Low-alkaline sulphur-resisting portland cement for road and production method thereof

A technology of road silicate and production method, which is applied in the field of low-alkali-sulfur-resistant road portland cement and its production, can solve the problems of inability to meet demand, high production cost, single performance of road portland cement clinker and the like , to achieve the effect of small dry shrinkage, strong sulfate resistance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

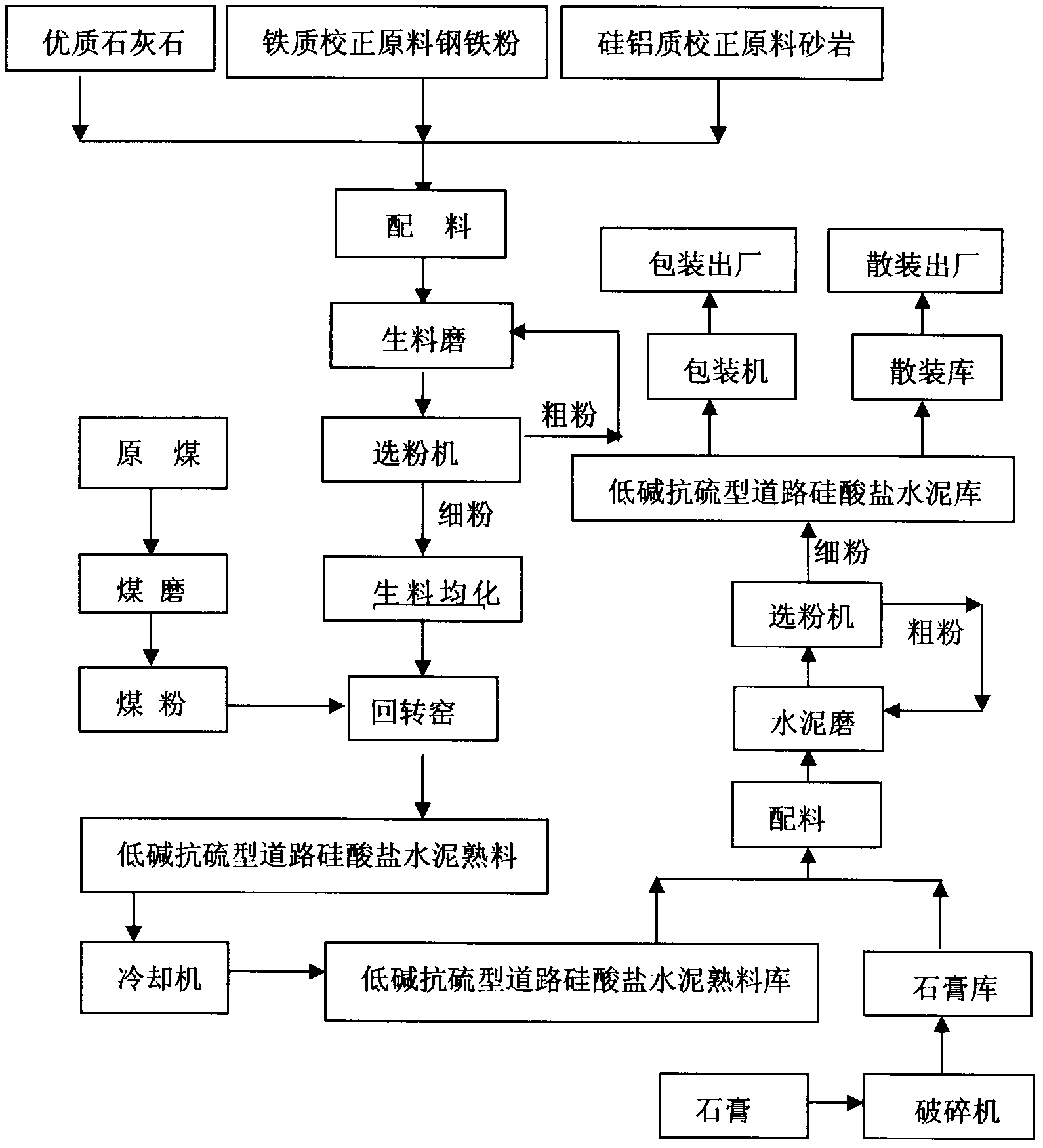

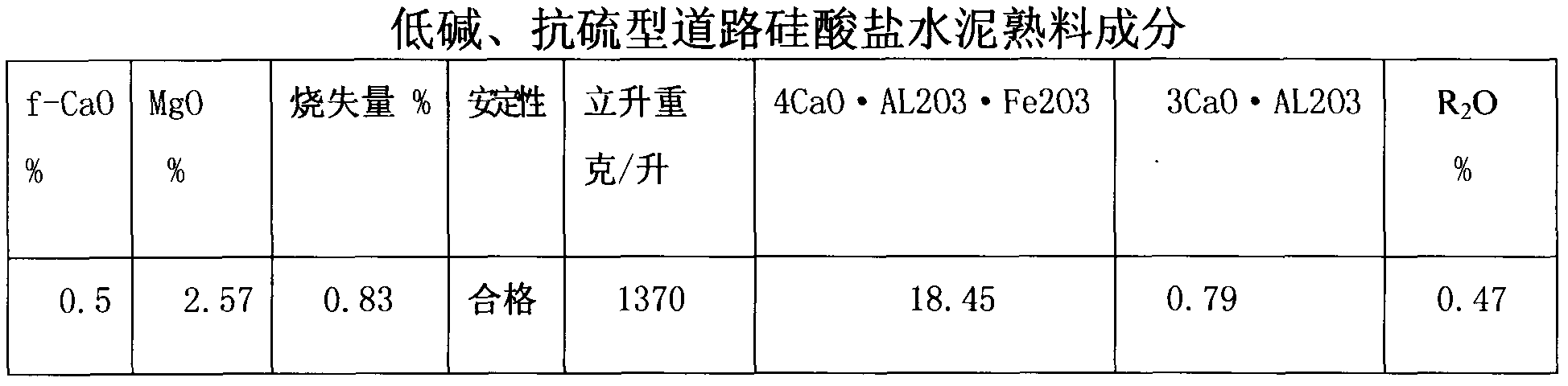

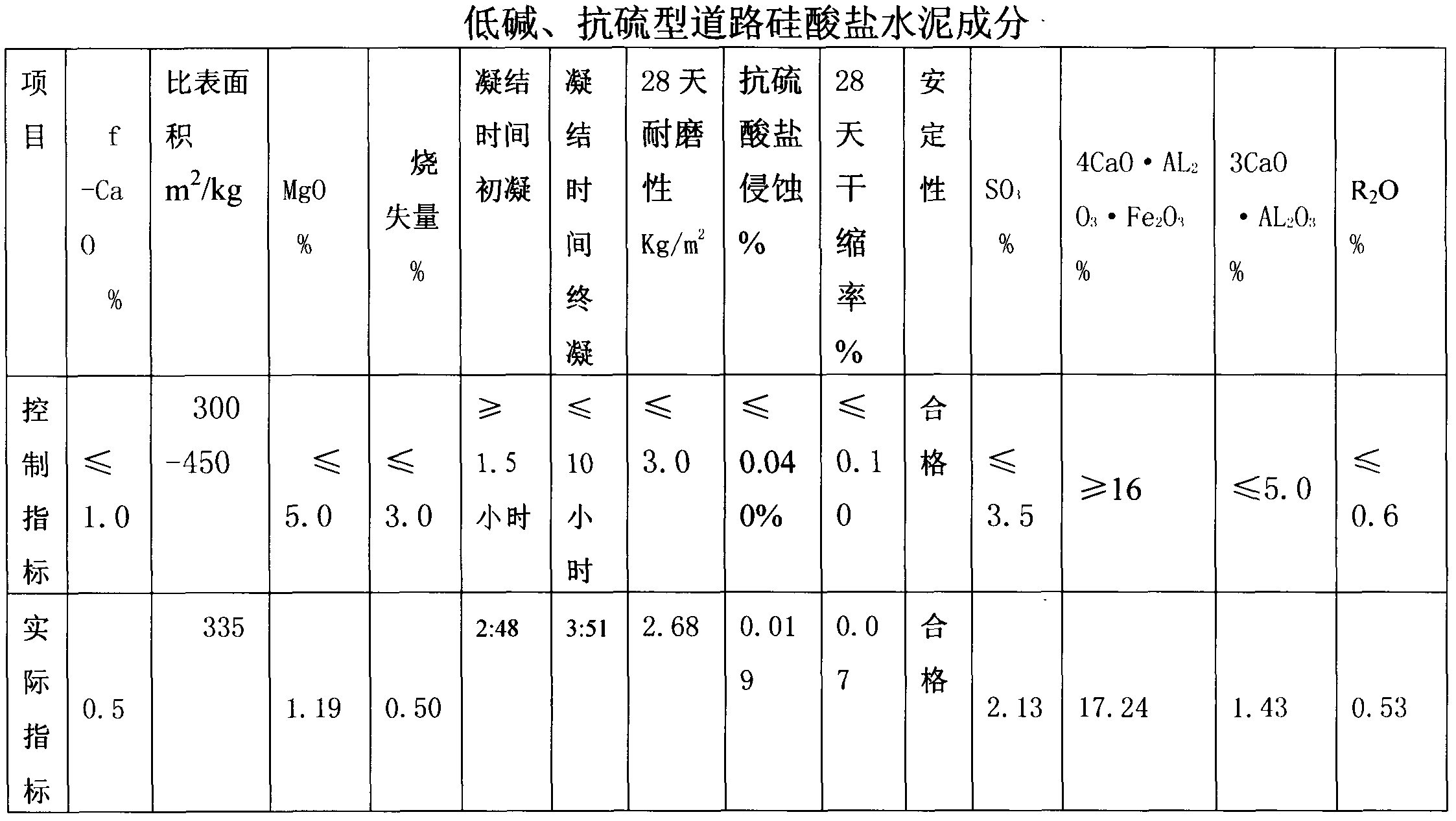

[0019] The invention uses high-quality limestone, sandstone and iron and steel powder with low alkali content as raw materials, and mixes 4%-8% of low-alkali iron and steel powder, 80%-82% of low-alkali limestone and 12%-14% of low-alkali sandstone to produce cooked material; then the clinker and low-alkali natural gypsum are ground in a certain proportion to make low-alkali sulfur-resistant road Portland cement.

[0020] In the present invention, 80%-82% of low-alkali high-quality limestone, 4%-8% of ferrous correcting raw material iron and steel powder, and 12%-14% of silicon-aluminum correcting raw material sandstone are batched into ¢2.4×13 Raw meal mill produces raw meal that complies with GB 13693-2005 road Portland cement clinker composition; then the raw meal is homogenized at 0.03-0.05Mpa pressure and then enters the rotary kiln; rotary kiln control parameters: calcination temperature of 1100-1300°C , The negative pressure of the kiln system is controlled at 2-4 kPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com