Electron multiplier dynode surface coating base plate frame

A technology of electron multiplier and dynode, which is applied in the field of surface engineering to achieve the effect of uniformity of film formation and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

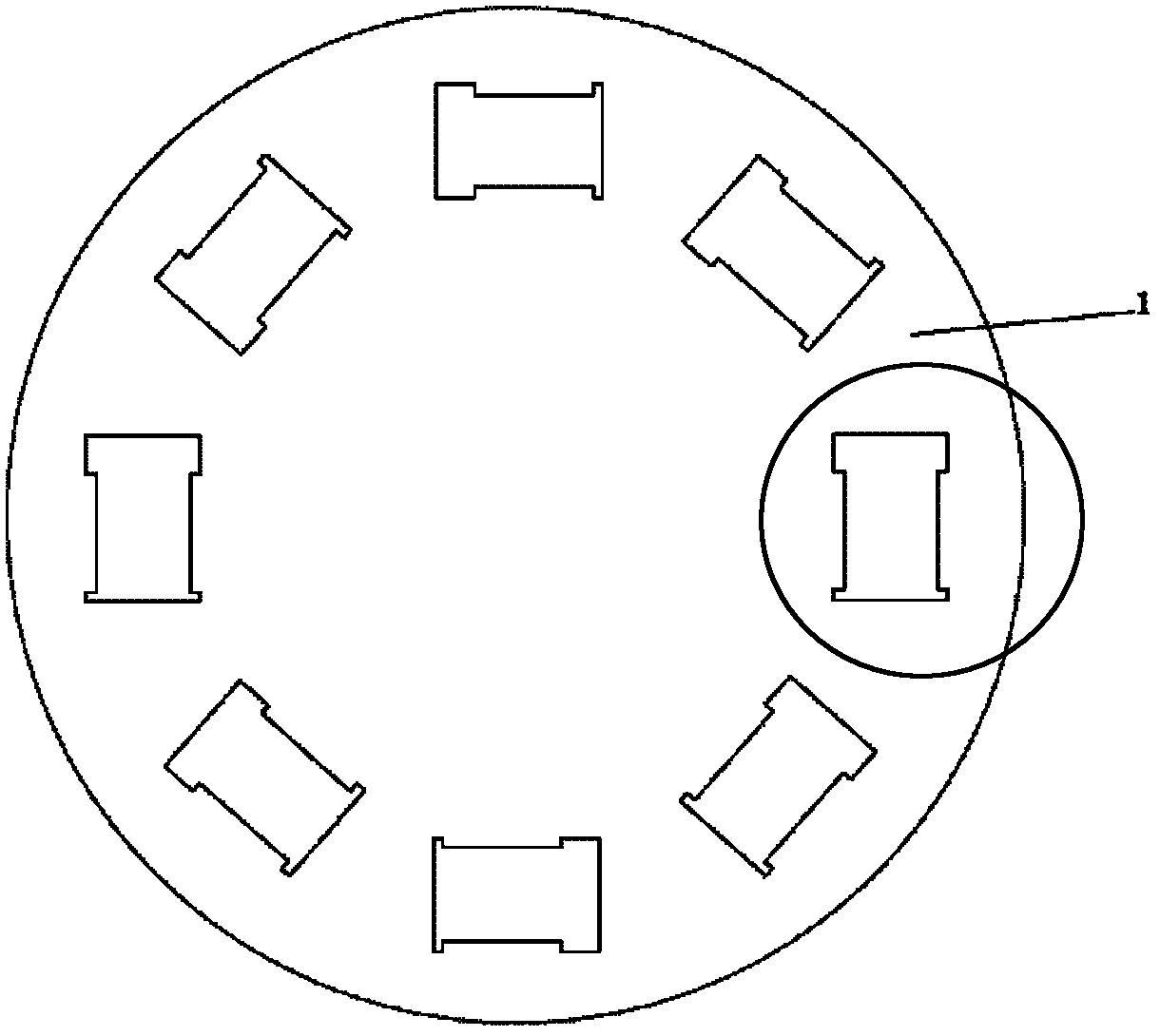

[0026] An electron multiplier dynamo polar surface coating substrate frame, the substrate frame 1 is a disk, and one or more I-shaped holes are equally spaced on the disk; the center of all the I-shaped holes reaches the circle The distance from the center of the disc is equal;

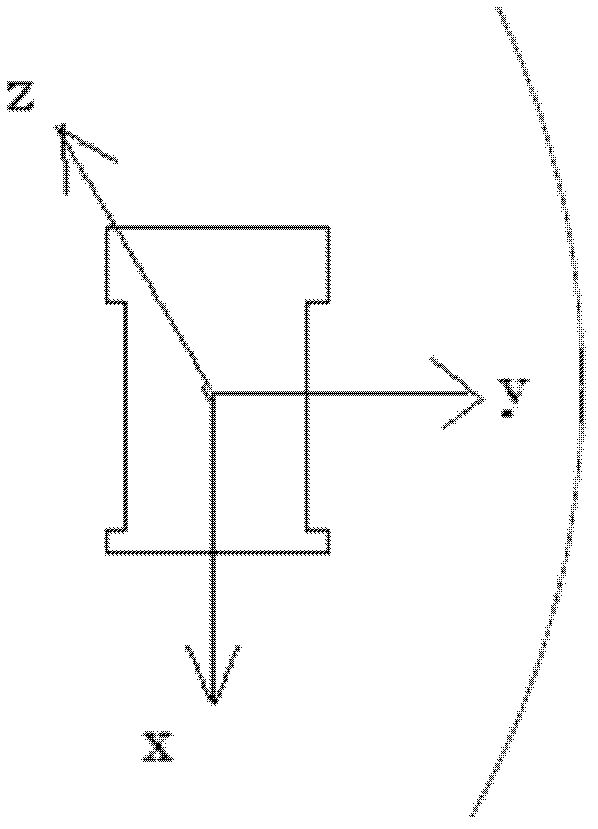

[0027] Along the x-axis direction, the hole length of the I-shaped hole is 20mm;

[0028] Along the y-axis direction, the two ends of the I-shaped hole are respectively provided with the upper outer protrusion and the lower outer protrusion of the hole. The upper outer protrusion is 15mm long and 15mm wide, and the lower outer protrusion is 15mm long and 9mm wide; I-shaped The width of the middle part of the hole is 8mm;

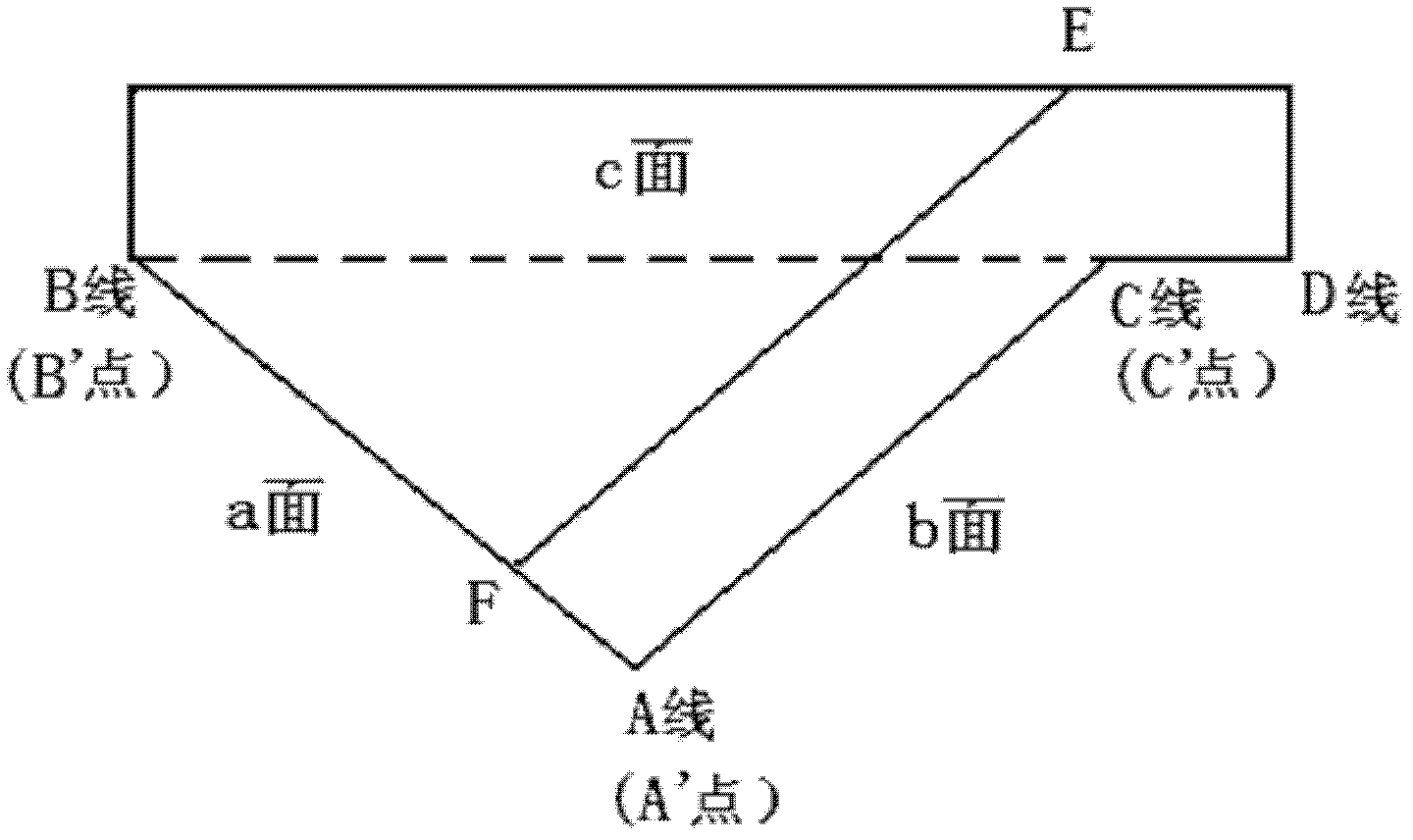

[0029] Along the z-axis direction, two symmetrical side plates 2 are respectively provided under the two sides of the middle part of the I-shaped hole, and the two side plates 2 are perpendicular to and merged with the base frame 1; the side plates 2 are triangular, with a, b, c t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com