Three-dimensional micro nanometer contact scanning probe

A scanning probe, micro-nano technology, applied in the field of micro-nano measurement, can solve the problems of low detection sensitivity and accuracy of strain gauges, uneven stress distribution, easy fracture of silicon membrane structure, etc., to reduce inter-axis coupling interference and large elastic range , the effect of good time stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In this embodiment, the structure of the three-dimensional micro-nano contact scanning probe is set as follows:

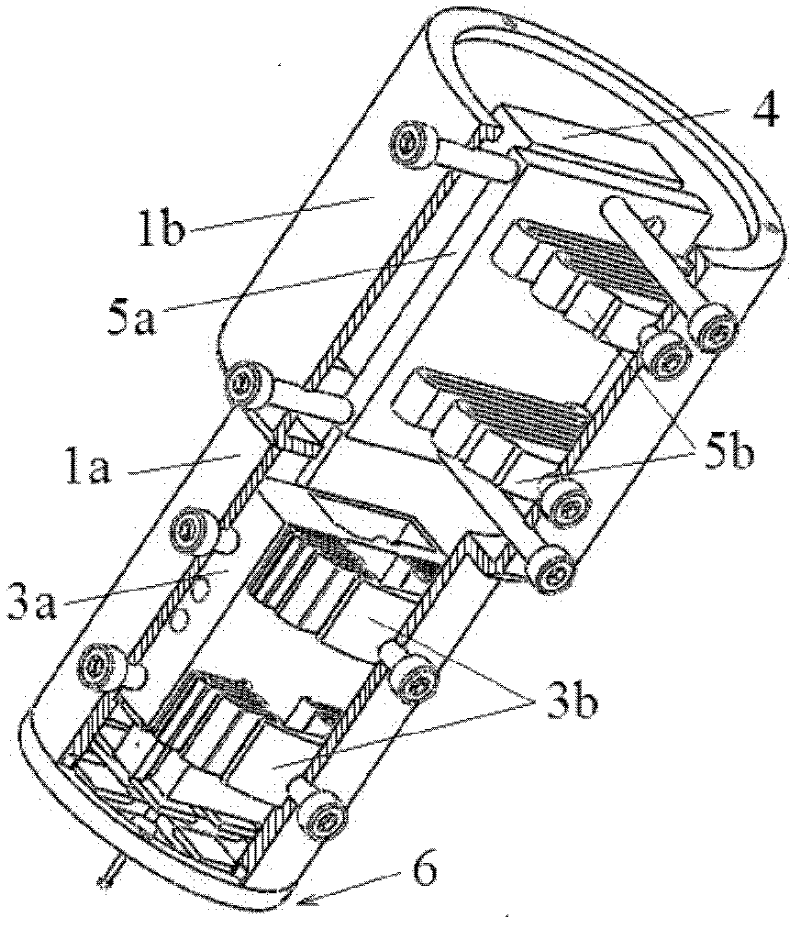

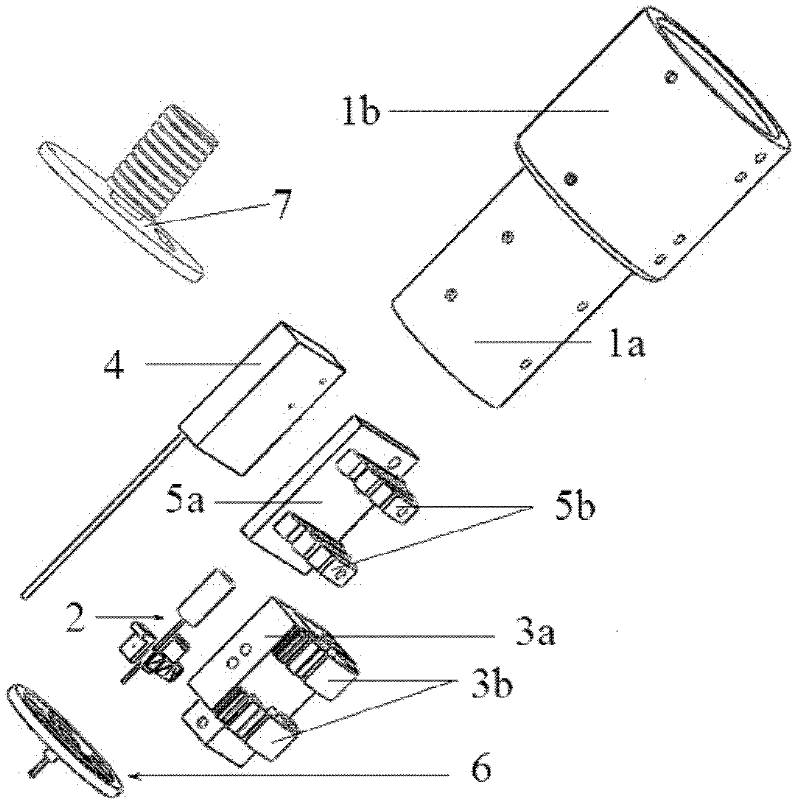

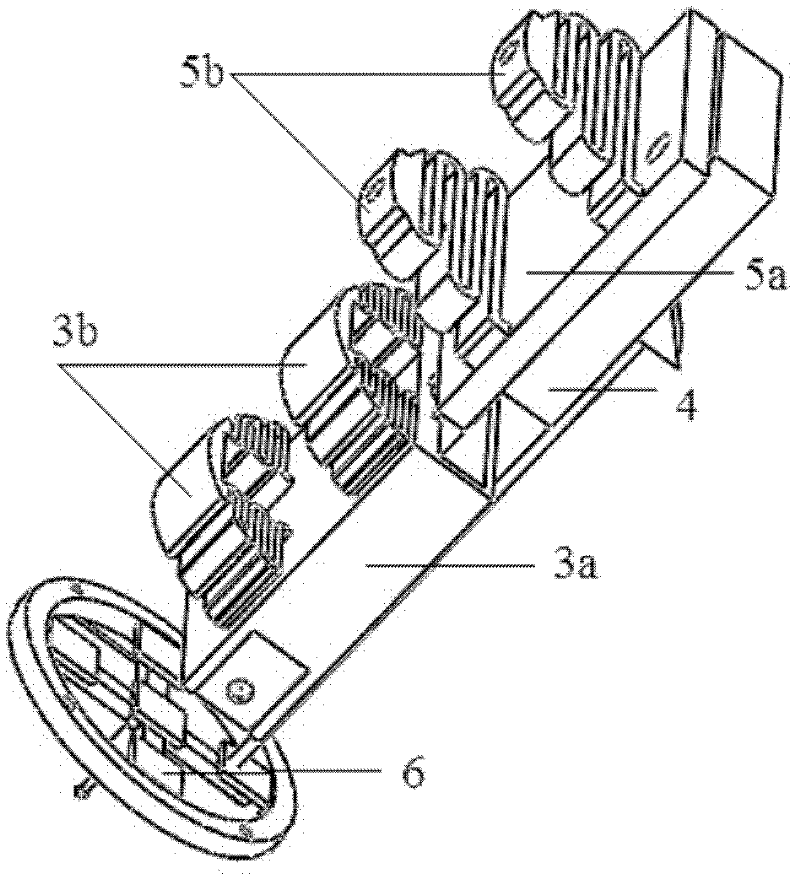

[0042] see figure 1 , figure 2 and image 3 , the measuring unit is set as follows: the front cylinder 1a and the rear cylinder 1b are connected to form a cylinder; in the front cylinder 1a, the anti-reflection miniature Michelson interferometer 2 is fixedly arranged in the installation box 3a; In the cylinder 1b, the two-dimensional angle sensor 4 based on the DVD optical pick-up head is fixedly installed on the mounting plate 5a; a cylinder cover 7 with external threads is arranged at the afterbody of the rear section cylinder 1b, with the cylinder cover 7 on the cylinder cover 7 The external thread is fixedly connected to the frame of the nanometer three-dimensional coordinate measuring machine;

[0043] 6b and Figure 6a , the detection head 6 is set as follows: a fixed ring 8 is set on the front end face of the front section cylinder 1a, a cross su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com