Curved surface film forming method for dynode of electron multiplier

A technology of electron multiplier and film forming method, which is applied in the direction of electron multiplier detailed information, dynode, electrode system manufacturing, etc., to achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

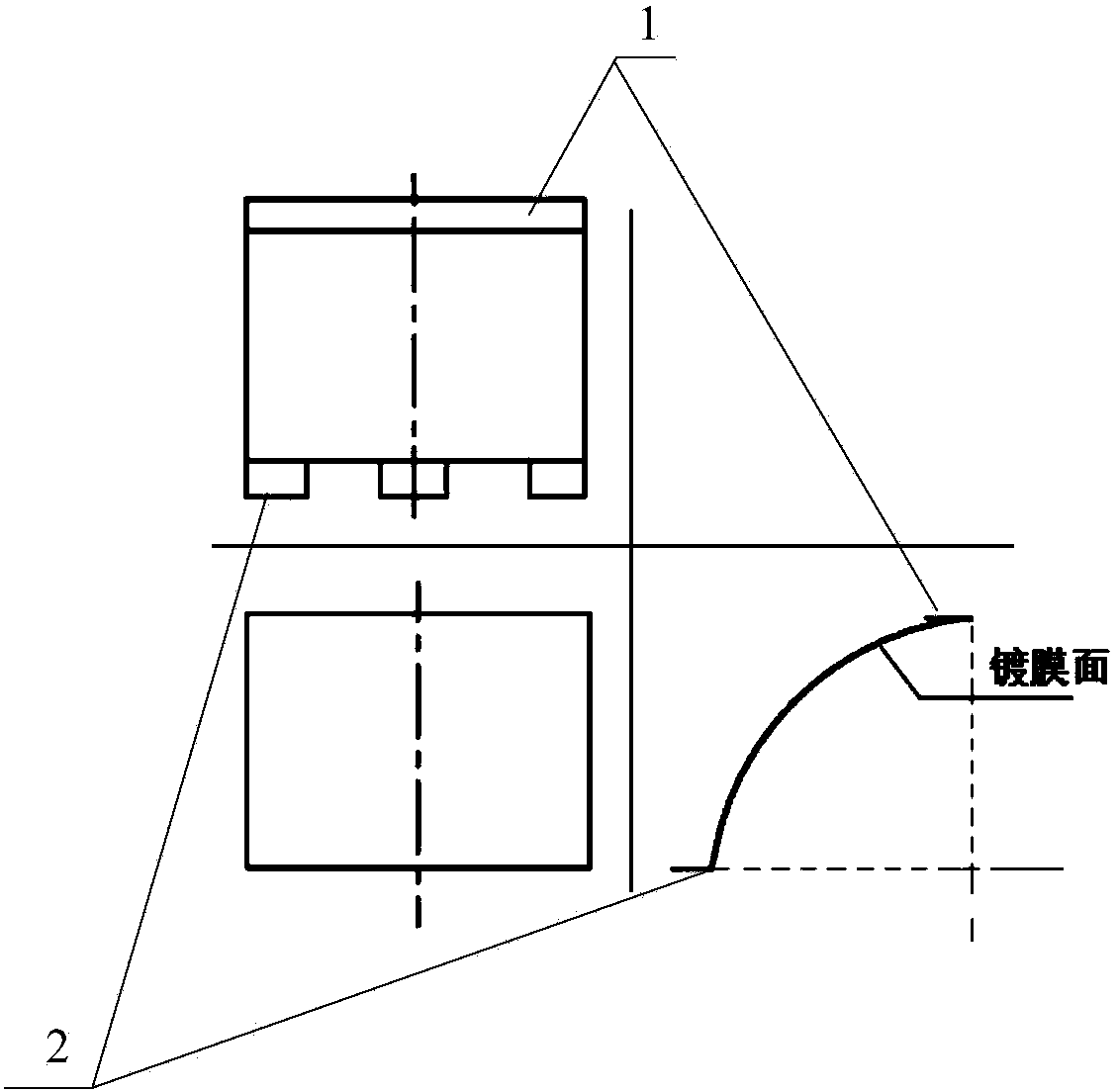

[0021] Embodiments of the present invention will be described below with reference to the drawings.

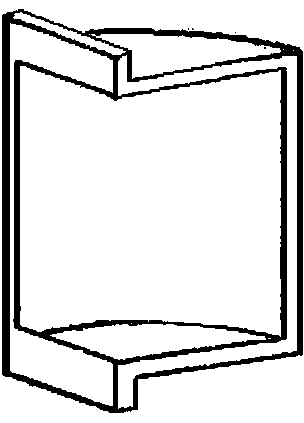

[0022] The present invention aims at the problem of coating defects on the curved surface of the electron multiplier dynapole. In order to meet the requirements of the curved surface coating of the dynapole, a brand-new film formation idea is adopted: first, the secondary electron emission is plated on a stainless steel curved inner lining with a certain radian. The functional thin film is then mounted to the electron multiplier dynode. Since the film coating on the curved inner liner can ensure the uniformity of the film coating, the film forming method can meet the film coating requirements of the electron multiplier dynode curved surface substrate.

[0023] The implementation steps of the electron multiplier dynode curved surface film forming method are as follows:

[0024] Step 1. Curved lining processing:

[0025] refer to figure 2 , according to the size and radian o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com