Airborne smoke bar spreading device

A technology of flame rods and shells, which is applied in the field of airborne flame rod spreading devices, can solve problems such as complicated installation process, reduced applicability, and easy damage to the installation position, and achieve the goals of enhanced universal applicability, reduced local stress, and reduced wind resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

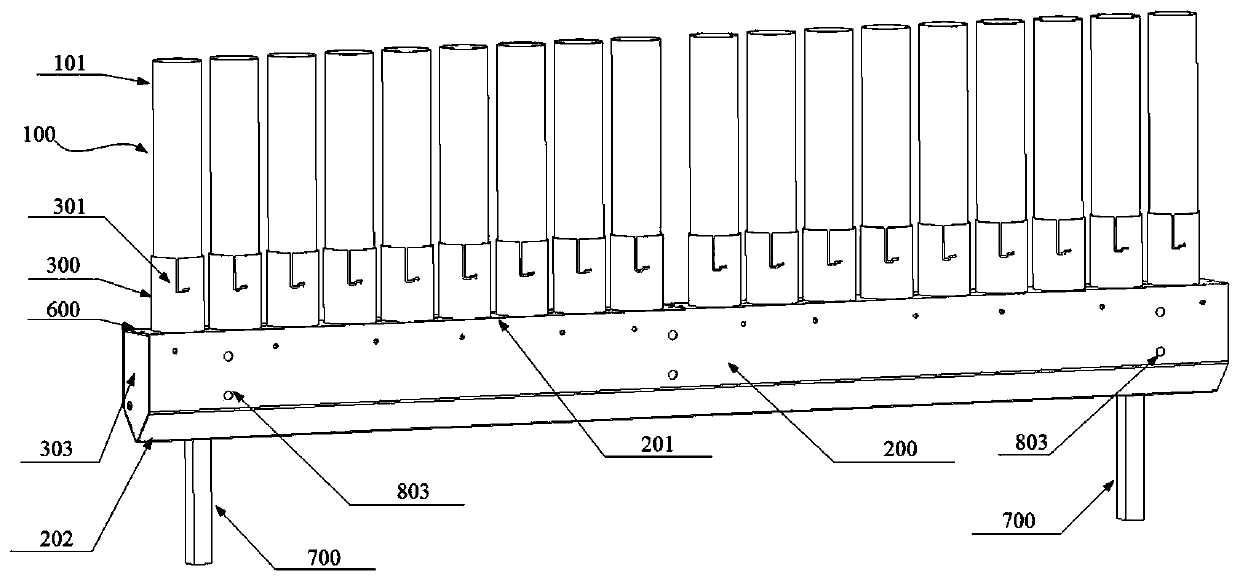

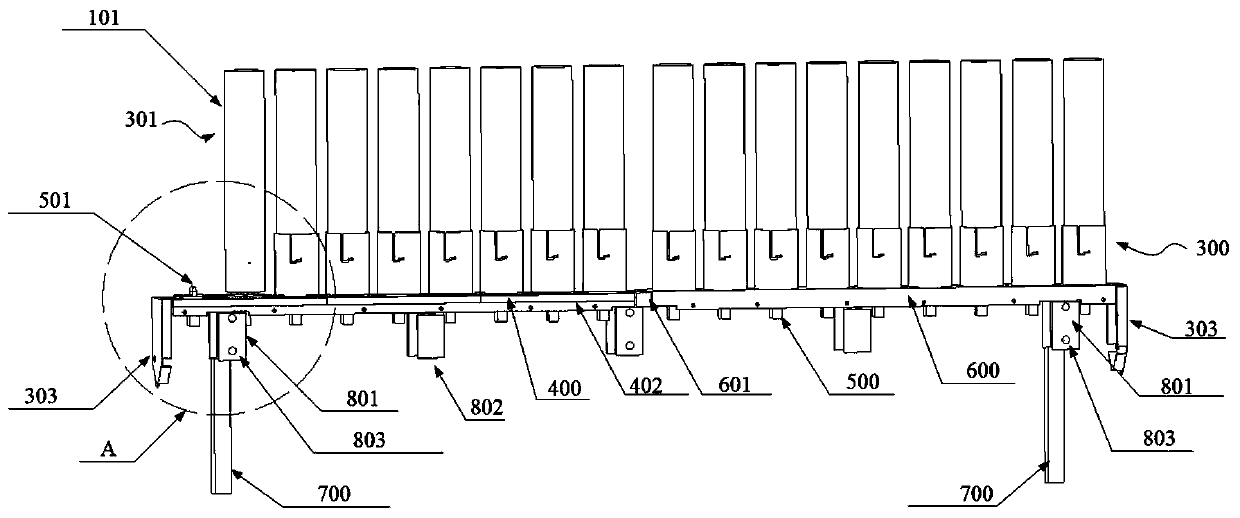

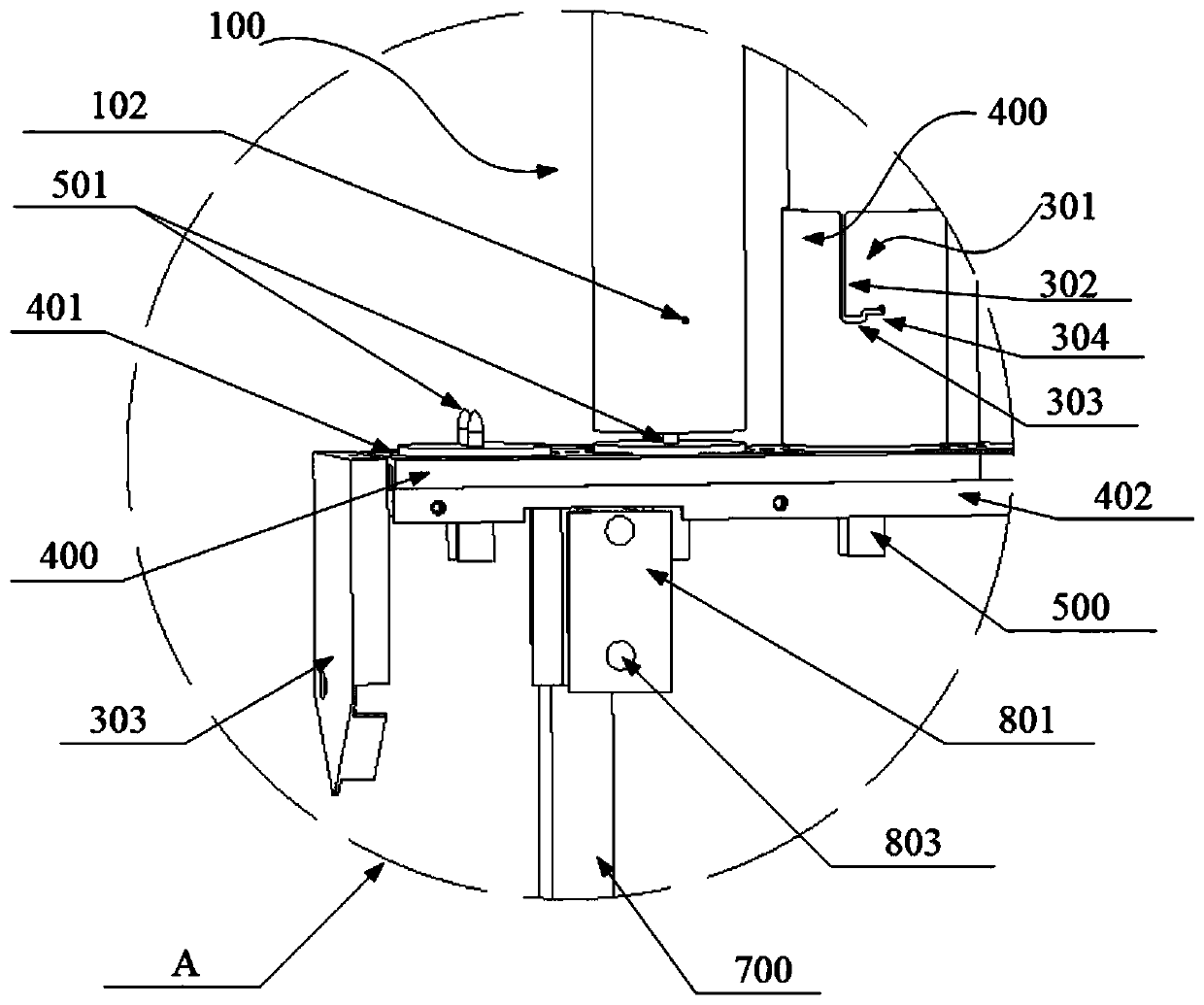

[0034] Such as Figure 1-3As shown, an airborne flame rod spreading device in this embodiment includes several flame rods 100, a spreading housing 200, several flame rod tubes 300, several flame rod tube bases 400, several end covers 600, several fixing plates 402, A number of spring structures 500, a number of positive and negative electrode columns, a V-shaped end cap 203, a number of first support plates 801, a number of second support plates 802, and a number of brackets 700, and a number of flame bars 100 are parallel to each other and spaced in a "one" shape Arranged in a row, the flame rod 100 is provided with a number of positioning pins 102, and the flame rod tube 300 is provided with a number of limiting grooves 301, and the positioning pins 102 are inserted into the limiting grooves 301 and rotated at a certain angle The locating pin 102 is snapped into the limiting groove 301, the flame bar base 400 is provided with a plurality of circular grooves 401, the end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com