A bridge beam lifting system mounted on a pier

A technology for bridge piers and bridges, which is applied in the field of bridge beam lifting equipment to achieve good synchronous lifting, improving effect, fixing effect and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

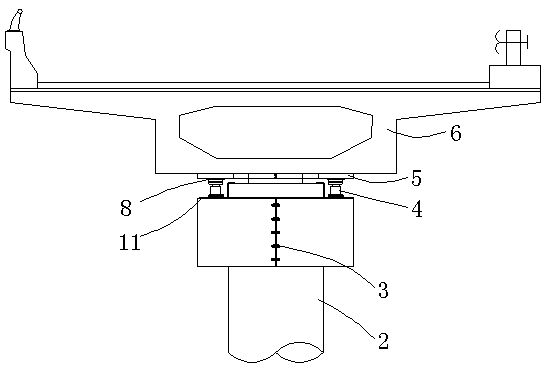

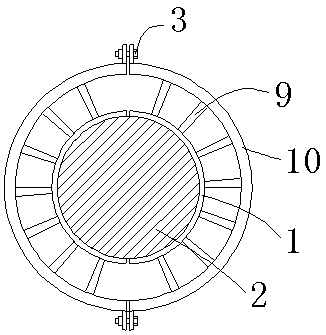

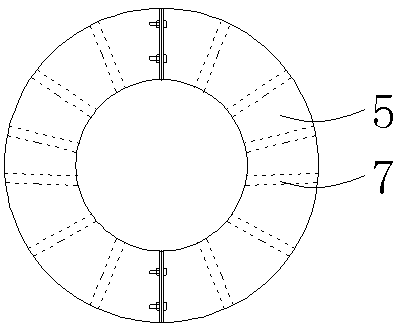

[0037] The best embodiment: as Figure 1 to Figure 3As shown, a bridge girder body lifting system installed on a bridge pier includes a bridge pier fixing device and a lifting assembly. The bridge pier fixing device includes two oppositely arranged fixing pieces 1, and the fixing piece 1 is vertically arranged and has an arc shape in the horizontal direction. The fixed piece 1 is fitted and fixed along the circumferential surface of the bridge pier 2, and there is a gap for deformation between the two fixed pieces 1. Solid deformation fastening bolts 3, a horizontal support platform is formed on the upper surface of the pier fixing device, and the lifting assembly includes an upward jack 4 arranged on the support platform along the circumferential direction of the pier, wherein the lifting assembly also includes an overall horizontal ring....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com