Patents

Literature

30results about "Multiplier electrode arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

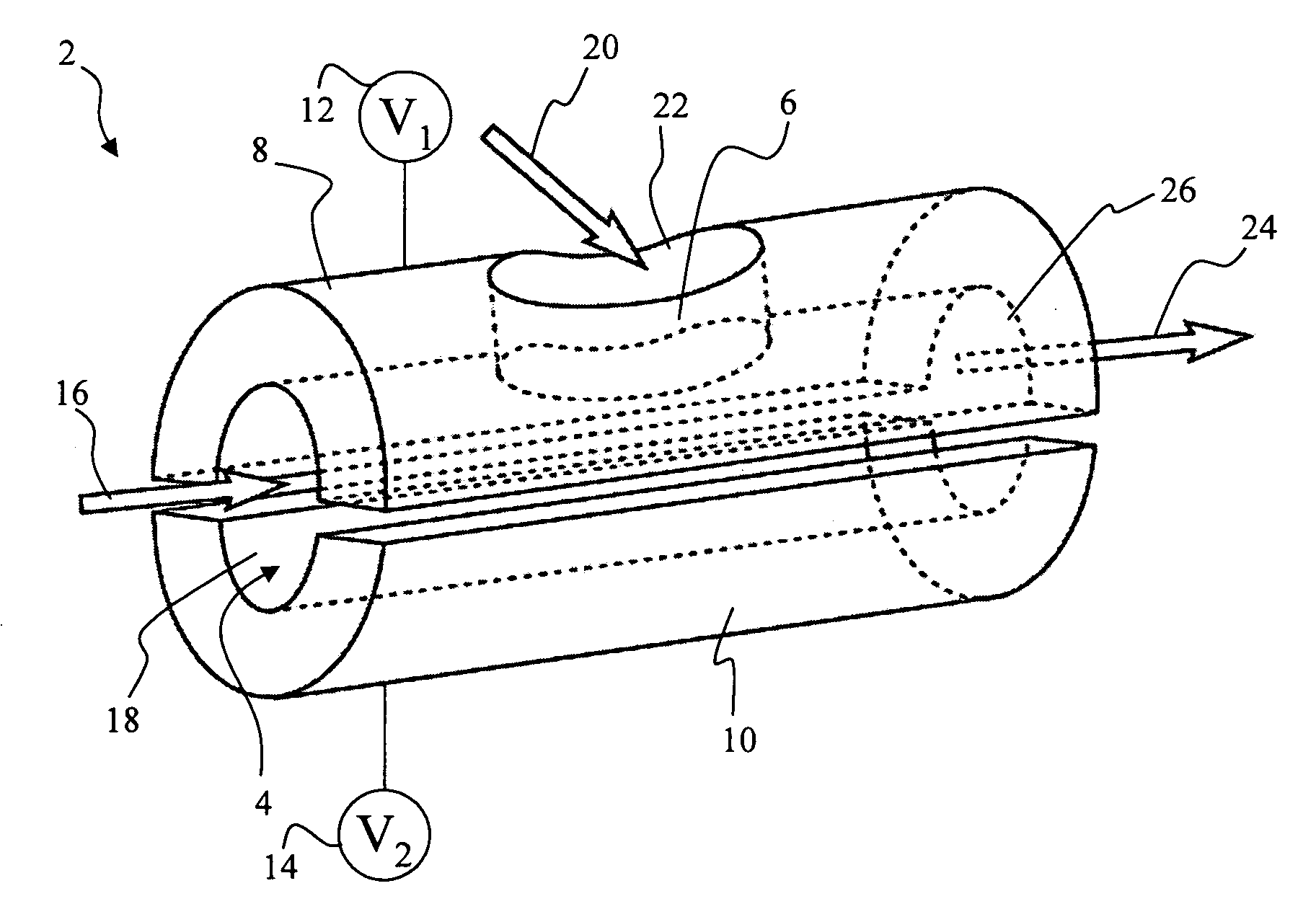

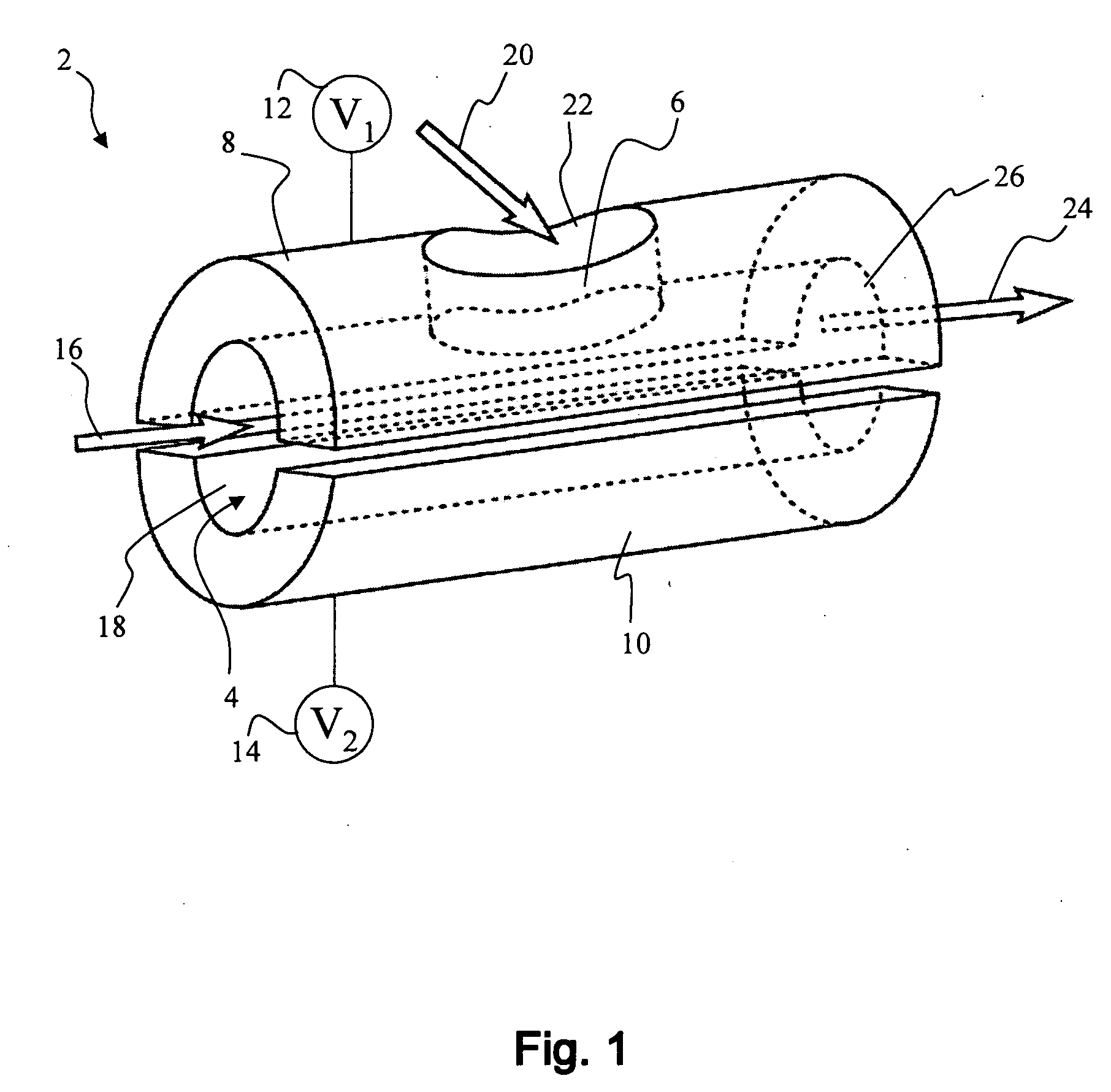

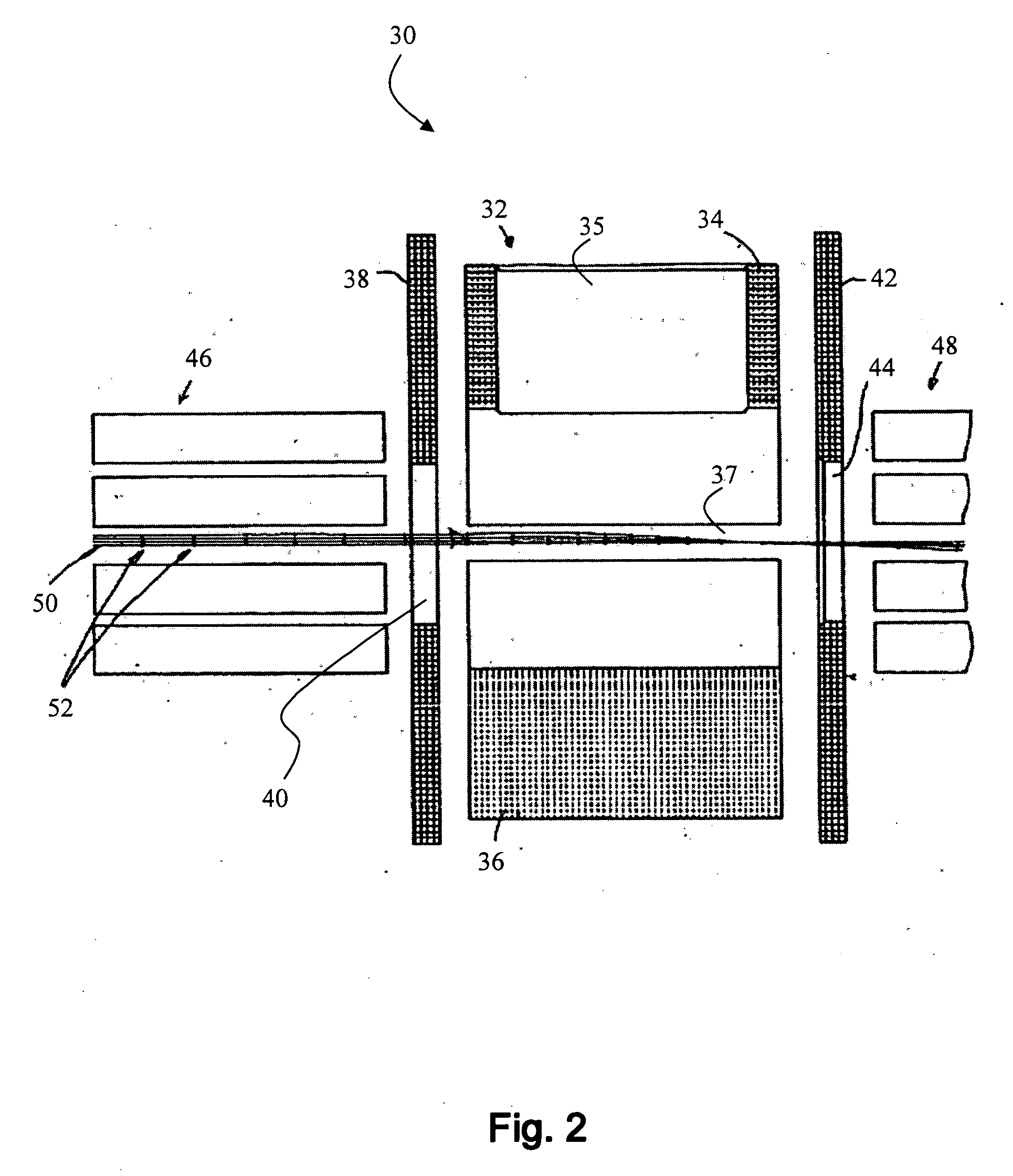

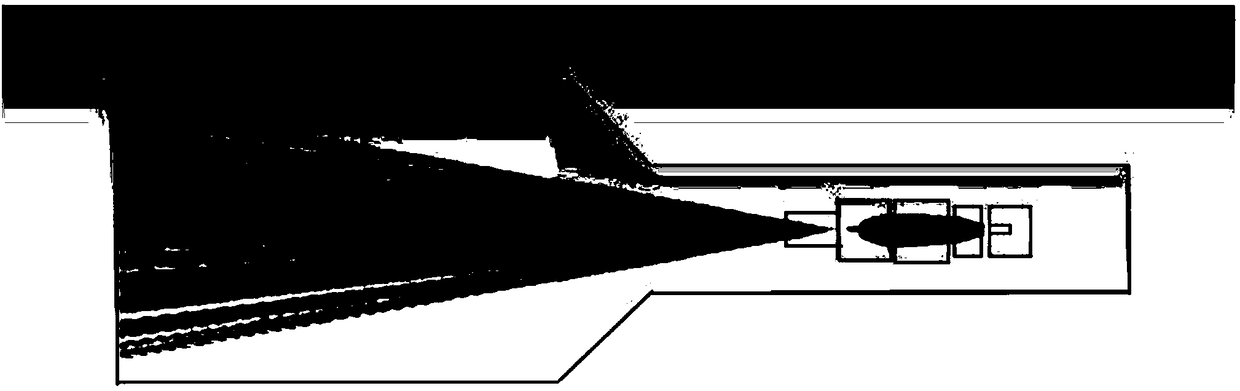

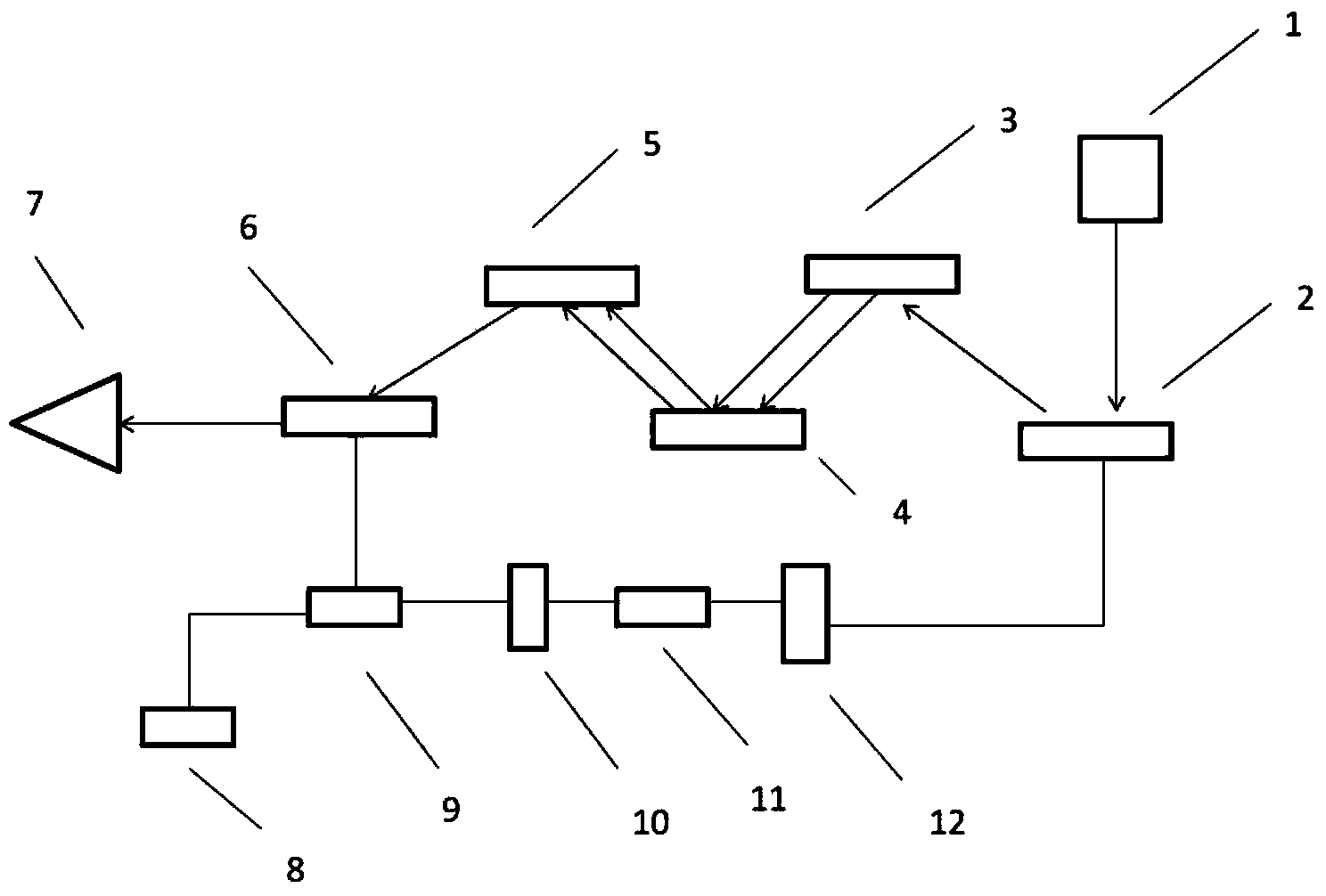

Lens device for introducing a second ion beam into a primary ion path

ActiveUS20070045531A1Multiplier electrode arrangementsSamples introduction/extractionMass Spectrometry-Mass SpectrometryIon beam

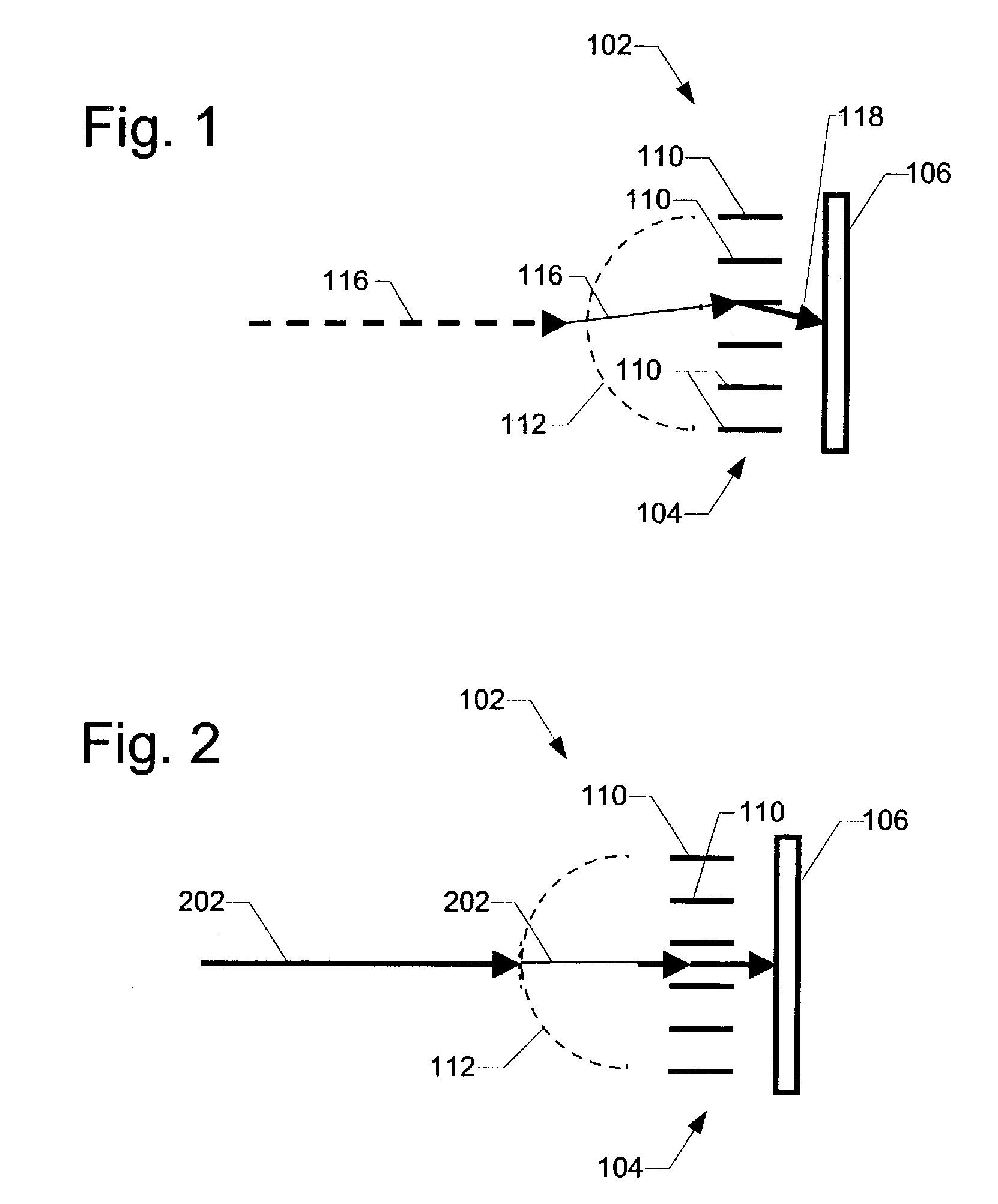

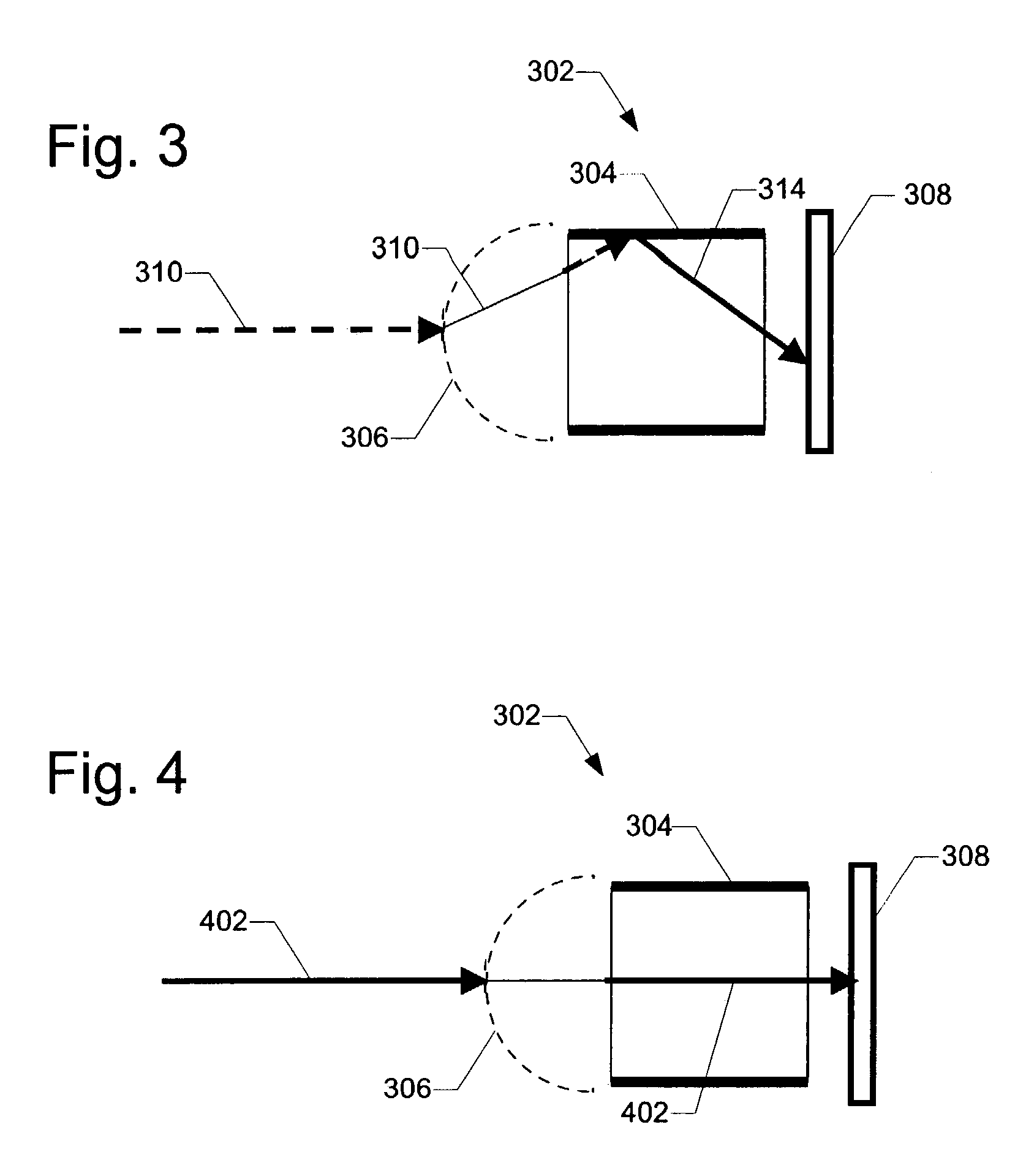

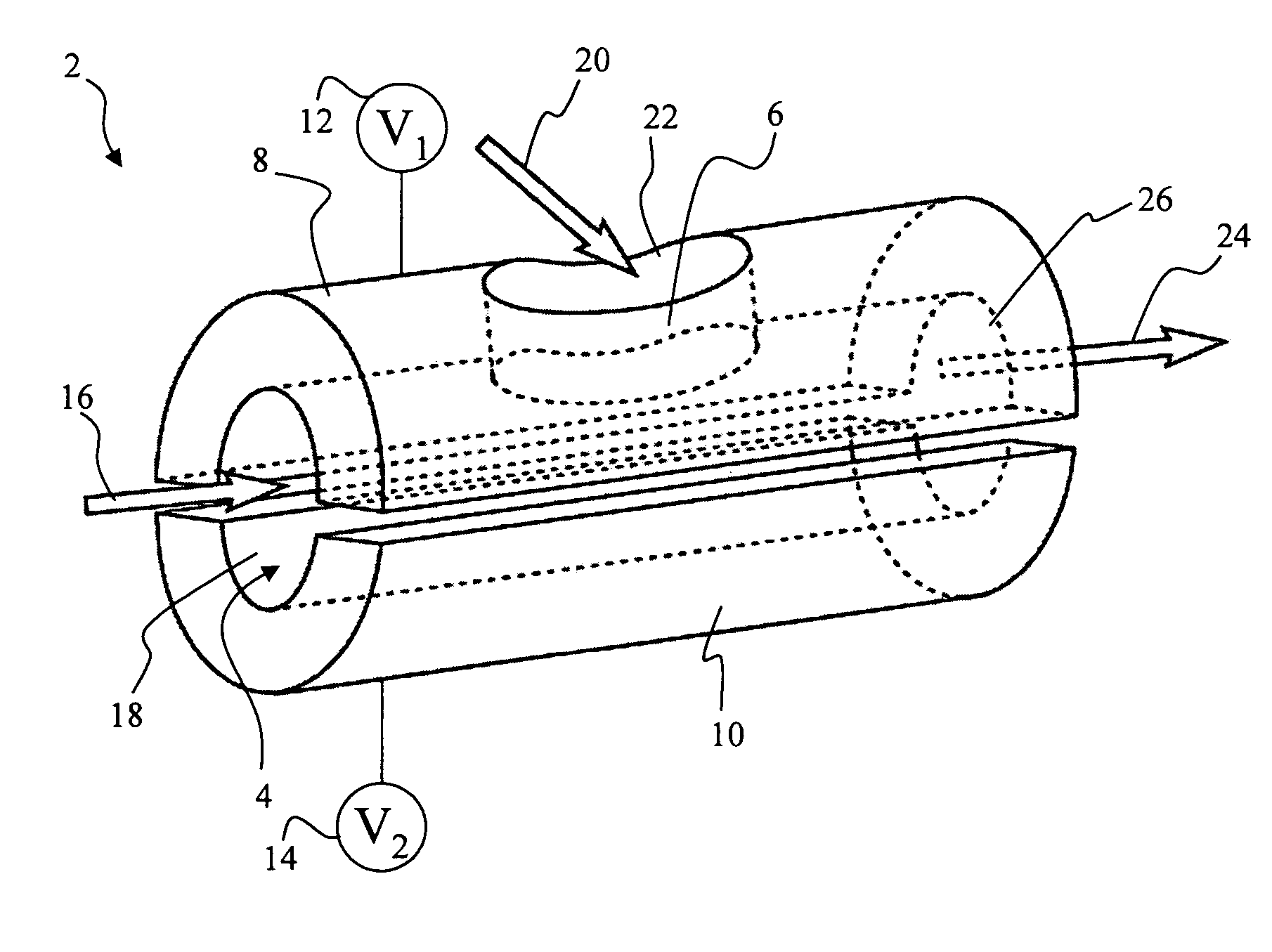

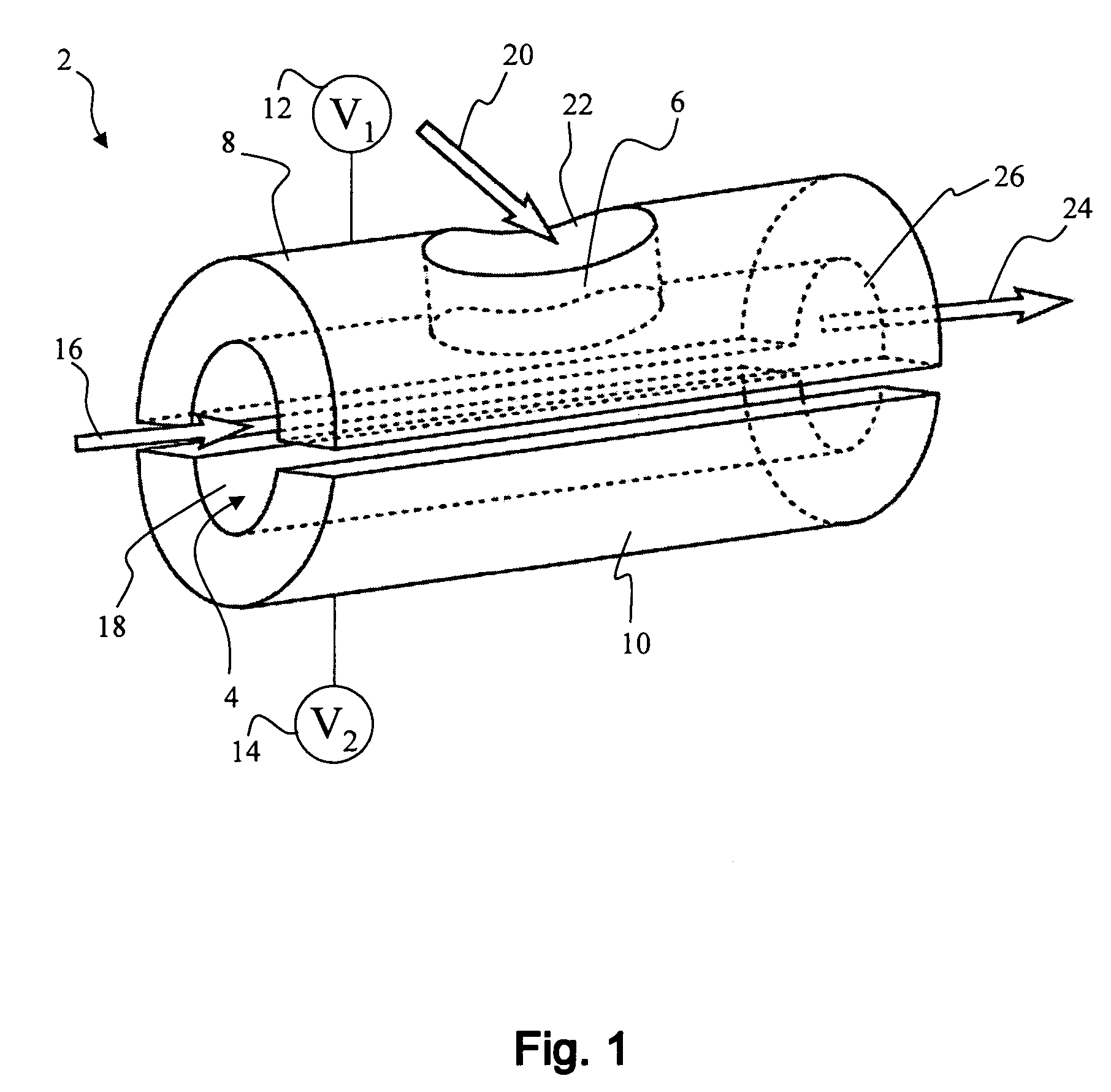

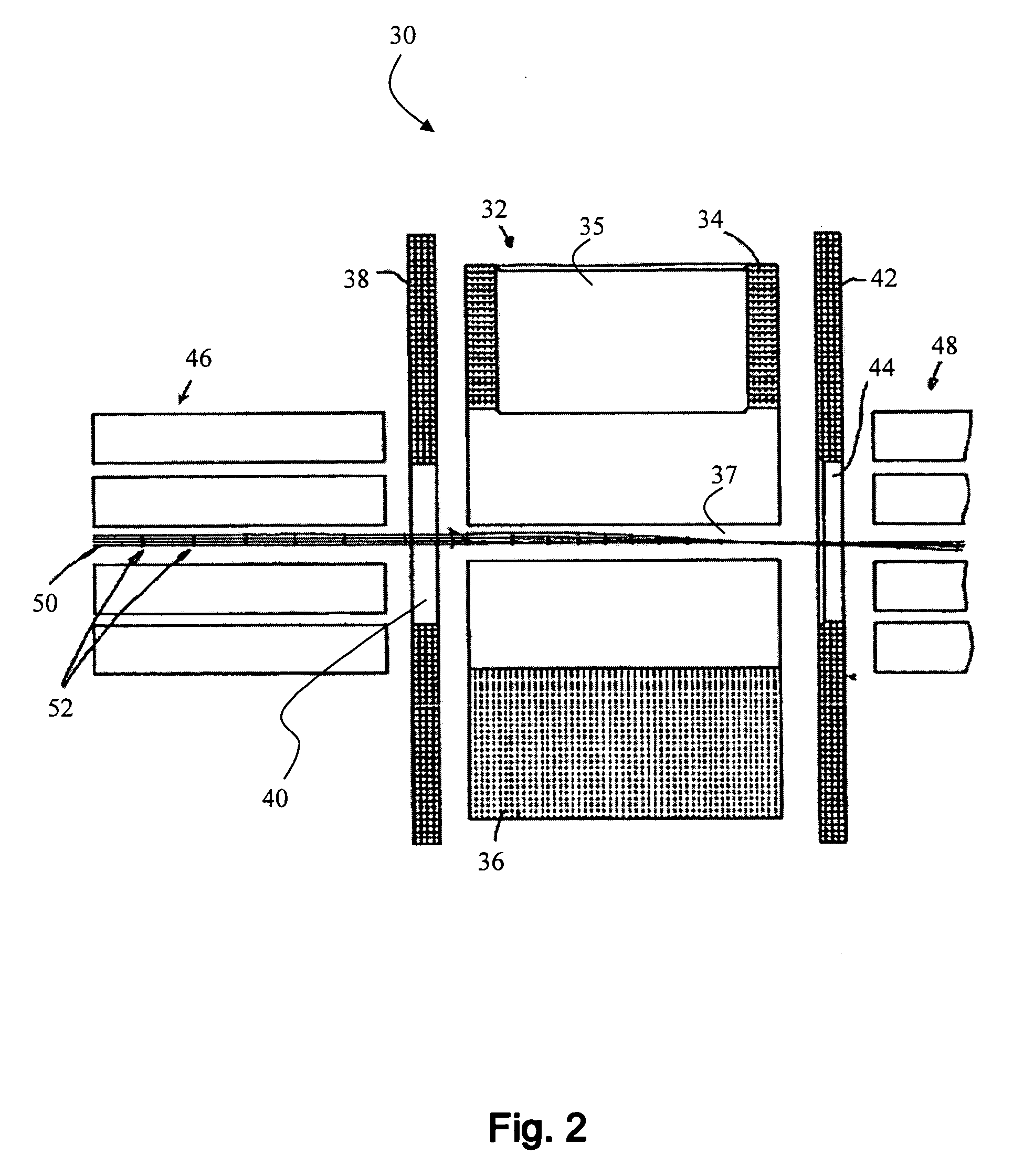

The invention provides a device for introducing ions into the primary ion path of a mass spectrometry system. In general, the device contains an electrical lens having a primary ion passageway and a secondary ion passageway that merges with the primary ion passageway. In certain embodiments, the electrical lens contains a first part and a second part that, together, form the primary ion passageway. The first part of the lens may contain the secondary ion passageway.

Owner:AGILENT TECH INC

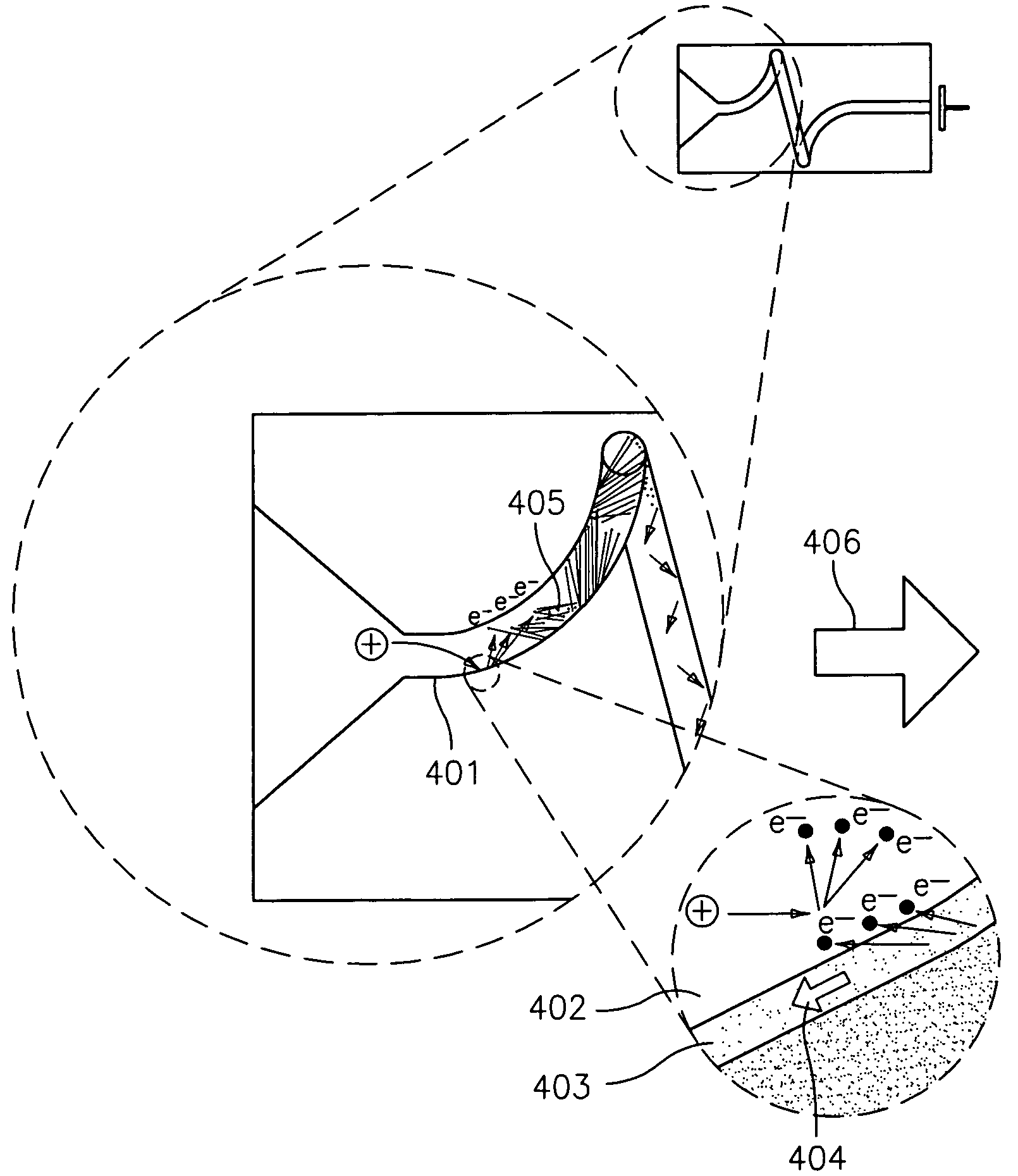

Particle detector suitable for detecting ions and electrons

InactiveUS7009187B2Easy to useThermometer detailsSpectrometer detectorsParallel plateParticle physics

A particle detector switchable from an ion detector to an electron detector includes an ion-to-electron converter and a scintillator detector. With one set of voltages on the components, the converter has minimal impact on the electron trajectories so the electrons are efficiently detected by the scintillator detector. With different voltage settings on the components, the detector can be operated in positive ion mode to collect positive ions with adequate efficiency for most FIB applications. The ion-to-electron converter is preferably in the shape of a cylinder or includes multiple parallel plates

Owner:FEI CO

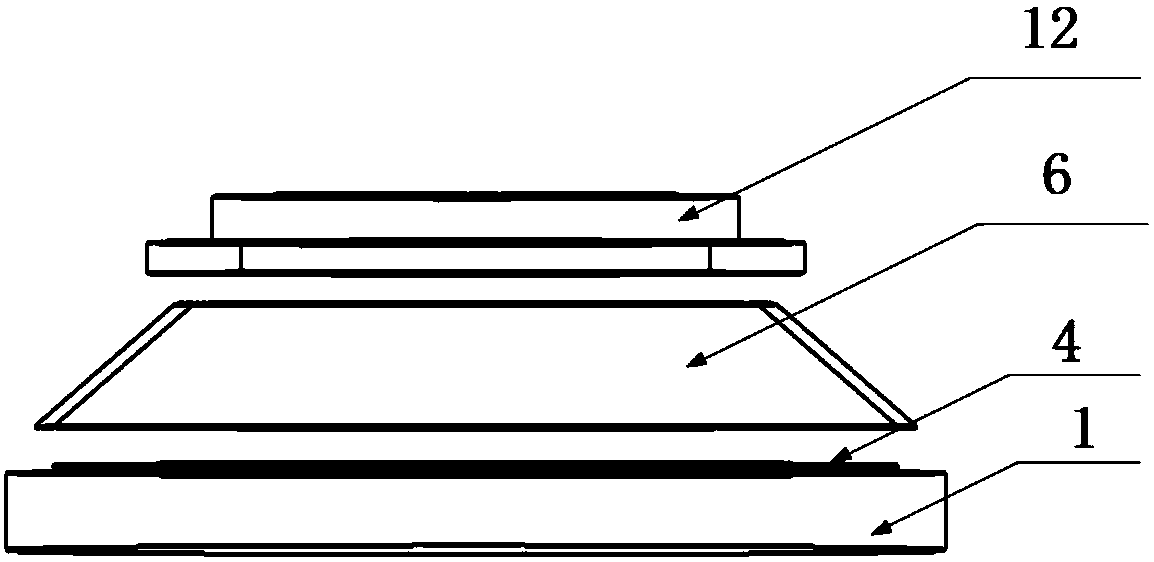

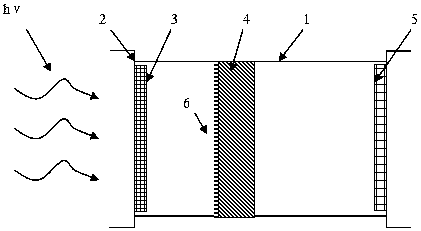

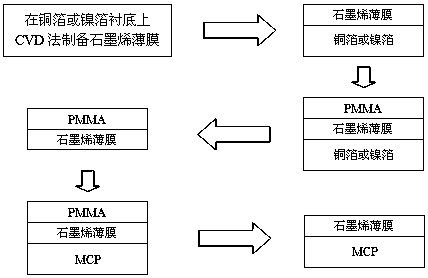

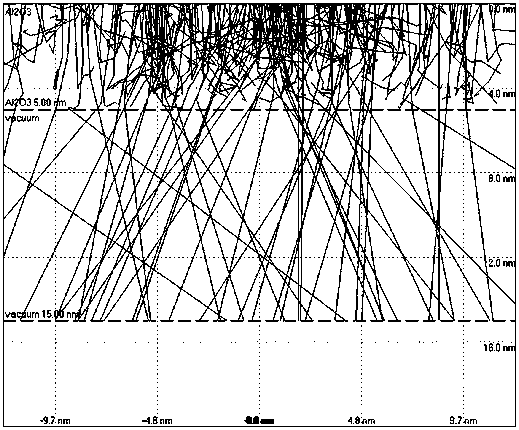

Novel micro-channel plate electrode with ion blocking function and manufacturing method thereof

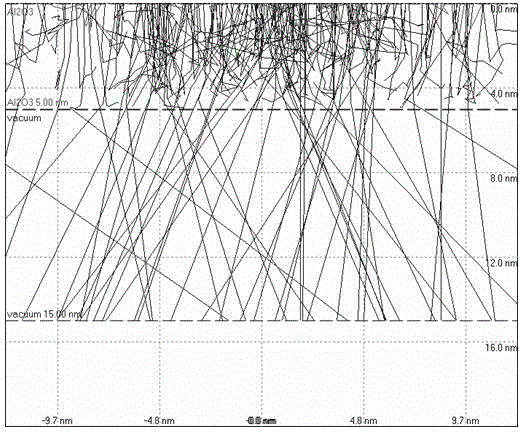

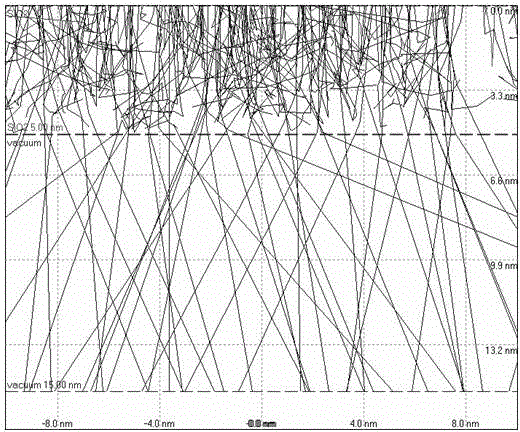

ActiveCN104465295AAct as an electrodeElectrode function hasMultiplier electrode arrangementsCold cathode manufactureScattering effectEngineering

The invention provides a novel micro-channel plate electrode with the ion blocking function. The novel micro-channel plate electrode is manufactured on the input or output face of a negative electron affinity photoelectric cathode type vacuum photoelectric detecting device and used for exerting working voltage on normal work of a micro-channel plate. A manufacturing method comprises the steps that a uniform single-layer or multi-layer graphene film high in strength and coverage is manufactured on the input or output face of the micro-channel plate in a transferring mode, and has the conventional micro-channel plate electrode effect and the ion barrier film function, and the negative electron affinity photoelectric cathode type vacuum photoelectric detecting device is mainly composed of an optical window at the front end, a photoelectric cathode on the optical window, a middle micro-channel plate, an anode at the rear end, and a sealed ceramic metal tube shell. The novel micro-channel plate electrode has the advantages that the electron penetration rate is greatly increased compared with that of the traditional structure of a nickel-chromium metal electrode and a Al2O3 or SiO2 ion barrier film, the scattering effect on electrons is reduced, the detecting efficiency of the device is improved, and the signal to noise ratio of the device is increased.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Lens device for introducing a second ion beam into a primary ion path

ActiveUS7372042B2Stability-of-path spectrometersMultiplier electrode arrangementsMass Spectrometry-Mass SpectrometryIon beam

The invention provides a device for introducing ions into the primary ion path of a mass spectrometry system. In general, the device contains an electrical lens having a primary ion passageway and a secondary ion passageway that merges with the primary ion passageway. In certain embodiments, the electrical lens contains a first part and a second part that, together, form the primary ion passageway. The first part of the lens may contain the secondary ion passageway.

Owner:AGILENT TECH INC

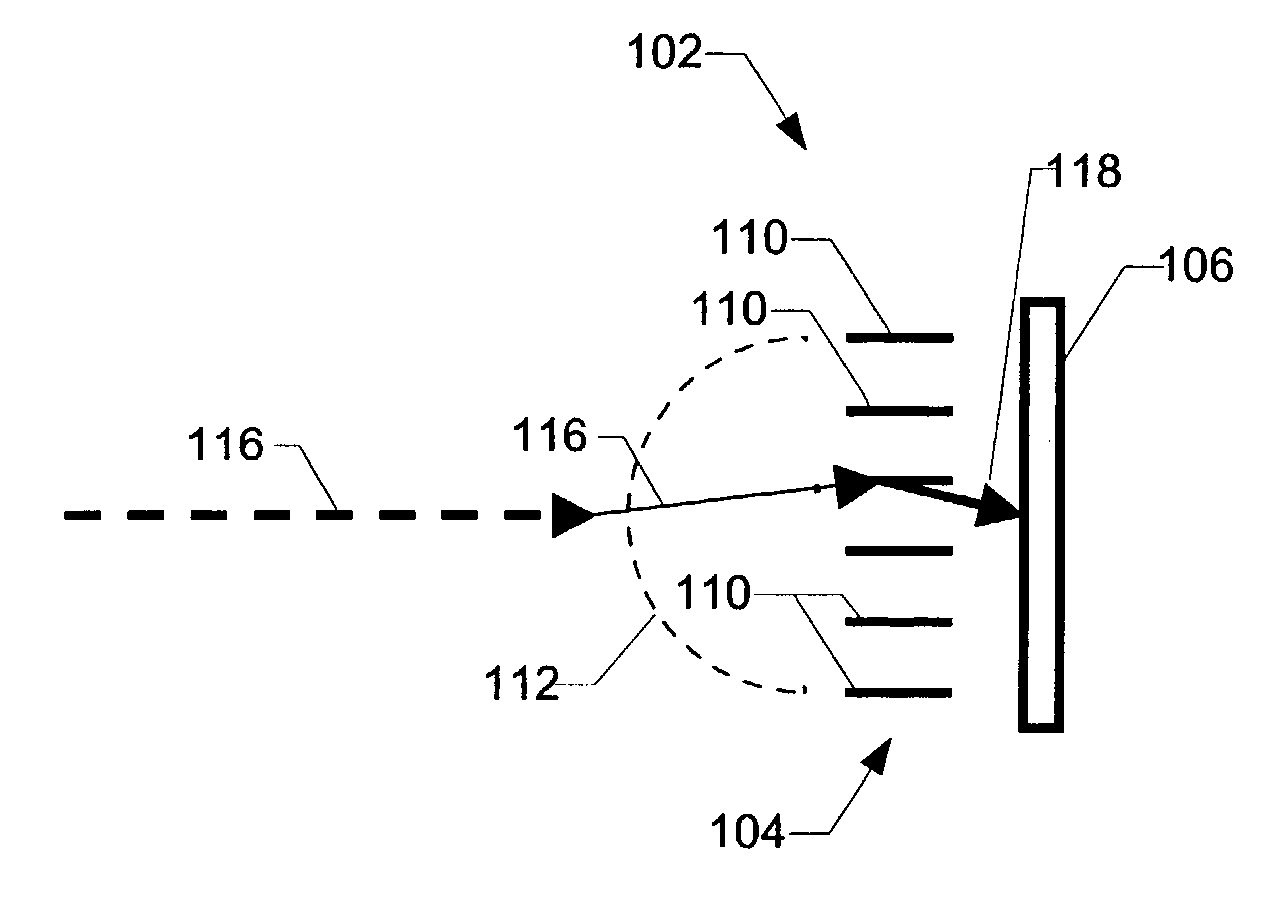

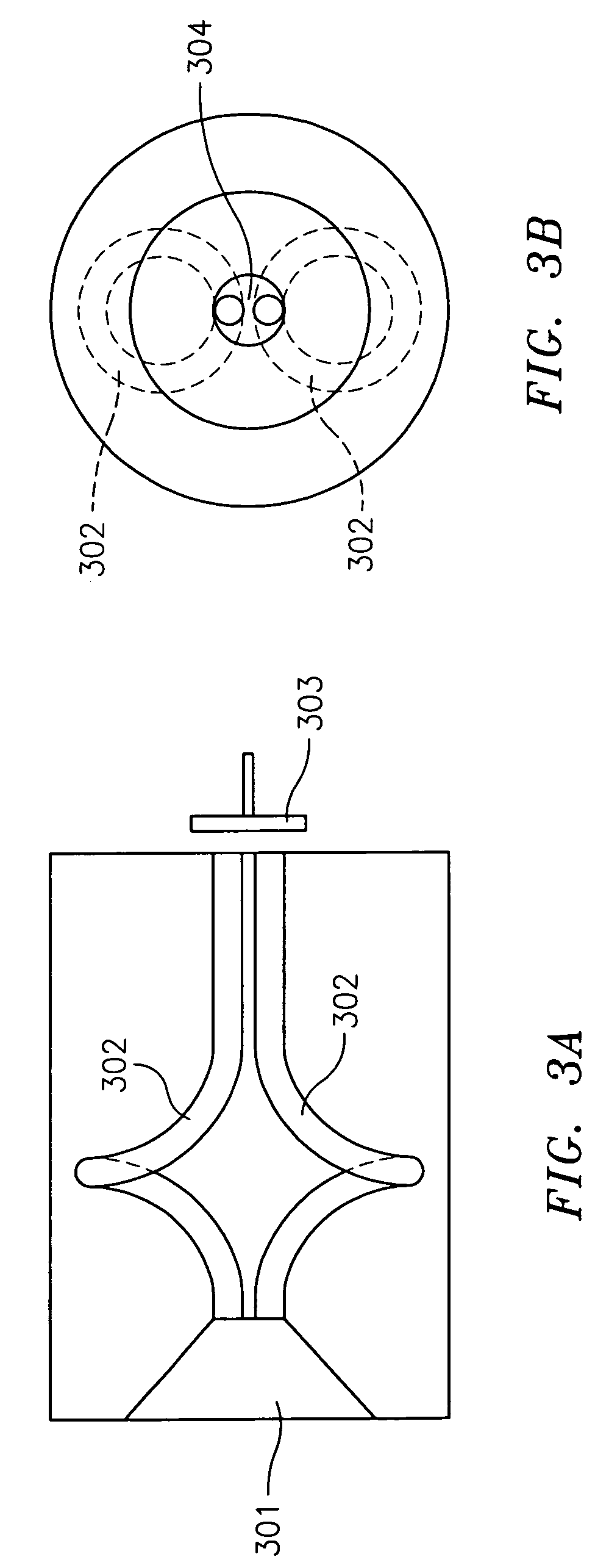

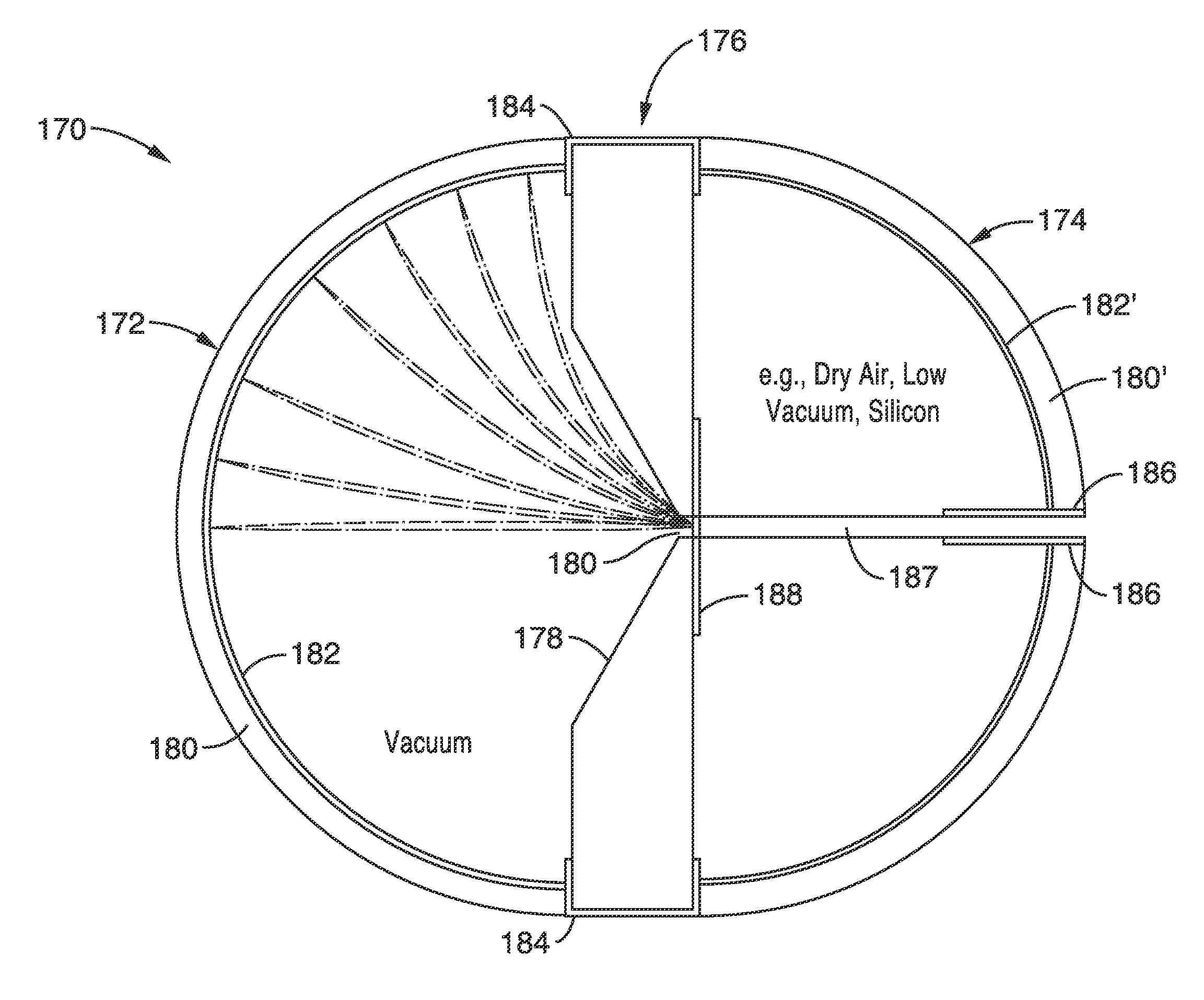

Vacuum photosensor device with electron lensing

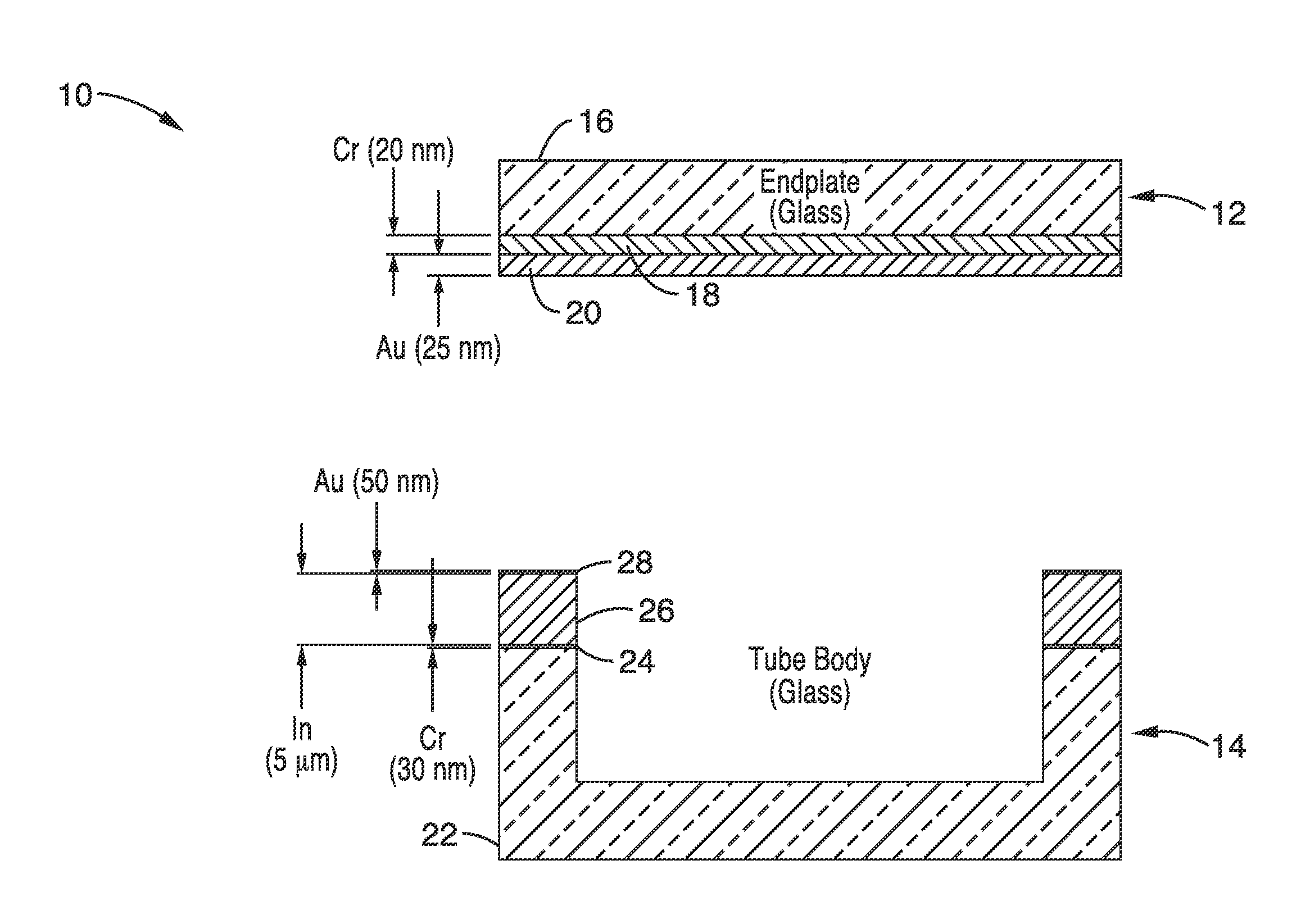

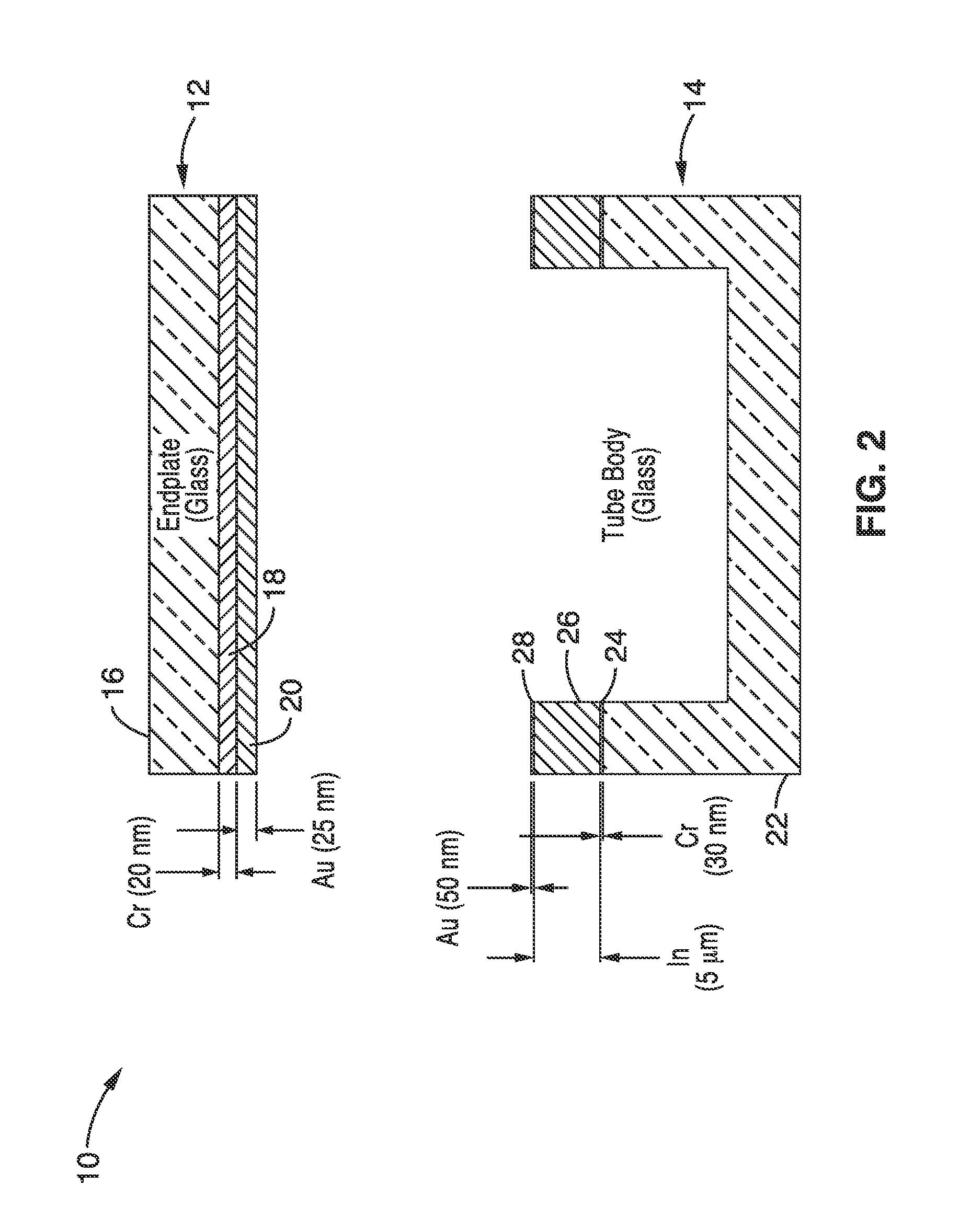

ActiveUS20130112856A1Lower levelScalable mass productionMultiplier electrode arrangementsBeam/ray focussing/reflecting arrangementsPhotocathodeEngineering

A scalable vacuum photosensor configured to simplify mass production with a housing having an evacuated first side at an ultrahigh vacuum and a second side which does not require high vacuum. The first side of the device is sealed to a base plate, having a central electron readout element, using an oxide-free sealing technique, with the deposited sealing areas serving as high voltage throughputs from the first to second sides. A conductive photocathode layer on the transparent first side converts photons to photoelectrons and concentrates the photoelectrons upon the readout. The first and second sides together form an electrostatic lens for accelerating and focusing photoelectrons upon the readout, preferably having a scintillator which generates secondary light measured by an optical detector in the second side of the housing.

Owner:RGT UNIV OF CALIFORNIA

Silicate skin glass, micro-pore optics and preparation method thereof

ActiveCN106630596AHigh tensile strengthSmall coefficient of thermal expansionMultiplier electrode arrangementsCathode ray concentrating/focusing/directingMedicineThermal expansion

The present invention relates to silicate skin glass, micro-pore optics and a preparation method thereof. The silicate skin glass is composed of the following components in molar percentages: 60-80% of SiO<2>, 5-20% of Bi<2>O<3>, 0.1-3.5% of Al<2>O<3>, 0.1-10% of a total content of Na<2>O, K<2>O and Cs<2>O, and 3-15% of a total content of MgO, BaO and CaO. The micro-pore optics are prepared from the silicate skin glass. The silicate skin glass is used to prepare the micro-pore optics and improves the tensile strength of the micro-pore optics, so that the micro-pore optics have the tensile strength greater than 65 MPa. A thermal expansion coefficient of the silicate skin glass is small, which solves the problems that the microporous micro-pore optics are deformed and broken, and the thermal expansion coefficient of the micro-pore optics at 20 DEG C to 300 DEG C is 60x10^7-90x10^7 / DEG C.

Owner:CHINA BUILDING MATERIALS ACAD

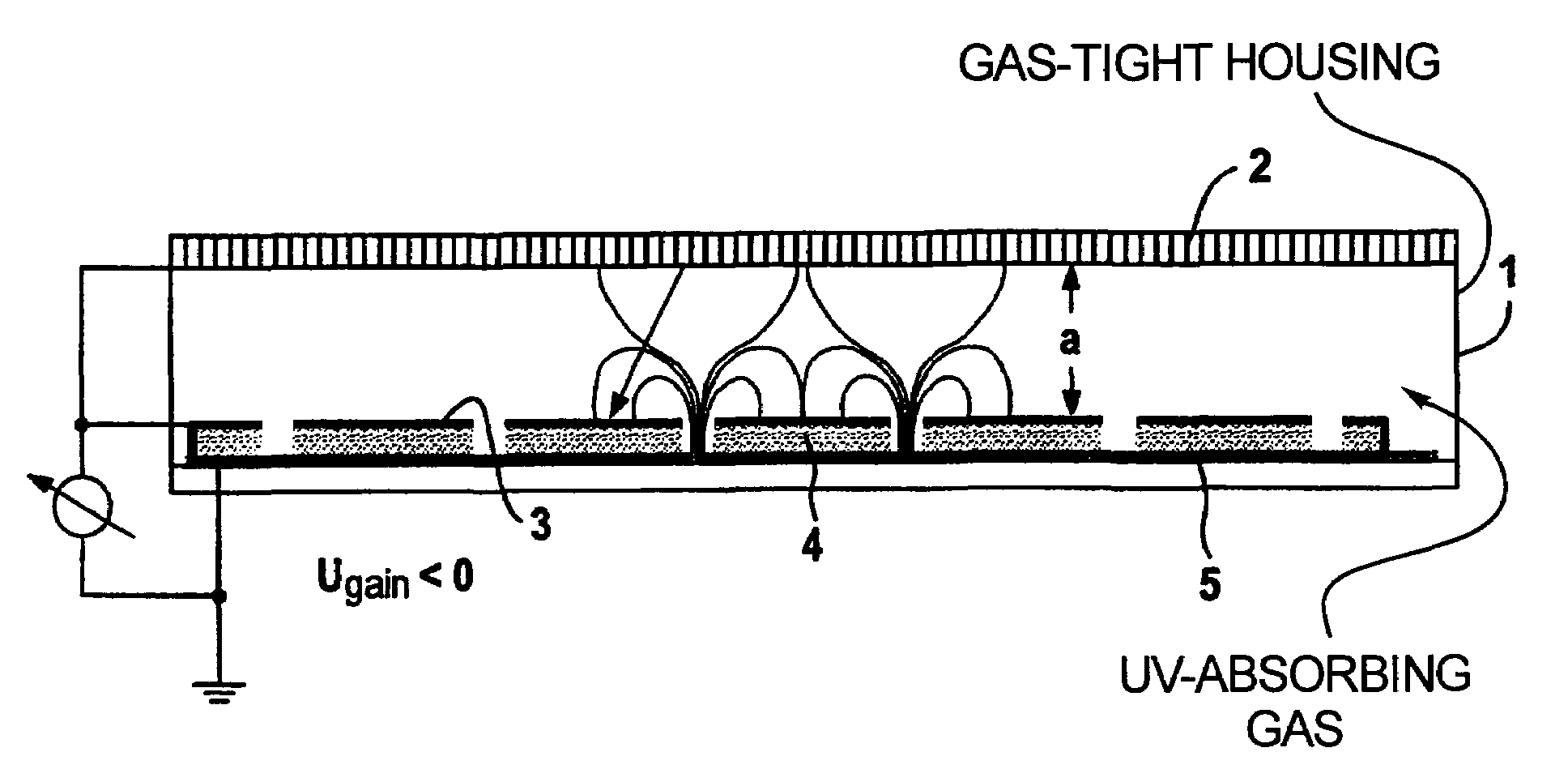

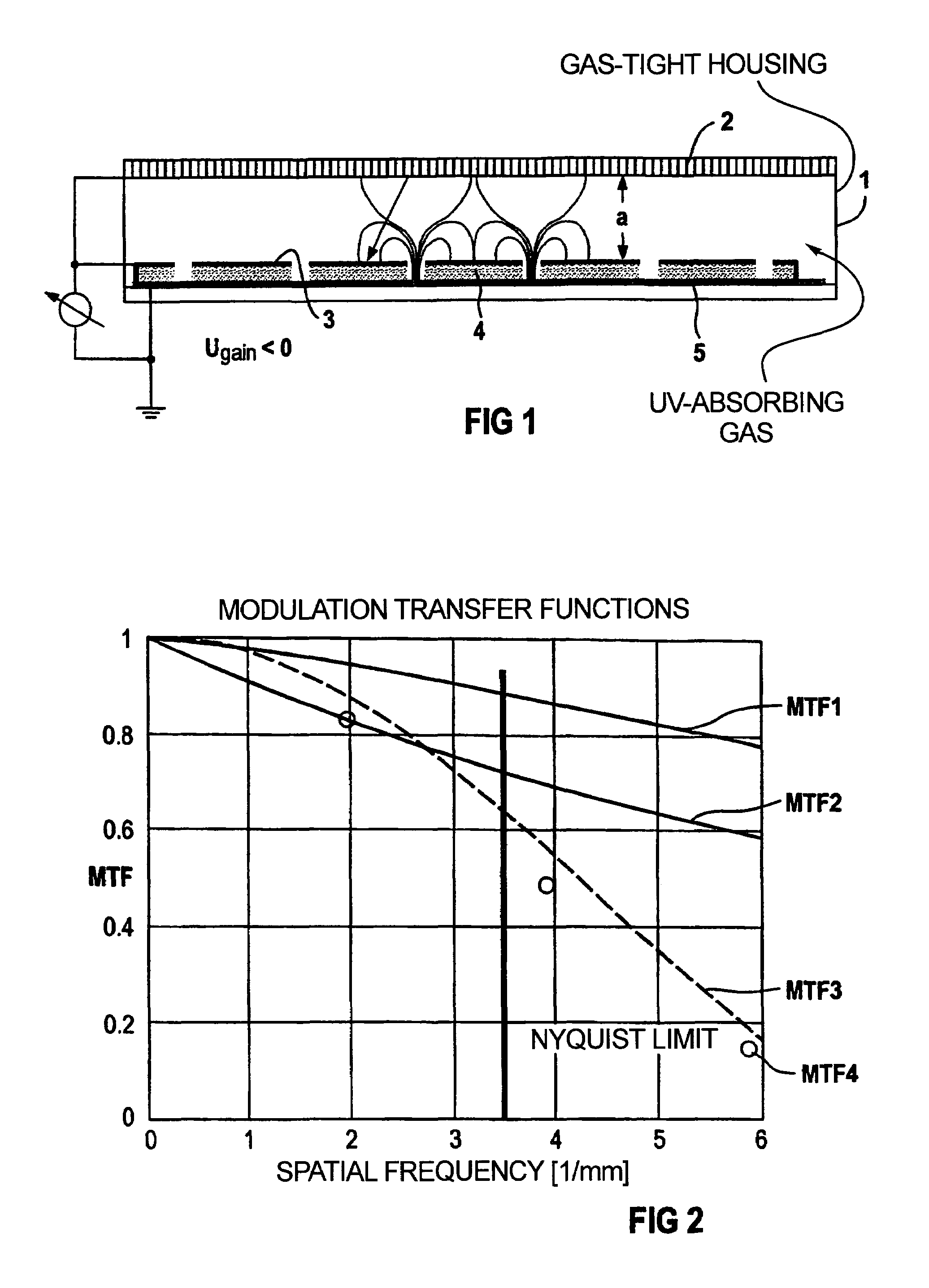

Radiation converter

InactiveUS7022994B2Improve dynamic rangeEasy to useTelevision system detailsX-ray/infra-red processesPhotocathodeX-ray

A radiation converter has a radiation absorber for generating photons dependent on the intensity of incident x-ray radiation, a photocathode arranged downstream of the radiation absorber in the radiation propagation direction at a distance therefrom and serving for generating electrons dependent on the photons emerging from the radiation absorber, a device for accelerating the electrons emerging from the photocathode onto an electron detector for generating electrical signals dependent on the impinging electrons, an electron multiplier arranged between the photocathode and the electron detector, the electrons emerging from the photocathode being multiplied by the electron multiplier.

Owner:SIEMENS AG

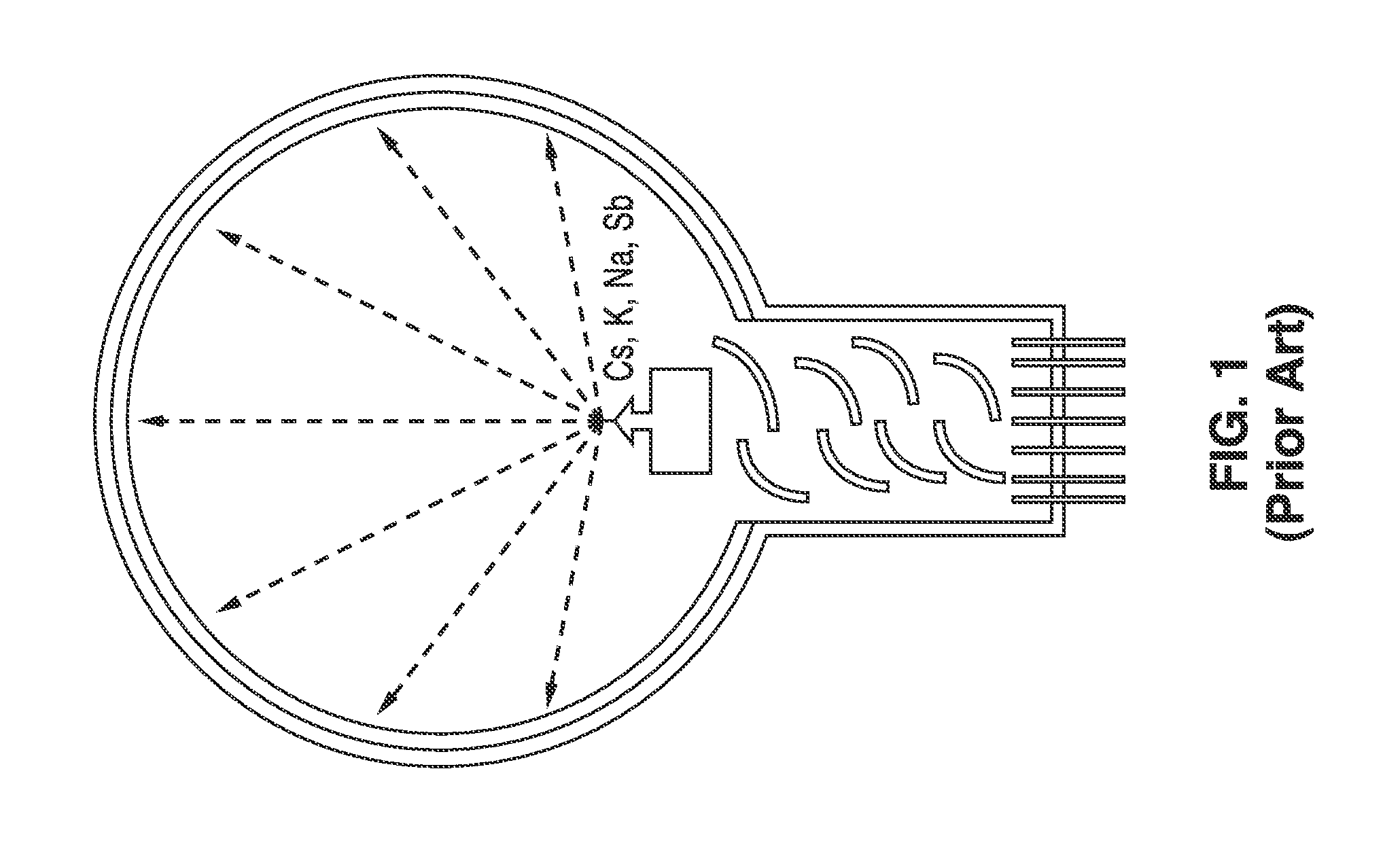

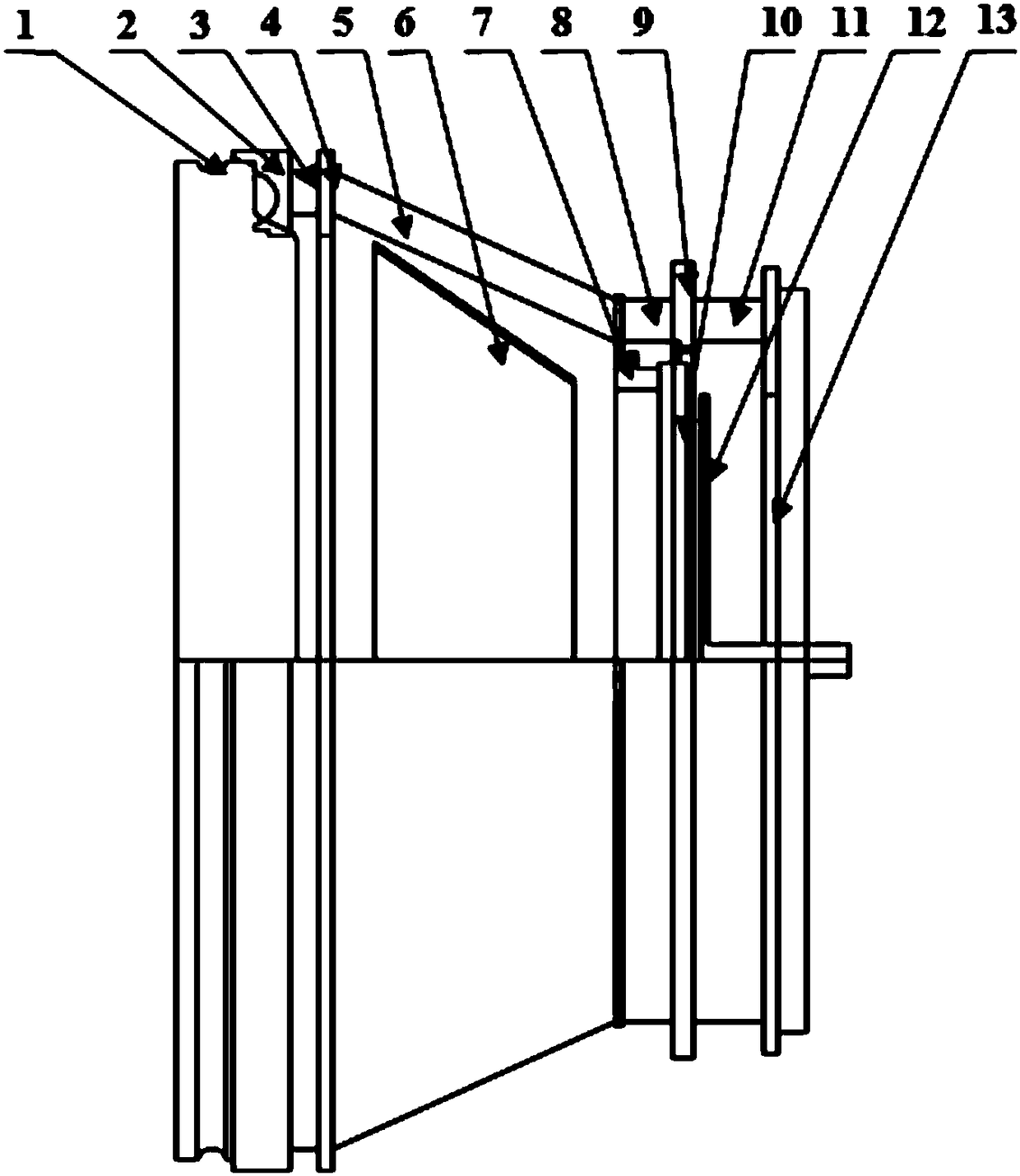

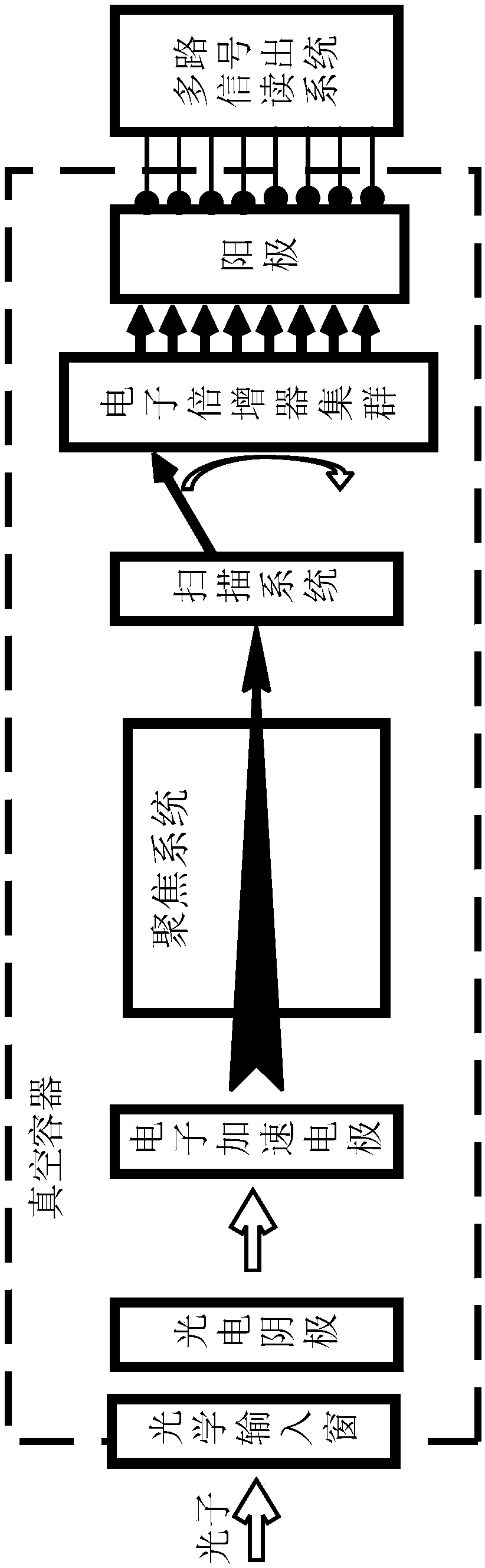

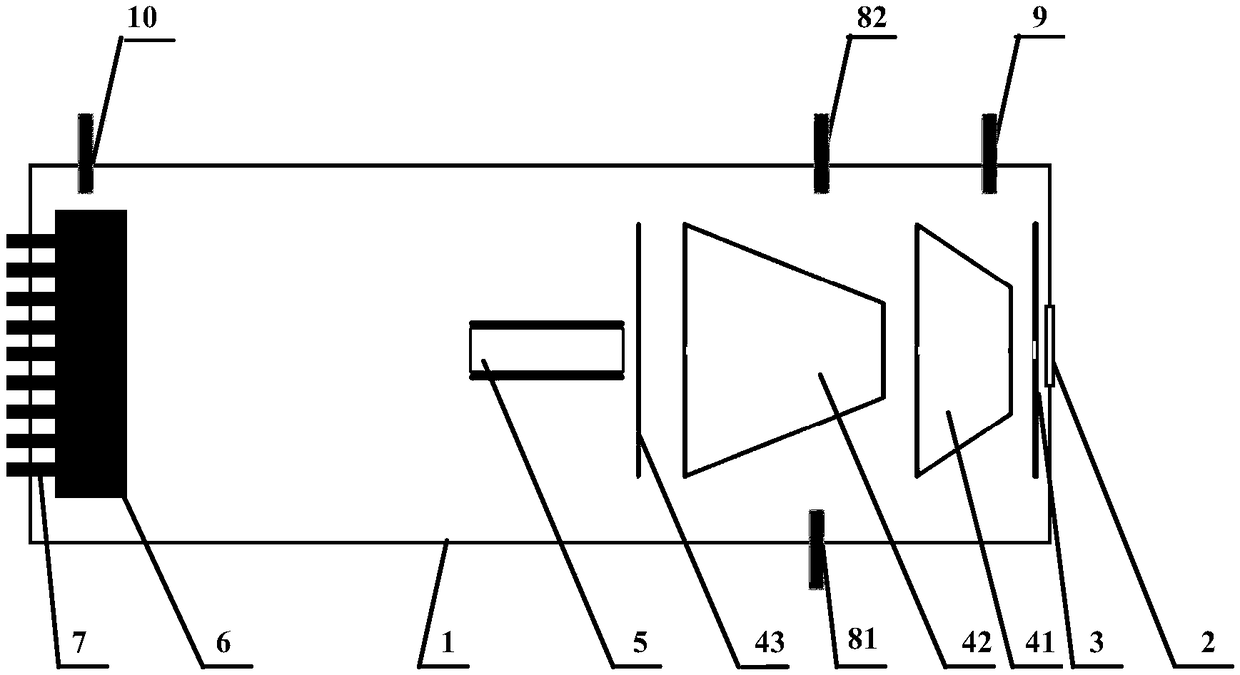

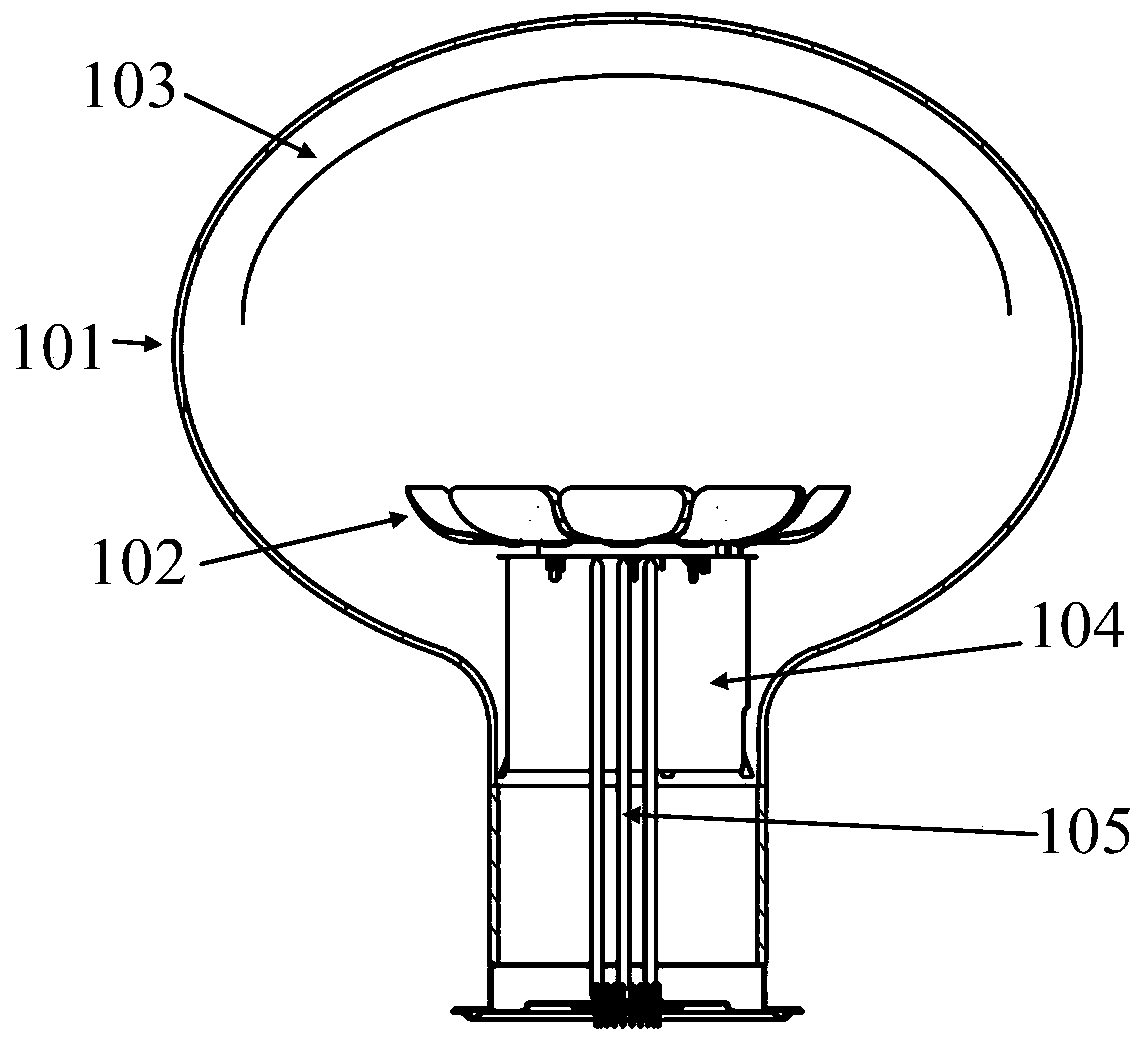

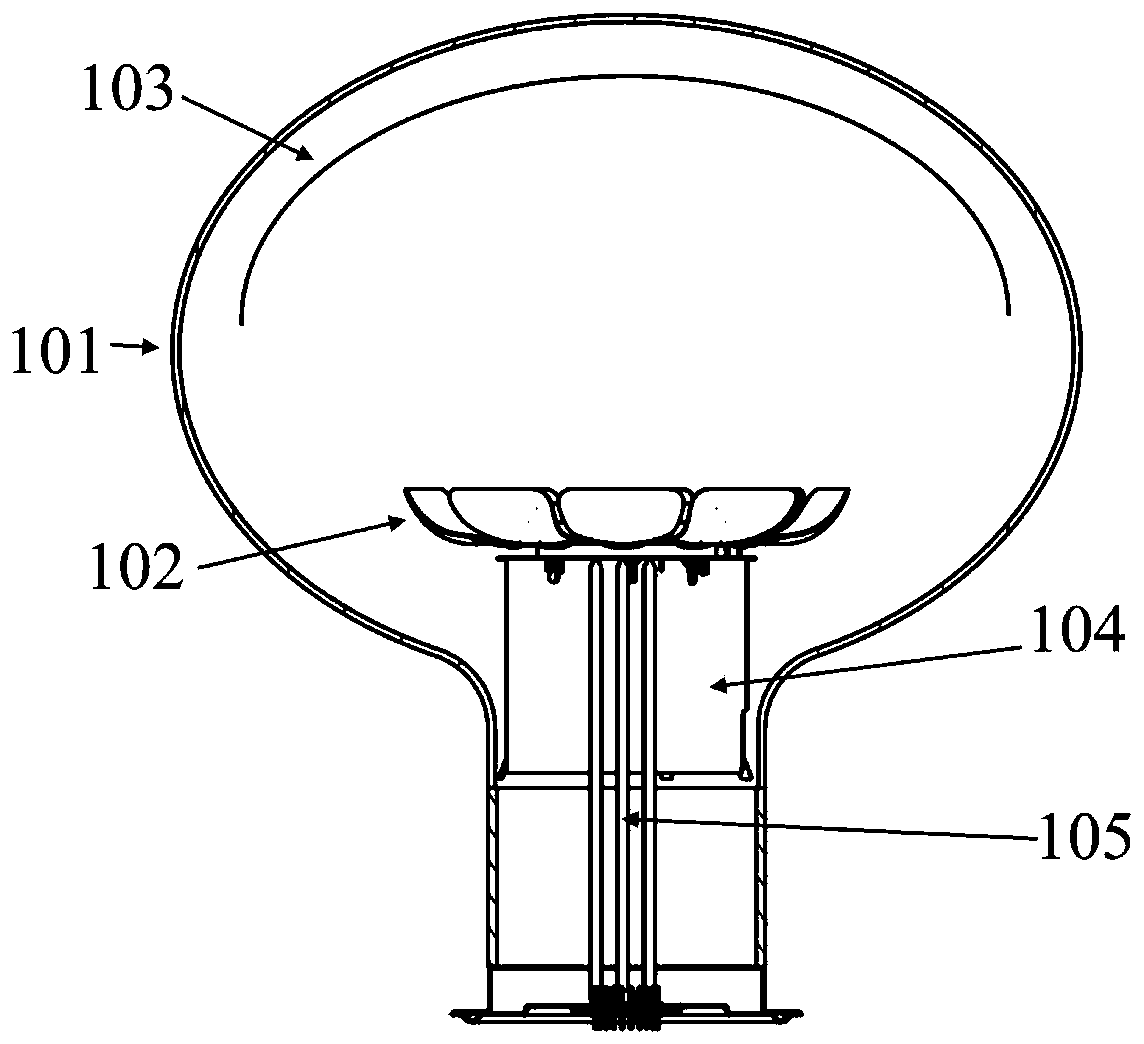

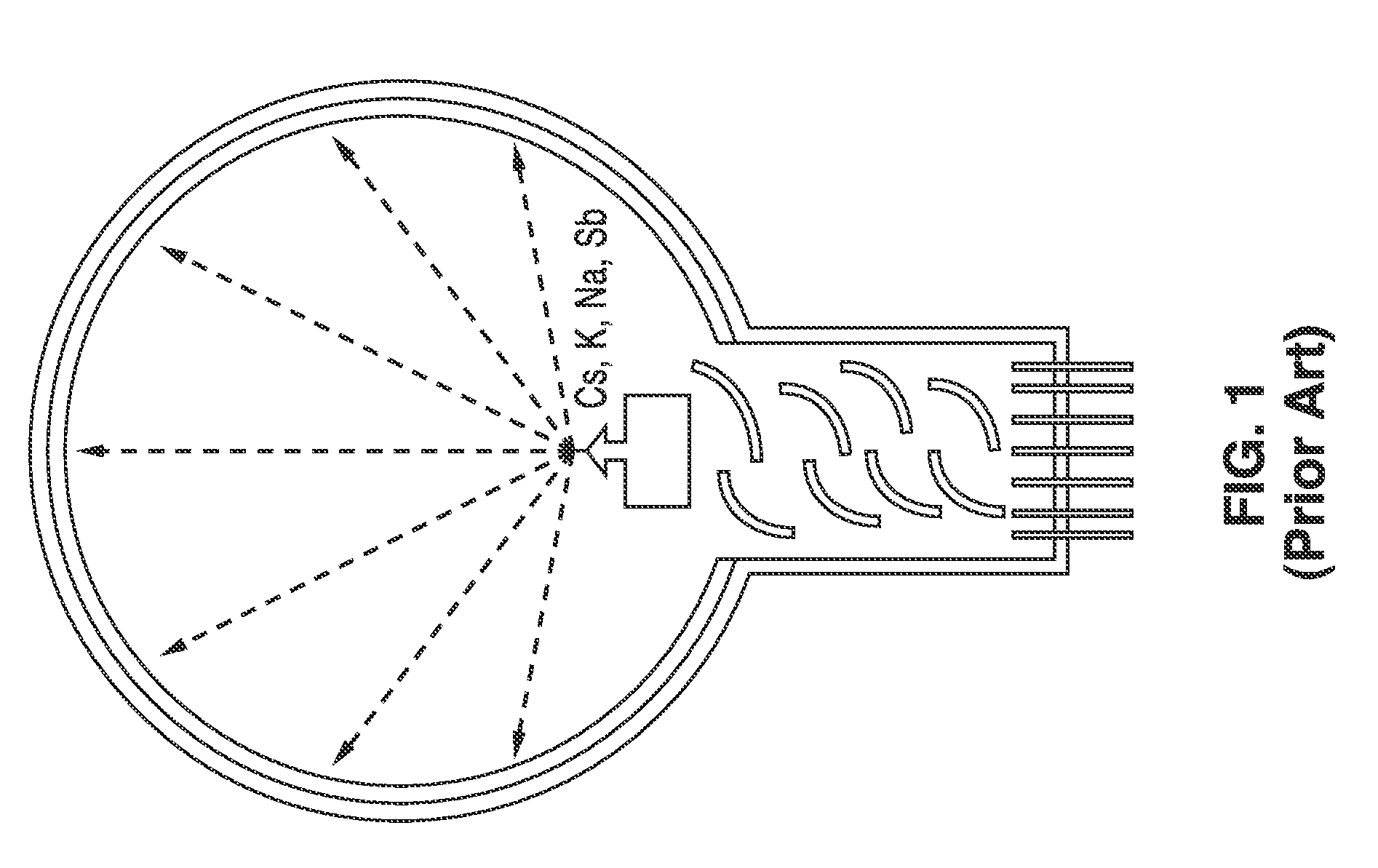

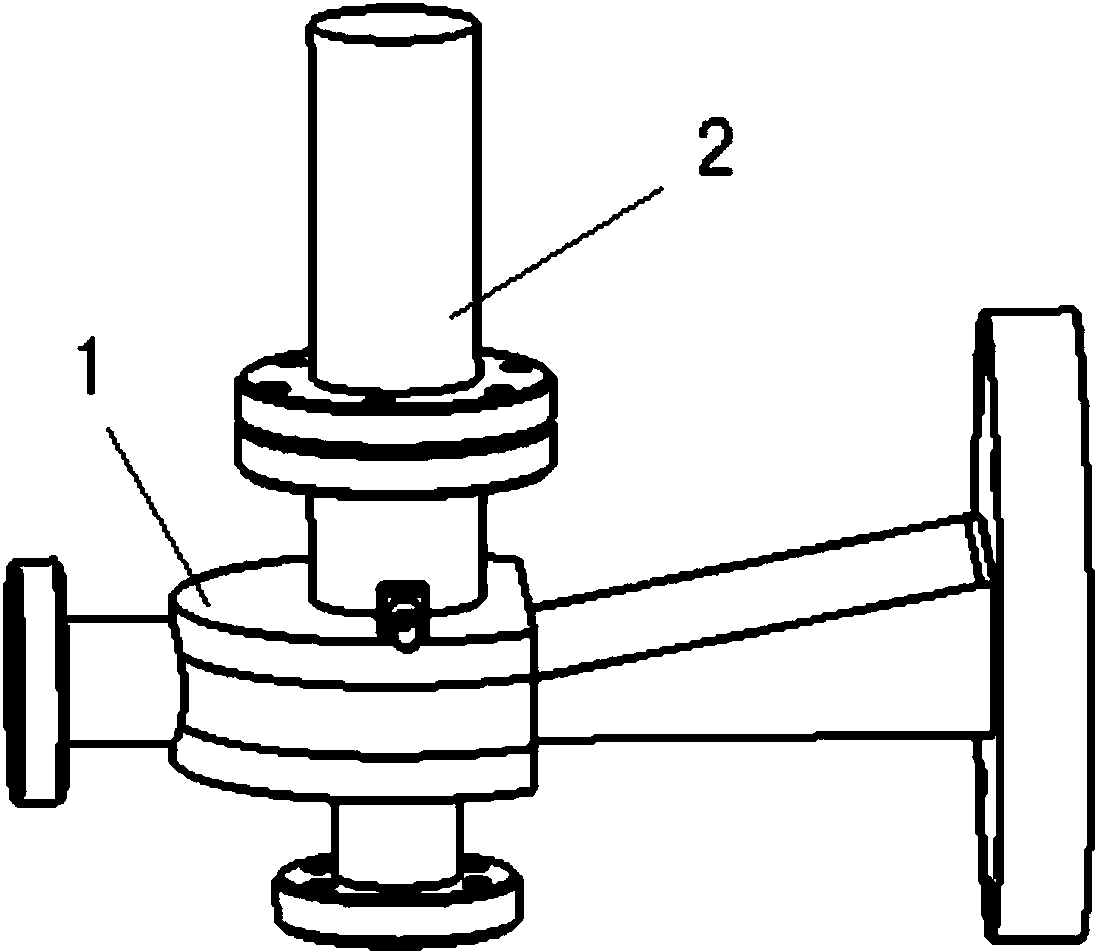

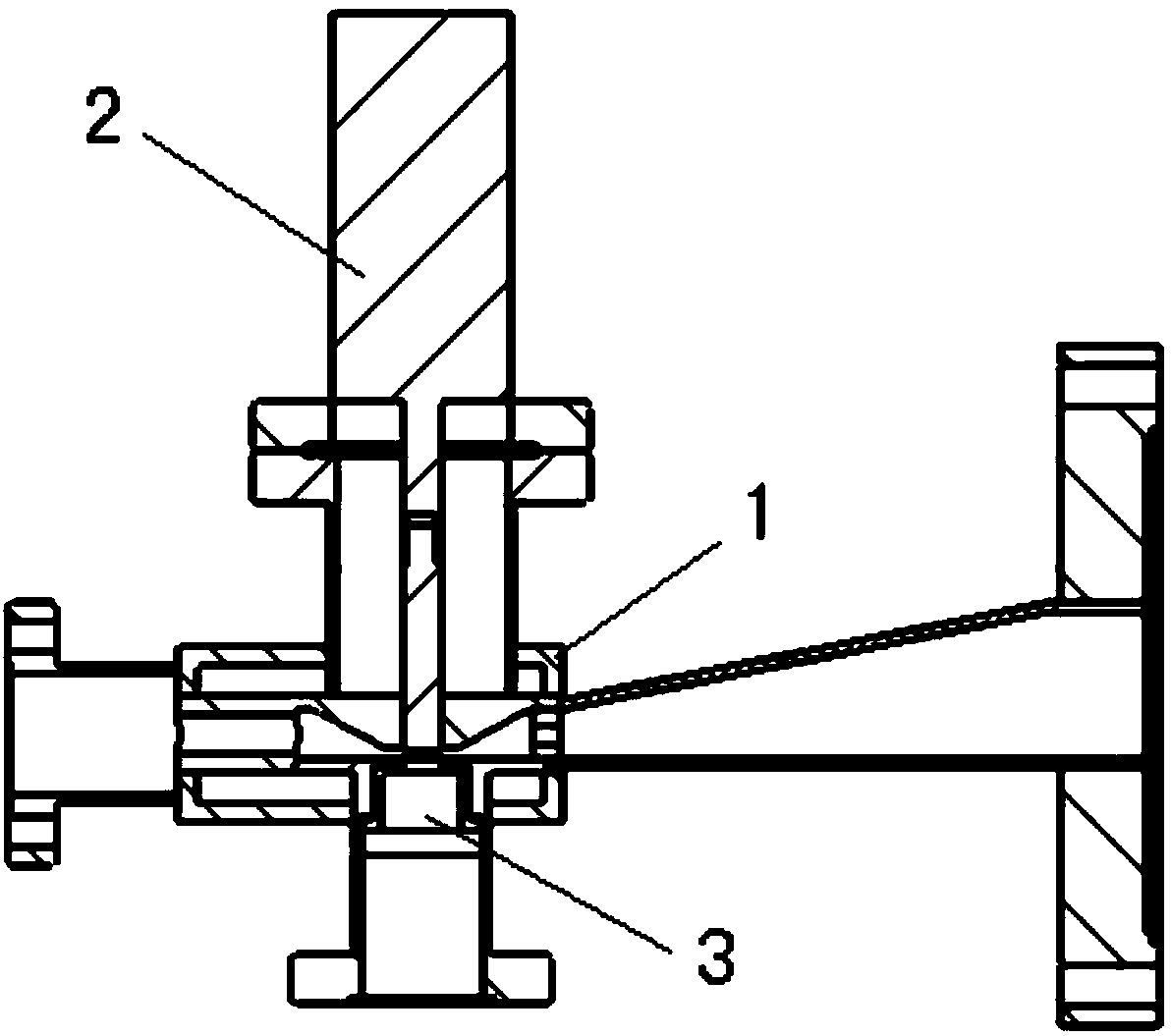

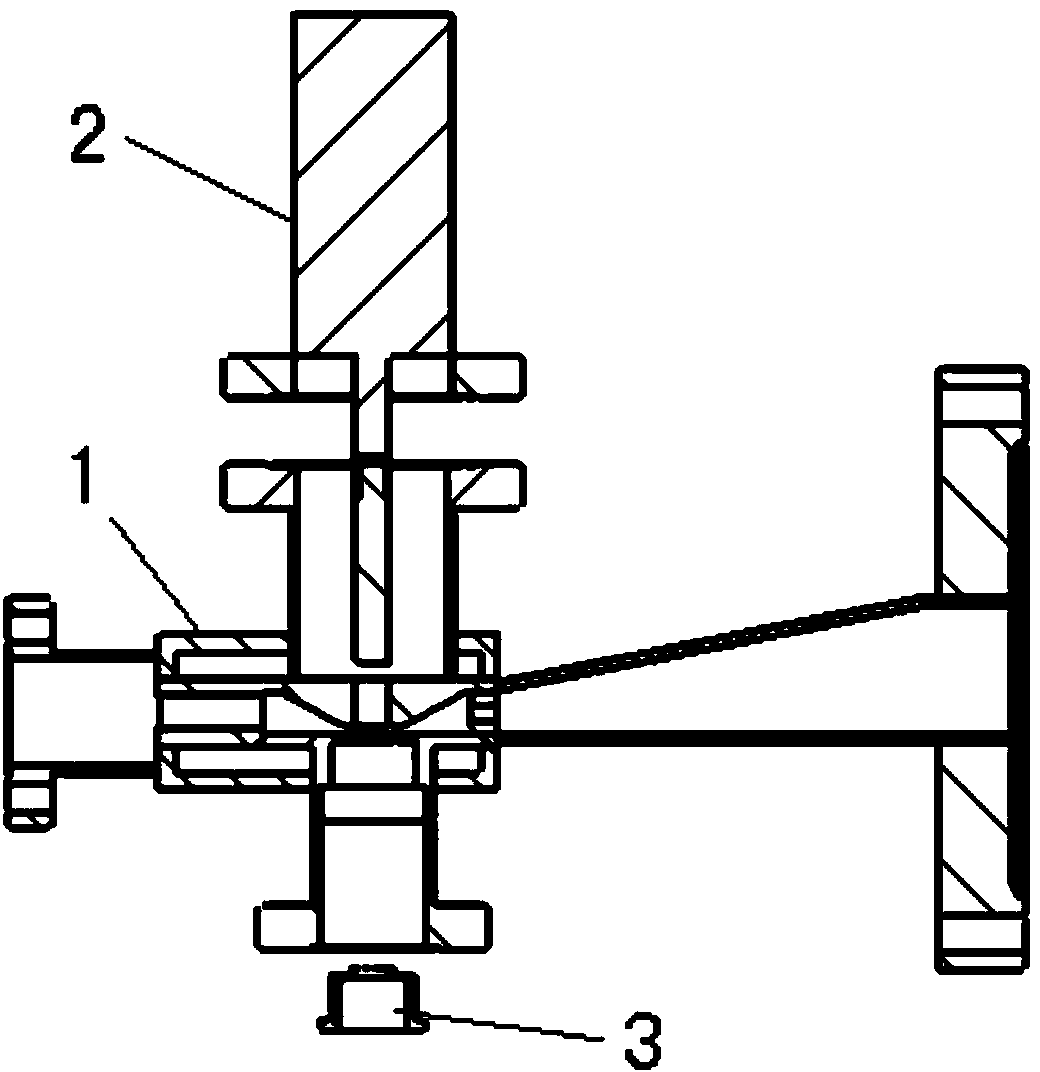

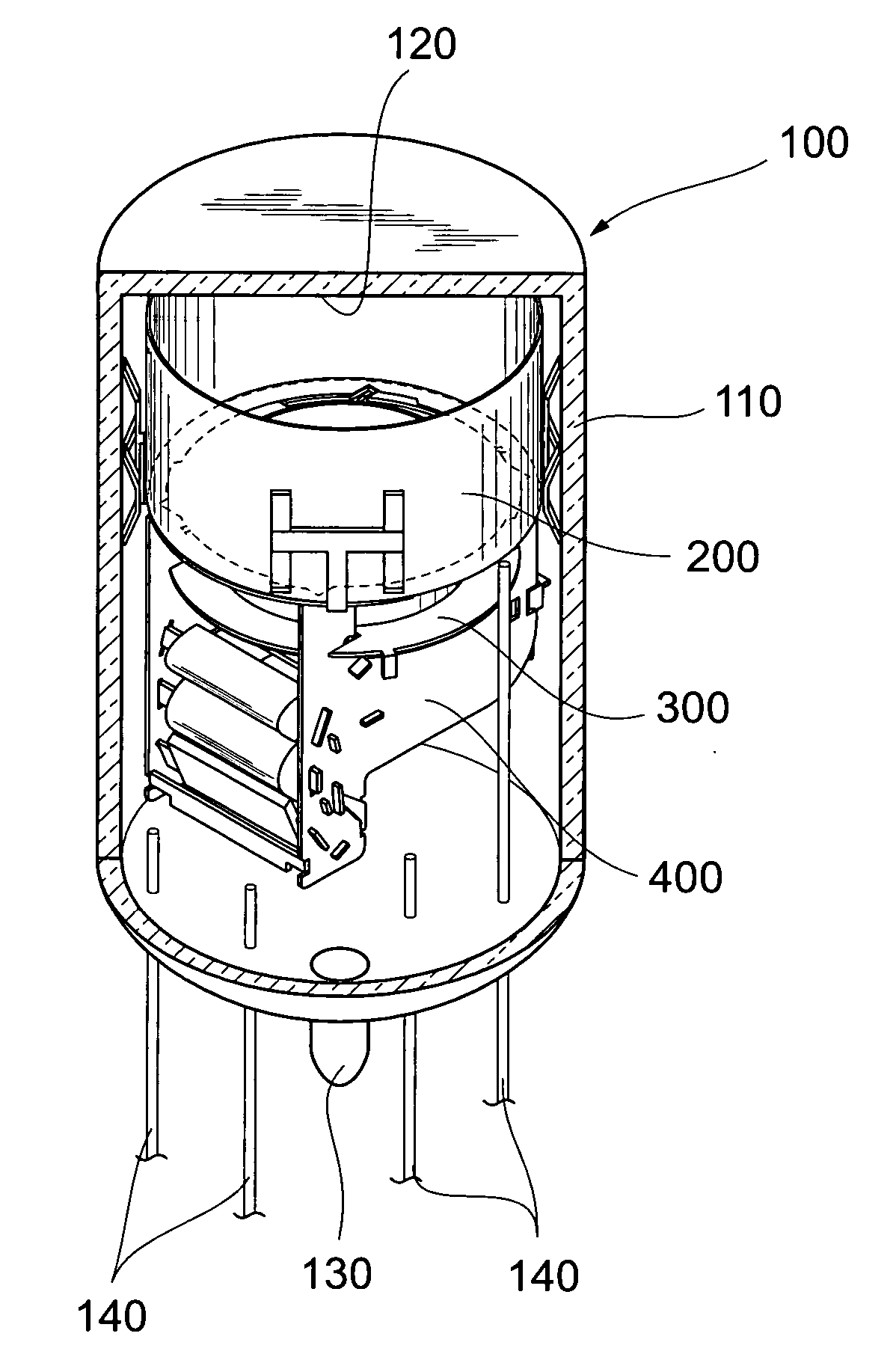

Gating focus type photomultiplier tube

PendingCN108257844AWith strobe functionWith electronic focus functionMultiplier electrode arrangementsPhotovoltaic detectorsPhotocathode

The invention belongs to the technical field of photoelectric detection devices, and particularly relates to a gating focus type photomultiplier tube. The structure of the gating focus type photomultiplier tube comprises a vacuum container, one end of the vacuum container is provided with an input window, the inner surface of the input window is provided with a negative pole, and the other end ofthe vacuum container is provided with a positive pole; a gate electrode, a focusing electrode and an electron multiplier are arranged between the negative electrode and the positive electrode in turn.The gating focus type photomultiplier tube solves the technical problem that the effective detection area of an existing photoelectric detection device is limited. The gating focus type photomultiplier tube is a photomultiplier tube not only provided with a gating function and but also provided with an electronic focusing function. The gating focus type photomultiplier tube has the advantages that the magnifying power focusing function enables the electrons emitted by a large-area photocathode to be sent onto the electron collecting surface of a small-sized electron multiplier, thereby increasing the detection area of the photomultiplier tube.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

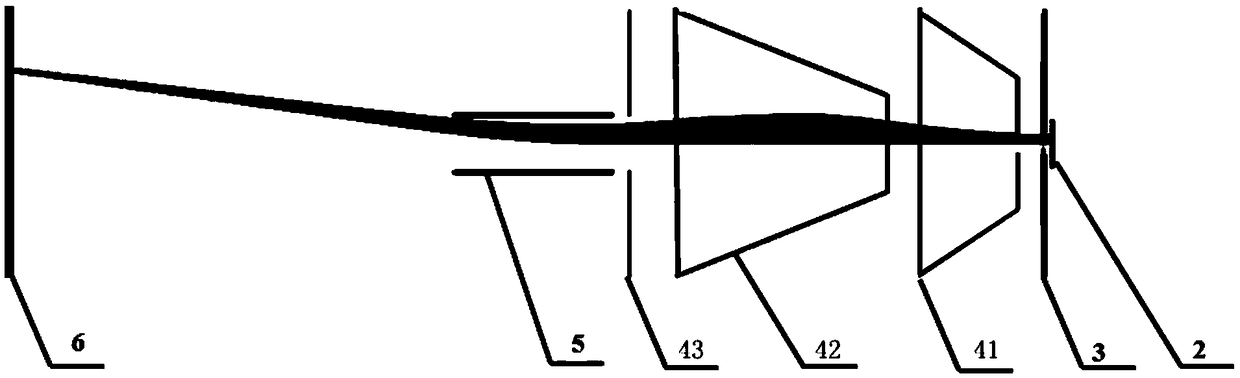

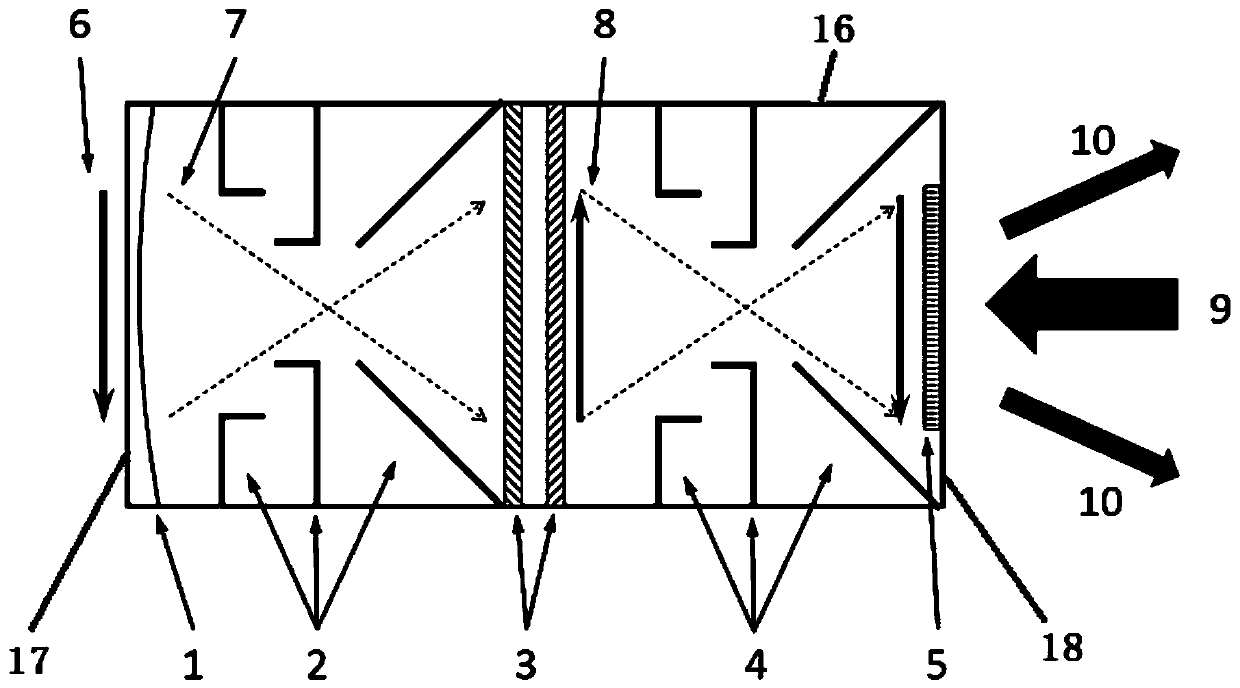

A focusing scanning type photomultiplier tube

PendingCN109065434AHigh sampling frequencyEnough outputMultiplier electrode arrangementsElectron multiplicationPhotomultiplier

In order to solve the technical problem of low detection accuracy of lidar, A focusing-scanning type photomultiplier tube By providing a focusing system in a vacuum vessel of the photomultiplier tube,The scanning system and the electron multiplier cluster located at the focal point of the focusing system enable different electron multiplier regions to receive the signal electrons to be multipliedand output according to the time sequence, so that the same electron multiplier region has enough electron multiplication, electronic output and performance recovery time; Because the number of the electron multiplier cluster is tens or hundreds, the sampling frequency of the photomultiplier tube can be increased by tens or hundreds of times, and can be raised to the order of tens of GHz when theelectron multiplier cluster is effectively utilized.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

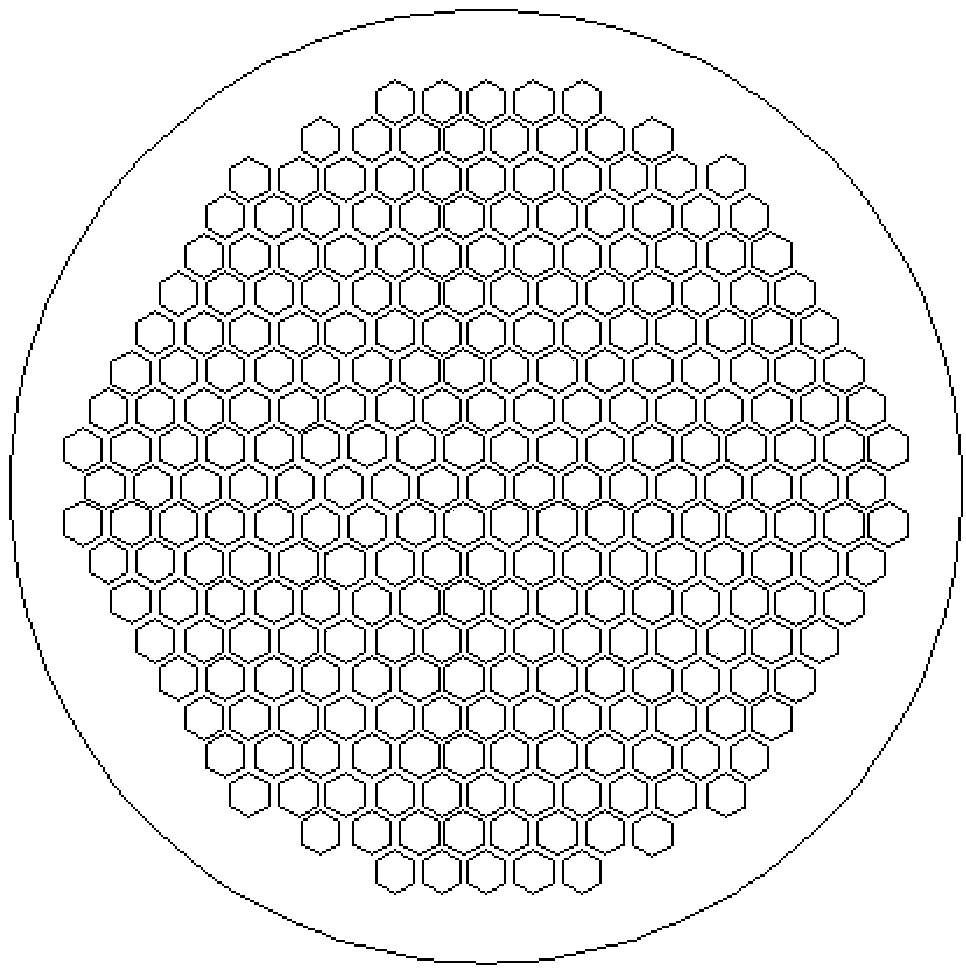

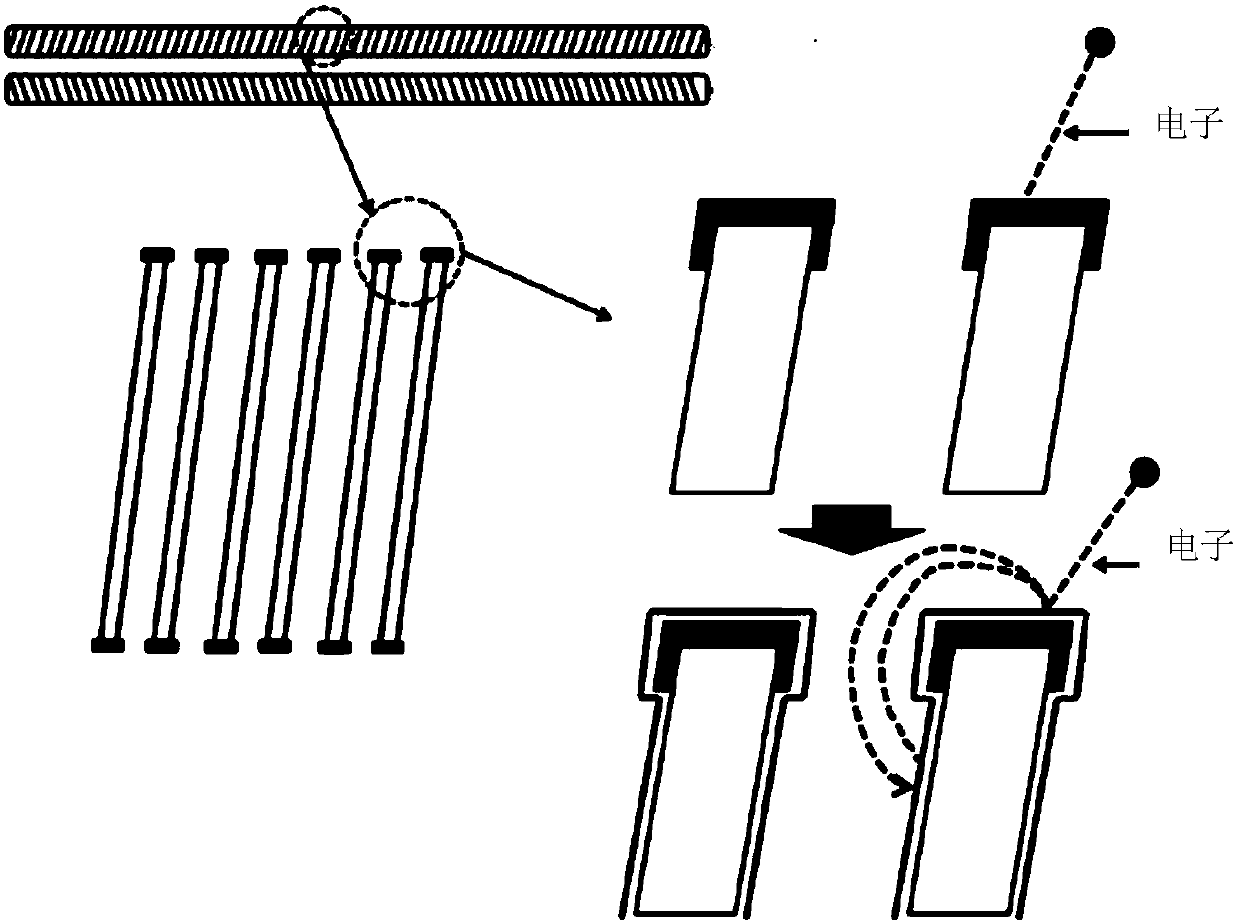

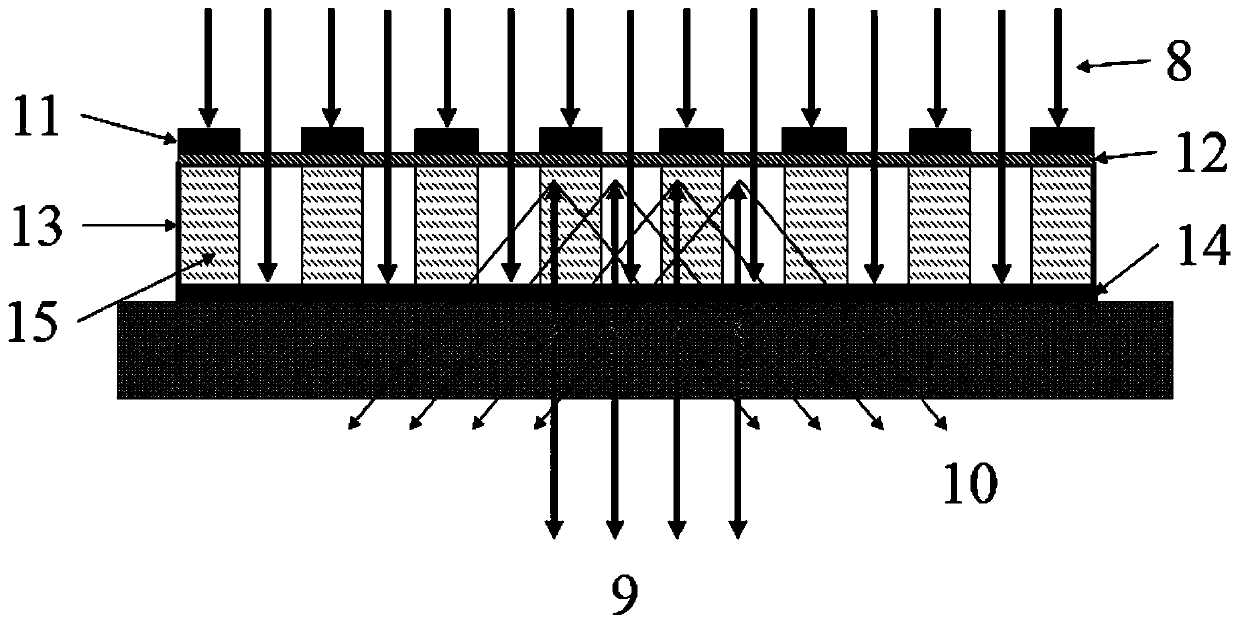

Low-delay-pulse, low-crosstalk and high-collection-efficiency micro-channel plate

PendingCN107785227AIncrease the opening areaIncrease spaceMultiplier electrode arrangementsElectron lossEngineering

The invention relates to low-delay-pulse, low-crosstalk and high-collection-efficiency micro-channel plate. The micro-channel plate comprises a two-dimensional array composed of a plurality of parallel channels. An input electrode layer is plated on the upper end surface of the two-dimensional array. An output electrode layer is plated on the lower end surface of the two-dimensional array. The improvement of the invention is embodied as an input port arranged in the input electrode layer and an output port arranged in the output electrode layer. The input port is communicated with the upper ends of the channels, and the output port is communicated with the lower ends of the channels. The input port is gradually reduced from top to bottom, so that the opening area of the channels of the micro-channel plate is larger than 90%. The surface of the input electrode is covered with a thin film with a high secondary electron emission coefficient. According to the micro-channel plate, the opening area of micro-channels is large, so that the probability of electrons entering the channels is increased. The collecting efficiency is improved. The thin film made of the high-secondary electron emission material and covered on the surface of the electrode can reduce the probability of electron loss falling on the surface of the electrode. As a result, the collecting efficiency is further improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Double-focusing electrode for photomultiplier and photomultiplier

ActiveCN110896020AImprove collection efficiencyImprove time characteristicsMultiplier electrode arrangementsEngineeringPhotomultiplier

Owner:NORTH NIGHT VISION TECH

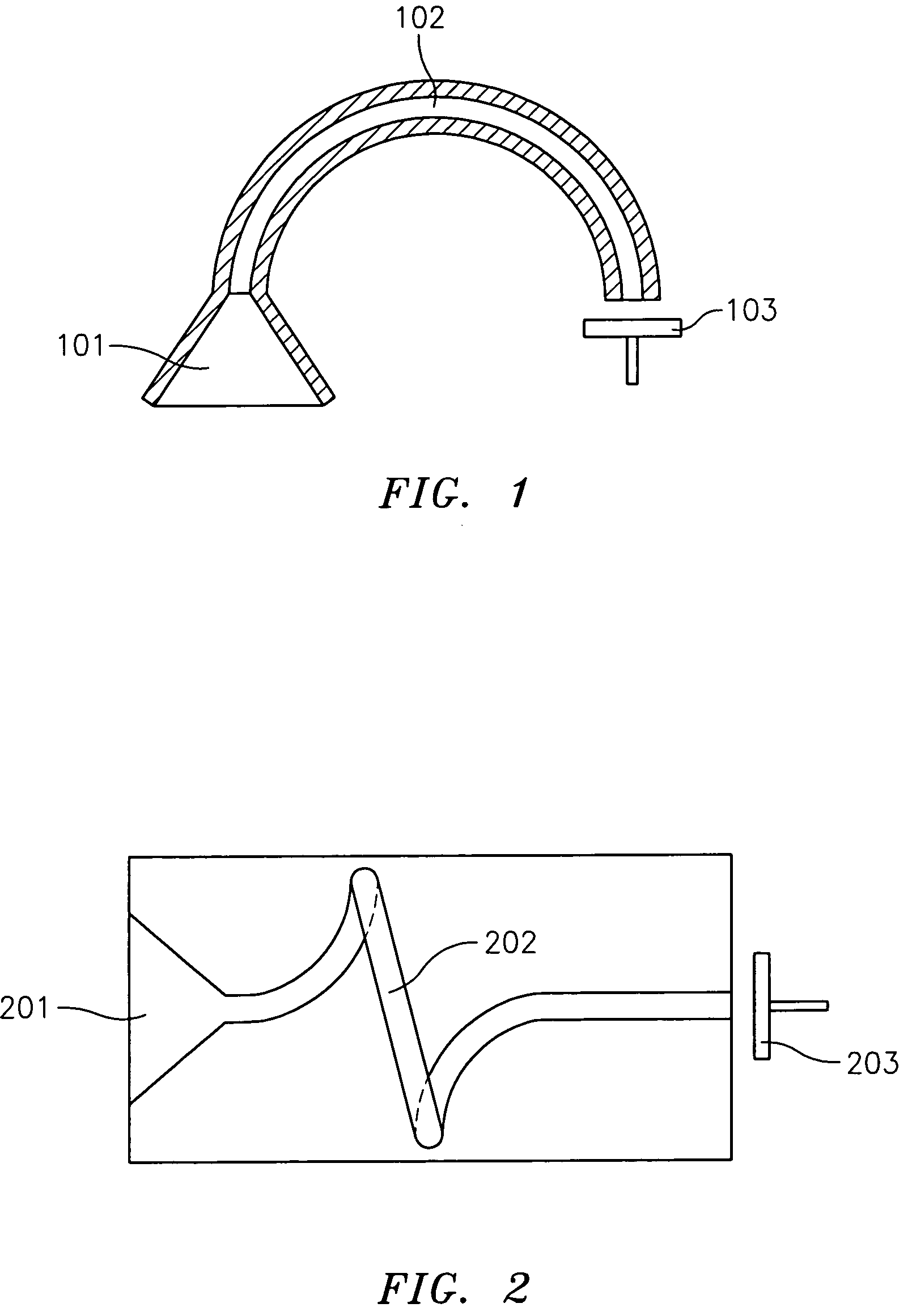

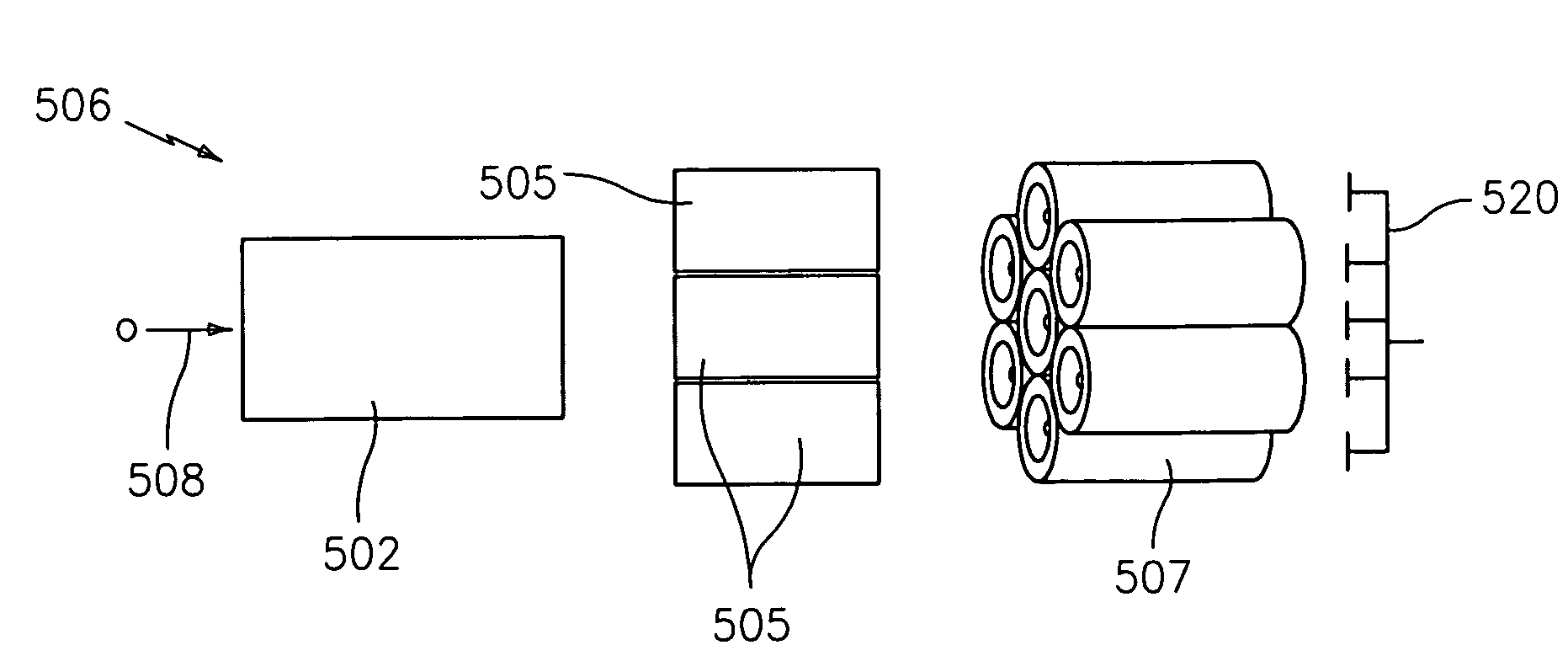

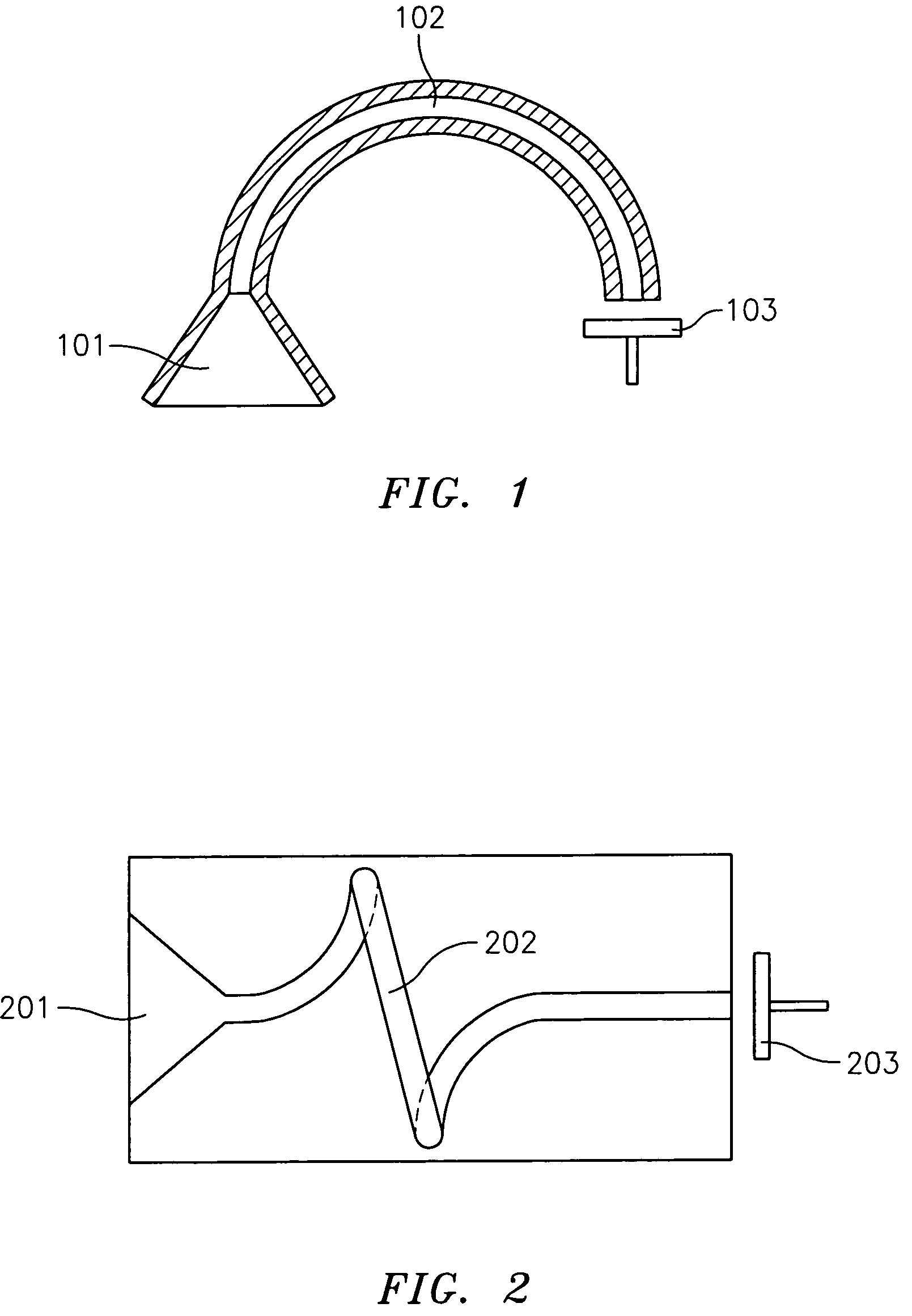

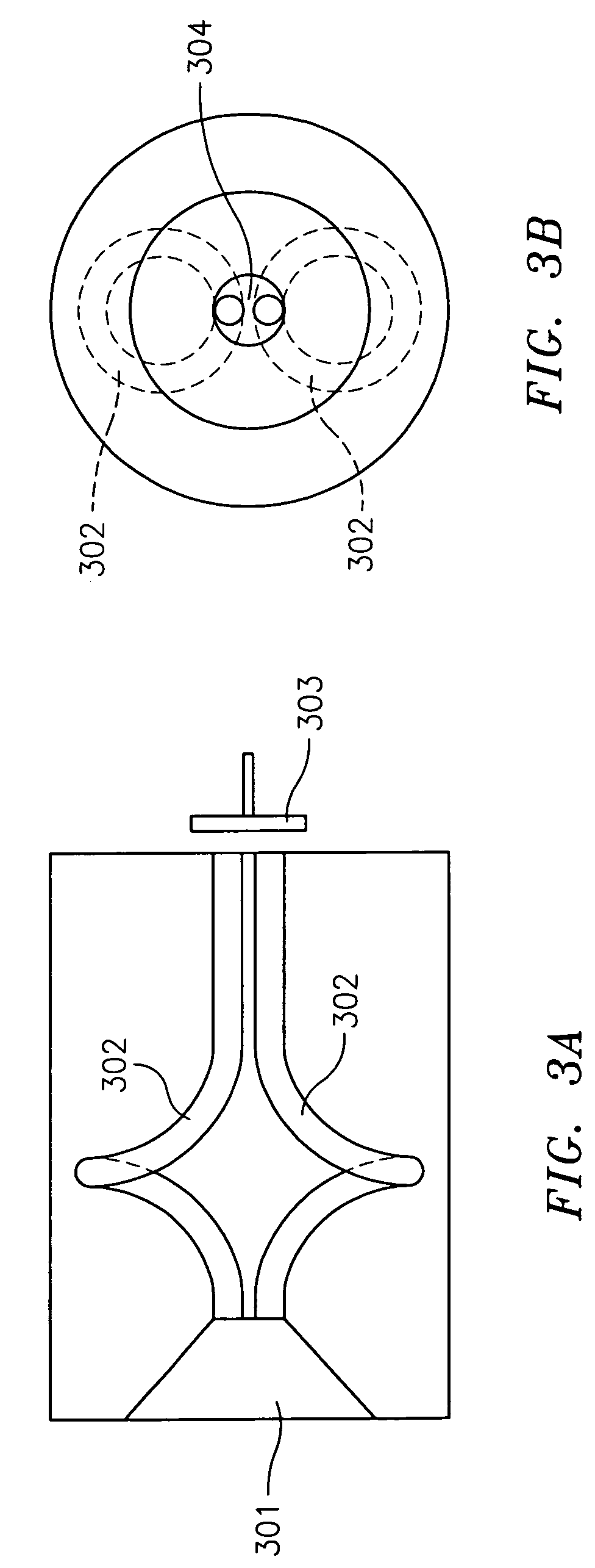

Tandem continuous channel electron multiplier

A channel electron multiplier including a single channel CEM for receiving an input particle. A multi-channel CEM is positioned after the single channel CEM for receiving emissions from the single channel CEM. An electron collector is positioned after the multi-channel CEM for generating a pulse current in response to emissions from the multi-channel CEM.

Owner:ADAPTAS SOLUTIONS LLC

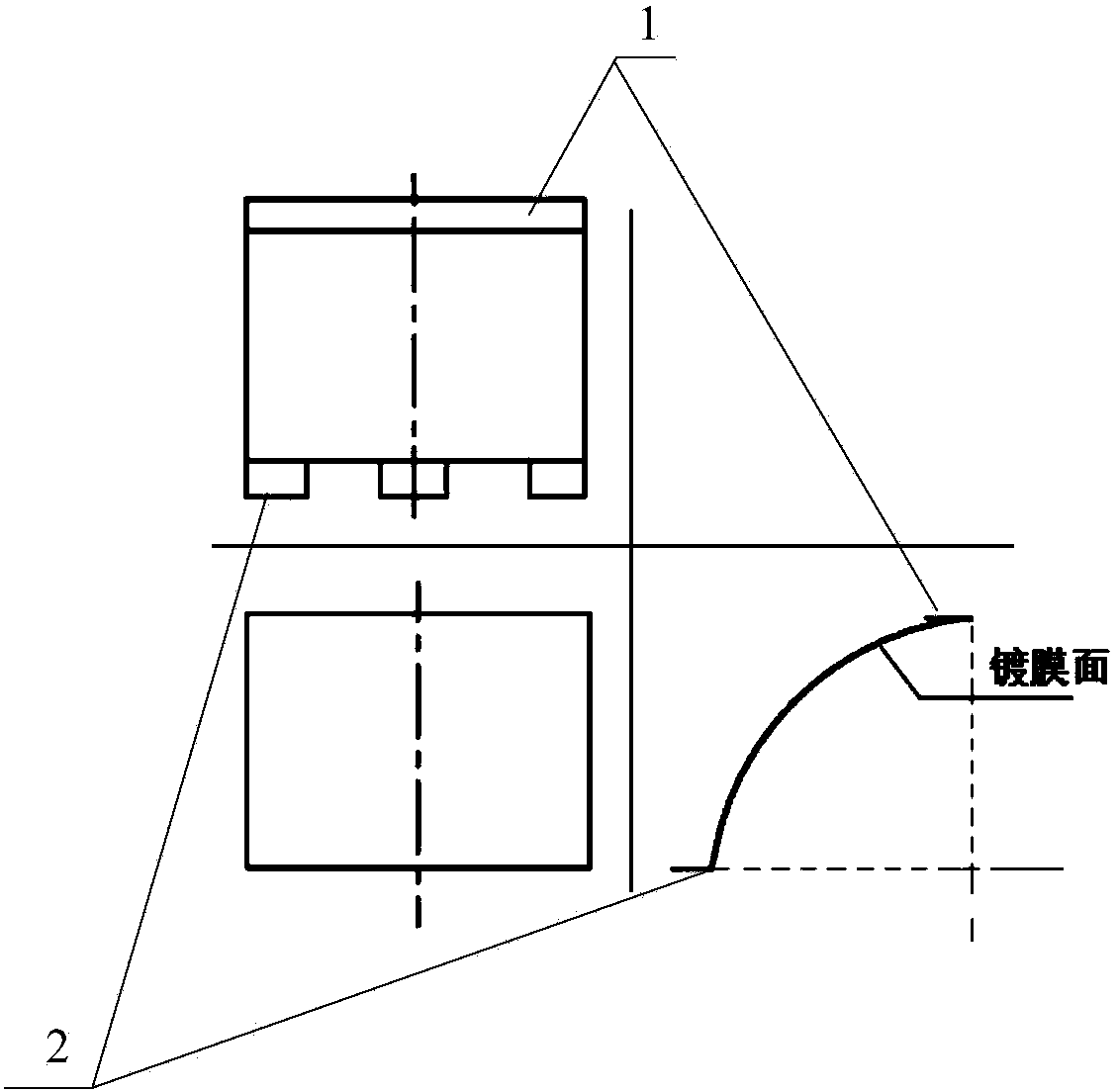

Curved surface film forming method for dynode of electron multiplier

InactiveCN104362058ASolve the uniformity of film formationFix stability issuesMultiplier electrode arrangementsVacuum evaporation coatingElectron multiplierDynode

The invention discloses a curved surface film forming method for a dynode of an electron multiplier and effectively solves the problems of stability and uniformity in coating of films onto specific curved surfaces of dynodes of electron multipliers. The method includes: processing a curved surface liner with to-be-bent areas at two ends according to the size and radian of a to-be-coated inner surface of a dynode shell of the electron multiplier, wherein one of the to-be-bent areas is reversely folded by 180 degrees towards the outside of the curved surface to form a folded portion, and the other to-be-bent area is cut to form n rectangular toothed fasteners; coating a film onto the curved surface liner; mounting the coated curved surface liner on the inner surface of the dynode shell of the electron multiplier, and fixing with the folded portion and the rectangular toothed fasteners.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Inverted image enhanced ultrafast imaging detector

InactiveCN110487757AOvercoming the problem of easy vacuum breakdownHigh spatio-temporal resolutionMultiplier electrode arrangementsFluorescence/phosphorescencePhotocathodeSurface mounting

The invention relates to an inverted image enhanced ultrafast imaging detector, and solves the problem that a semiconductor chip in an existing double-near-surface-mount structure is prone to vacuum breakdown. The detector comprises a shell, an input window, an output window, a photoelectric cathode, a first electrostatic focusing electrode, a micro-channel plate, a second electrostatic focusing electrode and a semiconductor detection chip, an input window and an output window are arranged at the two ends of the shell respectively. The inner surface of the input window is plated with a layer of conductive film, and the photoelectric cathode is manufactured on the conductive film; the semiconductor detection chip clings to the inner surface of the output window; a first electrostatic focusing electrode, a micro-channel plate and a second electrostatic focusing electrode are sequentially arranged between the photoelectric cathode and the semiconductor detection chip; the first electrostatic focusing electrode and the second electrostatic focusing electrode are the same; and the input surface and the output surface of the micro-channel plate are loaded with the working voltage.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

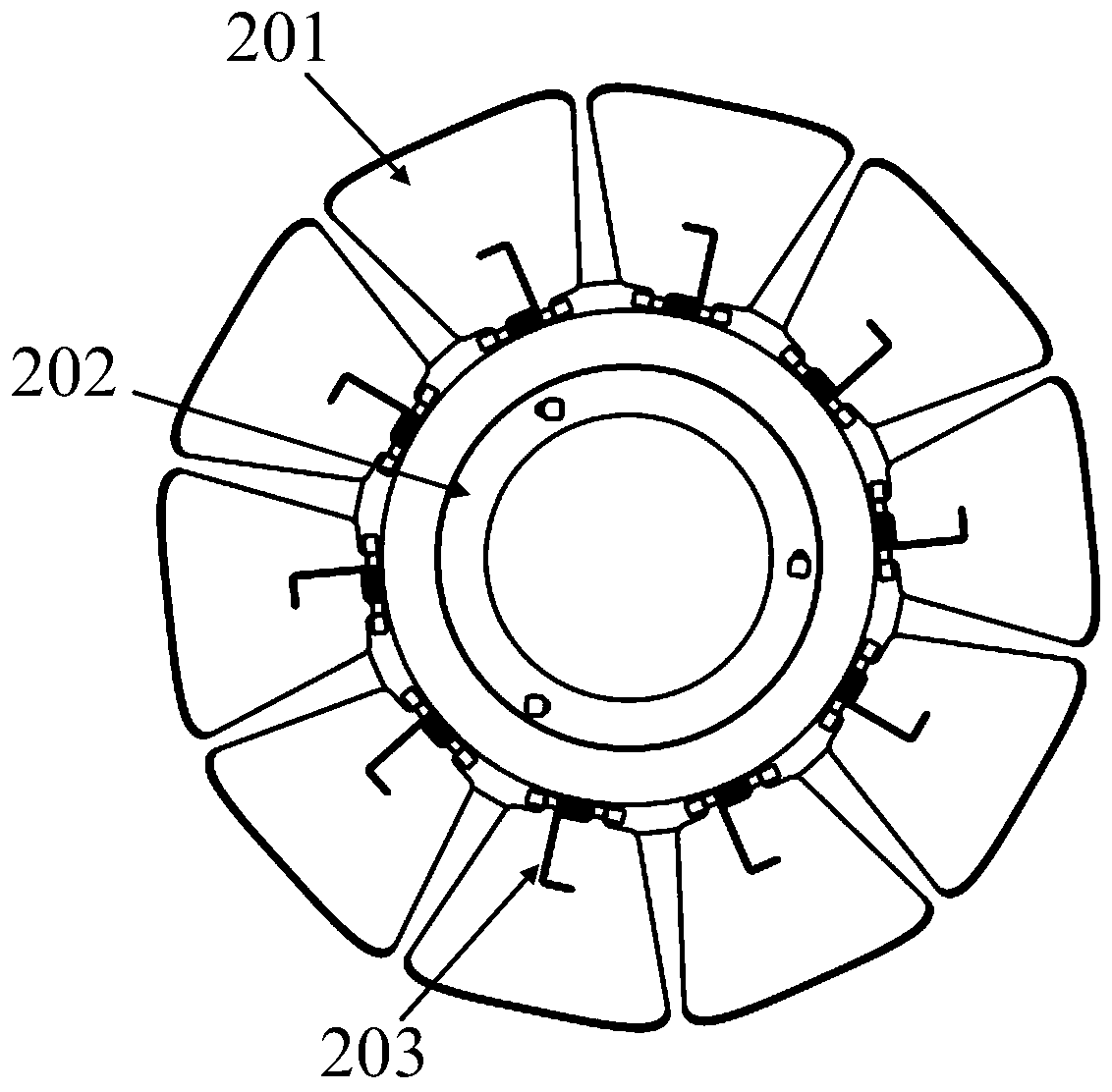

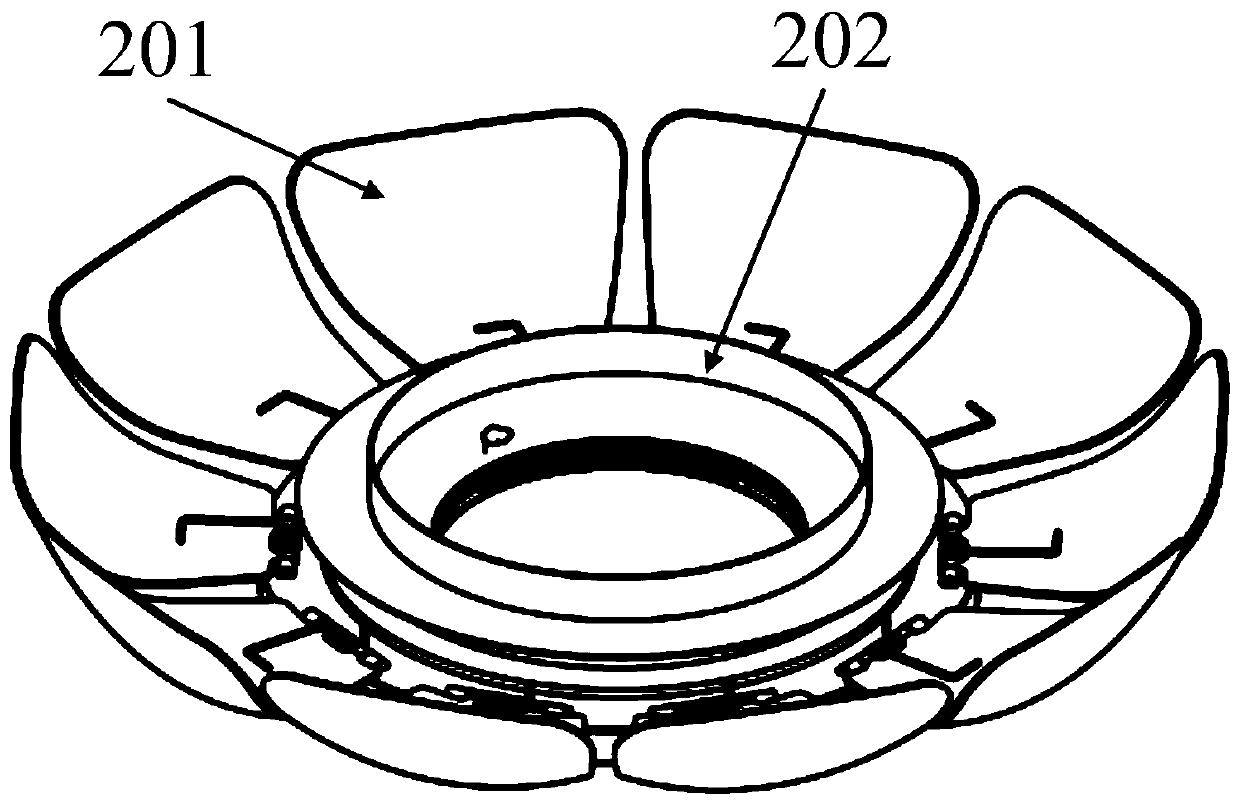

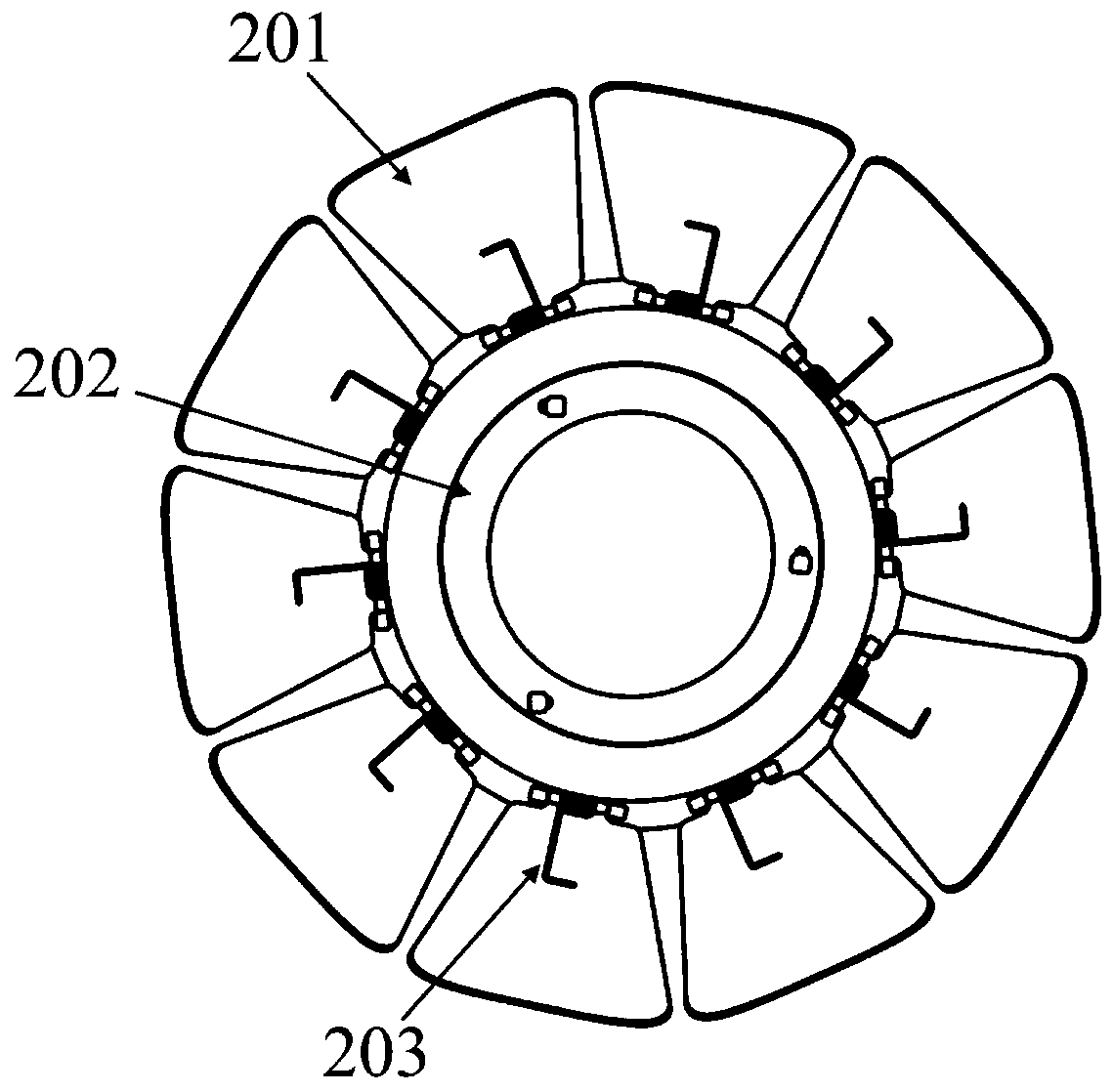

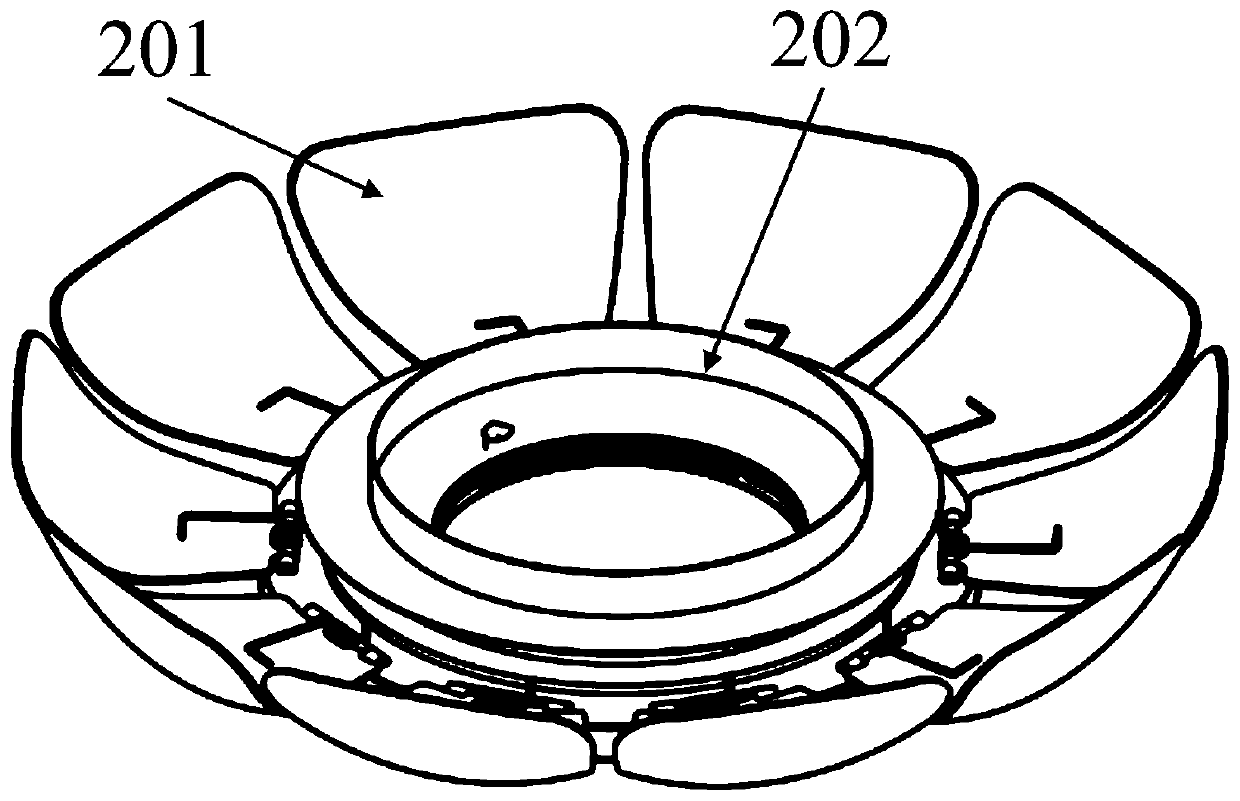

Double focusing electrode for photomultiplier tube and photomultiplier tube

InactiveCN110211861AImprove collection efficiencyImprove time characteristicsMultiplier electrode arrangementsElectrical connectionPhotomultiplier

The present invention provides a double focusing electrode for a photomultiplier tube and a photomultiplier tube. The double focusing electrode comprises a bowl-shaped auto-expanding focusing electrode and a secondary focusing electrode. The bowl-shaped auto-expanding focusing electrode comprises an annular bottom plate and a rotating shaft, a curved blade, a torsion spring and a triggering devicearranged on the bottom plate. The secondary focusing electrode is an annular metal electrode fixed on the annular bottom plate. An insulating component is arranged between the secondary focusing electrode and the bottom plate for forming insulation between the secondary focusing electrode and the bowl-shaped focusing electrode composed by the curved blade. An electrical connection plate is further connected with the secondary focusing electrode. The electrical connection plate passes through the insulating component and the bottom plate, extends below the bottom plate to lead the secondary focusing electrode out and electrically connected with the lead system of the photomultiplier tube. Through the implementation of the present invention, the photoelectron collection and detection efficiency can be improved.

Owner:NORTH NIGHT VISION TECH

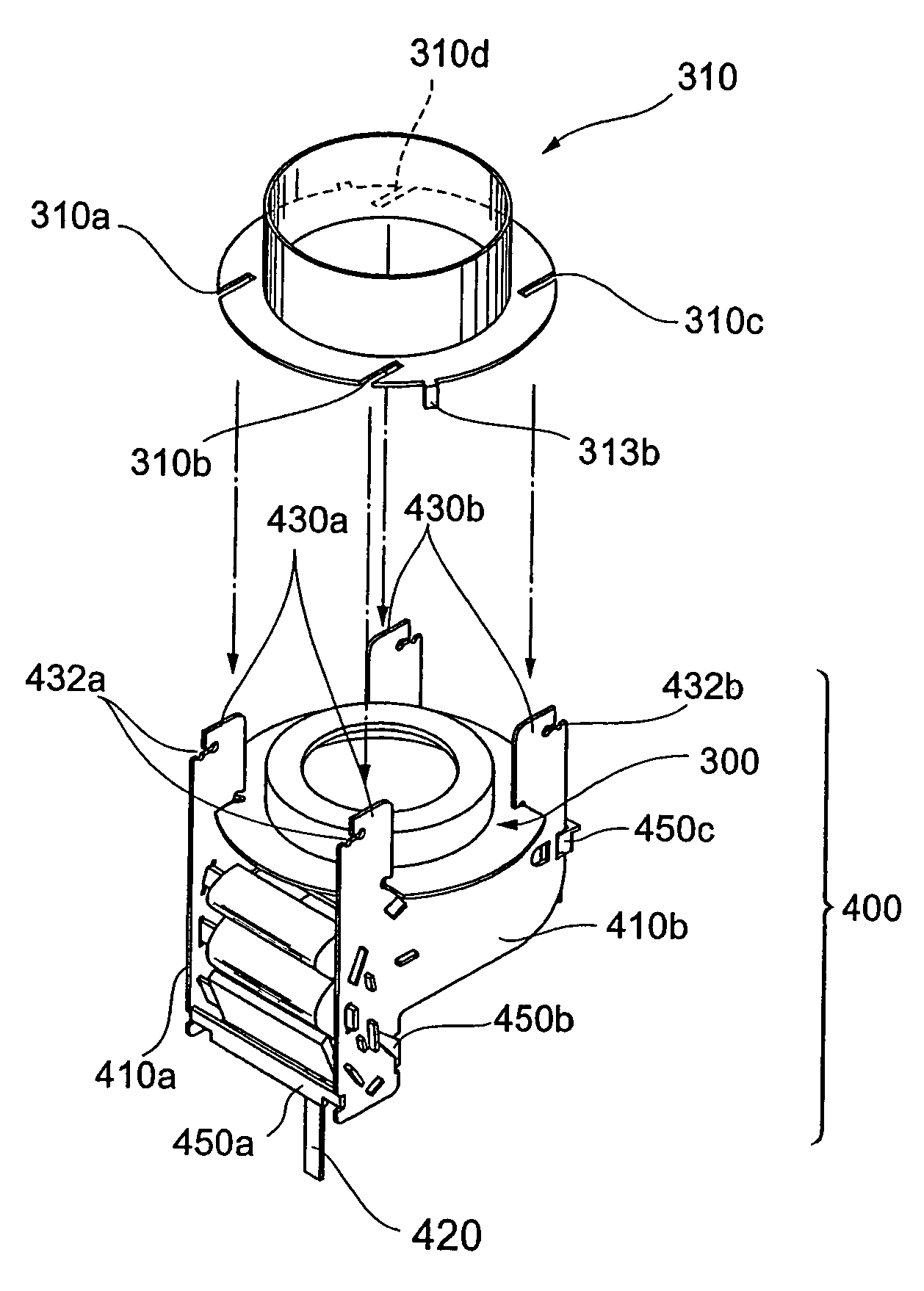

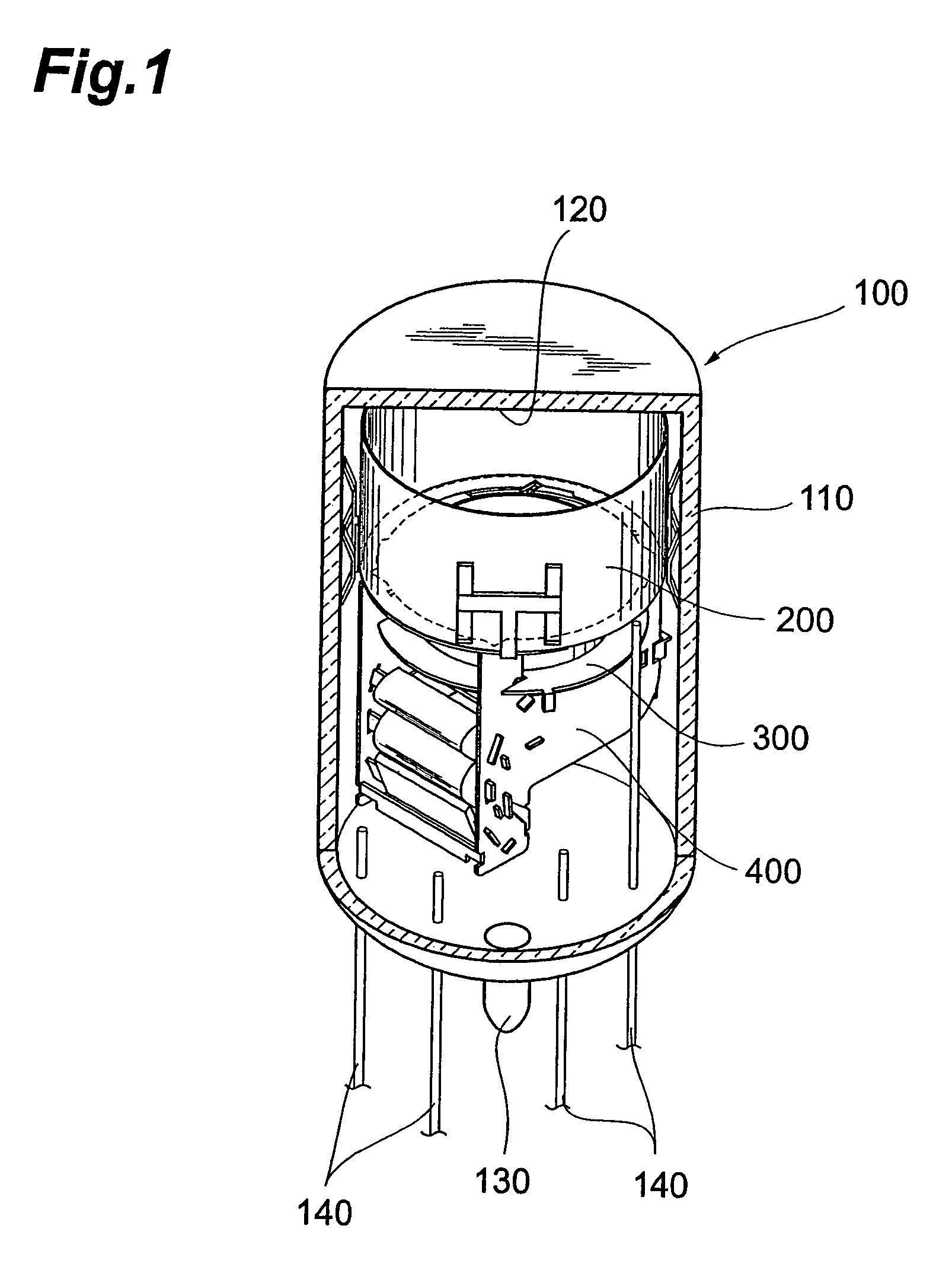

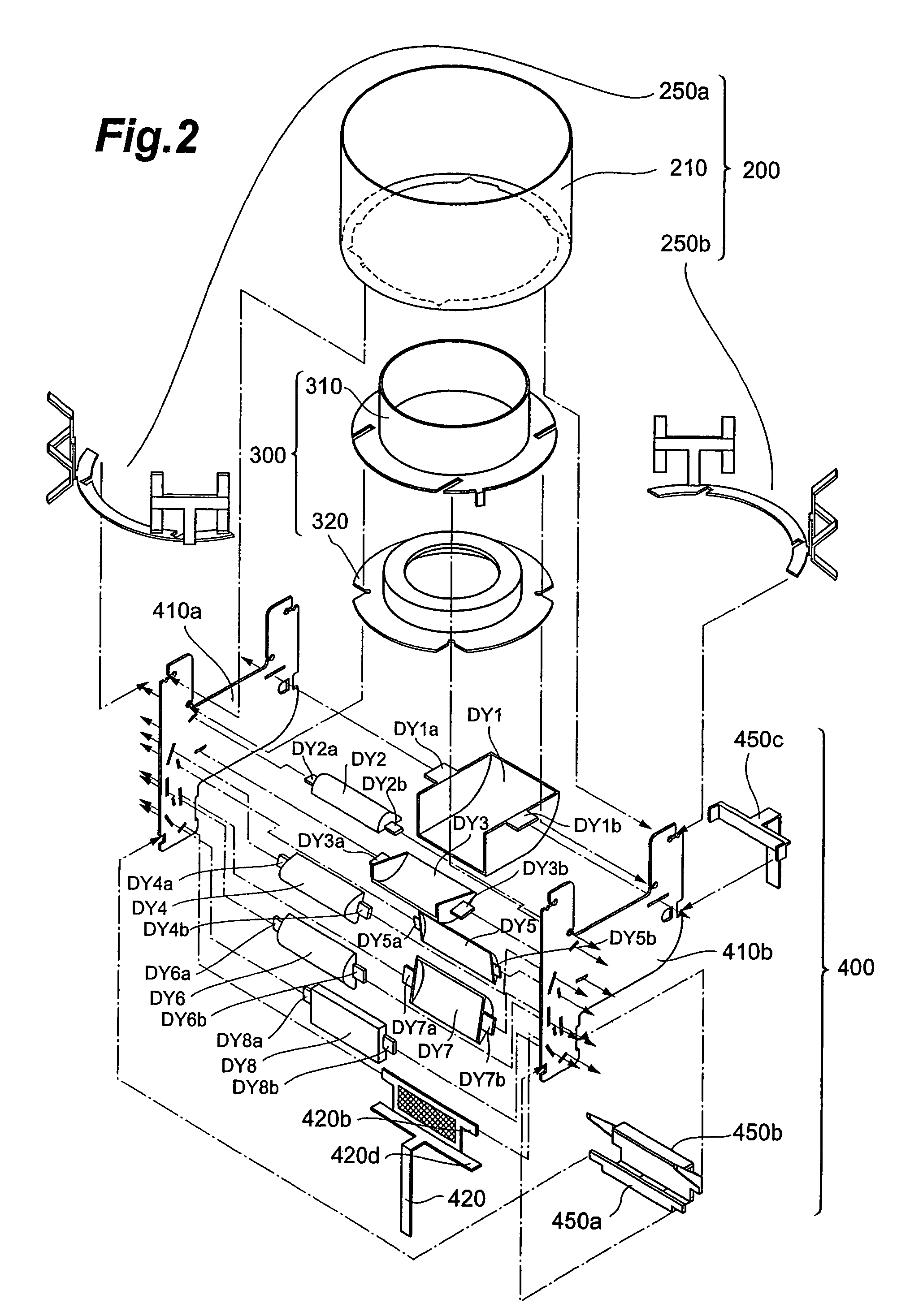

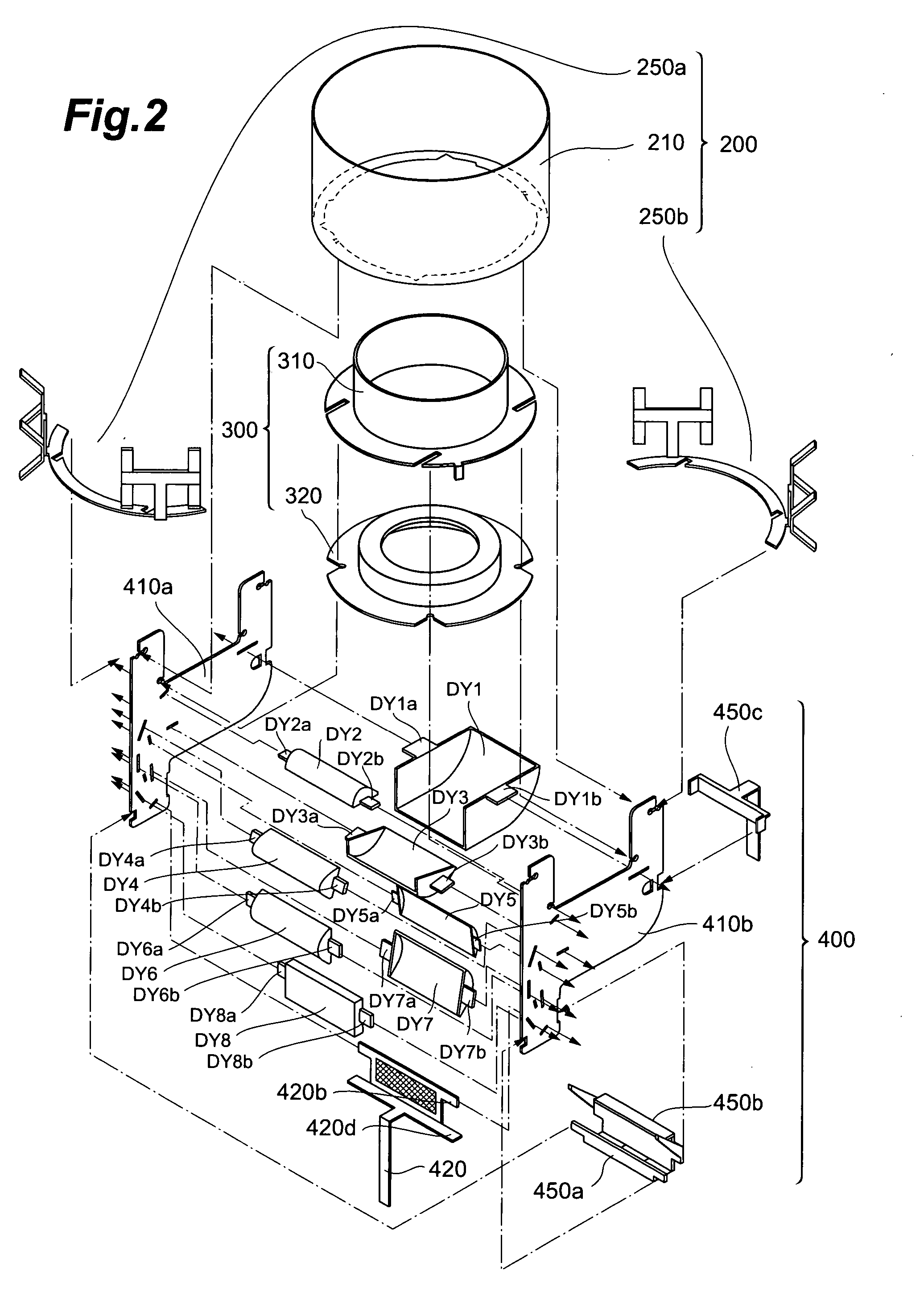

Photomultiplier including a seated container, photocathode, and a dynode unit

InactiveUS7498741B2Easy alignmentImprove productivityMultiplier electrode arrangementsControl electrodesProduction ratePhotocathode

The present invention relates to a photomultiplier having a structure for performing a high gain and achieving a higher productivity in a state keeping or improving an excellent high-speed response. In the photomultiplier, an electron-multiplying unit accommodated in a sealed container has a structure that enables an integrated assembly of a focusing electrode, an accelerating electrode, a dynode unit, and an anode. Specifically, the accelerating electrode composes a lower electrode and an upper electrode fixed each other by welding at a plurality of spots. The lower electrode is held at a pair of insulating support members in a state for the pair of insulating support members to grasp unitedly it together with the dynode unit and anode. Additionally, the upper electrode has one or more slit grooves for pinching a part of the pair of insulating support members. With this construction, the accelerating electrode constituted by the lower electrode and upper electrode is fixed at the pair of insulating support members in a state to be aligned with high accuracy by using the pair of insulating support members as a reference member.

Owner:HAMAMATSU PHOTONICS KK

Tandem continuous channel electron multiplier

A channel electron multiplier including a single channel CEM for receiving an input particle. A multi-channel CEM is positioned after the single channel CEM for receiving emissions from the single channel CEM. An electron collector is positioned after the multi-channel CEM for generating a pulse current in response to emissions from the multi-channel CEM.

Owner:ADAPTAS SOLUTIONS LLC

Vacuum photosensor device with electron lensing

ActiveUS9064678B2Lower levelScalable mass productionMultiplier electrode arrangementsBeam/ray focussing/reflecting arrangementsPhotocathodeEngineering

Owner:RGT UNIV OF CALIFORNIA

Silicate skin glass, curved surface square hole microchannel plate and preparation method thereof

ActiveCN106630596BHigh tensile strengthSmall coefficient of thermal expansionMultiplier electrode arrangementsCathode ray concentrating/focusing/directingMedicineThermal expansion

Owner:CHINA BUILDING MATERIALS ACAD

Micro channel plate

ActiveUS8508110B2Avoid deformationBreakage failureMultiplier electrode arrangementsMaterial analysis by optical meansEngineeringMechanical engineering

Owner:HAMAMATSU PHOTONICS KK

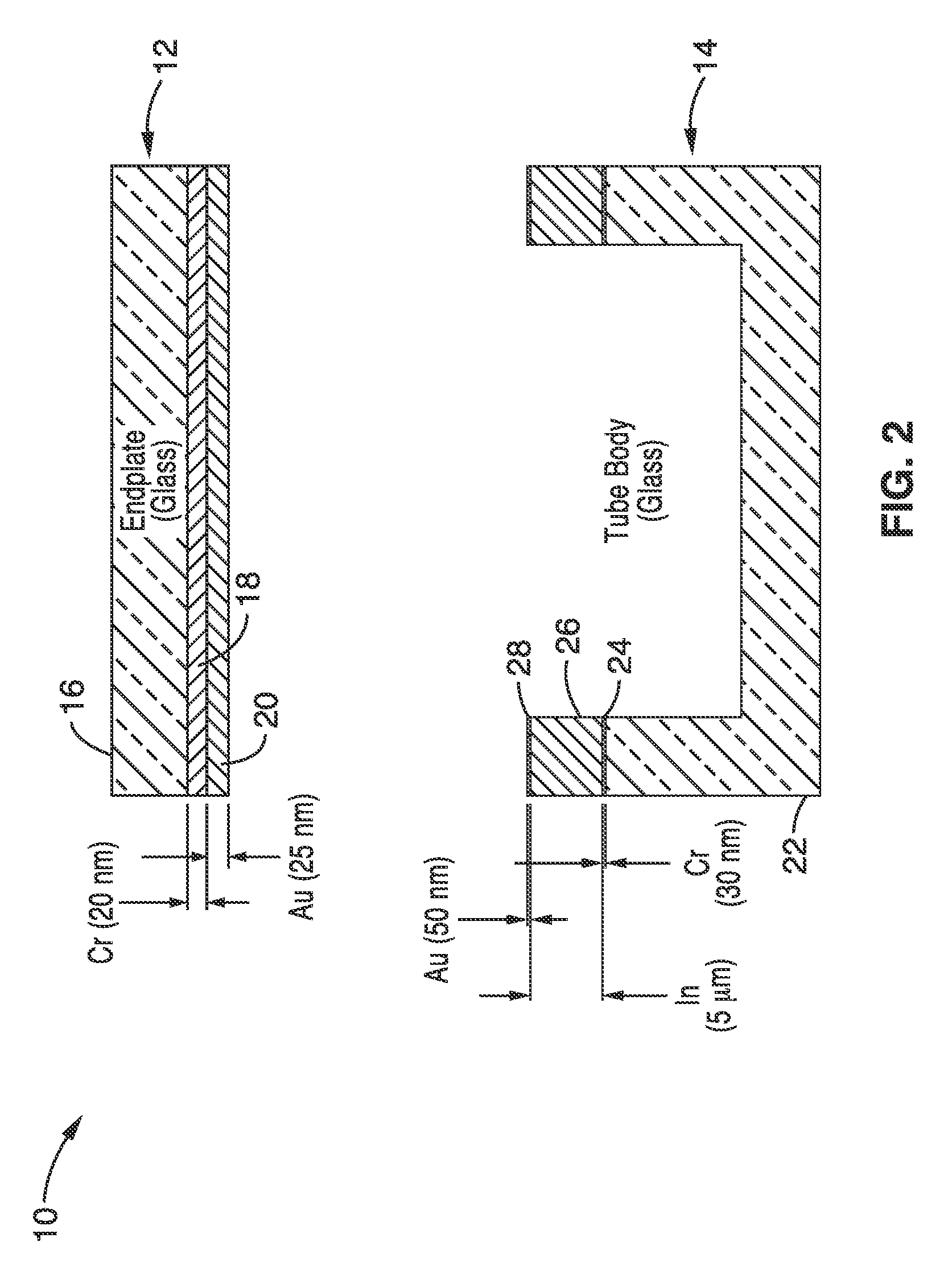

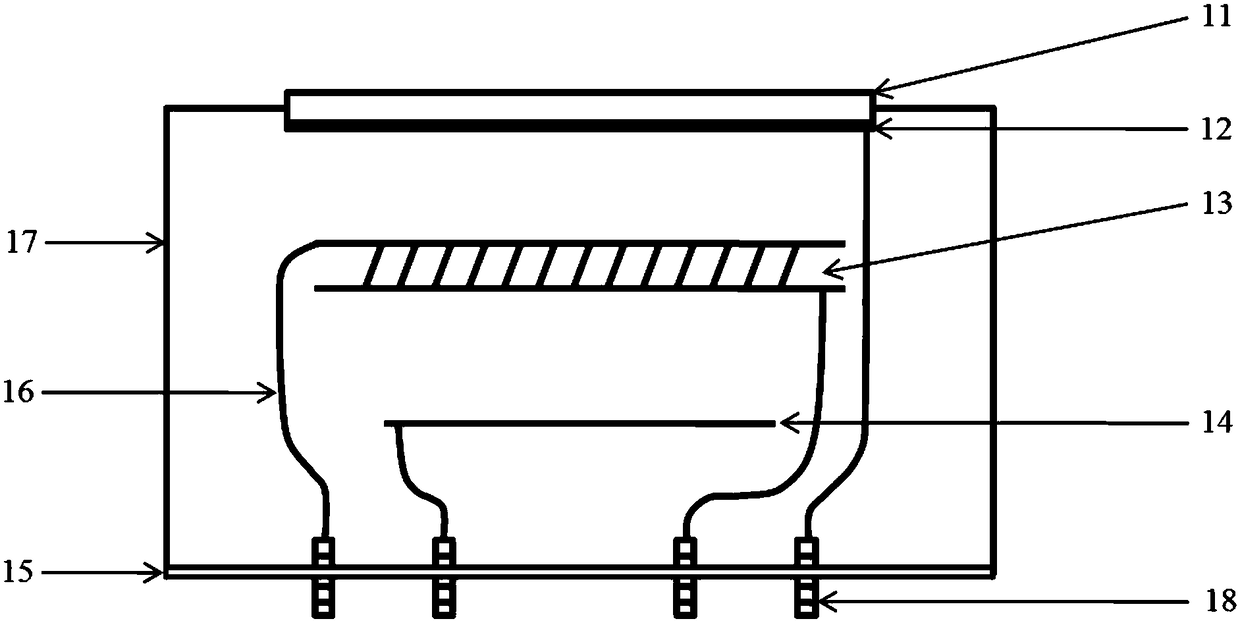

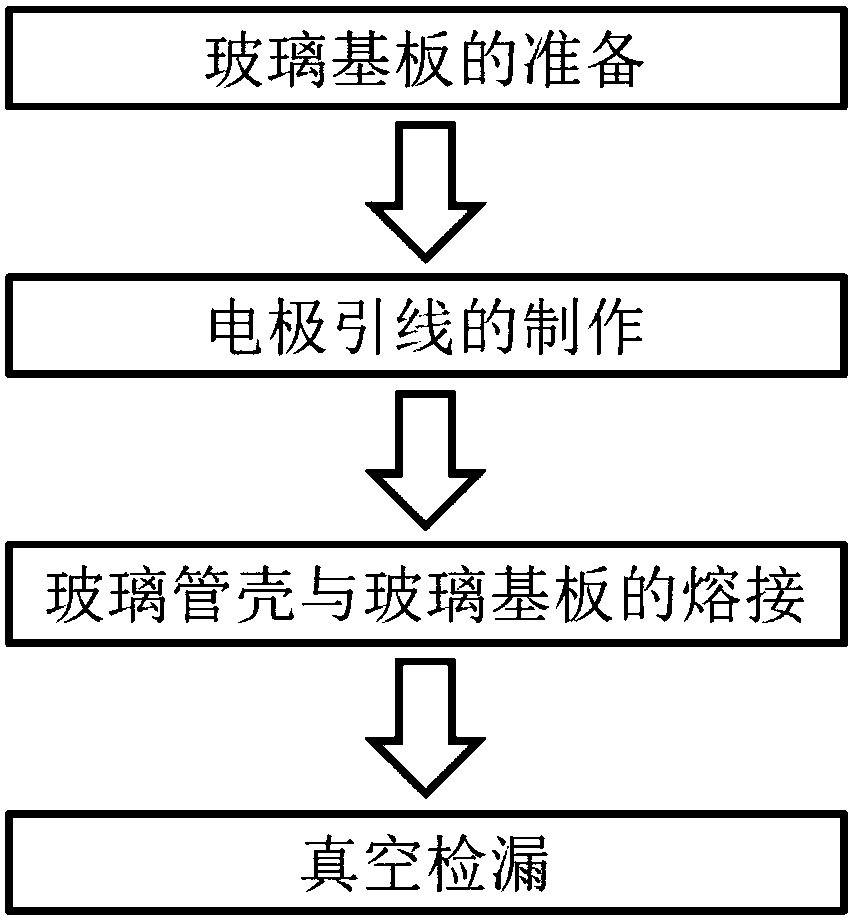

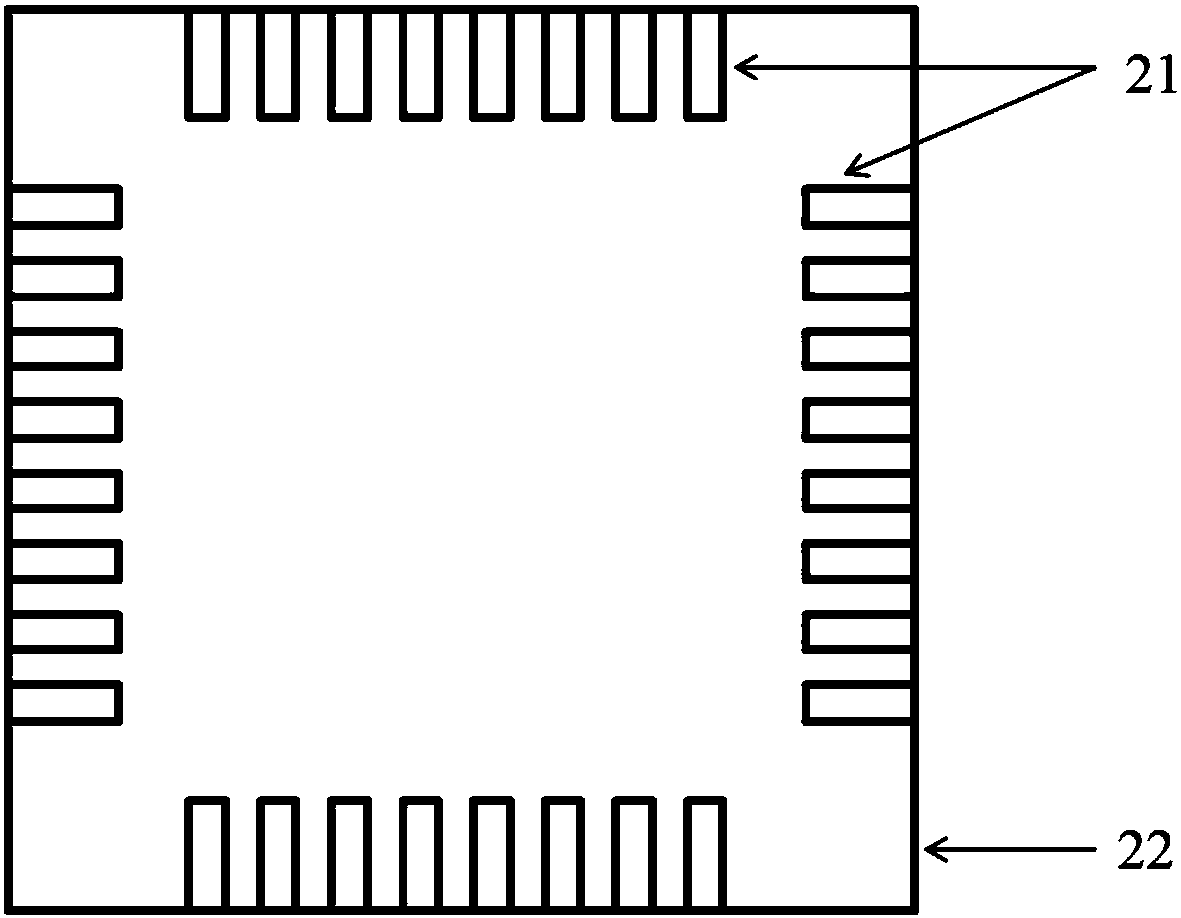

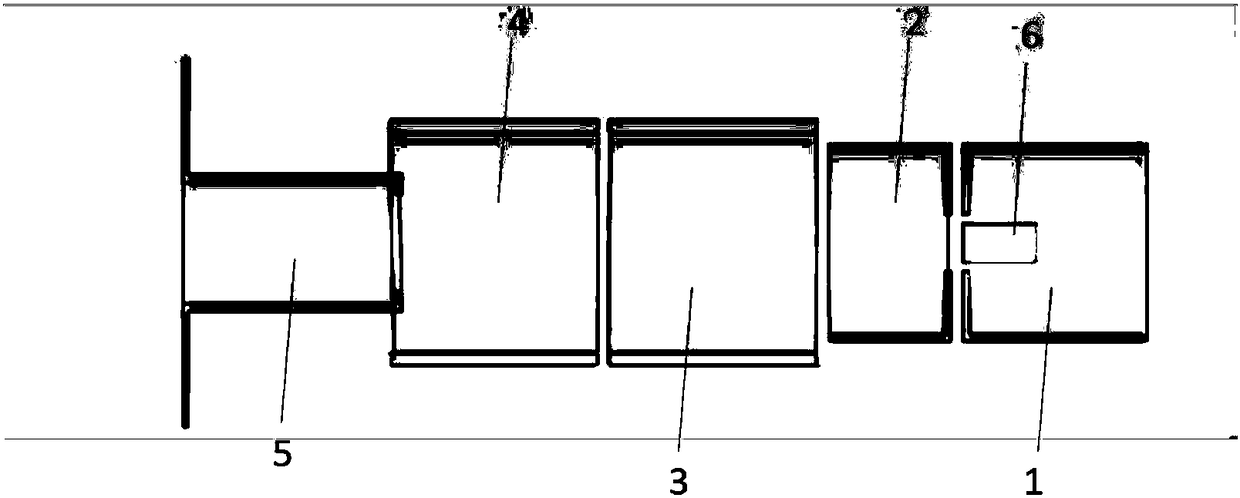

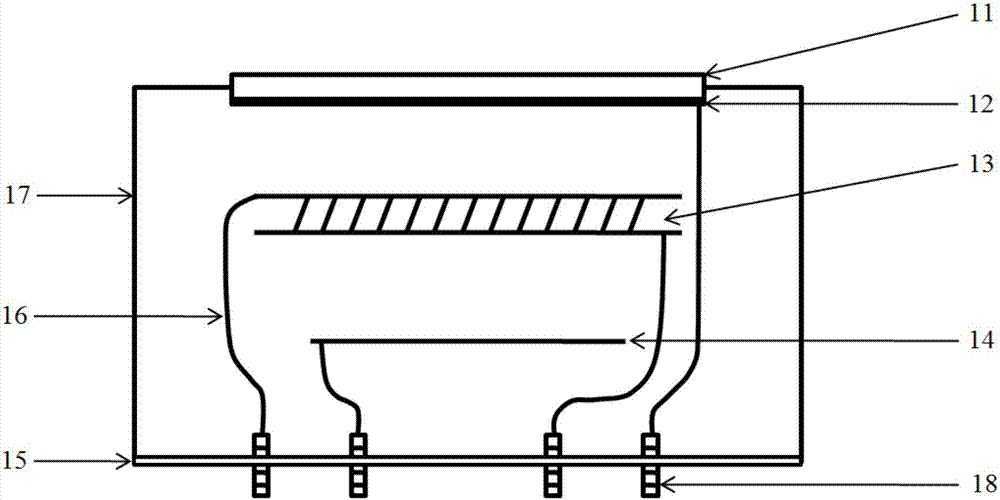

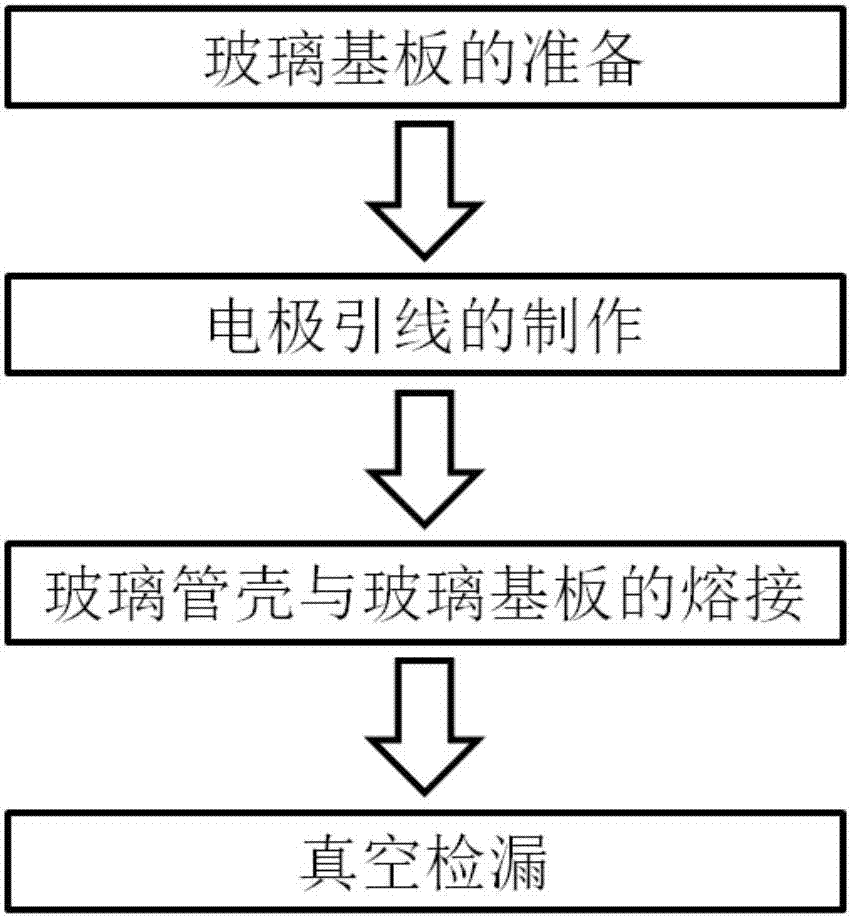

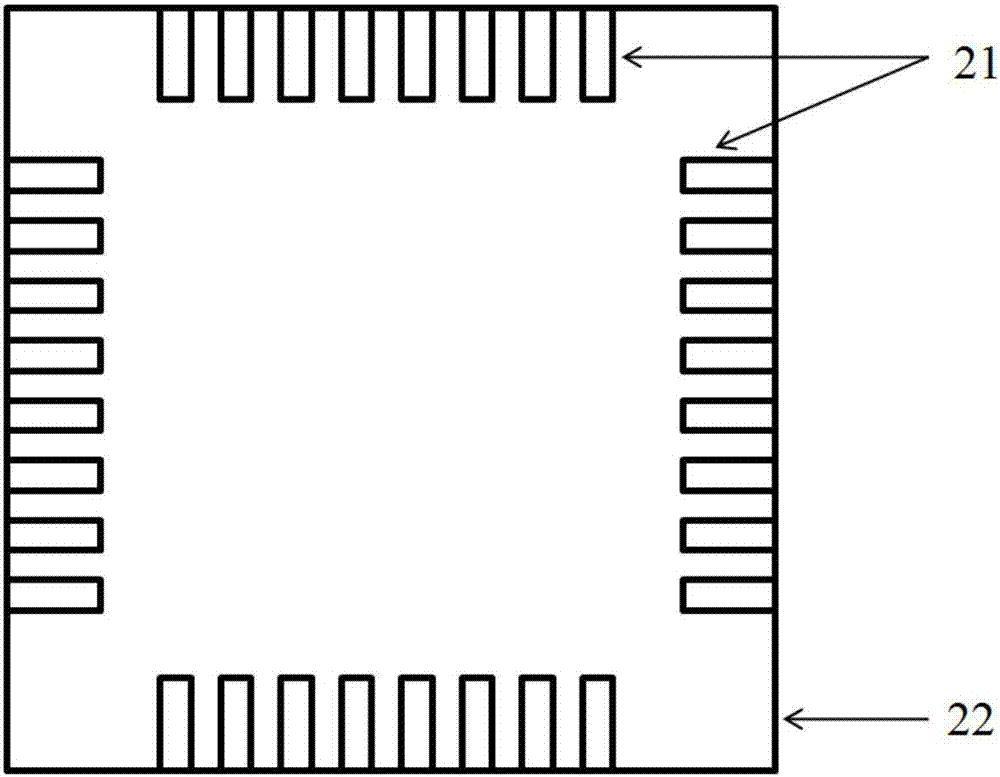

Electrode lead unit, vacuum optoelectronic device and manufacturing method thereof

ActiveCN106876229BPrevent burstImprove performanceMultiplier electrode arrangementsCold cathode manufactureNight visionHigh density

The invention belongs to the technical field of photoelectric devices, and relates to an electrode lead unit, a vacuum photoelectric device and a manufacturing method thereof. The electrode lead unit comprises a glass substrate, a glass package and multiple electrode leads; the glass package is welded on the surface of the glass substrate; the electrode leads are distributed on the welding surface between the glass package and the glass substrate; and one end of each electrode lead is located at the inner side of the glass package, and the other end of the electrode lead is located at the outer side of the glass package. Due to the manufactured electrode lead unit and no limitation from the diameter of a Kovar alloy wire at the tail end of an anode, a vacuum photoelectric device with hundreds of readout channels can be manufactured. The size of the electrode can reach tens of microns minimally, manufacturing of a high-density electrode lead can be realized, the electrode can be applied to multiple vacuum photoelectric devices such as a hybrid photodetector and a multi-anode photomultiplier tube, and has a wide application prospect in multiple fields such as high-energy physics, cosmic exploration, low light level night vision, and medical instruments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Uniform projection type electron optical structure

ActiveCN108231527AWill not interceptEasy to adjustMultiplier electrode arrangementsHigh pressureHigh voltage

The invention discloses a uniform projection type electron optical structure, which comprises a cathode region, a beam-forming region, and an electron gun outlet region; a cathode is arranged in the cathode region, the cathode projects electrons, and a cathode emission surface is formed; from the cathode emission surface, the electrons pass through the beam-forming region and the electron gun outlet region to emit, ultimately forming a projection region; the beam-forming region comprises at least two subbeam-forming regions, each subbeam-forming region is of a metal barrel structure, and moreover, the potentials of all the metal barrels can be separately regulated to control the forms of electron beams in the regions; the beam-forming region generates a primary upside-down real image for the cathode emission surface; the projection region is a secondary upside-down real image of the cathode emission surface, and ultimately, the electrons are uniformly projected. Compared with the priorart, a metal grid does not need to be arranged, a high-voltage electric field is used for being focused to project the secondary upside-down real image of the cathode to a required region, and the uniformity of the electron beam of the projection region is ensured by the optimized structure.

Owner:上海极优威光电科技有限公司

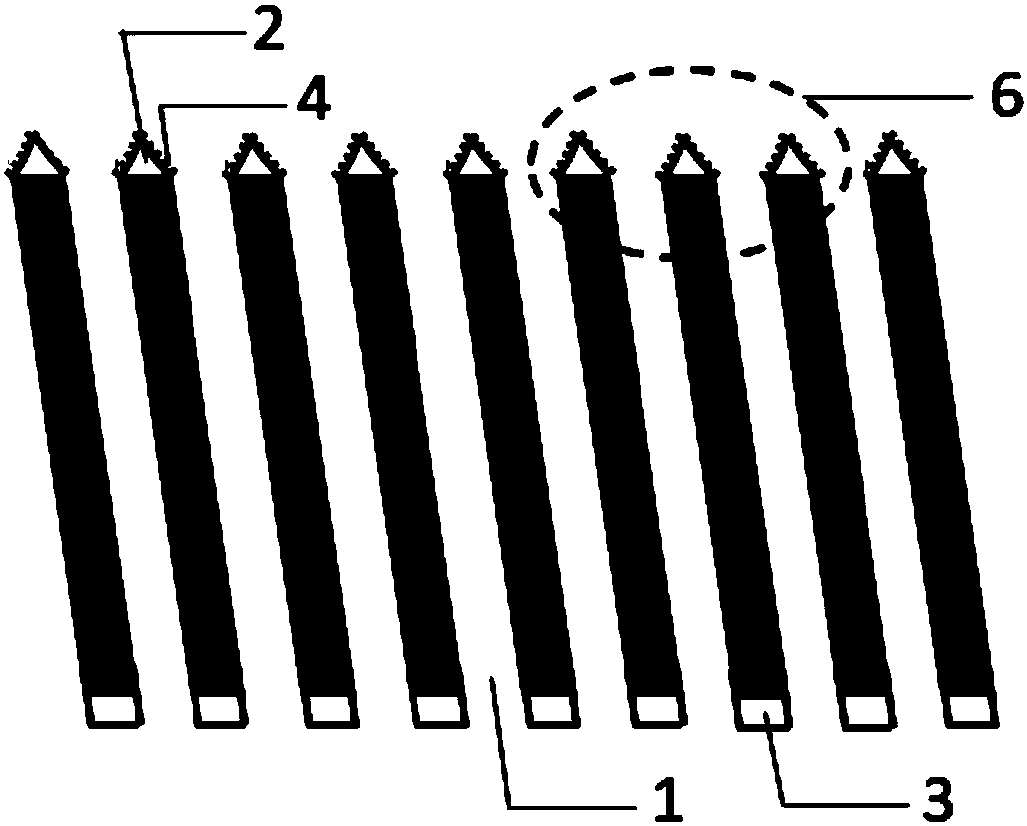

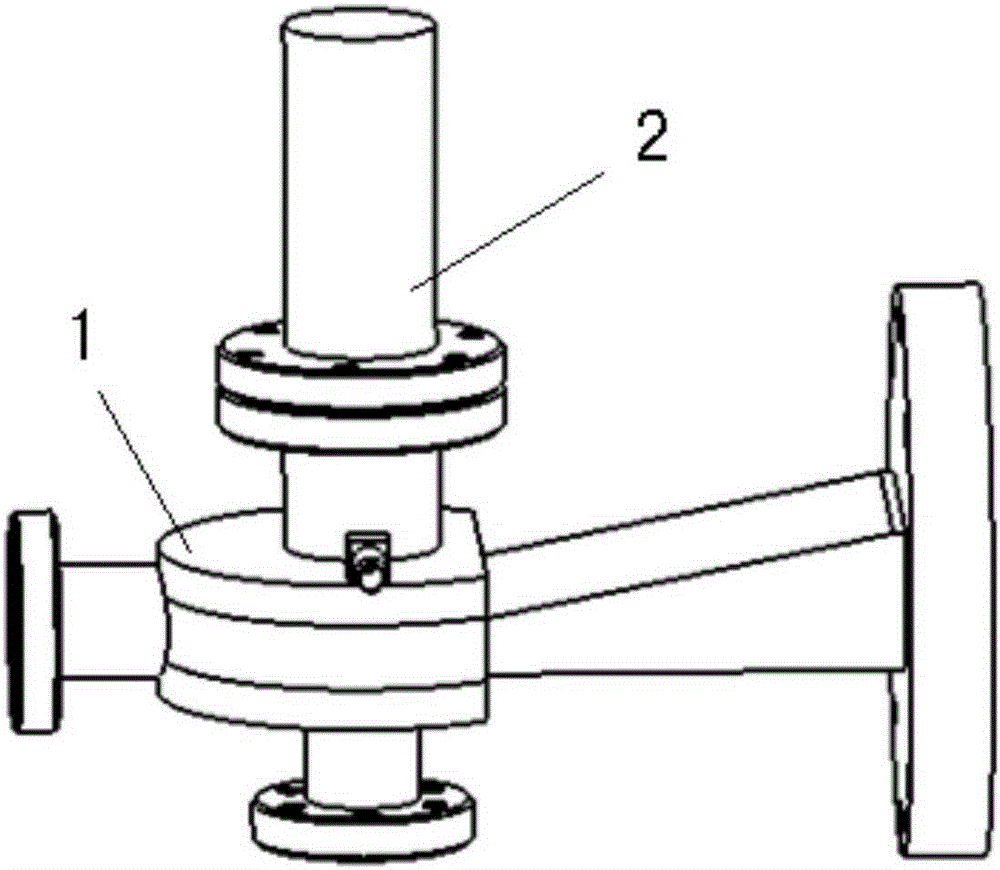

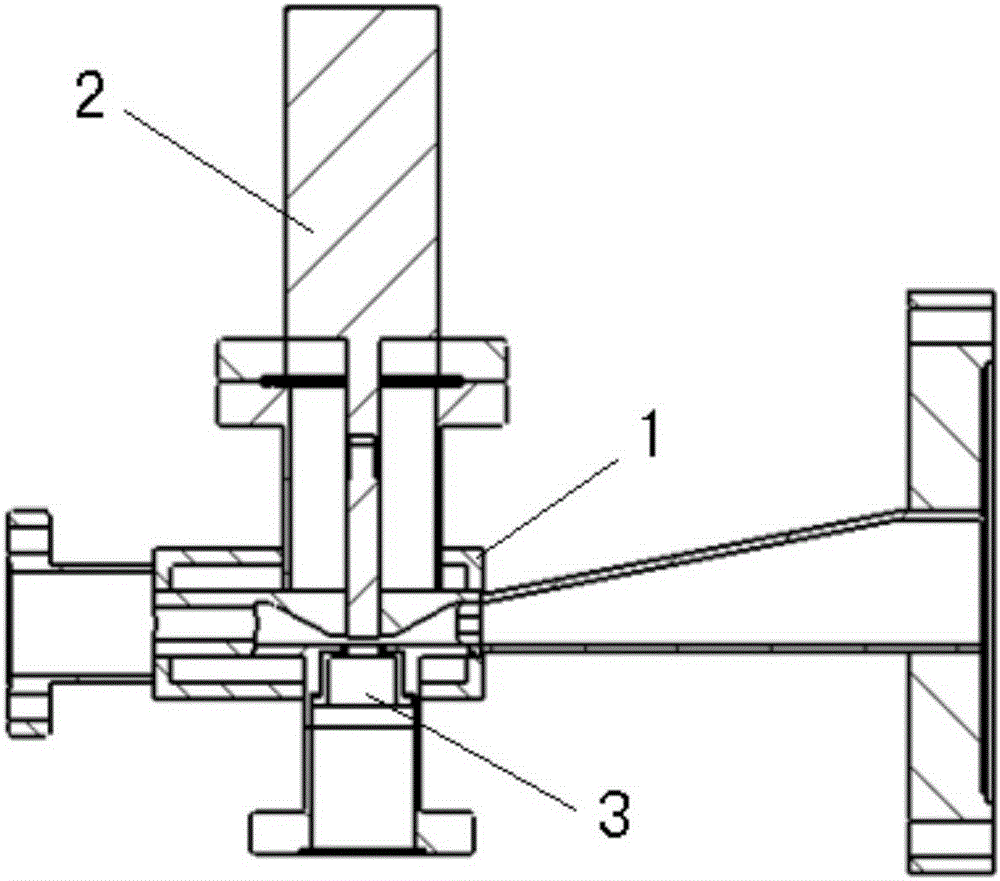

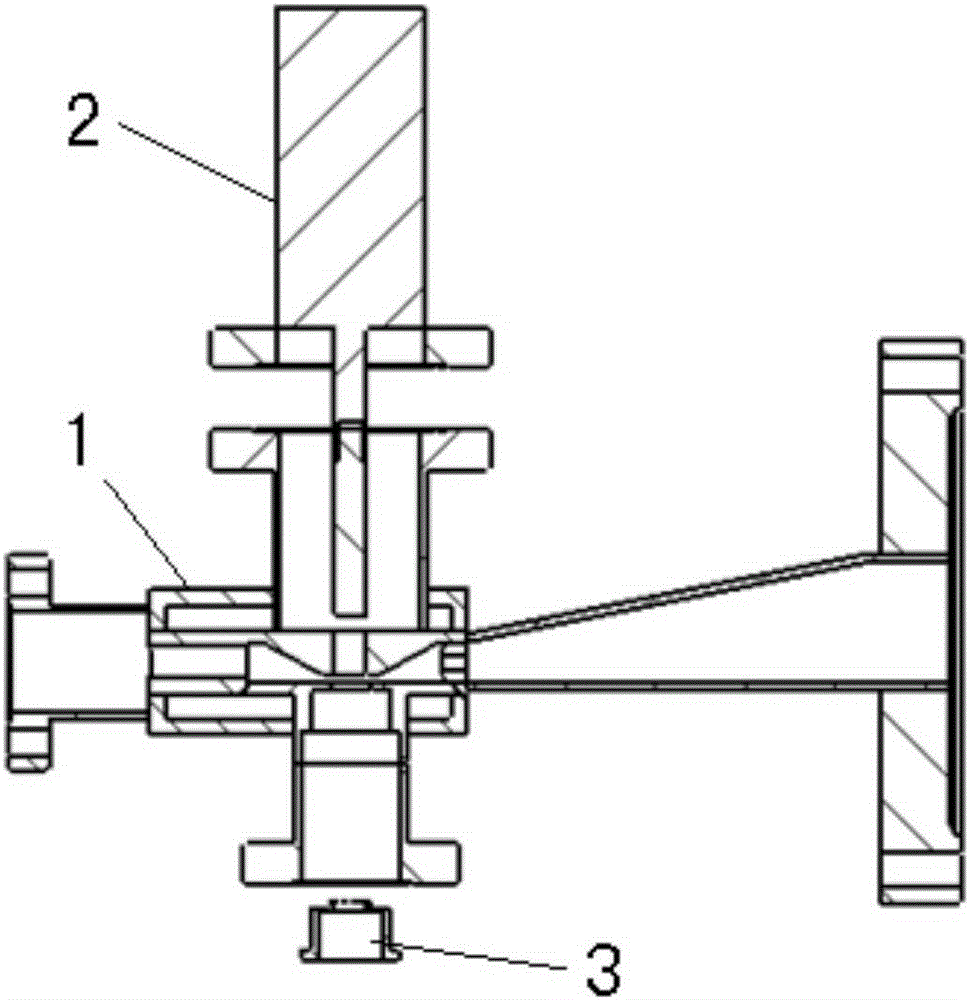

Self-current-stabilizing micropulse electronic gun based on secondary electron multiplying

InactiveCN104008947AChange sizeEasy to installMultiplier electrode arrangementsSecondary electronsEngineering

The invention relates to a self-current-stabilizing micropulse electronic gun based on secondary electron multiplying. The electronic gun comprises an inwards concave cavity, a groove is formed in the bottom of the inwards concave cavity, a round hole is formed in the top of the inwards concave cavity, and the cathode stretches into the round hole; a channel through the groove is formed in the arc-shaped end face side of the inwards concave cavity, and a rectangular hole is formed in the rectangular end face side; a through hole is formed in the center of a round cover plate at the top of a grid cover plate, and the grid cover plate is clamped on a stepped structure on the periphery of the groove; threads are arranged on the inner wall face of a hollow pipe at the bottom of the grid cover plate; two water tank outer shells are welded to the two ends of the cavity respectively and provided with holes; a first pipeline flange is connected with the cathode, penetrates through the holes of the water tank outer shells and then is tightly connected with the top of the inwards concave cavity, a second pipeline flange and the hollow pipe at the bottom of the grid cover plate are welded together, and a third pipeline flange is welded to the arc-shaped end face of the inwards concave cavity; a tapered waveguide outlet end is welded to the rectangular end face of the inwards concave cavity, and a tapered waveguide flange is welded to the inlet end.

Owner:PEKING UNIV

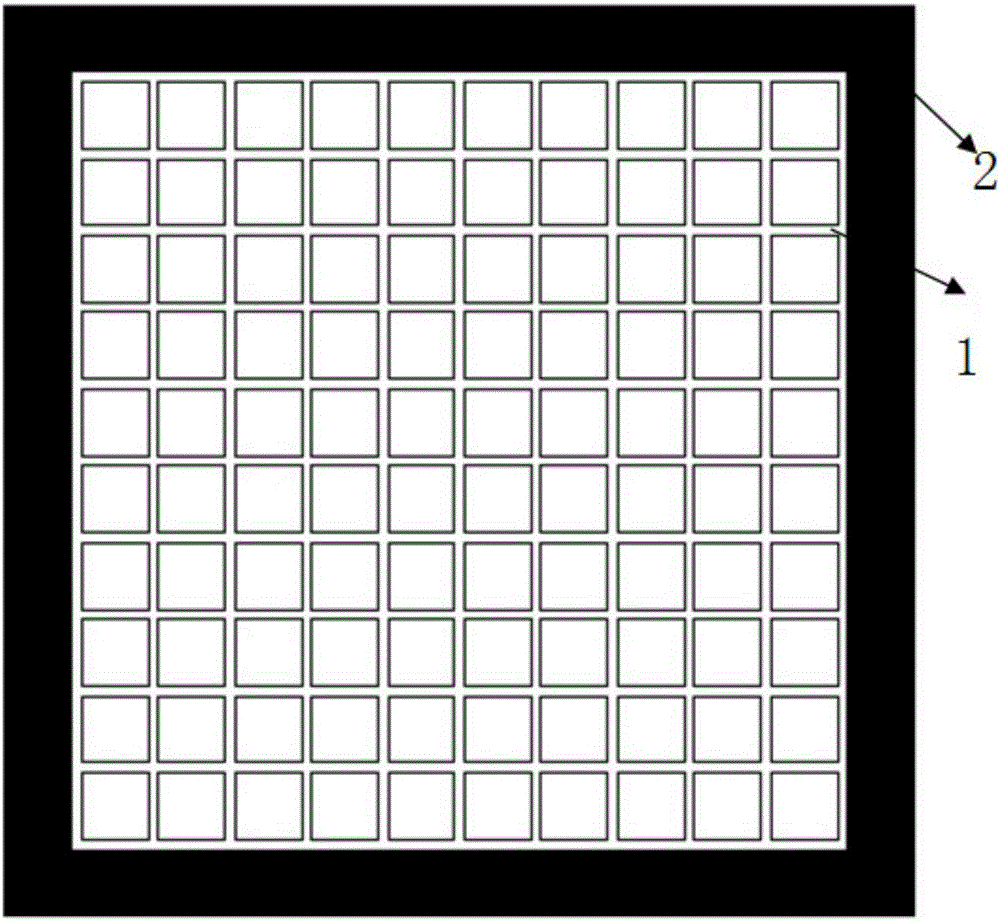

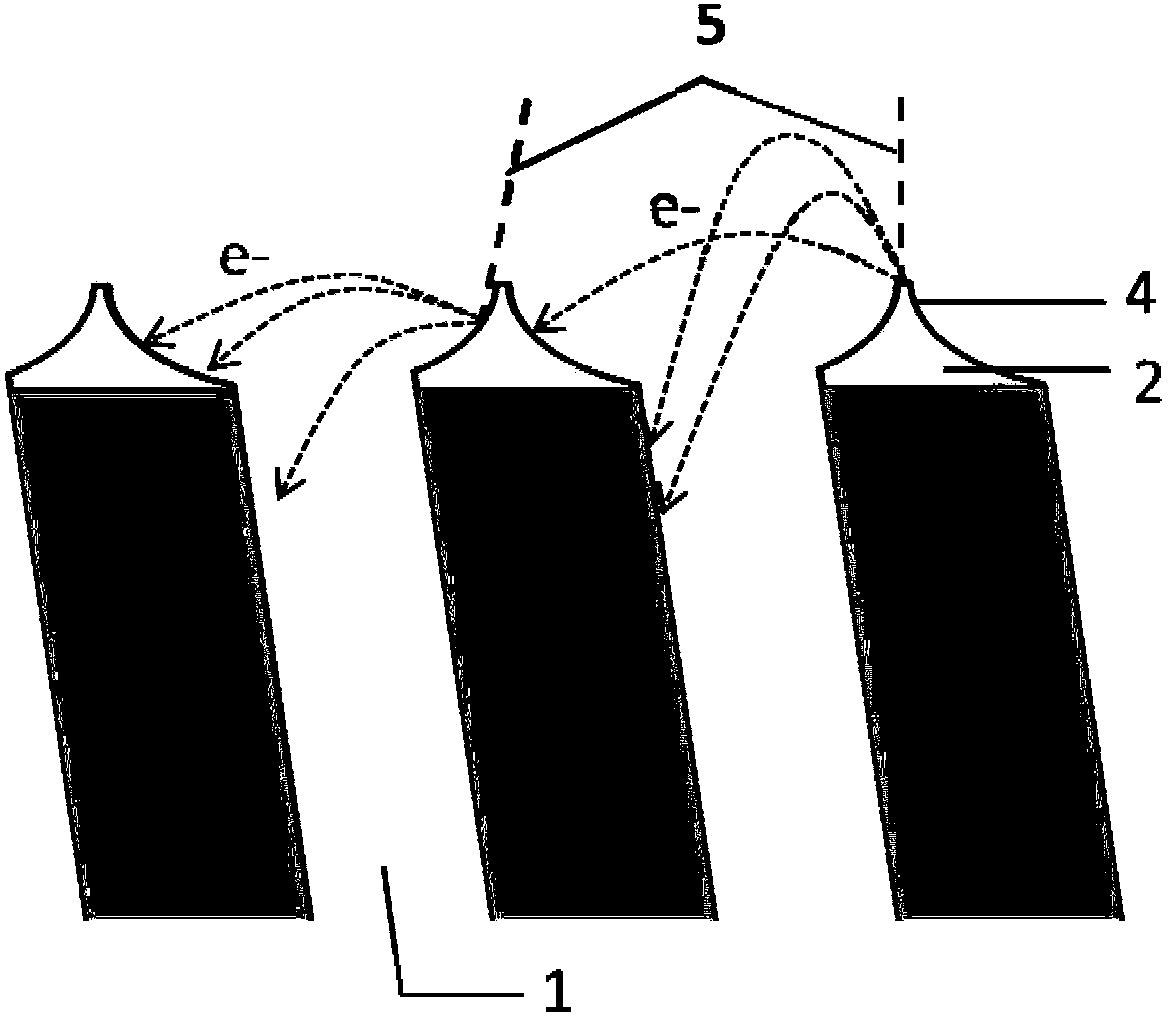

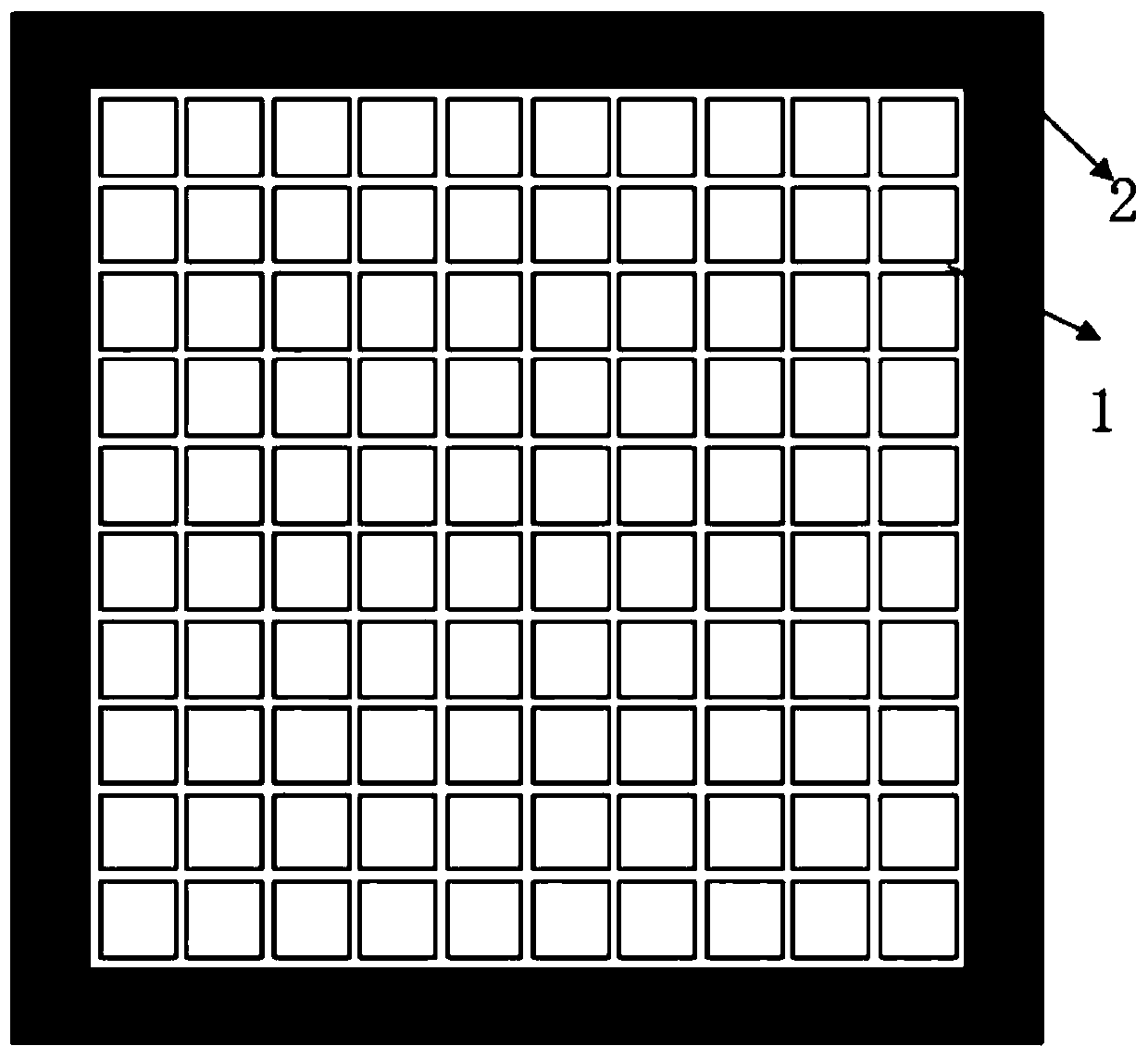

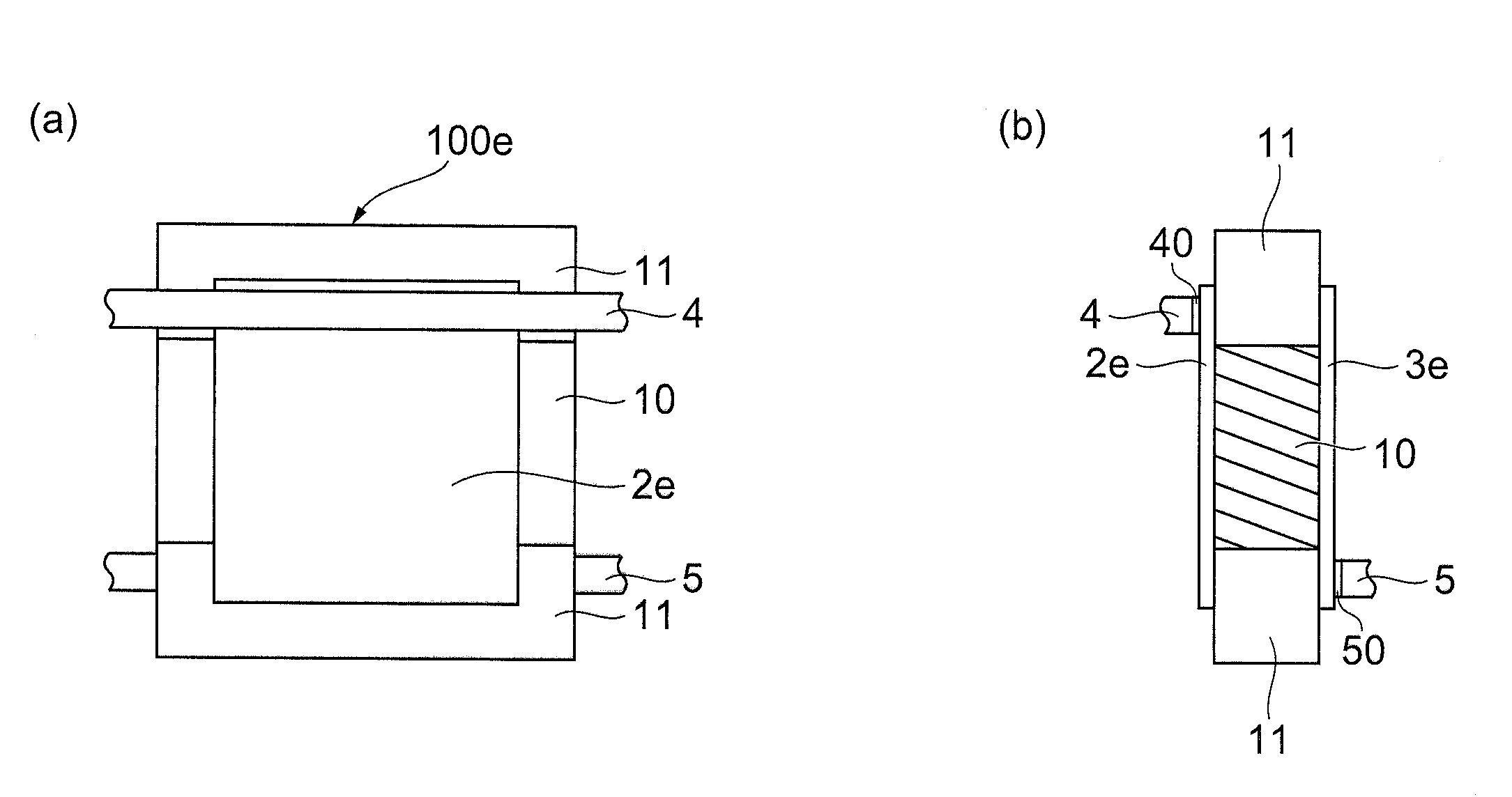

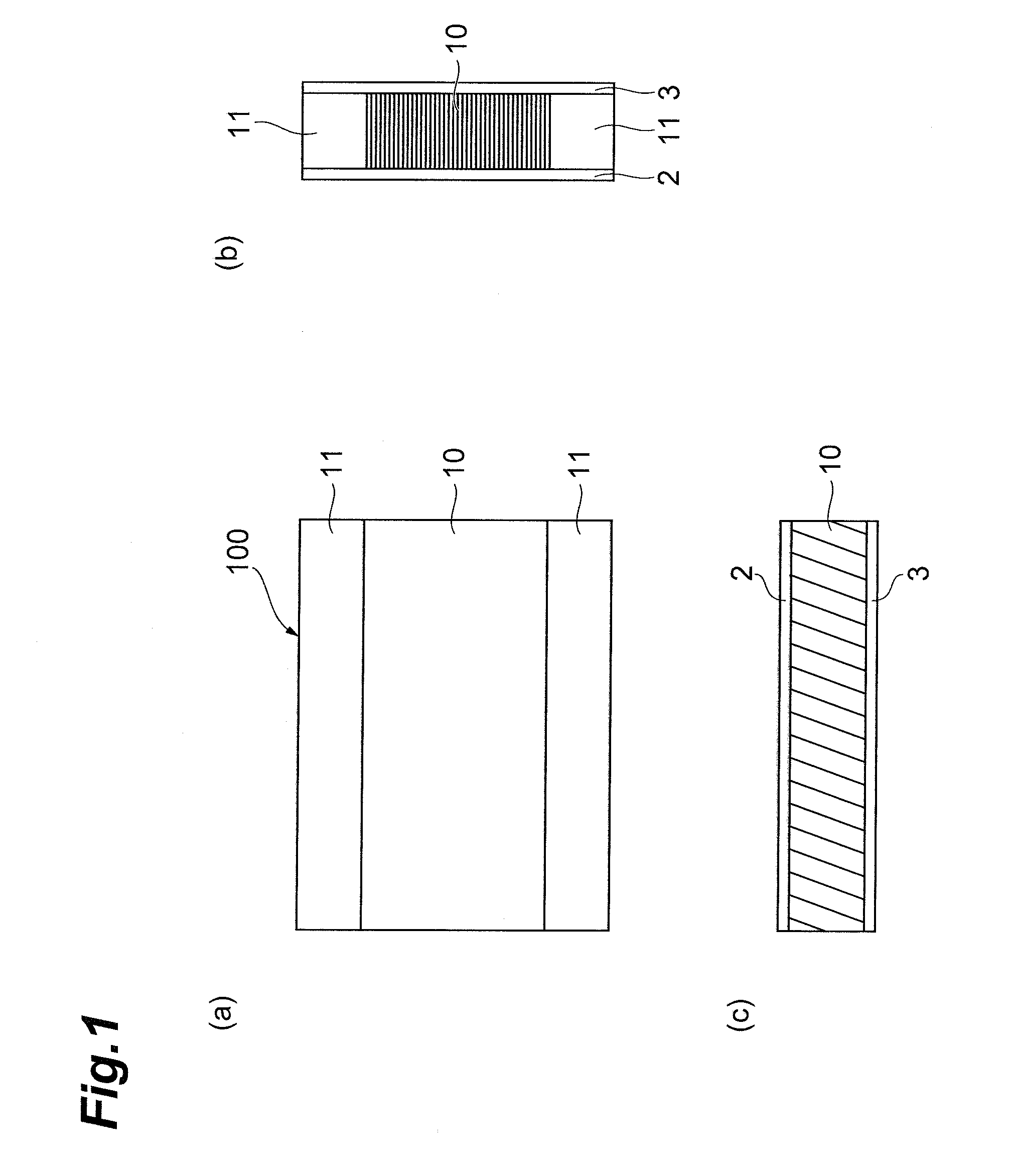

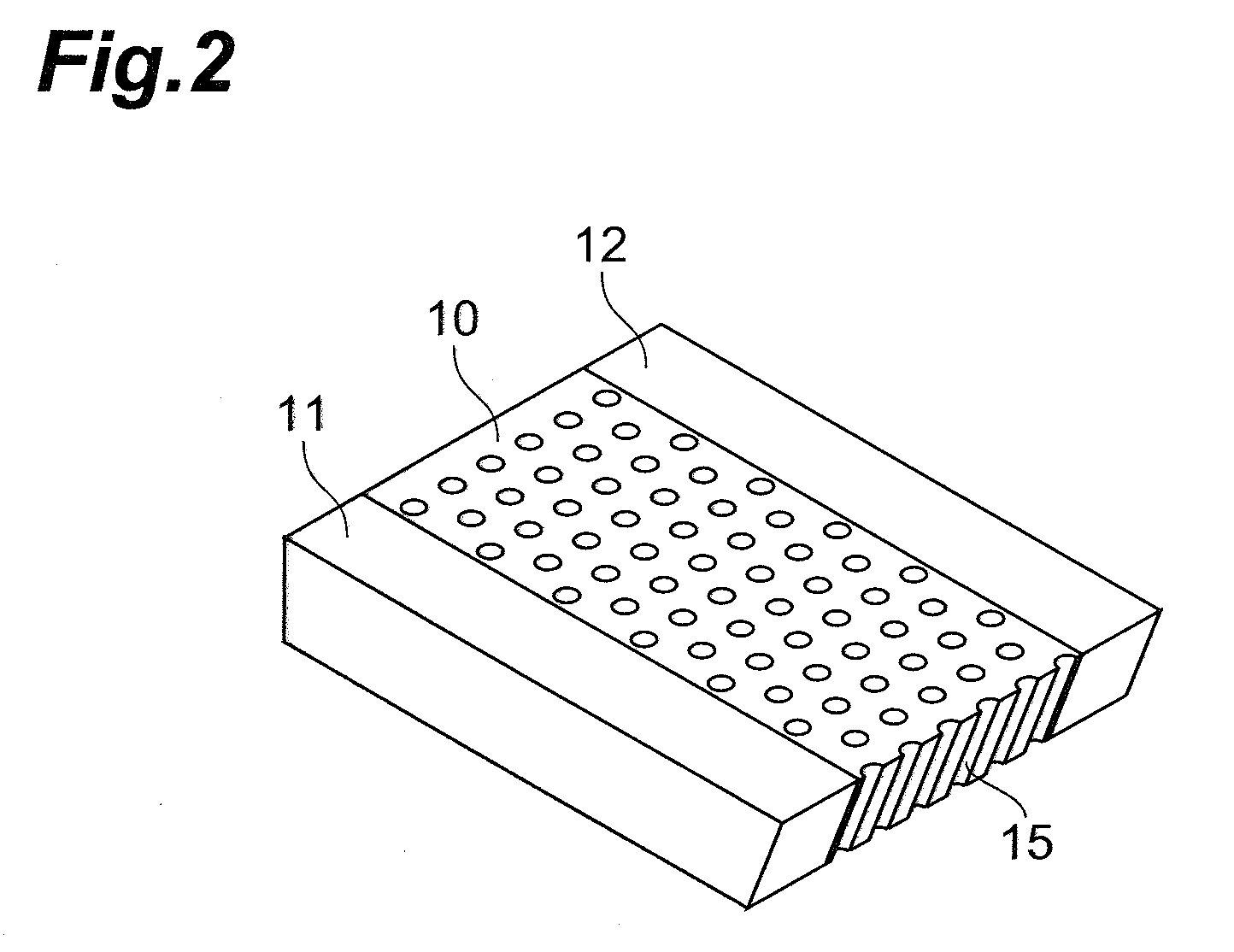

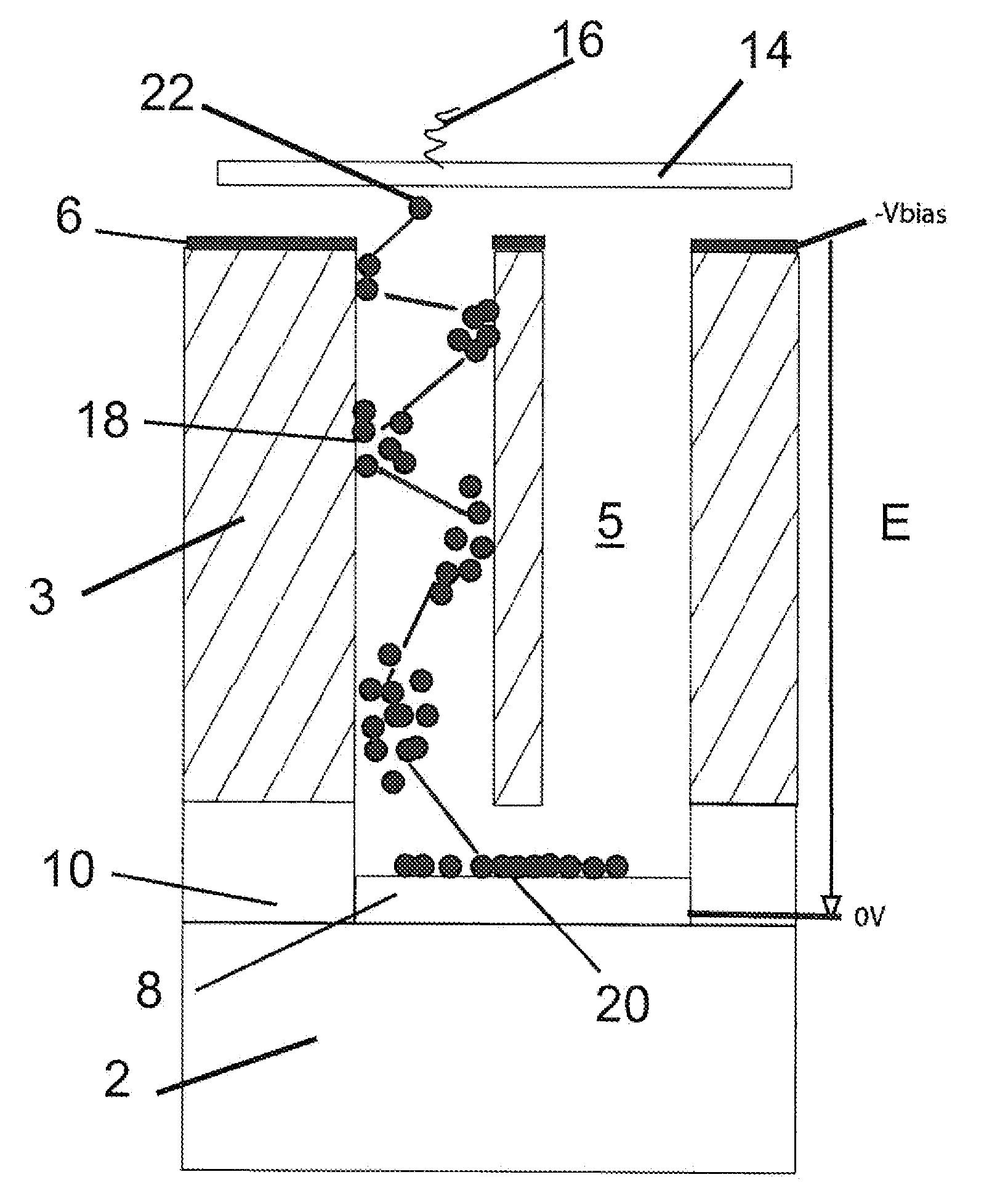

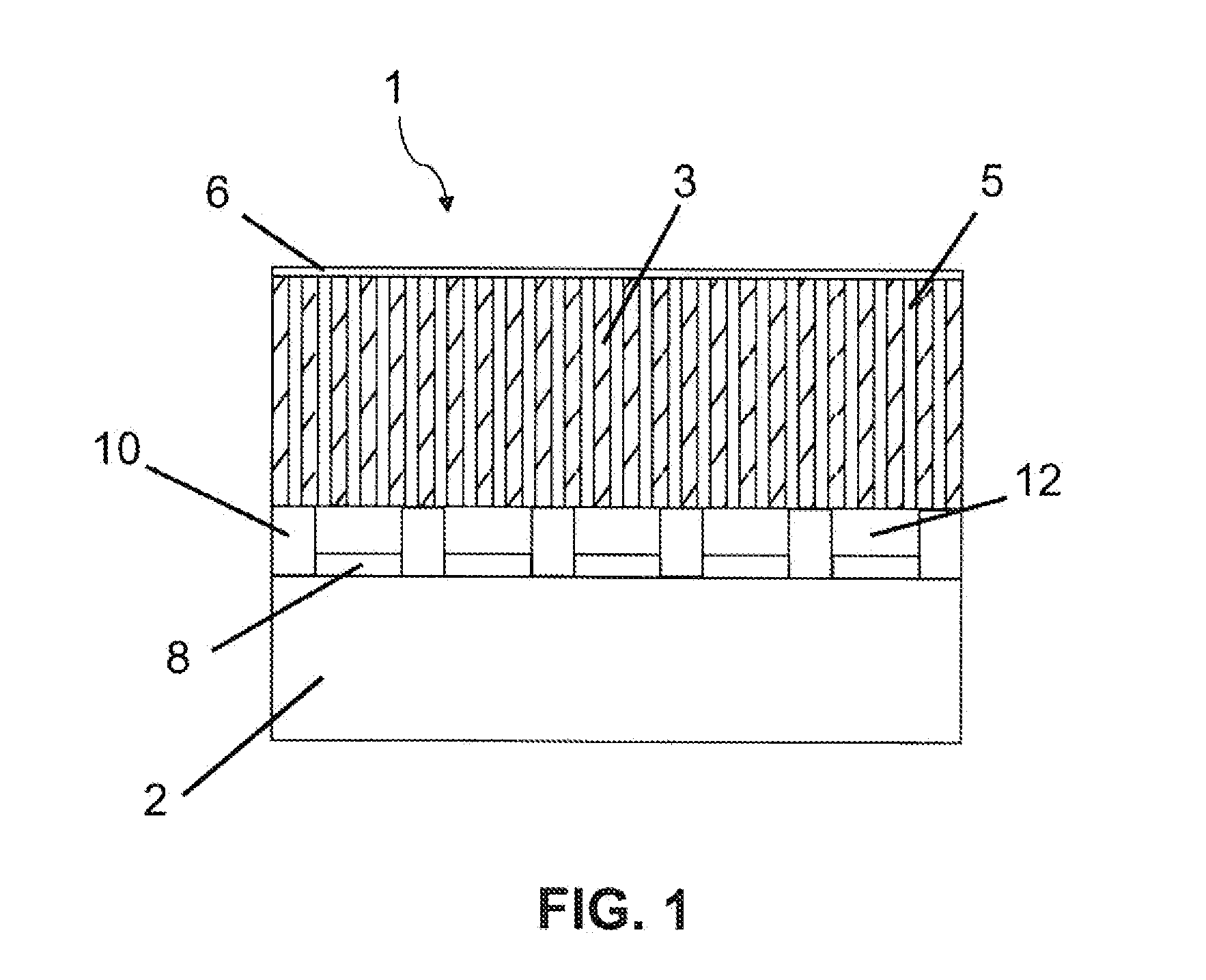

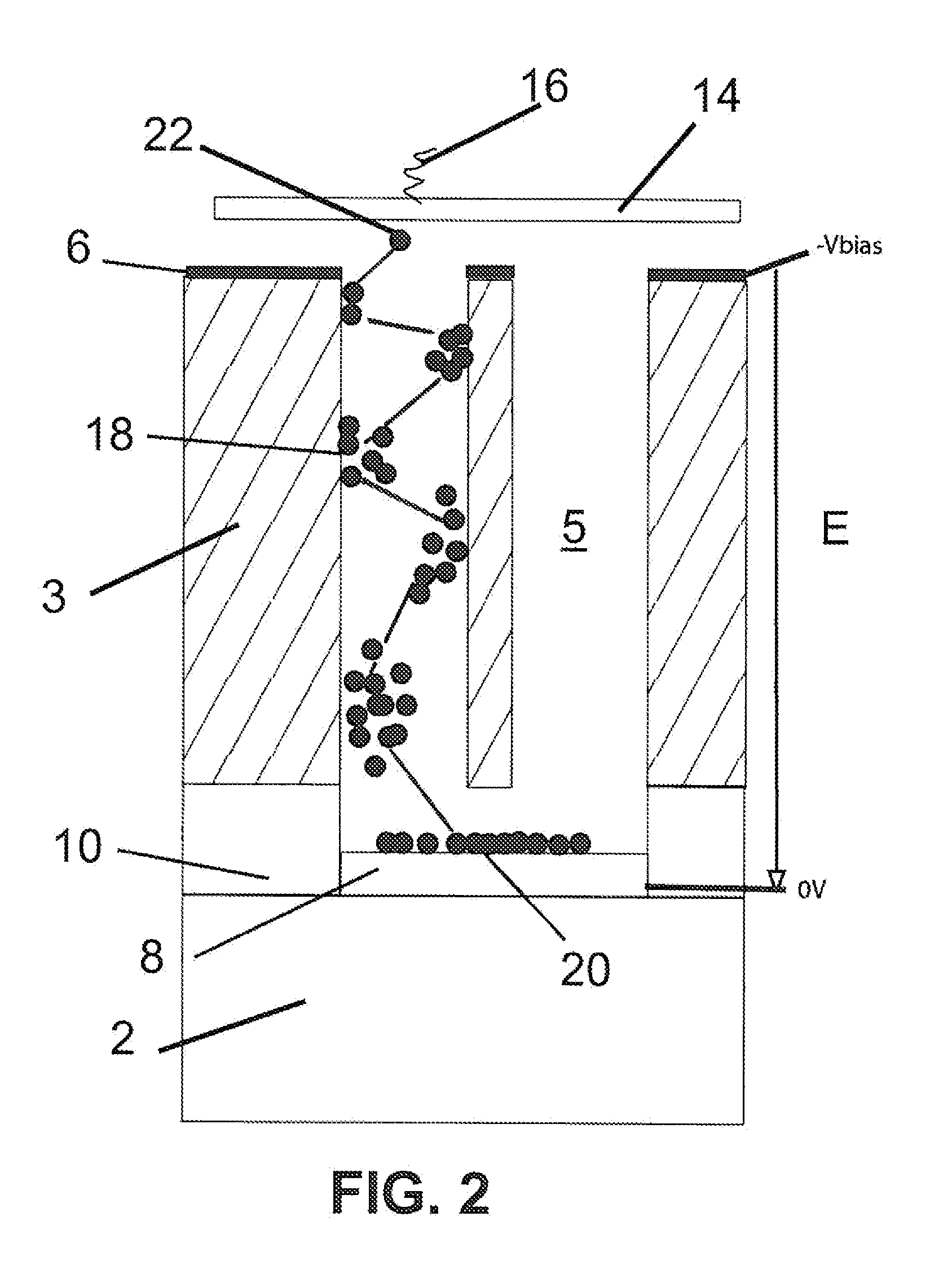

Microchannel plate and its manufacturing method

ActiveUS20120187278A1Multiplier electrode arrangementsPretreated surfacesAmorphous siliconEngineering

A microchannel plate (1) having an array of channels (5),includes a substrate (2) and, deposited on the substrate, a hydrogenated amorphous silicon film (3) having a thickness ranging between 50 μm and 200 μm, preferably between 80 μm and 120 μm, the film including the array of channels (5). Preferably, the substrate (2) is an integrated circuit having an internal electronic readout circuit and pixilated collection electrodes (8), and the film (3) is integrated on the substrate (2). The channels (5) may be formed by a Deep Reactive Ion Etching (DRIE) process.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

High-power photomultiplier

InactiveCN104051217AEliminate continuous fatigue instabilitySolve the problem of increased dark currentMultiplier electrode arrangementsPhotocathodeSecondary electrons

A high-power photomultiplier is characterized by including an incident light source, a photocathode, a primary electron emitter, a secondary electron emitter, a tertiary electron emitter, a quaternary electron emitter, a photocurrent output device, a grounding protection device, a primary current attenuation, a secondary current attenuation, a tertiary current attenuation and a quaternary current attenuation; wherein the primary electron emitter is made of a cesium antimonide nickel alloy electrode material, the second electron emitter is made of a lanthanum oxide alloy electrode material, the tertiary electron emitter and the quaternary electron emitter are made of a cobalt oxide copper beryllium alloy electrode material, the photocurrent output device is provided with a beam filter membrane with the thickness of 2.98 micrometers, and the beam filter membrane is an N-metachromicacid europium iodide nano composite filter membrane.

Owner:成都中远千叶科技有限公司

A self-stabilizing micropulse electron gun based on secondary electron multiplication

InactiveCN104008947BChange sizeEasy to installMultiplier electrode arrangementsEngineeringSecondary electrons

The invention relates to a self-current-stabilizing micropulse electronic gun based on secondary electron multiplying. The electronic gun comprises an inwards concave cavity, a groove is formed in the bottom of the inwards concave cavity, a round hole is formed in the top of the inwards concave cavity, and the cathode stretches into the round hole; a channel through the groove is formed in the arc-shaped end face side of the inwards concave cavity, and a rectangular hole is formed in the rectangular end face side; a through hole is formed in the center of a round cover plate at the top of a grid cover plate, and the grid cover plate is clamped on a stepped structure on the periphery of the groove; threads are arranged on the inner wall face of a hollow pipe at the bottom of the grid cover plate; two water tank outer shells are welded to the two ends of the cavity respectively and provided with holes; a first pipeline flange is connected with the cathode, penetrates through the holes of the water tank outer shells and then is tightly connected with the top of the inwards concave cavity, a second pipeline flange and the hollow pipe at the bottom of the grid cover plate are welded together, and a third pipeline flange is welded to the arc-shaped end face of the inwards concave cavity; a tapered waveguide outlet end is welded to the rectangular end face of the inwards concave cavity, and a tapered waveguide flange is welded to the inlet end.

Owner:PEKING UNIV

A novel microchannel plate electrode with ion blocking function and its manufacturing method

ActiveCN104465295BAct as an electrodeElectrode function hasMultiplier electrode arrangementsCold cathode manufacturePhotocathodePhotodetector

The invention is a microchannel plate electrode with ion blocking function, which is made on the input or output surface of the microchannel plate in the negative electron affinity photocathode type vacuum photodetection device, and is used to apply working voltage to the normal operation of the microchannel plate , production method: on the input surface or the output surface of the microchannel plate, transfer and manufacture a high-strength, uniform and high-coverage single-layer or multi-layer graphene film, so that the film layer has both conventional microchannel plate electrode functions and With the function of ion barrier film, the negative electron affinity photocathode type vacuum photodetector is mainly composed of the front light window, the photocathode on the light window, the middle microchannel plate, the rear anode, and the sealed ceramic metal shell. composition. The advantages can greatly improve the electron transmittance compared with the structure of the traditional nickel-chromium metal electrode plus Al2O3 or SiO2 ion barrier film, reduce the scattering effect on electrons, and improve the detection efficiency and signal-to-noise ratio of the device.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Photomultiplier

InactiveUS20060220552A1Easy alignmentImprove productivityMultiplier electrode arrangementsControl electrodesProduction rateEngineering

Owner:HAMAMATSU PHOTONICS KK

Electrode lead unit, vacuum photoelectric device and manufacturing method thereof

ActiveCN106876229APrevent burstImprove performanceMultiplier electrode arrangementsCold cathode manufactureNight visionHigh density

The invention belongs to the technical field of photoelectric devices, and relates to an electrode lead unit, a vacuum photoelectric device and a manufacturing method thereof. The electrode lead unit comprises a glass substrate, a glass package and multiple electrode leads; the glass package is welded on the surface of the glass substrate; the electrode leads are distributed on the welding surface between the glass package and the glass substrate; and one end of each electrode lead is located at the inner side of the glass package, and the other end of the electrode lead is located at the outer side of the glass package. Due to the manufactured electrode lead unit and no limitation from the diameter of a Kovar alloy wire at the tail end of an anode, a vacuum photoelectric device with hundreds of readout channels can be manufactured. The size of the electrode can reach tens of microns minimally, manufacturing of a high-density electrode lead can be realized, the electrode can be applied to multiple vacuum photoelectric devices such as a hybrid photodetector and a multi-anode photomultiplier tube, and has a wide application prospect in multiple fields such as high-energy physics, cosmic exploration, low light level night vision, and medical instruments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

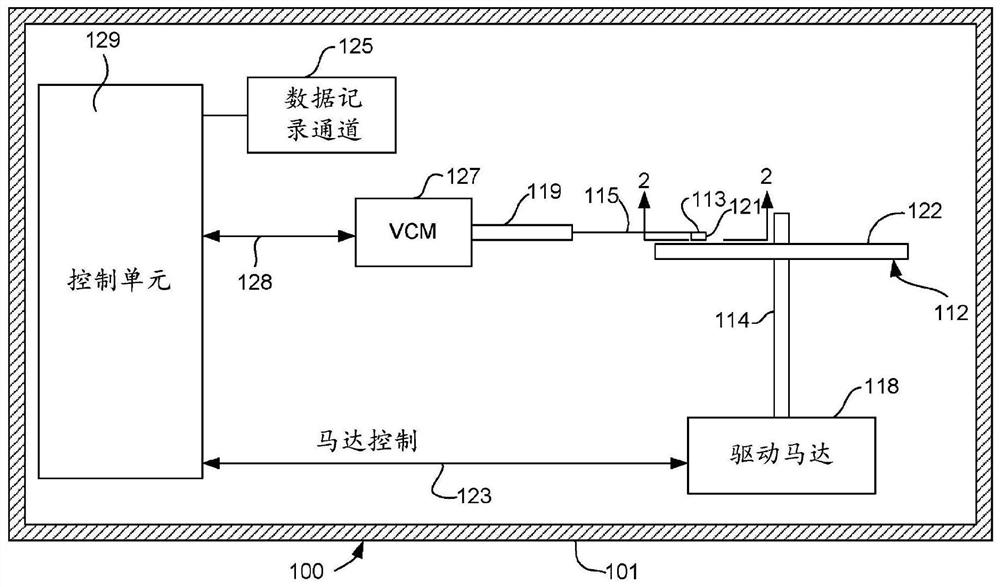

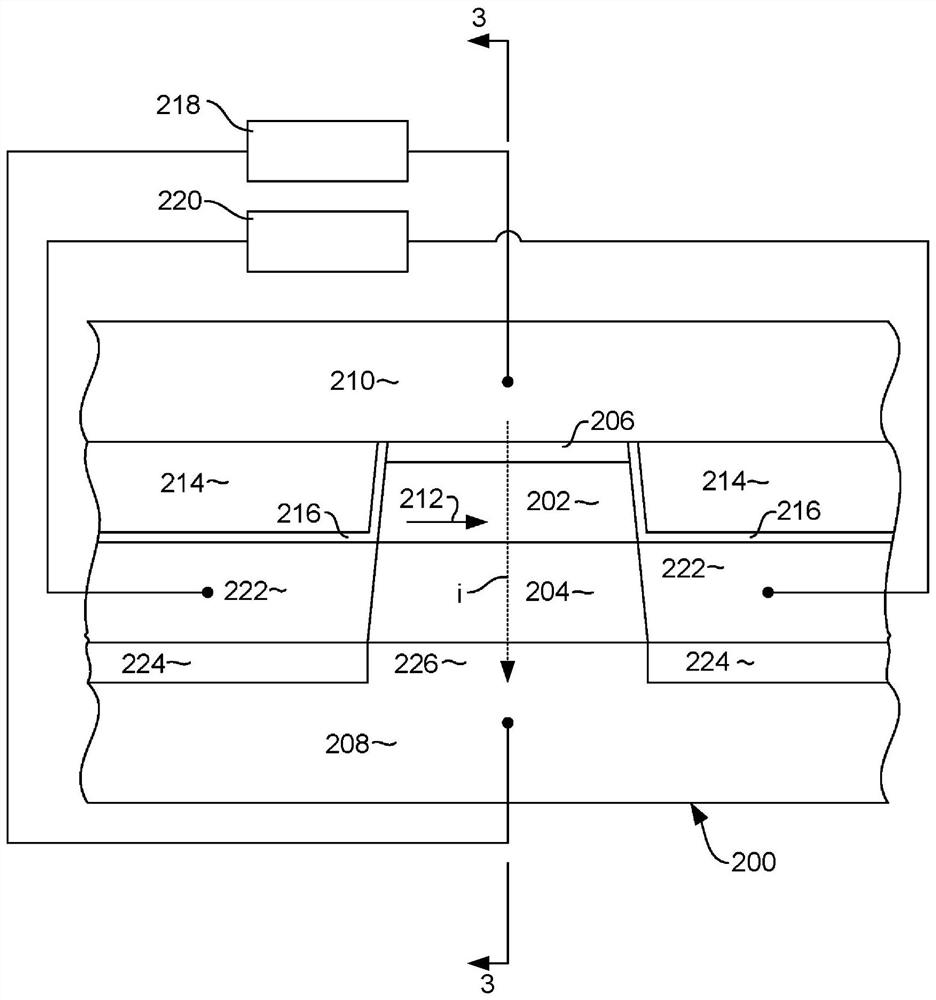

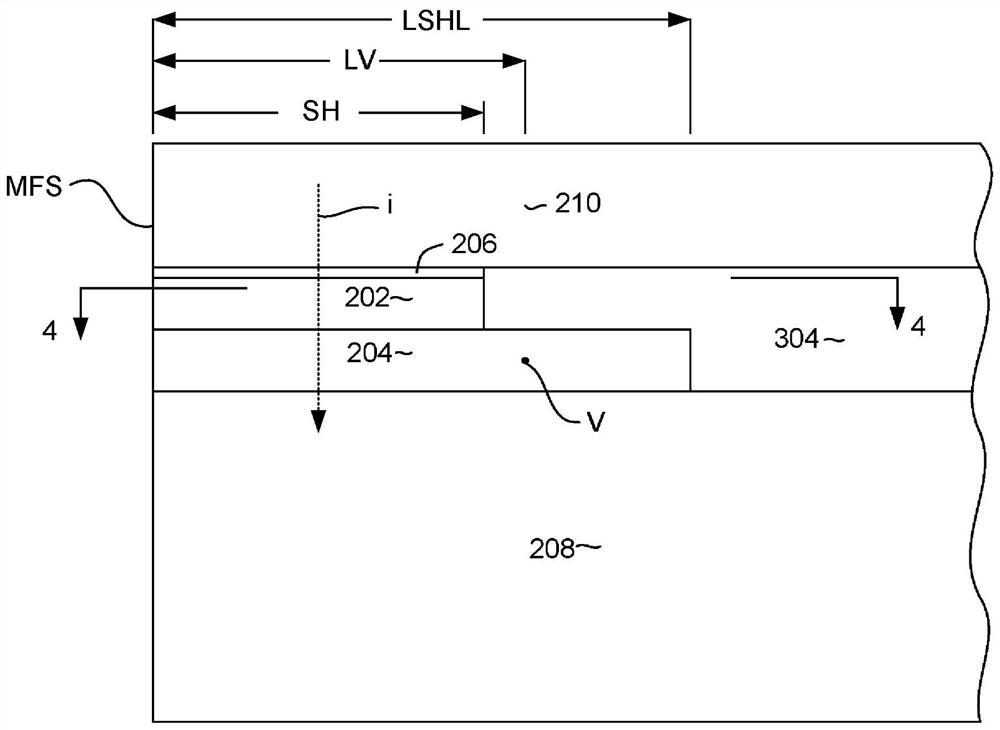

Magnetic sensors using the inverse spin Hall effect

ActiveCN109690338BMultiplier electrode arrangementsMagnetic measurementsSpin Hall effectHemt circuits

Owner:WESTERN DIGITAL TECH INC

Popular searches

Electron/ion optical arrangements Ion sources/guns Isotope separation Beam/ray deflecting arrangements Beam deviation/focusing by electric/magnetic means Semiconductor/solid-state device manufacturing Photoelectric discharge tubes Electric discharge lamps Semiconductor devices Glass reforming apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com