Bracket for measuring head of flying-probe tester and design method of bracket

A technology of flying probe testing machine and design method, which is applied in the field of flying probe testing machines, can solve problems such as inability to guarantee quality and long development cycle of the probe bracket, and achieve the effects of moderate rigidity, short development cycle, and guaranteed test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

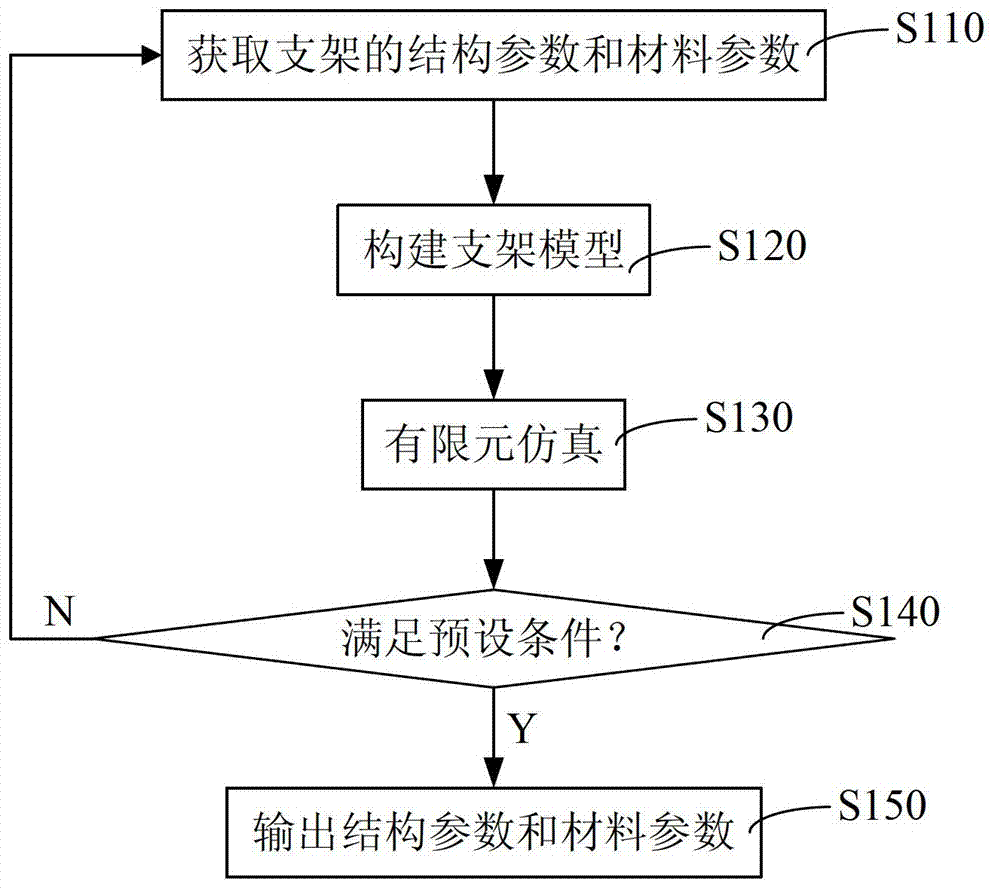

[0019] Please refer to figure 1 , this embodiment discloses a method for designing a probe bracket of a flying probe testing machine, which includes the following steps:

[0020] Step S110, acquiring structural parameters and material parameters of the stent.

[0021] Step S120, constructing a scaffold model according to the structural parameters and material parameters of the scaffold.

[0022] Step S130, performing finite element simulation on the bracket model.

[0023] Step S140, judging whether the simulation result satisfies the preset condition, if yes, execute step S150, if not, return to step S110.

[0024] Step S150, outputting the structural parameters and material parameters of the bracket.

[0025] This method of constructing the bracket model and adopting finite element simulation has a short development period and can guarantee the quality. The bracket designed according to this method meets the material and structural requirements, and can keep the test nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com