Sound pressure sensor

A sound pressure sensor and sensing layer technology, applied in instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problem of insufficient sensitivity of the sound pressure sensor, achieve moderate overall stiffness, improve sensitivity, and ensure sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

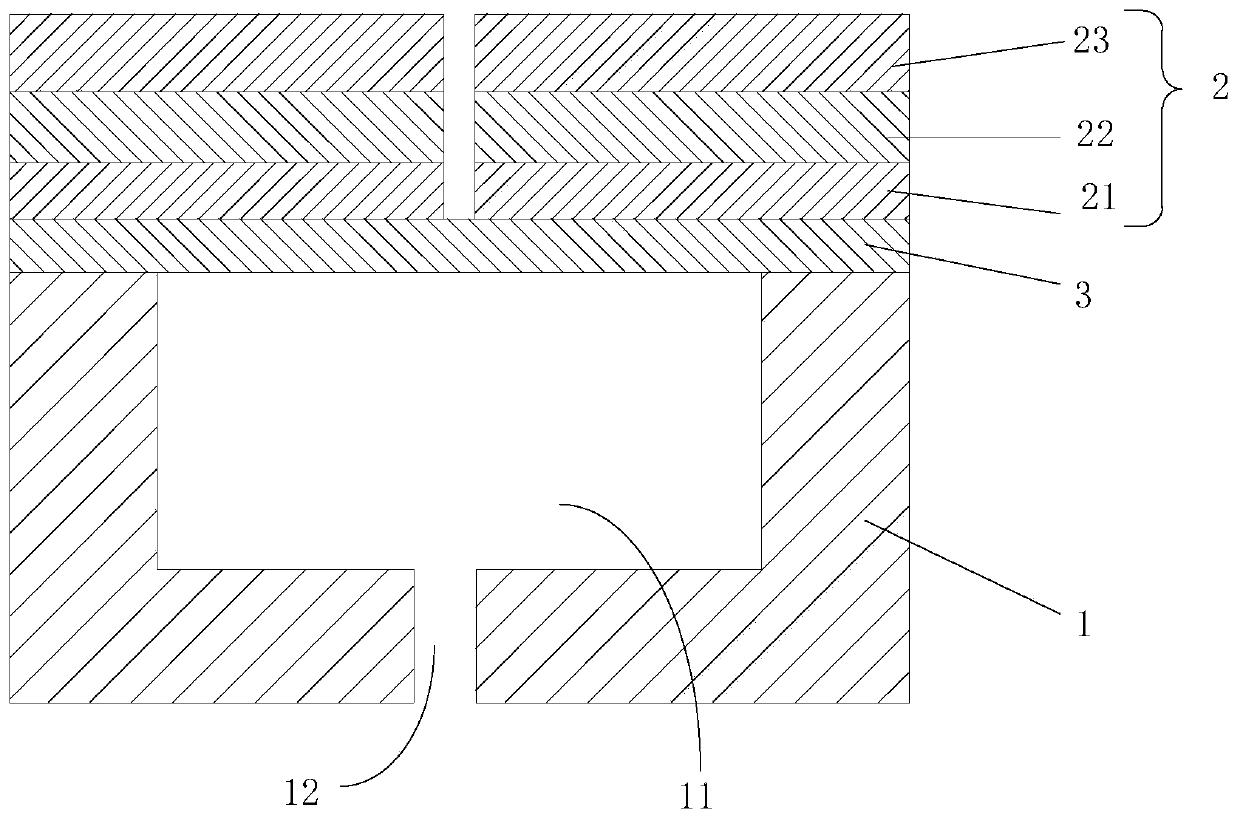

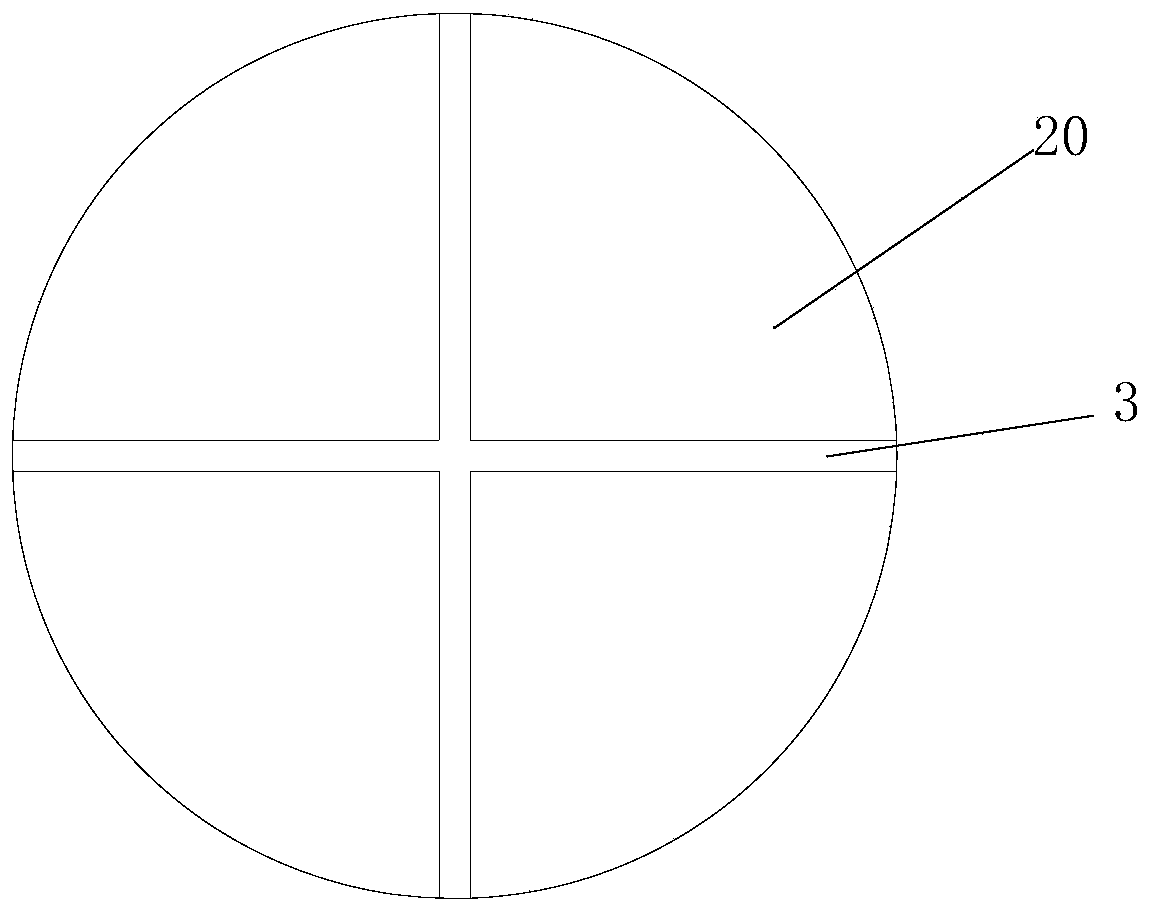

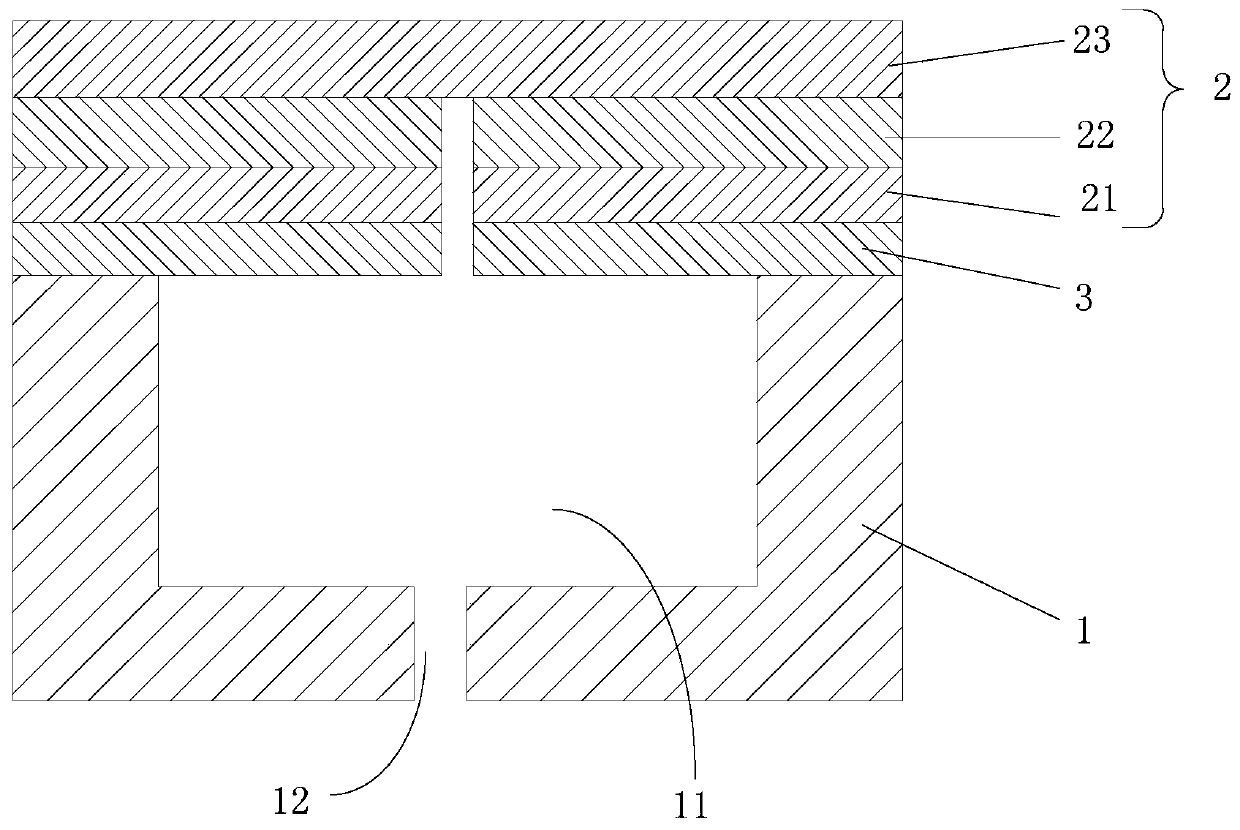

[0033] Such as Figure 1-Figure 4 As shown, the first embodiment of the present invention proposes a sound pressure sensor, which includes: a substrate 1, a sensing layer 2 and an elastic layer 3; the first end of the substrate 1 is provided with a recessed space toward the opposite second end 11. The sensing layer 2 is laminated with the elastic layer 3, and covers the first end of the substrate 1 and is connected to the substrate 1; wherein, the sensing layer 2 takes the center point as the initial division point , evenly divided into more than or equal to 2 sub-sensing layers 20, there is a preset distance between two adjacent sub-sensing layers 20, and the sensing layer 2 can drive the elastic layer 3 to the The deformation in the concave space 11 of the substrate 1 converts the acoustic wave signal into an electrical signal.

[0034] Specifically, the substrate 1 can be rigid, for example, the substrate 1 can be a glass substrate, or the substrate 1 can be elastic, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com