Fermentation method of Pu'er tea and Pu'er tea made by fermentation method

A fermentation method and a technology for fermenting tea, which are applied in the field of Pu'er tea, can solve problems such as unfavorable economic benefits of Pu'er tea, uneven quality of Pu'er tea, and regulation and control of tea pile fermentation conditions, so as to reduce manpower, achieve consistent fermentation degree, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

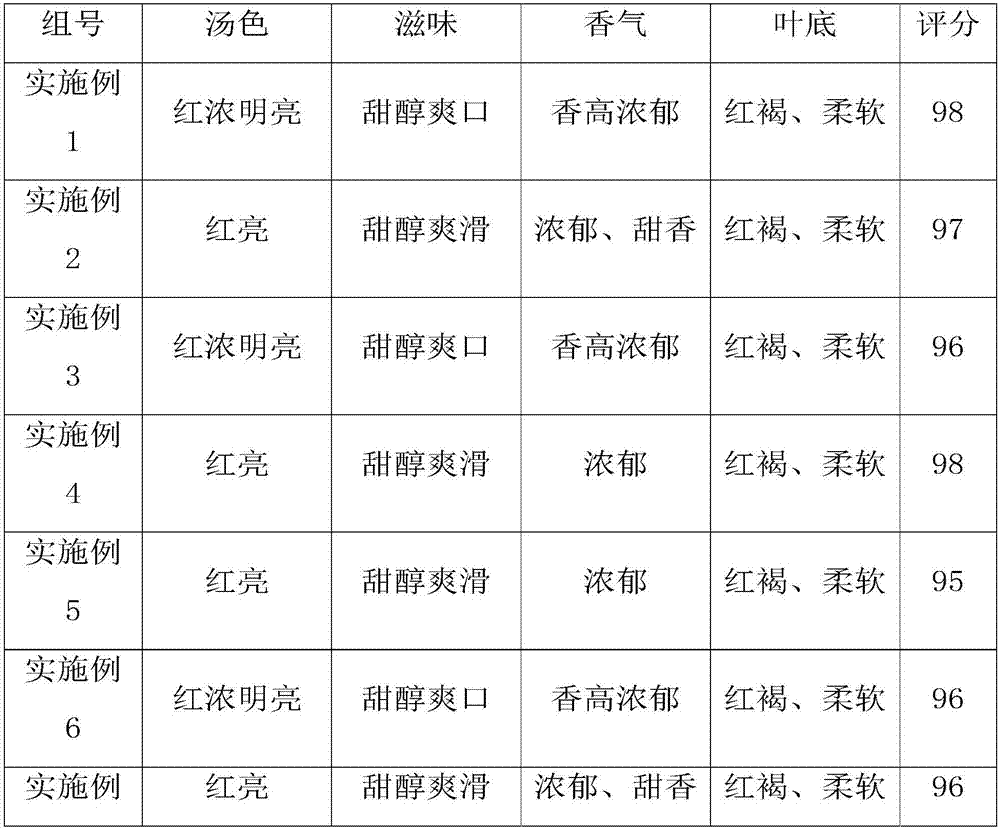

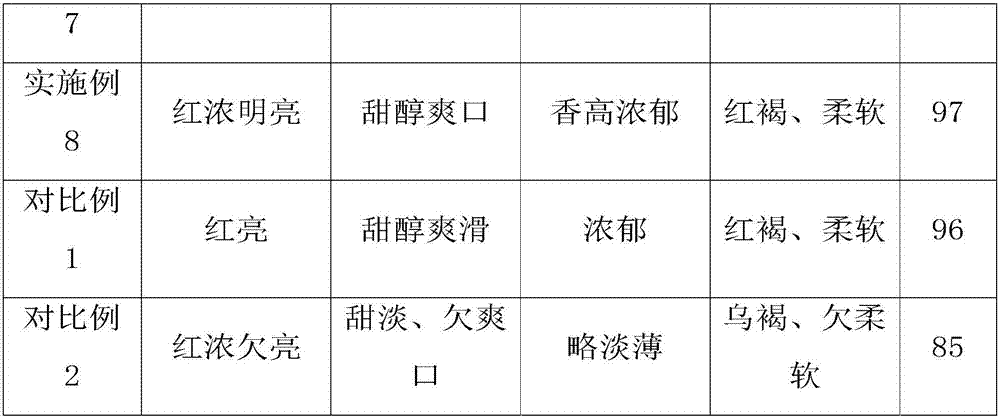

Examples

Embodiment 1

[0033] Put 30kg of sun-dried green mao tea on the waterproof cloth, spray 9kg of water on the sun-dried green mao tea, wait for 5 hours until the sun-dried green mao tea fully absorbs water and becomes soft, then put all the tea leaves in a wooden fermentation box, and keep it at room temperature Under the condition of less than 20 ℃, carry out fermentation. Keep the temperature of the tea heap in the fermentation tank at 45-60°C during the fermentation process, turn over the heap every 8 days, the total number of times of turning over the heap is 4 times, keep the moisture content in the fermentation process at 30%, until the fermentation is completed, After the fermentation is completed, take out the tea leaves in the fermentation box, spread them on the waterproof cloth to form a cooling tea with a thickness of 10cm, and set a cooling ditch with a width, depth and spacing of 5cm, and spread the cooling until the moisture content of the tea leaves is 12 %, and then use a dry...

Embodiment 2

[0035] Put 100kg of sun-dried qingmao tea on a tarp, spray 30kg of water on the sun-dried qingmao tea, wait for 8 hours until the sun-dried green maocha fully absorbs water and becomes soft, then put all the tea leaves in a wooden fermentation box, and keep it at room temperature Under the condition of less than 20 ℃, carry out fermentation. Keep the temperature of the tea heap in the fermentation tank at 45-60°C during the fermentation process, turn over the heap every 5 days, the total number of times of turning over the heap is 5 times, keep the moisture content of 25% during the fermentation process, until the fermentation is completed, After the fermentation is completed, take out the tea leaves in the fermentation box, spread them on a waterproof cloth to form a cooling tea with a thickness of 20 cm, and set a cooling ditch with a width, depth and spacing of 10 cm, and cool the tea until the moisture content of the tea leaves is 10 cm. %, and then use a dryer to dry the ...

Embodiment 3

[0037] Put 50kg of sun-dried green mao tea on a tarp, spray 14kg of water on the sun-dried green mao tea, wait for 6 hours until the sun-dried green mao tea fully absorbs water and becomes soft, then put all the tea leaves in a wooden fermentation box, and keep it at room temperature Under the condition of less than 20 ℃, carry out fermentation. Keep the temperature of the tea heap in the fermentation tank at 45-60°C during the fermentation process, turn over the heap every 7 days, the total number of times of turning over the heap is 5 times, keep the moisture content in the fermentation process at 38%, until the fermentation is completed, After the fermentation is completed, take out the tea leaves in the fermentation box, spread them on the waterproof cloth to form a 15cm-thick cooling tea, and set up a cooling ditch with a width of 8cm, a depth of 7cm, and a distance of 8cm, and spread the cooling until the water content of the tea leaves The water content is 11%, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com