CO2 gas shielded welding wire with tensile strength of 650MPa for coating-free weathering steel bridge and wire rod

A gas-shielded welding wire, tensile strength technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of unstable deposited metal strength and impact performance, difficulty in drawing gas-shielded welding wire, alloy Solve the problems of element burning and other problems, achieve excellent atmospheric corrosion resistance, realize stable copper plating process, and moderate stiffness of welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

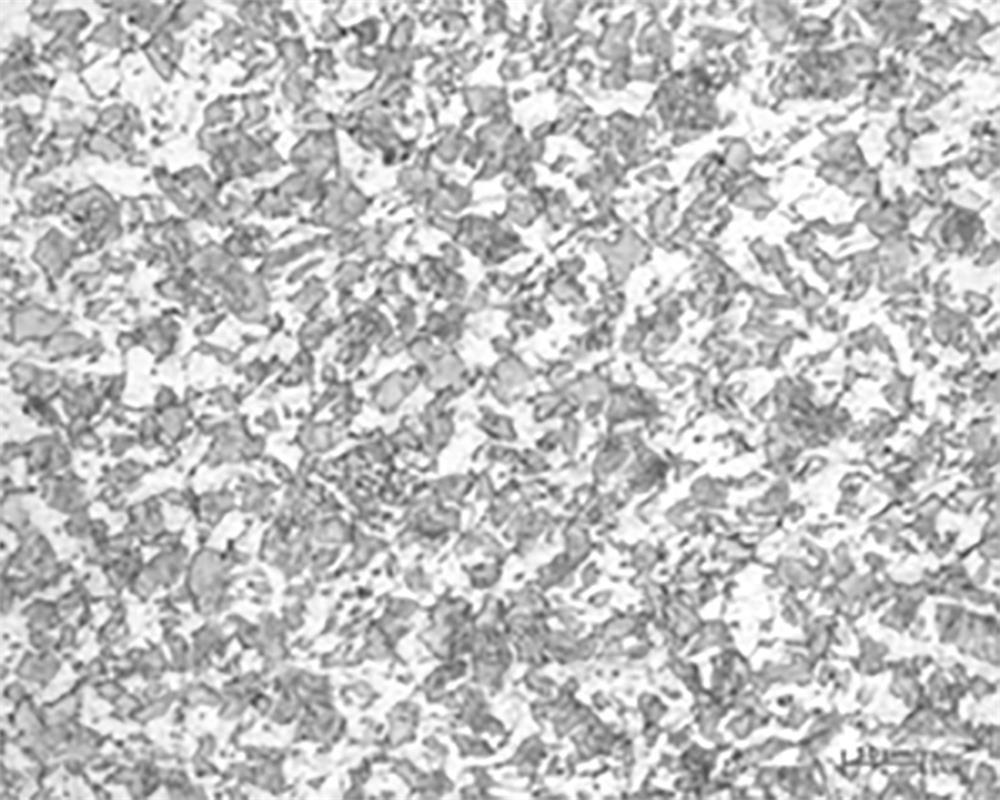

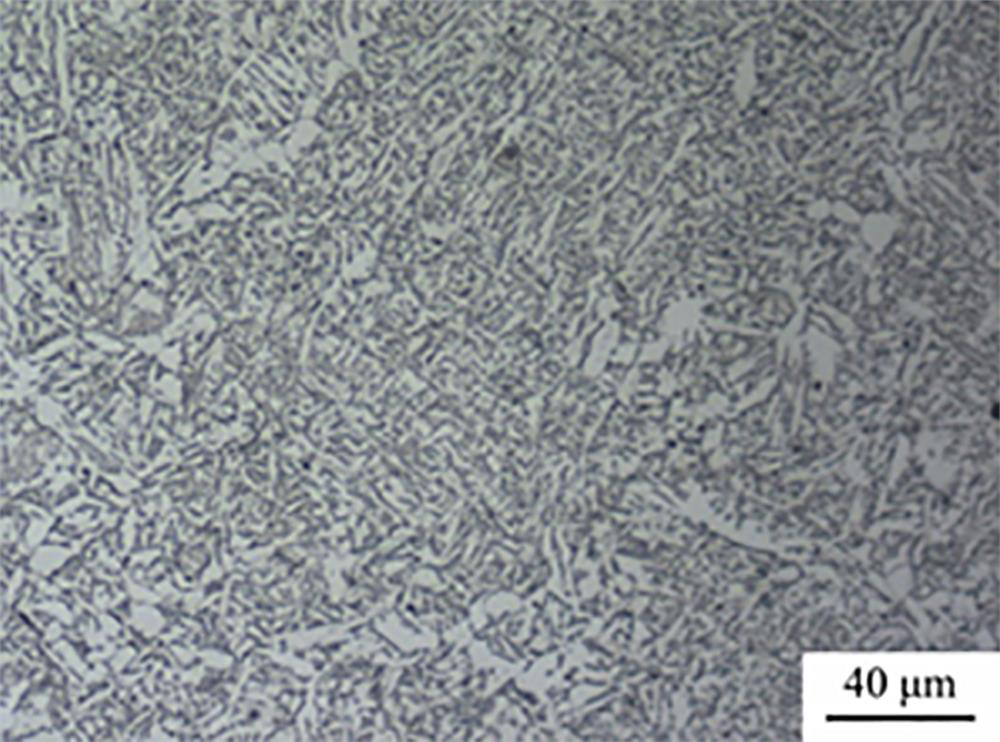

Image

Examples

Embodiment Construction

[0037] The invention provides a coating-free weather-resistant steel bridge with a tensile strength of 650MPa grade CO 2 Wire rod for gas shielded welding wire, its chemical composition includes: C: 0.04~0.09, Si: 0.55~0.85, Mn: 1.70~2.10, P: ≤0.015, S: ≤0.005, Cr: 0.46~0.65, Ni: 1.10~1.80, Cu: 0.15~0.38, Ti: 0.10~0.20, B: 0.003~0.005, Al: ≤0.015, Zr: ≤0.045, Ce: ≤0.030, O: ≤0.050, N: ≤0.070, Yu The amount is Fe and unavoidable impurities.

[0038] The content of C, Si, Mn, Cr, Ni, Cu, Ti, B satisfies 650≤Sy≤730, among them, Sy=9.8×(36+68.3[C]+5.9[Si]+5.7[Mn]+7.3[ Cr]+3.7[Ni]+9.0[Cu]+39[Ti+B]).

[0039] Specifically, its chemical composition contains one or more of Al, Zr, and Ce.

[0040] Based on the above CO 2 Wire rod for gas shielded welding wire, the present invention also provides a CO 2 A gas shielded welding wire made by drawing the above-mentioned wire rod.

[0041] The wire rod does not require intermediate annealing during the process of drawing the wire to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com