Seat framework and processing technology thereof

A seat frame and frame technology, which is applied in the field of transportation, can solve the problems of difficult processing of seat frames, reduced seat comfort, insufficient seat comfort, etc., to avoid processing multiple parts, moderate rigidity, and avoid precision. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

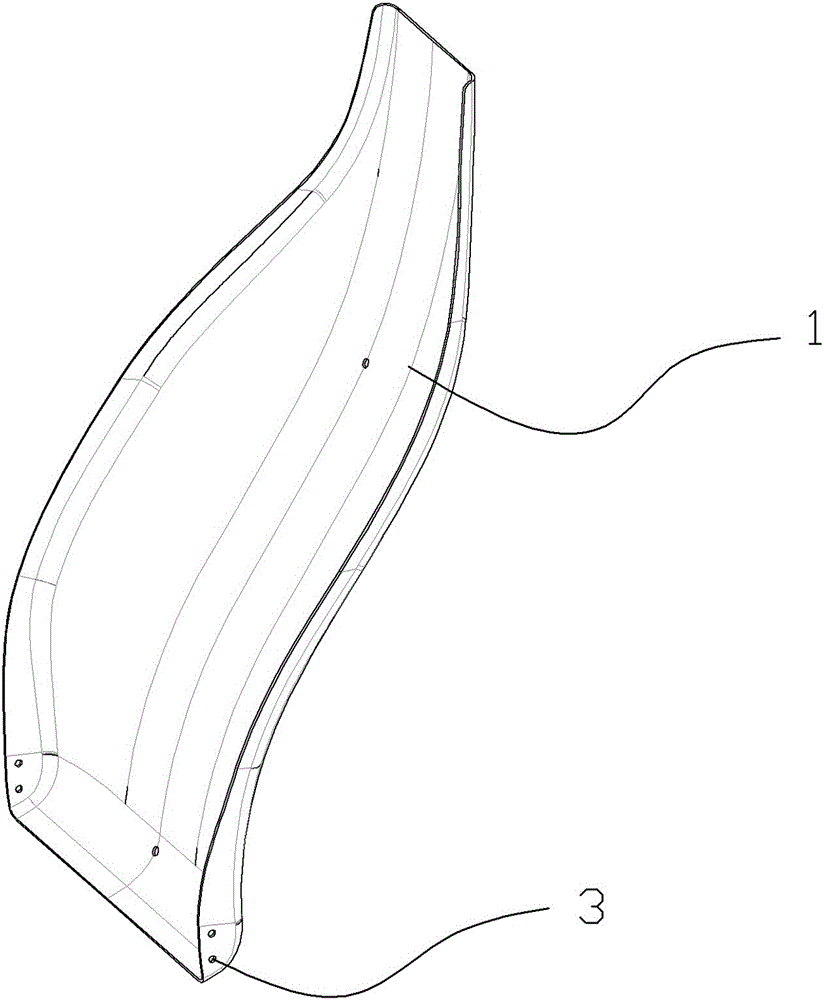

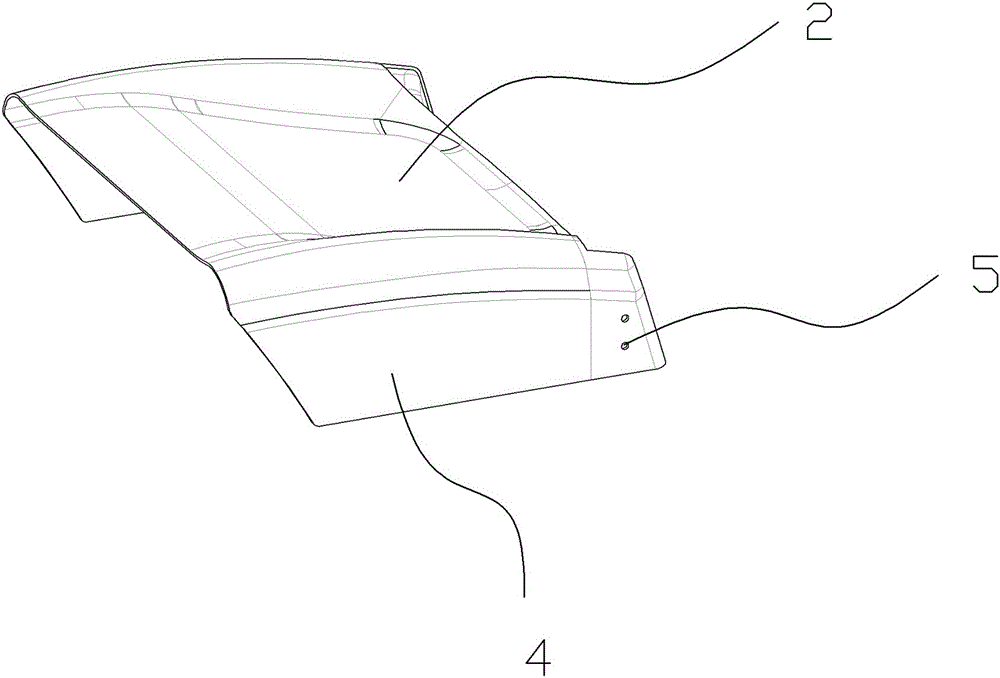

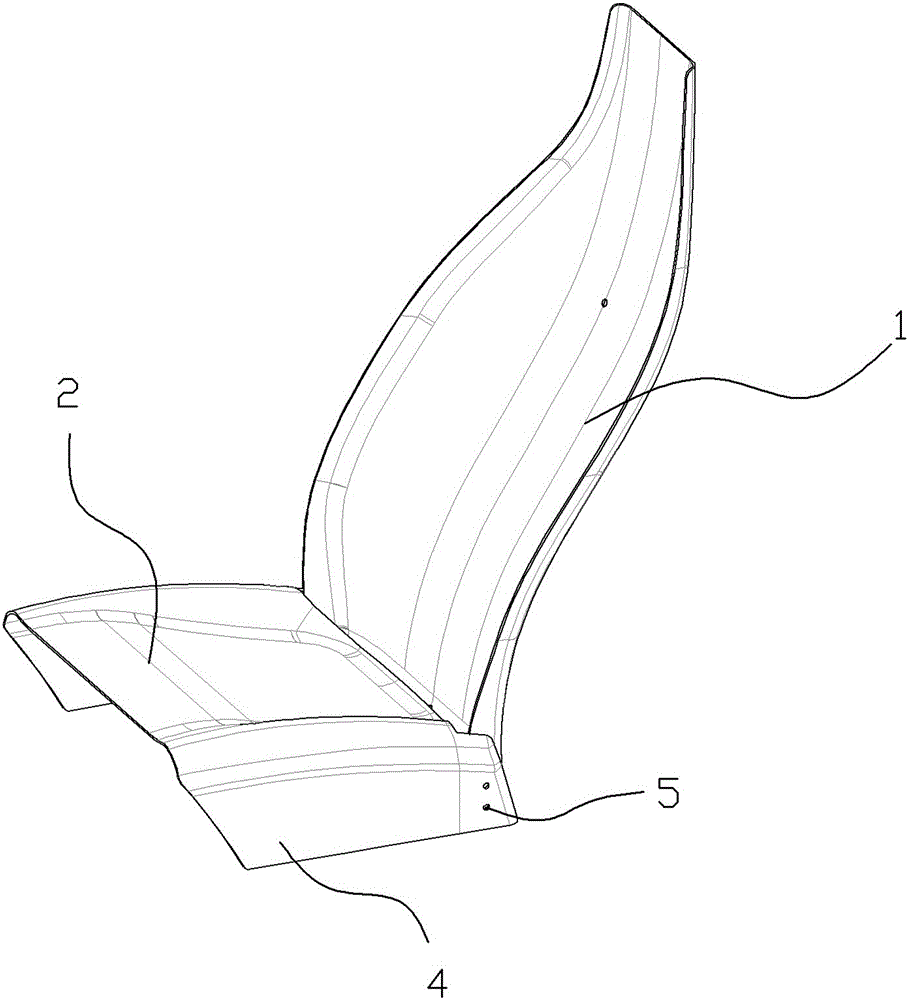

[0015] A seat frame includes a backrest frame 1 and a seat pan frame 2 which are respectively composited and integrally formed by multiple layers of continuous glass fiber plastic sheets. The backrest frame 1 is in a wave shape and has a wave crest width of 200-450mm, such as 200mm, 300mm, 430mm or 450mm, etc., of which 430mm is the best choice, and the peak height is 40~100mm, such as 40mm, 70mm, 94mm or 100mm, etc., of which 94mm is the best choice, and the trough width is 200~450mm, such as 200mm, 300mm, 430mm Or 450mm, among which 430mm is the best choice, and the trough depth is 40~100mm, such as 40mm, 70mm, 94mm or 100mm, among which 94mm is the best choice. The bottom of both sides of the backrest frame (1) is provided with symmetrical In the first connecting hole (3), the side of the seat plate bone material (2) that contacts the human body is in the shape of an arc with high front and low back, and the arc is 55-65°, such as 55°, 60° or 65°, etc. 60° is the best choice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com