Bionic texture and coating layer cooperated anti-friction cutter and design method thereof

A biomimetic texture and synergistic technology, applied in the field of mechanical cutting tools, can solve problems such as weakening the cooling and lubrication effect, and achieve the effects of small internal stress, improved lubrication performance and friction performance, and uniform stress distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

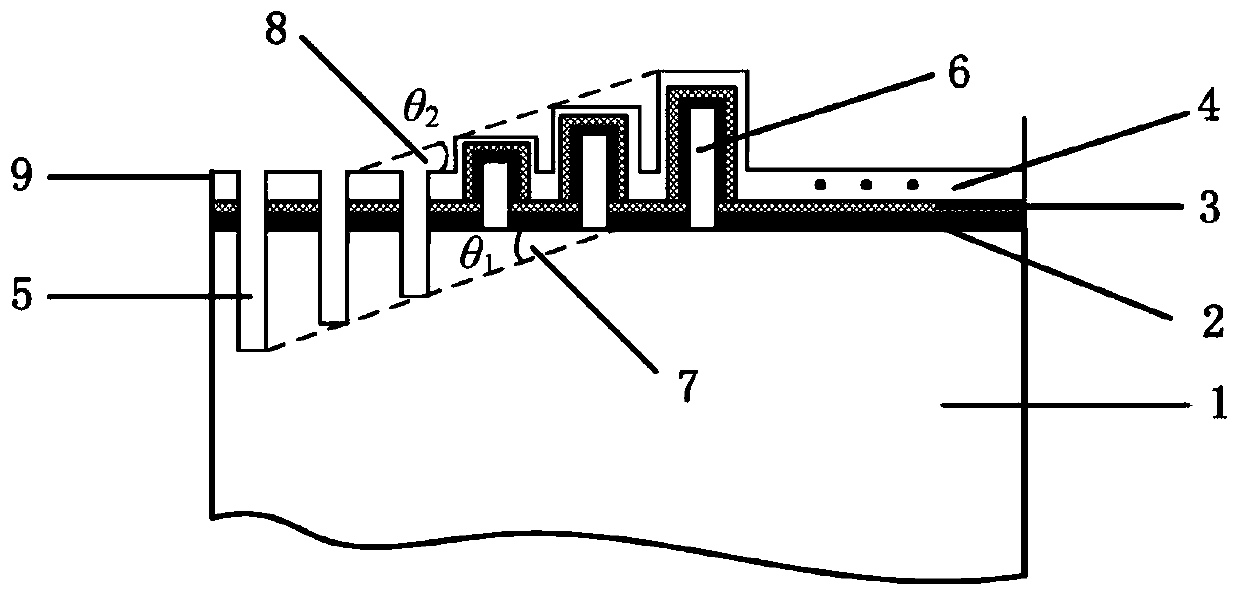

[0016] A bionic texture and coating synergistic anti-friction tool, the tool base material is cemented carbide, the tool base material rake face cutter-chip contact area has a composite texture of bionic circular hole-shaped micro-pits and cylindrical micro-protrusions , the depth of the micro-pit texture gradually decreases away from the tool tip, and the height of the micro-protrusion texture gradually increases away from the tool tip; the texture and the surface of the substrate have AlZrTaC+TiVBN alternately distributed nano-layered coatings, and alternate layered coatings The layer contains 20 layers of AlZrTaC and 20 layers of TiVBN single layer, and the thickness of the single layer of AlZrTaC and TiVBN is 50nm.

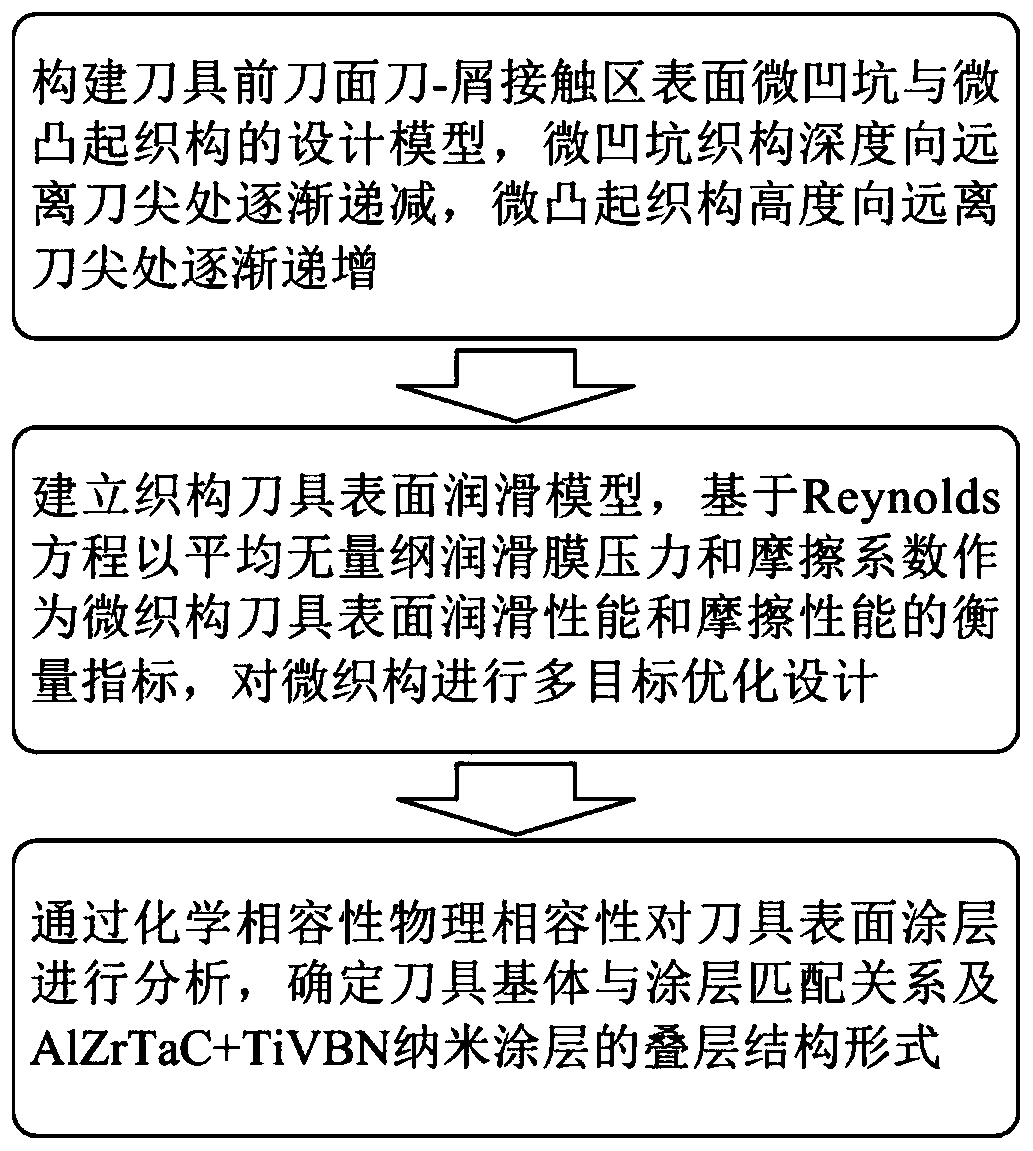

[0017] The bionic texture and coating synergistically reduce friction tool, and its design method is as follows:

[0018] (1) Under the condition of water-based cutting fluid lubrication, according to the contact state of the tool-chip contact interface and th...

example 2

[0022] A bionic texture and coating synergistic anti-friction tool, the tool base material is cemented carbide, and the tool-chip contact area on the rake face of the tool base material has a composite texture of bionic triangular micro-pit and quadrilateral micro-protrusion, micro-concave The depth of the pit texture gradually decreases away from the knife tip, and the height of the micro-protrusion texture gradually increases away from the knife tip; the texture and the surface of the substrate have AlZrTaC+TiVBN nano-layered coatings alternately distributed, and the alternate layered coatings contain 10 A single layer of AlZrTaC and 10 layers of TiVBN, and the thickness of a single layer of AlZrTaC and TiVBN increases sequentially from the substrate to the outside.

[0023] The bionic texture and coating synergistically reduce friction tool, and its design method is as follows:

[0024] (1) Under the condition of oil-based cutting fluid lubrication, according to the contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com