Corrugated paper cup and production method thereof

A technology of corrugated paper cups and paper cups, applied in the field of corrugated paper cups, can solve the problems of insufficient disclosure, undisclosed specific technologies and implementation plans, etc., and achieve the effects of improved economic benefits, promising foreign trade prospects, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

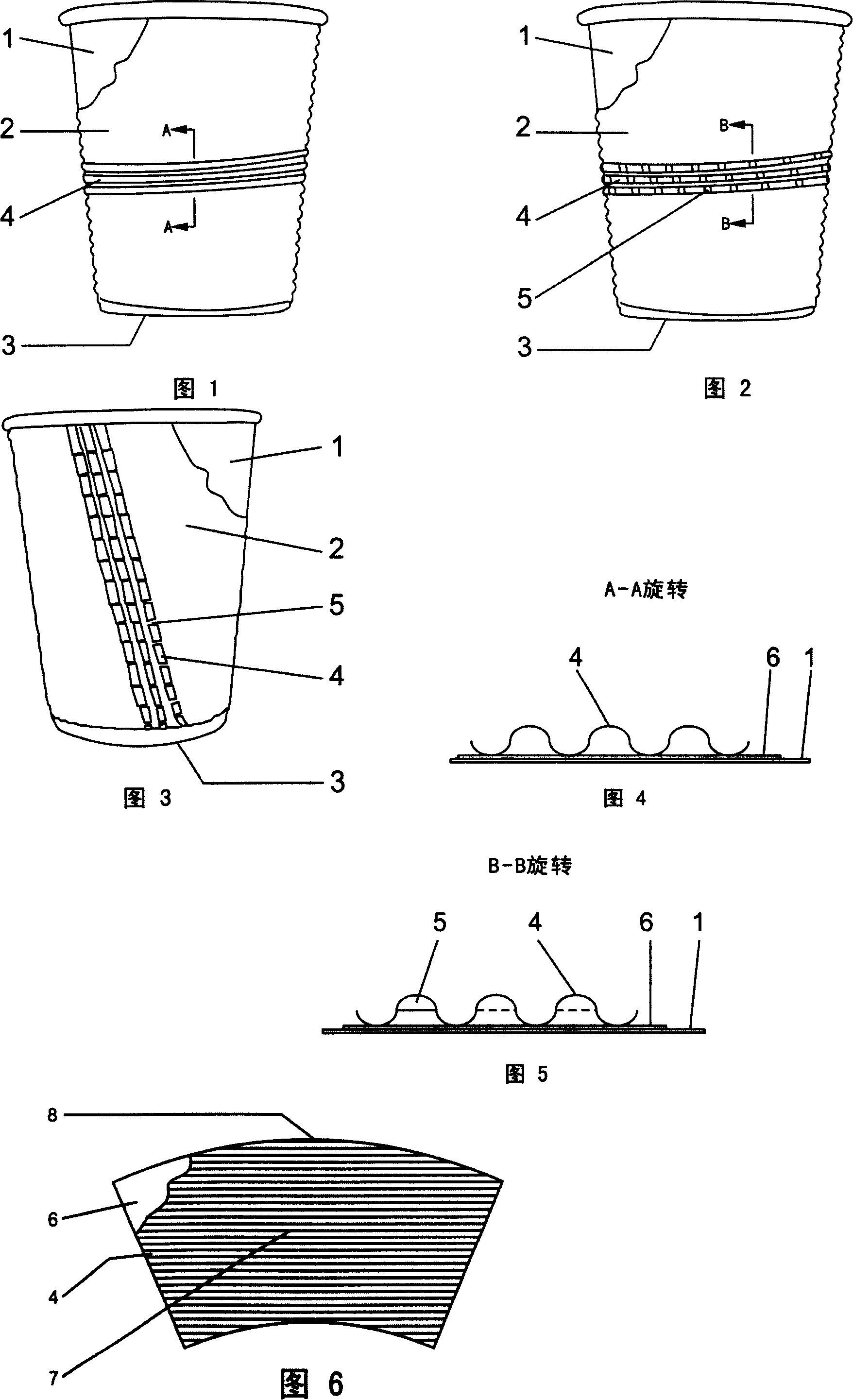

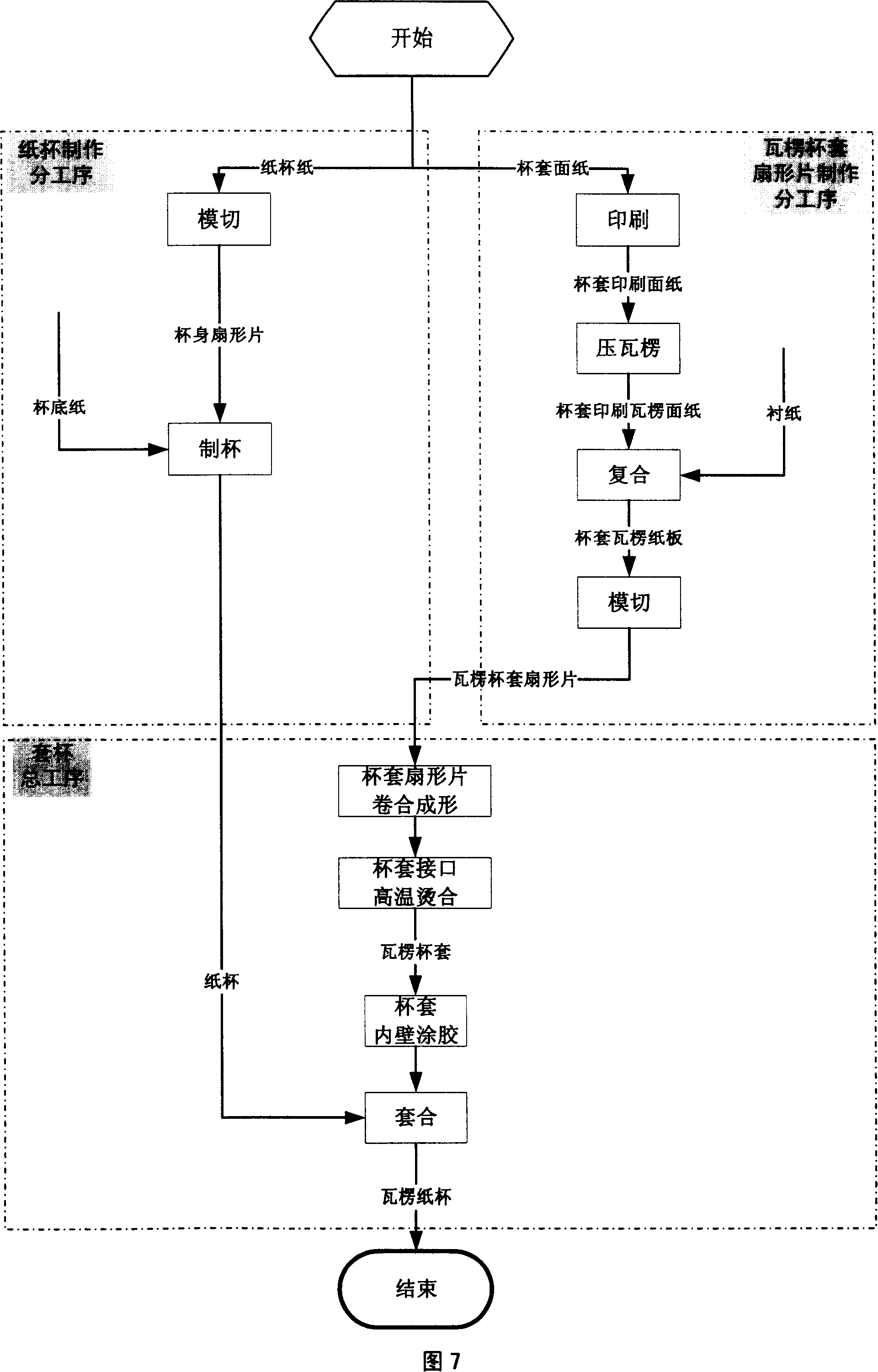

[0020] The implementation mode takes the production process of a corrugated paper cup as an example. The production process begins → divided into two sub-processes first, and then synthesized into a general process: the sub-process one is the production of paper cups, the other is the production of corrugated fan-shaped sheets, and the general process is cup sleeves.

[0021] The sub-processes of making paper cups: paper cup paper → die cutting → die cutting into fan-shaped pieces of the cup body → forming on the paper cup forming machine and cup bottom paper → paper cup (cup to be set);

[0022] The sub-processes of making corrugated cup sleeve fan-shaped pieces: cup sleeve surface paper → printing (if it is without pattern or color, this process is not required) → cup sleeve printing surface paper → corrugated pressing → cup sleeve printing corrugated surface paper → With backing paper→composite→corrugated cardboard for cup sleeves→press the required graphics on the corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com