Method for manufacturing fixing heating roller coated with teflon film silastic

A technology for fixing heating rollers and manufacturing methods, applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography, etc., which can solve the problem of poor control of thickness and uneven fluorine coating , shorter service life and other problems, to achieve the effect of moderate pressure and stiffness, uniform surface, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

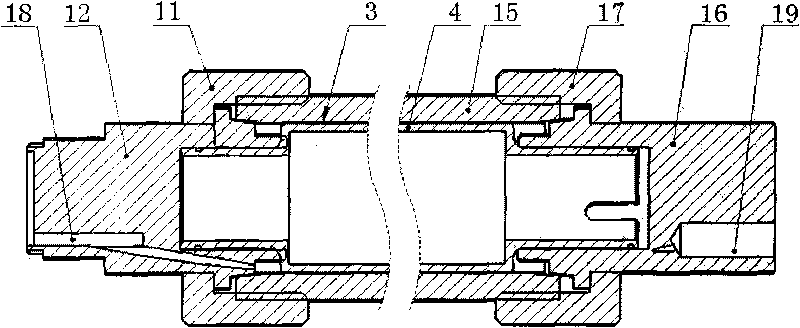

[0027] The invention discloses a method for manufacturing a Teflon film-coated silicone rubber fixing heating roller. First, a fluorine sleeve 3 is placed on the outer peripheral surface of an aluminum tube 4 , and then a silicone layer is injected between the aluminum tube 4 and the fluorine sleeve 3 . The fluorine sleeve 3 is made of a cylindrical Teflon film.

[0028] The concrete steps of manufacturing method of the present invention are described as follows:

[0029] The first step, the assembly of the fluorine sleeve and the aluminum tube:

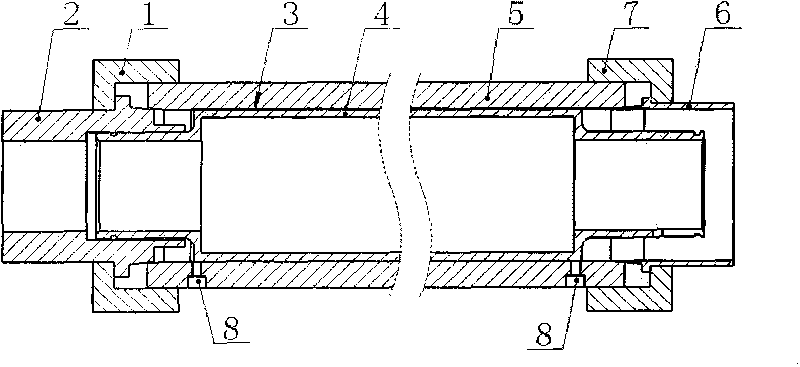

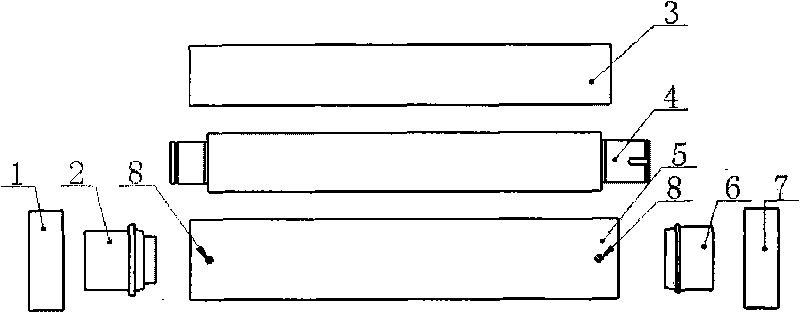

[0030] see figure 1 and figure 2 , shown in the middle is an aluminum tube 4, the aluminum tube 4 is covered with a fluorine sleeve mold 5, between the aluminum tube 4 and the fluorine sleeve mold 5 is a fluorine sleeve 3, and the fluorine sleeve 3 is obtained from Ordered directly from the manufacturer. The outer diameter of the fluorine sleeve 3 is smaller than the outer diameter of the aluminum tube 4, so the aluminum tube 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com