Patents

Literature

94results about How to "Low drying shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

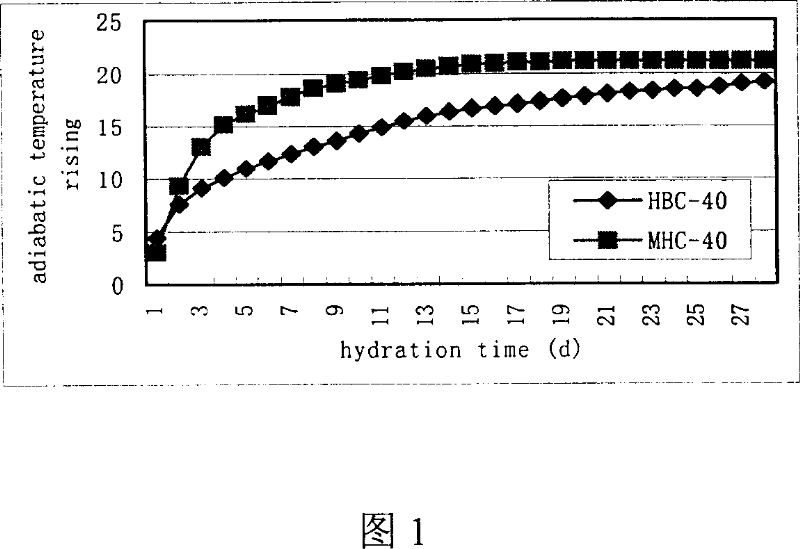

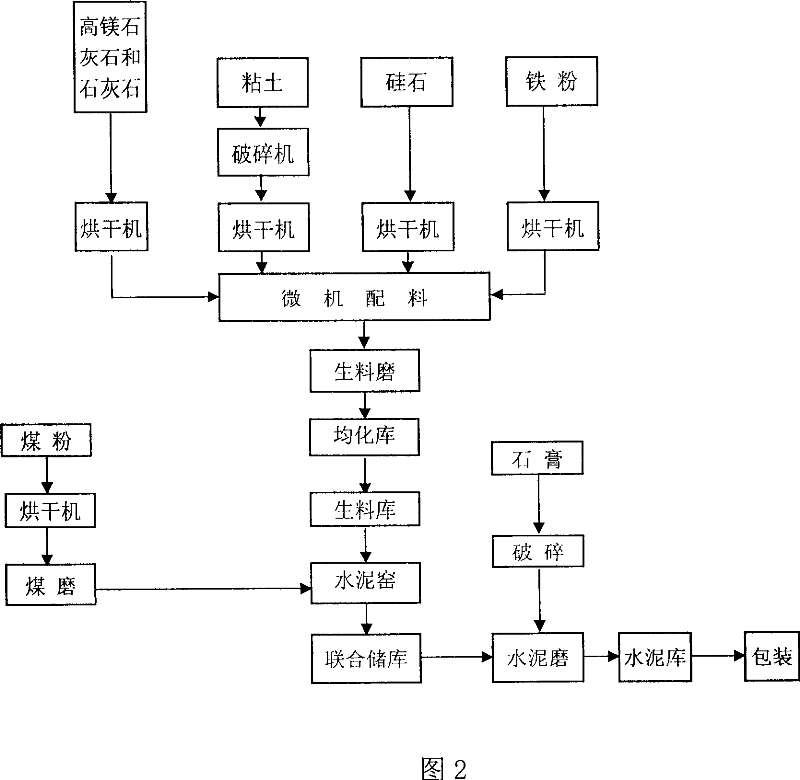

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

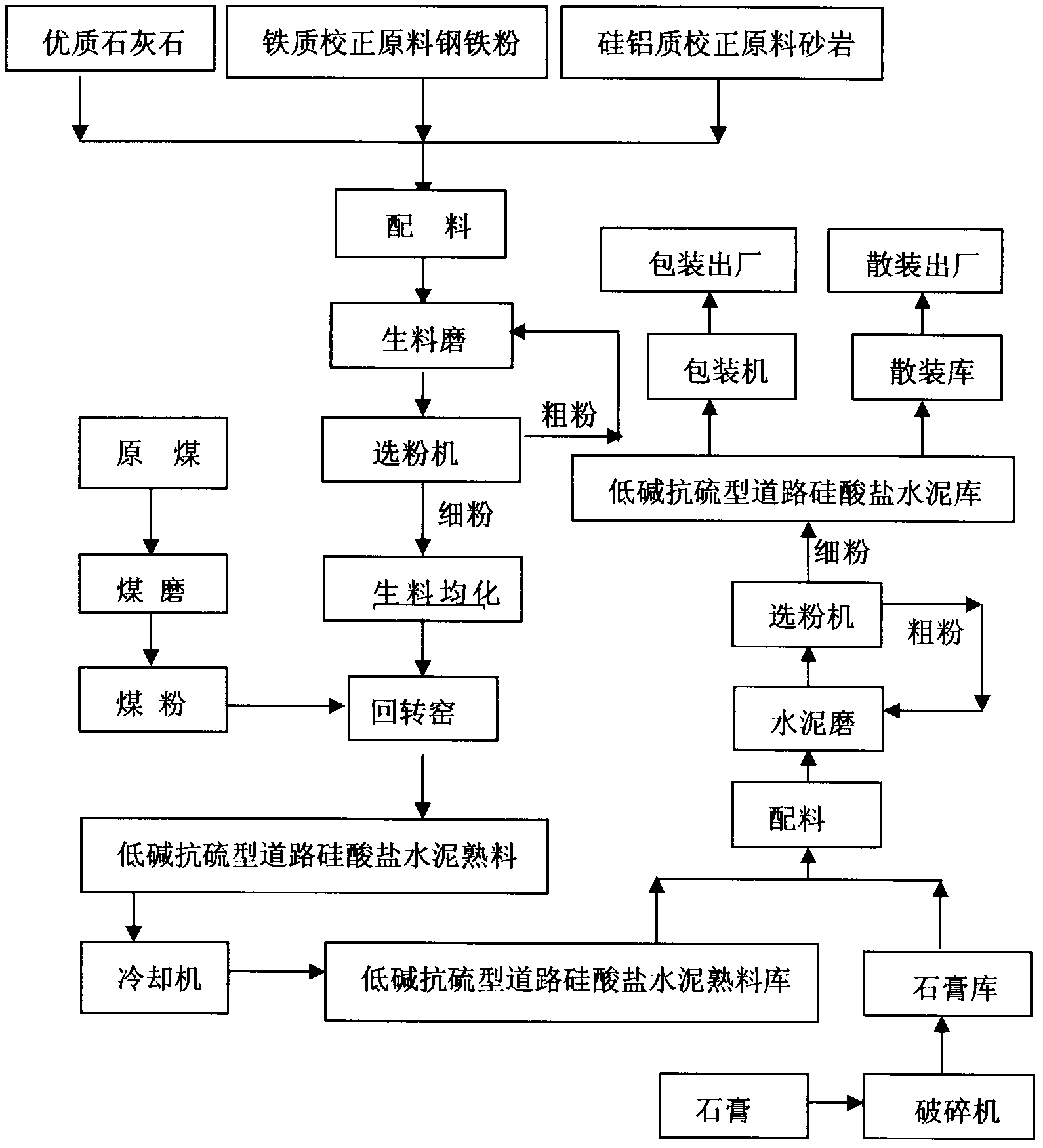

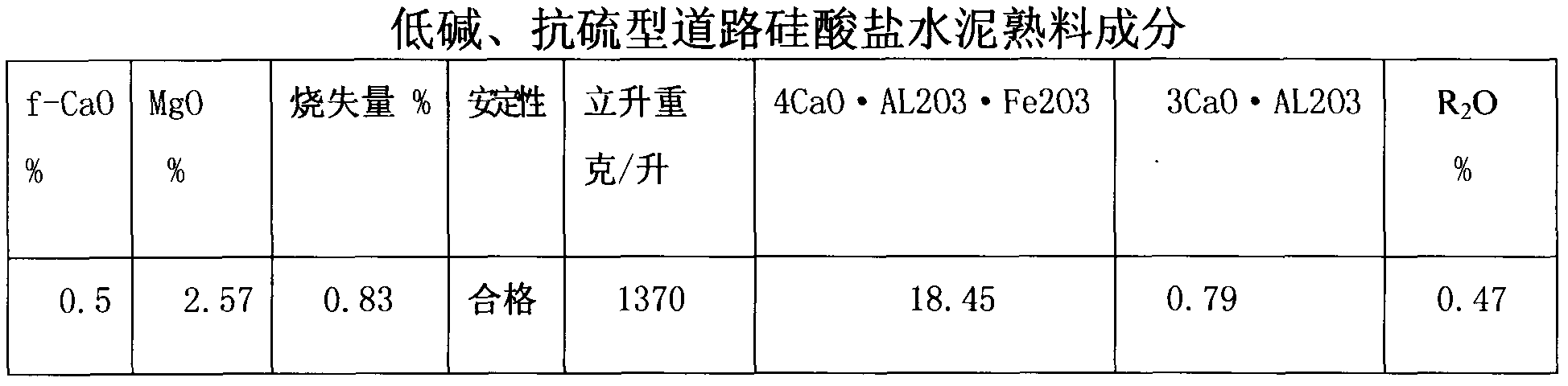

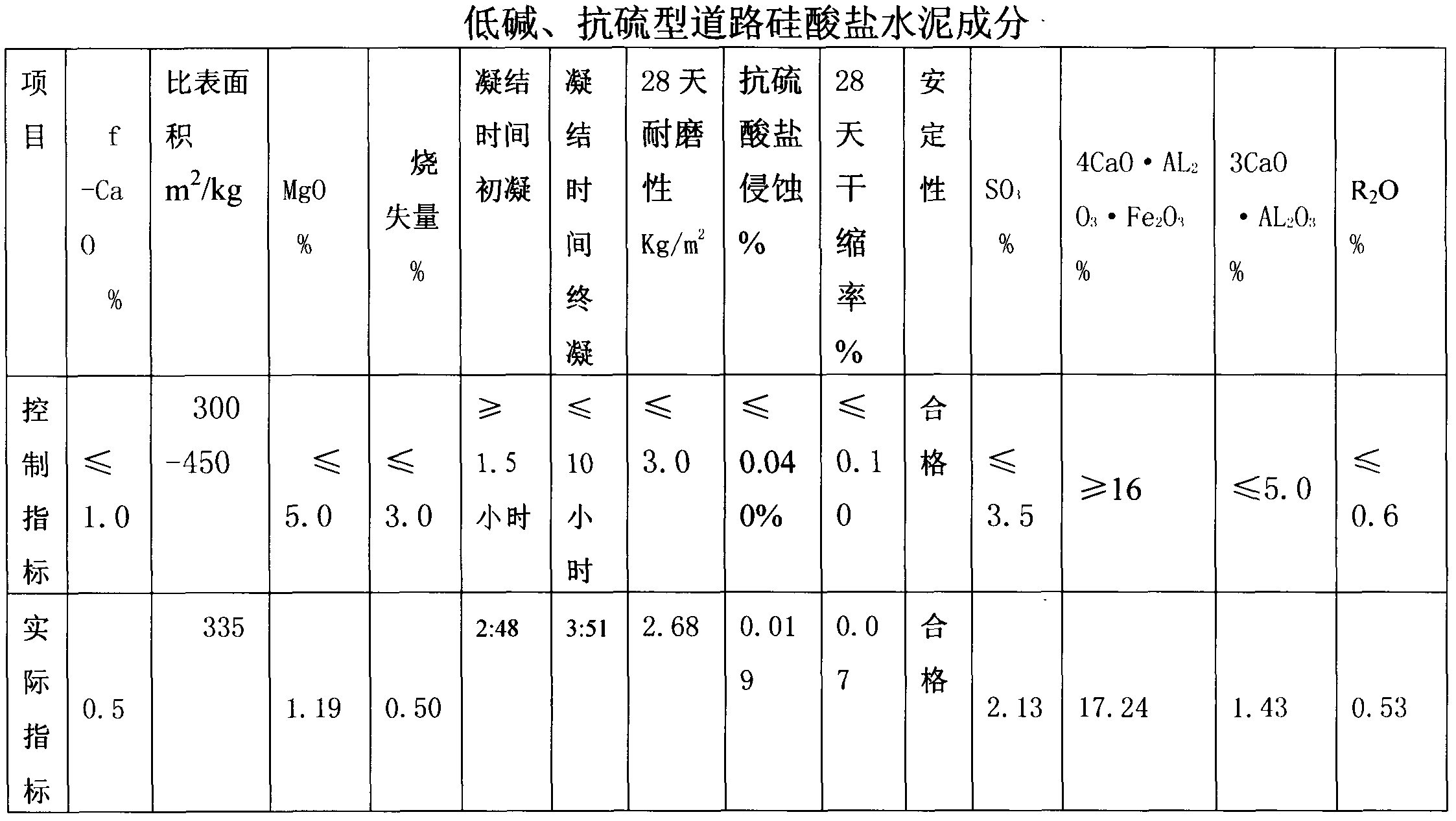

Low-alkaline sulphur-resisting portland cement for road and production method thereof

The invention discloses a low-alkaline sulphur-resisting portland cement for road and a production method thereof. The method comprises the following steps: using 80-82 % of low-alkaline high-quality limestone, 12-14 % of low-alkaline sandstone and 4-8 % of low-alkaline steel powder as raw materials to produce clinker; then grinding the clinker with low-alkaline natural gypsum according to a certain proportion to prepare low-alkaline sulphur-resisting portland cement for road. The prepared cement has low dry-shrinkage ratio, good wear resistance, and strong sulfate resistance. The method can reduce the production cost and significantly improve the properties of the portland cement for road.

Owner:XINJIANG TIANSHAN CEMENT CO LTD

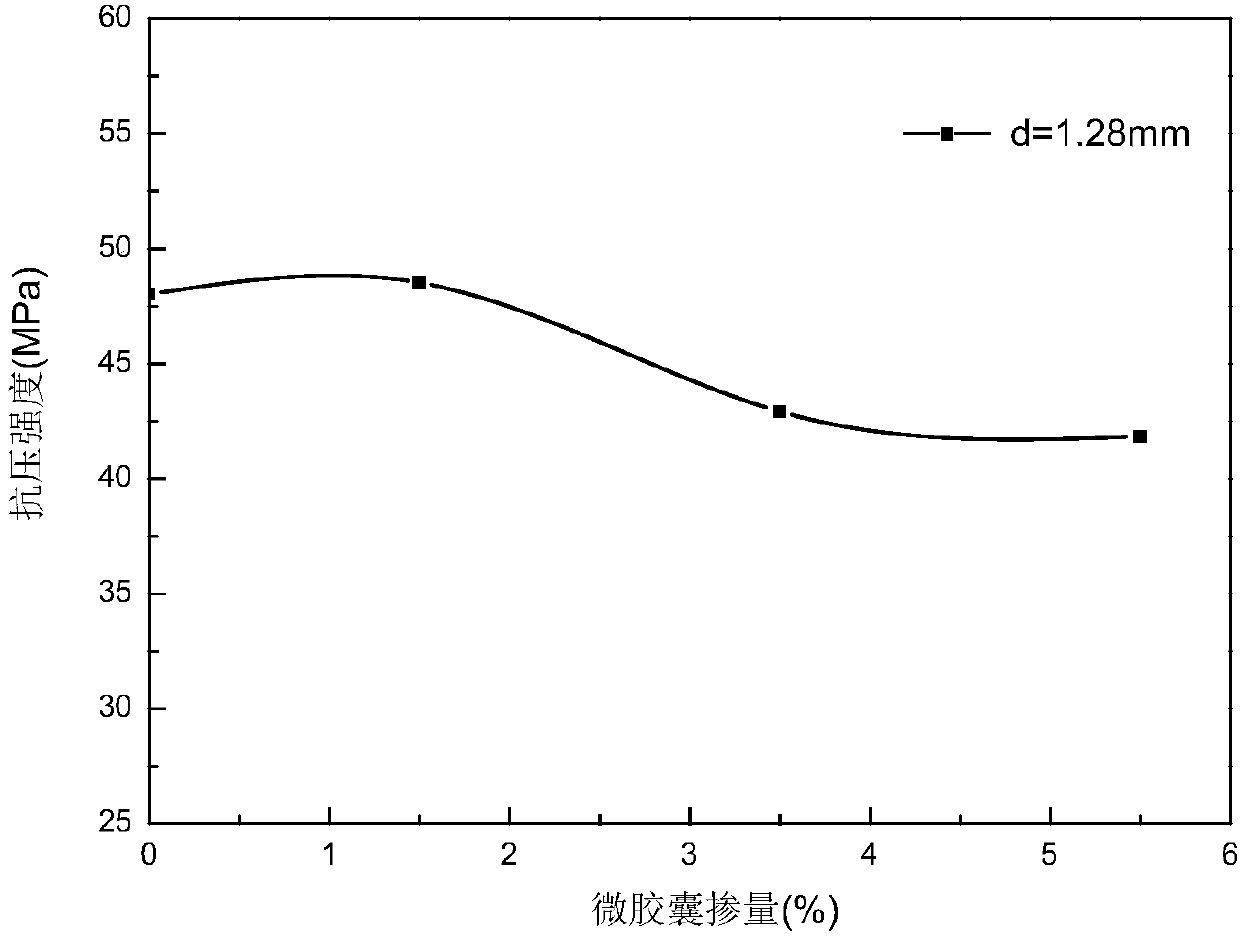

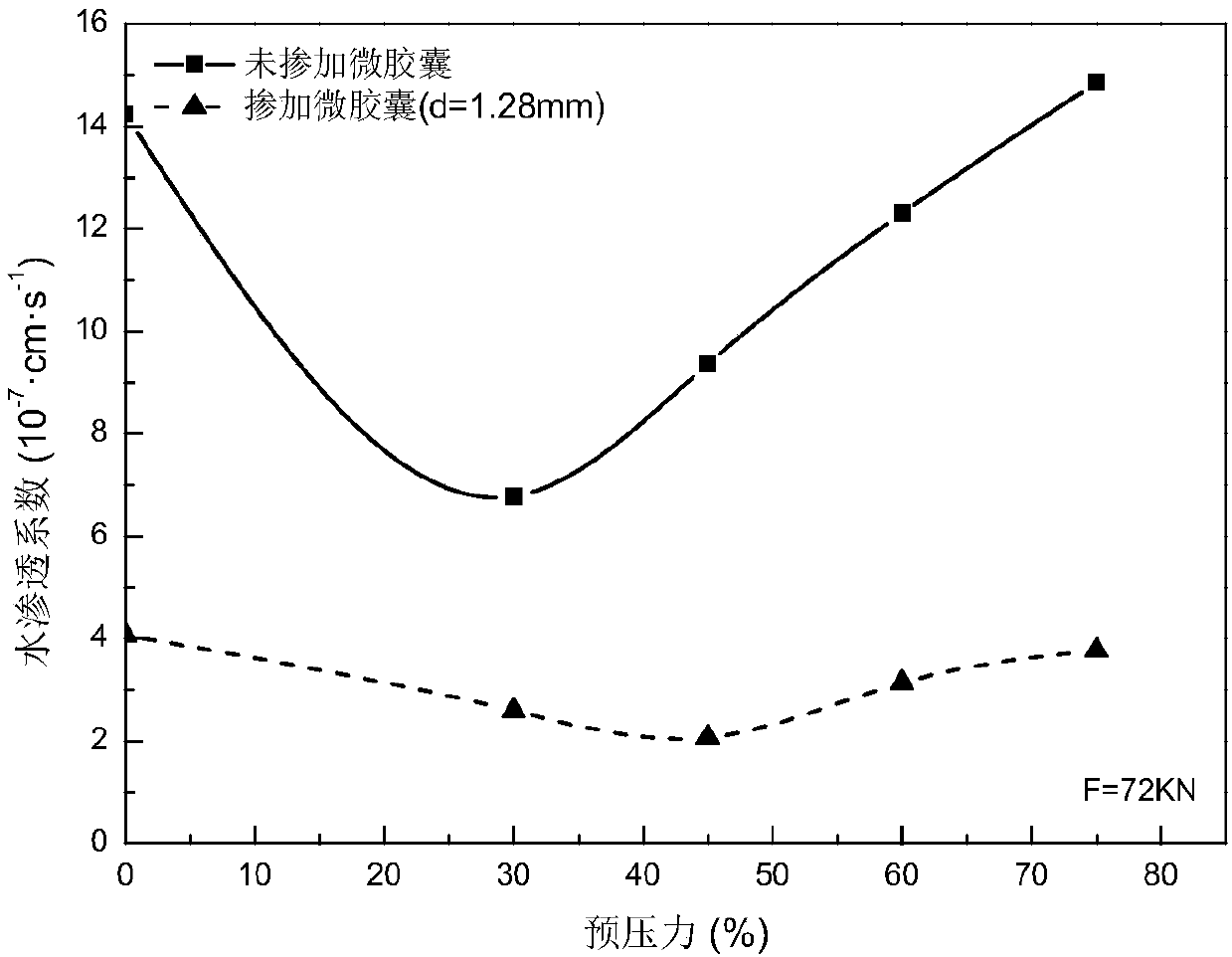

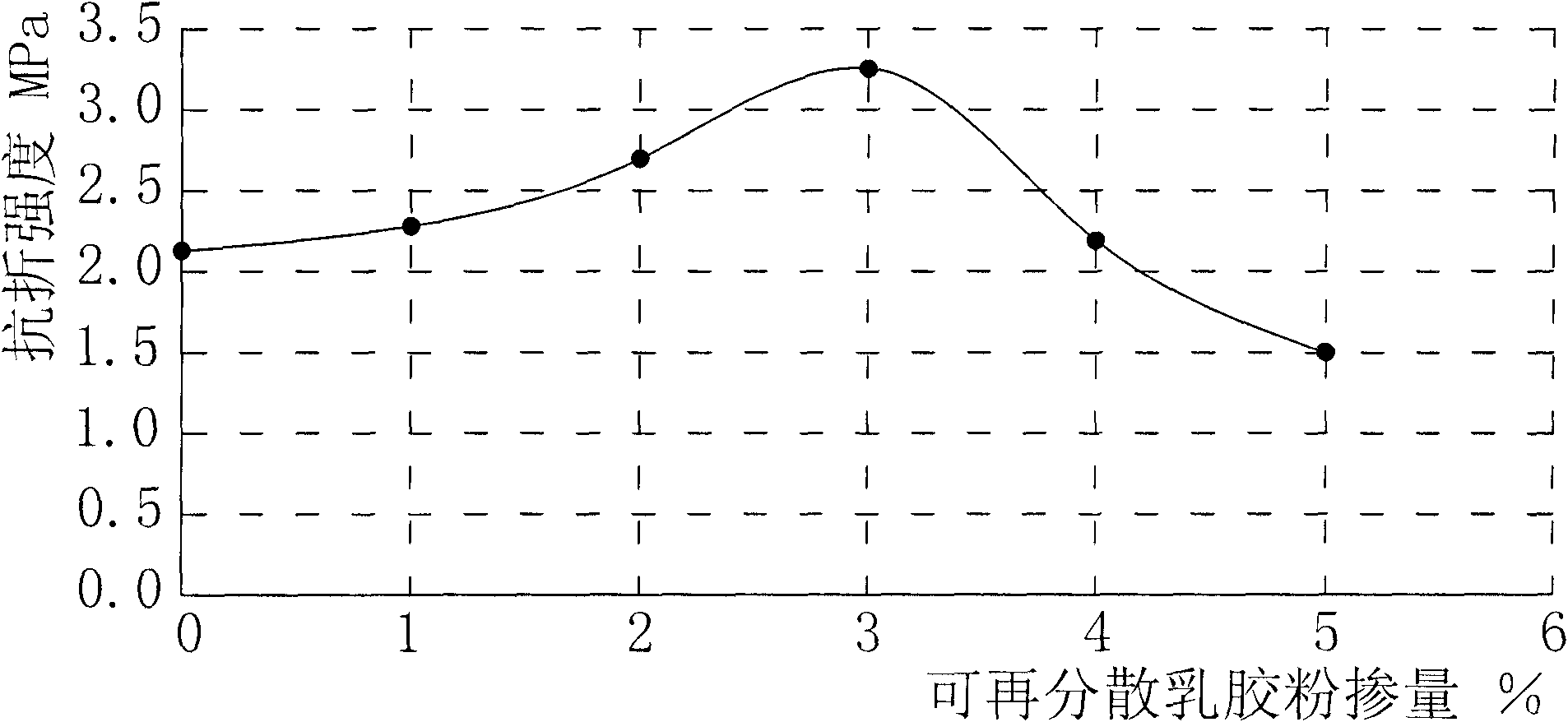

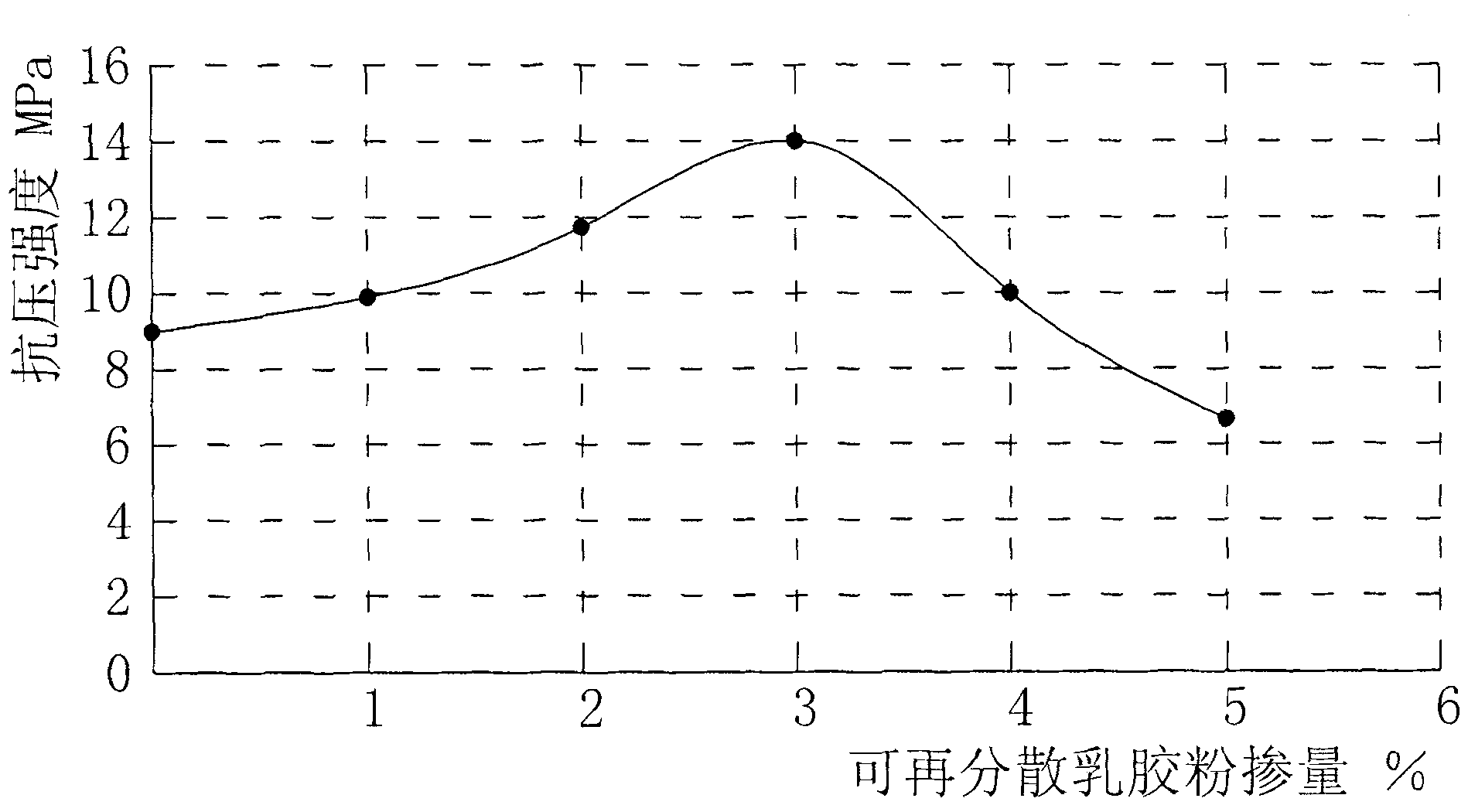

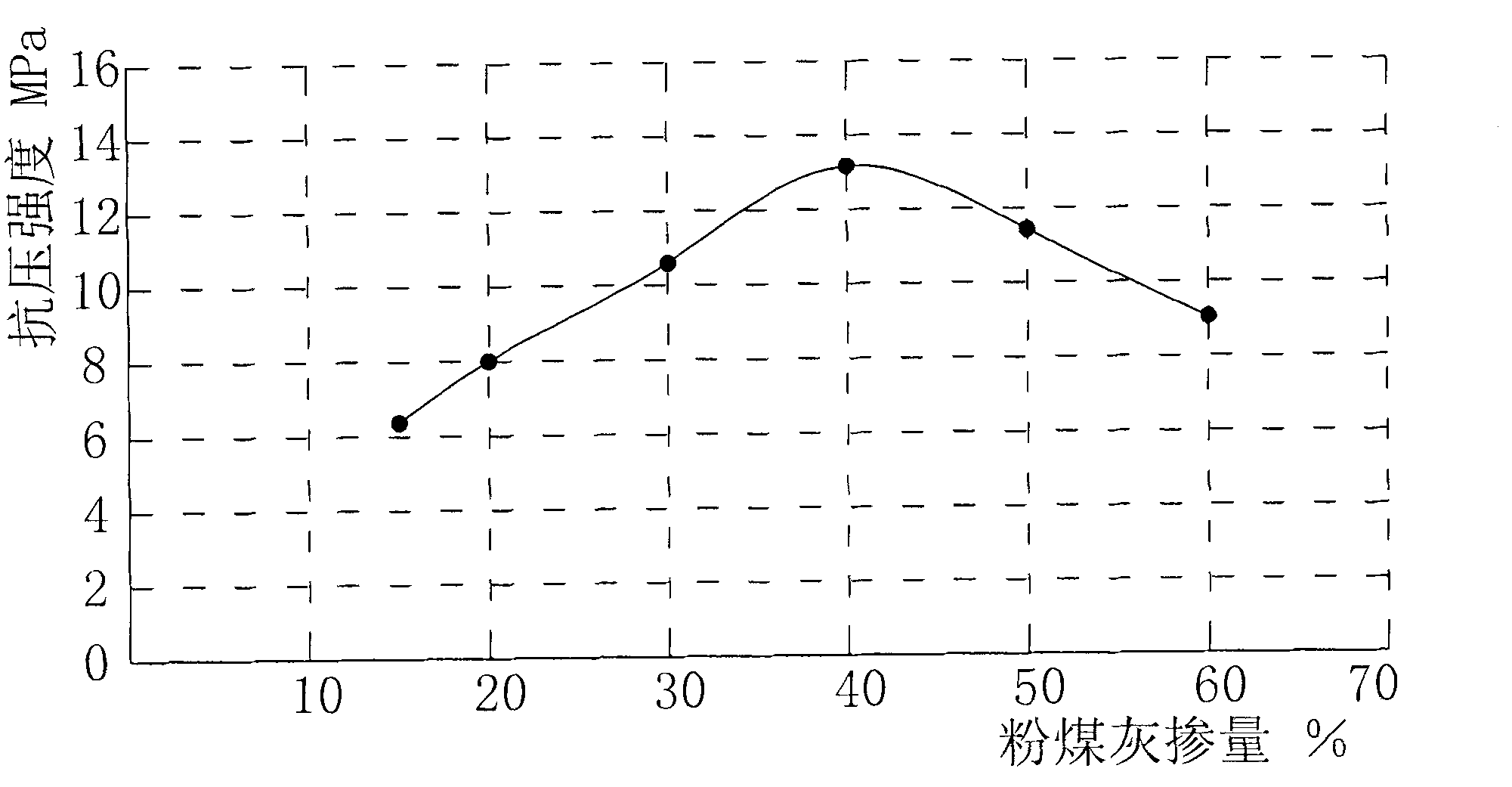

Swelling type micro-capsule/cement-based self-repair system

The invention relates to a swelling type micro-capsule / cement-based self-repair system. Calcium alginate is used as capsule walls, epoxy resin is used as capsule cores, accordingly, swelling type micro-capsules can be prepared, and the particle sizes of the micro-capsules range from 300 micrometers to 2.5 mm; basic components in a self-repair cement-based materials include cement, sand, the micro-capsules, water and epoxy resin curing agents, and the adding quantity of the micro-capsules is 0.5-10 wt% of the cement. The cement, the sand and the micro-capsules are uniformly stirred and dispersed, the water and the epoxy resin curing agents are poured into mixtures with the cement, the sand and the micro-capsules, and pouring forming, form stripping and curing are carried out after the water, the epoxy resin curing agents and the mixtures are uniformly stirred, so that the swelling type micro-capsule / cement-based self-repair system can be formed. The swelling type micro-capsule / cement-based self-repair system has the advantages that the micro-capsules have water absorption and swelling characteristics, accordingly, water can be compensated in cement hydration procedures, and the swelling type micro-capsule / cement-based self-repair system has an internal curing function; processes for synthesizing the swelling type micro-capsule / cement-based self-repair system are simple, the swelling type micro-capsule / cement-based self-repair system is good in mechanical property, is difficult to break in cement mixture stirring procedures and can be uniformly dispersed in the cement-based materials, and accordingly cracks can be self-repaired.

Owner:BEIJING UNIV OF TECH

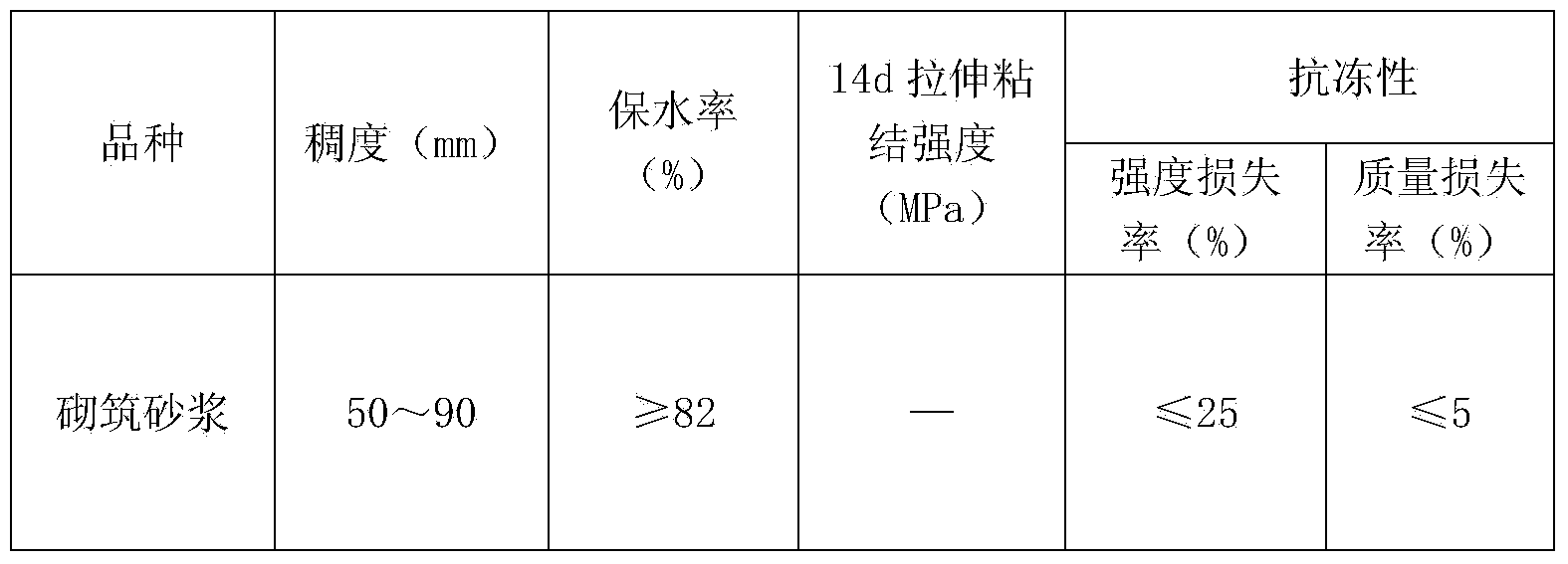

Light-weight dry-mixed masonry mortar

The invention discloses light-weight dry-mixed masonry mortar. The light-weight dry-mixed masonry mortar comprises the following components in percentage by weight: 200 to 300 percent of concrete, 80 to 120 percent of pulverized fuel ash, 400 to 1,400 percent of aerated concrete gains, 80 to 140 percent of vitrified beads, 0.8 to 1.6 percent of PP fibers, 2 to 12 percent of latex powder, and 3 to 15 percent of compound air entraining agent. The mortar has the advantages of avoiding field stirring and mixing, reducing construction dusts and noise pollution and reducing space occupation, along with precise mixing ratio, small concrete use amount, low cost, only need of adding water and mixing uniformly during construction, small material consumption and waste, convenient storage and transport and use, high binding strength, low shrinkage, high freezing resistance durability, low conductivity, good heat preservation, good workability, convenient construction, and the like; by substituting the aerated concrete gains for sand and using the pulverized fuel ash, the light-weight dry-mixed masonry mortar has the characteristics of industrial waste utilization, environmental protection, and low cost.

Owner:JIANGSU RONGNENG GROUP

Masonry mortar produced by construction solid waste

The invention discloses a masonry mortar produced by construction solid waste. The masonry mortar comprises the following raw materials in parts by weight: 150-200 parts of cement, 900-1,200 parts of construction solid waste, 20-30 parts of glazed hollow beads, 30-40 parts of limestone, 10-20 parts of shell powder, 2-3 parts of magnesium sulfate heptahydrate, 5-10 parts of redispersible emulsion powder, 2-3 parts of polytetrafluoroethylene fibers, 0.8-1 part of Butyl tin tris-2-ethylexanoate, 2-3 parts of calcium phosphate, 4-6 parts of graphite powder, 1-2 parts of nano carbon powder, 1-2 parts of aluminium dihydric phosphate, 0.8-1 part of triethavolamine oleate soap and 2-4 parts of aluminum nitride powder. The masonry mortar provided by the invention is low in cost, can be used only by adding water and uniformly stirring according to the required amount during construction operation, is low in material consumption and waste, and has the advantages of high adhesion strength, low dry shrinkage rate, excellent anti-freezing durability, low thermal conductivity, good heat preservation performance, favorable workability, environmental friendliness and innocuity.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

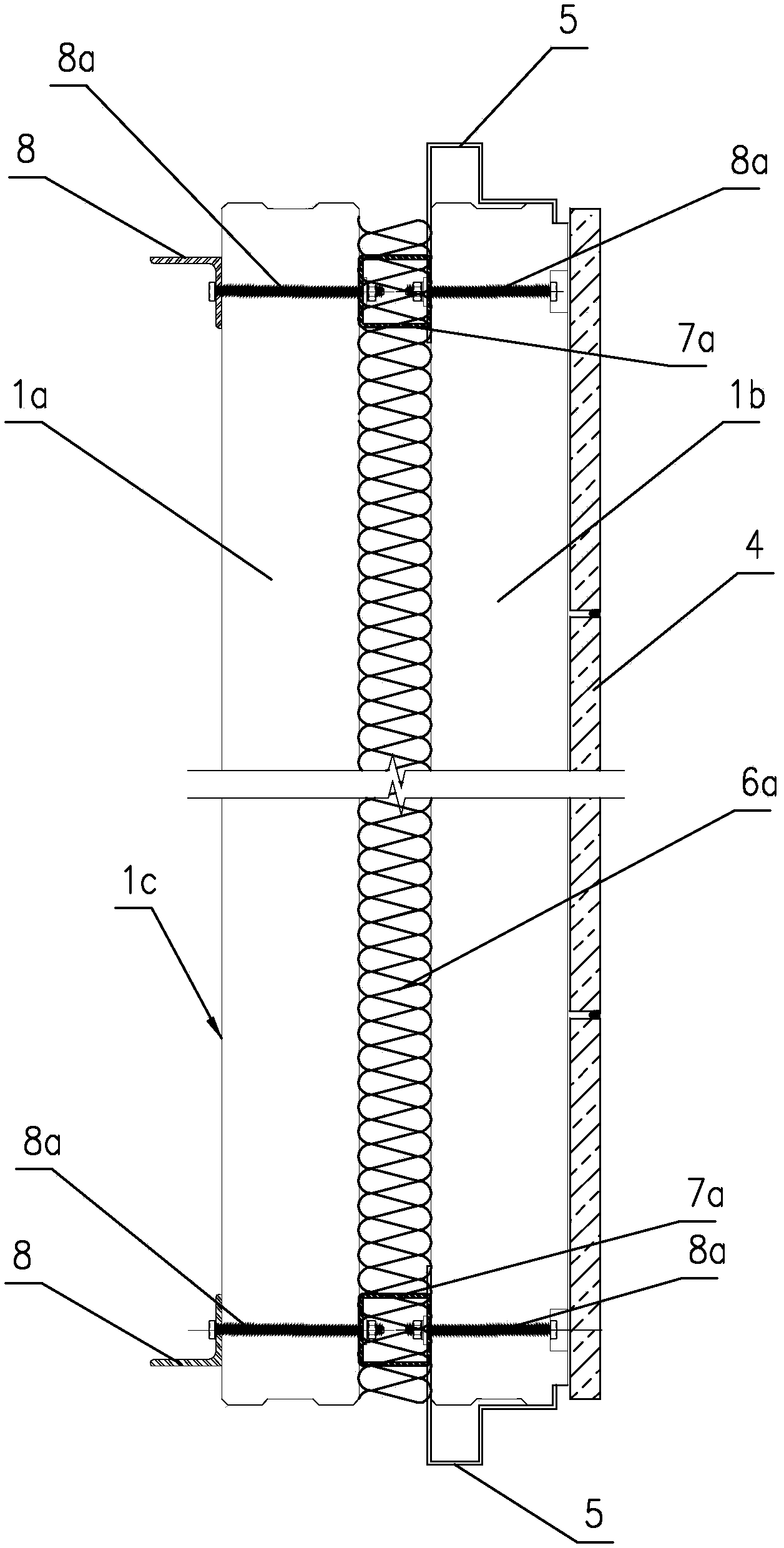

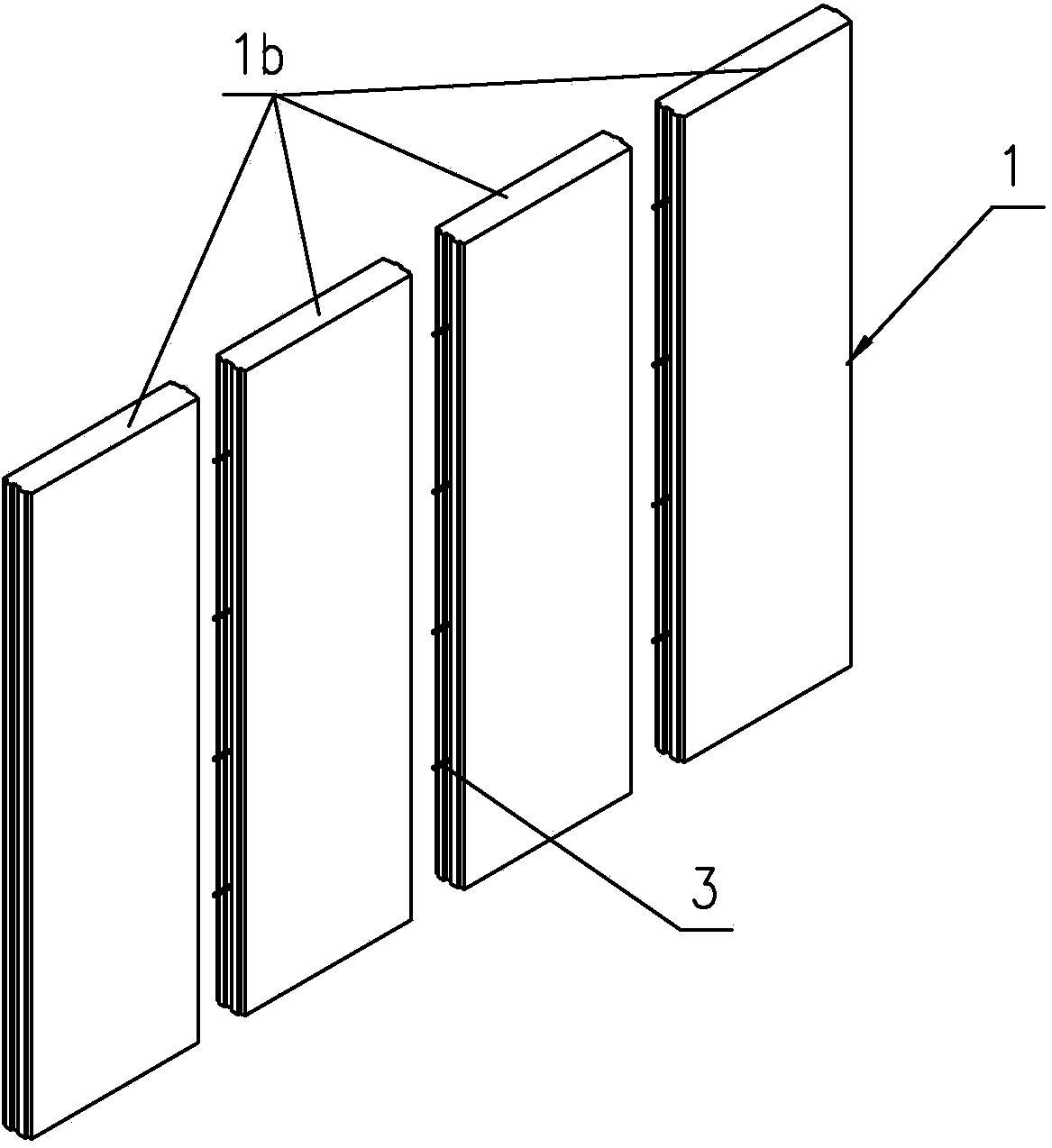

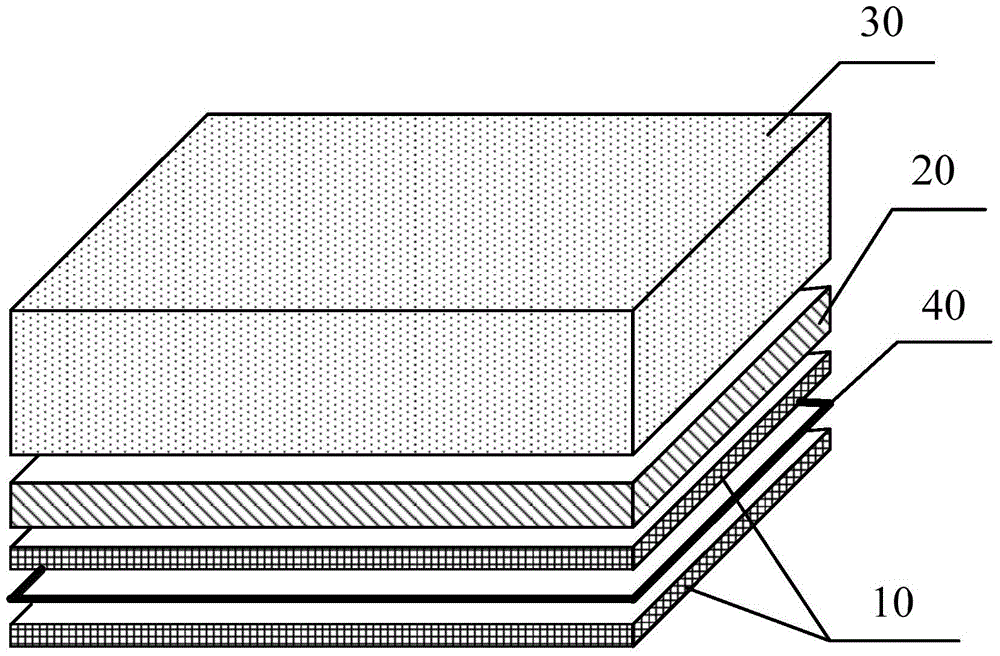

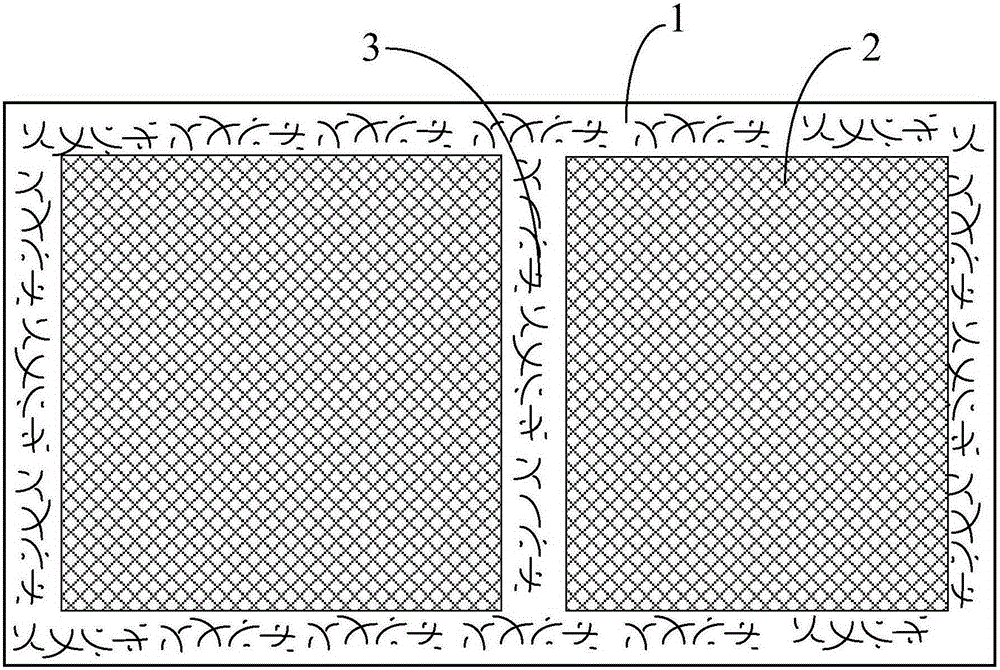

Self-heat-insulation decoration integral multifunctional light-weight concrete composite plate and curtain wall

The invention discloses a self-heat-insulation decoration integral multifunctional light-weight concrete composite plate, which mainly consists of an inner light-weight concrete plate, an outer light-weight concrete plate and heat insulation materials, wherein the outer surface of the outer light-weight concrete plate is used for installing a decoration surface; the inner light-weight concrete plate and the outer light-weight concrete plate are opposite, and in addition, a gap is formed between the inner light-weight concrete plate and the outer light-weight concrete plate; the heat insulation materials are filled in the gap; the inner light-weight concrete plate and the outer light-weight concrete plate are connected and fixed through a connecting structure; and pendants used for being connected with a building main body structure are arranged on the inner light-weight concrete plate. The self-heat-insulation decoration integral multifunctional light-weight concrete composite plate is based on the self structural strength of the light-weight concrete plate; in addition, the double-layer structure formed by the inner and outer light-weight concrete plates and the heat insulation materials arranged in the gap formed between the inner and outer light-weight concrete plates are suitable to be used for building exterior wall enclosure systems in northern area with cold weather; high strength, heat insulation performance, fireproof performance, waterproof performance, low dry shrinkage rate and good sound isolation performance are realized; the factory prefabrication and the in-site installation are realized; construction waste is little; and the installation is safe and fast.

Owner:GUANGDONG HEYUAN LIANTIAN BUILDING INDZATION MFG

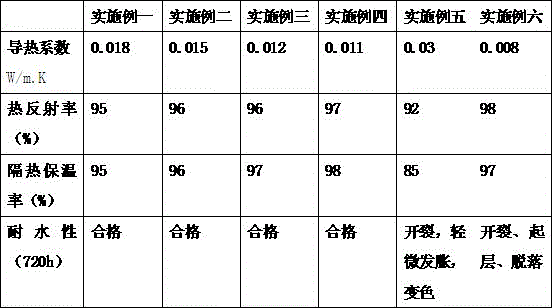

Aerogel thermal insulation coating and preparation method thereof

The invention discloses an aerogel thermal insulation coating and a preparation method thereof, belongs to the field of thermal insulation coatings and aims at solving the problems that the thermal insulation coating in the prior art has large heat conduction, low thermal insulation inhibition ratio and a poor thermal insulation effect. The aerogel thermal insulation coasting is prepared from materials in parts by weight: 100 to 110 parts of film forming agent, 40 to 100 parts of filler and 2 to 8 parts of fire resistant fiber, wherein the filler is prepared from 20 to 40 parts of silicon dioxide aerogel cement and 5 to 10 parts of nanometer hollow silicon microsphere, and an aid is prepared from 3 to 6 parts of binder, 1 to 4 parts of penetrant, 0.5 to 5 parts of thickener, 0.1 to 0.4 part of active agent and 2 to 3 parts of defoamer. The coating disclosed by the invention can form a three-dimensional network hollow structure on the surface of a building wall body, the three-dimensional network hollow structure is formed by sealed microspheres which are connected together, and a fine nano-porous network structure of aerogel and the nanometer hollow silicon microspheres can form a stacked static-state air set; thus, heat conductivity coefficient of a coating is smaller than 0.015W / m.K, and heat conductivity can be effectively prevented.

Owner:XINHUASHENG ENERGY SAVING TECH CO LTD

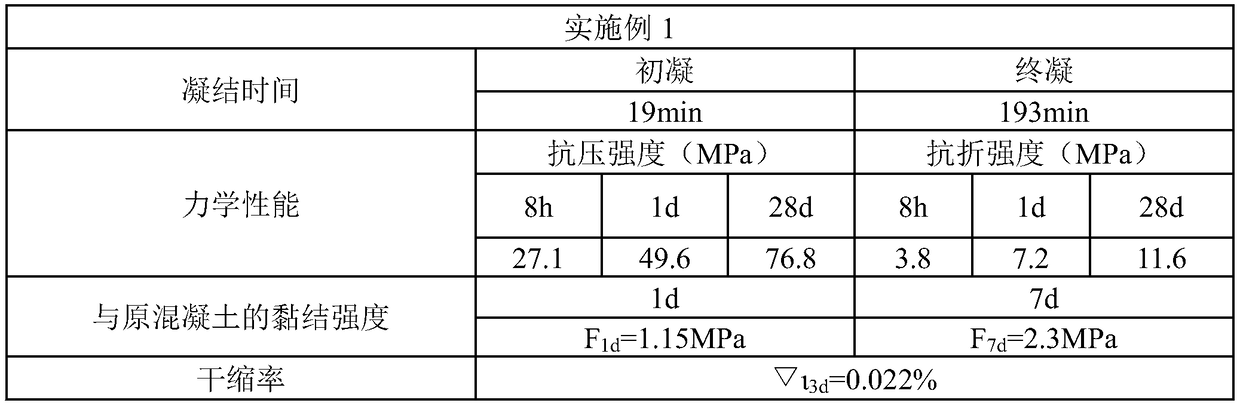

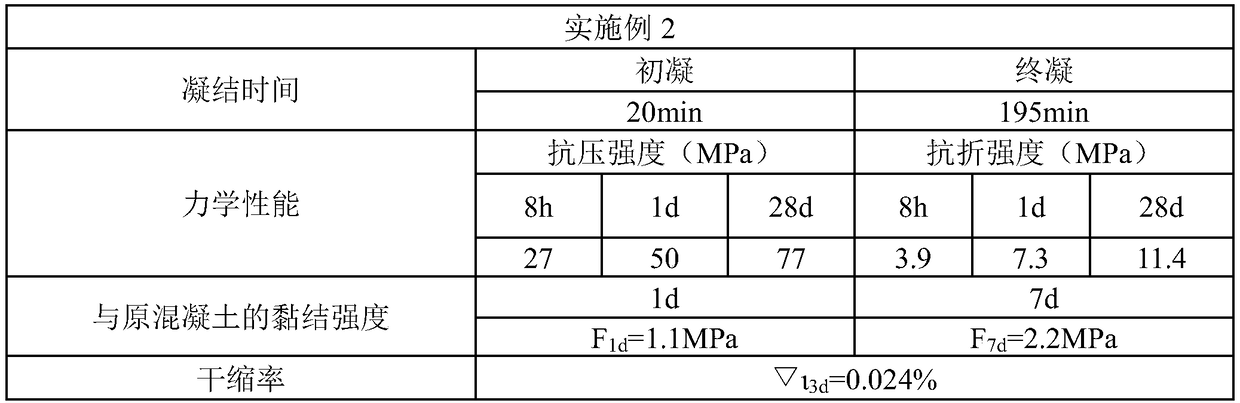

Fast hardening early strength type composite repair mortar

The invention belongs to the technical field of a building material, and provides fast hardening early strength type composite repair mortar. The mortar is prepared from the following ingredients in percentage by weight: 5 to 10 percent of water, 20 to 30 percent of cement, 1 to 5 percent of silicon ash, 1 to 5 percent of fly ash, 50 to 70 percent of quartz sand, 0.4 to 0.5 percent of compound early strength agents, 0.06 to 0.1 percent of water reducing agents, 1 to 5 percent of rubber powder and 0.06 to 0.8 percent of hybrid fiber, wherein the composite early strength agent is prepared from an ingredient A and an ingredient B; the ingredient A is lithium carbonate; the ingredient B is a mixture of triethanolamine and aluminum sulfate; the quartz sand consists of coarse sand, medium sand and fine sand; and the hybrid fiber consists of basalt fiber and polypropylene fiber. The fast hardening early strength type composite repair mortar solves the problems of reduced strength, high dry shrinkage rate and low bonding strength of the repair mortar in the prior art.

Owner:JILIN JIANZHU UNIVERSITY

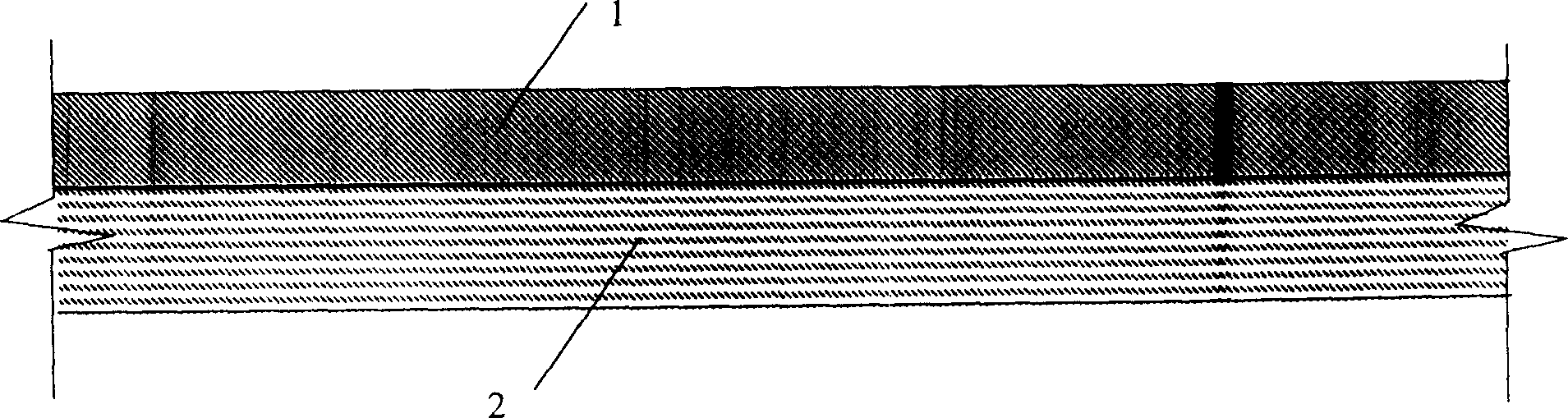

Road surface structure of rolling flexiable fibre cement concrete and construction method thereof

InactiveCN100999889AReduce dosageImprove economyPaving reinforcementsIn situ pavingsFrostRoad surface

The present invention relates to road structure and construction technology, and is especially road structure of rolled flexible fiber cement concrete and its construction process. The base layer of rolled flexible fiber cement concrete and paved on the foundation layer is formed through mixing flexible fiber, cement and water to form cementing material, adhering broken stone, sand, stuffing, etc with the cementing material, and rolling. The rolled flexible fiber cement concrete has obviously improved early plastic shrinking, dry shrinking and hot shrinking performance, obviously raised anticracking performance, toughness, impact strength, frost resistance and erosion resistance, and doubled antifatigue performance. The road with the rolled flexible fiber cement concrete structure has the features of simple construction, fast construction, short curing period, wide application range and raised performance.

Owner:易志坚 +3

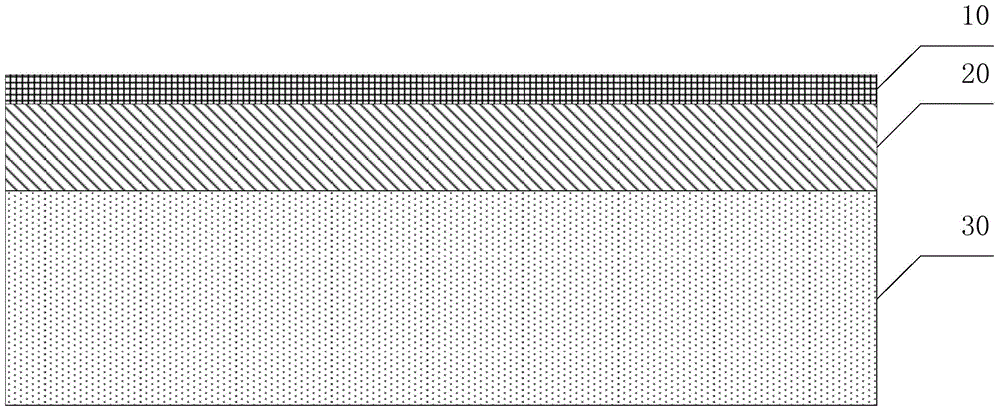

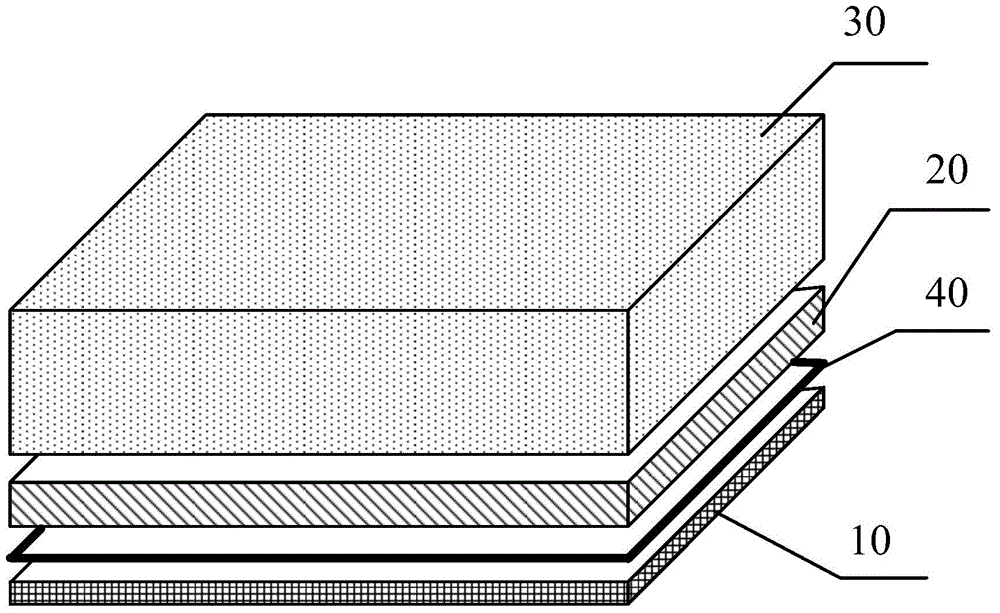

Crack-proof GRC composite prefabricated member and manufacture method thereof

ActiveCN105133778ALow drying shrinkageReduce the chance of crackingConstruction materialCeramic shaping apparatusSurface layerCrack resistance

The invention discloses a crack-proof GRC composite prefabricated member and a manufacture method thereof. The crack-proof GRC composite prefabricated member comprises a GRC surface layer, a GRC structure layer and a concrete layer, which are consolidated as a whole, wherein the GRC surface layer and the concrete layer are respectively disposed at two sides of the GRC structure layer. In the invention, the weight proportion of quartz sand to cement, the weight proportion of quartz sand of 80 mesh to quartz sand of 60 mesh, and the weight of ceramic micropowder in the GRC surface layer are adjusted to thereby effectively reduce the drying shrinkage rate and the crack generation rate of GRC surface layer so that durability and decoration effect of the GRC surface layer and crack-resistance are improved.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

Novel flexible composite shotcrete layer support material

The present invention relates to a novel flexible composite shotcrete layer support material which comprises the following components in parts by weight: 80-100 parts of cement, 80-120 parts of sands, 100-120 parts of stones, 60-100 parts of rubber particles, 40-60 parts of coal ash, 20-30 parts of hooked end steel fibers, 50-80 parts of water, 6-7 parts of a crosslinking agent, 5-8 parts of an additive, 2-10 parts of polyamic acid resin with a solid content of 10%-25% and 3-5 parts of a 1% silane coupler solution. The prepared shotcrete layer material is greatly improved in compression strength, rupture strength and flexural toughness. The novel flexible composite shotcrete layer support material can be applied to the field of support to surrounding rocks of complex rock layers with characteristics of high stress, soft rock, expansion, flowing deformation, fault structure fracture zones, mining influence and the like or other dynamic pressure tunnel as well as the field of underground engineering of tunnels, subways and the like.

Owner:SHANDONG UNIV

Mud material for producing gangue baked perforated insulating brick

The invention discloses a mud material for producing a gangue baked perforated insulating brick, comprising the following ingredients: 25-40 wt% of loess, 40-65 wt% of gangue, 5-15 wt% of small expended and vitrified ball, and water, wherein, the water content in the mud material is 10-15 %. According to the invention, blank making, air drying, seting, sintering, air cooling and kiln-out step can be carried out according to brickmaking method of the perforated brick in the prior art, wherein, the sintering temperature is controlled to 850-1100 DEG C, and the sintering time is controlled to 6-8 h. Detection result shows that the produced perforated brick by the method disclosed herein has the compressive strength of a compression face being 6.5 MPa, the water absorption being less than 18.3 %, the thermal resistance being no less than 1.1, and the dry shrinkage being less than 0.03 %. The produced perforated brick has the advantages of light weight, heat preservation, thermal insulation, fire resistance, aging resistance, low water absorption, low dry shrinkage and the like. The use of the perforated insulating brick in building construction can reduce the deadweight of the building, and has good heat preservation and fire resistance.

Owner:王新明

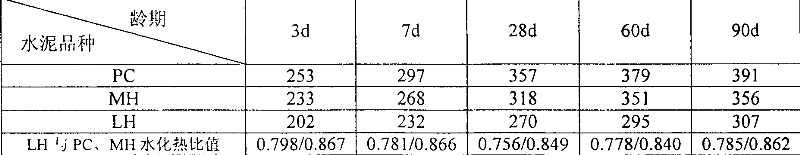

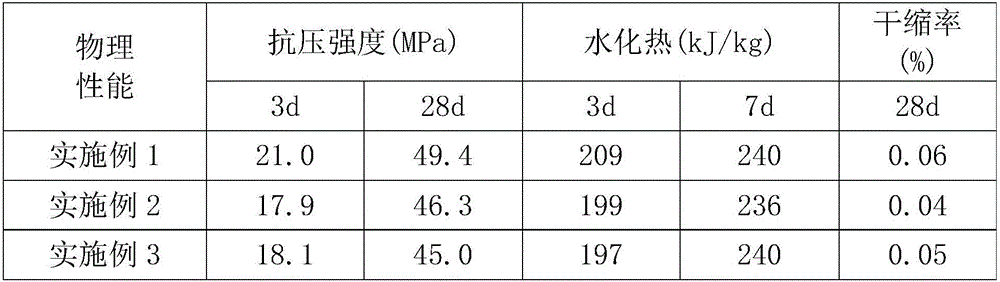

Low-heat Portland cement with high early strength and preparation method and application thereof

InactiveCN110204228AHigh heat of hydrationHigh low heat of hydrationCement productionCrack resistanceSlag

Owner:CHINA BUILDING MATERIALS ACAD

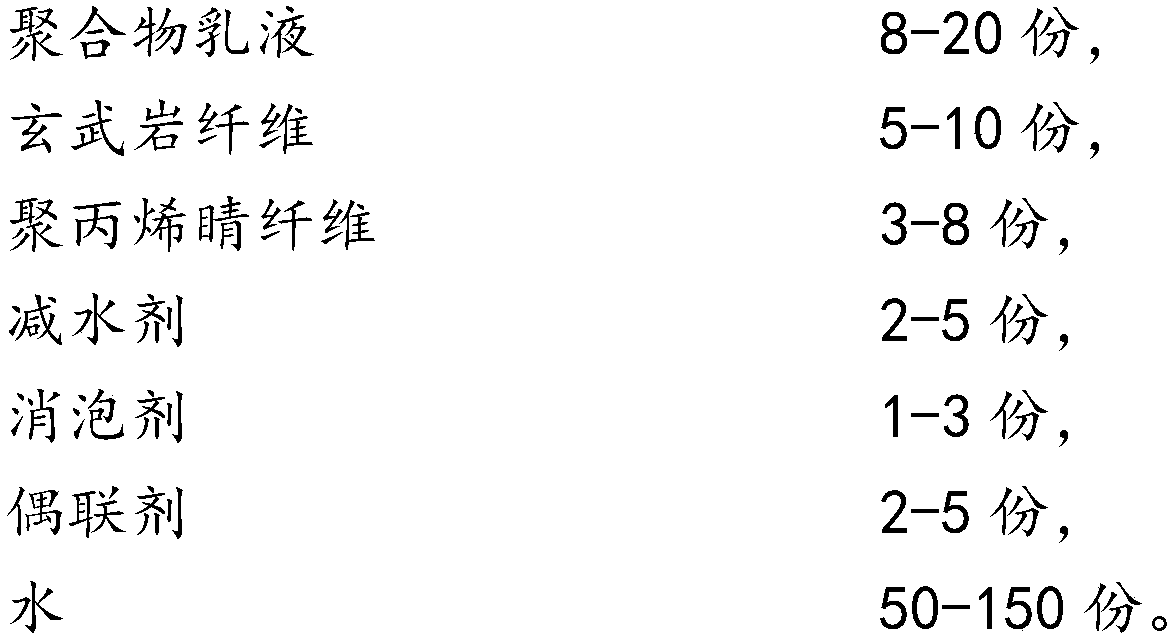

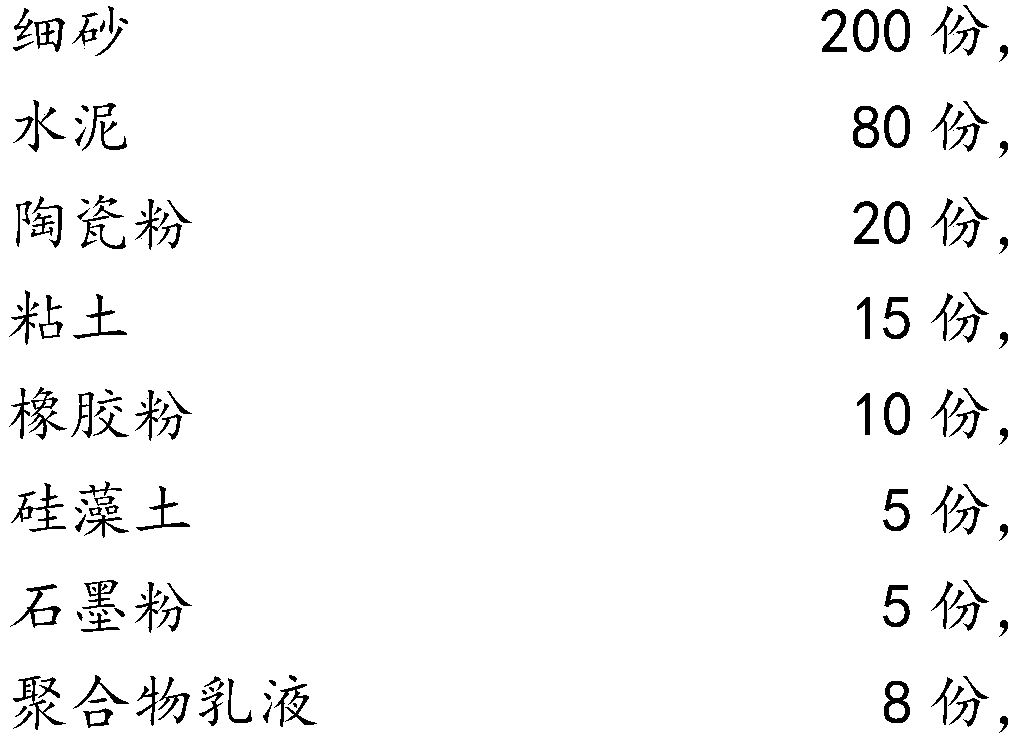

Polymer cement-based modified mortar

The invention discloses polymer cement-based modified mortar. The polymer cement-based modified mortar comprises the following raw materials in parts by mass: 200 to 350 parts of fine sand, 80 to 140parts of cement, 20 to 30 parts of ceramic powder, 15 to 25 parts of clay, 10 to 30 parts of rubber powder, 5 to 15 parts of diatomite, 5 to 15 parts of graphite powder, 8 to 20 parts of polymer emulsion, 5 to 10 parts of basalt fiber, 3 to 8 parts of polyacrylonitrile fiber, 2 to 5 parts of a water-reducing agent, 1 to 3 parts of a defoaming agent, 2 to 5 parts of a coupling agent and 50 to 150 parts of water. The polymer cement-based modified mortar has advantages of high structural strength, high waterproofness, high toughness, high bending strength, high volume stability, high durability,high freezing resistance, high early strength and good use effect, and is not liable to crack.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

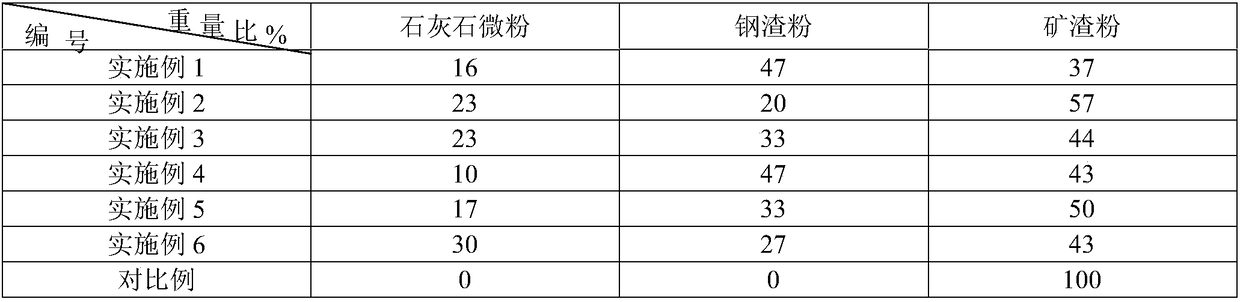

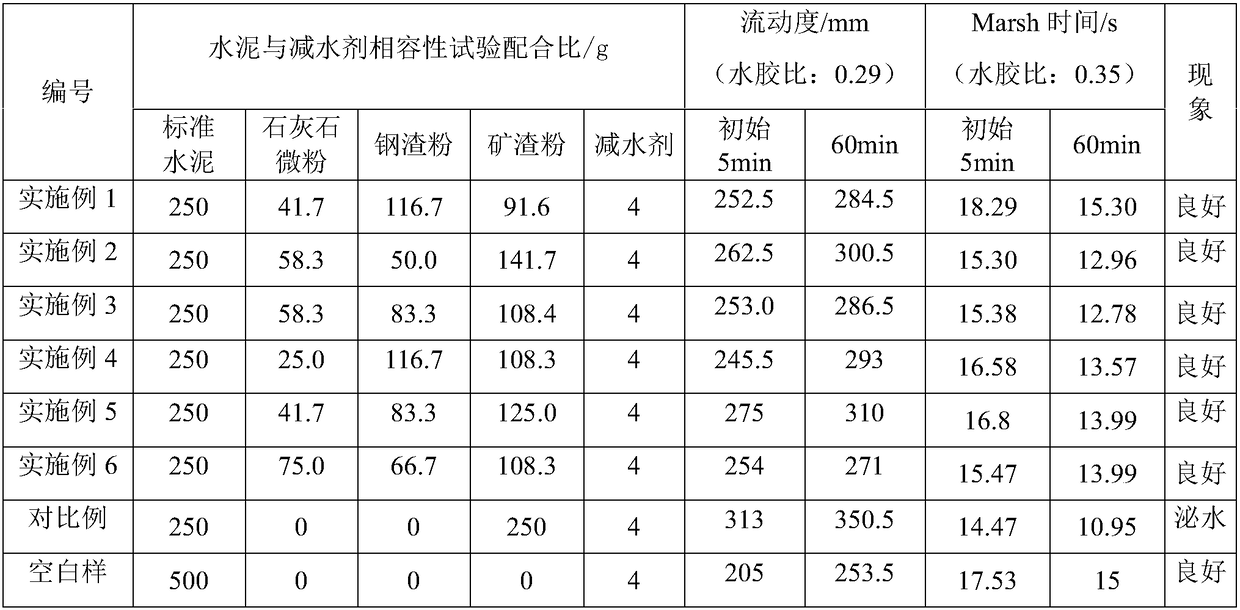

Limestone micro powder-steel slag powder-slag powder composite admixture and preparation process thereof

The invention provides a limestone micro powder-steel slag powder-slag powder composite admixture and a preparation process thereof. The composite admixture comprises 10-30% of limestone micro powder,20-50% of steel slag powder, and 30-60% of slag powder according to a weight ratio. The preparation method comprises the following steps: drying, crushing, grinding, grading or sieving limestone andsteel slag respectively to obtain limestone micro powder and steel slag powder; and then uniformly mixing the limestone micro powder, the steel slag powder and the slag powder according to proportionsto obtain a limestone micro powder-steel slag powder-slag powder composite admixture, wherein the slag powder performance meets an S95 level technical requirement in GB / T18046-2017 'Granulated blastfurnace slag powder for cement, mortar and concrete'. According to the invention, high-activity S95-grade slag powder is selected, and through mutual excitation of limestone micro powder, steel slag powder and slag powder, a micro-aggregate effect is generated, so that the compatibility of the admixture with cement and a water reducing agent is improved, the dry shrinkage rate of cement mortar isreduced, and the concrete strength is improved.

Owner:SHAOGUAN COLLEGE

Method for controlling shrinkage of recycled aggregate concrete

The invention discloses a method for controlling shrinkage of recycled aggregate concrete. The low-shrinkage recycled concrete is prepared by adopting aggregate pre-wetting treatment and an expandingagent compensation and shrinkage dual control technology and is prepared from 20-40 parts of natural sand, 25-45 parts of natural stone, 2-15 parts of recycled fine aggregate, 10-30 parts of recycledcoarse aggregate, 5-15 parts of cement, 0.5-10 parts of pulverized fuel ash, 0.5-10 parts of slag powder, 0.1-3 parts of expanding agent, 3-8 parts of water and 0.1-1.5 parts of water reducer. The shrinkage of recycled aggregate concrete is controlled by adopting the dual control technology, the slump degree of newly stirred recycled concrete reaches 220-240 m, the slump degree H60 within 1 hour reaches 210-230 nm, the shrinkage of the recycled concrete is controlled to 4.0-10-4 or below under the situation that 50% of the recycled aggregate is replaced, and the compressive strength reaches C50 or above.

Owner:国检测试控股集团北京有限公司 +1

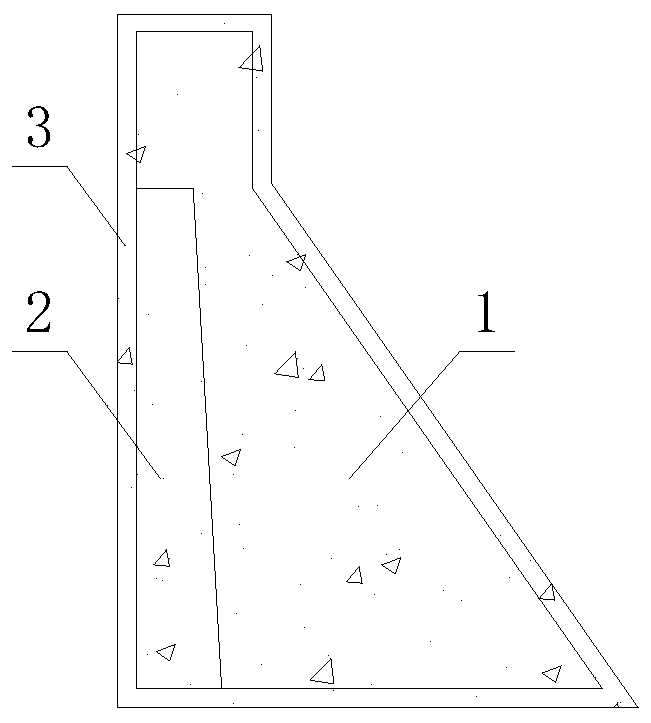

Ultra-high admixture amount flyash grinding concrete material damming method and structure thereof

PendingCN109809745AReduce dosageIncrease dosageBarrages/weirsSolid waste managementRoller-compacted concreteTemperature control

The invention discloses an ultra-high admixture amount flyash grinding concrete material damming method and a structure thereof. The admixture amount of flyash in grinding concrete is increased, the admixture amount of flyash in upstream-face C9020 three-graded anti-seepage grinding concrete is expected to be increased to 60%, the admixture amount of flyash in in-dam C9015 three-graded grinding concrete is expected to be increased to 70% to 80%, and a high-performance additive is adopted to lower water amount and cement amount of concrete. According to the ultra-high admixture amount flyash grinding concrete material damming method and the structure thereof disclosed by the invention, hydrated high temperature increase of concrete is effectively reduced, air shrinkage and self-shrinkage ofconcrete are reduced, temperature control and anti-cracking measures are simplified, temperature control and anti-cracking cost is reduced, and a certain economic benefit is achieved. Simplified temperature control and anti-cracking measures bring possibility to seam parting and chunk parting of a dam concrete structure, construction speed is increased, conditions are created for bringing forwardtime limit of the construction, and the economic benefits are remarkable; at the same time, flyash solid waste is greatly utilized, generated energy-conserving and emission-reducing ecological and environmental benefits are obvious.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Preparation method of recycled aggregate, and dry-mixed mortar

The invention relates to a preparation method of recycled aggregate. The preparation method comprises the following steps: repeatedly crushing and refining construction waste, and screening to obtainparticles with the diameter of less than 30 mm; putting the particles into an eddy current sorting machine and a magnetic sorting machine, removing metal particles, and sorting to obtain coarse aggregate; crushing and refining the coarse aggregate into fine aggregate with the diameter of 0.5-5 mm; fully stirring and mixing the fine aggregate and a coupling agent diluted by alcohol, and enabling the alcohol to completely volatilize to obtain fine aggregate subjected to surface coupling treatment; and fully stirring and mixing the fine aggregate subjected to surface coupling treatment with polyethylene glycol dissolved in clear water, and heating and drying to obtain the recycled aggregate. The invention also relates to a dry-mixed mortar and a preparation method thereof. The construction waste is utilized, and waste is turned into valuables; and circular economy is developed, and sustainable development of the building mortar is realized.

Owner:佛山市南海承骏科技有限公司

Hydrated magnesium silicate-based cementing material containing magnesium oxysulfate-based waste and preparation method of hydrated magnesium silicate-based cementing material

The invention belongs to the technical field of building materials, and particularly relates to a hydrated magnesium silicate-based cementing material containing magnesium oxysulfate-based waste and a preparation method of the hydrated magnesium silicate-based cementing material. The hydrated magnesium silicate-based cementing material comprises the following raw materials: 30-50 parts of light calcined magnesia powder, 60-75 parts of silica fume, 45-70 parts of water, 1-2 parts of a water reducer, 0.25-0.75 part of a retarder, and 5-12 parts of magnesium oxysulfate-based waste. The magnesium oxysulfate-based waste is any one or a combination of any two or more of leftover materials in the production process of magnesium oxysulfate wallboards, waste magnesium oxysulfate wallboards and waste magnesium oxysulfate insulation boards. The cementing material has the advantages of good fluidity, small shrinkage deformation, high strength and the like; and meanwhile, the problems that the magnesium oxysulfate-based waste is difficult to treat and process, low in utilization rate and the like can be effectively solved. The magnesium oxysulfate-based waste material is adopted, so that the product cost is reduced, the adverse effect of solid waste on the environment is reduced, meanwhile, the development of the magnesite industry in the future is greatly influenced, and comprehensive utilization and even efficient utilization of resources are really realized.

Owner:辽宁科大中驰镁建材科技有限公司

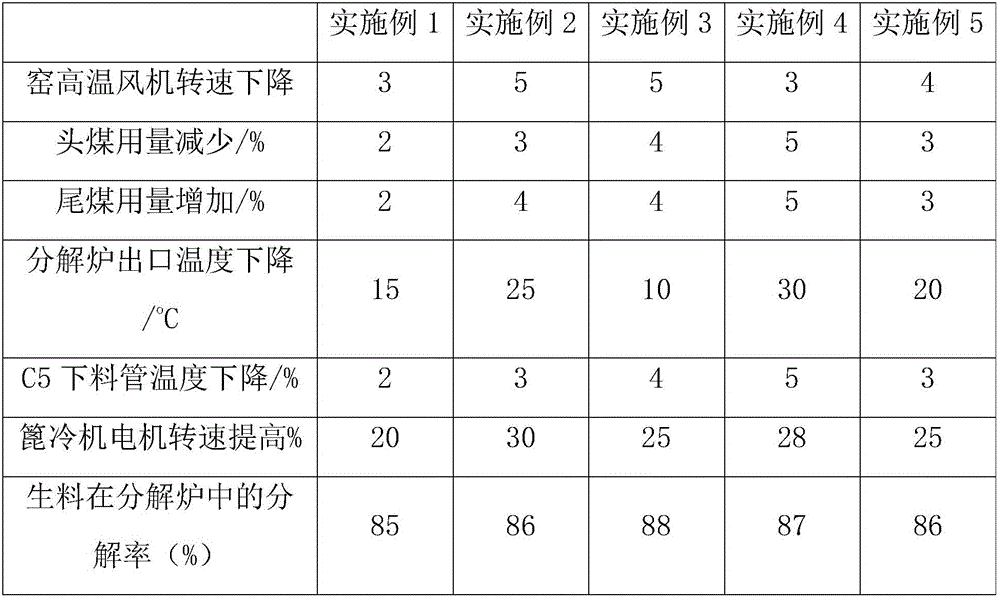

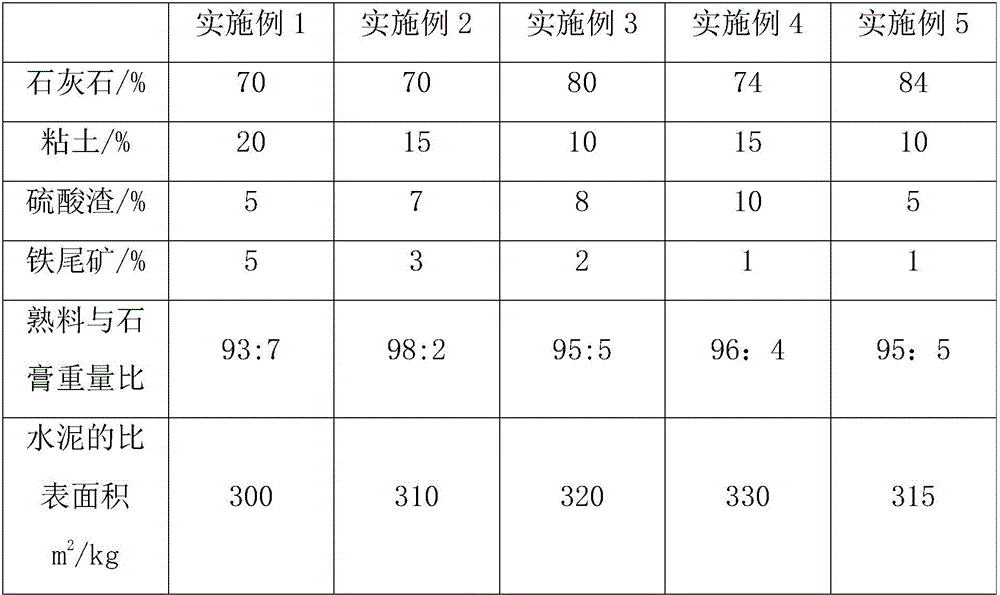

Low-heat silicate cement clinker for maritime work and preparation method thereof

The invention relates to a preparation method of low-heat silicate cement clinker for maritime work. The preparation method comprises the following steps: (1) mixing and grinding the following components in percentage by mass into powder: 70 to 84 percent of limestone, 10 to 20 percent of clay, 5 to 10 percent of sulfate slag and 1 to 5 percent of iron tailings to obtain a cement raw material; (2) decomposing the cement raw material in a decomposing furnace, then calcining at the temperature of 1,350 to 1,400 DEG C for 30 to 45 min, and cooling to obtain the cement clinker, wherein on the basis of the parameters of the decomposing and calcining production processes of the existing cement raw material of the same yield, the following parameters of the calcining process of the cement raw material are adjusted respectively according to the yield of the cement clinker of 500 to 10,000 t / day: the rotating speed of a high-temperature fan of a kiln is reduced by 3 to 5 percent, the use amount of head coal is reduced by 2 to 5 percent, the use amount of tailings is increased by 2 to 5 percent, the outlet temperature of the decomposing furnace is reduced by 10 to 30 DEG C, the temperature of a C5 discharging pipe is reduced by 2 to 5 percent, and the rotating speed a motor of a grate cooler is increased by 20 to 30 percent. Cement prepared from the cement clinker disclosed by the invention is low in water heat and dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD +1

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

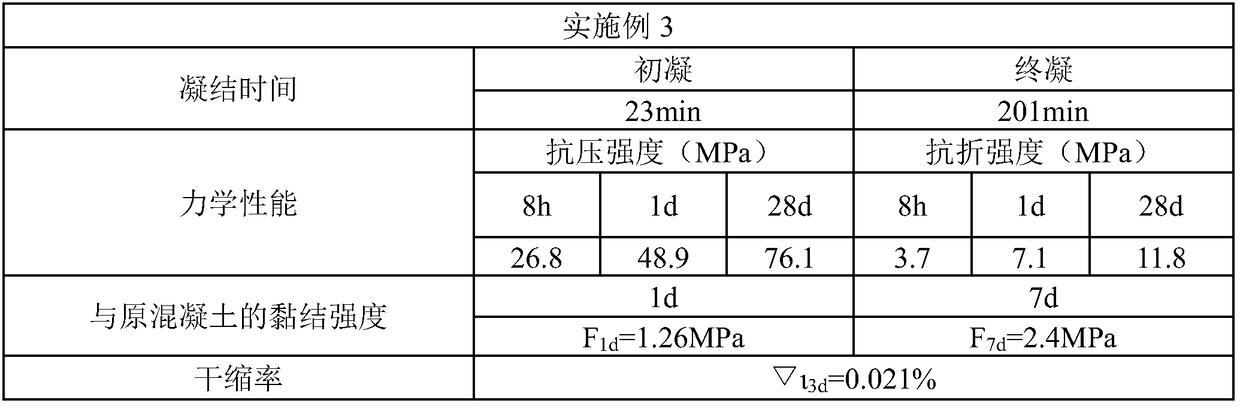

Slab ballastless track wide-narrow joint quick repair polymer concrete and preparation method thereof

The invention discloses a CRTS II type slab ballastless track wide-narrow joint quick repair polymer concrete, which is characterized by comprising the following components in parts by weight: 38-58 parts by weight of cement; 5-7 parts by weight of fly ash; 42-62 parts by weight of gravel; 10-20 parts by weight of sand; 10-30 parts by weight of an expansion agent; 17-20 parts by weight of water; 5-9 parts by weight of a water reducing agent; 0-2 parts by weight of a coagulant; 0-2 parts by weight of a retarder and 0.5 to 1.5 parts by weight of a concrete modifier. The slab ballastless track wide-narrow joint quick repair polymer concrete has the advantages of fast hardening, high bonding strength, small dry shrinkage rate, good bonding capability with a track plate after pouring and compact inside. Meanwhile, the slab ballastless track wide-narrow joint quick repair polymer concrete has high hourly strength, can greatly shorten the construction period and improve the construction efficiency, and overcomes the defects of slow hardening, low adhesive force, poor durability and the like in the prior art.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

High-anti-permeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a high-anti-permeability cement-based repair material for tunnel engineering. The repair material consists of portland cement, coal ash, silica fume, steel slag powder, rock powder, tailing sand, quartz sand, attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fibers, PET fibers, a polycarboxylic acid water reducer and a defoaming agent. The repair material has the characteristics of easy construction, good working performance, good water retention performance, high compressive strength, high anti-permeability level, high toughness and adhesion, excellent durability and the like; and the repair material can be suitable for construction initial protection or engineering later maintenance and repair of lining concrete in the tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Weight-increasing anti-radiation cement for nuclear power project

The invention discloses a weight-increasing anti-radiation cement for nuclear power project. The weight-increasing anti-radiation cement is prepared from, by mass, 70-80% of nuclear power cement clinker, 10-20% of barite, 3-5% of iron ore powder, 2.0-4.0% of gypsum, 2.0-6.0% of borax, 1.0-3.0% of silica fume, and 0.08-0.2% of lithium chloride, wherein unprocessed material ingredients with saturated ratio KH=0.870+ / -0.02, silica ratio n=2.75+ / -0.1 and aluminum ratio P=0.7+ / -0.1 are calcined to obtain the nuclear power cement clinker. The weight-increasing anti-radiation cement for nuclear power project has the performances of being low in hydration heat, low in dry shrinkage rate, high in density and high in strength, moreover, can effectively shield the alpha ray, beta ray, gamma ray, X ray and neutron ray.

Owner:葛洲坝石门特种水泥有限公司

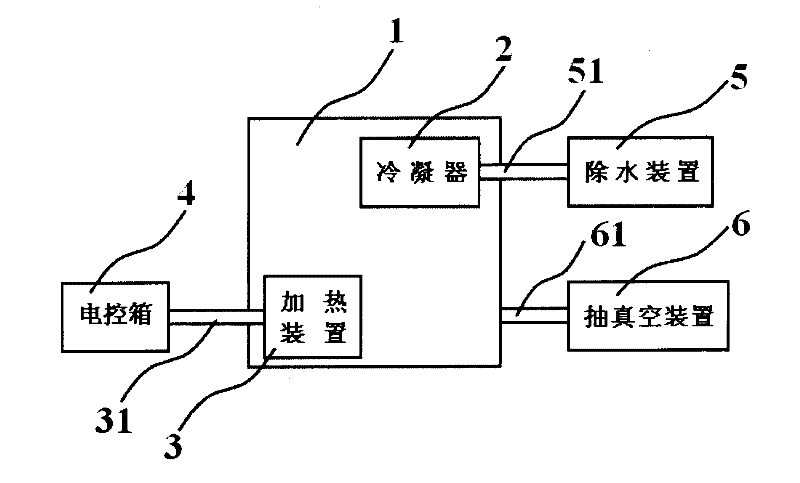

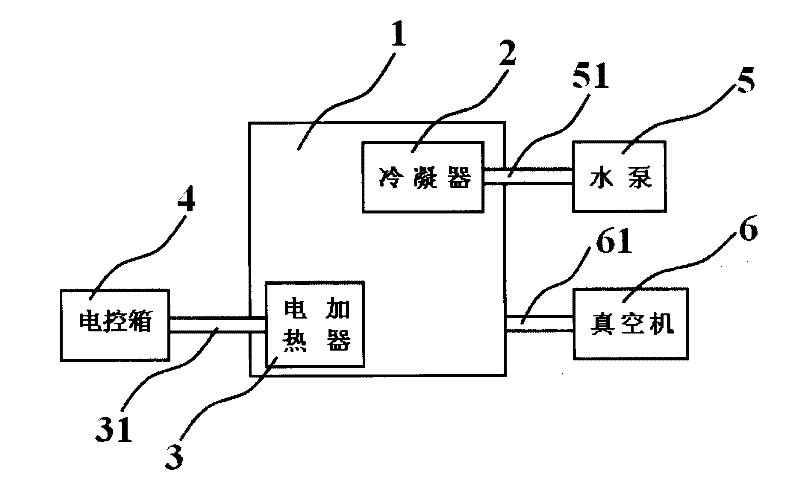

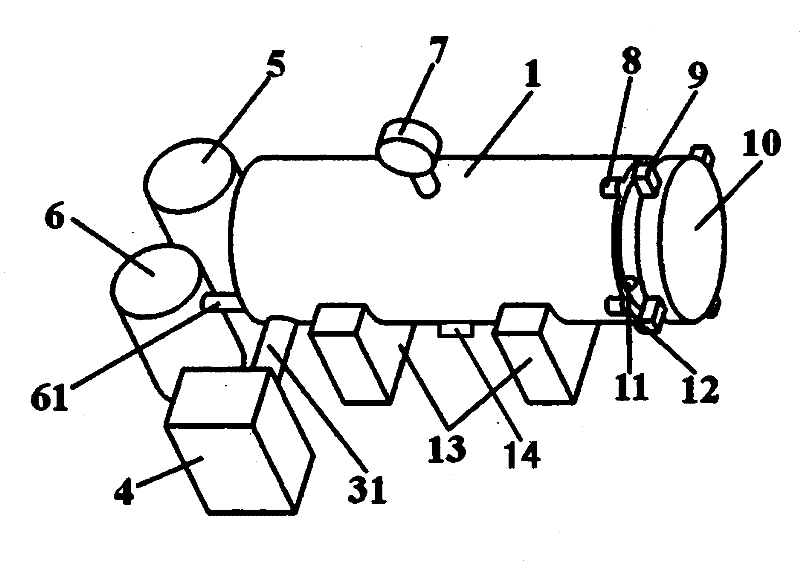

Method and device for drying wood

InactiveCN102252502ASmall demotion rateLow drying shrinkageDrying using combination processesWater dischargePliability

The invention relates to a method for drying wood. The method is characterized by sequentially comprising the steps of: processing wood into wood segments in required size, placing the wood segments in a drying device and sealing the drying device; starting up a heating device, heating the drying device to ensure that a temperature reaches 65-80 DEG C and is kept for 20 minutes to 2 hours; starting up a vacuumizing device, vacuumizing the drying device to ensure that the absolute pressure intensity is enabled to be within the range of not less than -0.098 MPa and not greater than -0.05 MPa and is kept for 20 minutes to 2 hours; starting up a water-discharging device to pump out water; and turning off the heating device, the vacuumizing device and the water-discharging device and taking out of the wood segments. According to the method, resin membranes inside the wood are damaged for realizing quick drying, the water permeability and the air permeability of the wood are improved and the flexibility is increased. The method provided by the invention has the advantages of simplicity, short drying time, high efficiency, energy saving, cost reduction, low wood degrading rate, and the like. The invention further discloses a drying device.

Owner:于玺泽

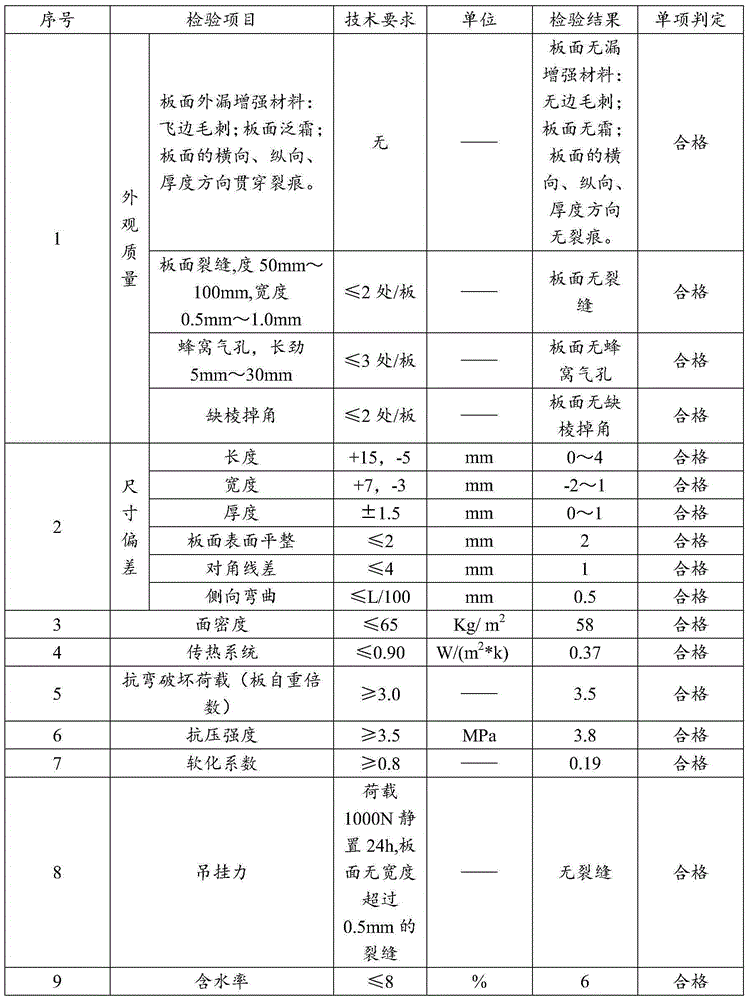

Glass-fiber-enhanced inorganic/organic composite lightweight partition wall

A glass-fiber-enhanced inorganic / organic composite lightweight partition wall is made from an enhancement material, brine, magnesium oxide powder, a composite modifying agent, an additive and a filling material. The brine is magnesium chloride solution. The composite modifying agent is composed of, by weight, 40%-50% of distilled water, 15%-20% of a stable phase agent, 10%-15% of a water resisting agent, 3%-5% of a stable magnesium ion reagent, 5%-8% of an anti-deformation reagent, 5%-10% of a coagulant and 5%-10% of a retarder. The additive is composed of fly wash and straws. The glass-fiber-enhanced inorganic / organic composite lightweight partition wall is composed of a covering material, the filling material and reinforcing bars; the covering material and the reinforcing bars are made of the same material; the reinforcing bars are disposed between two pieces of the filling material. The glass-fiber-enhanced inorganic / organic composite lightweight partition wall is a novel low-carbon green energy-efficient environment-friendly lightweight partition wall.

Owner:NINGXIA ZHONGHUI SHENGFENG BUILDING MATERIAL CO LTD

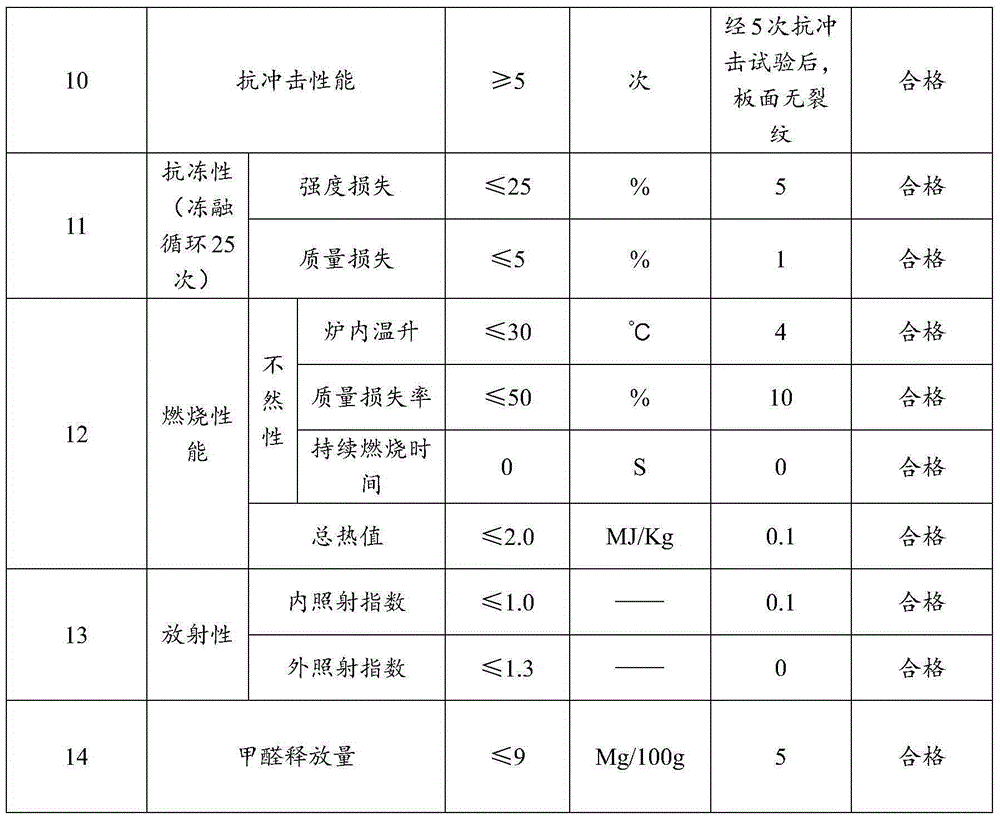

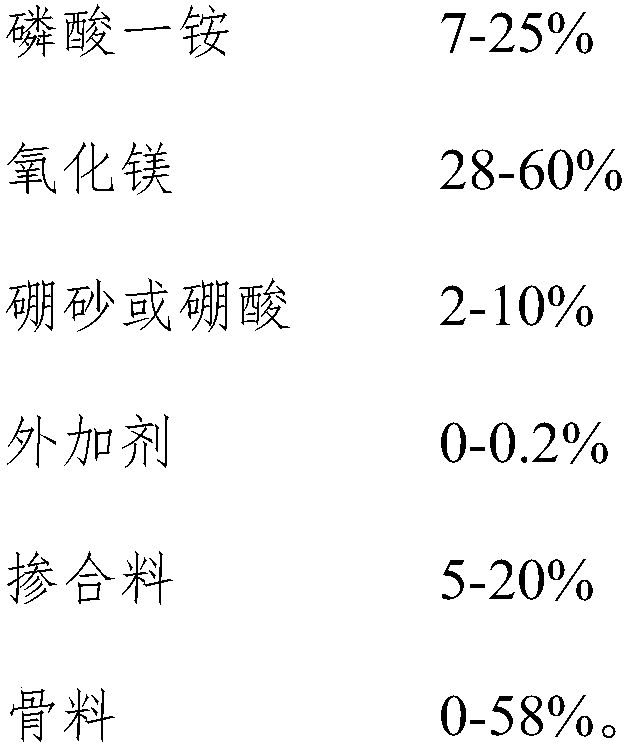

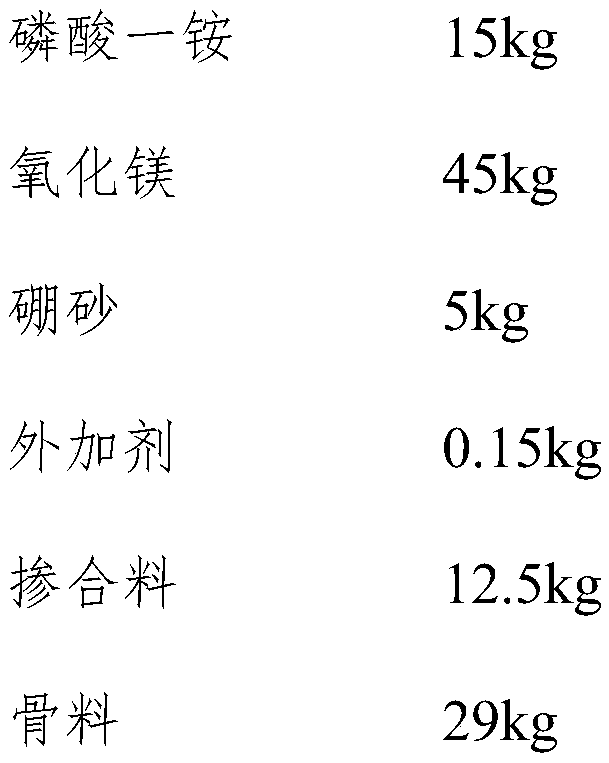

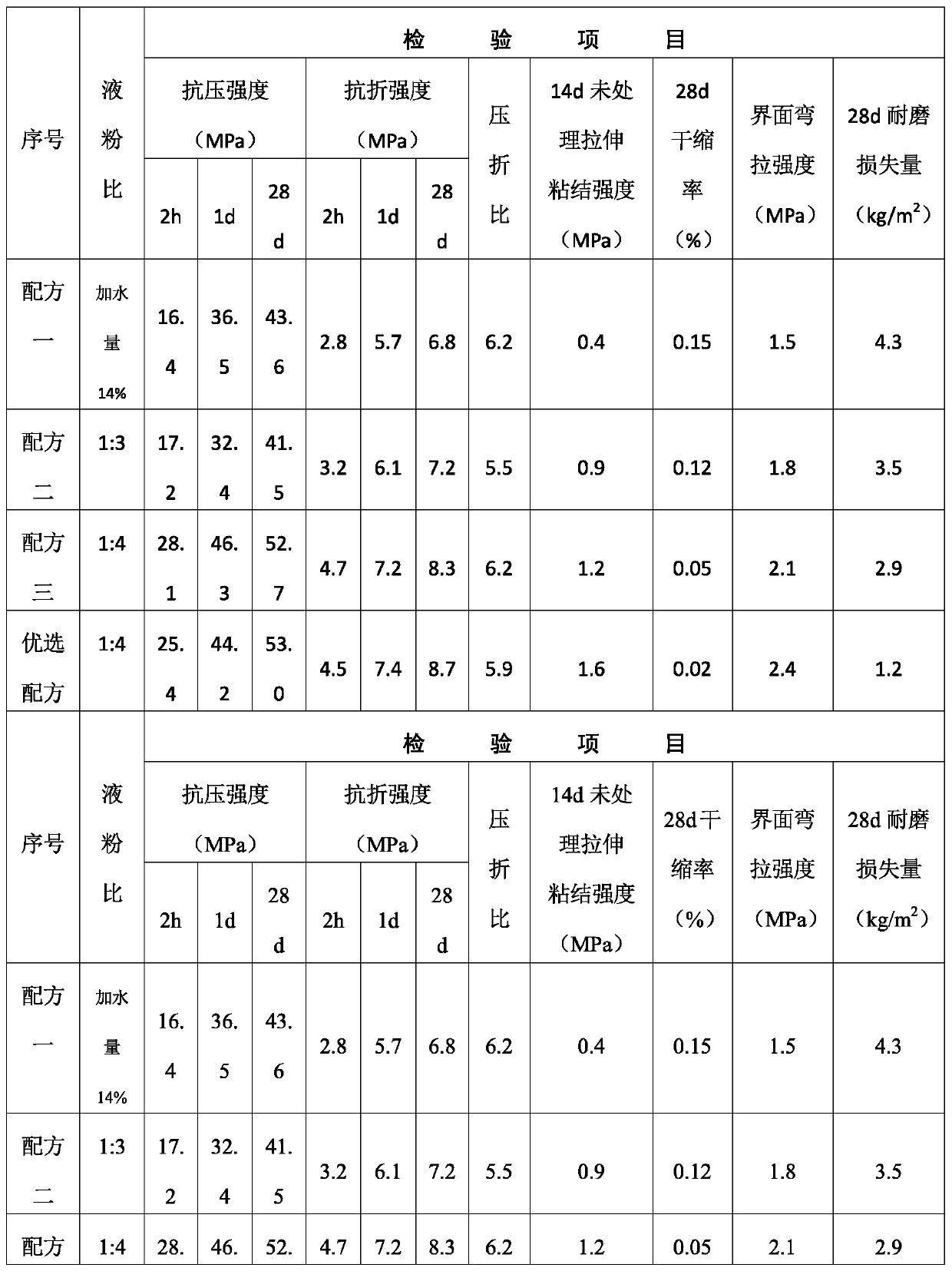

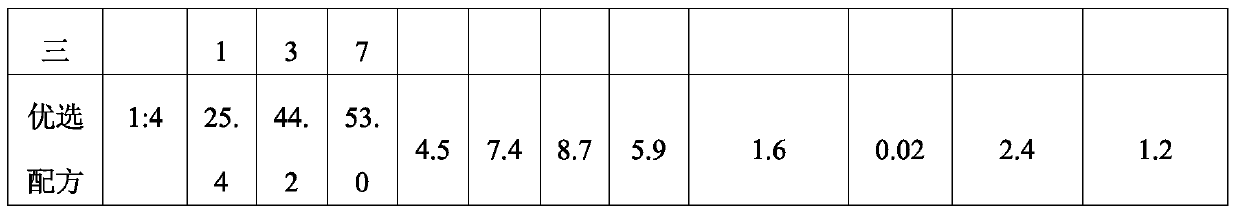

Concrete crack repairing material based on phosphorus magnesium material and construction technology thereof

The invention relates to the technical field of the concrete repair and in particular to a concrete crack repairing material based on a phosphorus magnesium material and a construction technology thereof. The concrete crack repairing material based on the phosphorus magnesium material is obtained by mixing monoammonium phosphate, magnesium oxide, borax or boric acid, an additive, an admixture andaggregate according to a specific proportion, and in a repairing process of a concrete crack, interface treatment does not need to be performed. The prepared concrete crack repairing material based onthe phosphorus magnesium material has the characteristics of short coagulation time, high compressive strength in early stage, high breaking strength, high bonding strength, low dry shrinkage rate, good durability, high abrasive resistance and the like, and is capable of solving problems in the prior art that cost is high, ageing is easy and service life is short, the material is harmful to a human body in a construction process, the construction technology is complicated, the bonding strength of a bonding surface of old and new materials is low, integrality of a repairing structure is weak,longer maintenance time is needed and the like.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Ultra-thin layer repairing agent and construction technology thereof

The invention discloses an ultra-thin layer repairing agent, which comprises a polymer modified polymer liquid material and cement powder according to a mass ratio of 1: 4, wherein the polymer modified polymer liquid material comprises the following raw materials in percentage by weight: 40-65% of modified polymer building emulsion, 30-55% of clean water, 1-5% of a film forming additive, 0.1-0.5%of butyl citrate, 0.1-0.5% of a bactericidal preservative, 0.1-1% of a dispersant and 0.2% of a defoaming agent; the cement powder comprises the following raw materials in percentage by weight: 30-50%of ultra-high strength low alkalinity sulphoaluminate cement, 10-30% of ordinary portland cement, 5-20% of heavy calcium, 1-10% of an expansion agent, 20-40% of refined high wear-resistant graded stones, 0.1-1.5% of a high-performance polycarboxylate water reducer, 0.01-0.5% of a high-efficiency setting accelerator / retarding material, 0.1-5% of redispersible latex powder and 0.01-0.07% of a powder defoamer. The ultra-thin layer repairing agent has the advantages of high strength, high adhesion, good wear resistance, noise reduction, low shrinkage rate, no crack, etc.

Owner:LANXI SANLI BUILDING MATERIALS

Method for producing cedar laminated wood board

InactiveCN103481339AWide variety of sourcesSoft materialWood veneer joiningPulp and paper industryHardness

The invention relates to the technical field of manufacturing of composite boards, in particular to a method for producing a cedar laminated wood board. The method specifically comprises the following steps: making a half-finished core veneer by taking cedar raw wood as a major raw material; combining into a finished laminated wood board. Due to the implementation of the production method, the utilization ratio of the used cedar raw material is up to about 90 percent, and the utilization ratio of other raw materials is only about 70 percent; the hardness and flatness of a formed finished product are superior to the conventional laminated wood board, the board flatness is high, and the board is prevented from being deformed easily, is light in weight and is beneficial to use; the cedar laminated wood board can be efficiently protected from dampness and corrosion. Due to the implementation of the method, value of cedar wood can be added in a multistage way, and the industrial added value is increased.

Owner:GUANGXI LINGYUN YONGJIAN WOOD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com