Engine valve device

An engine valve and valve technology, which is applied to engine components, machines/engines, valve devices, etc., can solve problems such as poor valve sealing, and achieve the effects of avoiding wear, improving sealing, and reducing local stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

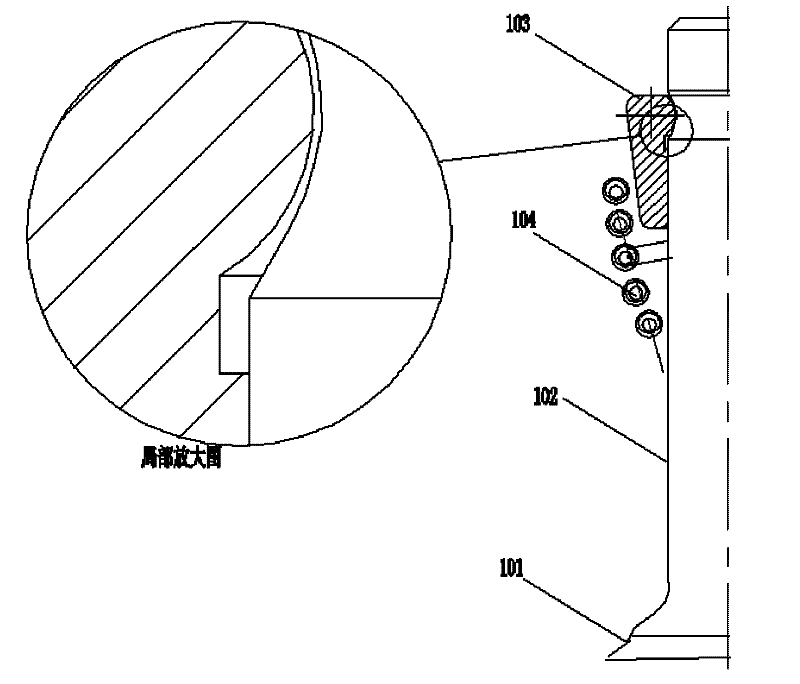

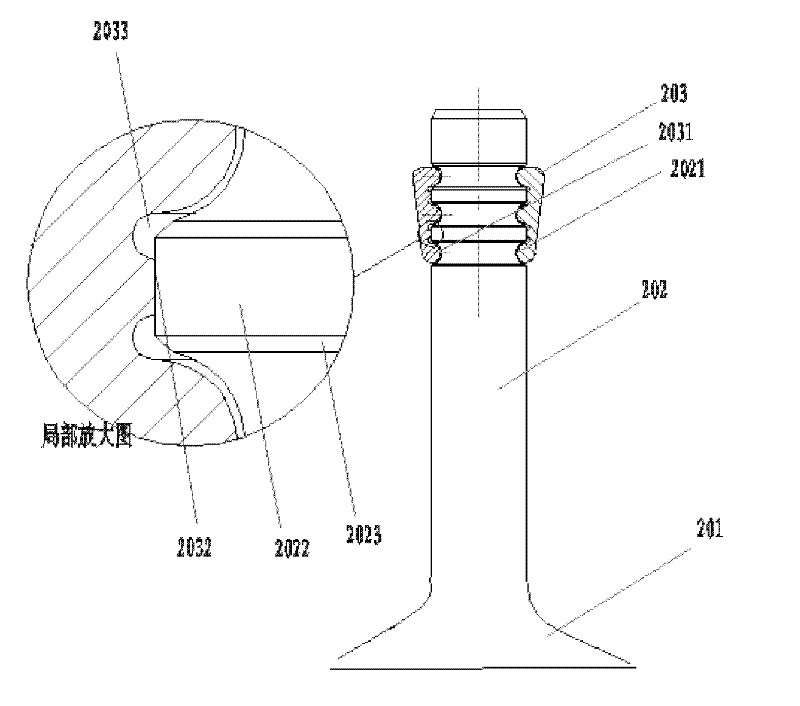

[0016] The embodiment of the present invention reforms the traditional engine valve device. At least three lock clip grooves are arranged on the upper end of the valve stem. The lock clip grooves are separated by convex belts. At the same time, a corresponding structure is set in the valve lock clip, the height of the convex surface is less than the groove depth of the lock clip groove; the diameter of the convex surface band is smaller than the diameter of the concave surface band, using this valve structure, even under the action of the spring lock When the clamp is locked on the valve stem, the valve stem can still rotate freely around the axis of the valve stem, thereby better sealing the cylinder and solving the problem of air leakage in the process of engine compression and work in the prior art.

[0017] In order to understand the purpose and technical characteristics of the present invention more clearly, the present invention will be further described in detail below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com