Road surface structure of rolling flexiable fibre cement concrete and construction method thereof

A technology of cement concrete and flexible fibers, which can be applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of high cost of steel fiber cement concrete, restrictions on large-scale promotion and application, and increased construction costs. Road performance and durability, good economic benefits, and the effect of reducing cement content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

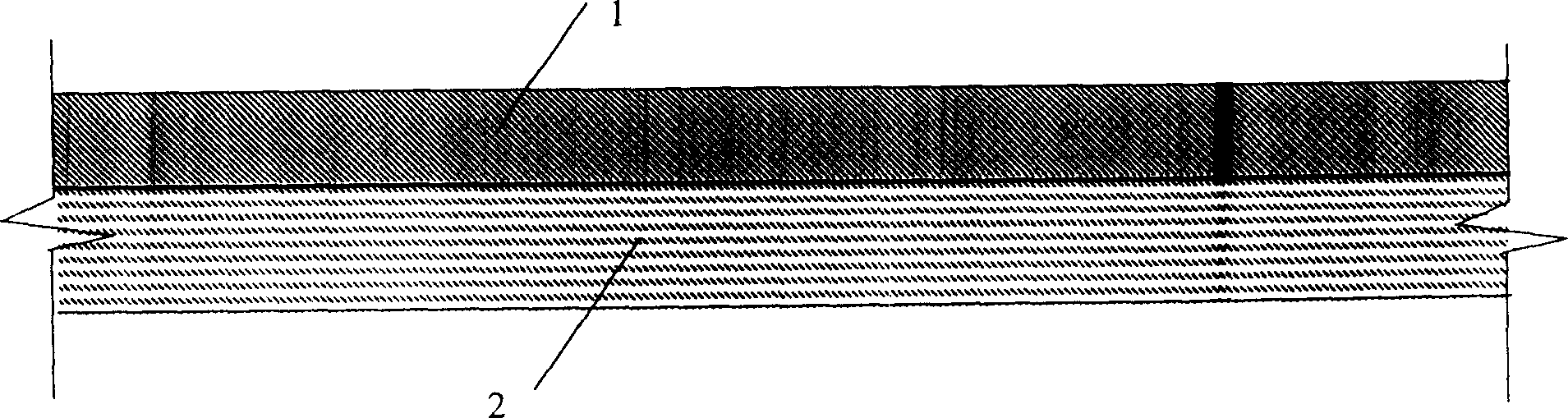

[0036] As shown in the accompanying drawings, a rolled flexible fiber cement concrete pavement surface layer 1 is paved on the surface of the base layer 2 .

[0037] Concrete construction method of the present invention:

[0038] A typical embodiment is proportioned as (one cubic meter of rolled flexible fiber cement concrete): polypropylene monofilament fiber 1kg, common silicate 42.5 #Put 300kg of cement, 1330kg of gravel with a maximum particle size of no more than 31.5mm, 730kg of river sand, 70kg of fly ash, and 3kg of water reducing agent into a mixer for dry mixing until uniform, then add 130kg of water for wet mixing until the mixture is evenly mixed , after the flexible fiber cement concrete mixture is transported to the site, the method of mechanical paving is adopted, and the thickness is 20cm. It is evenly paved on the base layer 2, and the traditional cement concrete vibration method is not used for construction, but it is rolled and rolled by a road roller. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com