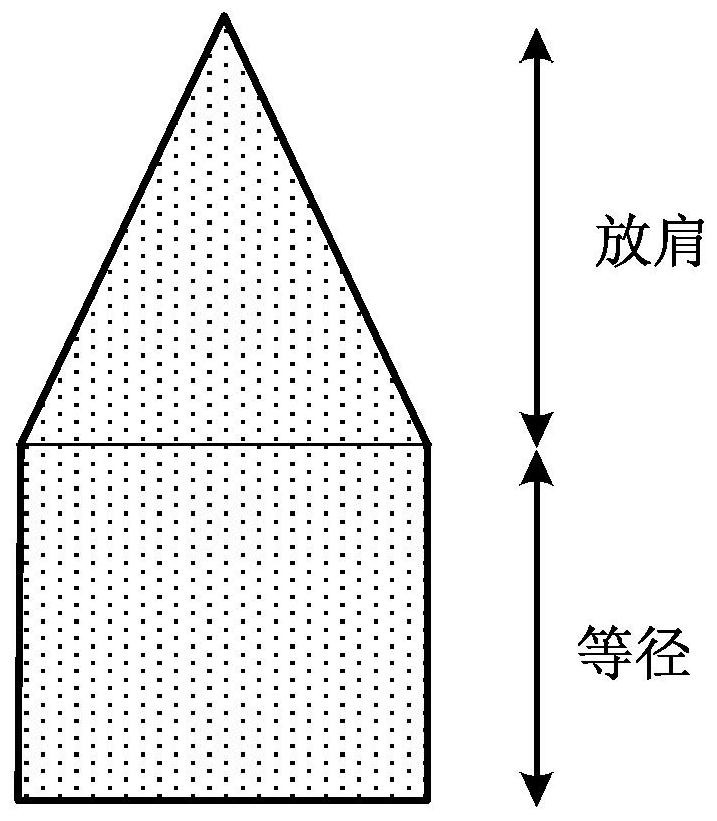

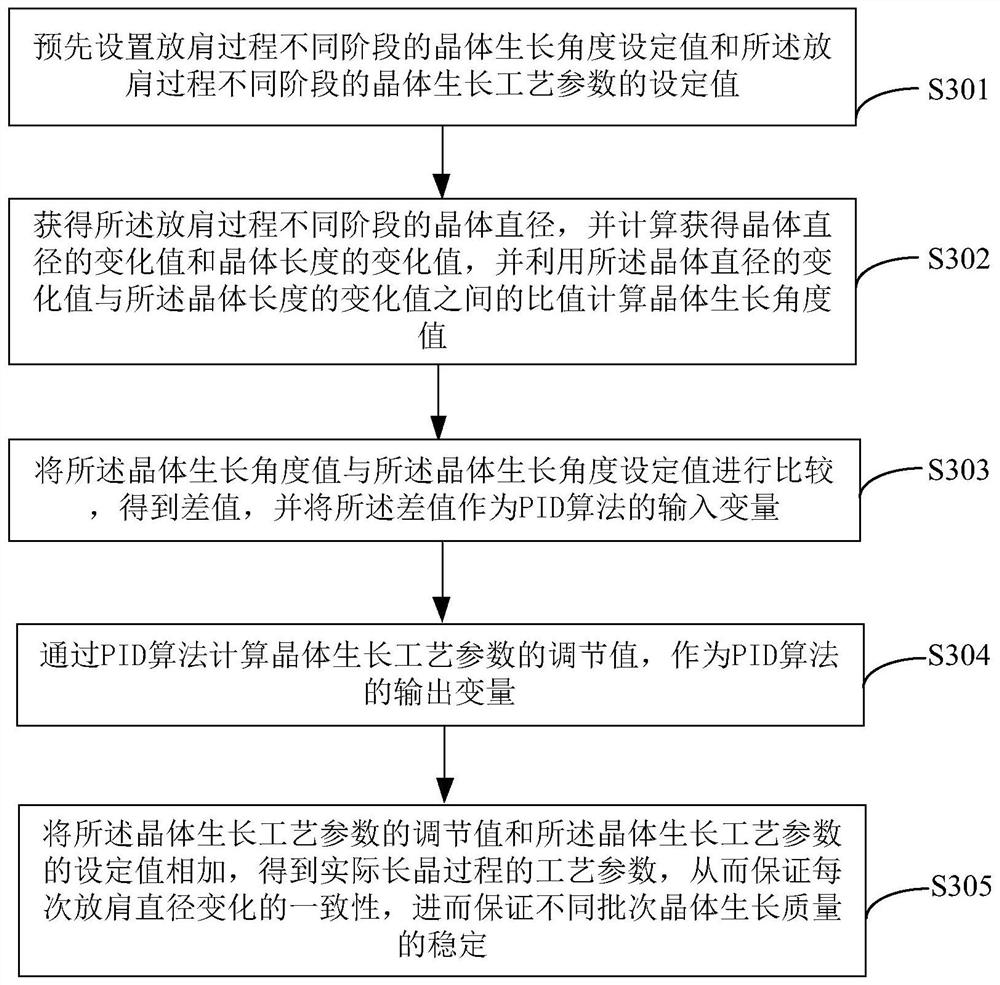

Crystal growth control method, device and system and computer storage medium

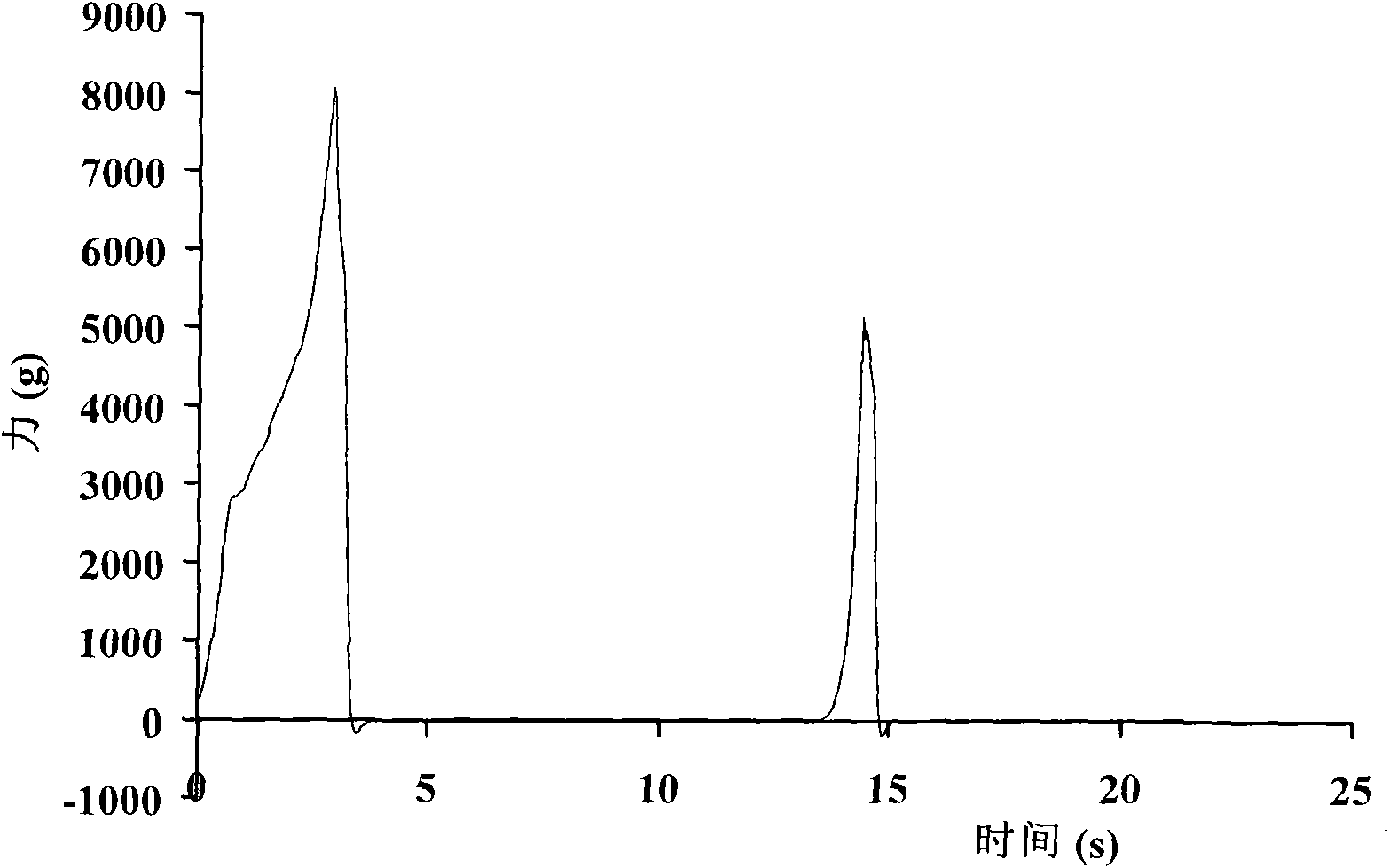

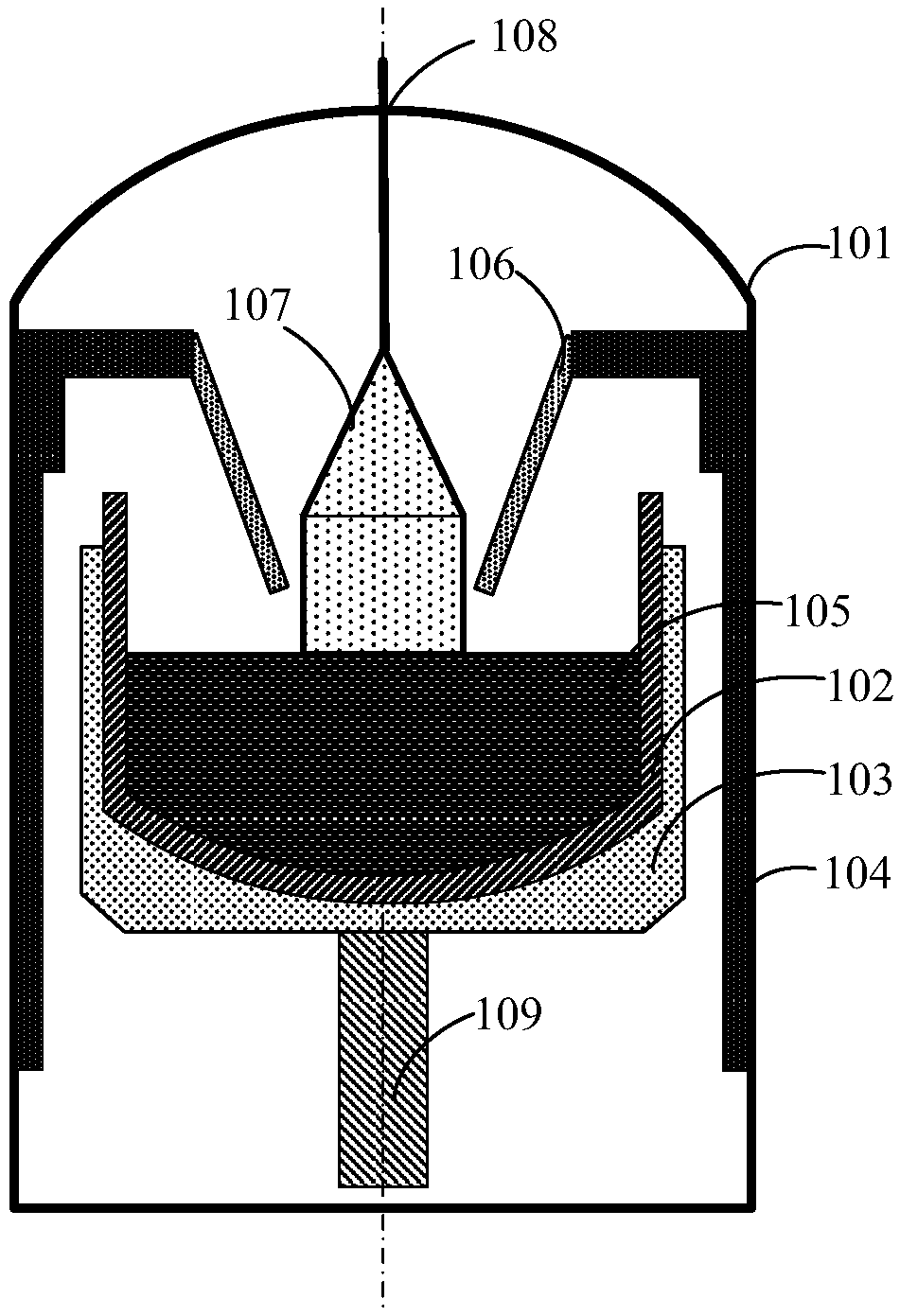

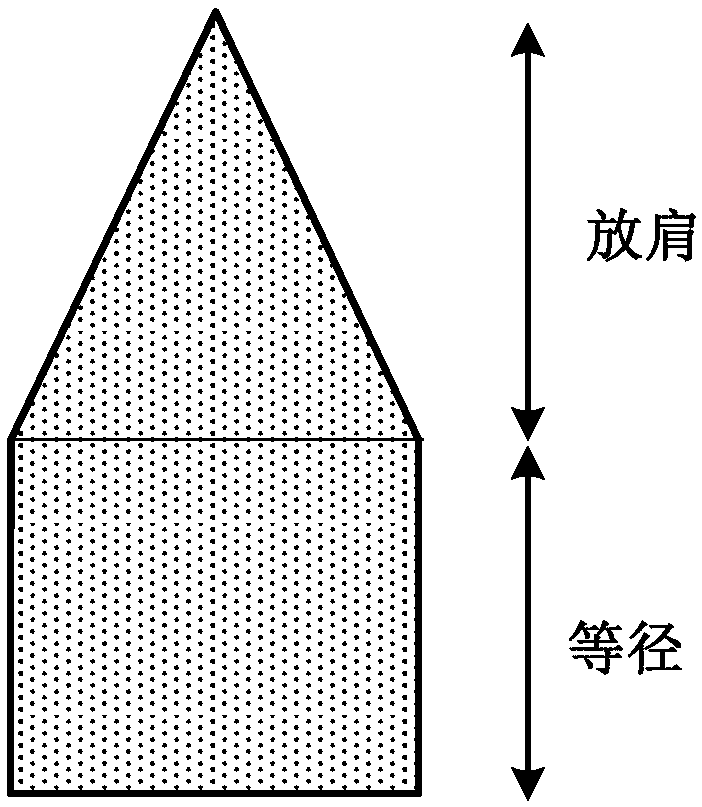

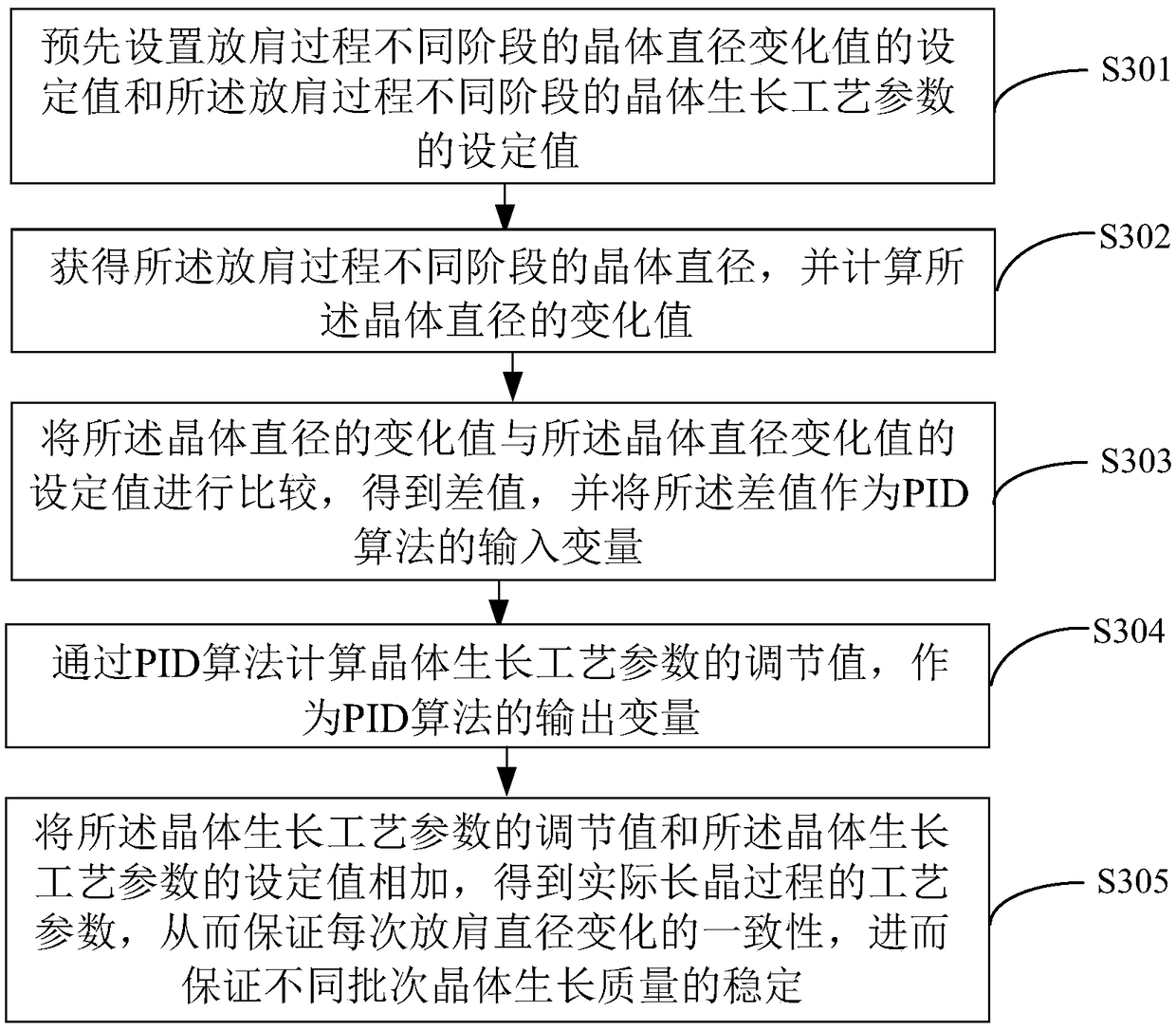

InactiveCN109183141AConsistent qualityGood repeatabilityPolycrystalline material growthBy pulling from meltEngineeringPhases of clinical research

The invention provides a crystal growth control method, device and system for a shouldering process and a computer storage medium. The method comprises: presetting crystal diameter change values and crystal growth process parameters at different stages of the shouldering process, acquiring crystal diameters at different stages of the shouldering process, calculating a change value, comparing the change value of the crystal diameters and the set values to obtain a difference value as an input variable of a PID algorithm, calculating an adjustment value of the crystal growth process parameter through the PID algorithm, wherein the adjustment value is used as an output variable of the PID algorithm, and adding the adjustment value of the crystal growth process parameter to the set value to obtain a process parameter in the actual crystal growth process. The PID algorithm is used for controlling and adjusting the diameter change of the shouldering process, prevents the influence of the thermal field slight change on the shouldering process, guarantees the consistent change of the crystal diameters and improves the repeatability and process stability of the shouldering process.

Owner:ZING SEMICON CORP

Planting method of selenium-rich mangoes

InactiveCN105613172AEarly emergence timeGood seedling qualityAnimal corpse fertilisersExcrement fertilisersFungicideEconomic benefits

The invention discloses a planting method of selenium-rich mangoes. The planting method is characterized by comprising steps as follows: land selection, seedling culture, field planting, pruning and trimming, nutrient and water management, orchard management and pest control. The planting method adopts a fertilizer technology such as selenium-rich bio-organic fertilizer, selenium-rich organic-liquid active fertilizer, organic fertilizer and the like, so that soil environment is effectively improved, the content of organic matters and selenium in soil is greatly increased, the selenium content of the planted mangoes is high, the mango yield is high, the detection indicates that the selenium content of the mango is 0.40-0.45 mg / kg, furthermore, according to the insecticide technology adopting botanical insecticides and botanical fungicides, the better insecticidal efficacy is realized while nutrition is guaranteed, and the economic benefit is very obvious.

Owner:广西绿希望农业发展有限公司

Elongated pinecone apple tree form and trimming method thereof

ActiveCN105493915AImprove lighting conditionsSame sizeCultivating equipmentsHorticulture methodsMain branchEngineering

The invention discloses an elongated pinecone apple tree form and a trimming method thereof; the integral tree form is in an elongated pinecone shape; the tree is 3.5-4.5m in height when approaching a full bearing period, and has 25-30 main branches; the tree is 2.8-3m after lowering the cap, the main trunk is 1.0-1.5 m in height, the tree has 18-22 main branches, a main branch opening angle is 110-130 degrees, the main branch is 50-70cm in length on the upper portion of the crown, and 110-130cm on the lower portion of the crown; the spacing between the main branches is 10-20cm; the main branches are arranged in a spiral manner around the main trunk; the branch-trunk ratio is 1:3-6; the branch group-main branch ratio is 1:5-7. The tree form is small on top and big in bottom, tidy and standard, strong in main trunk, strong in wind-resistance, ventilating and light transmission, suitable for close planting, and is a high yield, stable yield, high-quality and high efficiency tree form; the trimming method complies with the trend that tree body frame decreases and trimming is simplified; the method is easy to handle, and good for promotion in wind-line close planting apple gardens.

Owner:赤峰市林业科学研究院

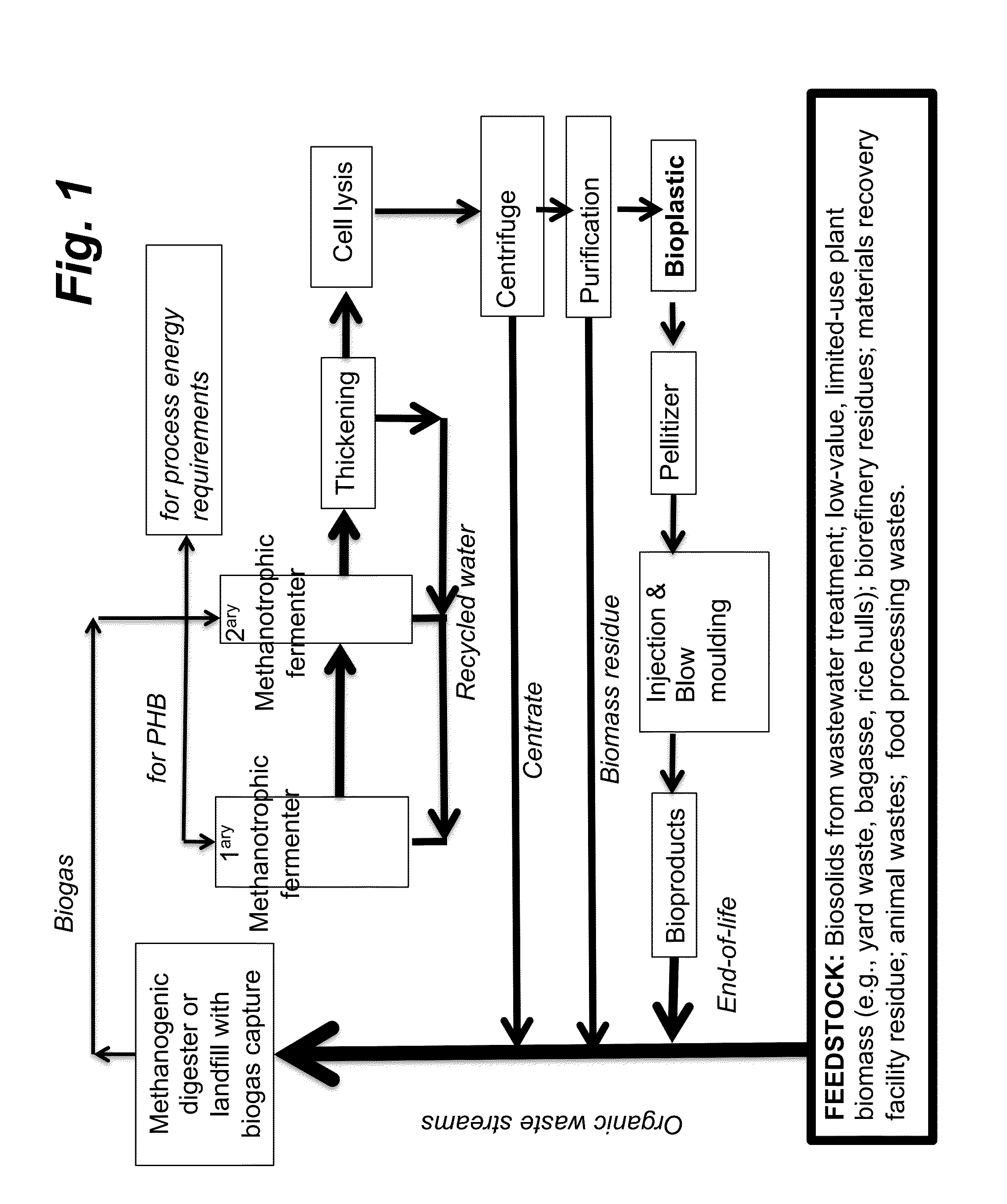

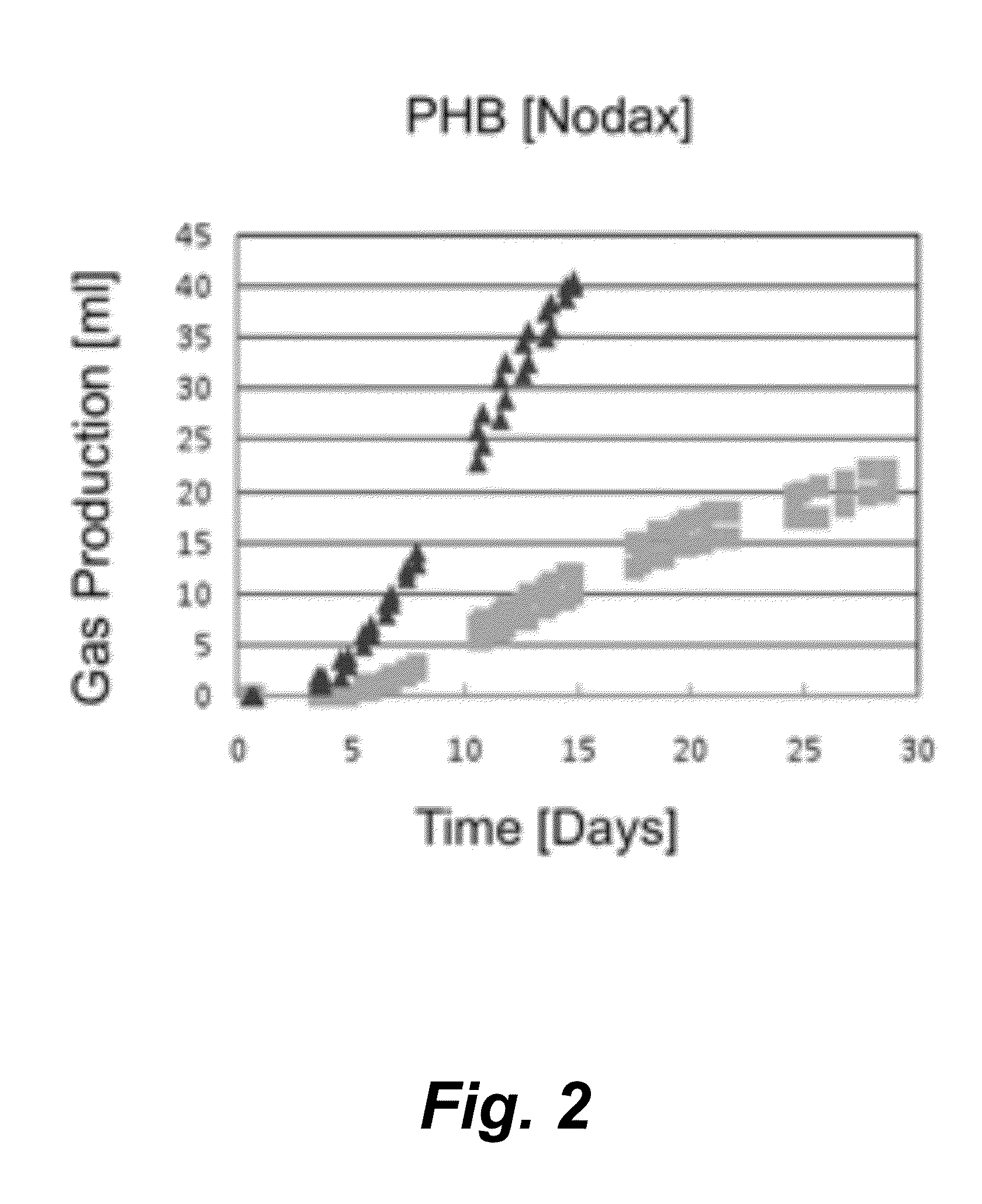

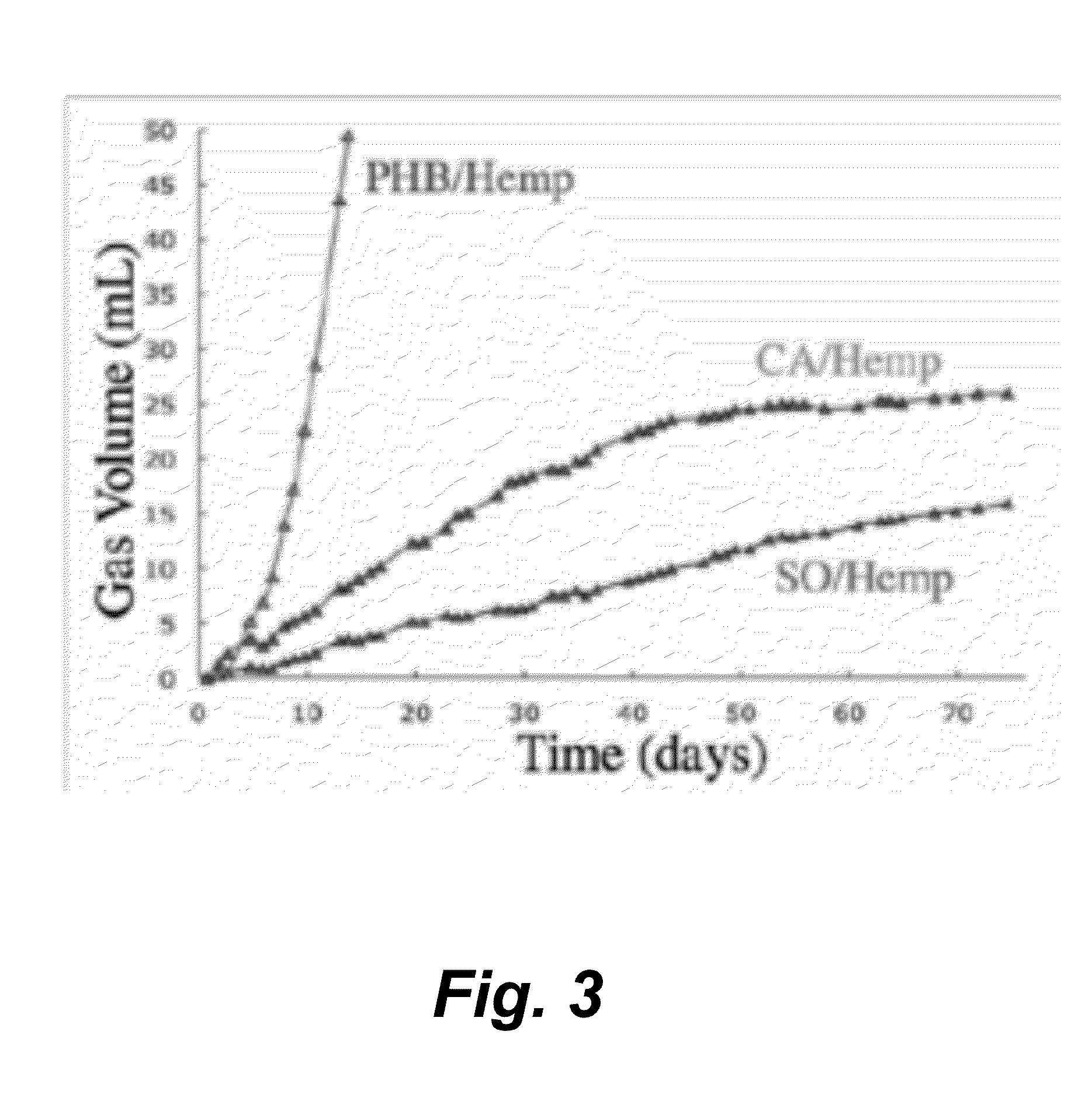

Production of PHA using Biogas as Feedstock and Power Source

InactiveUS20130071890A1Stable supplyQuality improvementOrganic chemistryPlastic recyclingPower gridProcess engineering

Methods for producing bioplastics from biogas include techniques for the production of PHB using a dirty biogas (e.g., methane from landfill, digester) as both a power source for the process and as feedstock. Biogas is split into two streams, one for energy to drive the process, another as feedstock. Advantageously, the techniques may be implemented off the power grid with no dependence upon agricultural products for feedstock.

Owner:CRIDDLE CRAIG S +7

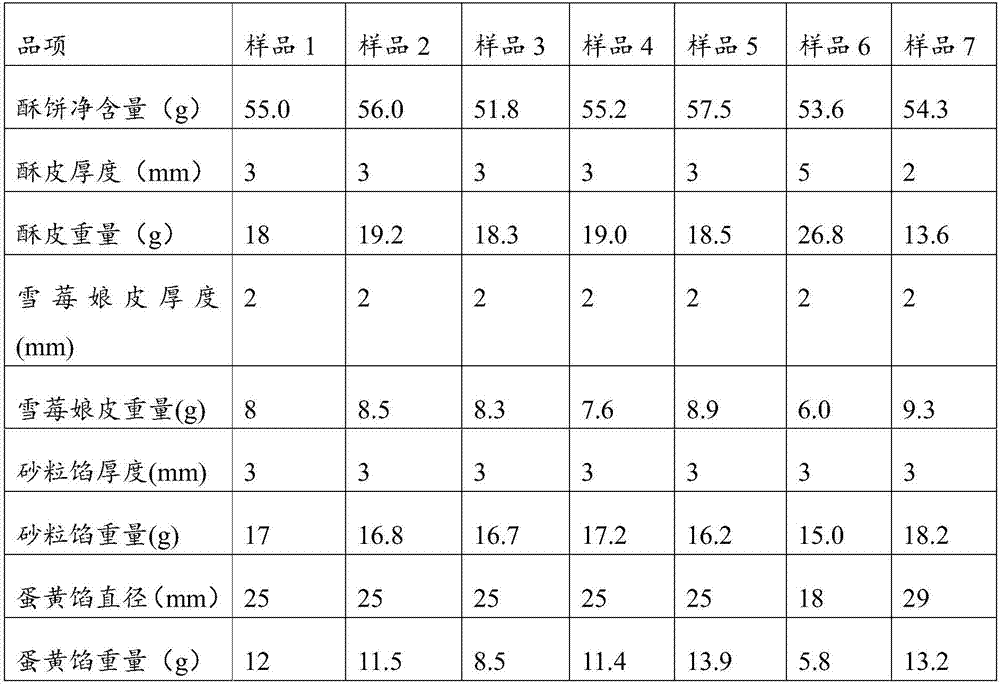

Egg-yolk puff and preparation method for same

The egg-yolk puff is made of the following raw material according to weight by parts: 10 to 40 parts of bread flour, 5 to 25 parts of cake flour, 8 to20 parts of butter, 2 to 10 parts of white sugar; 20 to 50 parts of ghee, 45 to 150 parts of stuffing, 0.01 to 0.04 part of foodstuff additive and 1 to 10 parts of water. The invention further provides an eggy-yolk puff preparation method for the same. The technology process is formed by weighing raw material, preparing doughs, covering ghee, pressing the doughs, opening the ghee, injecting stuffing, forming, brushing egg liquid, baking, cooling and packaging. The raw material can be easily achieved; the egg-yolk puff prepared by the method contains well-bedded multi-layered stuffing; the external layer is compact and crispy; the stuffing is soft and tender but not sweet and greasy; the puff cake has pure taste and fragrance and is not greasy; the egg-yolk puff is produced via a semi-mechanical way, so labor intensity can be reduced and production efficiency can be reduced; and the egg-yolk puff quality can be easily remained the same.

Owner:广西朗盛食品科技有限公司

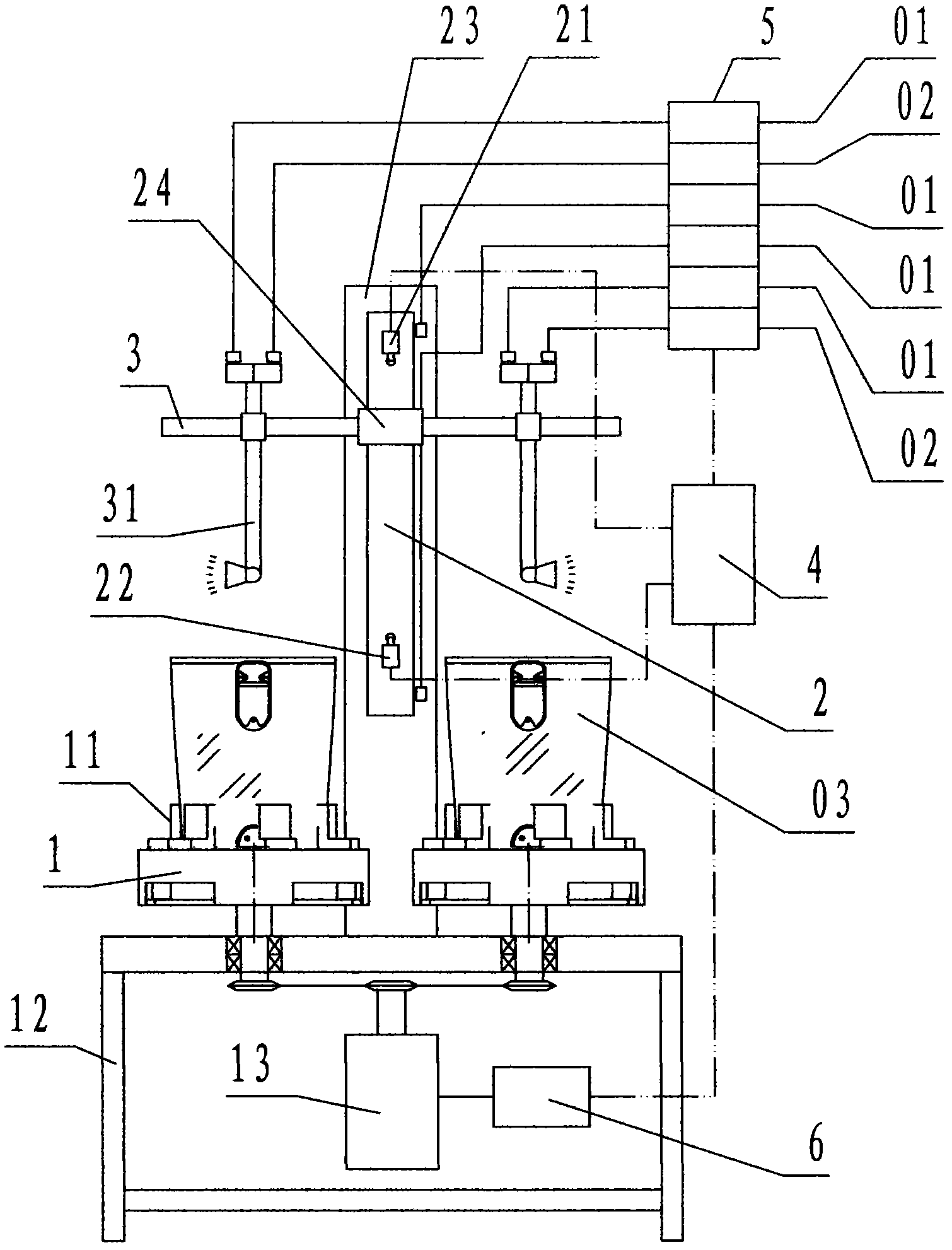

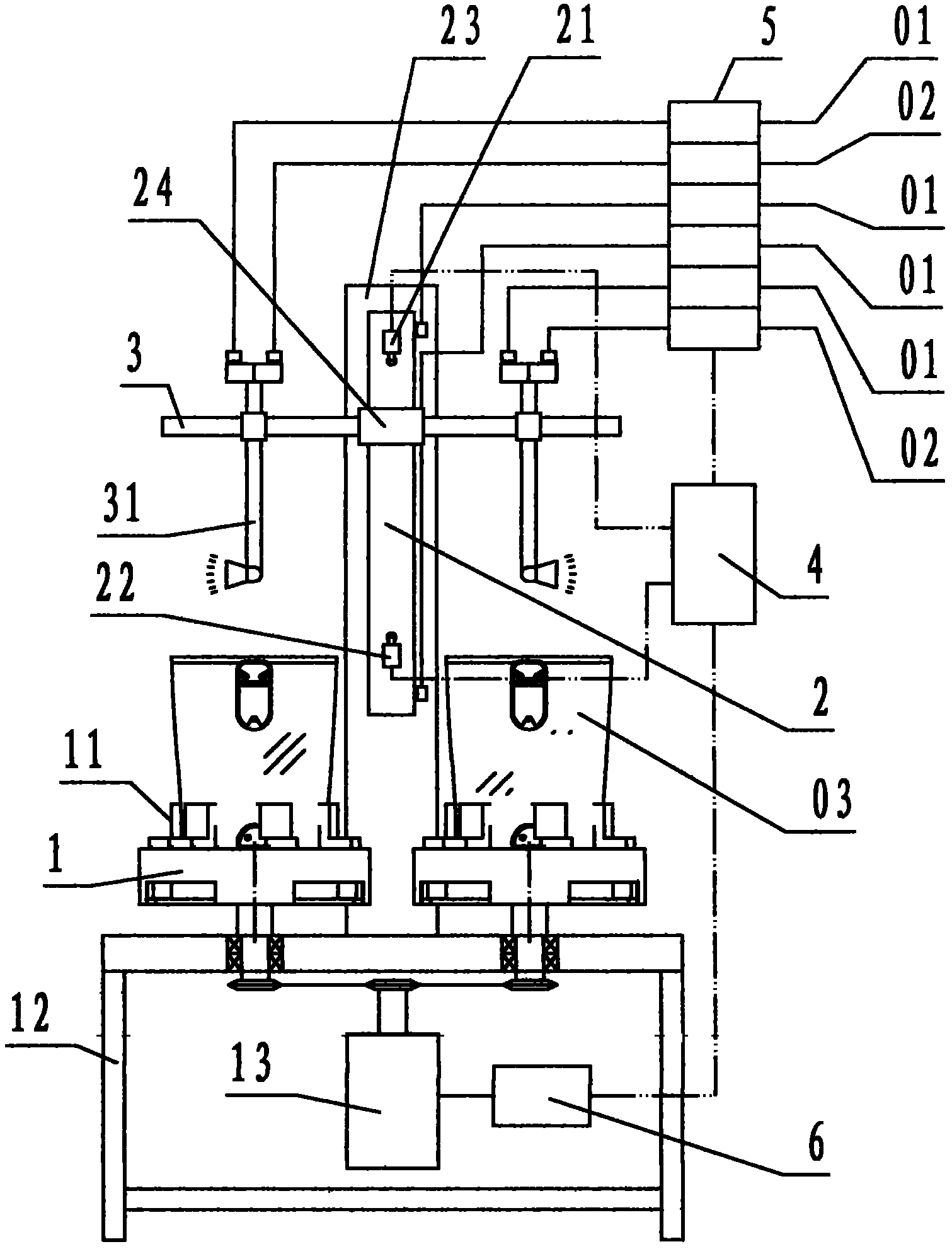

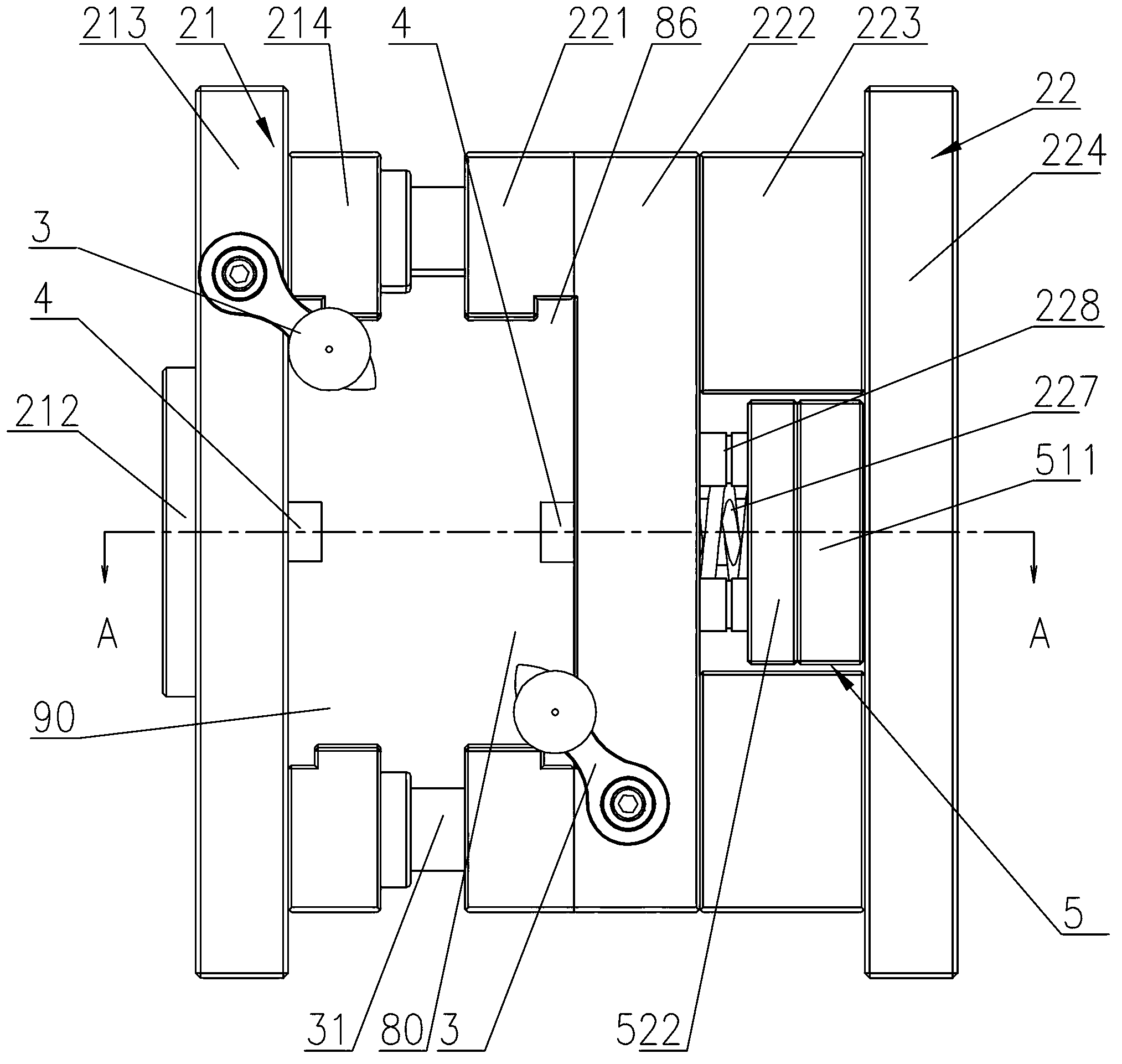

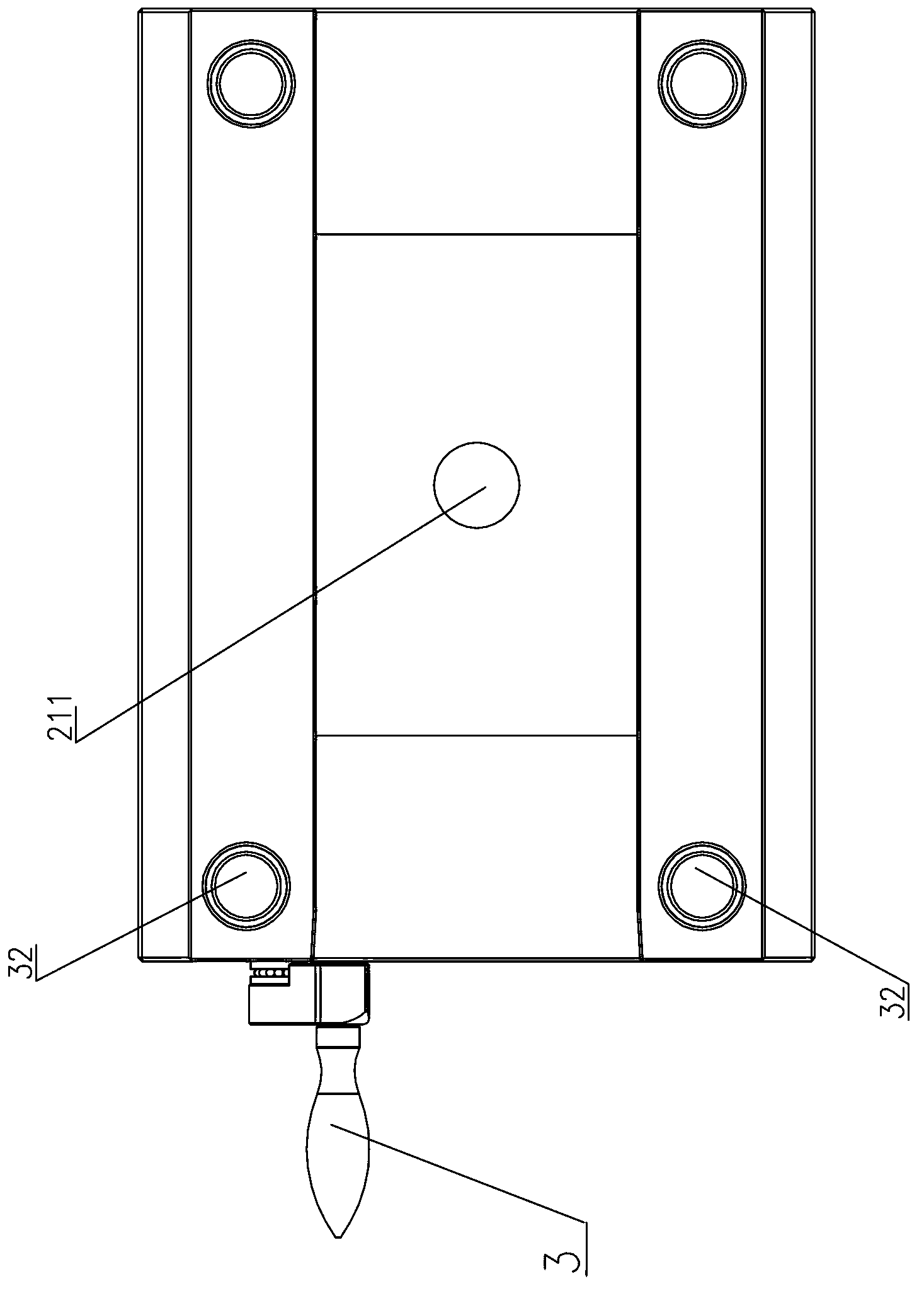

Automatic inner wall spraying device for round cup-shaped injection molding products

InactiveCN102626684AOvercome consistencyOvercome costsLiquid surface applicatorsSpraying apparatusFrequency conversionProgrammable logic controller

The invention discloses an automatic inner wall spraying device for round cup-shaped injection molding products. The automatic inner wall spraying device comprises a rotary workbench (1), a base (12), a motor (13), an air cylinder (2), a cantilever (3), a spray gun (31), a bracket (23), a PLC (Programmable Logic Controller) (4), an electromagnetic valve (5) and a frequency-conversion speed regulator (6). According to the invention, the device consisting of the rotary workbench, the motor, the air cylinder, the cantilever, the spray gun, the PLC, the electromagnetic valve and the frequency-conversion speed regulator is adopted; and when the automatic inner wall spraying device works, the round cup-shaped product is clamped on the rotary workbench and driven by the motor to rotate at a constant speed, the air cylinder drives the cantilever to carry the spray gun to be inserted into a cavity of the round cup-shaped product to spray up and down at a constant speed, and the PLC controls the spray gun to be started and stopped through the electromagnetic valve and controls the air cylinder to act up and down. Due to the technical scheme that the frequency-conversion speed regulator controls the rotating speed of the motor, the inner wall of the round cup-shaped injection molding product is sprayed to reach the purposes of keeping consistency of quality, reducing cost, improving efficiency and reducing waste.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

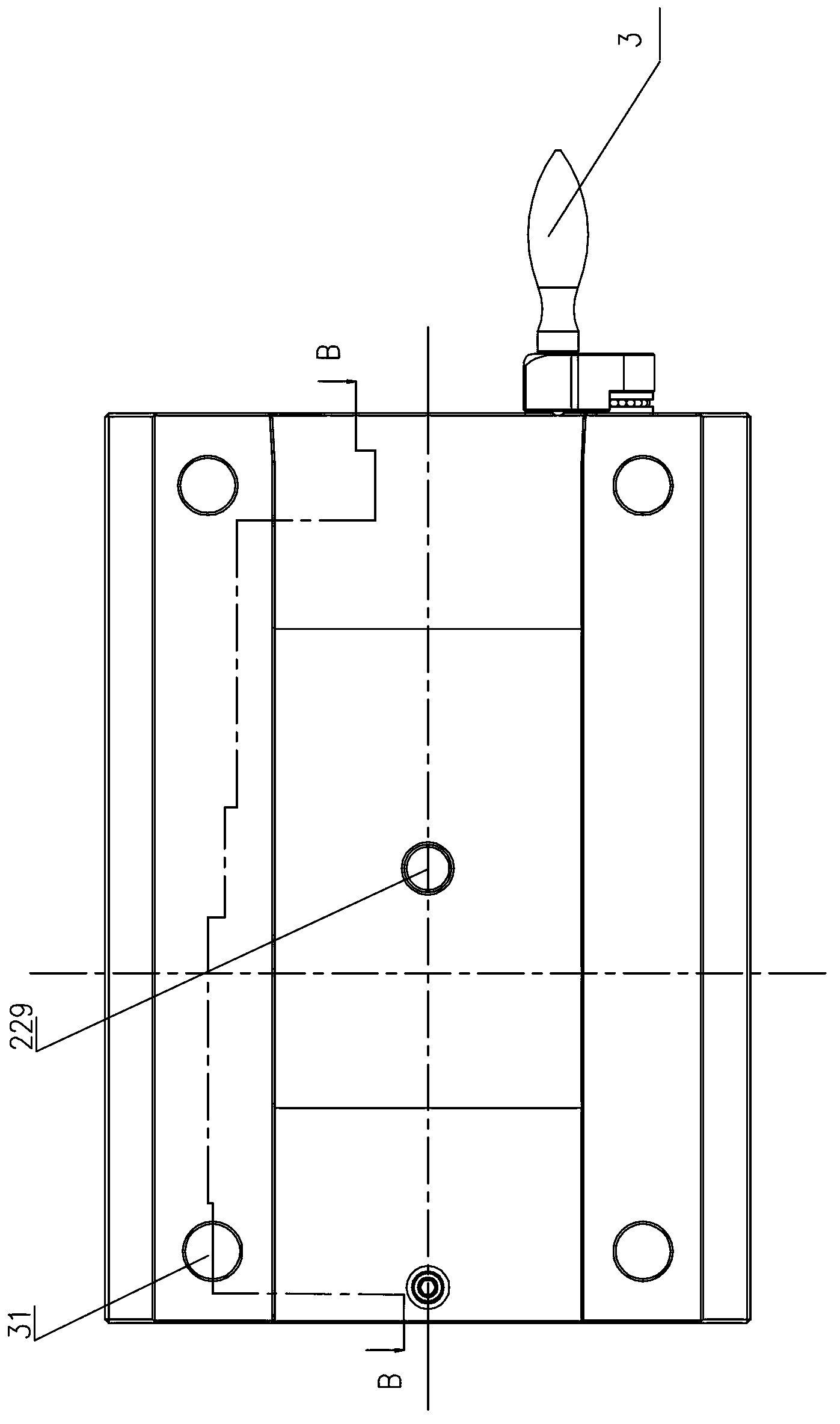

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

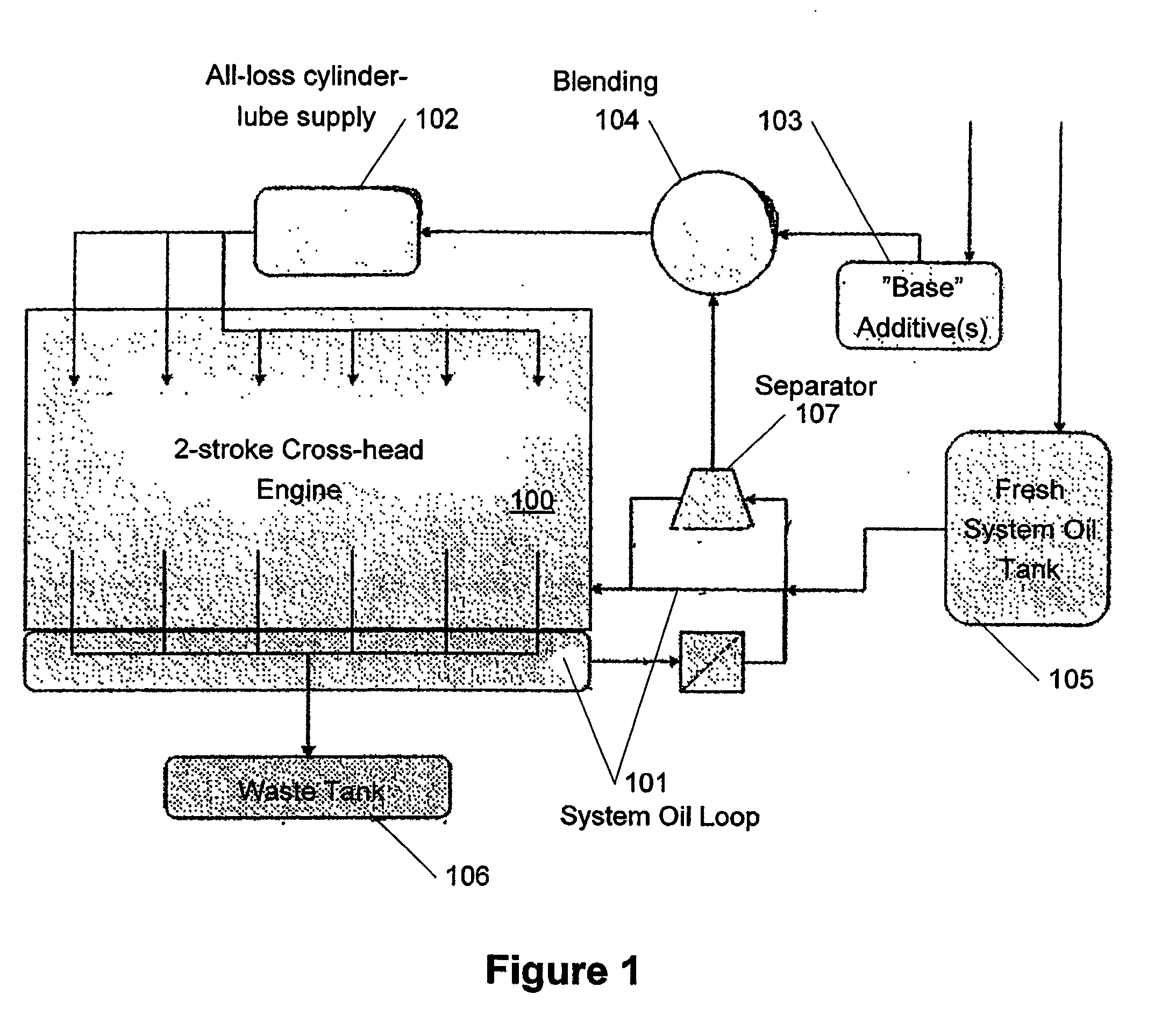

Method and system for modifying a used hydrocarbon fluid to create a cylinder oil

ActiveUS20060068995A1Simplified and cost-effectiveSignificant comprehensive benefitsOrganic chemistryOrganic compound preparationEngineeringLubricant

This invention relates to a method (and a corresponding system) of creating a cylinder oil, the method comprising modification of at least one initial fluid (101) by determining the TBN(s) of the at least one initial fluid, determining a desired TBN of a cylinder oil (102) and adjusting the TBN(s) of the at least one initial fluid (101) accordingly by blending the at least one initial fluid (101) with suited additive(s) (103). In this way, a method (and system) for modifying initial fluid(s) to create a cylinder oil by adjusting TBN is obtained. This provides significant economical benefits since lubricants that otherwise would have to be disposed of can be re-used as a total-loss cylinder lubricant. Further cylinder oil does not have to be purchased. The oil(s) used to blend the cylinder oil is / are of more consistent quality as it is replenished contrary to the traditional practice which reduces machinery wear, etc. Thus, the replenishment of the initial fluid(s) provides enhanced and consistent performance of the initial fluids resulting in greatly reduced component wear and equipment lifecycle cost. Even further, a more environmentally friendly method / system is provided since waste, in the form of spent oil(s) that is discarded after prolonged use, is reduced as it is converted into a cylinder oil.

Owner:A P MOLLER AS

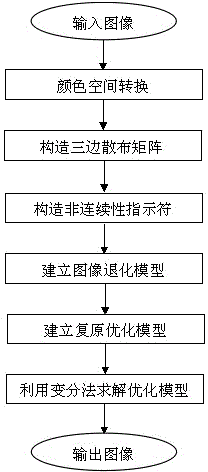

Image local structure self-adaption recovery method based on non-continuity indicator

The invention provides an image local structure self-adaption recovery method based on a non-continuity indicator. The image local structure self-adaption recovery method based on the non-continuity indicator comprises the first step that a read image is initialized and an input RGB image is converted to a YCbCr color space; the second step that a trilateral scatter matrix is built and robustness to noise is improved; the third step that the non-continuity indicator is built to represent image local structure characteristics dynamically; the fourth step that an image degradation model is built; the fifth step that an image recovery optimization model is built according to the built non-continuity indicator, and the built model depends on the image local structure characteristics continuously; the sixth step that the recovery optimization model is resolved through a variational method, a gradient descent flow corresponding to the optimization model is obtained and is discretized through the half-point format, and an optimal recovery image is obtained. According to the image local structure self-adaption recovery method based on the non-continuity indicator, the recovery process can be controlled in a self-adaption mode according to the image local structure characteristics, more detailed structures of the image can be recovered, and the quality of the image is improved remarkably.

Owner:SOUTHEAST UNIV

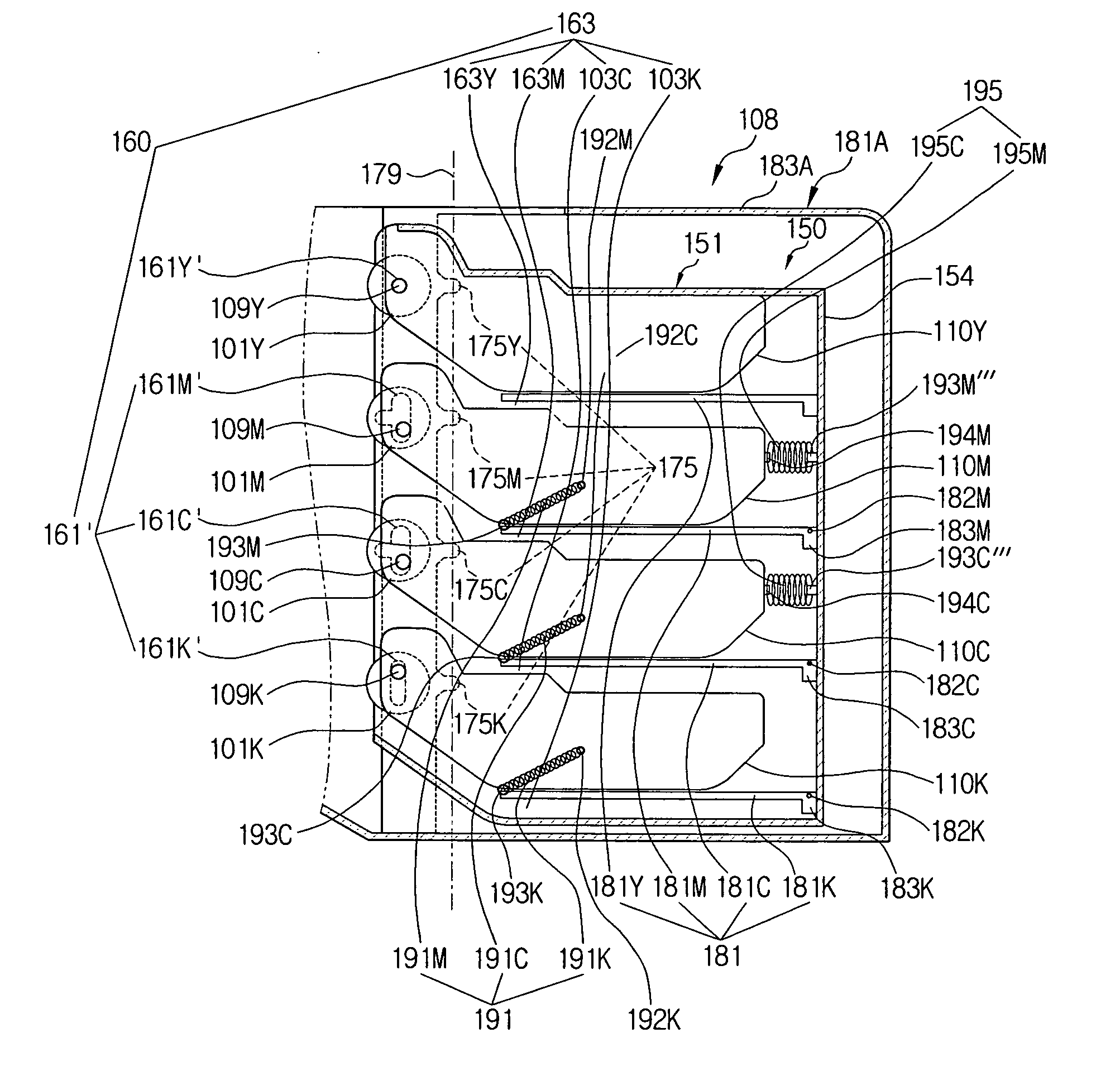

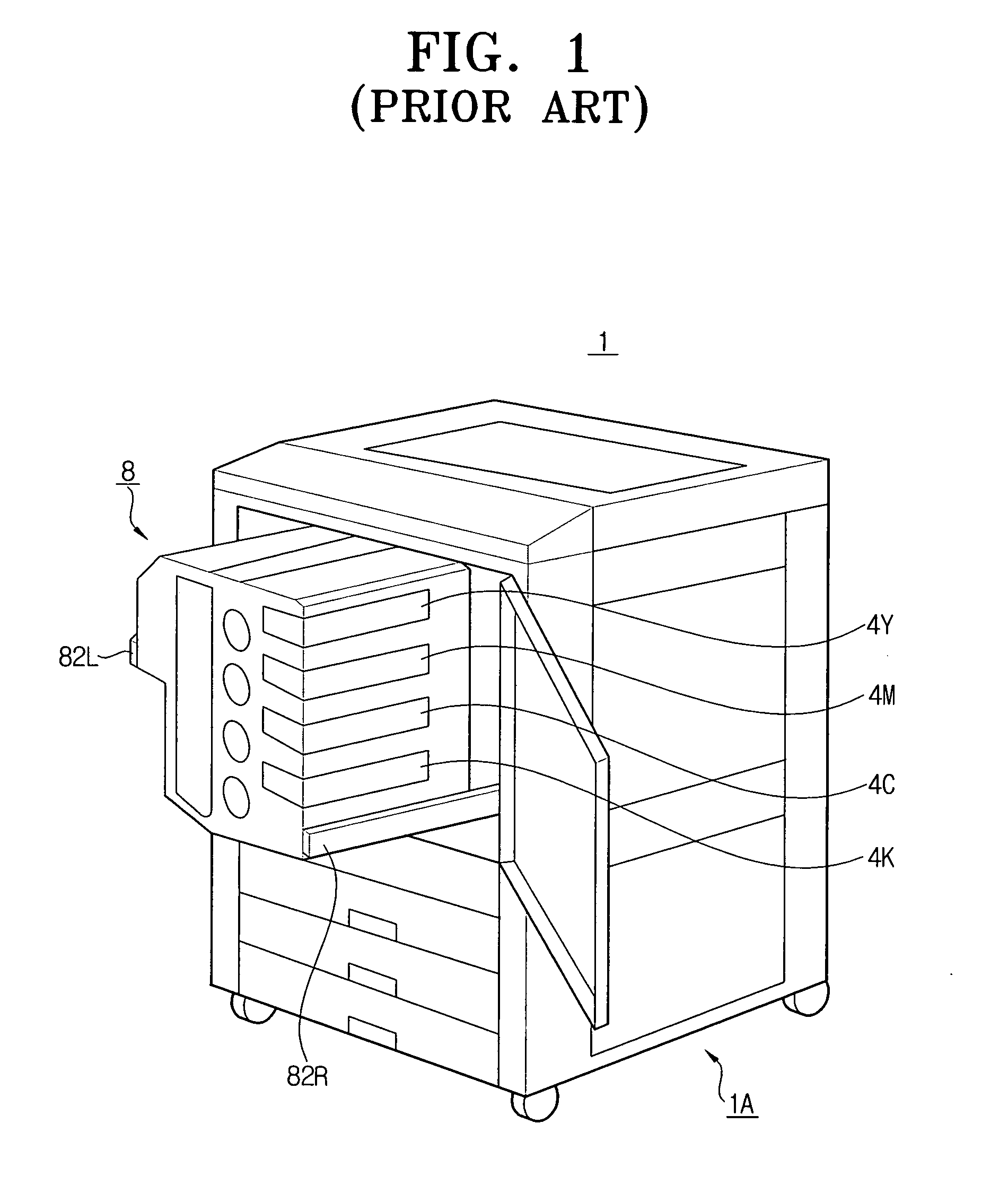

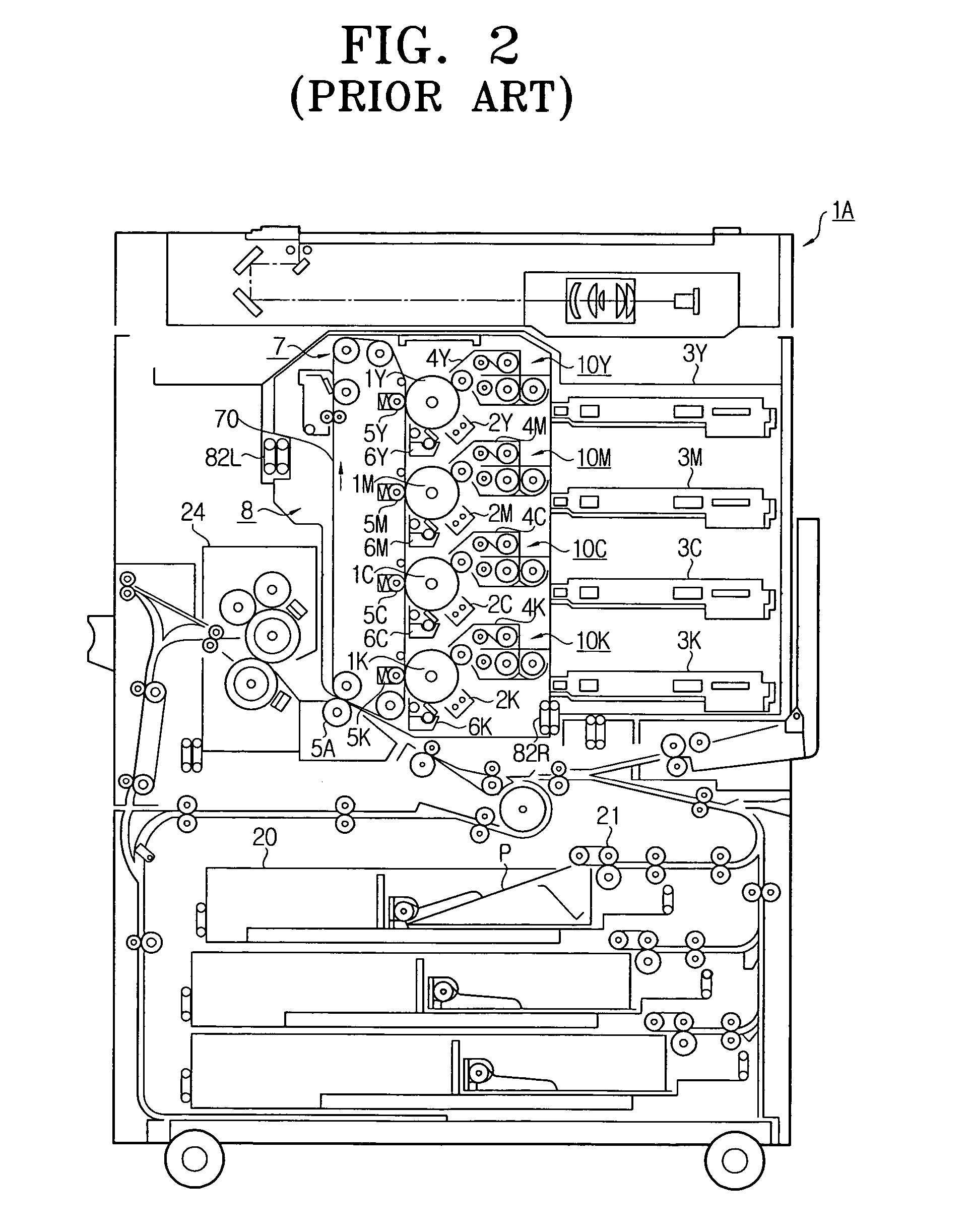

Tandem color image forming device

InactiveUS20050002690A1Consistent qualityPosition be fixElectrographic process apparatusEngineeringMechanical engineering

A tandem color image forming device comprises an image forming cartridge including a cartridge frame having a supporting part receiving a plurality of image forming units in parallel to modularize in a body, and a movable fixing part supporting at least one of a plurality of center shafts of photosensitive bodies disposed in the plurality of image forming units to be unmovable, but rotatable, and the other of the plurality of center shafts of the photosensitive bodies to be movable and rotatable when the plurality of image forming units are received in the cartridge frame, and a mounting frame formed at a main body to mount the image forming cartridge therein, and having a shaft receiving part formed at a position corresponding to both ends of the center shafts of the photosensitive bodies of the image forming units to receive both ends of the center shafts of the photosensitive bodies when the image forming cartridge is mounted in the mounting frame. The tandem color image forming device can accurately fix the center shafts of the photosensitive bodies of the image forming units in position when the image forming cartridge is assembled in the mounting frame, thereby obtaining a high quality image reliably.

Owner:S PRINTING SOLUTION CO LTD

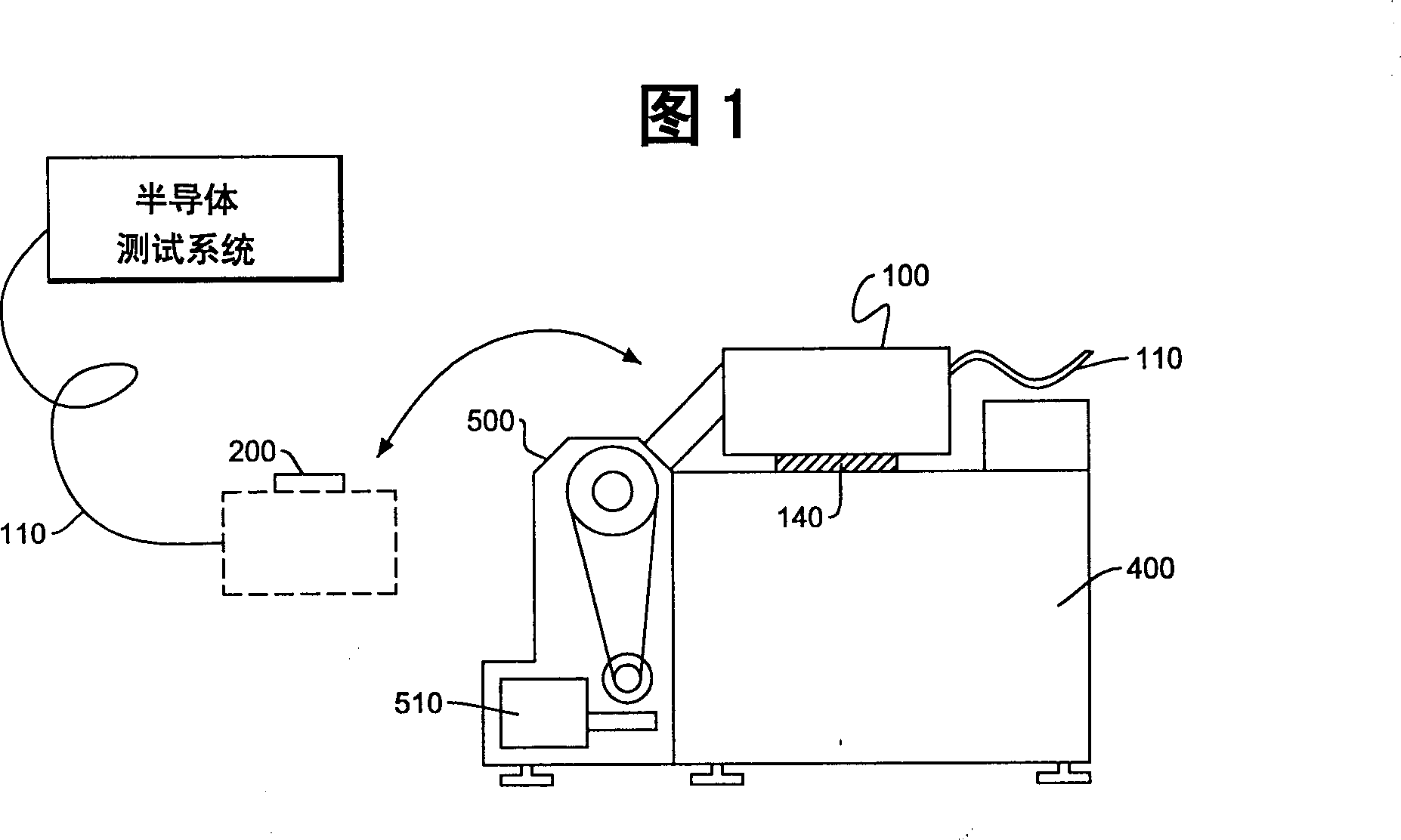

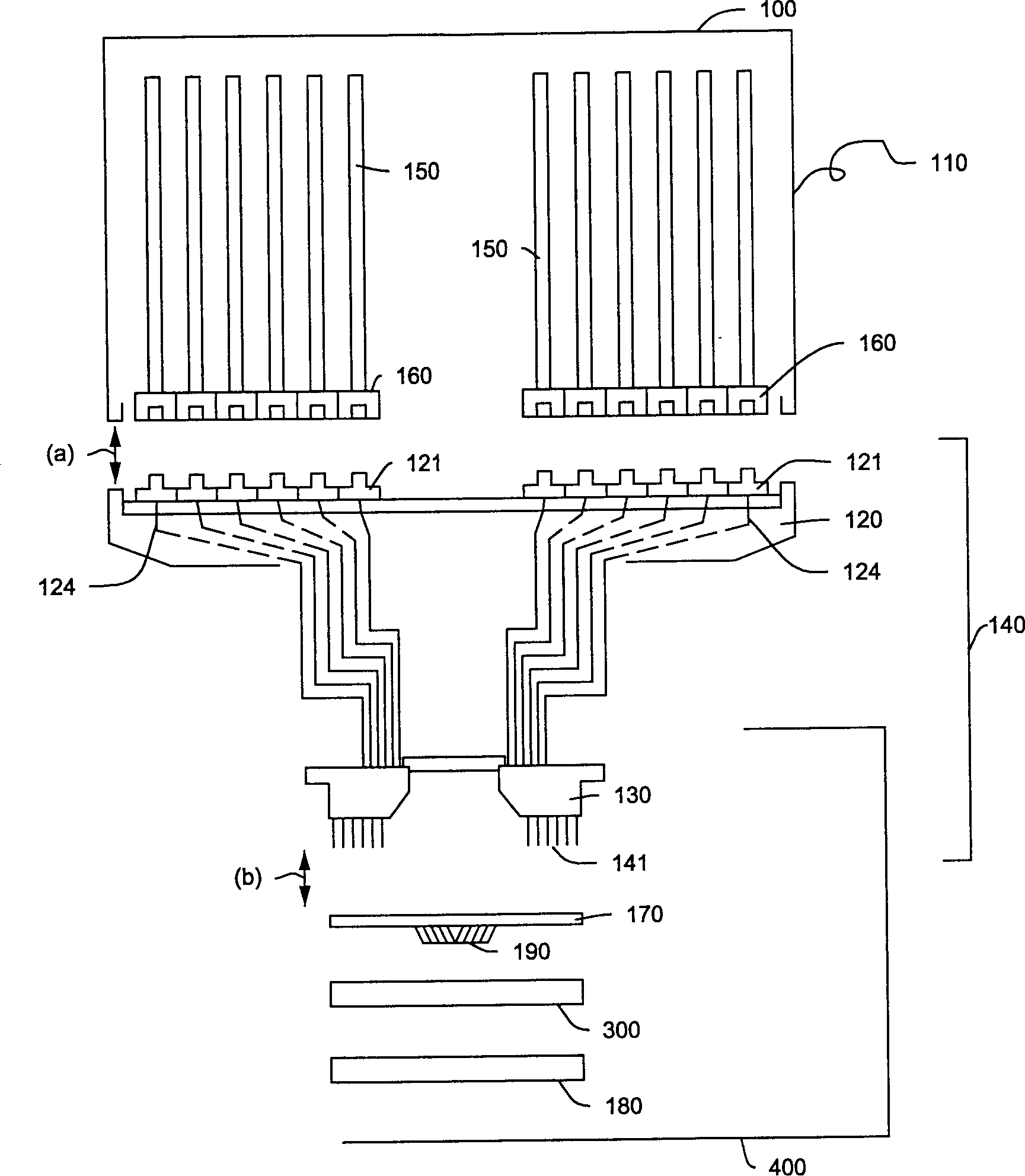

Contact structure member and production method thereof, and probe contact assembly using said contact structure member

InactiveCN1350325AImprove reliabilityConsistent qualitySemiconductor/solid-state device testing/measurementElectronic circuit testingContact padElectrical connection

A method of producing a contact structure for establishing electrical connection with contact targets. The contact structure is formed of a contact substrate and a plurality of contactors. The contactor has a contact portion which is oriented in a vertical direction to form a contact point, an intermediate portion which is inserted in a through hole provided on the contact substrate, and a base portion having a base end which functions as a contact pad and a spring portion provided between the base end and the intermediate portion for producing a resilient contact force when the contactor is pressed against the contact target.

Owner:株式会社鼎新

Processing method of green tea

InactiveCN105494699ASimple processing methodConsistent qualityPre-extraction tea treatmentBudGreen tea

The invention discloses a processing method of green tea. The method includes the steps of picking, withering, fixation, spreading and cooling, rolling, drying and packaging. Fresh leaves of tea trees with three leaves on one bud or four leaves on one bud are picked to serve as raw materials, vacuum anaerobic treatment is conducted on the tea leaves, hot wind withering is conducted, withered leaves are put into a fixation machine, the tea leaves are placed on a screen to be spread and cooled, the spread and cooled leaves are put into a rolling machine to be rolled, the rolled leaves are dried for 10-15 min at the temperature of 110-130 DEG C, the leaves are cooled to the normal temperature and dried for 20-25 min at the temperature of 80-100 DEG C, and the dried tea leaves are sealed, packaged, frozen and subjected to fragrance increase, and the finished product is obtained. The tea leaves processed through the method are firm in appearance, jade green in color and luster, stable in quality, durable in fragrance and thick and fresh in taste, and after the tea leaves are brewed into tea, the liquor color is transparent and bright, leaf bottoms are green and tender, and the taste is pure.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

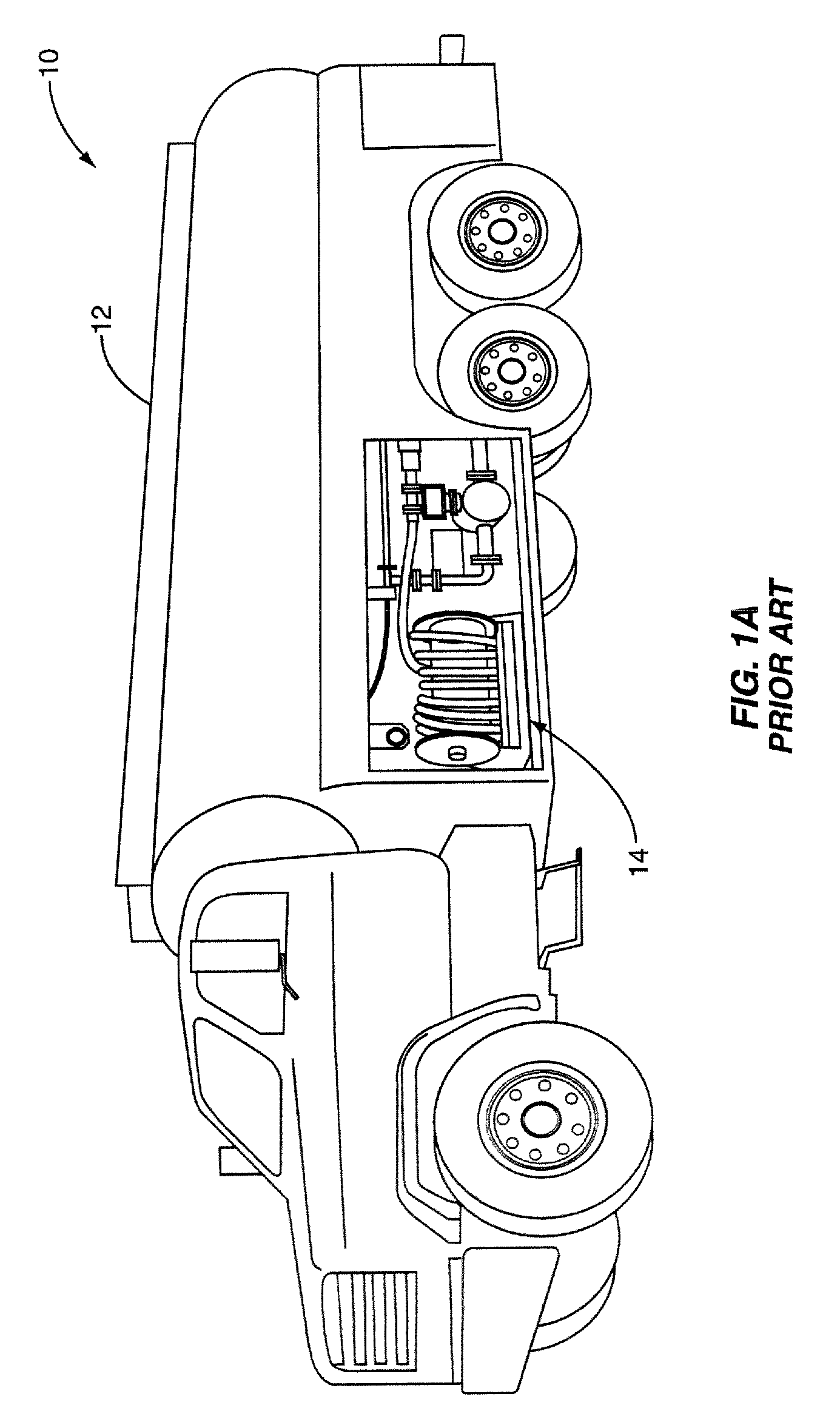

Automated fuel quality detection and dispenser control system and method, particularly for aviation fueling applications

ActiveUS8720499B2Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

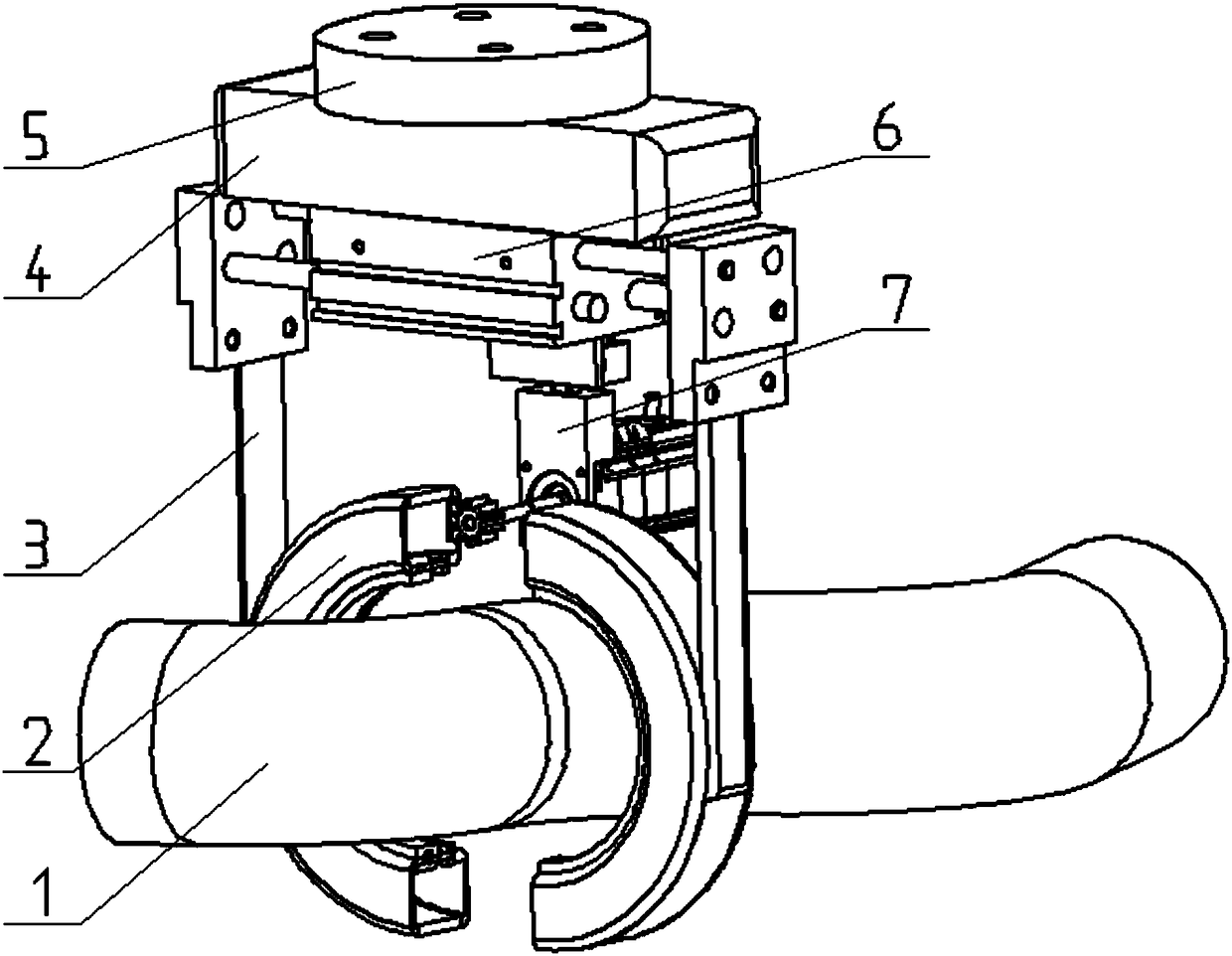

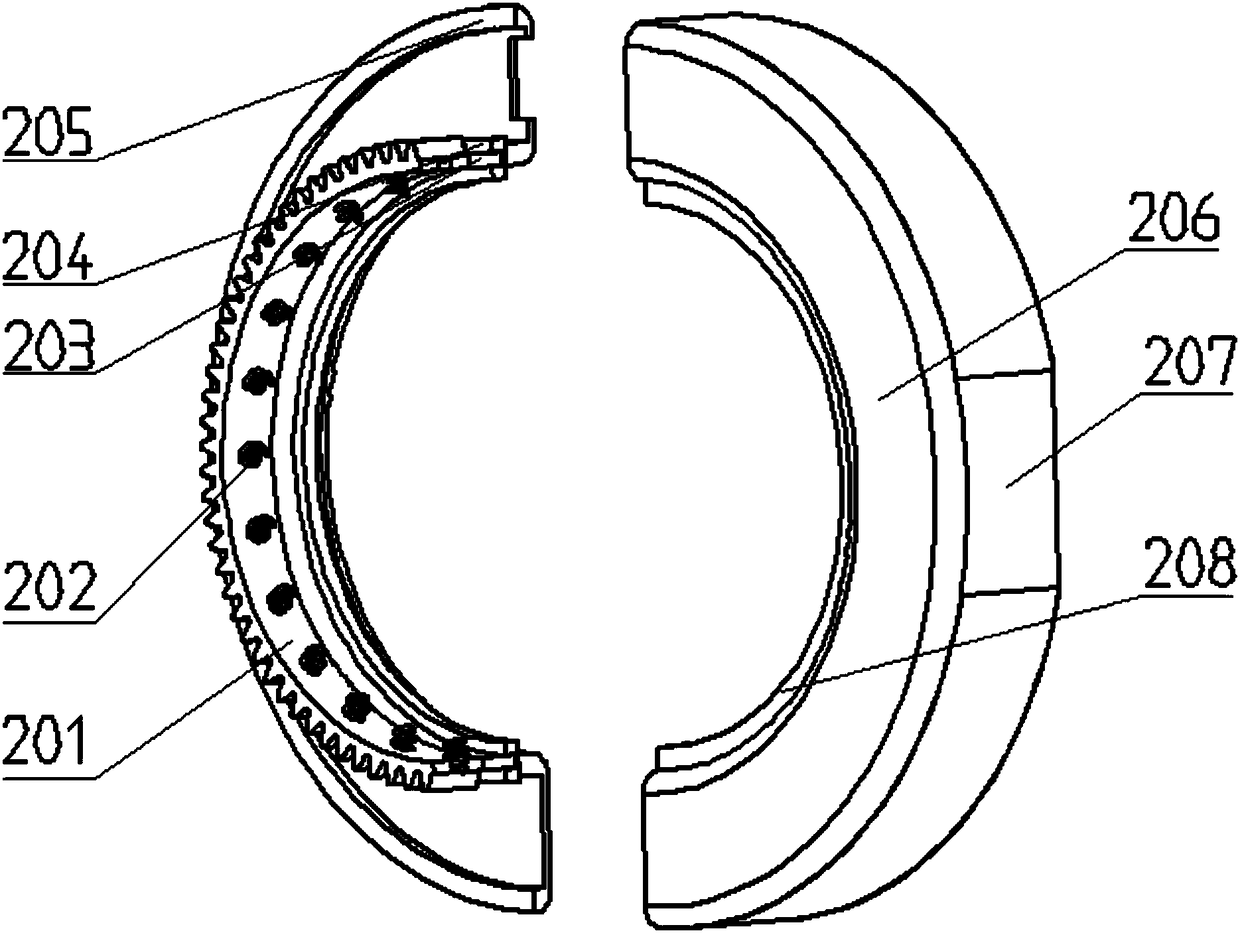

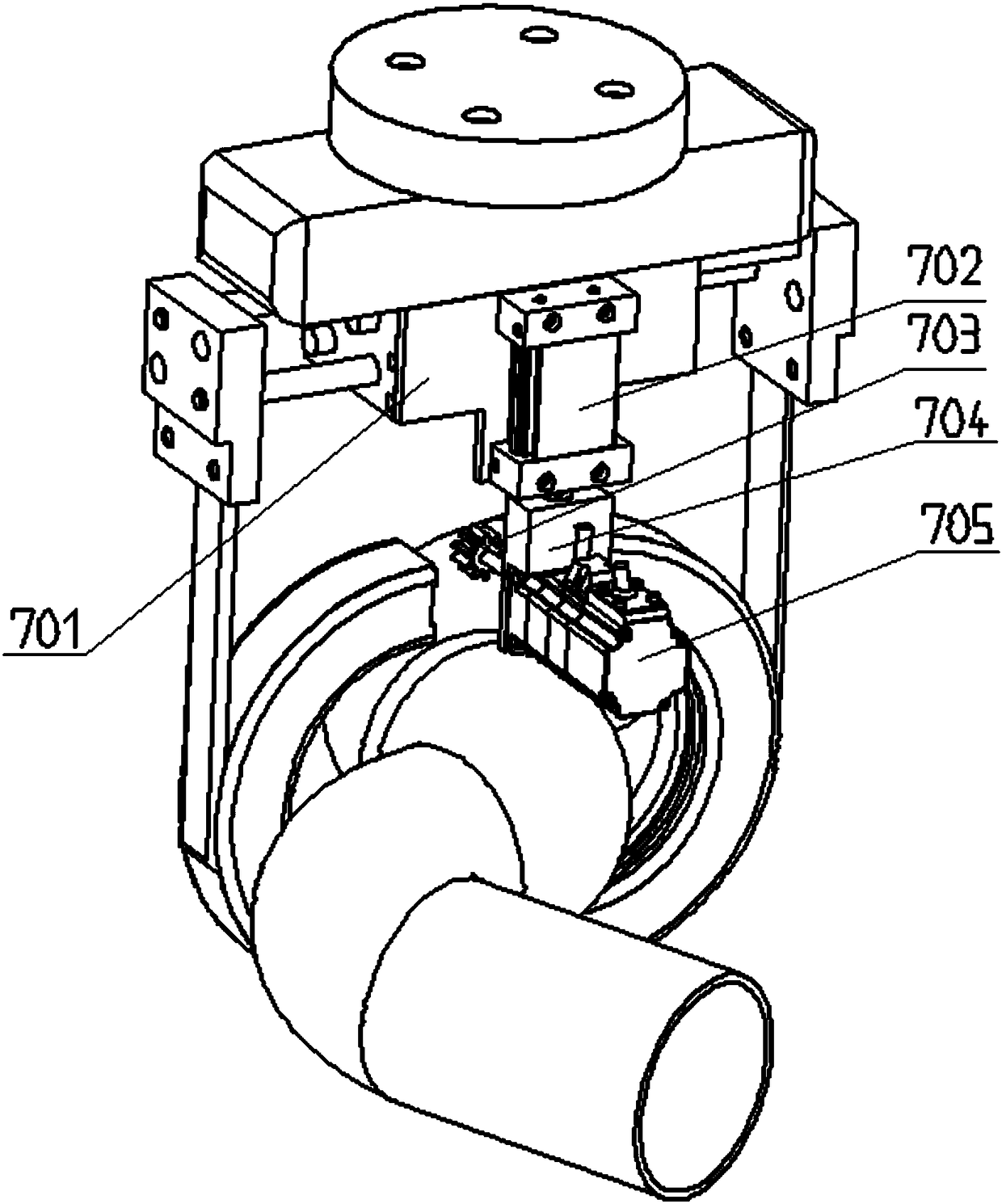

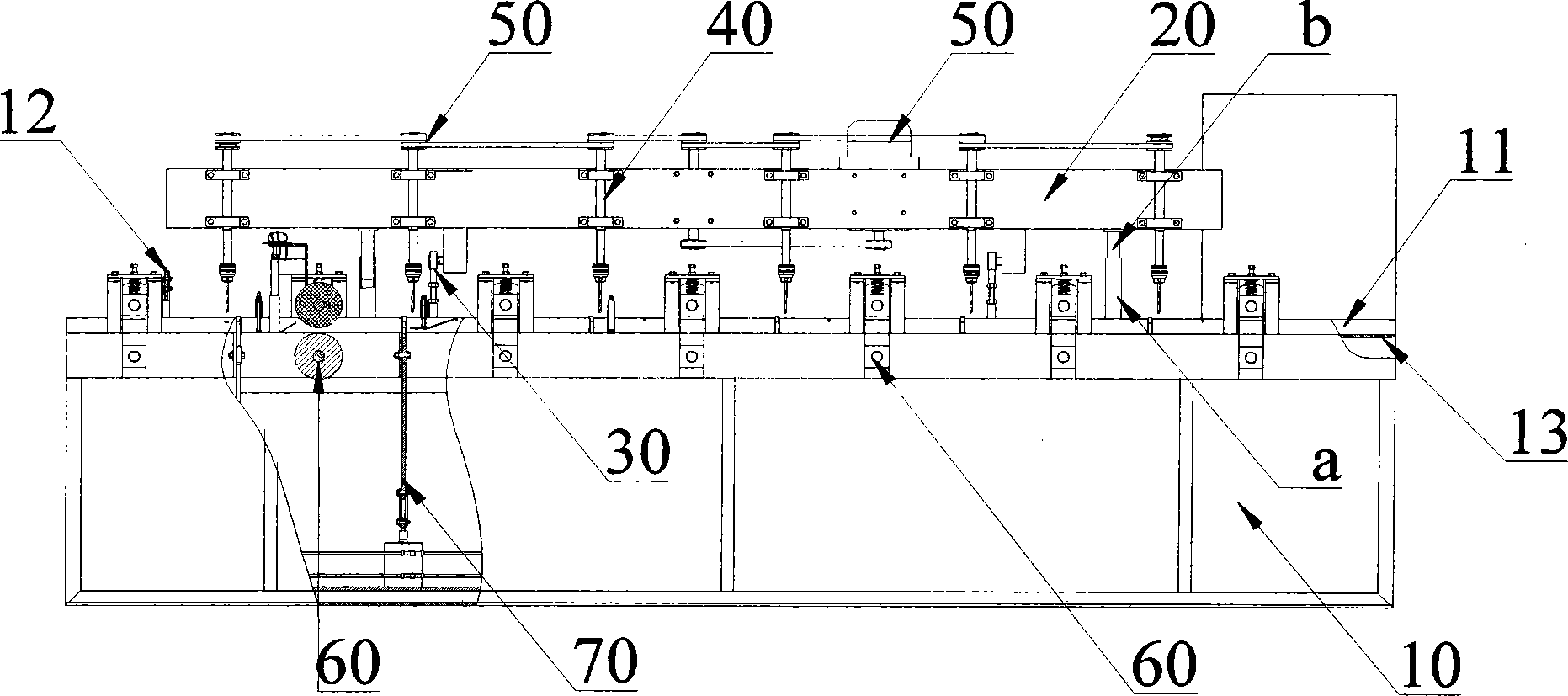

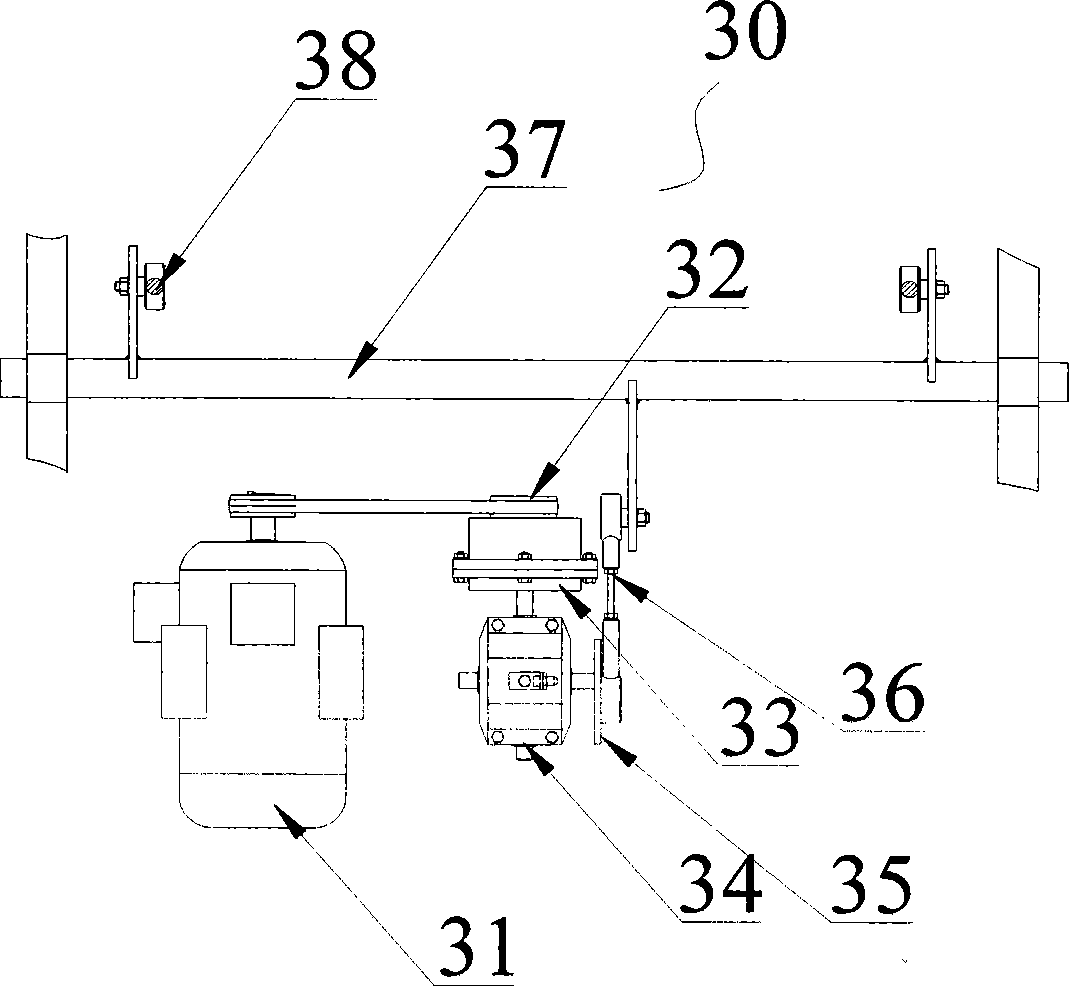

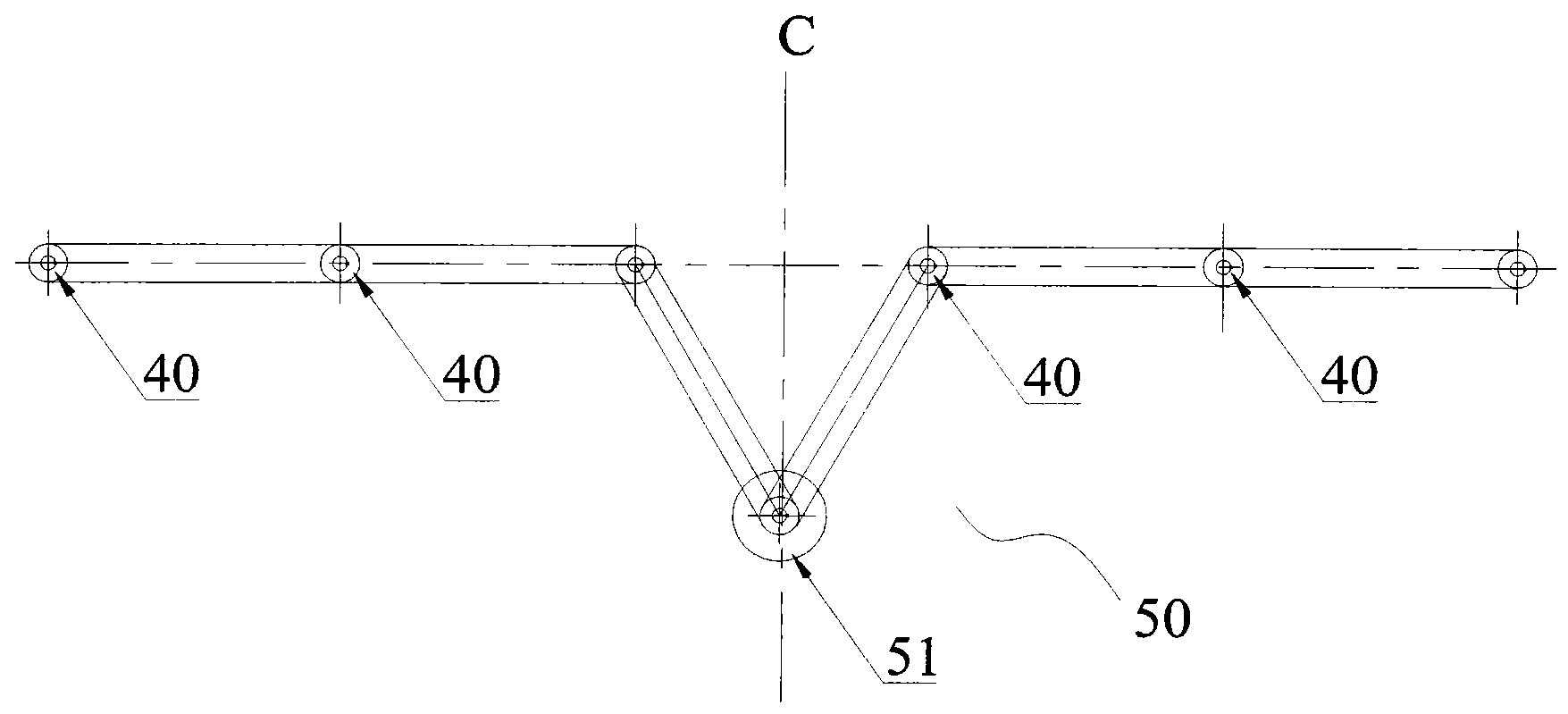

Circular pipe weld joint automatic grinding device

InactiveCN108214247ARealize automatic grinding processAchieve regulationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a circular pipe weld joint automatic grinding device and belongs to the field of grinding automatic equipment. The device is composed of a circular pipe, a grinding unit, supporting arms, a controller, a mounting flange, a wide gas claw and driving unit. The mounting flange is fixed to the controller. The wide gas claw is mounted under the controller. One side of a cylindermounting plate on the driving unit is mounted on the back side of the controller, and a thin cylinder is mounted on the other side of the cylinder mounting plate. A servo motor is connected with thethin cylinder through a motor fixing seat. A gear is mounted on a spindle of the servo motor. The supporting arms are mounted on paws on the two sides of the wide gas claw. Side covers in the grindingunit are connected with the supporting arms correspondingly. A front cover and a rear cover are mounted on the front and rear sides of the side covers correspondingly. A sliding guide rail is mountedon the rear cover. A semicircular gear ring is mounted on the sliding guide rail through a sliding block. Springs are mounted on the inner side of the semicircular gear ring, and a grinding materialis fixed through the springs. The circular pipe is fixed and all positions of a weld joint are exposed. Through the grinding device, the circular pipe splicing weld joint can be ground automatically.

Owner:SHANDONG SICHUANG ROBOT TECH CO LTD

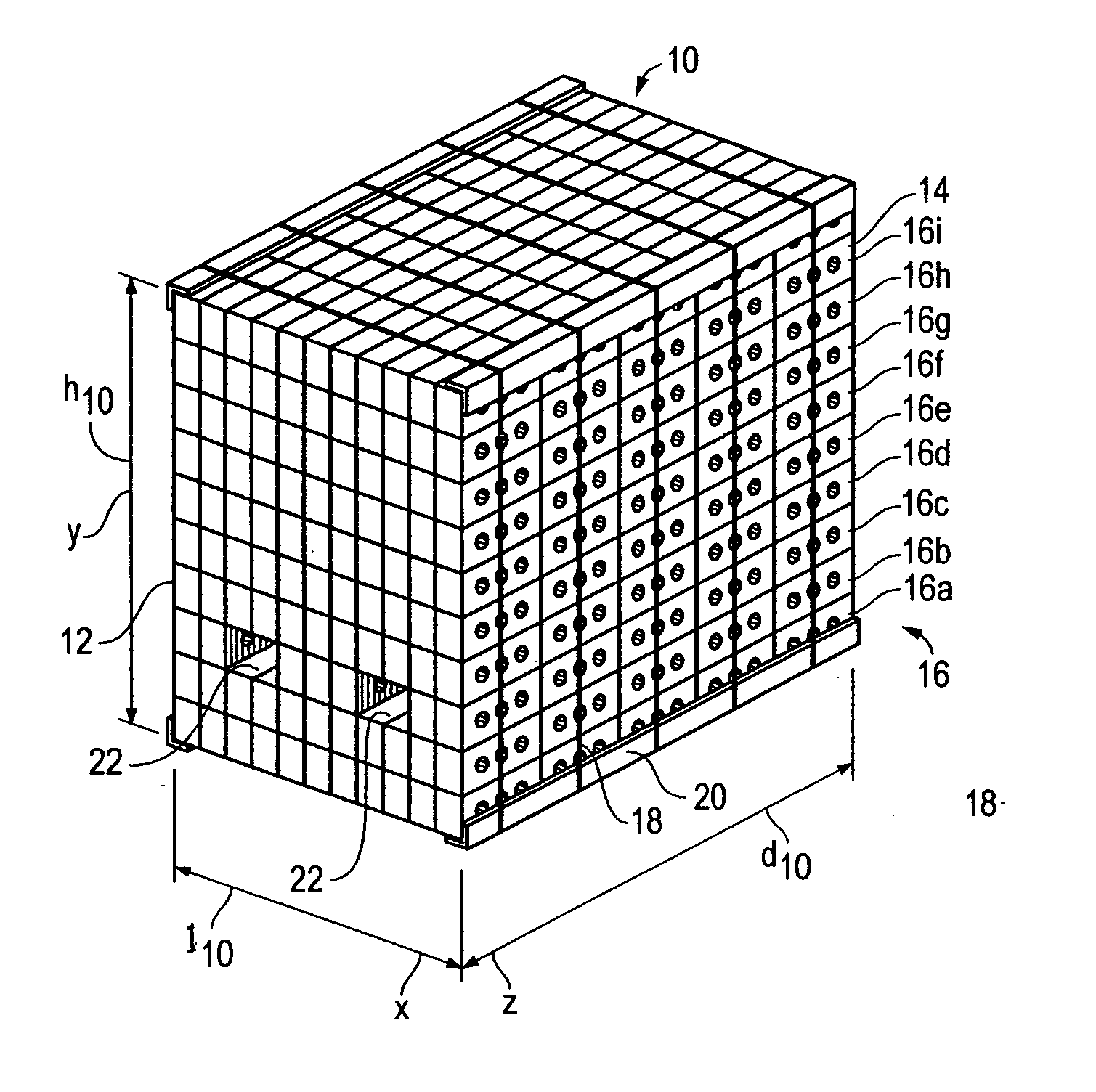

Polymeric void-board

An extruded polymeric void-board is configured for placement between adjacent horizontal layers of bricks to maintain an opening in a lower layer of the bricks. The void-board is formed as a relatively thin planar element having first and second surfaces. A plurality of parallel ribs extend from and generally transverse to the first side. The ribs have a predetermined height to width ratio and have a height that is less than a thickness of the planar element. The ribs being formed parallel to one another. A method for forming a bundle of bricks with the void-board is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

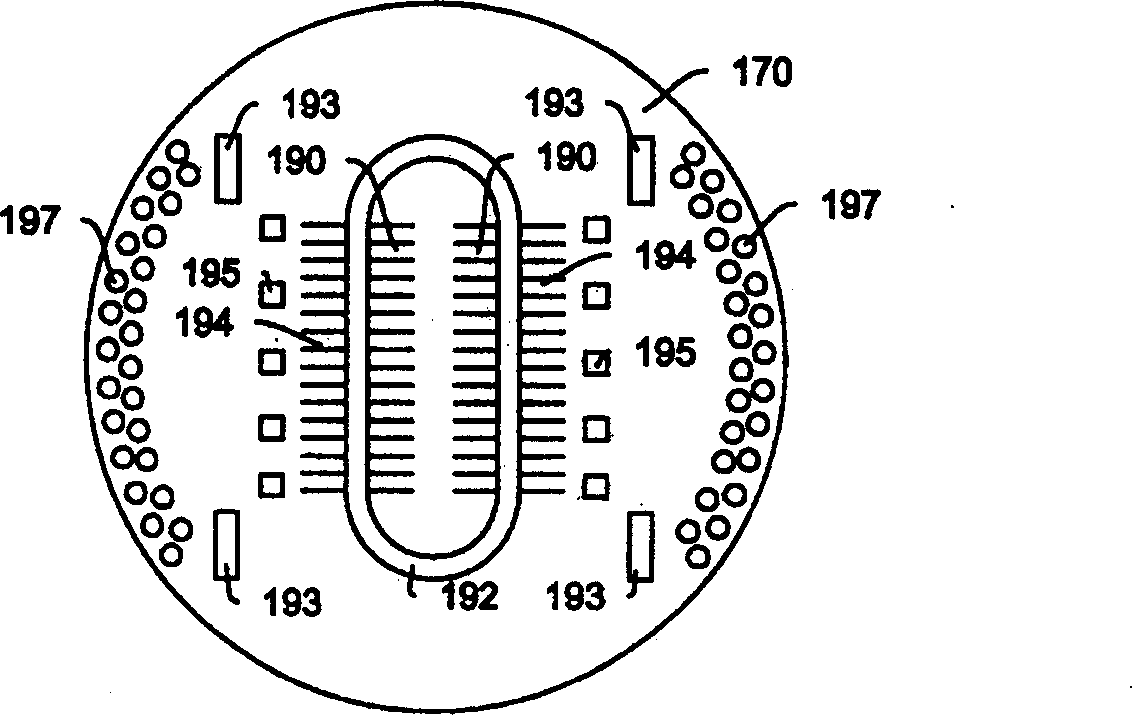

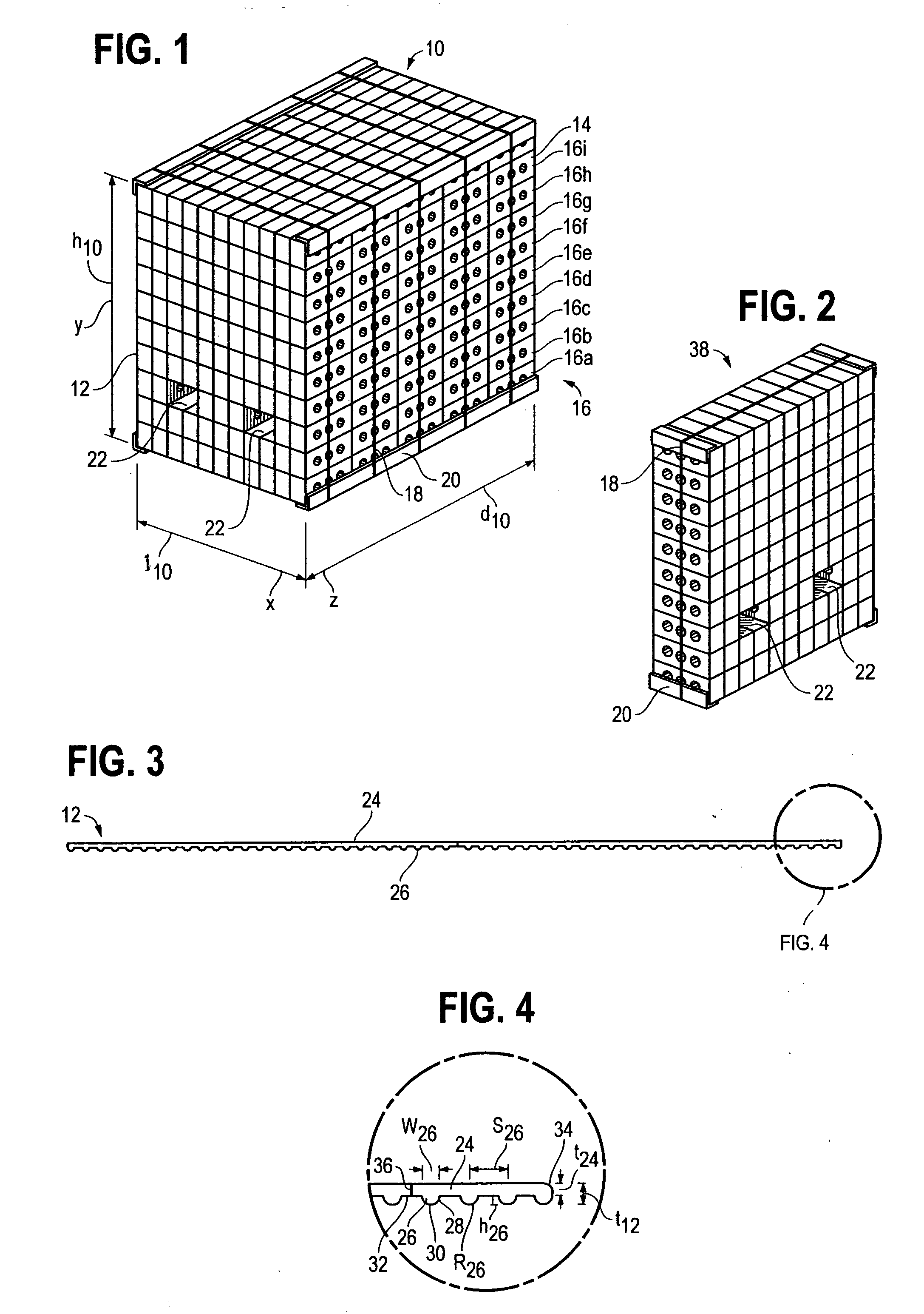

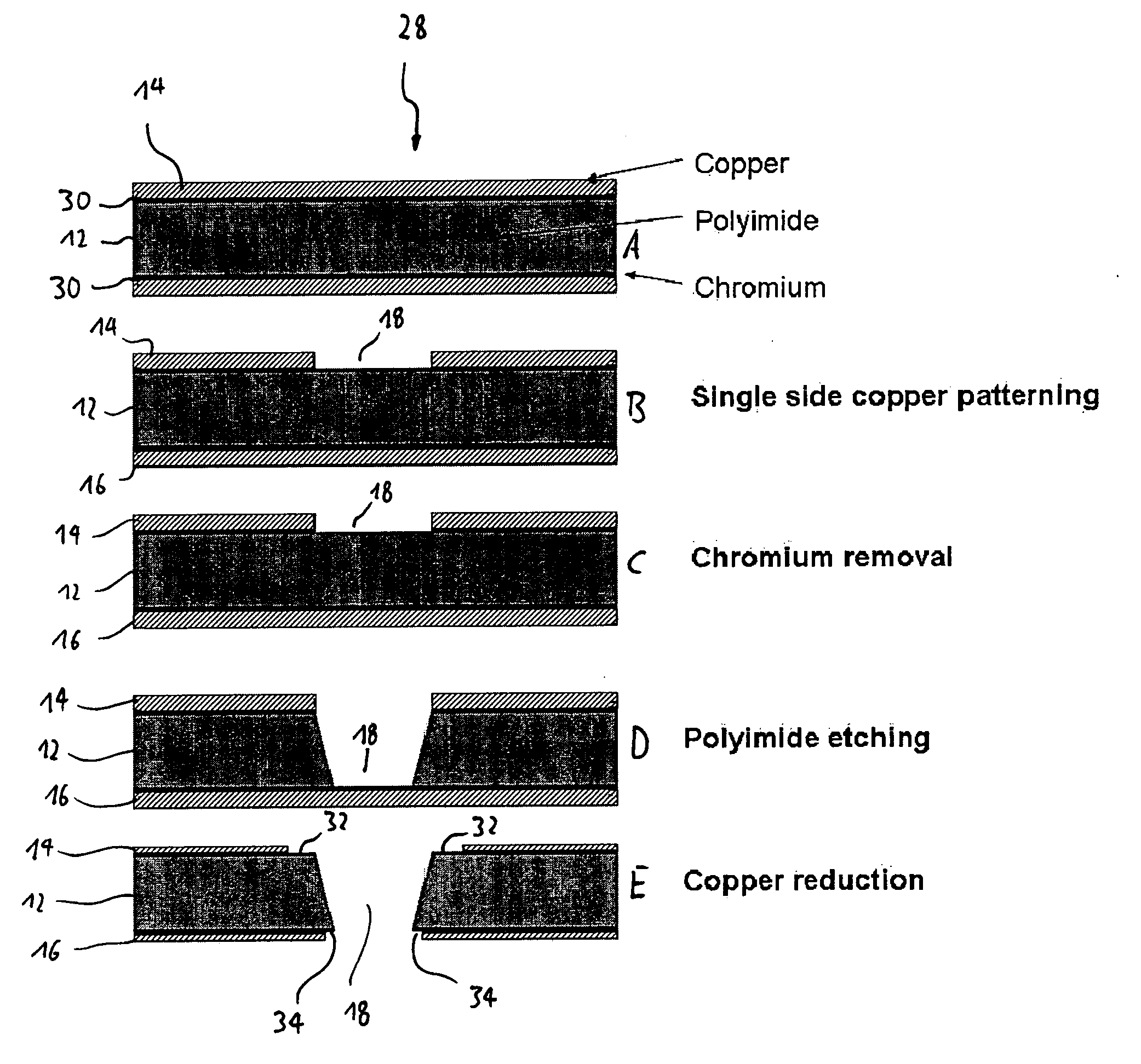

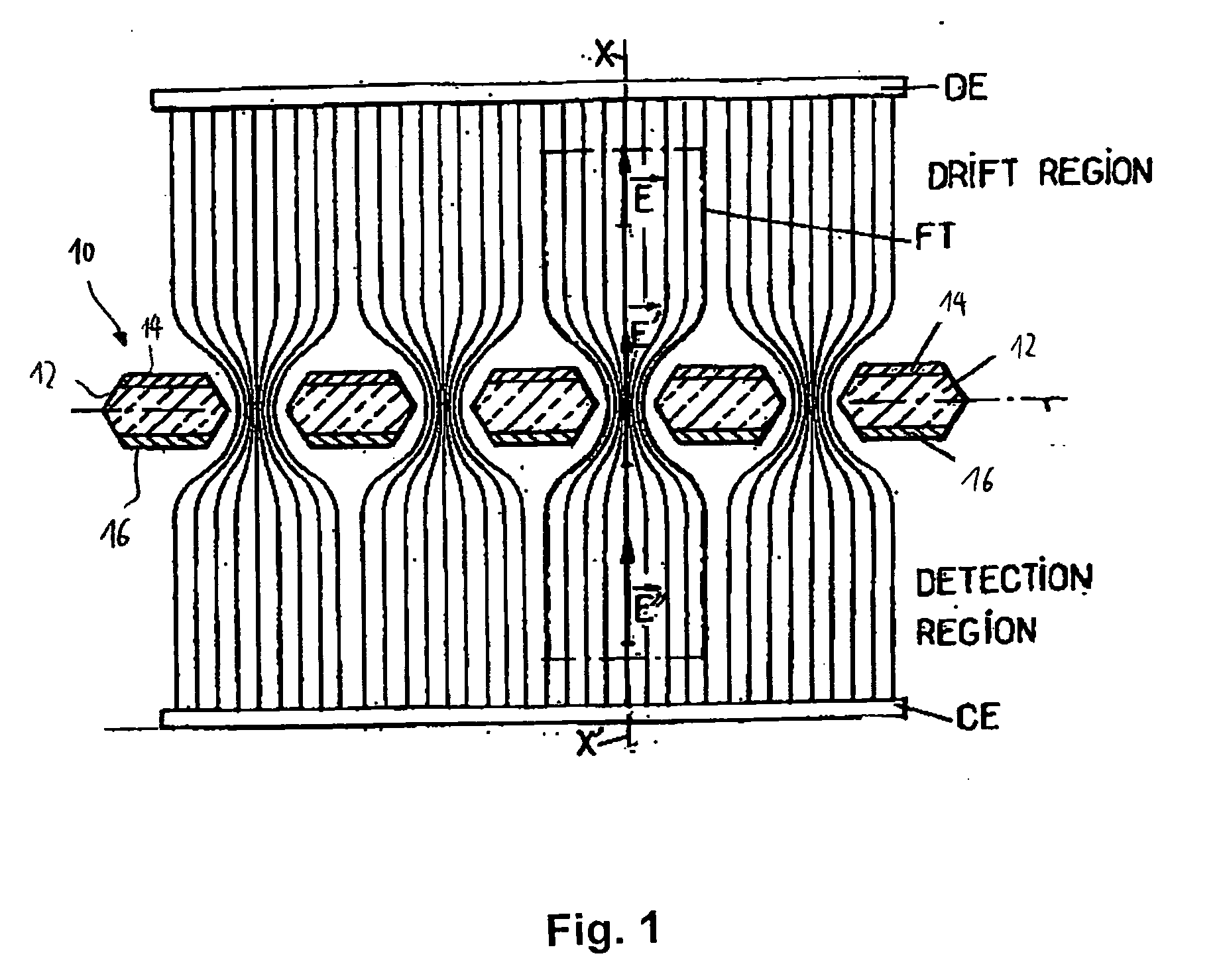

method of manufacturing a gas electron multiplier

InactiveUS20110089042A1Consistent qualityGood performanceElectrolysis componentsMultiplier electrode arrangementsMultiplier methodGas electron multiplier

Methods for manufacturing a gas electron multiplier. One method comprises a step of preparing a blank sheet comprised of an insulating sheet with first and second metal layers on its surface, a first metal layer hole forming step in which the first metal layer is patterned by means of photolithography, such as to form holes through the first metal layer, an insulating sheet hole forming step, in which the holes formed in the first metal layer are extended through the insulating layer by etching from the first surface side only, and a second metal layer hole forming step, in which the holes are extended through the second metal layer. Alternatively, the second metal layer hole forming step is performed by electrochemical etching, such that the first metal layer remains unaffected during etching of the second metal layer. In another embodiment, in the second metal layer hole forming step, the first and second metal layers are etched from the outside, thereby reducing the initial thicknesses of the first and second metal layers and the second metal layer is simultaneously etched through the holes in the first metal layer and the insulating sheet, said etching being maintained until the holes extend through the second metal layer, wherein said initial average thickness of the first and second metal layers is between 6.5 μm and 25 μm, preferably between 7.5 μm and 12 μm.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH

Crystal growth control method, device and system for shouldering process and computer storage medium

InactiveCN111690980AConsistent qualityGood repeatabilityPolycrystalline material growthBy pulling from meltComputational physicsControl theory

The invention provides a crystal growth control method, device and system for a shouldering process and a computer storage medium. The method comprises the following steps: presetting crystal growth angle set values of different stages of the shouldering process and set values of crystal growth process parameters of different stages of the shouldering process; acquiring crystal diameters of different stages of the shouldering process, calculating a change value of the crystal diameter and a change value of the crystal length, and calculating a crystal growth angle value through the ratio of the change value of the crystal diameter to the change value of the crystal length; comparing the crystal growth angle value with the crystal growth angle set value to obtain a difference value, and taking the difference value as an input variable of a PID algorithm; calculating an adjustment value of a crystal growth process parameter through a PID algorithm, which serves as an output variable of the PID algorithm; and adding the adjustment value of the crystal growth process parameter and the set value of the crystal growth process parameter to obtain the process parameter of the actual crystal growth process.

Owner:ZING SEMICON CORP

Machine for automatically removing joints of bamboo frame board and drilling holes in bamboo frame board

ActiveCN104029256AConvenience for subsequent useSimple structureStationary drilling machinesIrregularity removal devicesMachine partsEngineering

The invention relates to a machine for automatically removing joints of a bamboo frame board and drilling holes in the bamboo frame board. The machine comprises a worktable, a lifting table, a lifting table rotation mechanism, drill rods, a drill rod transmission mechanism and a machined part transmission mechanism, wherein a machined part feeding opening is formed in one side of the worktable; an opening and closing door is formed in the other side of the worktable; a joint removing cutter is arranged in the machined part feeding opening of the worktable; the lifting table is arranged above the worktable and located between the machined part feeding opening and the opening and closing door; the lifting table transmission mechanism is arranged at the bottom of an inner cavity of the worktable; the lifting table transmission mechanism is connected with the lifting table; a plurality of uniformly-arranged drill rods are arranged on the lifting table; the drill rod is vertical and downward and directly faces a table top of the worktable; the drill rod transmission mechanism is arranged on the lifting table; the drill rod transmission mechanism is connected with the drill rods; the machined part transmission mechanism is arranged on the table top of the worktable; the machined part transmission mechanism, the machined part feeding opening and the opening and closing door are arranged on the same straight line; the machined part transmission mechanism is arranged under the drill rods. When the machine is used, the working efficiency can be improved; meanwhile, groups of holes can be conveniently formed.

Owner:桃江县永利竹业机械研发有限公司

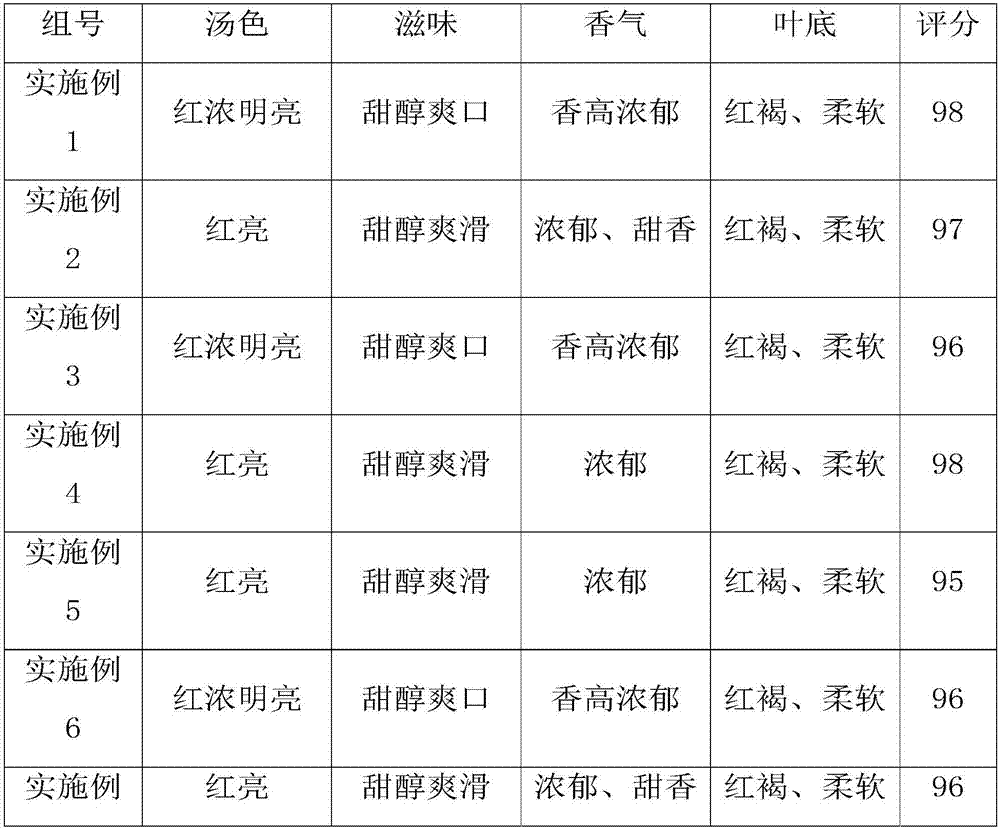

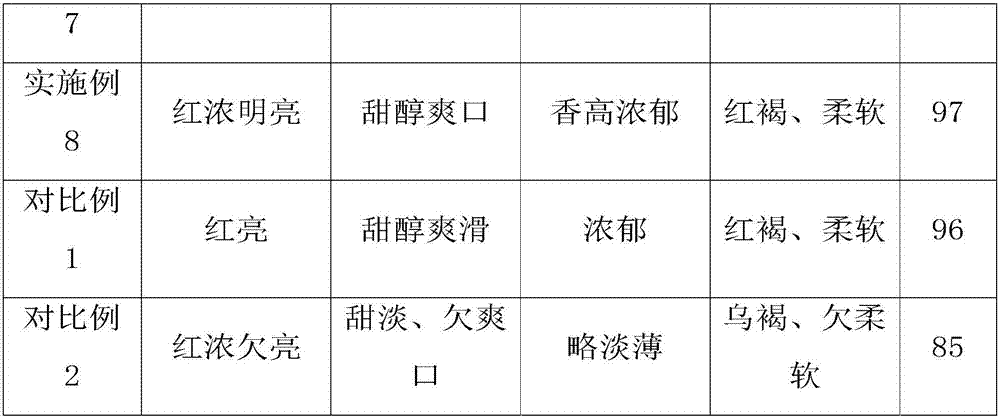

Fermentation method of Pu'er tea and Pu'er tea made by fermentation method

ActiveCN106922876AImprove qualityConsistent qualityPre-extraction tea treatmentRoom temperatureMaterial resources

The invention relates to a fermentation method of Pu'er tea and the Pu'er tea made by the fermentation method, and belongs to the field of tea processing. The fermentation method comprises the following steps of sprinkling water to 30-100kg of sunned semi-finished tea, putting the sunned semi-finished tea to which the water is spinkled in a wooden fermenting case, and performing fermentation under the room temperature of being higher than or equal to 20 DEG C, performing spreading for cooling, and performing drying so as to obtain the Pu'er tea. During fermentation, turning is performed once every 5-8d, the number of total turning times is 4-5, during fermentation, the temperature of the fermented tea piles is 45-60 DEG C, and the water sprinkling quantity when tea leaves are spinkled with water is 28-38% of the weight of the sunned semi-finished tea. The fermentation method is simple and convenient to operate, the investment of manpower and material resources during the production of the Pu'er tea can be reduced correspondingly, the production cost can be reduced to a certain extent, and the fermentation method is suitable for the field of high-end customization and teaching and research. The fermentation method is high in controllability, and comprehensive in fermentation, and the prepared Pu'er tea is stable in quality. The fermentation degrees of the Pu'er tea are consistent, the dry tea is black and brown and moistening in color, the tea soup is red, rich and bright in color, rich in fragrance, sweet and smooth in taste, and sweet after taste, and leaf bases are red, brown and soft.

Owner:谭清华

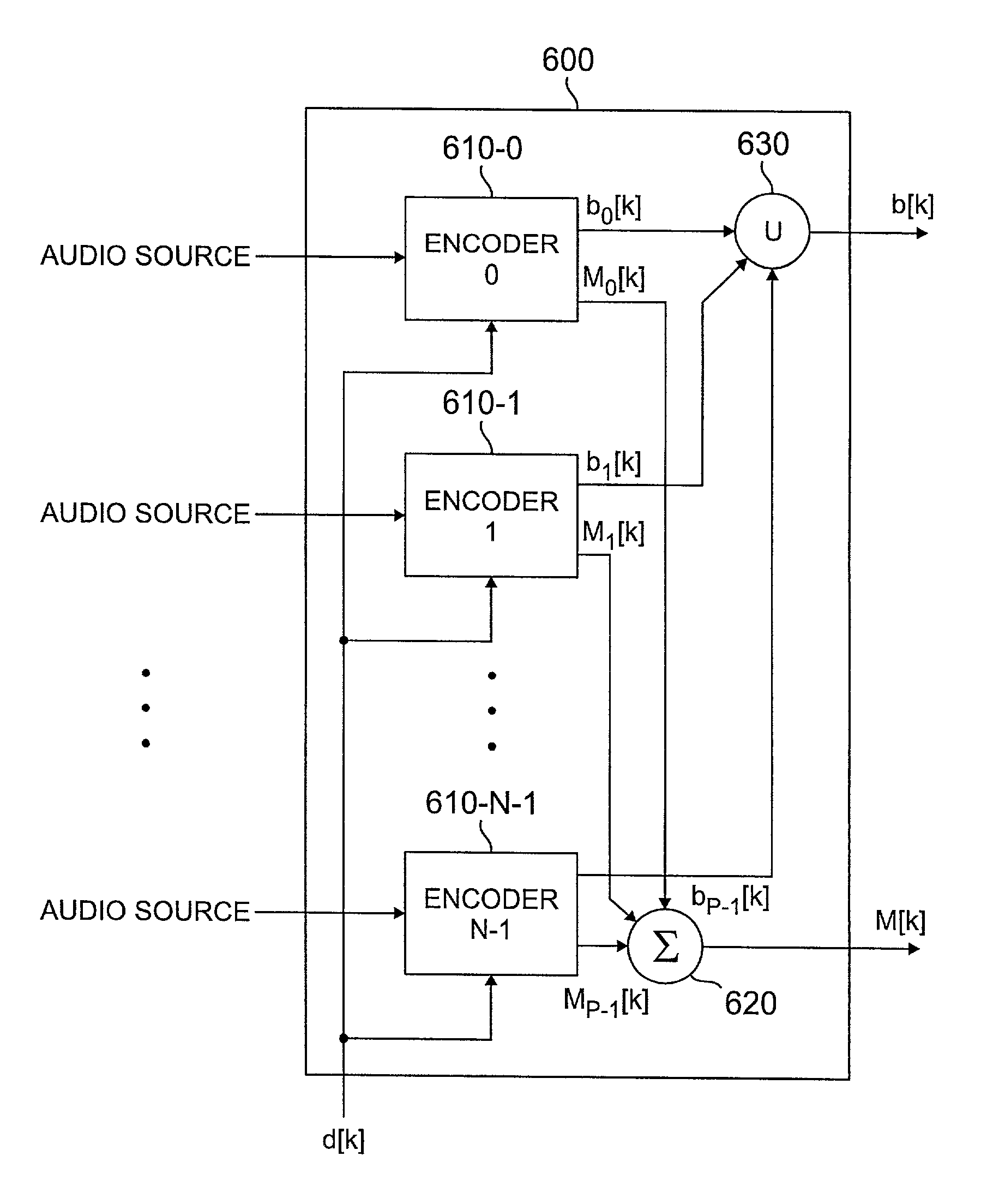

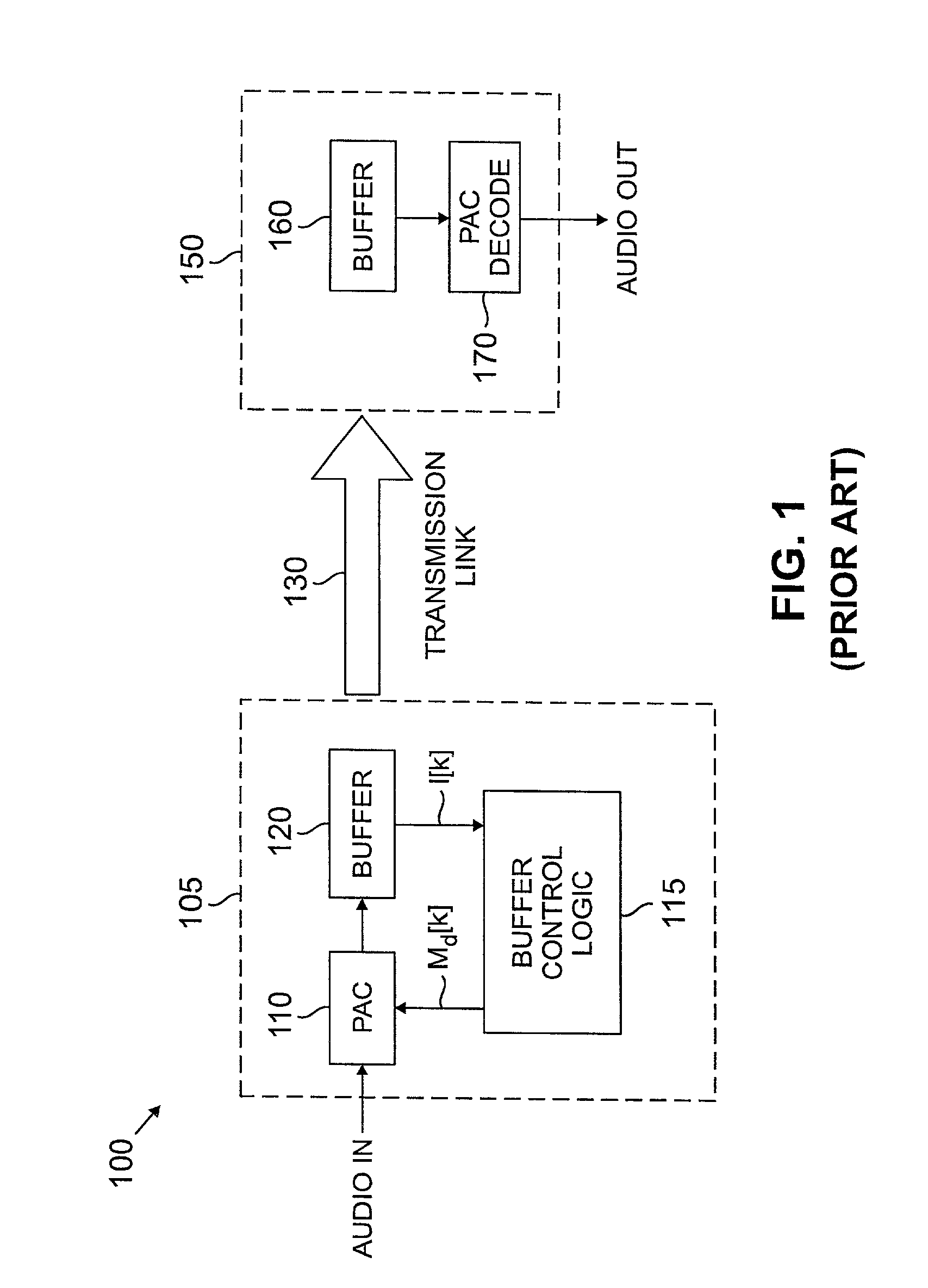

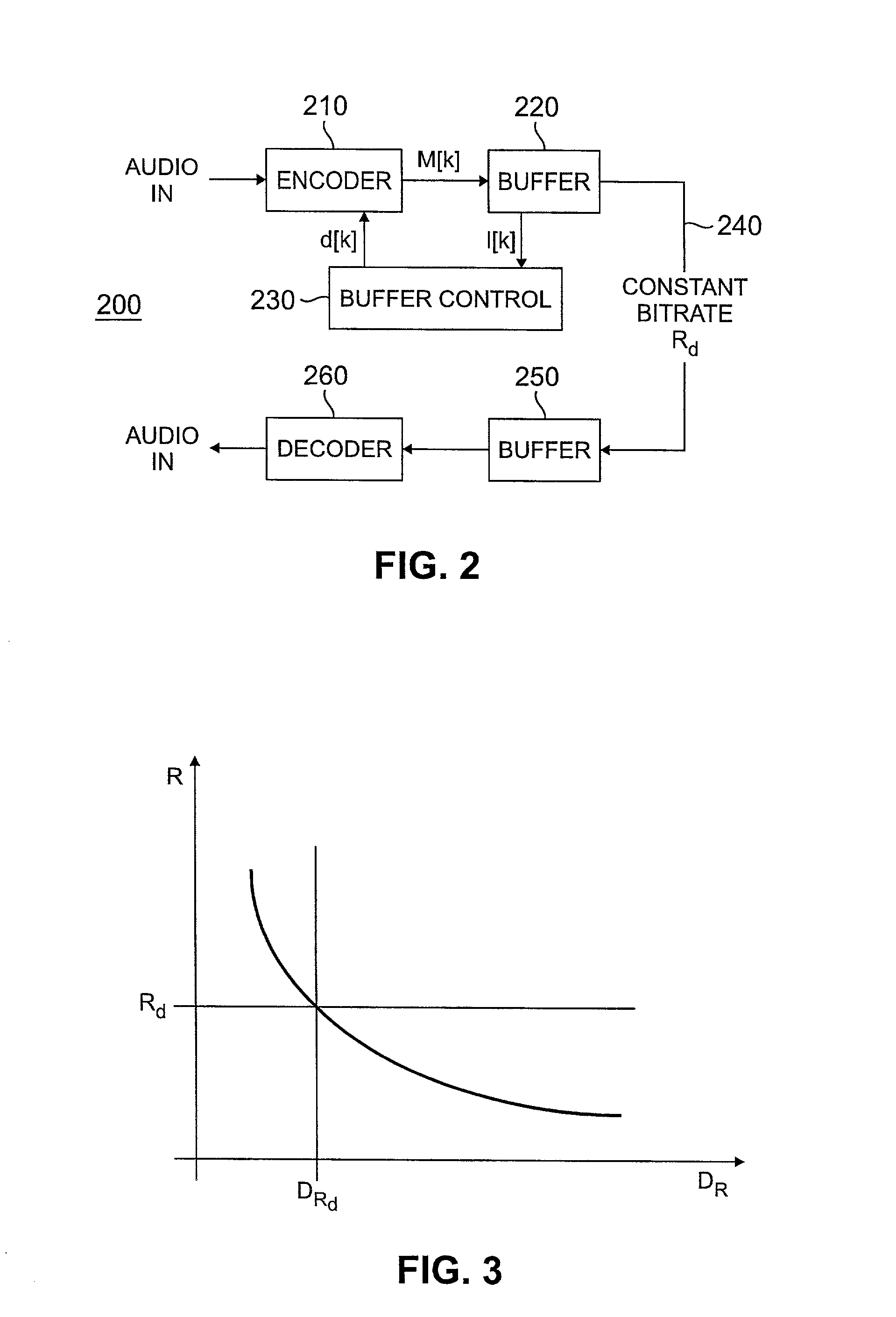

Distortion-based method and apparatus for buffer control in a communication system

ActiveUS7062429B2Reduces local variationConsistent perceptual qualityColor television with pulse code modulationColor television with bandwidth reductionBit allocationControl communications

A method and apparatus are disclosed for controlling a buffer in a communication system, such as a digital audio broadcasting (DAB) communication system. A more consistent perceptual quality over time provides for a more pleasing auditory experience to a listener. Thus, the disclosed bit allocation process determines, for each frame, a distortion d[k] at which the frame is to be encoded. Generally, the distortion d[k] is determined to minimize (i) the probability for a buffer overflow, and (ii) the variation of perceived distortion over time. A buffer level is controlled by partitioning a signal into a sequence of successive frames; estimating a distortion rate for a number of frames; and selecting a distortion such that the variance of the buffer level is bounded by a specified value. In one implementation, a signal is coded by partitioning the signal into a sequence of successive frames; encoding each frame k for each of a plurality of distortions Di to compute a frame bitrate; estimating an average bitrate Ri[k] for each of said plurality of distortions Di given current and past frame bitrates; interpolating between each of said pair of values for said average bitrate Ri[k] and said plurality of distortions Di to obtain an approximation of a function that maps a distortion to an estimated average bitrate; and encoding each frame with a distortion level determined from said function.

Owner:AVAGO TECH INT SALES PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com