Equiangular-spiral leaf spring

An isometric spiral and leaf spring technology, applied in the field of leaf springs, can solve the problems of difficult machining, complex shape expression and design, and achieve the effects of small local stress, simple shape and sealing method, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

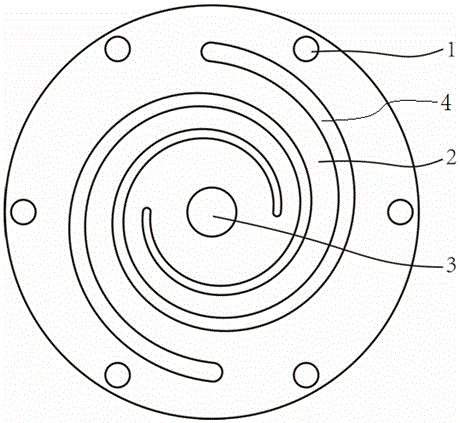

[0030] The leaf spring is a part formed by constructing a vortex groove line on a circular elastic sheet material with a hole in the center, and using laser cutting, wire cutting or chemical etching technology. Its thickness is generally 0.5mm ~ 3mm, and its material is generally spring stainless steel (1Cr18Ni9Ti) or (7C27Mo2).

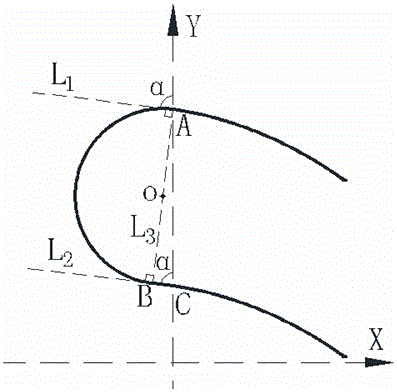

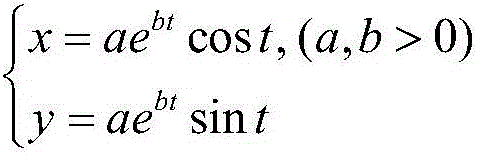

[0031] The invention uses equiangular spiral equations to determine the molded line of the leaf spring, and the inner and outer molded lines and the closed end curve form a vortex groove. Such as figure 1 As shown, the present invention has two vortex grooves 4 in total, and the two vortex grooves 4 are symmetrically distributed at an angle of 180°. The following is the polar coordinate mathematical equation of the profile.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com