Patents

Literature

84results about How to "Moderate stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

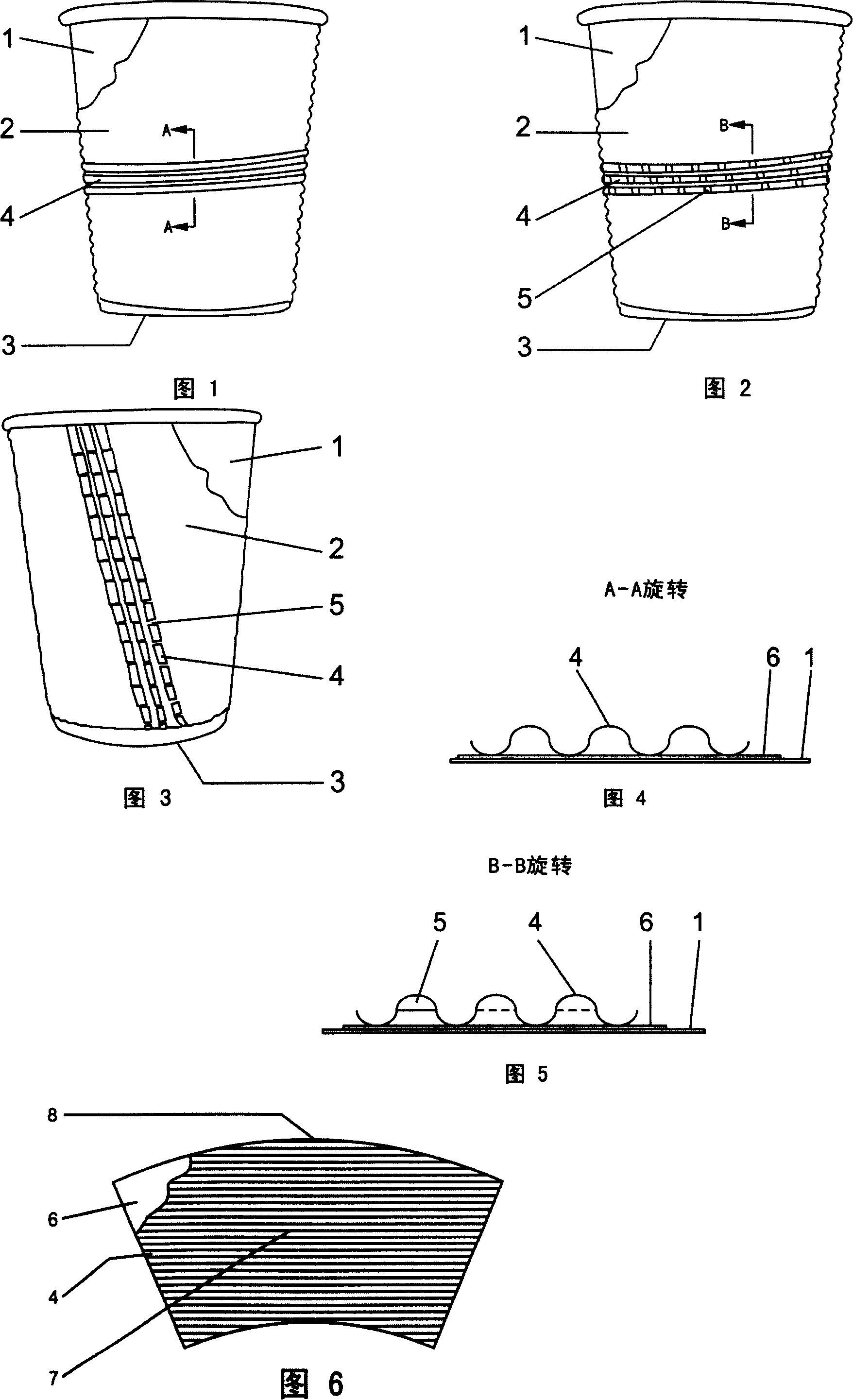

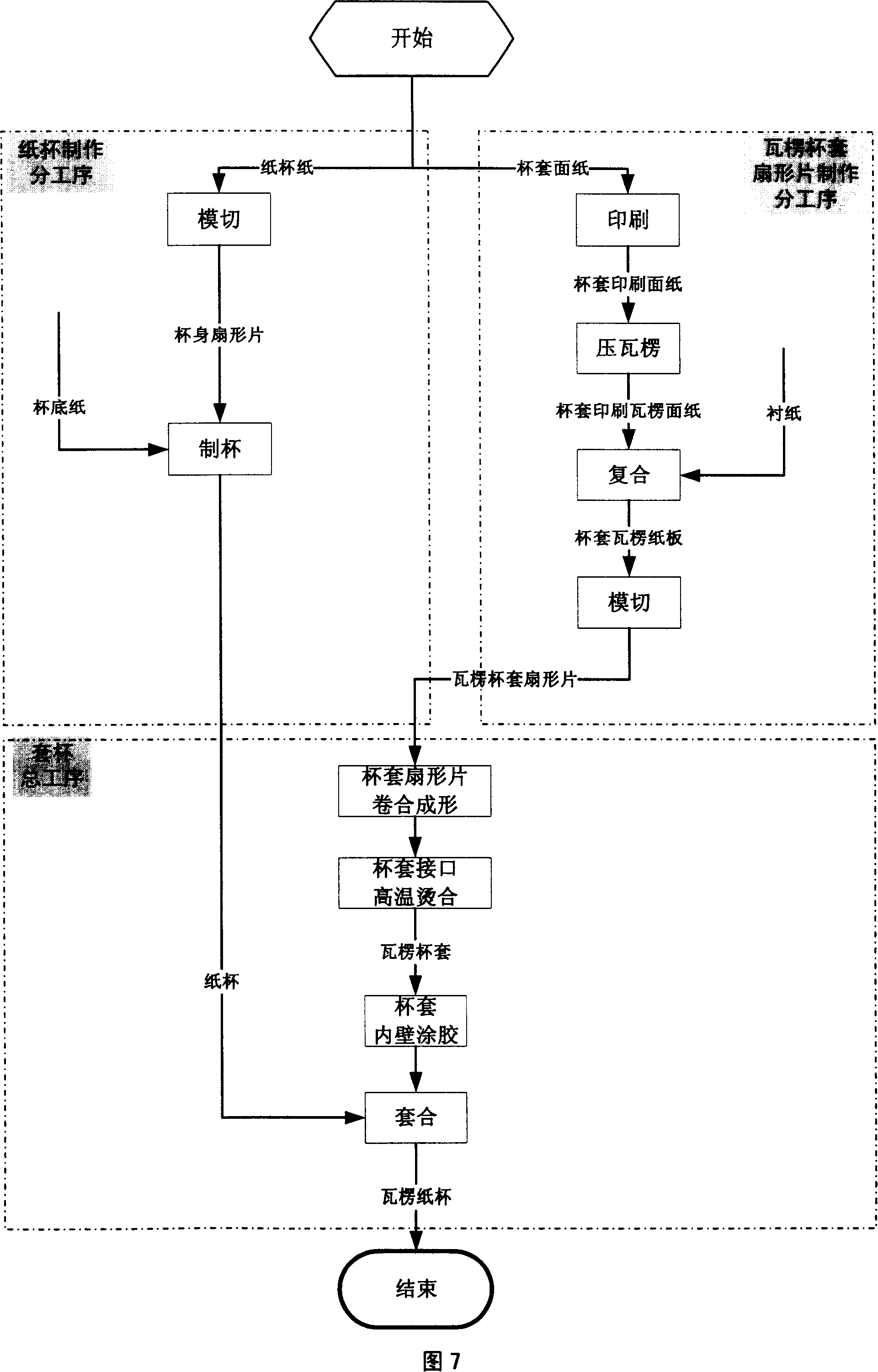

Corrugated paper cup and production method thereof

InactiveCN1961786ANice appearanceModerate stiffnessEnvelopes/bags making machineryBoxes/cartons making machineryAdhesiveEngineering

The invention relates to a corrugated paper cup, wherein it comprises cup body, bottom and sheath; said cup sheath is corrugated paper sheath, whose corrugated bars are transversely arranged; or the corrugated bar has groove; and its production comprises that producing the paper cup, and the corrugated cup sheath arc plates, and sheathing the cup; the arc plates are coiled and shaped, while the interfaces are combined at high temperature by ultrasonic wave; the inner wall is coated with adhesive to combine the cup. The invention has high thermal-insulated property and the batch production ability.

Owner:林泠镪

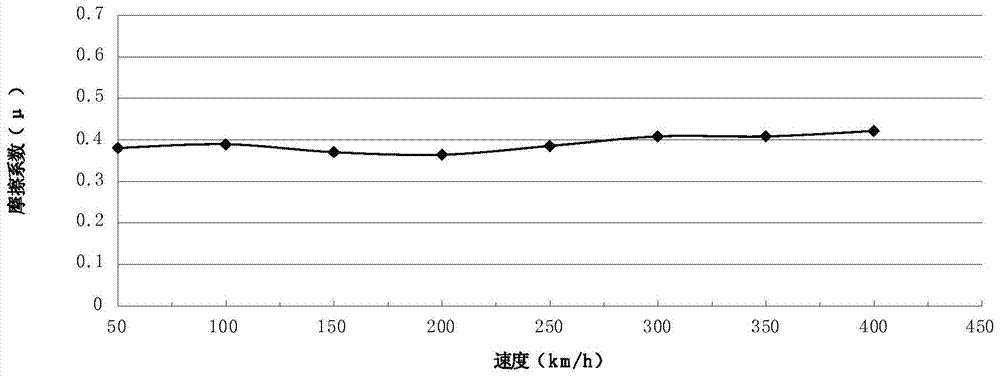

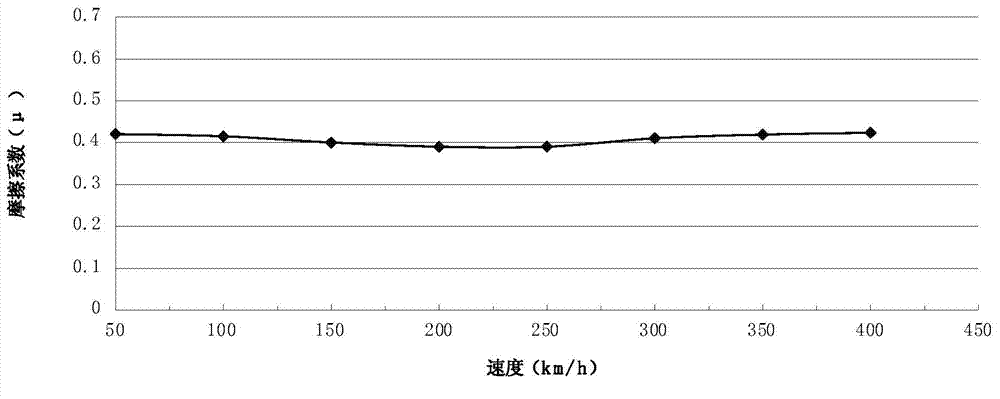

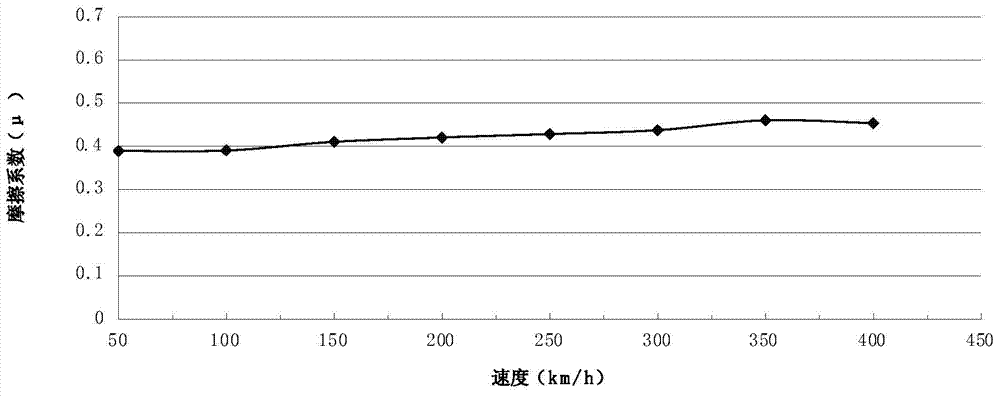

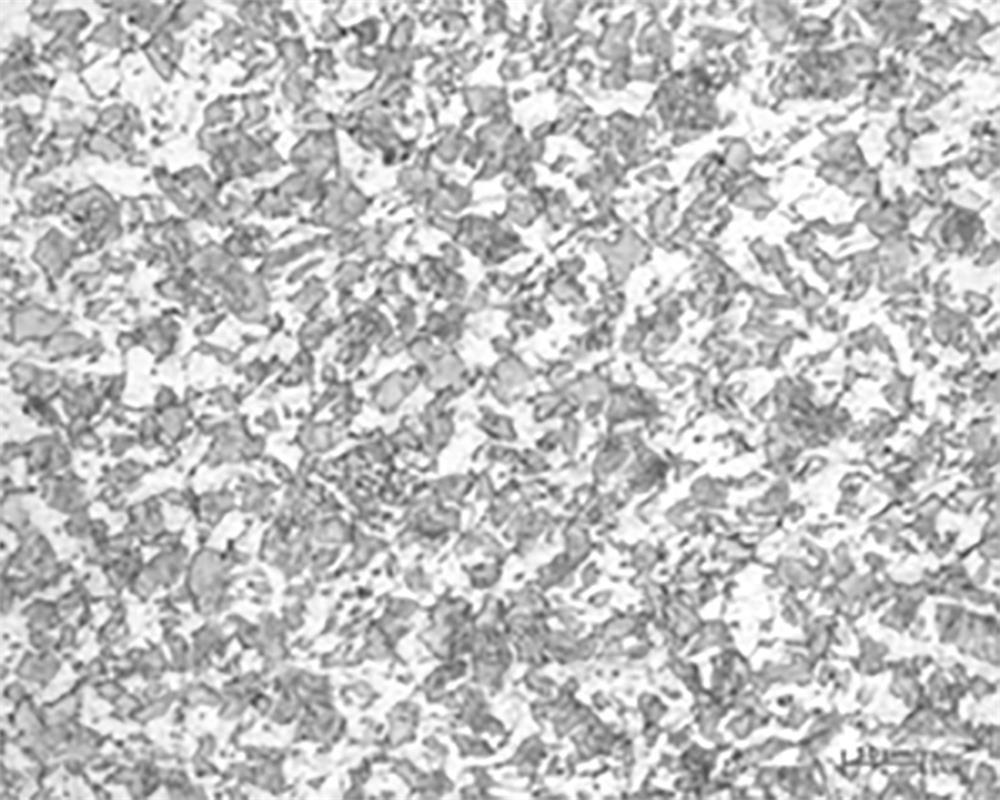

Copper-based powder dispersion ceramic as well as preparation method and application thereof

InactiveCN103667772AStrong impact pressureHigh mechanical strengthBraking membersCopperUltimate tensile strength

The invention relates to copper-based powder dispersion ceramic as well as a preparation method and application thereof, and relates to the field of ceramic materials. The copper-based powder dispersion ceramic is prepared from an anti-abrasion constituent element as one of the raw materials, wherein the anti-abrasion constituent element comprises the following components by mass percent of all the raw materials: 1-5 percent of diamond powder and 1-5 percent of titanium diboride powder. The copper-based powder dispersion ceramic is high in impact pressure resistance, high in mechanical intensity, high in friction and abrasion resistance, long in service life, high in heat dissipation property and heat recovery property, high in high-temperature and low-temperature resistance, high in acid, alkaline, oil, water and the like corrosion resistance and the like.

Owner:刘伟

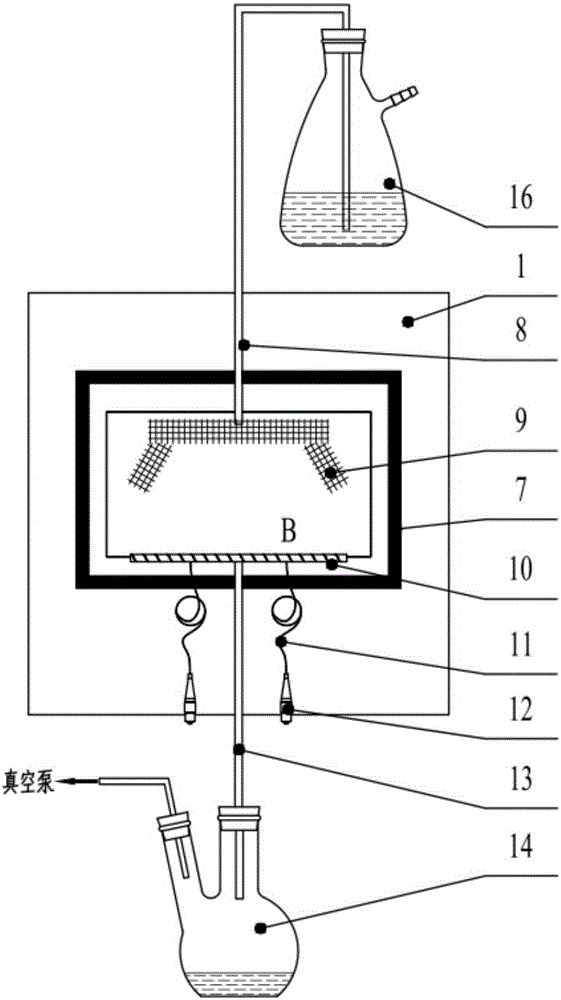

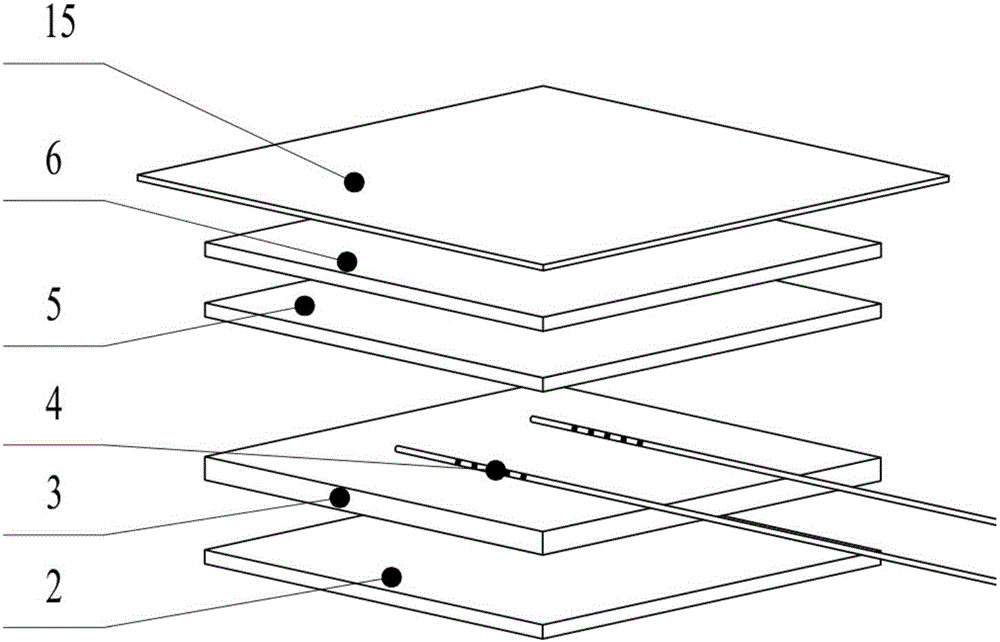

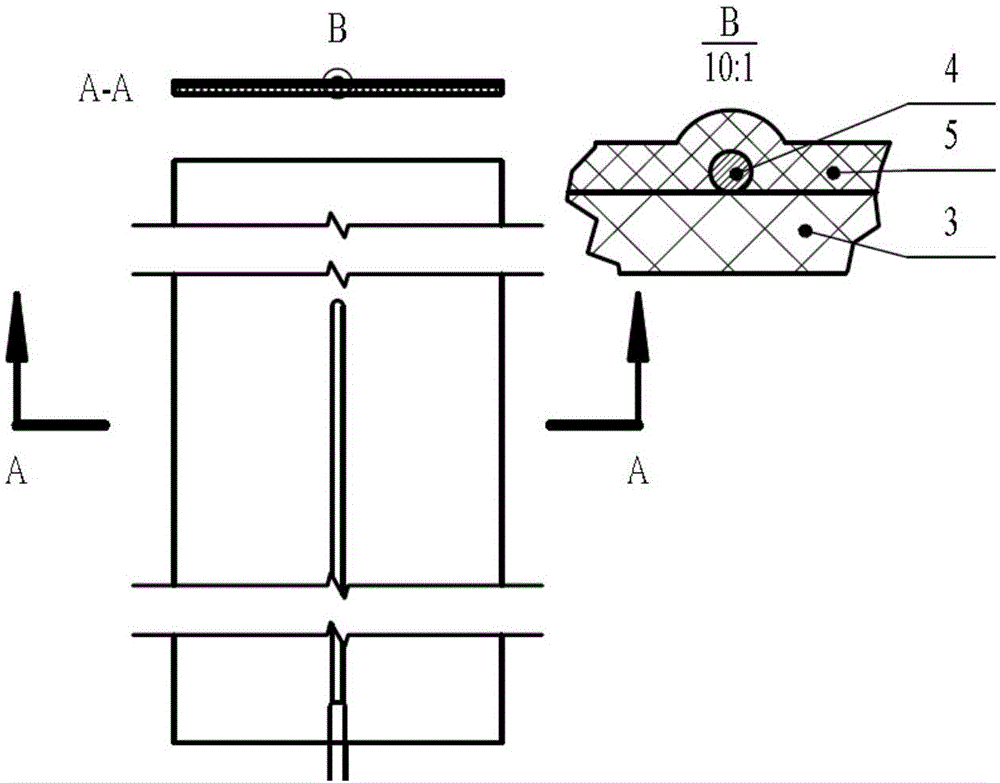

Manufacturing technology of glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

ActiveCN106633137AImprove performance and stabilityReduce internal stressMeasurement devicesOptical articlesFiberEpoxy

The invention discloses a manufacturing technology of a glass fiber / epoxy resin composite material substrate type fiber bragg grating sensor. The manufacturing technology comprises the steps that glass fiber / epoxy resin prepreg is procured to prepare a glass fiber / epoxy resin composite material substrate; a fiber bragg grating is fixed to the glass fiber / epoxy resin composite material substrate; the glass fiber / epoxy resin composite material substrate fixed with the fiber bragg grating is covered with a dry-state glass fiber cloth, vacuum aided filling of liquid epoxy resin is performed, and secondary curing molding is performed. The manufacturing technology adopts the secondary curing molding in the packaging process, the interlayer interface strength is remarkably improved, accordingly the testing precision and stability of the fiber bragg grating sensor are improved, batch production of the fiber bragg grating sensor can be achieved, and the manufacturing technology has wide market prospect and huge economic benefit.

Owner:SHANDONG UNIV

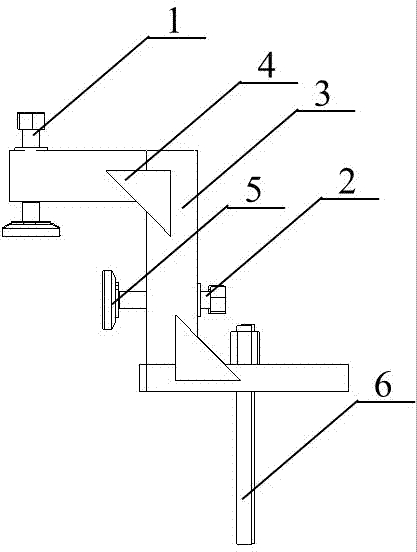

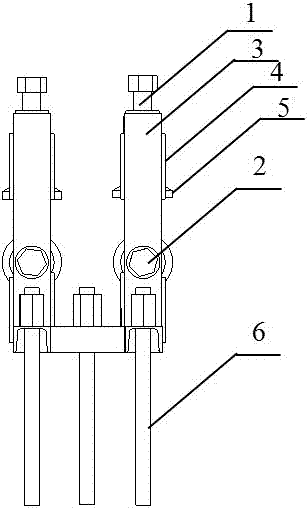

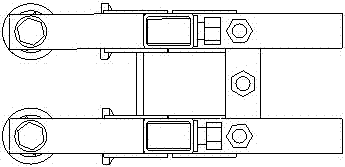

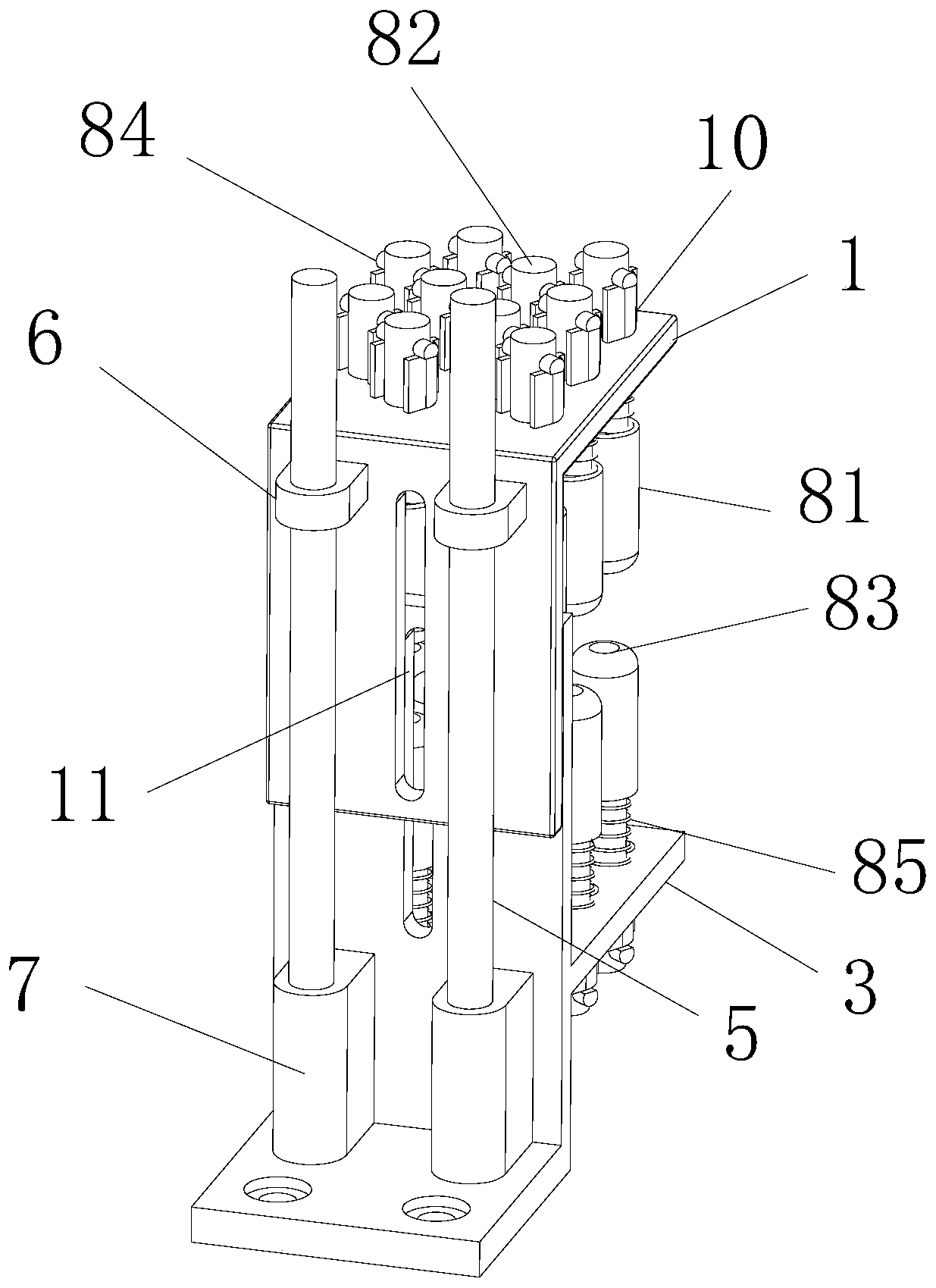

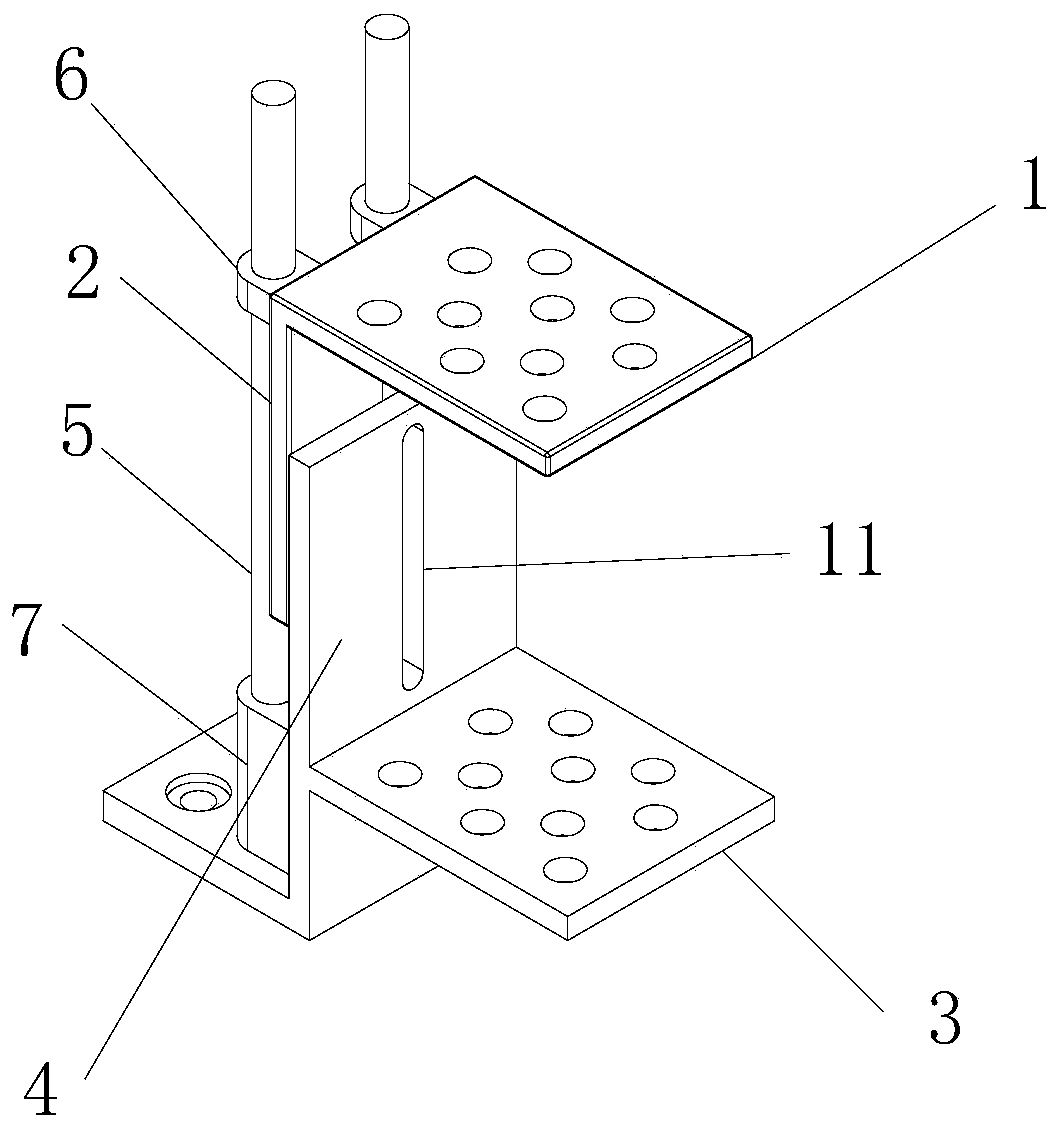

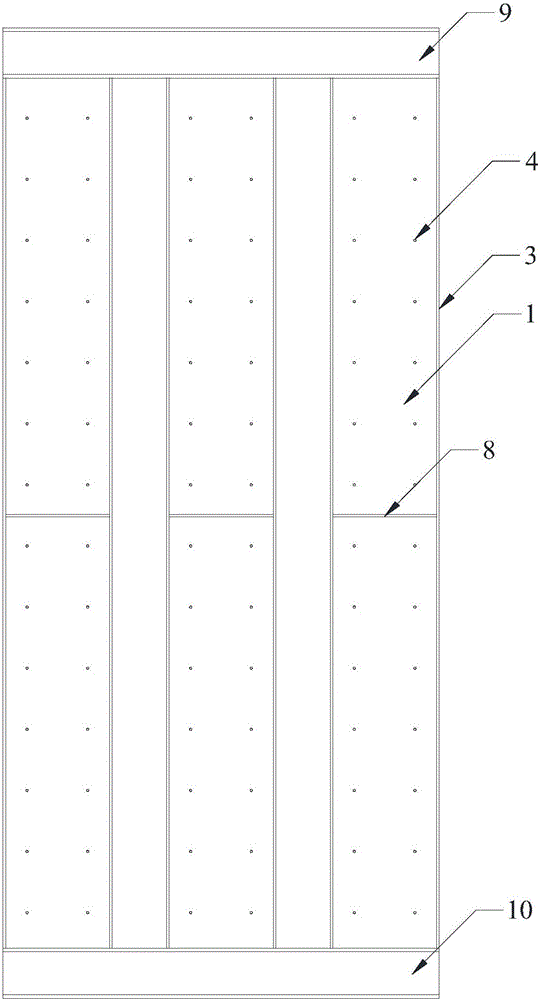

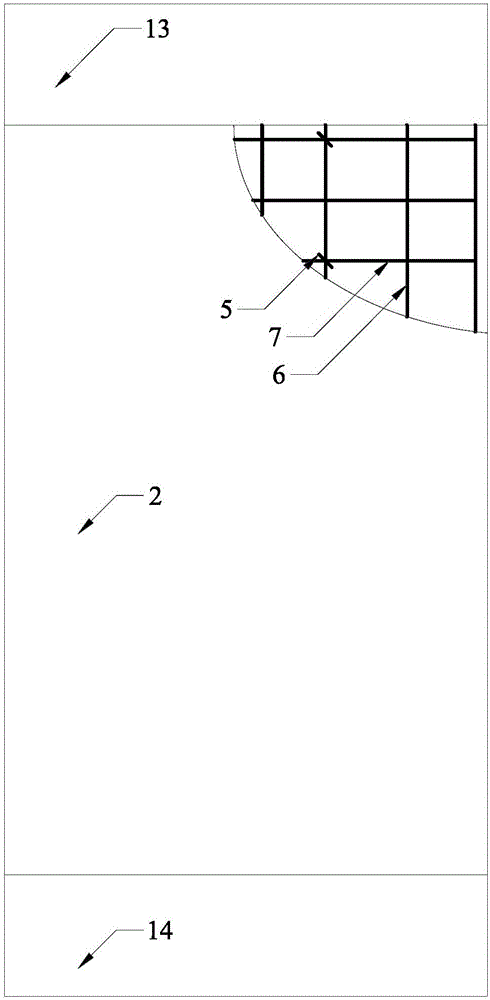

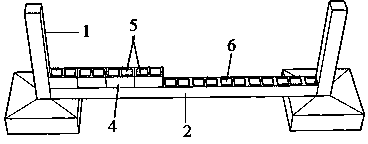

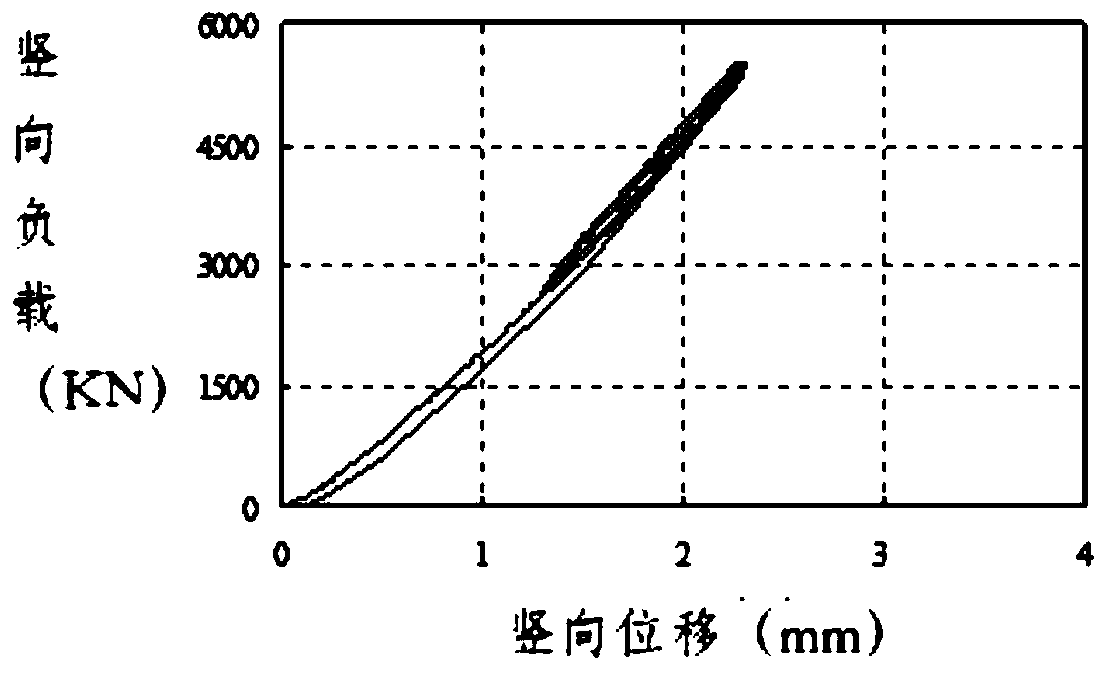

Pressing limiting device and method for slab ballastless track structure

ActiveCN108004855AMeet the needs of compression limitSmall and lightBallastwayStructural engineeringEngineering

The invention discloses a pressing limiting device and method for a slab ballastless track structure, which are used for solving problems of upwarp and warping diseases of the slab ballastless track structure of an operating line, realizing synchronous and integral deviation rectification of the laminated slab ballastless track structure and avoiding the dislocation of the laminated structure andupwarp secondary disease of a track slab in the deviation rectifying process.

Owner:沪杭铁路客运专线股份有限公司 +3

Universal curved-surface clamp

ActiveCN110026793AModerate stiffnessSmall preloadPositioning apparatusMetal-working holdersElastic componentIndustrial engineering

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD +1

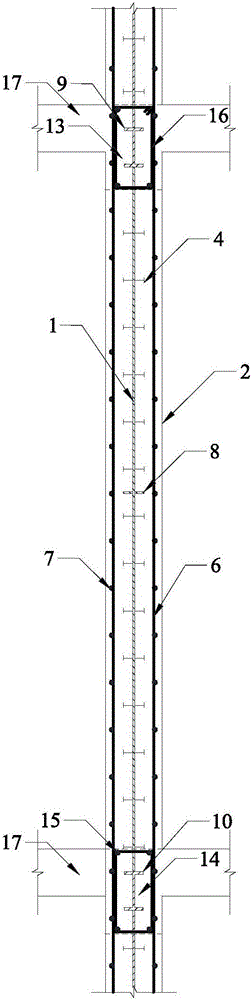

High-strength concrete composite shear wall with built-in segmented steel plates and construction method for same

ActiveCN106049708ALess prone to bucklingWork well togetherWallsHigh strength concreteHigh resistance

The invention belongs to the technical field of structure engineering and relates to a high-strength concrete composite shear wall with built-in segmented steel plates and a construction method for the same. The invention provides the high-strength concrete composite shear wall with the built-in segmented steel plates and further provides the building and construction method for the shear wall. The composite shear wall and the construction method for the same provided by the invention are characterized in that through segmented layout of the steel plate, concrete pouring and binding bar layout become convenient; a cooperative working ability of the steel plates and concrete is enhanced; bearing force is ensured; and deformability and an energy-dissipation capability of the composite shear wall can also be enhanced. In comparison with a composite shear wall covered by steel plates, the composite shear wall provided by the invention has higher resistance to high temperatures and can show better performance when a fire disaster takes place. Meanwhile, in comparison with a concrete composite shear wall with a whole steel plate, the shear wall provided by the invention has the advantages that conversion and transition among layers can be implemented through reduction of the quantity of the segmented steel plates; inter-layer rigidity transition becomes gentler; and the structure is also simpler.

Owner:TONGJI UNIV

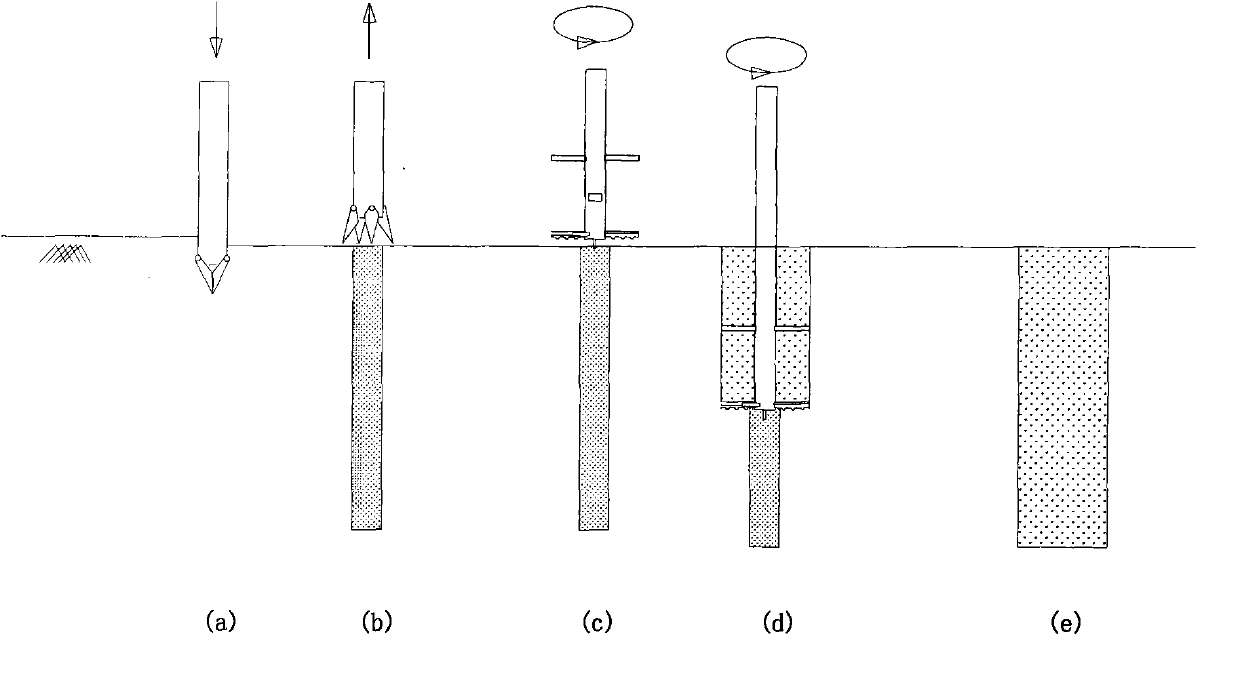

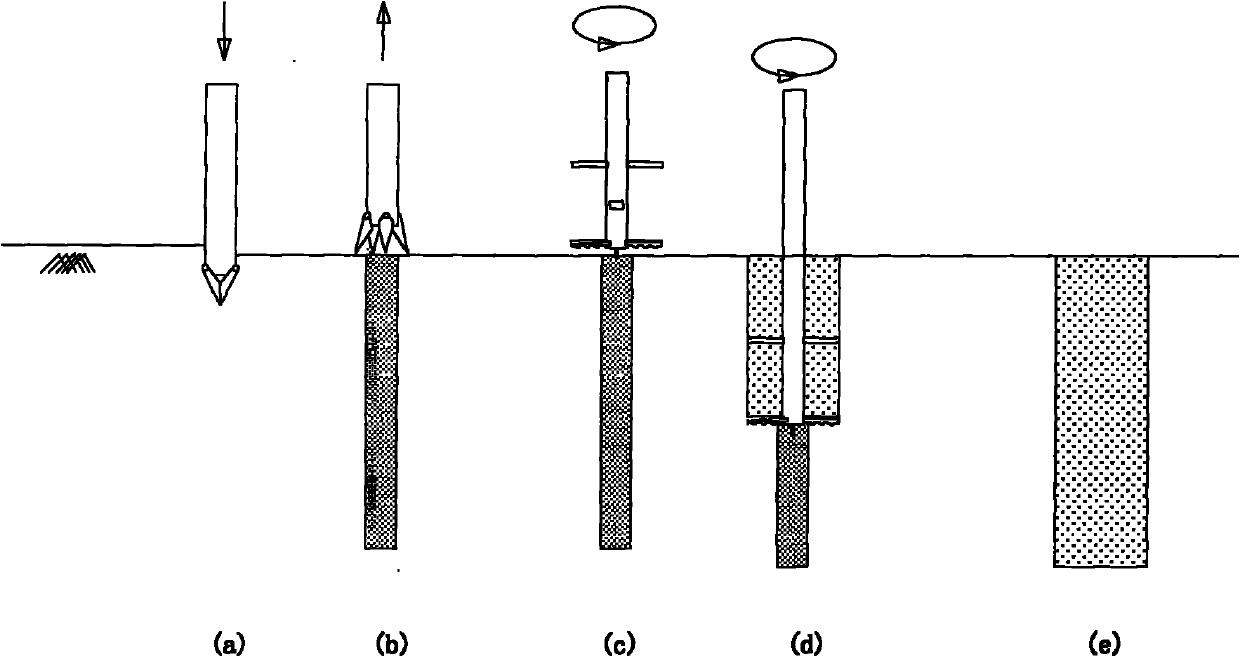

Foundation reinforcing method by using pre-added aggregate stirred pile

ActiveCN101793021AImprove reliabilityGuaranteed StrengthBulkheads/pilesSoil preservationEngineeringStructural engineering

The invention discloses a foundation reinforcing method by using pre-added aggregate stirred piles. The foundation reinforcing method is suitable for a weak soil or soft soil foundation. First, sandy aggregate is injected into the foundation through a machine to form sand piles, then the sand piles and the surrounding foundation soil thereof are stirred through blades of the machine and curing agent is added at the same time to enable the foundation soil and the sandy aggregate to be evenly mixed and be coagulated to form pile bodies for reinforcing the foundation. The piles and inter-pile soil jointly form a composite foundation, thereby reaching the goal of reinforcing the soft and weak foundation. Since sandy aggregate is added into the foundation in advance, the mixing proportion of the added sand can be greatly improved and controlled and the strength, the quality and the proper rigidity of the finished piles are ensured. The foundation reinforcing method is a foundation handling method which has the advantages of low cost, high reliability, easy adjustment and control, high adaptability and good technical economy.

Owner:赵阳 +1

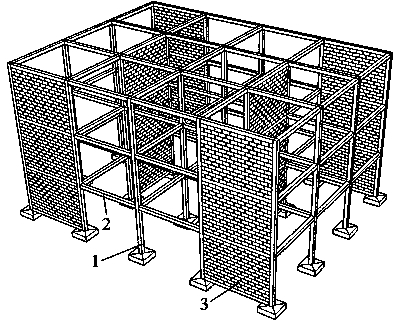

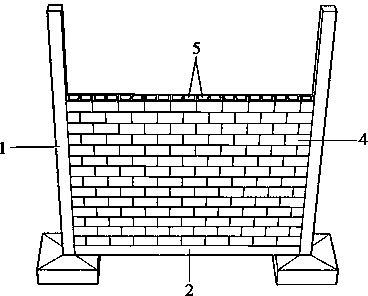

Steel frame-reinforced masonry shear wall composite structure and construction method thereof

The invention discloses a steel frame-reinforced masonry shear wall composite structure and a construction method thereof. The steel frame-reinforced masonry shear wall composite structure consists of a steel frame, reinforced masonry shear walls and floor slabs, wherein the steel frame is formed by welding steel frame columns and steel frame beams or connecting the steel frame columns with the steel frame beams by bolts; each reinforced masonry shear wall is formed by building blocks, mortar and grout concrete; the reinforced masonry shear walls are connected with the steel frame through vertical reinforcing steel bars in the reinforced masonry shear walls to form a whole. The concrete structure is that the overall shape of each steel frame beam is a rectangular cavity; holes are formed in the upper surface and the lower surface of the cavity of each steel frame beam; the positions of the holes are overlapped with the holes of each building block of the adjacent reinforced masonry shear wall; the vertical reinforcing steel bars pass through the holes of each steel frame beam and the holes of each building block; holes of the building blocks and the cavities of the steel frame beams are filled with the grout concrete The steel frame-reinforced masonry shear wall composite structure has the advantages of high anti-seismic property, quick construction, low comprehensive cost, excellent fire resistance, application to a structure system with large span and large space, and the like.

Owner:湖南湘江绿色建筑建材研究院有限公司

Bamboo glue sleeper and preparation method thereof

InactiveCN107009457AReduce carbon emissionsShorten the growth cycleBallastwayWood treatment detailsFiberCarbonization

The invention discloses a bamboo glue sleeper and a preparation method thereof. The preparation method comprises the following steps: (1) selecting a raw material; (2) cutting off the raw material according to a specified length, sectioning the cut-off raw material into strips, removing tabasheer and the bamboo outer skin, and processing the strips into thin bamboo skin pieces; (3) carrying out carbonization treatment on the thin bamboo skin pieces obtained in the step (2); (4) grinding the carbonized thin bamboo skin pieces into a siamesed fiber state; (5) putting the material obtained in the step (4) in phenol glue to carry out pressurization gumming; (6) carrying out automatic dehumidification on the material obtained in the step (5); (7) pressing and curing the material obtained in the step (6) into a slab; and (8) sawing the periphery width of the slab by 5 cm to eliminate the fringe effect during compression. The bamboo glue sleeper is low in carbon emission, environment-friendly and safe, does not deform when being affected with damp due to water, and is antiseptic, prevented from damage by worms, antiflaming and suitable for being used under a complex condition.

Owner:BEIJING JIAOTONG UNIV

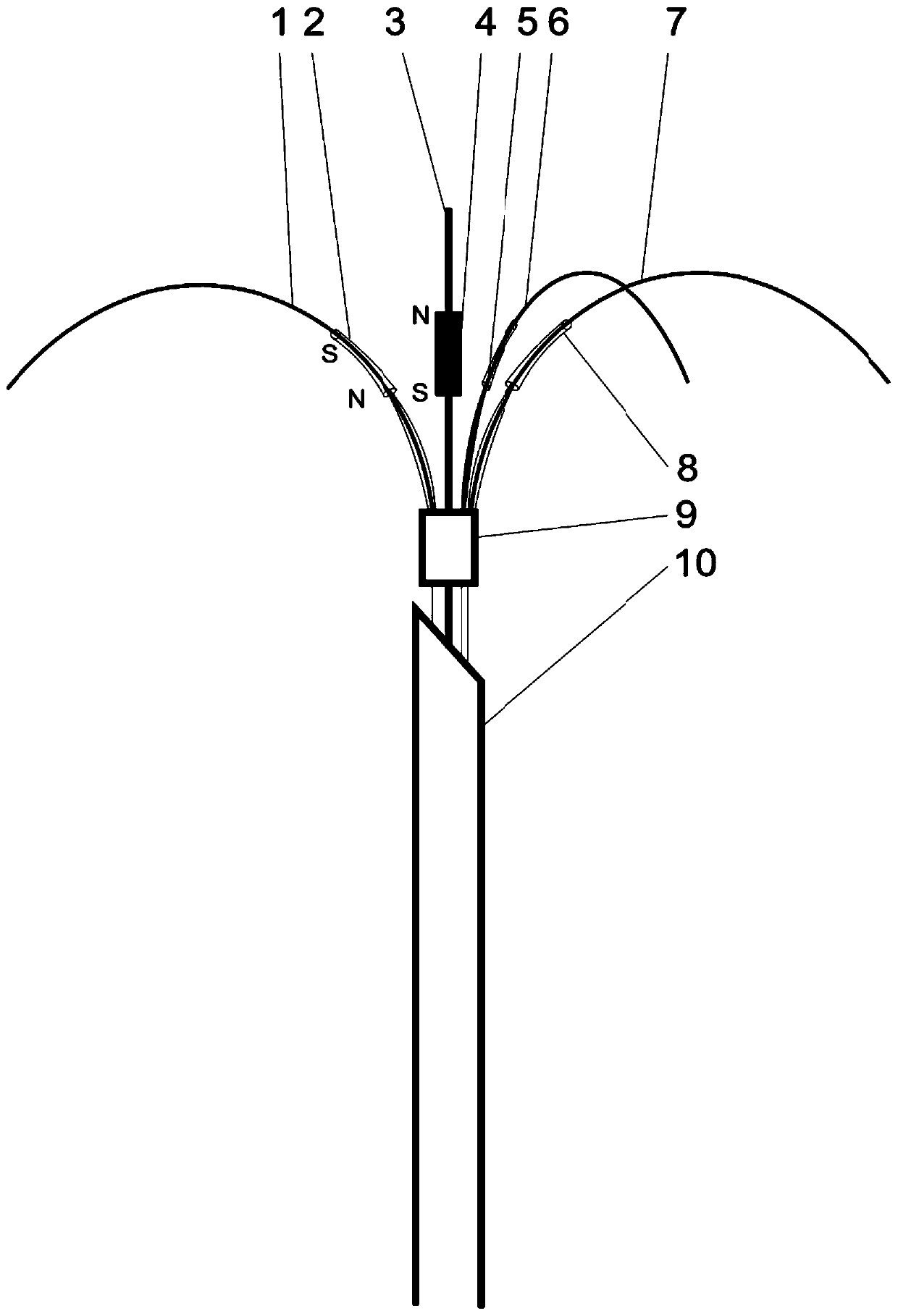

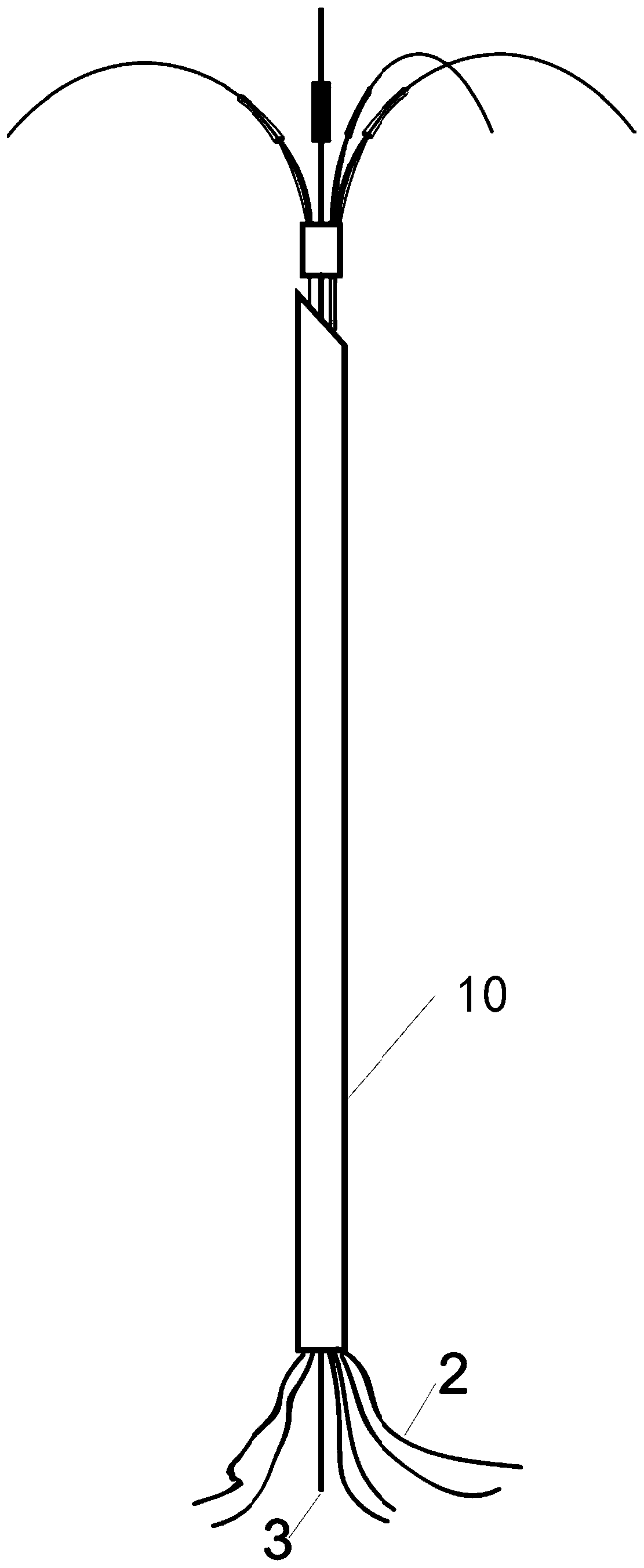

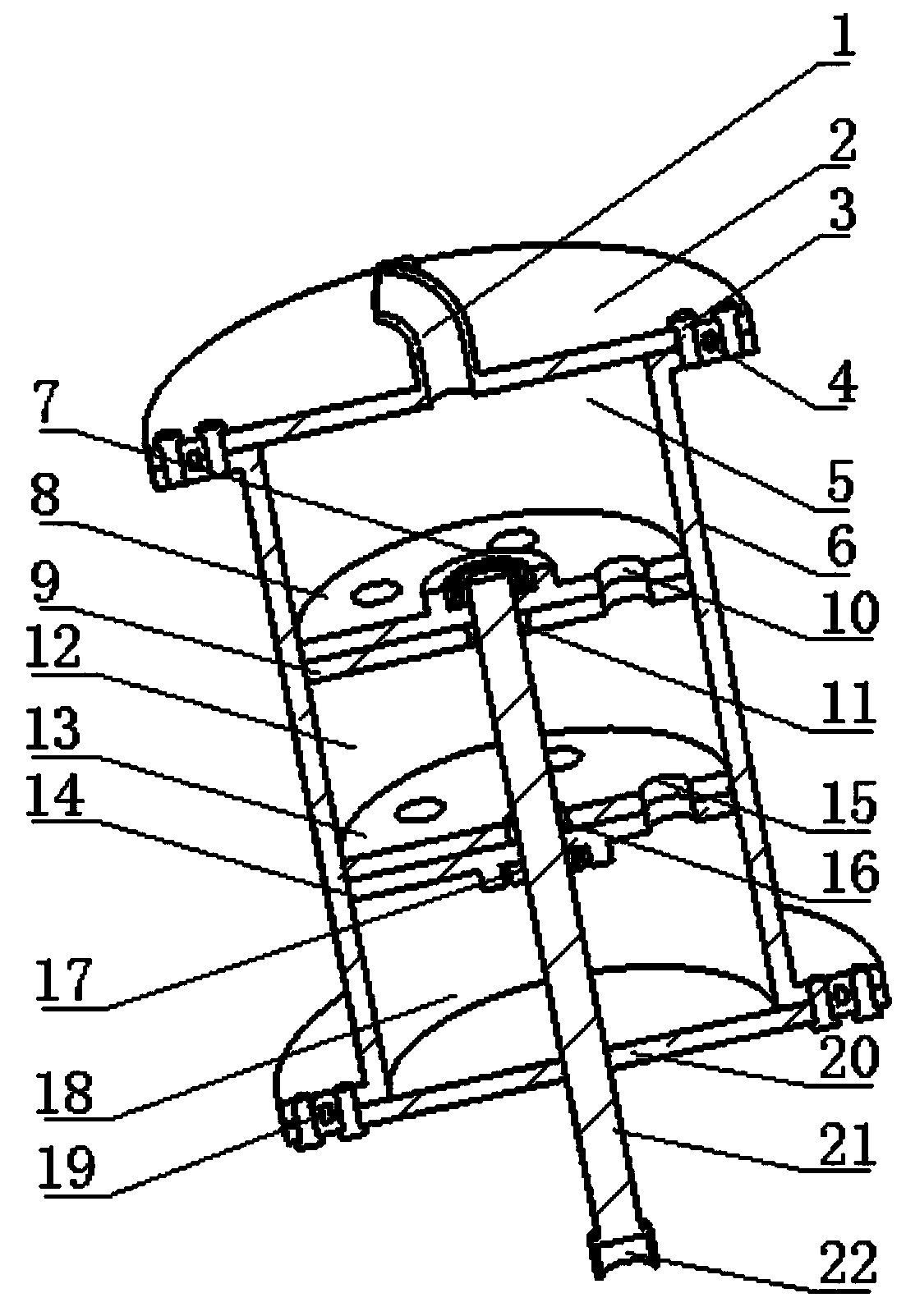

Multi-jaw active conformal ablation needle with function of magnetic control

ActiveCN110179537ASolve technical problems that cannot control the trajectory of motionModerate stiffnessSurgical instruments for heatingMagnetic tension forceBiomedical engineering

The invention discloses a multi-jaw active conformal ablation needle with a function of magnetic control and belongs to the technical field of medical care equipment. The multi-jaw conformal ablationneedle comprises flexible ablation electrodes, electromagnetic coils, a main needle and a magnetic part, wherein the number of the flexible ablation electrodes and the electromagnetic coils is N whichis more than or equal to 2; the N flexible ablation electrodes are circumferentially distributed around the main needle; each electromagnetic coil winds around the respective flexible ablation electrode; and the magnetic part is fixed on the main needle. When the multi-jaw active conformal ablation needle works, the strength and direction of a magnetic field formed around each electromagnetic coil by controlling the strength and direction of the current in the electromagnetic coil, the strength and direction of the magnetic force between the electromagnetic coils and the magnetic part can becontrolled, and the electromagnetic coils carrying the flexible ablation electrodes can be close to the main needle, or far away from the main needle or remained stable; and therefore, the motion locus of the multi-jaw active conformal ablation needle can be controlled, and the technical problem that the motion locus cannot be controlled in the prior art can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

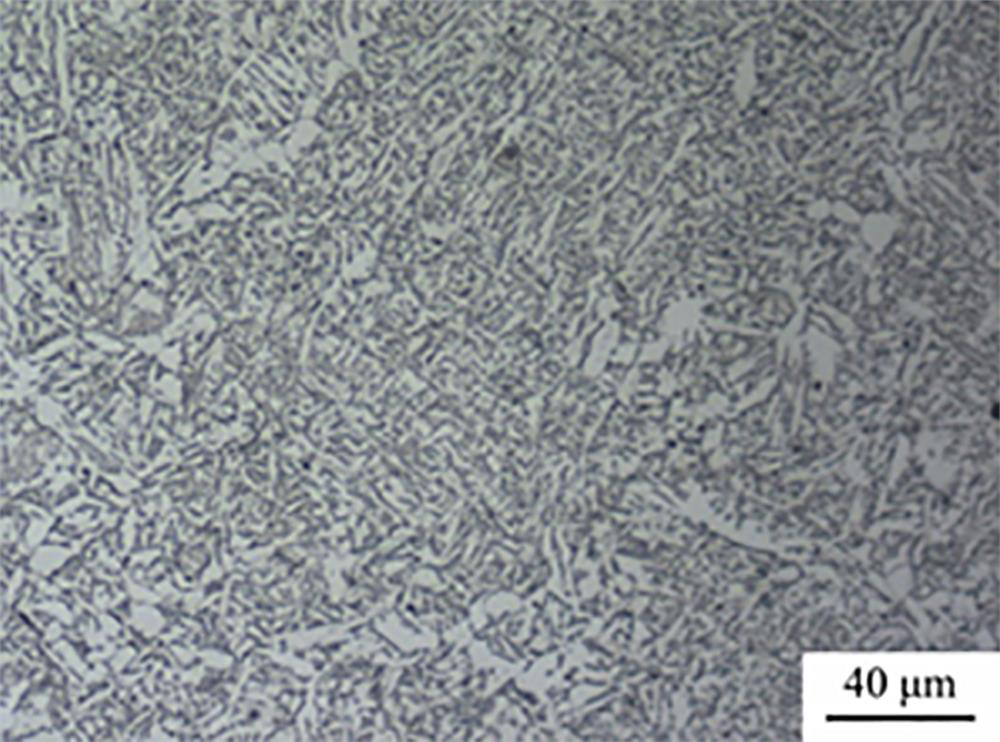

CO2 gas shielded welding wire with tensile strength of 650MPa for coating-free weathering steel bridge and wire rod

ActiveCN111975244AStrong crack resistanceGood atmospheric corrosion resistanceWelding/cutting media/materialsSoldering mediaWire rodCrack resistance

The invention discloses a wire rod for a CO2 gas shielded welding wire with tensile strength of 650MPa for a coating-free weathering steel bridge, and belongs to the field of weathering steel weldingmaterials. The wire rod comprises the following chemical components in percentage by mass: 0.04 to 0.09 percent of C, 0.55 to 0.85 percent of Si, 1.70 to 2.10 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.46 to 0.65 percent of Cr, 1.10 to 1.80 percent of Ni, 0.15 to 0.38 percent of Cu, 0.10 to 0.20 percent of Ti, 0.003 to 0.005 percent of B, less than or equal to 0.015 percent of Al, less than or equal to 0.045 percent of Zr, less than or equal to 0.030 percent of Ce, less than or equal to 0.050 percent of O, less than or equal to 0.070 percent of N, and the balance of Fe and inevitable impurities. The invention also discloses the CO2 gas shielded welding wire with the tensile strength of 650MPa for the coating-free weathering steel bridge, which is prepared by drawing the wire rod. The welding wire is used for welding coating-free weathering steel with the tensile strength of 650MPa, wherein the tensile strength of deposited metalis between 650MPa and 730MPa, and the welding wire has high crack resistance; and the yield strength is more than or equal to 500MPa, the elongation is more than or equal to 23 percent, and the low-temperature impact energy KV2 at the temperature of -40 DEG C is more than or equal to 60J.

Owner:YANSHAN UNIV

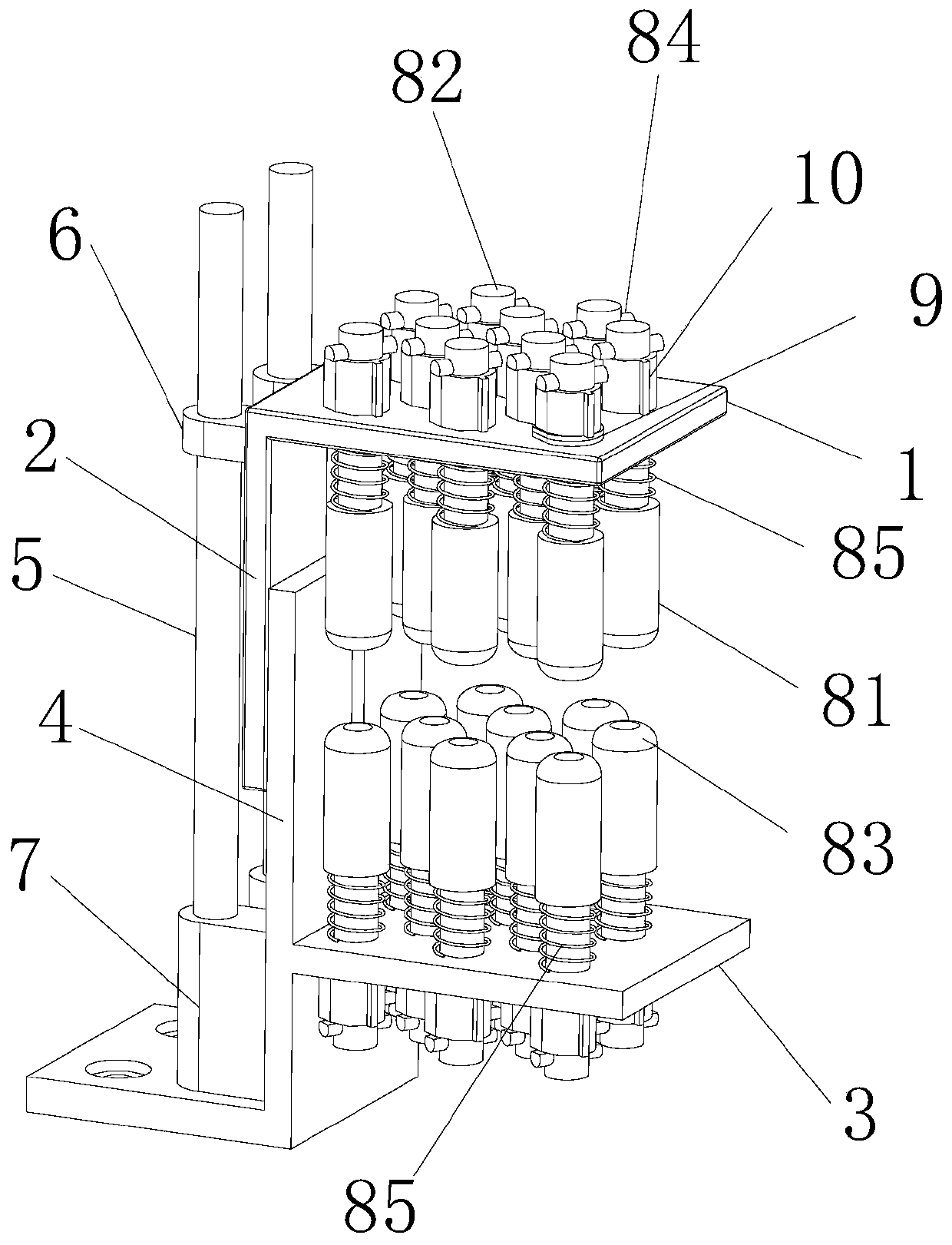

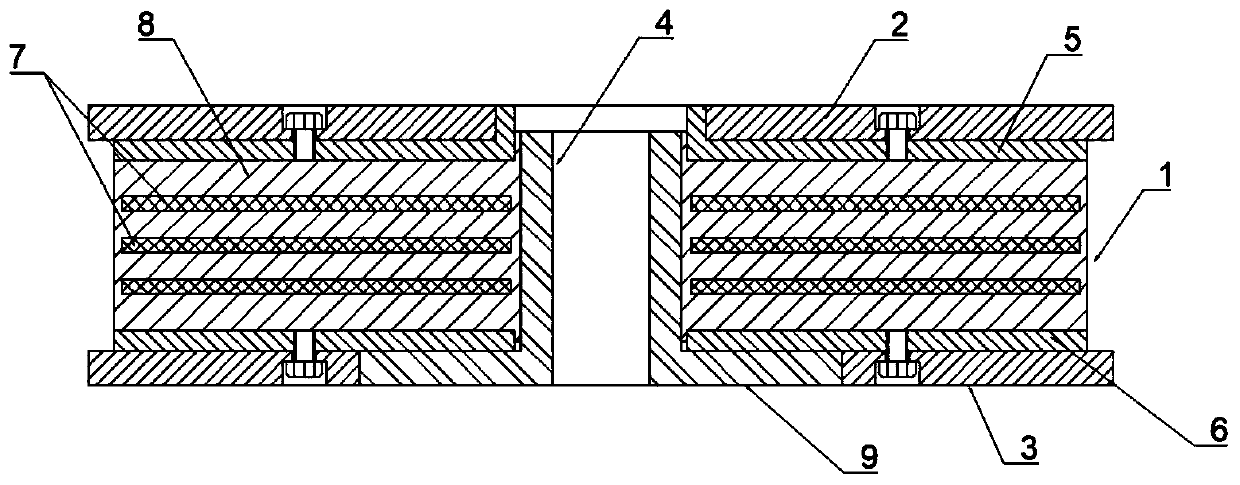

Anti-buckling low-frequency vibration isolation rubber support

ActiveCN110344502AImprove bearing capacityVibration does not appearProtective buildings/sheltersShock proofingEarthquake resistanceEngineering

The invention discloses an anti-buckling low-frequency vibration isolation rubber support comprising a rubber support body and anti-seismic casing pipes arranged in the rubber support body. Laminatedrubber is adopted for the rubber support body. The low rigidity required by low-frequency vibration isolation is achieved by increasing the thickness of the rubber. The anti-seismic casing pipes are embedded in the support in the vertical direction and sequentially penetrate through the rubber support body from top to bottom, a restraining effect is achieved for the high-flexibility rubber supportbody in the horizontal direction, an anti-buckling function is provided for the rubber support body under the vertical large-load effect, and a horizontal earthquake resistance function is also provided for the support. Rubber layers or isolation gaps are arranged between the anti-seismic casing pipes and the rubber support body or between the anti-seismic casing pipes to avoid rigid contact, andthe environment vibration spreading route achieved through a rigid contact face is isolated. By means of the anti-buckling low-frequency vibration isolation rubber support, low-frequency vibration isolation of environment vibration can be achieved, high bearing stability and anti-seismic capacity can also be ensured, and the anti-buckling low-frequency vibration isolation rubber support can be used for vibration isolation of civil engineering structures and all types of instruments and equipment.

Owner:GUANGZHOU UNIVERSITY

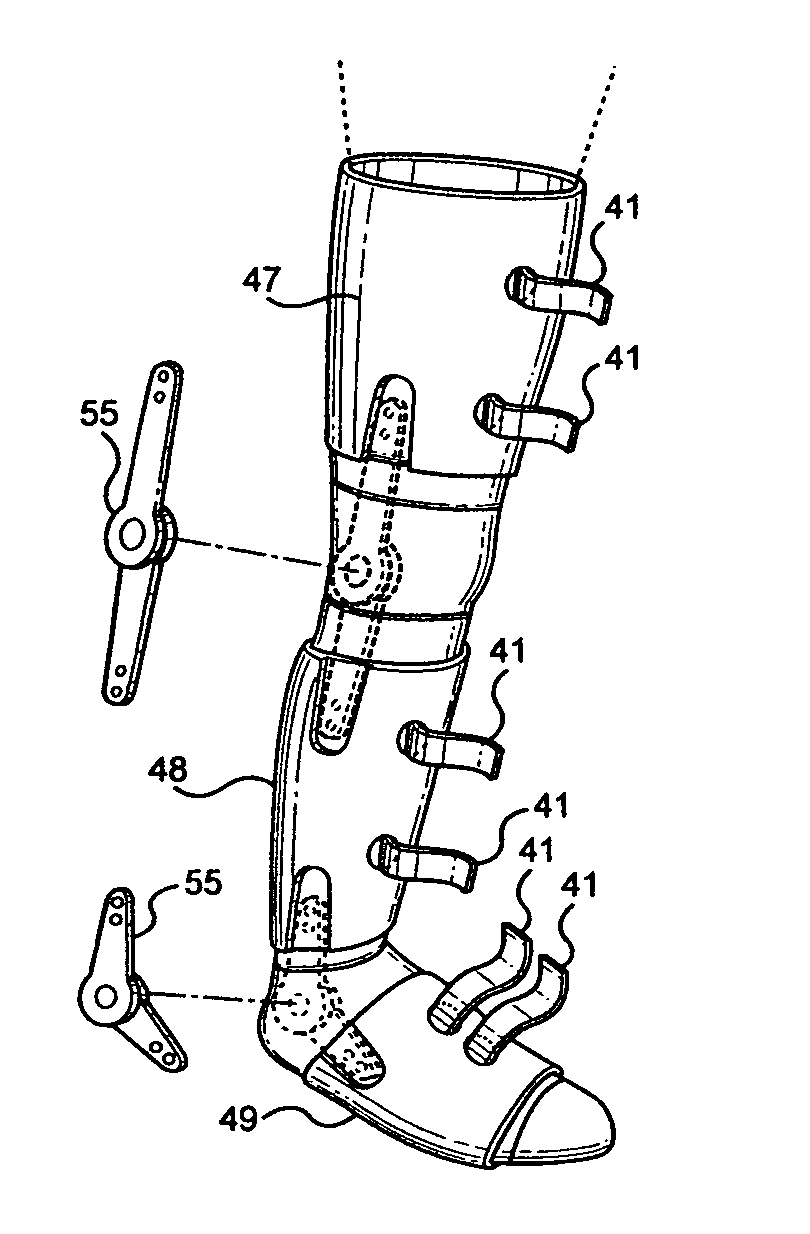

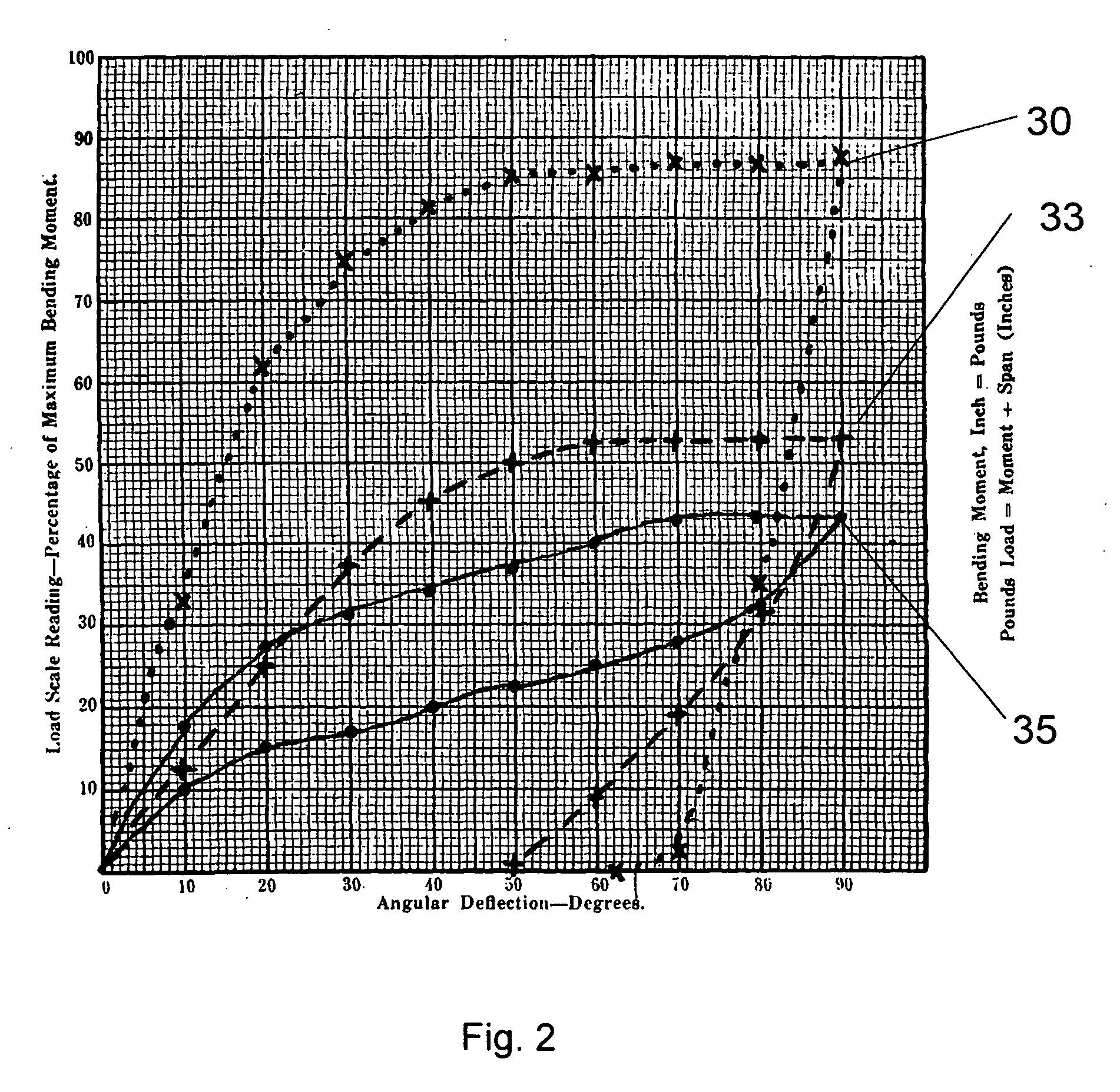

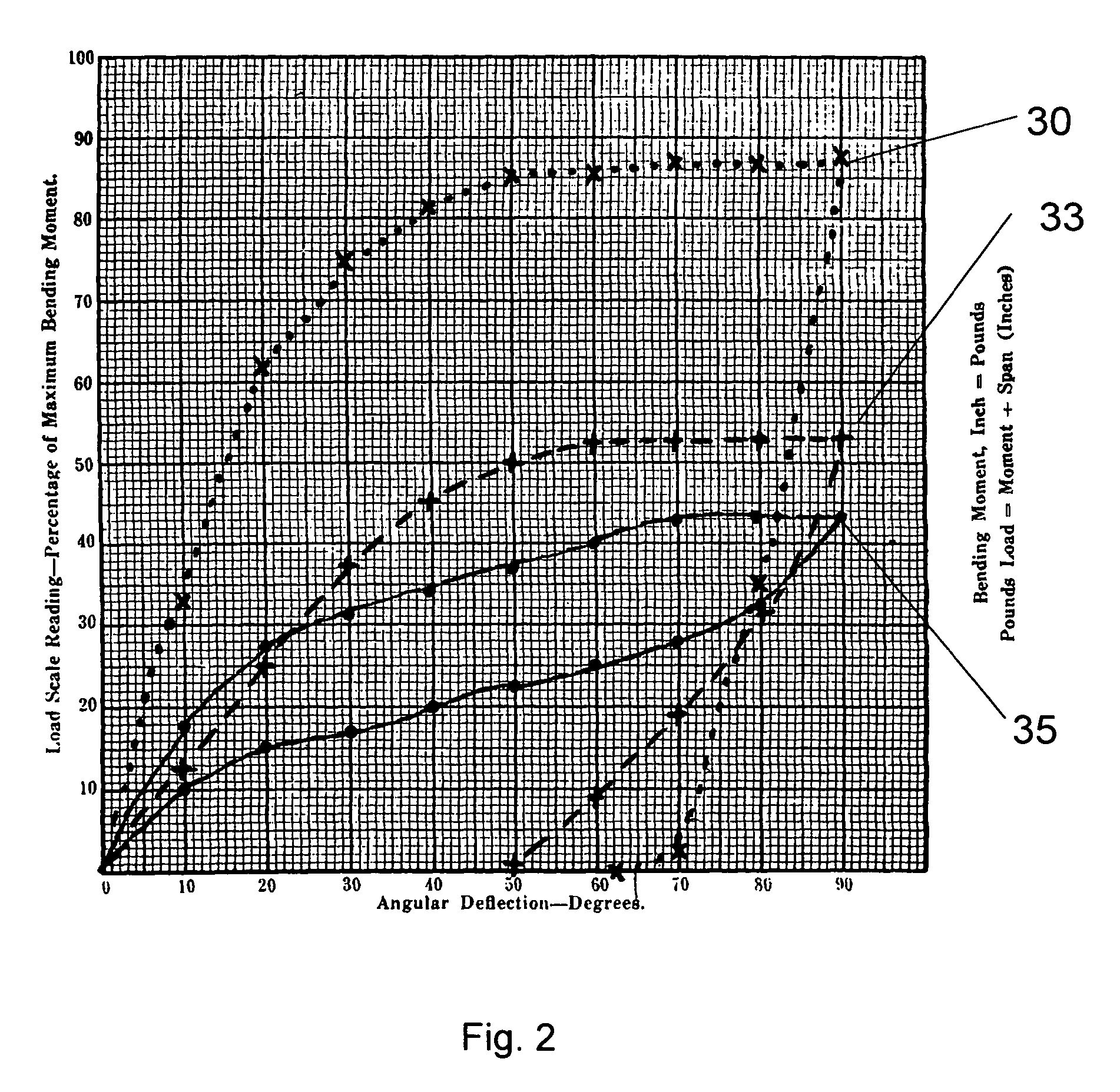

Braided orthotic products and methods of manufacture

This invention provides new above knee (AK) and below the knee (BK) orthotic devices and implements specific manufacturing processes for the production of orthotic devices through the automated, computer controlled bi-axial and tri-axial braiding of orthotic devices, over a mold or mandrel made of carved foam, plaster material or wax that is a replica of the patient's limb, and is created by a Computer Aided Design (CAD) file controlling a Numerically Controlled (CNC) machine tool. This method of manufacture using aerospace fibers such as graphite or Kevlar, and high performance resins, is used to create a orthotic device which is stronger and lighter weight than conventionally manufactured orthotic devices. Braiding also allows incorporation of woven cloth, tapes and other reinforcements into the braiding process for added strength at selected areas. The method dramatically decreases the production time and cost of the relative to conventional methods.

Owner:MENTIS SCI

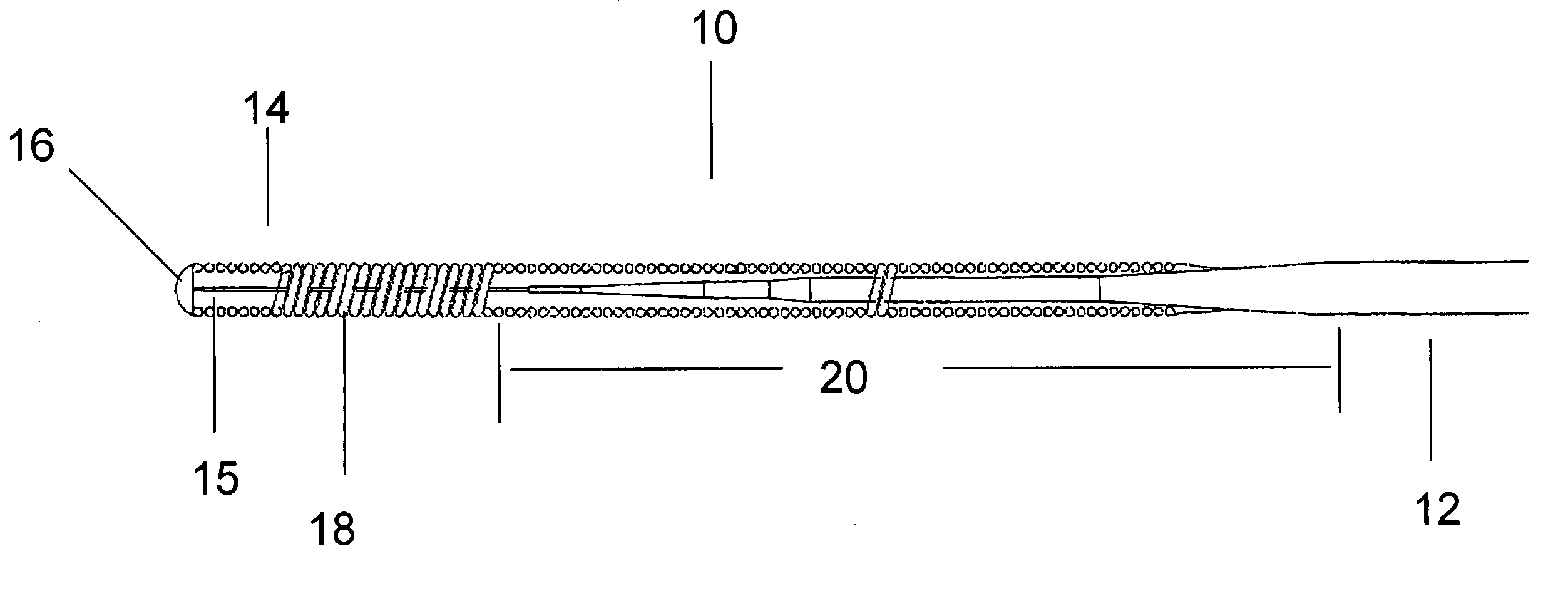

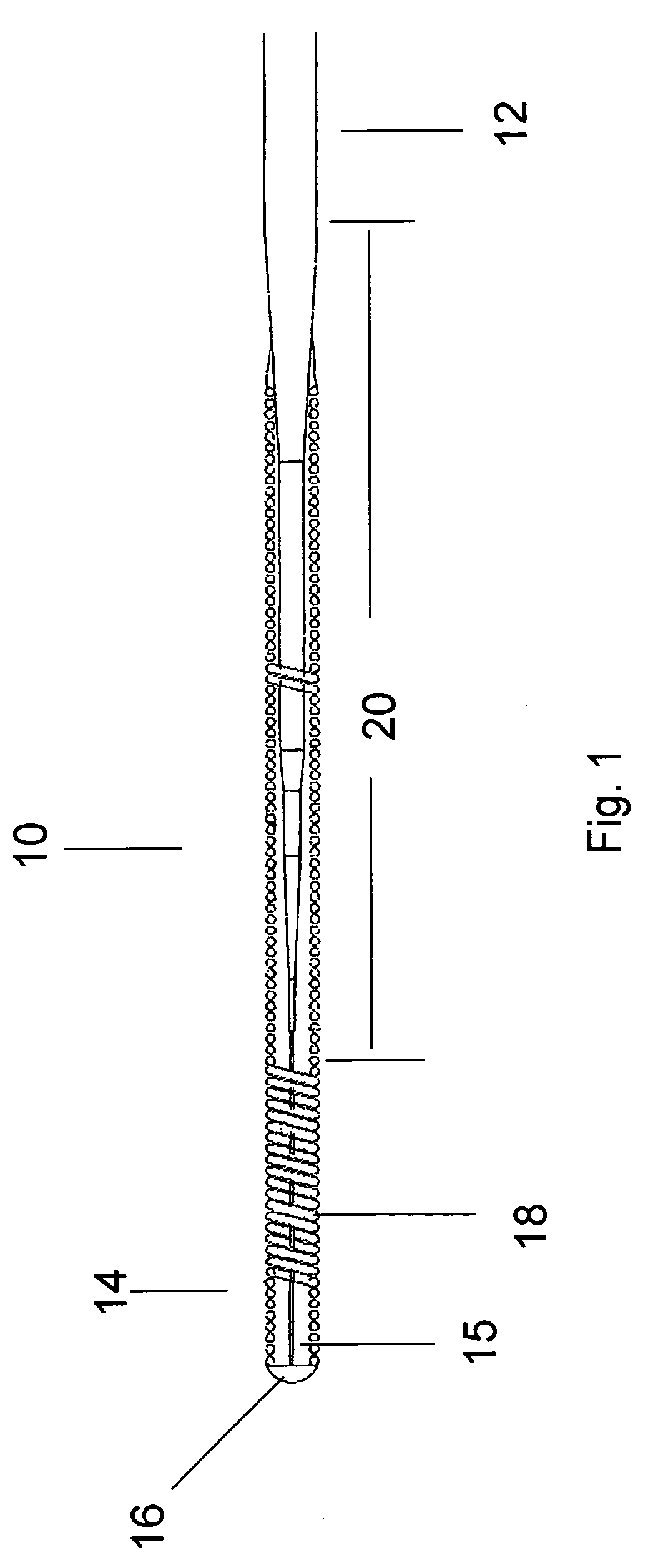

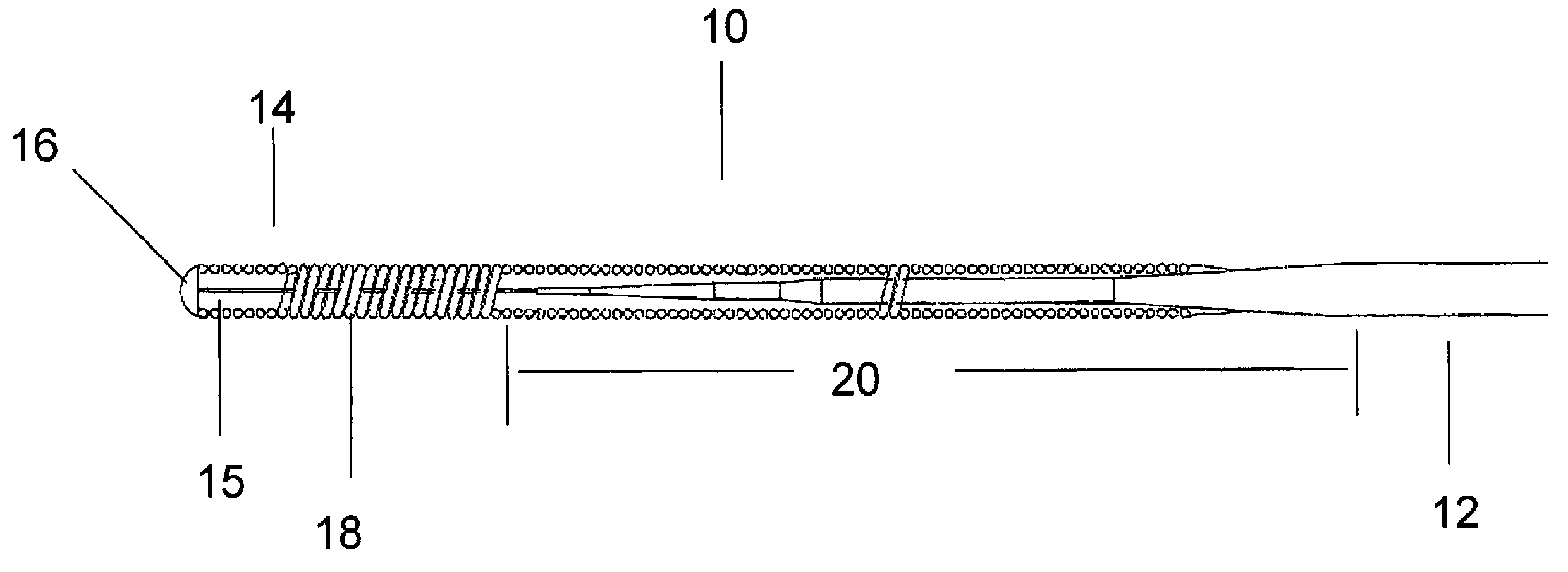

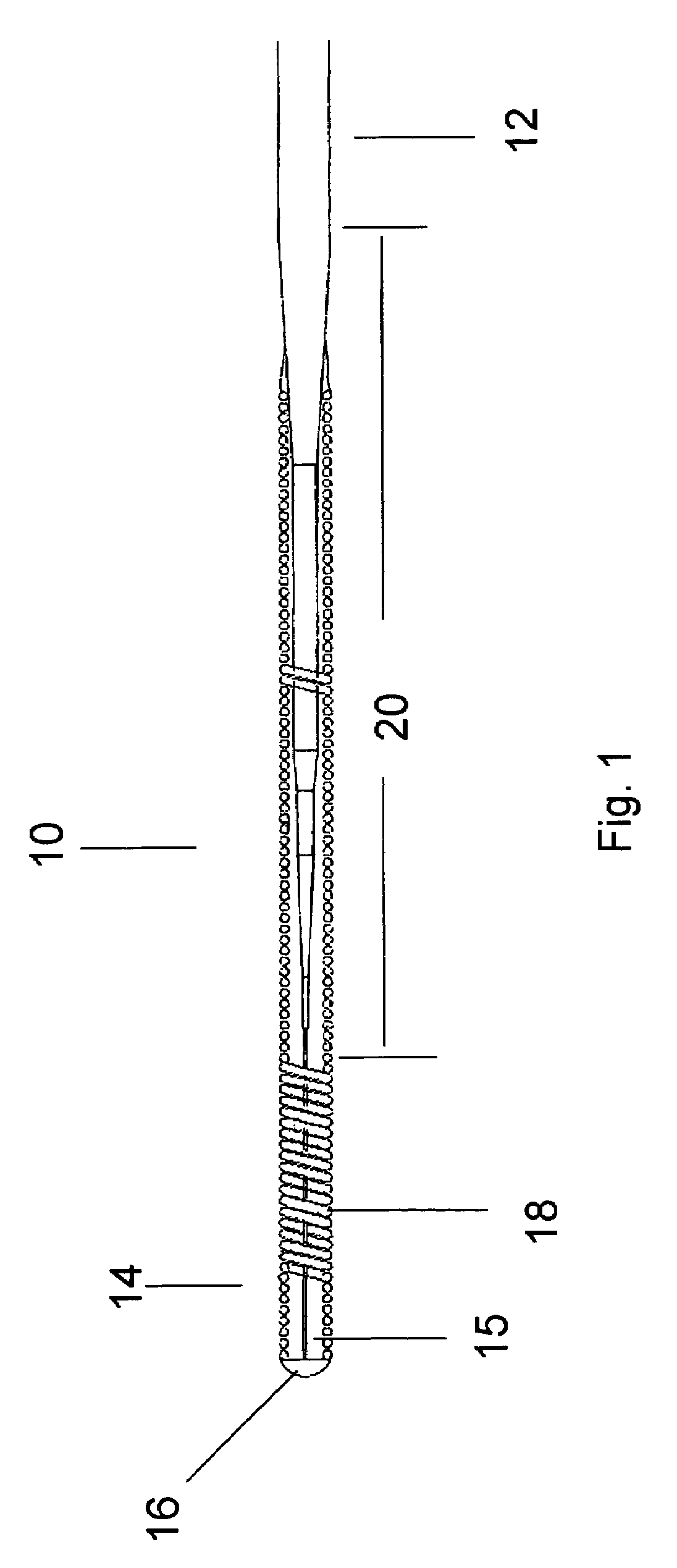

Titanium molybdenum alloy guidewire

InactiveUS20060089568A1High springbackHigh flexabilityGuide wiresDiagnostic recording/measuringNiti alloyTitanium

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zinc and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MX MEDICAL +1

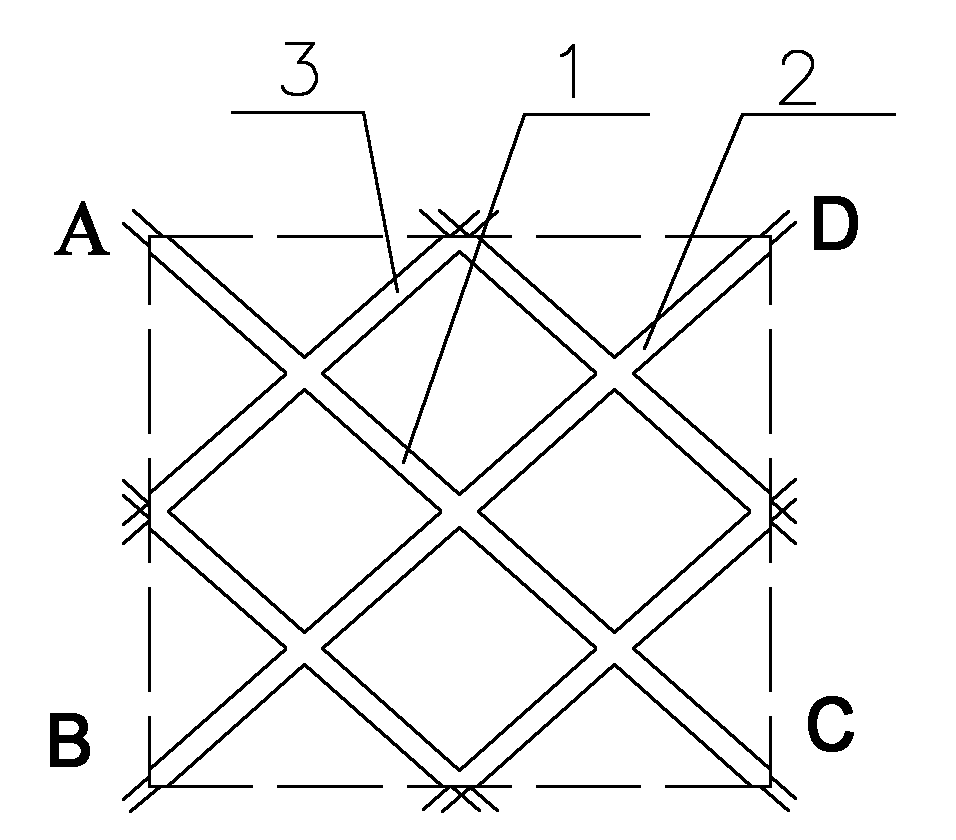

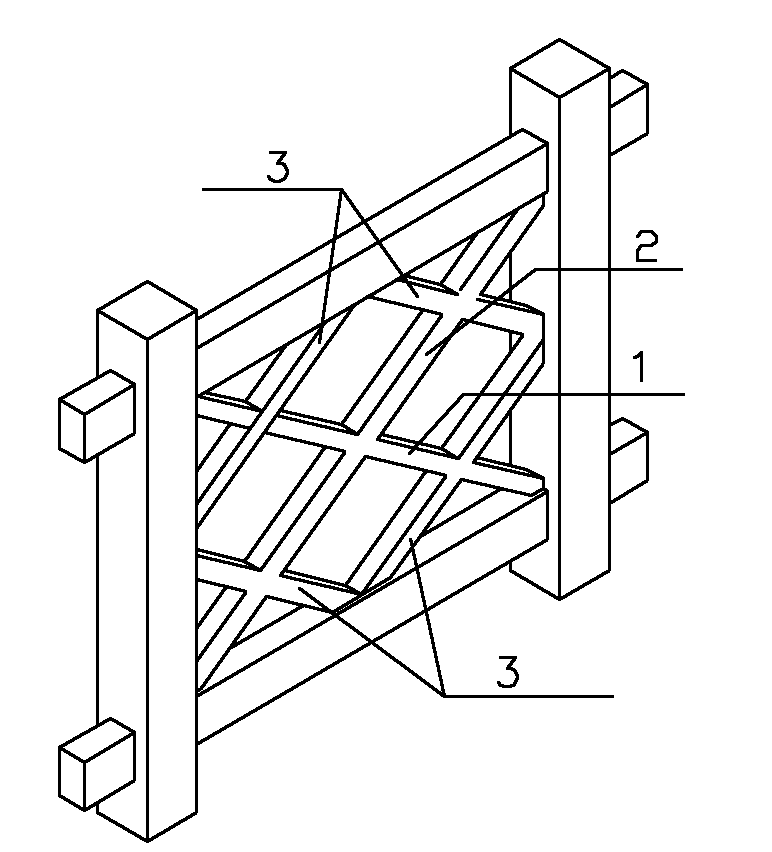

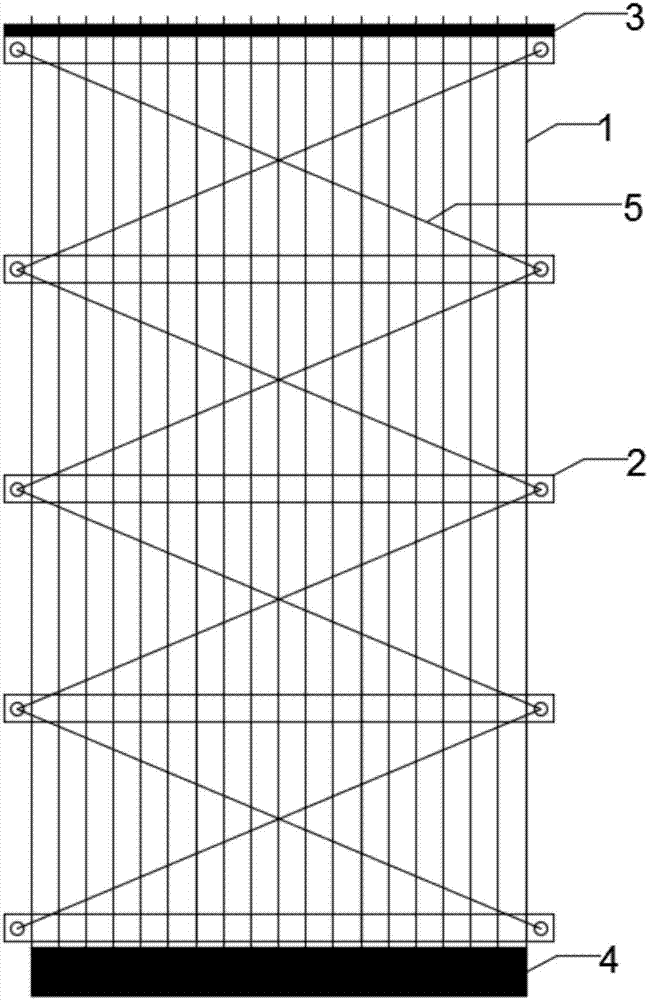

Cross bracing type reinforced concrete energy consuming device

InactiveCN101956434AReduce lateral displacementLight in massShock proofingRc framesArchitectural engineering

The invention relates to a cross bracing type reinforced concrete energy consuming device, which belongs to the field of resistance and absorption of earthquake for construction structures, and overcomes the defects that the framework structure of reinforced concrete is small in lateral rigidity and easy to laterally sway under the action of the earthquake, and a traditional energy consuming device has the defects of high construction cost and large construction difficulty. The energy consuming device comprises a first and a second main bracings as well as a first and a second assistant bracings in a rectangular area ABCD, wherein the first main bracing is arranged on the diagonal AC of the rectangle ABCD; the second main bracing is arranged on the diagonal BD of the rectangle ABCD; or the first main bracing is arranged in the position deviating from a first vertex and a third vertex in a distance of 1 to 1.5 times the height of a framework beam, and is crossed with the upper edge and the lower edge of the rectangle ABCD; the second main bracing is arranged in the position deviating from a second vertex and a fourth vertex in a distance of 1 to 1.5 times the height of the framework beam, and is crossed with the upper edge and the lower edge of the rectangle ABCD; the assistant bracings are arranged on connecting lines of bisection points of four edges of the rectangle ABCD; the first and the second main bracings as well as the first and the second assistant bracings form a hollow grid; and when used as a filling wall, the hollow grid is filled with energy absorbing materials.

Owner:BEIJING JIAOTONG UNIV

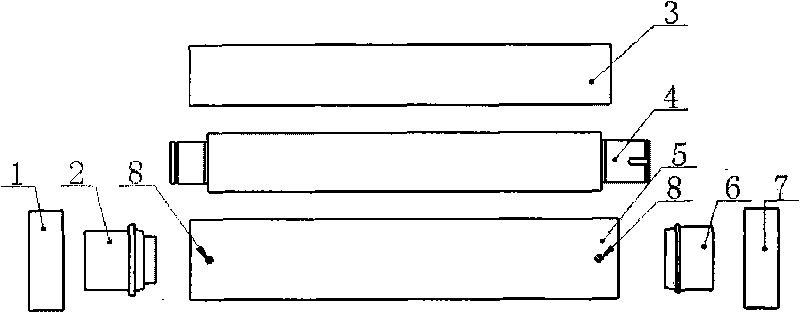

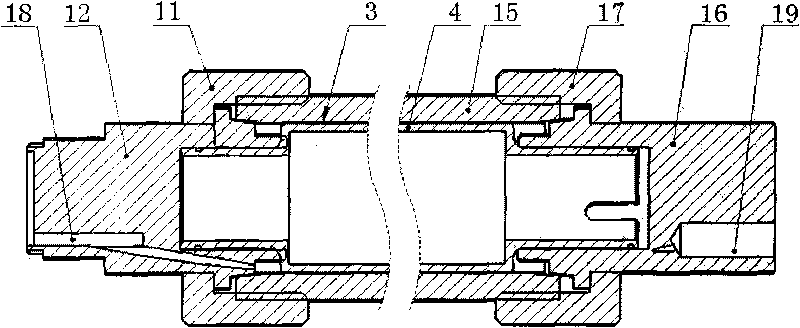

Method for manufacturing fixing heating roller coated with teflon film silastic

ActiveCN101702081AImprove uniformityHigh precisionElectrographic process apparatusEngineeringSilica gel

The invention relates to a method for manufacturing a fixing heating roller coated with teflon film silastic, comprising the following steps of: firstly, sheathing a fluorin jacket on the peripheral surface of an aluminium tube, and then infusing a silica gel layer between the aluminium tube and the fluorin jacket. The fluorin jacket is made of tubular teflon films. The invention has the advantages of simpler process, simple equipment, easy operation and low cost; and the manufactured fixing heating roller has high chemical stability and is suitable for high-speed printers and copiers.

Owner:BEIJING LASER HI TECH CO LTD

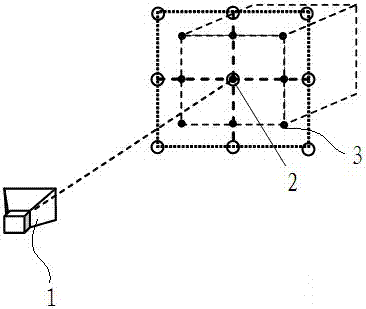

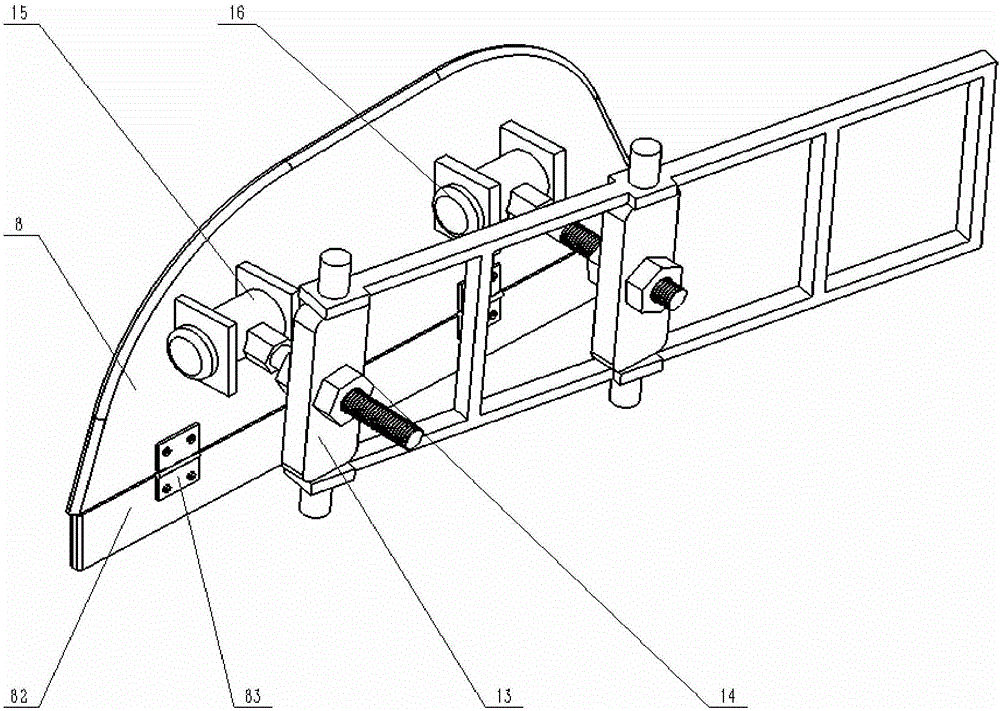

Automatic test device used for testing uniformity of antenna radiation field

ActiveCN107121600AEnvironmental factors are smallAvoid impact on test accuracyAntenna radiation diagramsStructural engineeringMechanical engineering

The invention discloses an automatic test device used for testing the uniformity of an antenna radiation field. The device comprises a regular geometric frame and a support bar separated from the geometric frame. The geometric frame is provided with a number of positioning bars capable of moving along the inner frame of the geometric frame. Each positioning bar is directed to the center of the geometric frame and is capable of telescoping. One end of the support bar is perpendicular to the cross section of the geometric frame and is directed to the center of the geometric frame. Probes are used for testing the antenna radiation field are arranged on one end of the support bar and the positioning bars. The automatic test device provided by the invention has the advantages of clever design, simple structure, easy operation, convenient use, low cost of making and maintaining, outstanding substantive characteristics and remarkable progress, and is suitable for large-scale application in the fields of antenna measurement and electromagnetic waves.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

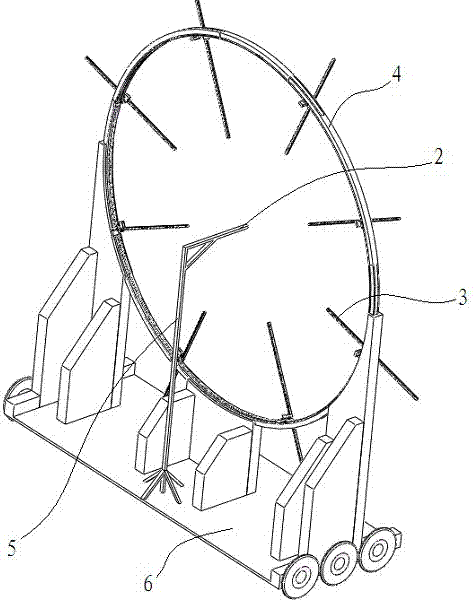

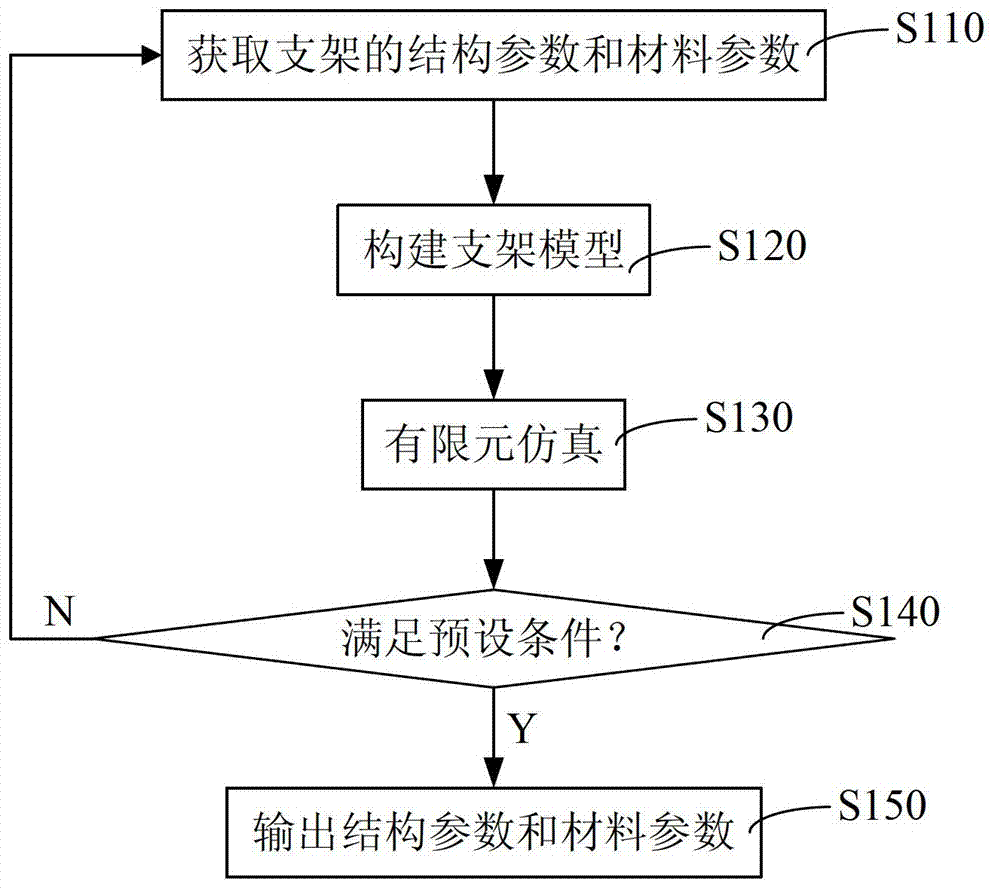

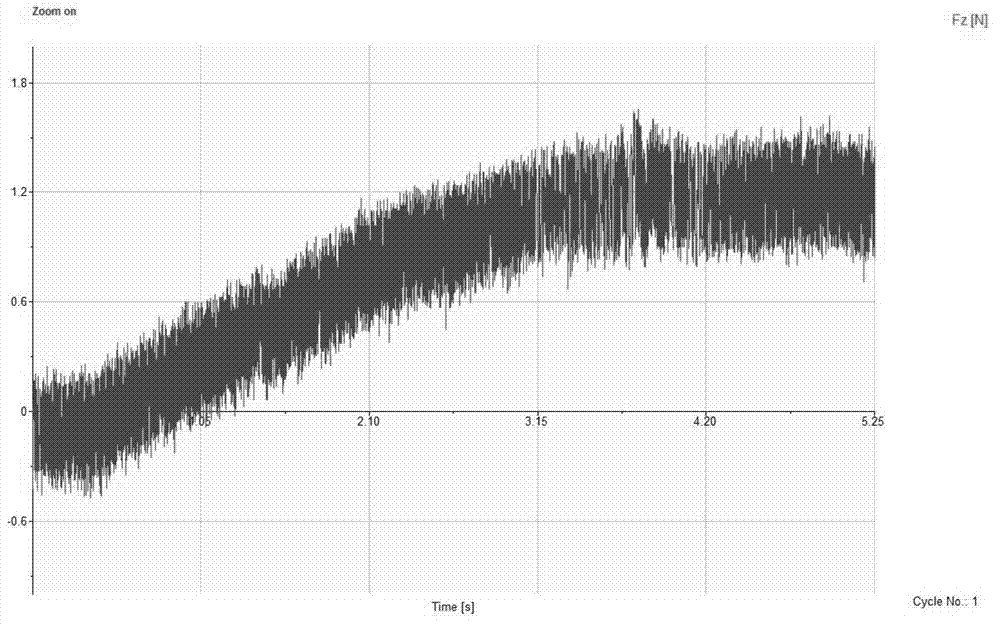

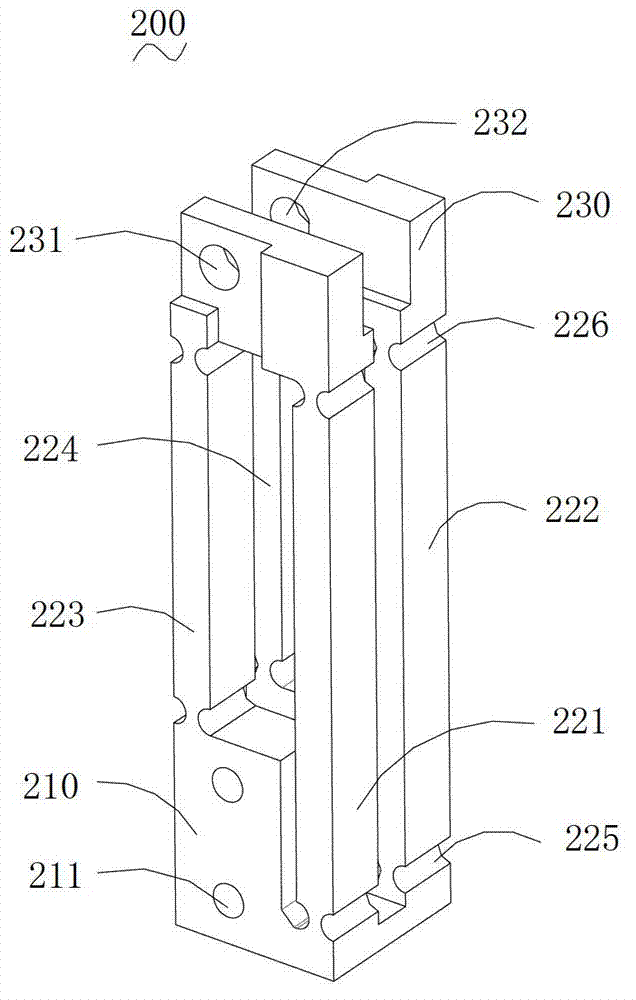

Bracket for measuring head of flying-probe tester and design method of bracket

ActiveCN102735884AModerate stiffnessShort development cycleElectronic circuit testingMeasurement instrument housingEngineeringFlying probe

The invention relates to a design method of a bracket for a measuring head of a flying-probe tester. The design method comprises the following steps of: acquiring structural parameters and material parameters of the bracket; constructing a bracket model according to the structural parameters and the material parameters of the bracket; performing finite element simulation on the bracket model; and when a simulation result is in accordance with preset conditions, outputting the structural parameters and the material parameters of the bracket. The bracket which is designed according to the method meets material and structural requirements; and after a test probe is subjected to reverse thrust of a contact surface of a printed circuit board (PCB), the test probe and the contact surface can keep still relative to each other in the backward movement process, and a test probe head cannot be heavily deflected, so testing accuracy is ensured, and scratches can be avoided. Meanwhile, the bracket is moderate in rigidness, and the problems of recessing of the PCB caused by over-high rigidness, high deformation caused by over-low rigidness and over-short service life can be solved. Moreover, the invention also provides the bracket which is designed according to the method.

Owner:HANS CNC SCI & TECH

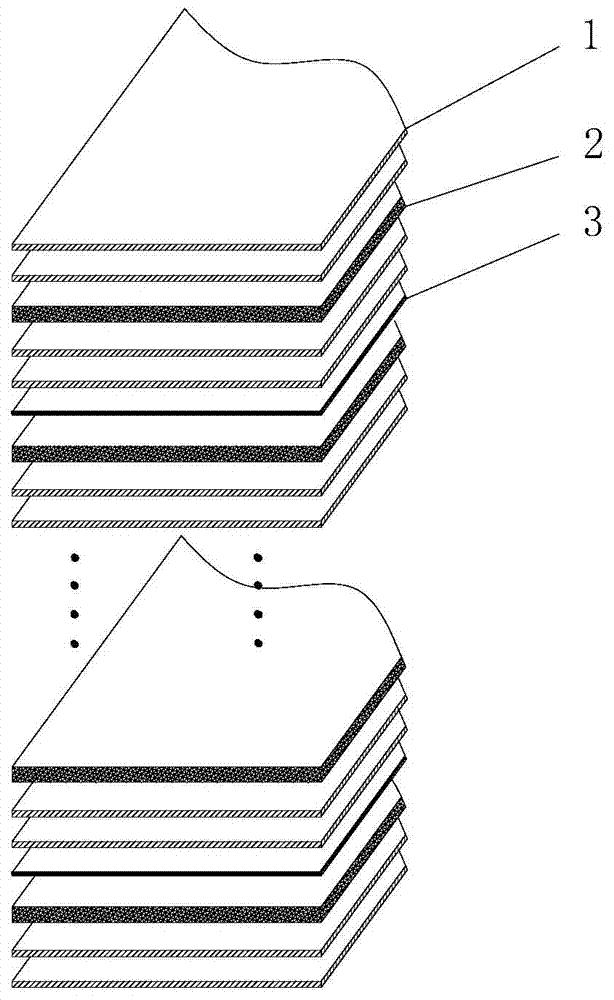

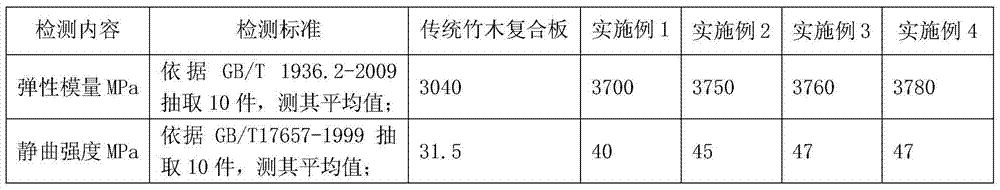

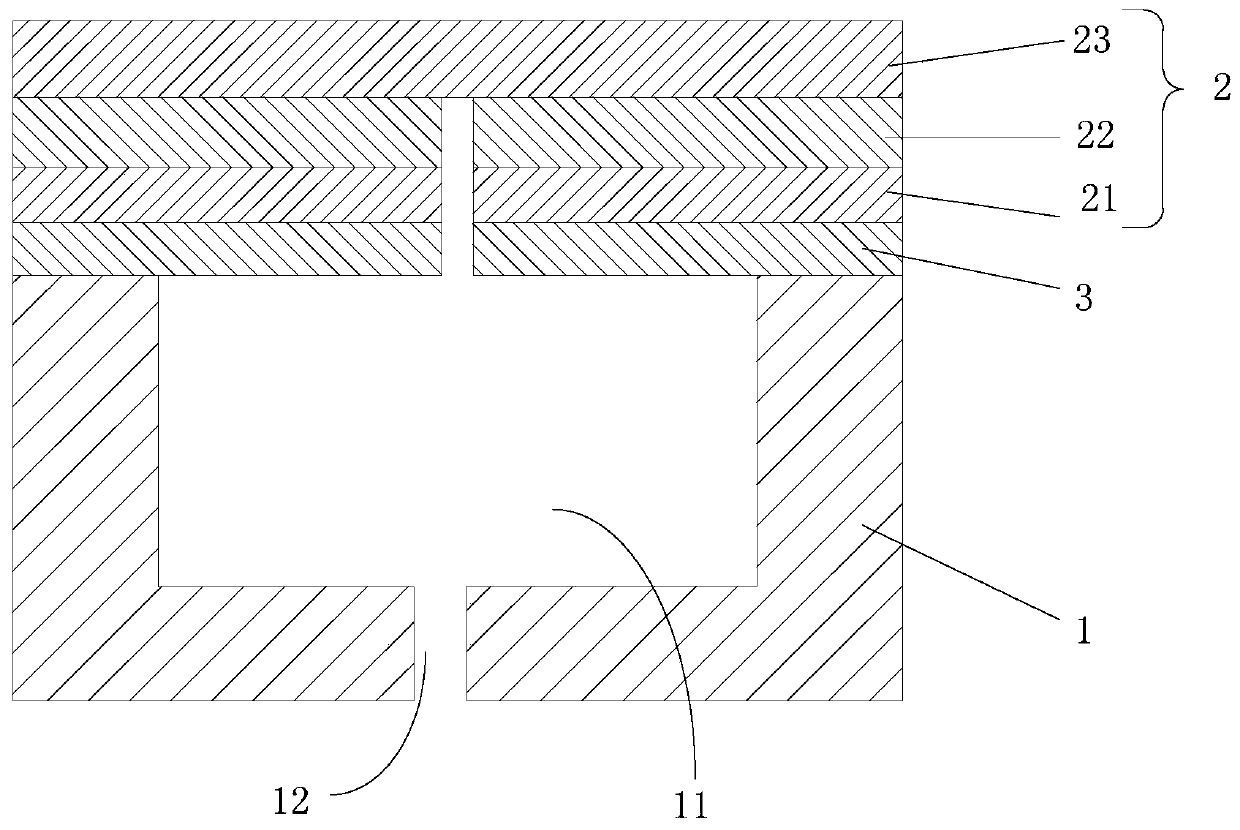

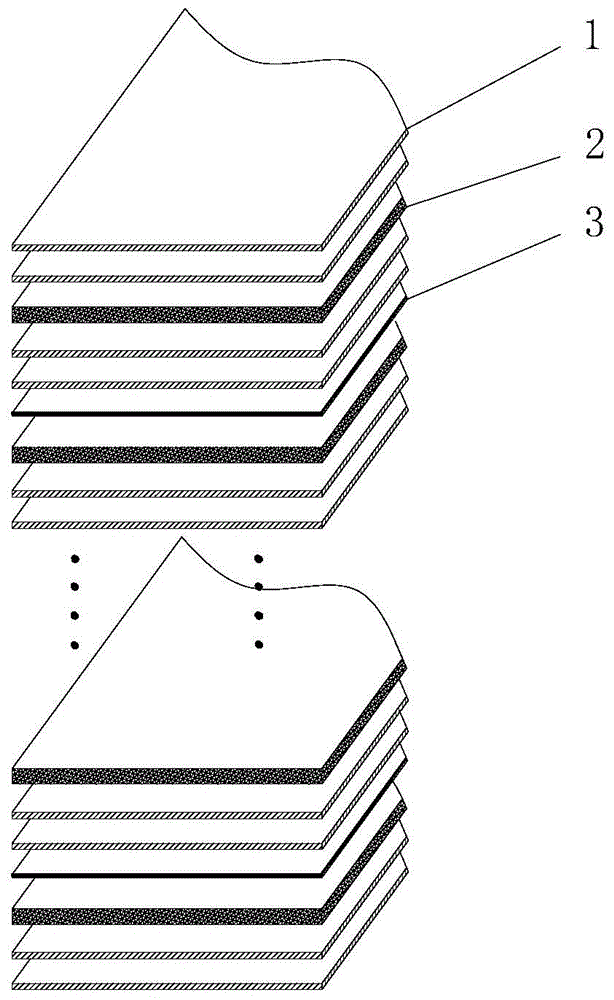

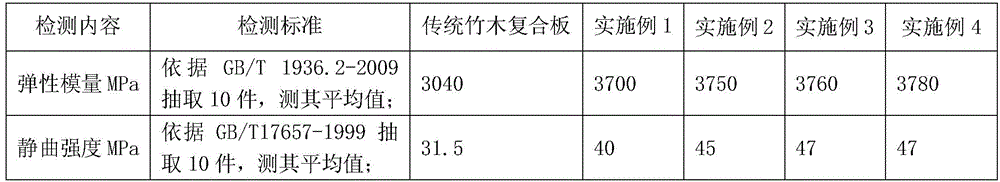

Bamboo and wood composite board and method for manufacturing same

ActiveCN104493916AImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

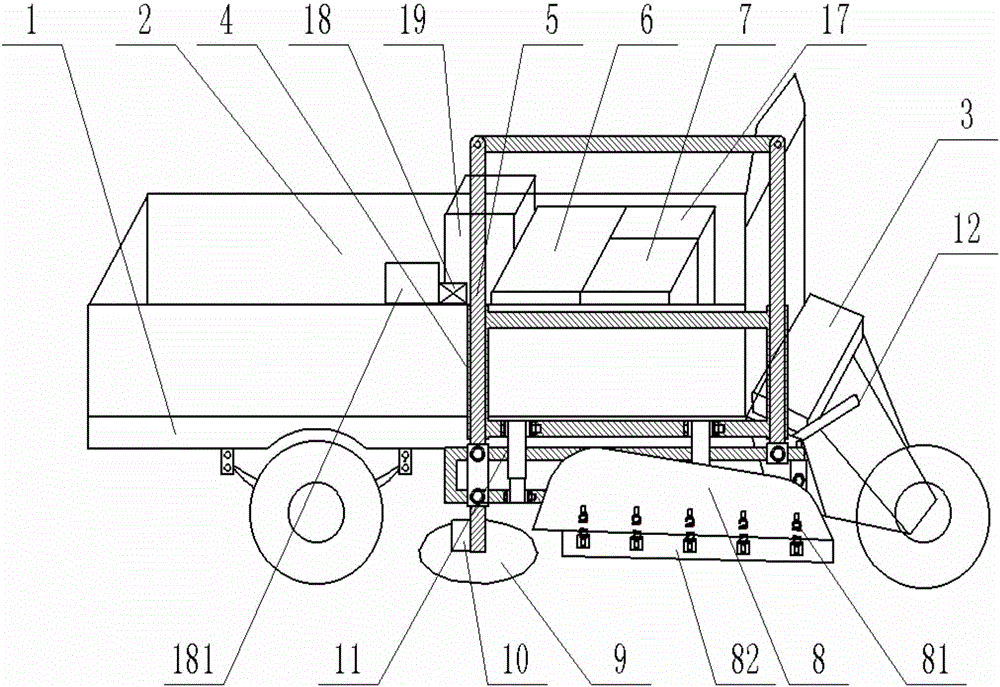

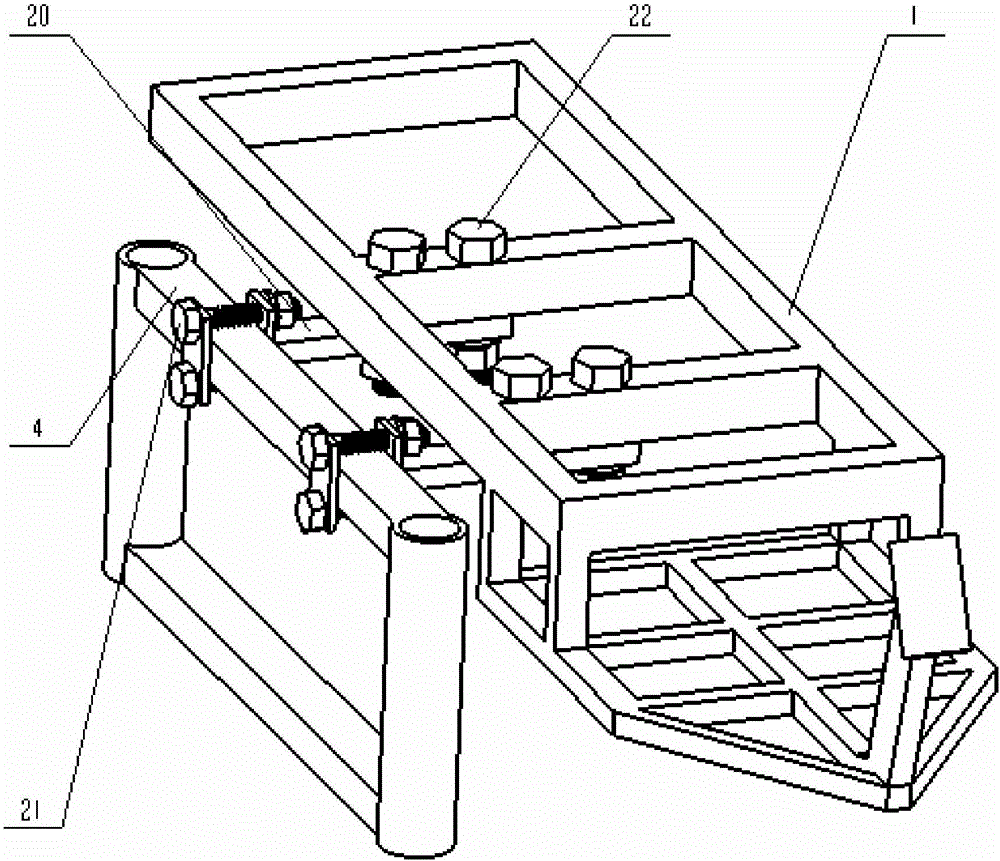

Portable cattle and sheep feeding stacker truck

The invention discloses a portable cattle and sheep feeding stacker truck. The portable cattle and sheep feeding stacker truck comprises a chassis and a stacking plate, wherein a carriage is arranged at the rear part of the chassis; a saddle is arranged at the front part of the carriage; a DC (direct-current) power supply, a circuit control structure, a hydraulic pump, a fuel tank and a hydraulic control structure are arranged in the carriage; a hydraulic pump motor II is connected with the DC power supply through the circuit control structure; the hydraulic pump is connected with a hydraulic cylinder and the fuel tank through a pipeline; a reversing valve and an overflow valve are arranged on the pipeline; a fixed bracket is arranged in the position close to the front part of the right side of the chassis; a movable bracket is arranged on the fixed bracket; the hydraulic cylinder is arranged on the fixed bracket; the movable bracket is connected with the outer end of a retractable piston rod of the hydraulic cylinder; the hydraulic cylinder is connected with the hydraulic pump through a hydraulic pipeline; the front side and the rear side of the stacking plate are connected with the movable bracket through bolts respectively. The portable cattle and sheep feeding stacker truck is light and flexible, saves manpower, realizes thorough cleaning and improves the working efficiency of a dairy cattle farm.

Owner:山东省饲料兽药质量检验中心

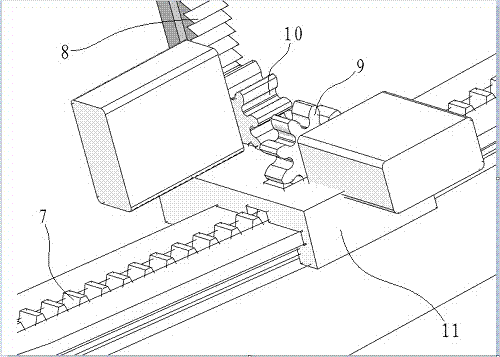

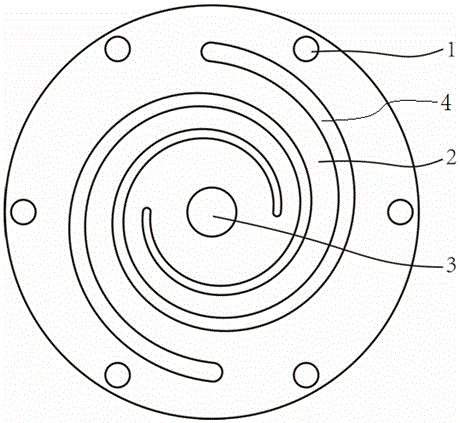

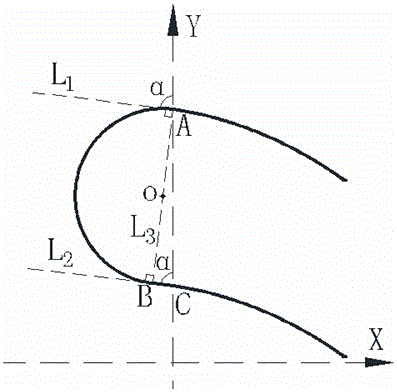

Equiangular-spiral leaf spring

ActiveCN106051036AUniform stress distributionReduce local stressNon-rotating vibration suppressionStress distributionEngineering

The invention relates to an equiangular-spiral leaf spring. The left spring comprises two vortex arms and two vortex grooves, wherein the two vortex grooves are symmetrically distributed at an angle of 180 degrees; vortex groove profiles are determined with the equiangular spiral equation as follows: r=ae<btheta> (a and b are larger than 0), a and b are constants, a refers to the adjustable vortex line pole deviation distance, b refers to the adjustable profile expansion speed, r refers to the polar radius, e refers to the Napierian base, and theta refers to the polar angle. Different leaf springs adopt different a and b values, vortex groove profiles which are deviated from poles in different positions and have different shapes can be obtained by changing parameters a and b of the profiles, starting positions and end positions of the vortex groove profiles can be controlled by changing the polar angle theta, and the leaf springs in different shapes can be designed according to different actual performance requirements. Seal ends of the equiangular-spiral vortex grooves are in semi-circular and linear smooth transition. The leaf spring is uniform in stress distribution, small in local stress, simple in profile and seal method design, convenient to machine, high in reliability and long in service life and has the higher radial rigidity and certain axial rigidity.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

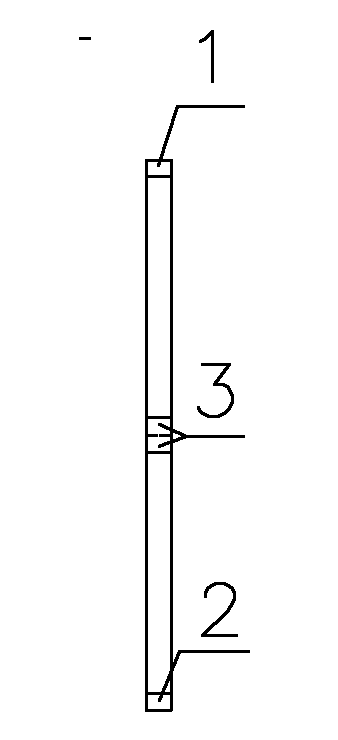

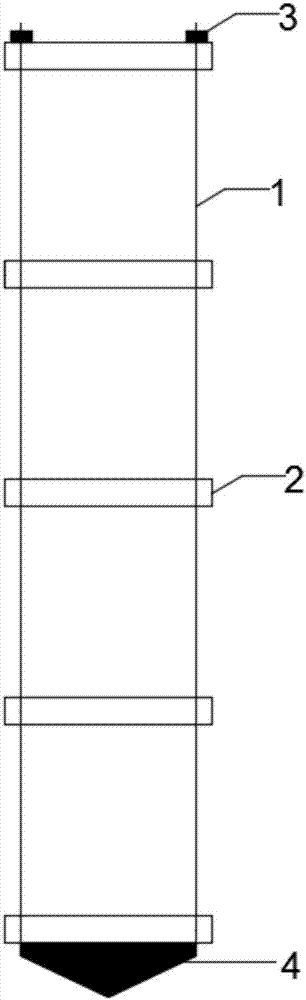

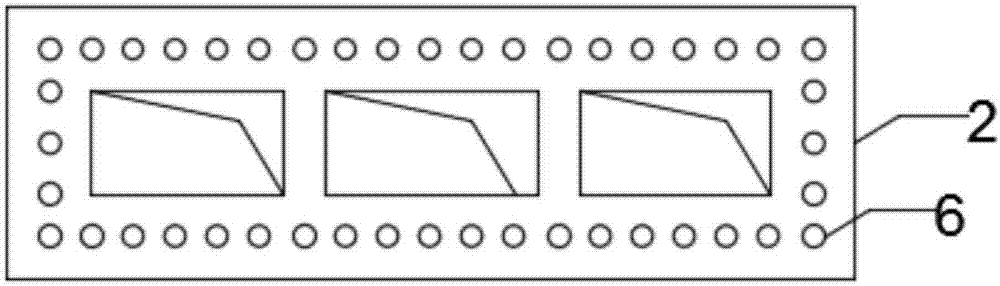

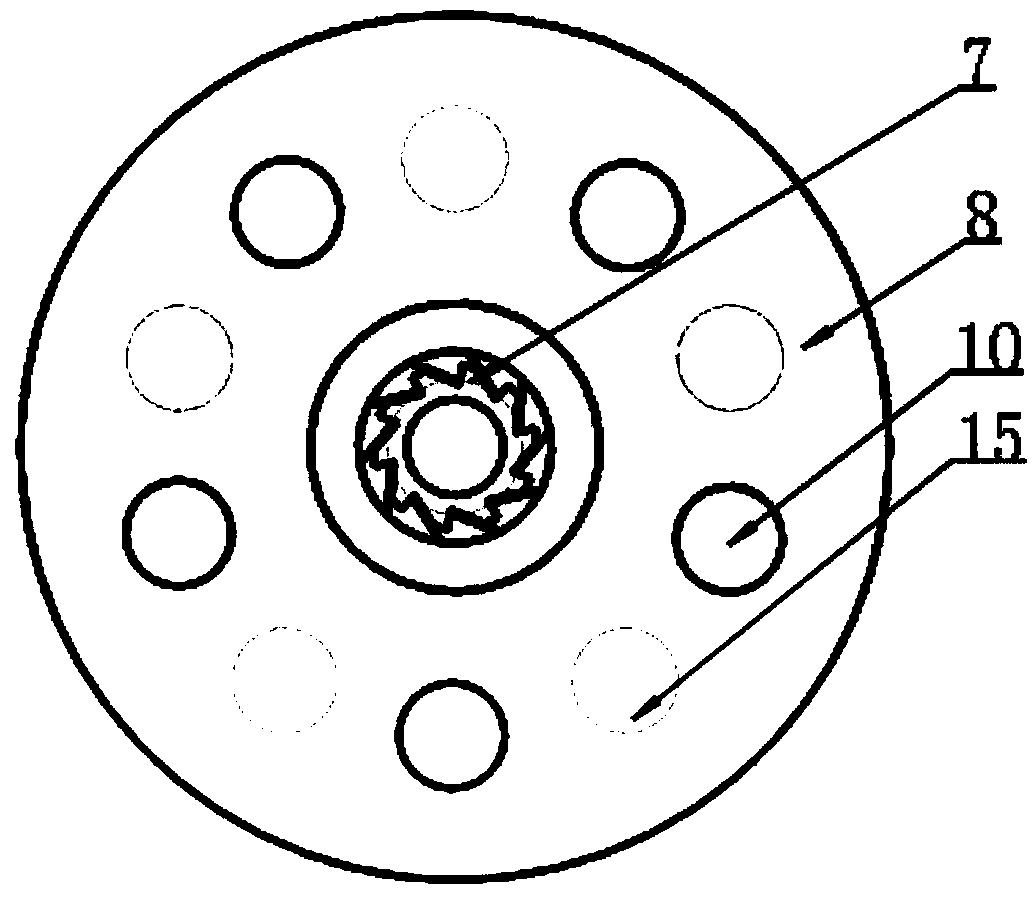

Flexible steel strand cage of underground diaphragm wall self-adaptive to trough deflection and construction method thereof

ActiveCN107419747AAdaptive skewEasy to handleArtificial islandsUnderwater structuresSlurry wallEngineering

The invention relates to a flexible steel strand cage of an underground diaphragm wall self-adaptive to trough deflection. The flexible steel strand cage comprises steel strands, a plurality of steel strand positioning discs and X-type diagonal draw steel bars. Steel strand perforated holes are formed in the plurality of steel strand positioning discs, and a group of steel strands vertically penetrate through the plurality of steel strand positioning discs in a spaced manner; a counterweight is fixed on the bottom steel strand positioning disc, and a clamp for clamping and locking the steel strands is arranged on the top steel strand positioning disc; and the X-type diagonal draw steel bars are fixed on two side faces between adjacent steel strand positioning discs. By replacing a conventional reinforcement cage which is relatively great in rigidity with the flexible steel strand cage, deflection of the trough can be self-adapted. Compared with a conventional trough deflection treatment mode, the flexible steel strand cage provided by the invention can quickly and economically treat the deflection problem; and the flexible steel strand cage can reach proper rigidity as needed.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

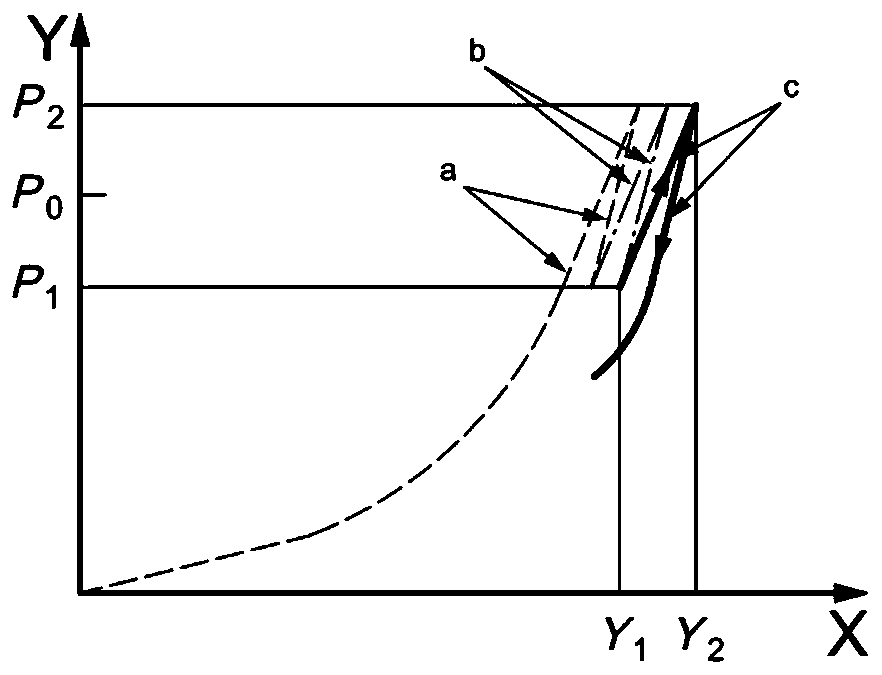

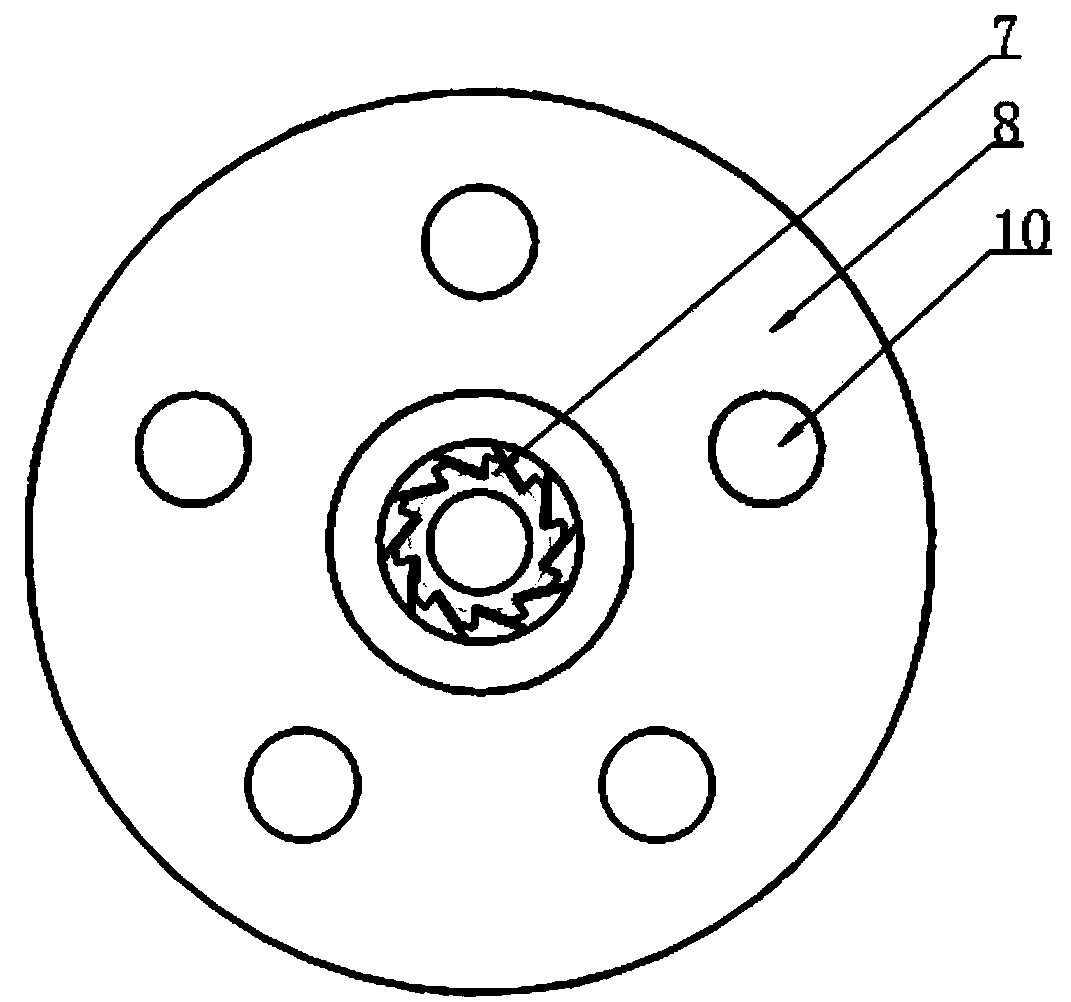

Volume-variable air spring auxiliary air chamber

InactiveCN108730397AModerate stiffnessImprove wear resistanceSpringsGas based dampersAir springEffective volume

The invention discloses a volume-variable air spring auxiliary air chamber, and relates to the technical field of automobile air spring auxiliary air chambers. The volume-variable air spring auxiliaryair chamber mainly comprises a first-stage air chamber body, a second-stage air chamber and a third-stage air chamber body and further comprises a connecting pipeline connected with a main air chamber body, a top cover, a separation plate, a ratchet wheel, a rotary disc, a ratchet wheel shaft and the like. According to the auxiliary air chamber, changing of the volume of the auxiliary air chambercan be achieved by controlling rotation of the rotary disc, and a driving mechanism drives the ratchet wheel shaft to rotate. The ratchet wheel on the ratchet wheel shaft rotates through the ratchetwheel shaft to interact with a pawl on the rotary disc, and then the rotary disc is driven to do circling motion. When a hole in the rotary disc is coaxial with a hole in a separation plate, the effective volume of the auxiliary air chamber changes, the rigidity of an air spring system is finally changed to meet various running working conditions of a vehicle, and the aim of improving the comprehensive performance of an air suspension system is achieved.

Owner:HAINAN UNIVERSITY

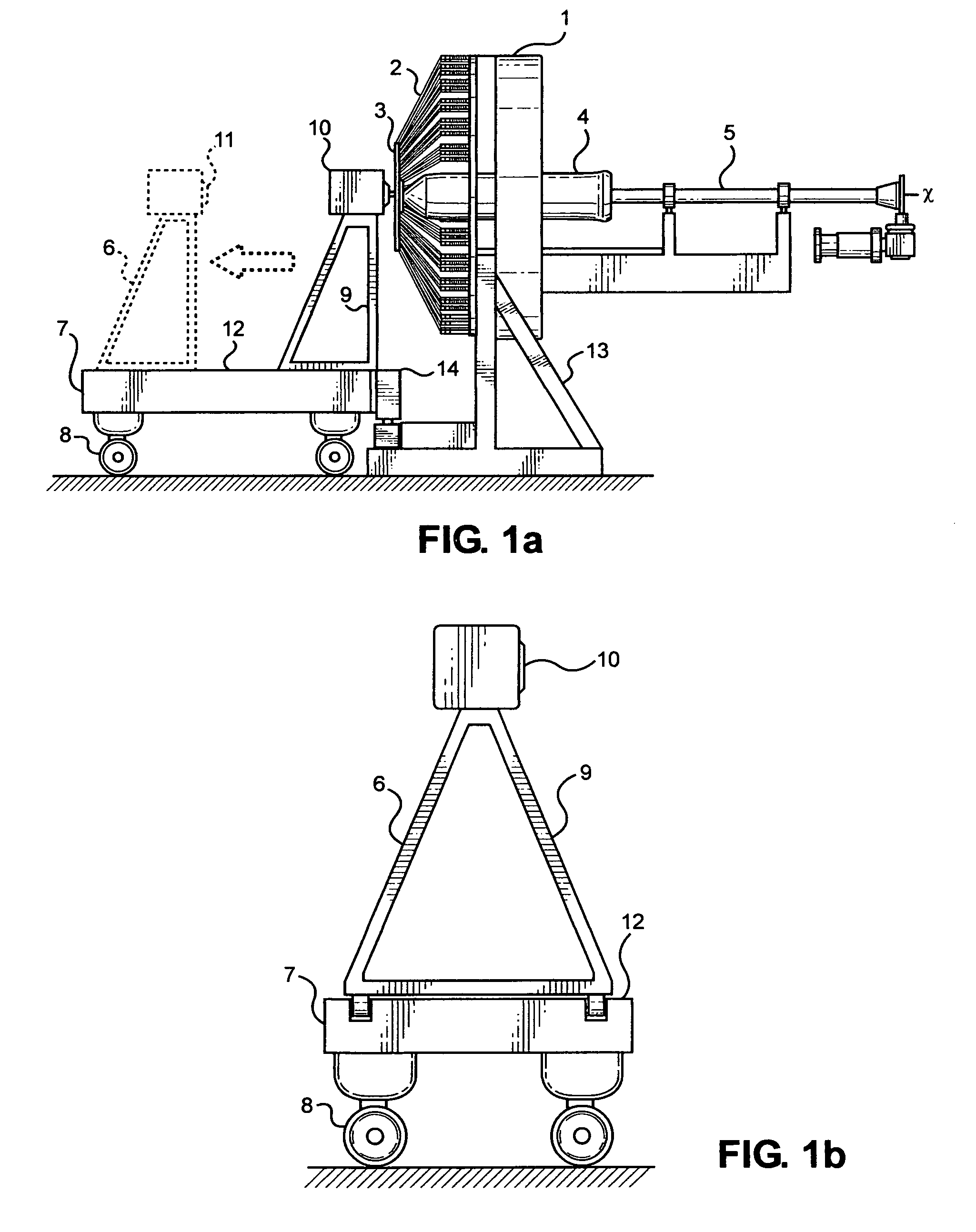

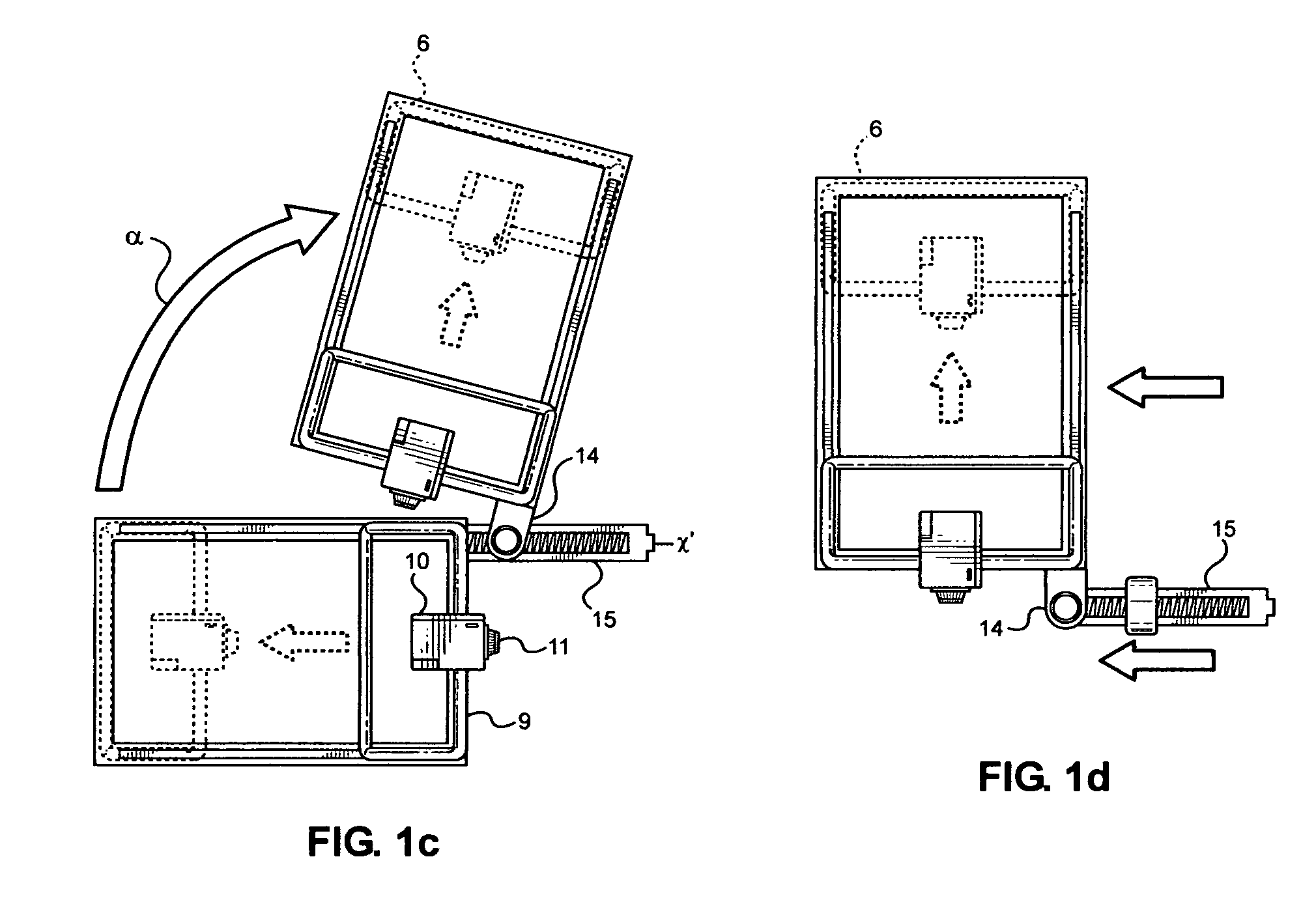

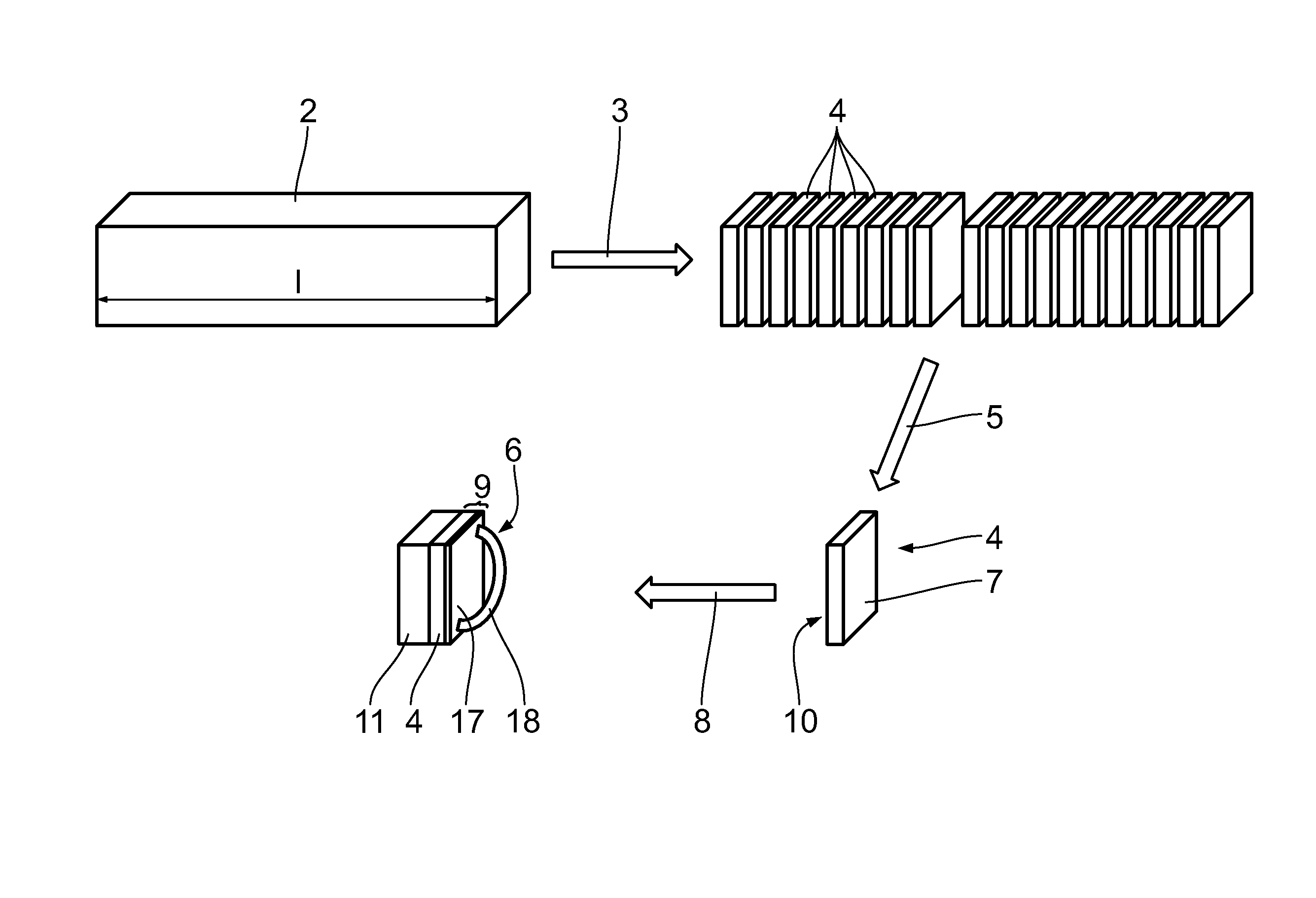

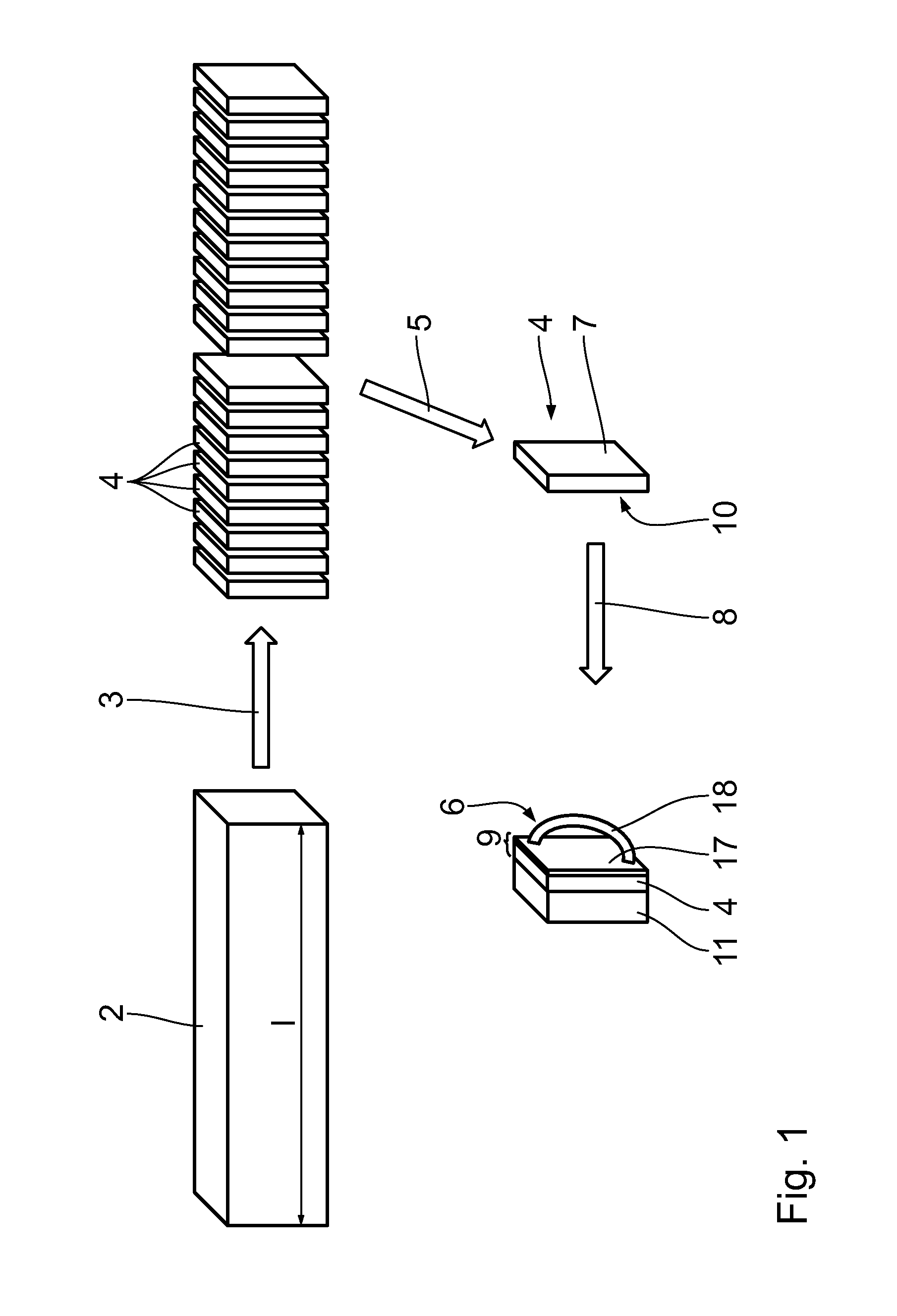

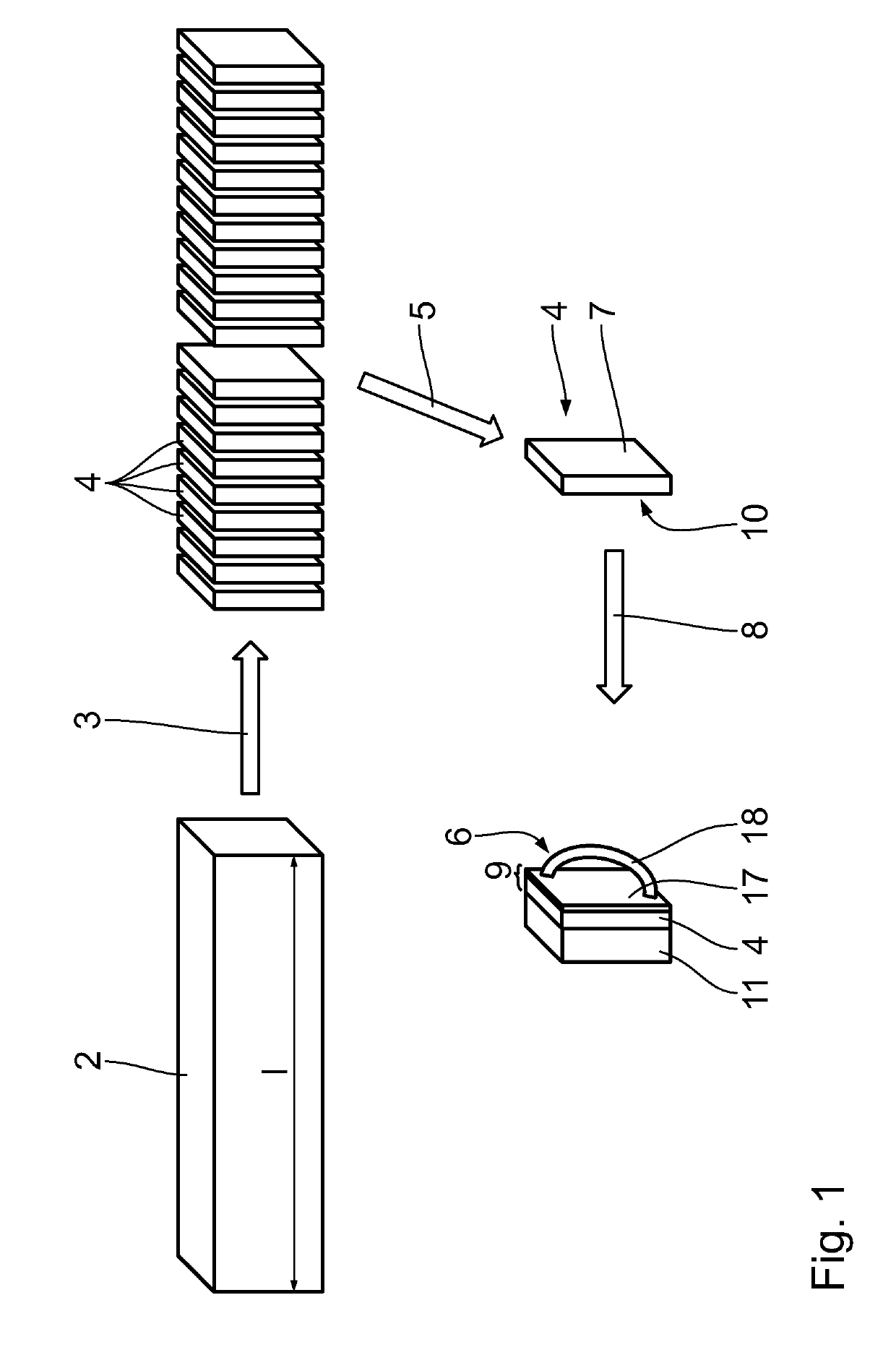

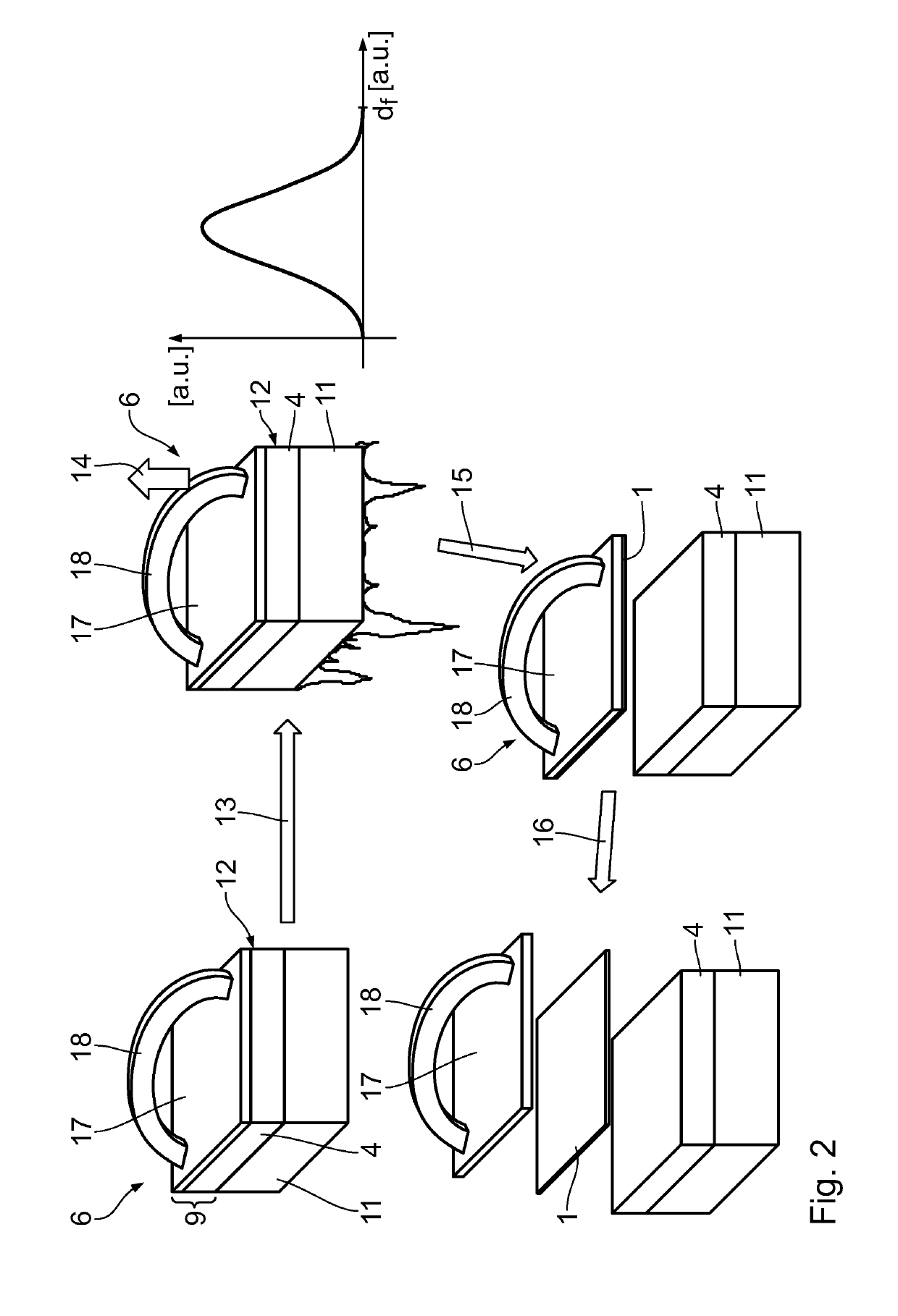

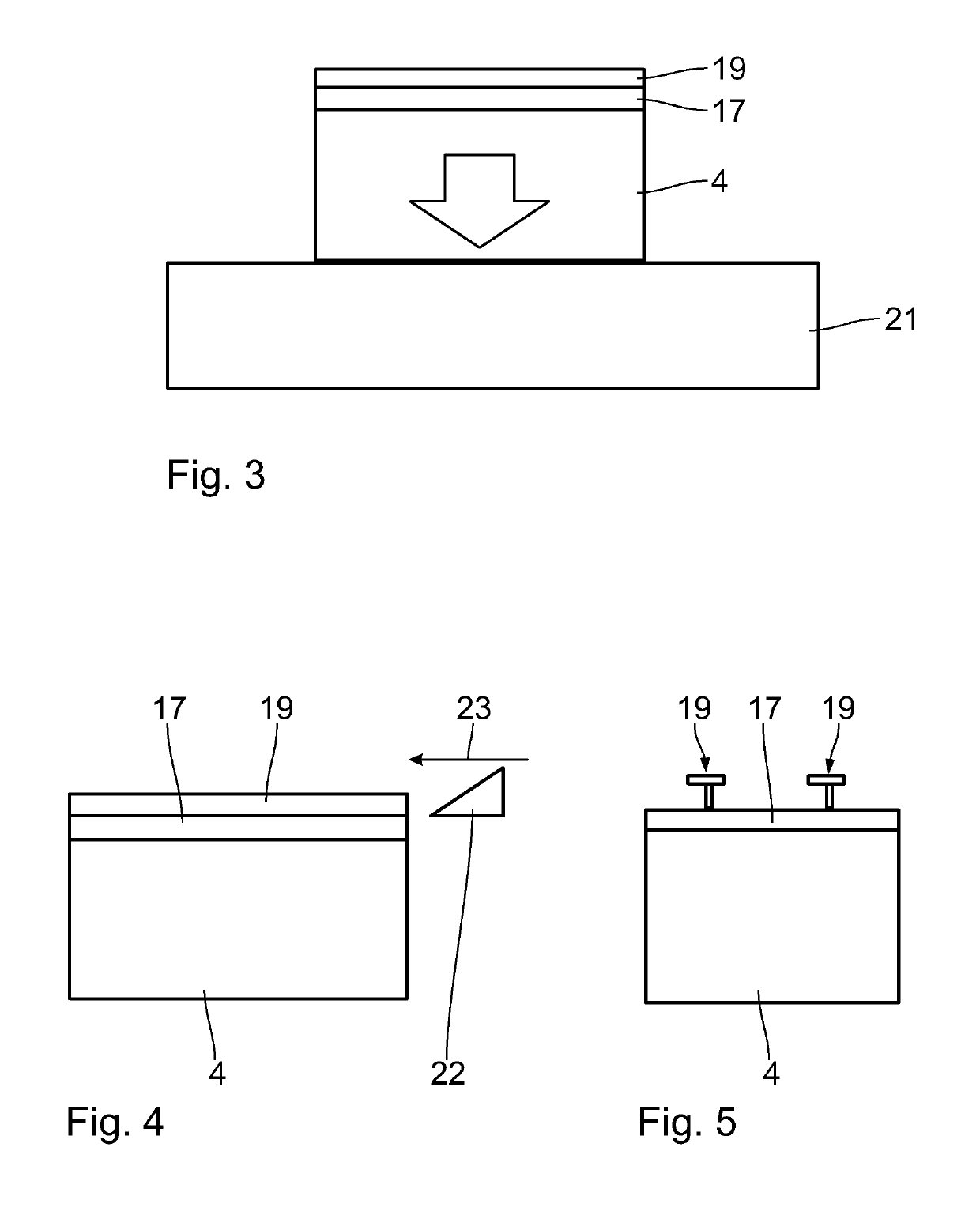

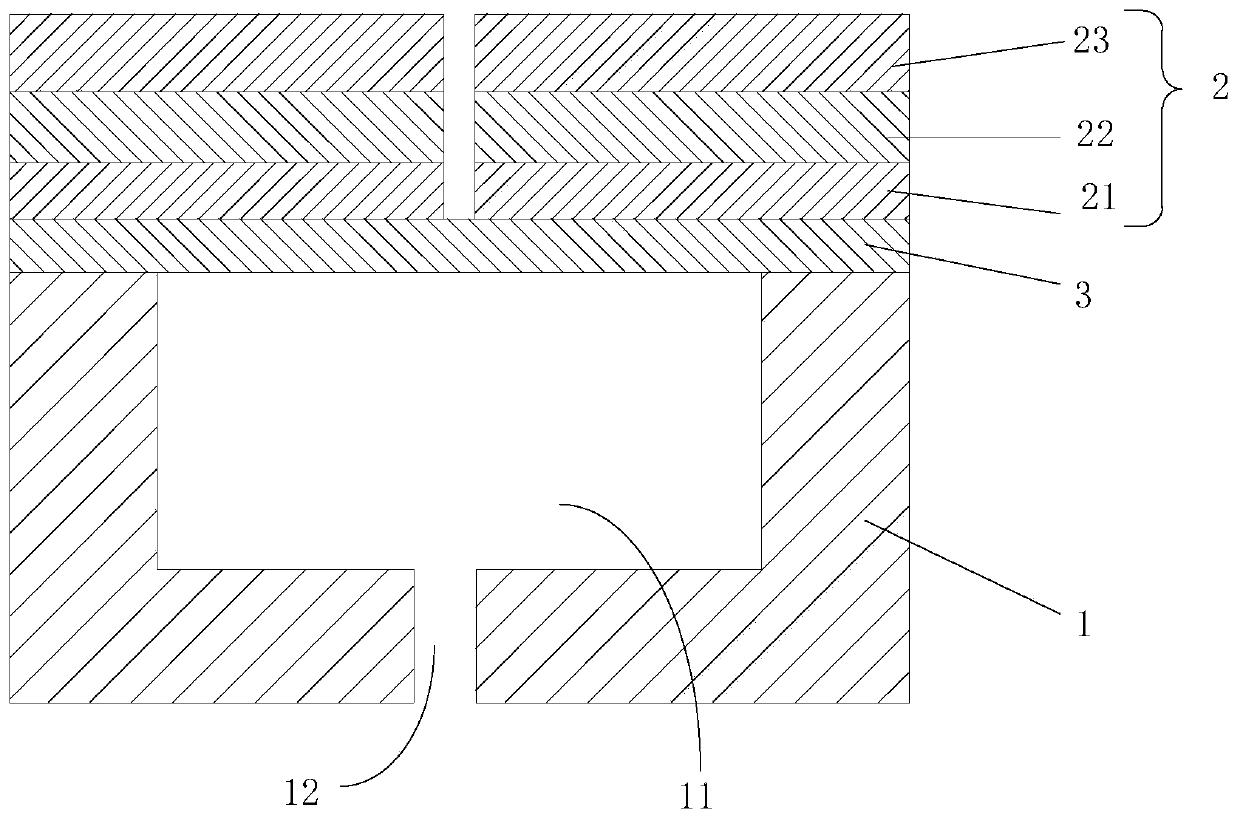

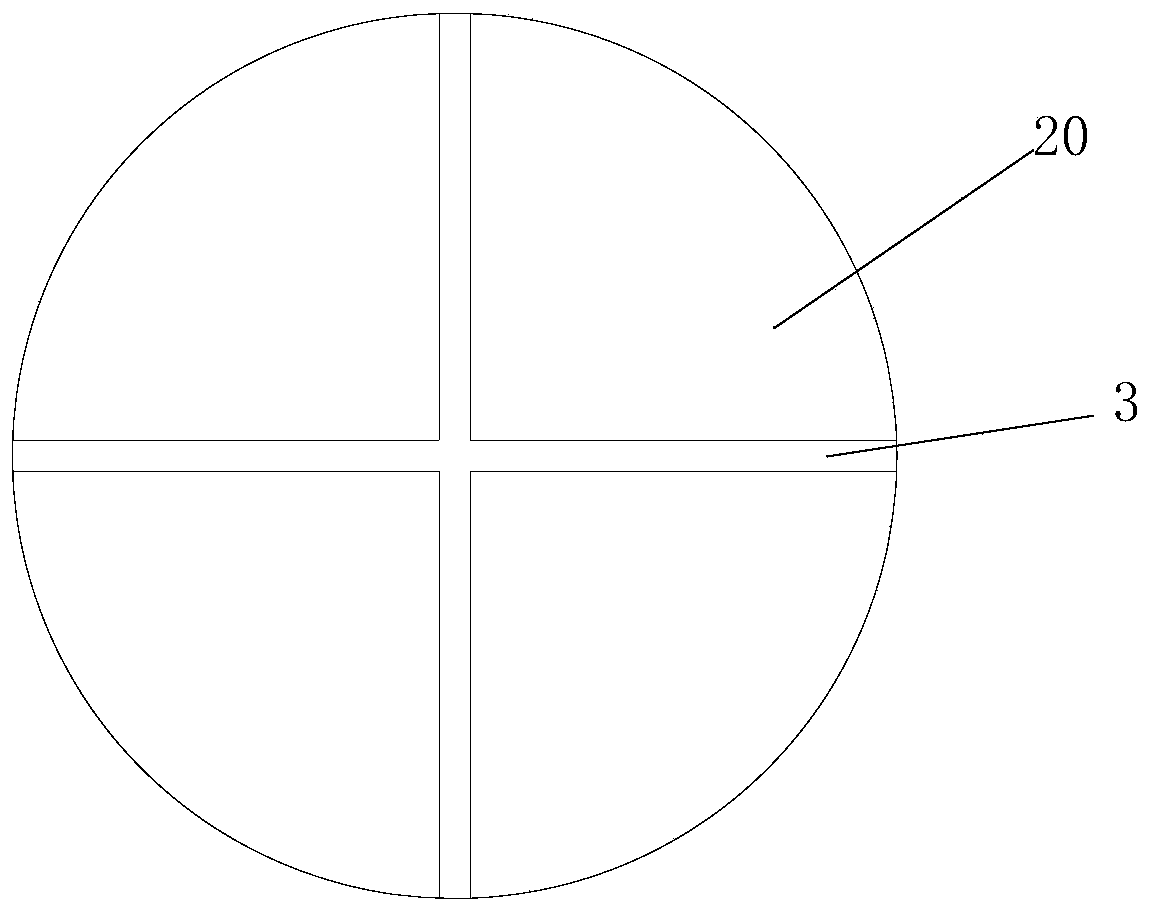

Method and device for cleaving wafers

ActiveUS20140263524A1Reduce the temperatureImprove heat transfer performanceMetal working apparatusArticle deliveryShear stressCrystalline materials

A method for cleaving wafers comprising the following steps: providing a slice of a crystalline material with at least a first plane side, providing at least one stressing means to be attached to said slice, wherein said at least one stressing means is at least in parts made of a material with a coefficient of thermal expansion different from that of the slice, attaching said stressing means to said first plane side of said slice to form a stack, inducing a thermal shear stress to said slice by applying a temperature change to said stack.

Owner:MAXEON SOLAR PTE LTD

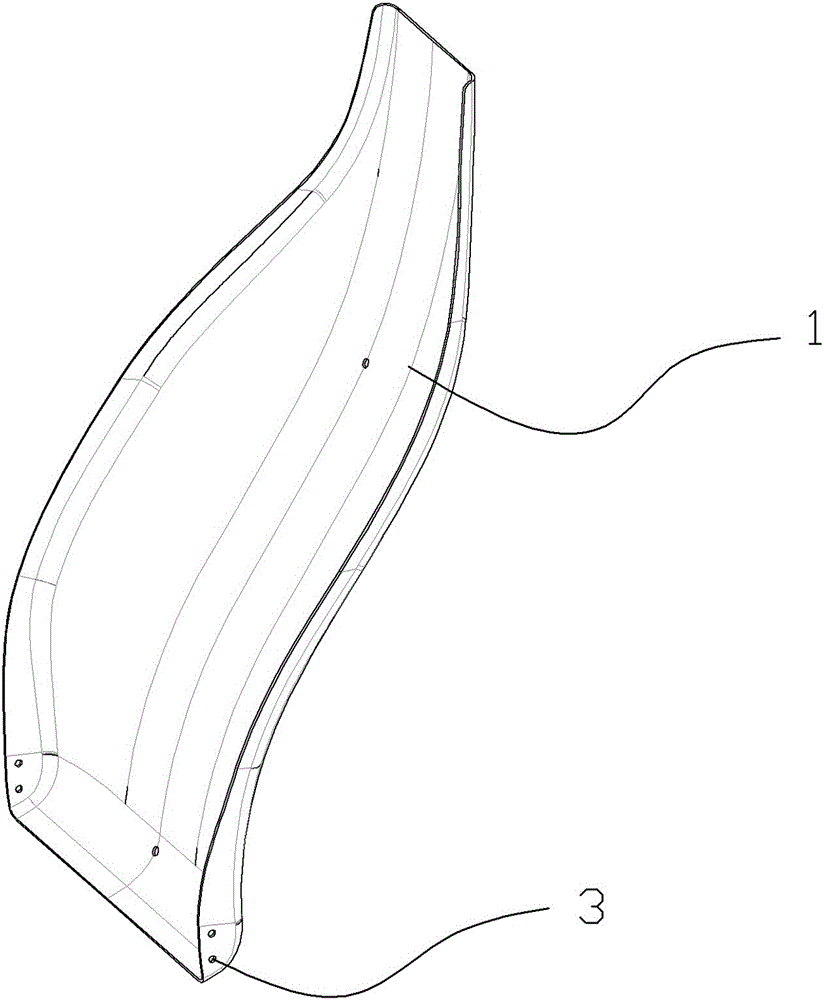

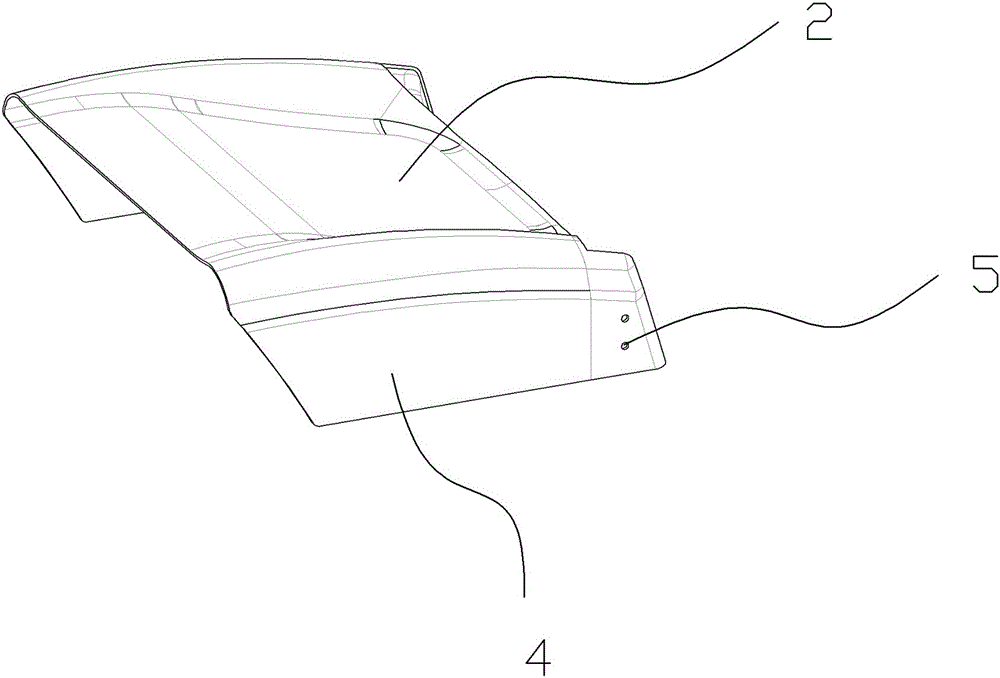

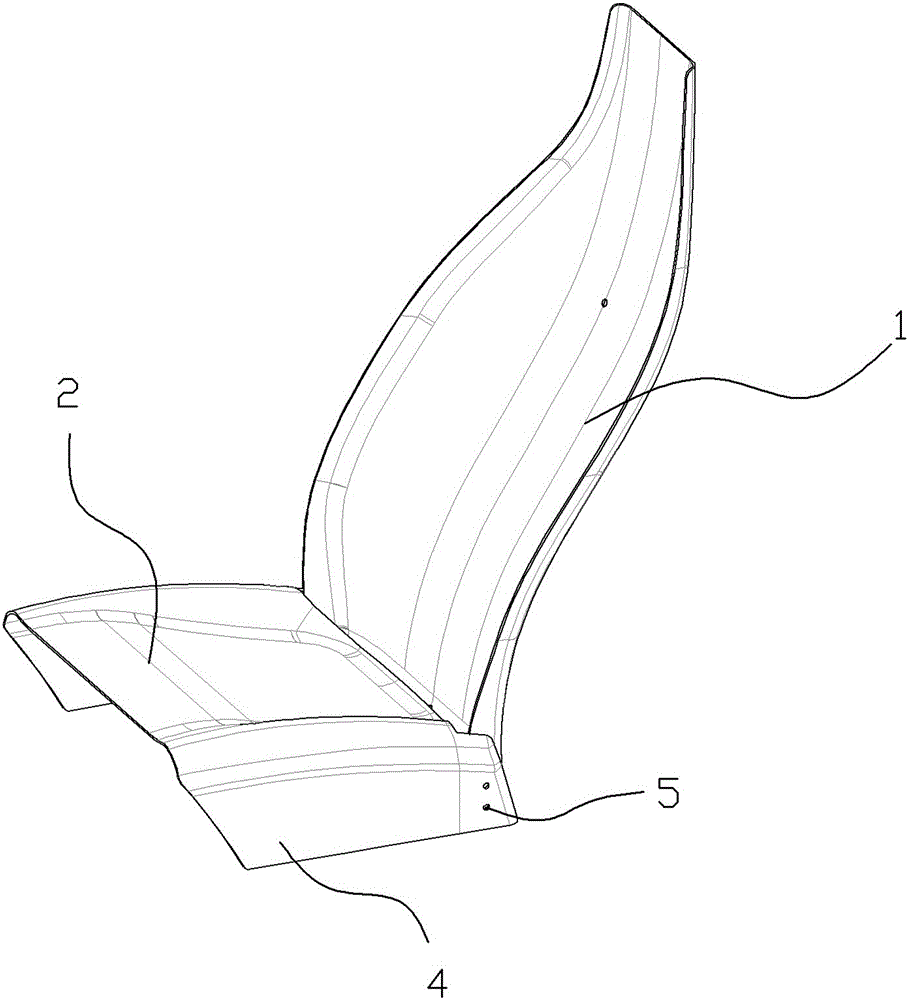

Seat framework and processing technology thereof

The invention relates to a seat framework and processing technology thereof. Due to the fact that a backrest framework and a seat disc framework are formed by composite integration of continuous glass fiber plastic sheets in multiple layers, the seat frame that is finished producing has good mechanical property and is low in weight, high in strength, moderate in rigidity and good in flexibility. Meanwhile, the backrest frame is the same as the seat disc framework in terms of thickness at all parts and uniform thickness is obtained so that the seat framework has good mechanical properties. Through adoption of the processing technology, the seat framework with a complicated curved surface complying with human engineering can be easily produced and used more comfortably. At the same time, processing technology is simplified and assembly difficulty of the seat framework is reduced.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Method and device for cleaving wafers

ActiveUS10421208B2High coefficient of thermal expansionModerate stiffnessPolycrystalline material growthAfter-treatment detailsShear stressCrystalline materials

A method for cleaving wafers comprising the following steps: providing a slice of a crystalline material with at least a first plane side, providing at least one stressing means to be attached to said slice, wherein said at least one stressing means is at least in parts made of a material with a coefficient of thermal expansion different from that of the slice, attaching said stressing means to said first plane side of said slice to form a stack, inducing a thermal shear stress to said slice by applying a temperature change to said stack.

Owner:MAXEON SOLAR PTE LTD

Sound pressure sensor

ActiveCN110987159AReduce stiffnessThe stiffness is reduced, that is, the vibration compliance of the induction layer is increased and the vibration compliance is reducedSubsonic/sonic/ultrasonic wave measurementUsing electrical meansEngineeringSound wave

The invention relates to a sound pressure sensor, and relates to the technical field of acoustoelectric sensing. According to the main technical scheme, the sound pressure sensor comprises a substrate, an induction layer and an elastic layer, wherein the first end of the substrate is provided with a concave space towards the opposite second end; the induction layer and the elastic layer are arranged in a stacked mode, and the induction layer covers the first end of the substrate and is connected with the substrate; the induction layer is uniformly divided into two or more sub-induction layersby taking a central point as a starting division point, and a preset distance is formed between every two adjacent sub-induction layers; and the induction layer can drive the elastic layer to deform towards the concave space of the substrate when being subjected to the pressure of sound waves and convert acoustic wave signals into electric signals. The sound pressure sensor solves the problem thata sound pressure sensor in the prior art is insufficient in sensitivity.

Owner:BOE TECH GRP CO LTD

A kind of bamboo-wood composite board and preparation method thereof

ActiveCN104493916BImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

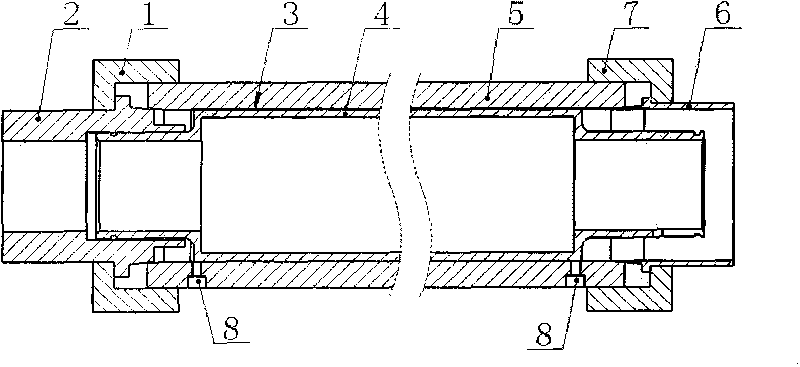

Titanium molybdenum alloy guidewire

InactiveUS7468045B2High springbackHigh flexabilityGuide wiresDiagnostic recording/measuringNiti alloyTitanium

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zirconium and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MX MEDICAL +1

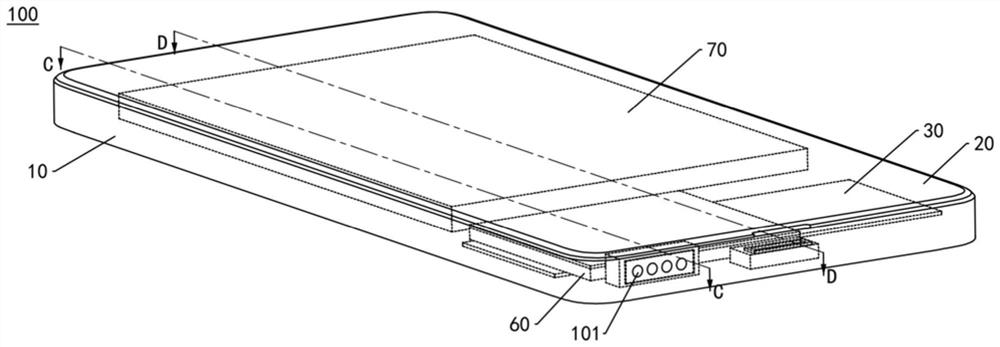

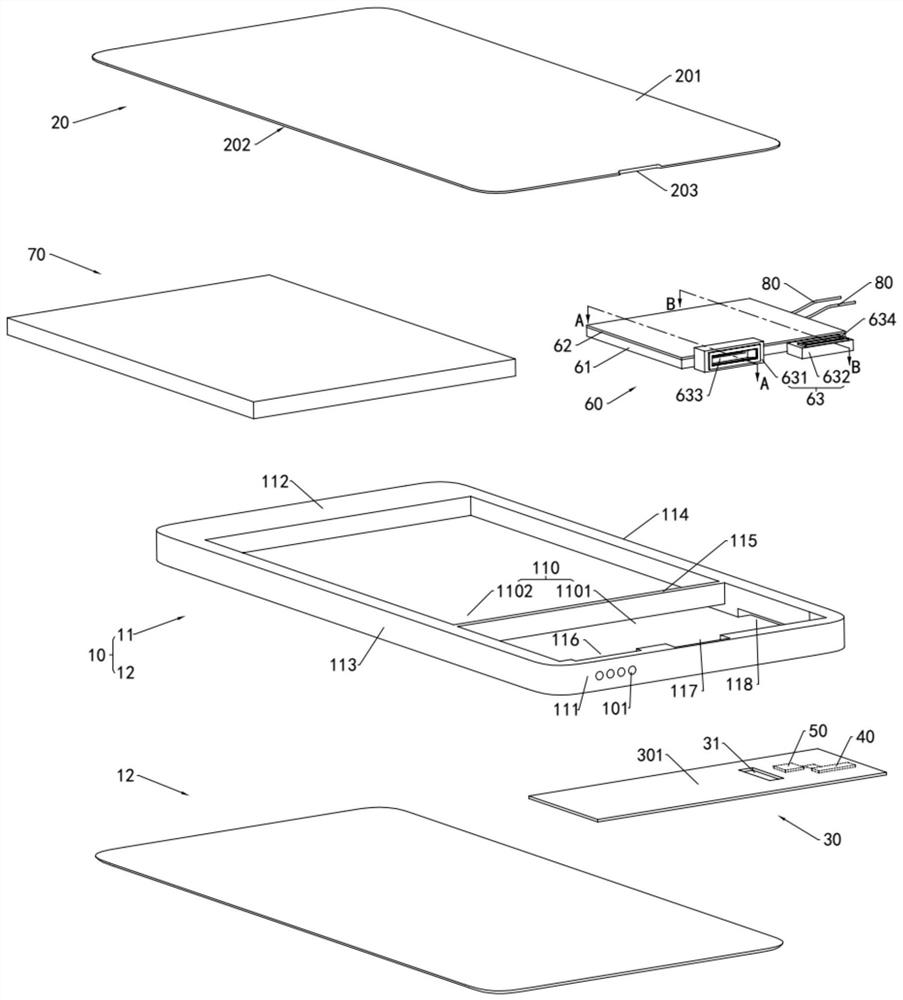

Loudspeaker inner core, loudspeaker module and electronic equipment

ActiveCN113055794AImprove low frequency sensitivityImprove low frequency responseTransducer casings/cabinets/supportsDiaphragm mounting/tensioningEngineeringLoudspeaker

The invention provides a loudspeaker inner core, which comprises a first frame, a first vibrating diaphragm and a first piezoelectric piece, wherein the first vibrating diaphragm comprises a middle part and an edge part surrounding the middle part; the edge part is mounted on the first frame; the first piezoelectric part is fixed on the surface, facing the first frame, of the middle part or the surface, deviating from the first frame, of the middle part; and the edge part is made of aluminum, aluminum magnesium alloy or magnesium aluminum alloy. When the loudspeaker inner core disclosed by the invention works, the edge part made of aluminum, aluminum-magnesium alloy or magnesium-aluminum alloy is moderate in rigidity and small in density, so that the vibration amplitude of the first vibrating diaphragm under the driving of the first piezoelectric piece can be effectively increased, the low-frequency sensitivity of the loudspeaker core is improved, the low-frequency frequency response of the loudspeaker core is improved, and the audio performance of the loudspeaker inner core is improved. The invention further provides a loudspeaker module and electronic equipment.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com