Constant-pressure inflation tool

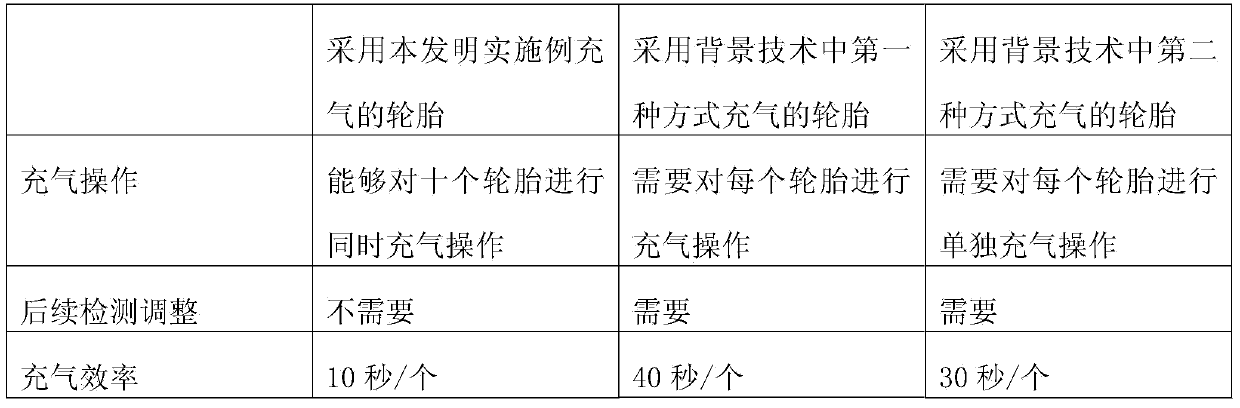

A technology of tooling and air pressure, which is applied in the field of constant pressure inflatable tooling, can solve the problems of increasing labor costs, reducing production efficiency, and reducing work efficiency, and achieves the effects of saving tire installation time, improving work efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

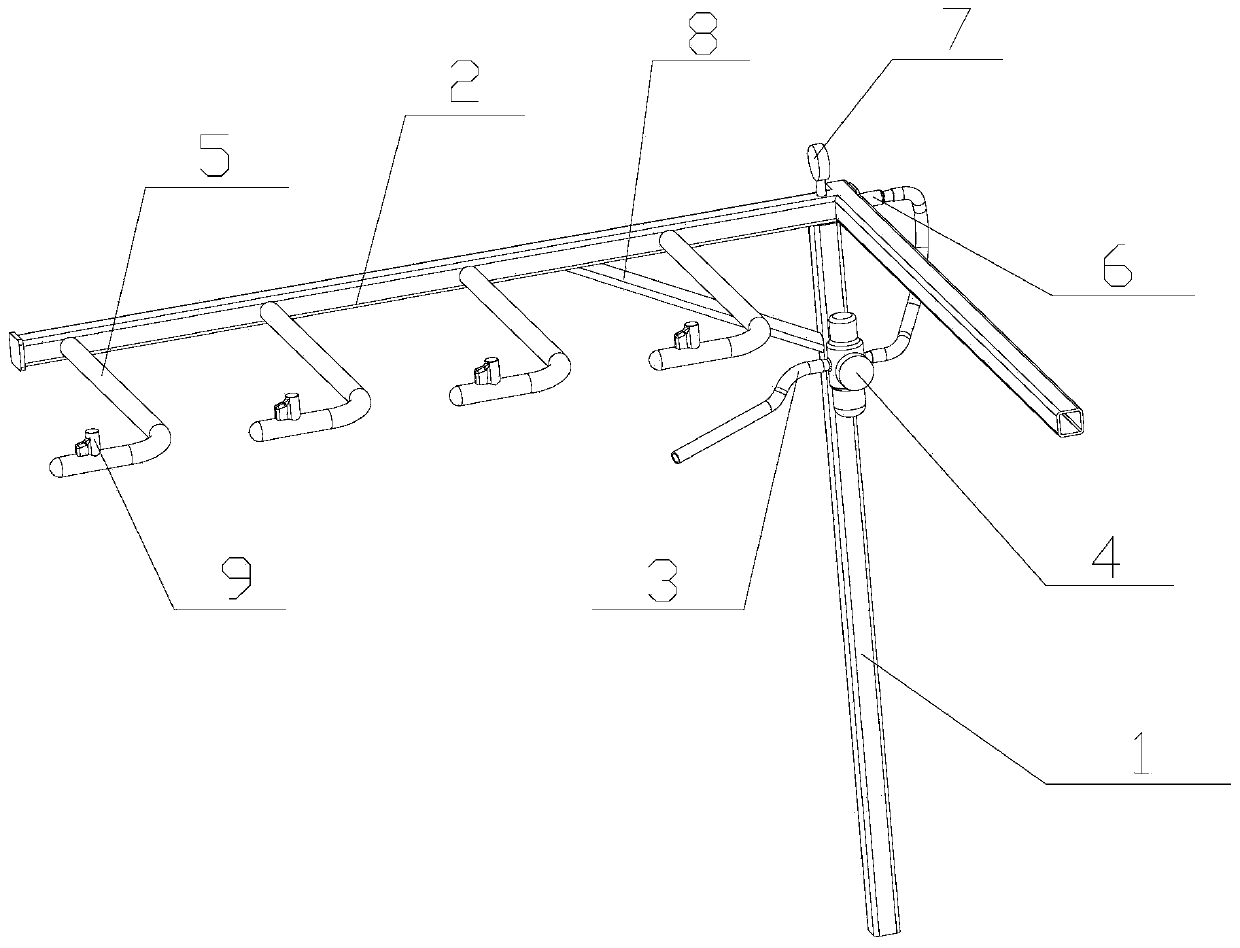

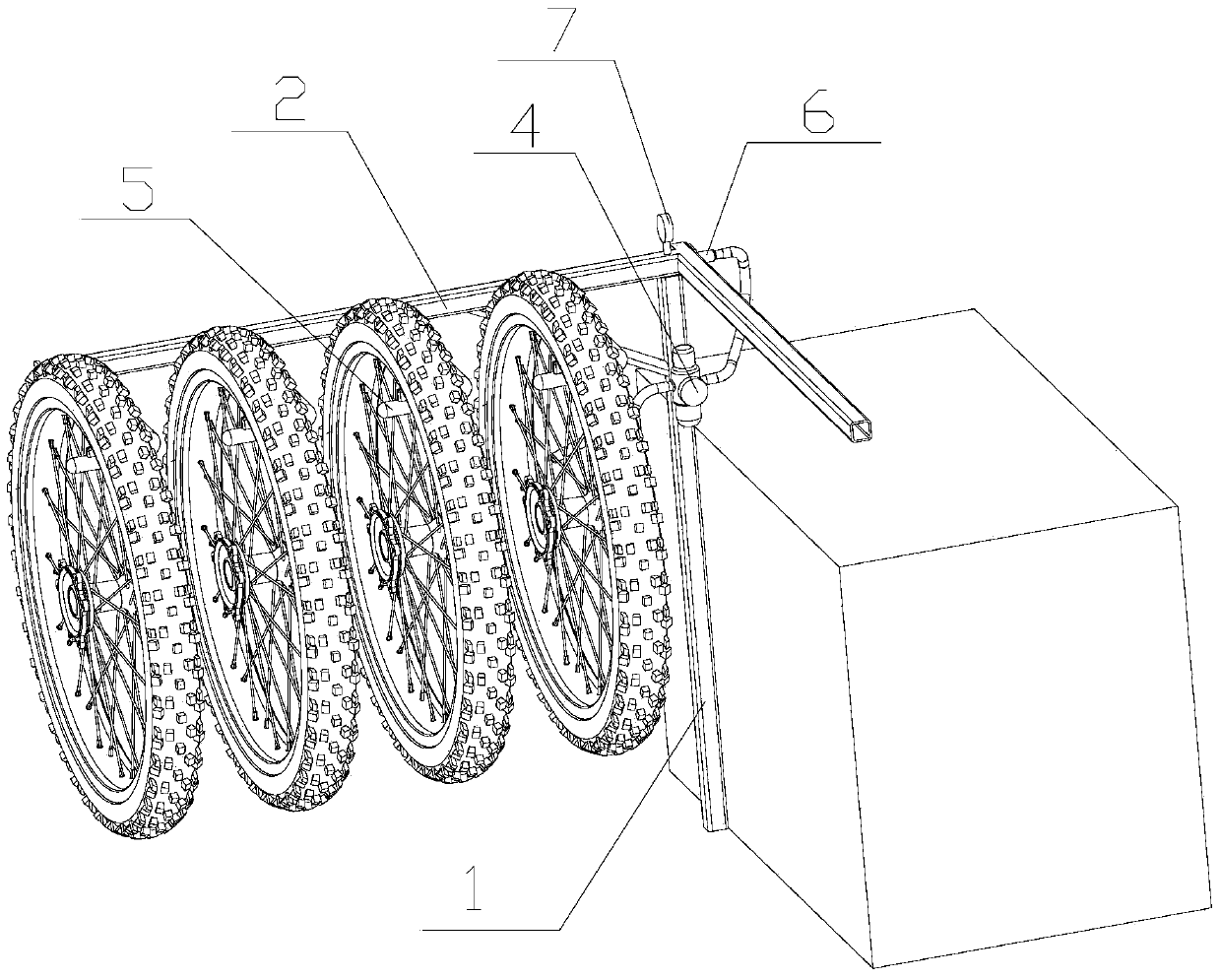

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] Referring to the accompanying drawings: the constant pressure inflation tooling in this embodiment includes a mounting tube-1 for being fixed on the tooling platform to play a supporting role, and the top of the mounting tube-1 is connected with a tire for supporting the tire to be inflated. Installation pipe two 2, the installation pipe two 2 and the installation pipe one 1 are vertically arranged, the installation pipe one 1 is connected with the air intake pipe 3 for inflating the tire on the installation pipe two 2, and the air intake pipe 3 is provided with an air intake pipe for adjusting The decompression valve 4 of the intake air pressure is installed at the junction of the installation pipe 1 and the intake pipe 3, and a group of outlet pipes 5 for supporting and inflating the tires are connected to the installation pipe 2. 5 is connected with a vent pipe 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com