Light-weight dry-mixed masonry mortar

A technology of masonry mortar and dry powder, which is applied in the field of masonry mortar, which can solve the problem of cohesion, water retention, deformation, flexibility, impermeability, air content, poor hardness, and it is difficult to guarantee the use function of wall materials without endowing them Mortar quality and other issues, to achieve the effect of low drying shrinkage, good workability, and good heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The cement used in the light dry powder masonry mortar of the present invention adopts the ordinary Portland cement specified in GB175-2007.

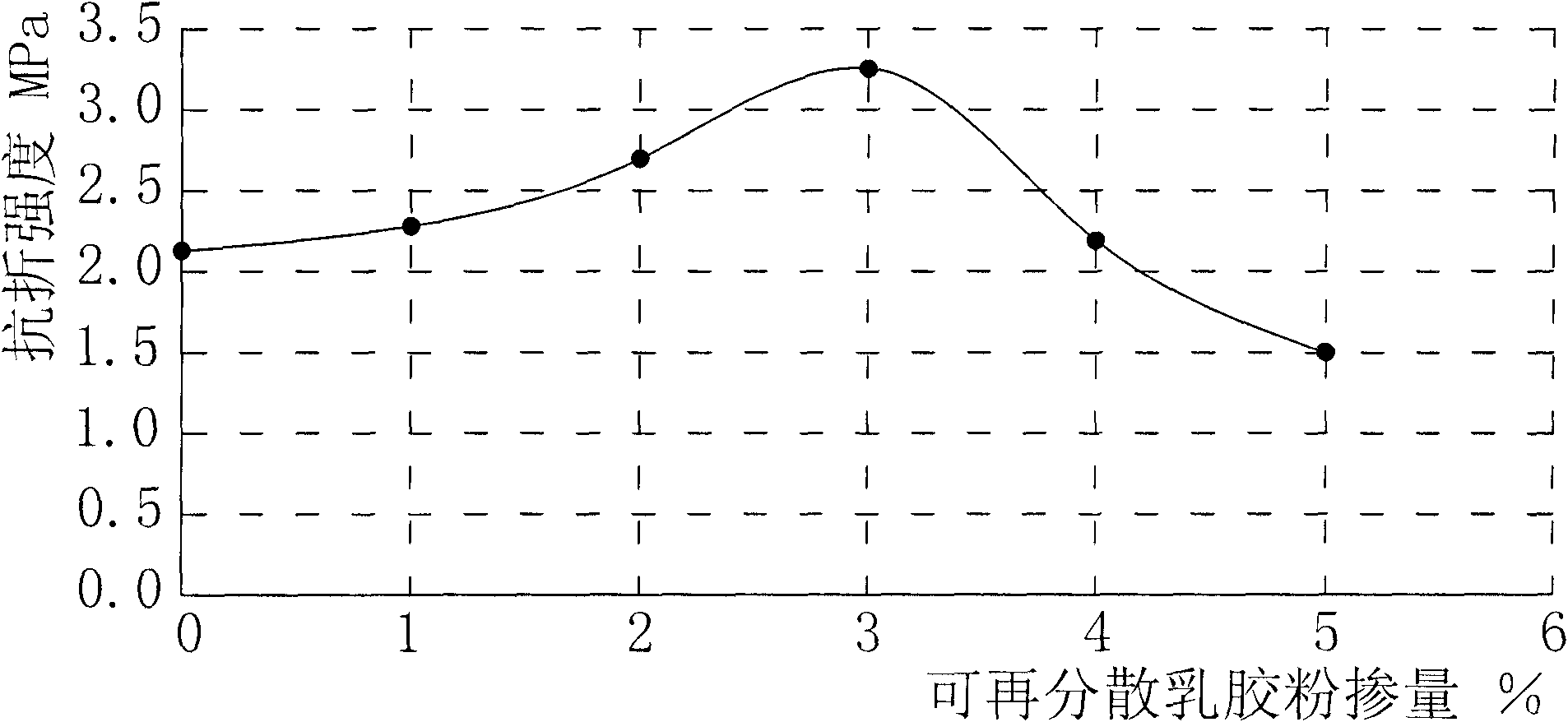

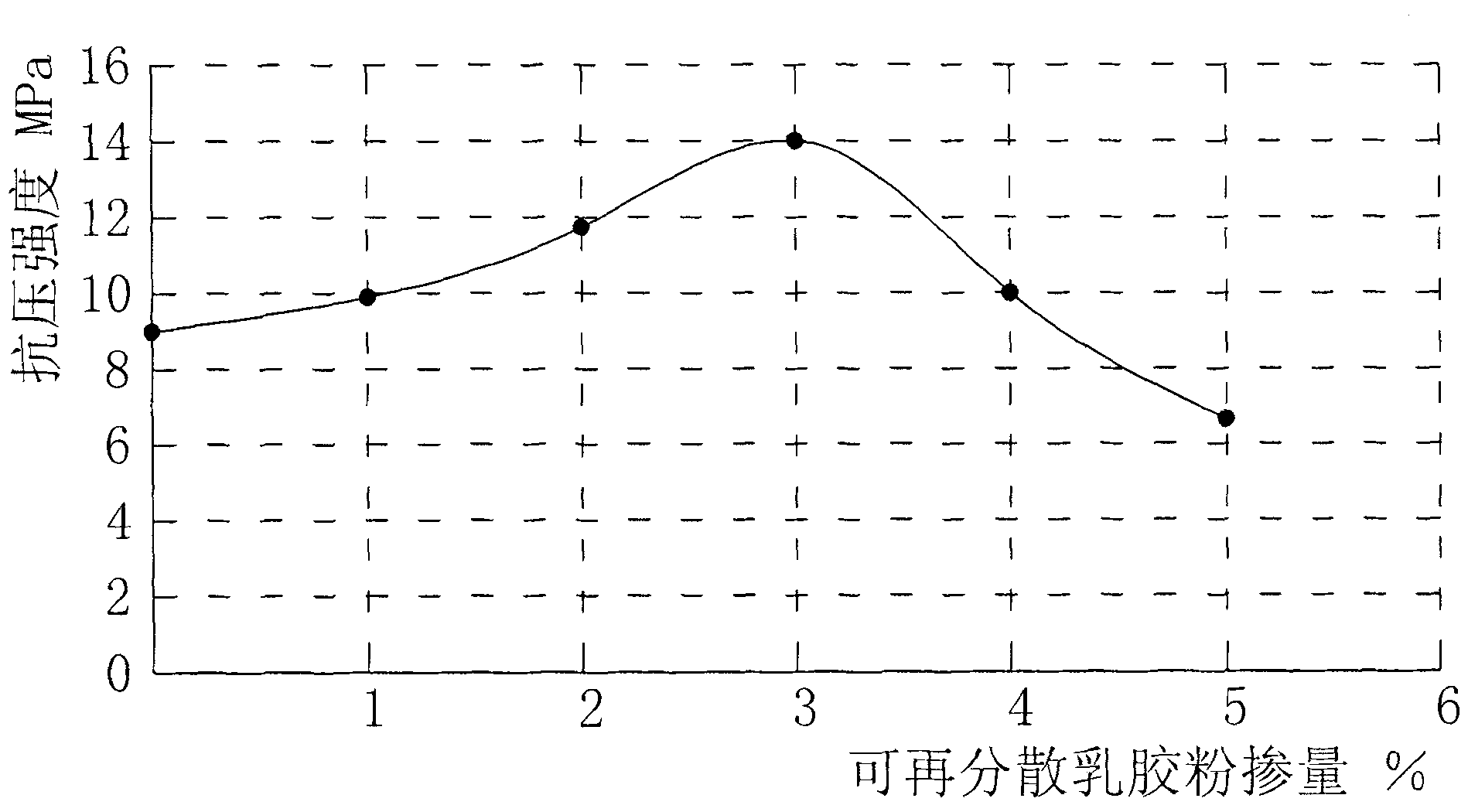

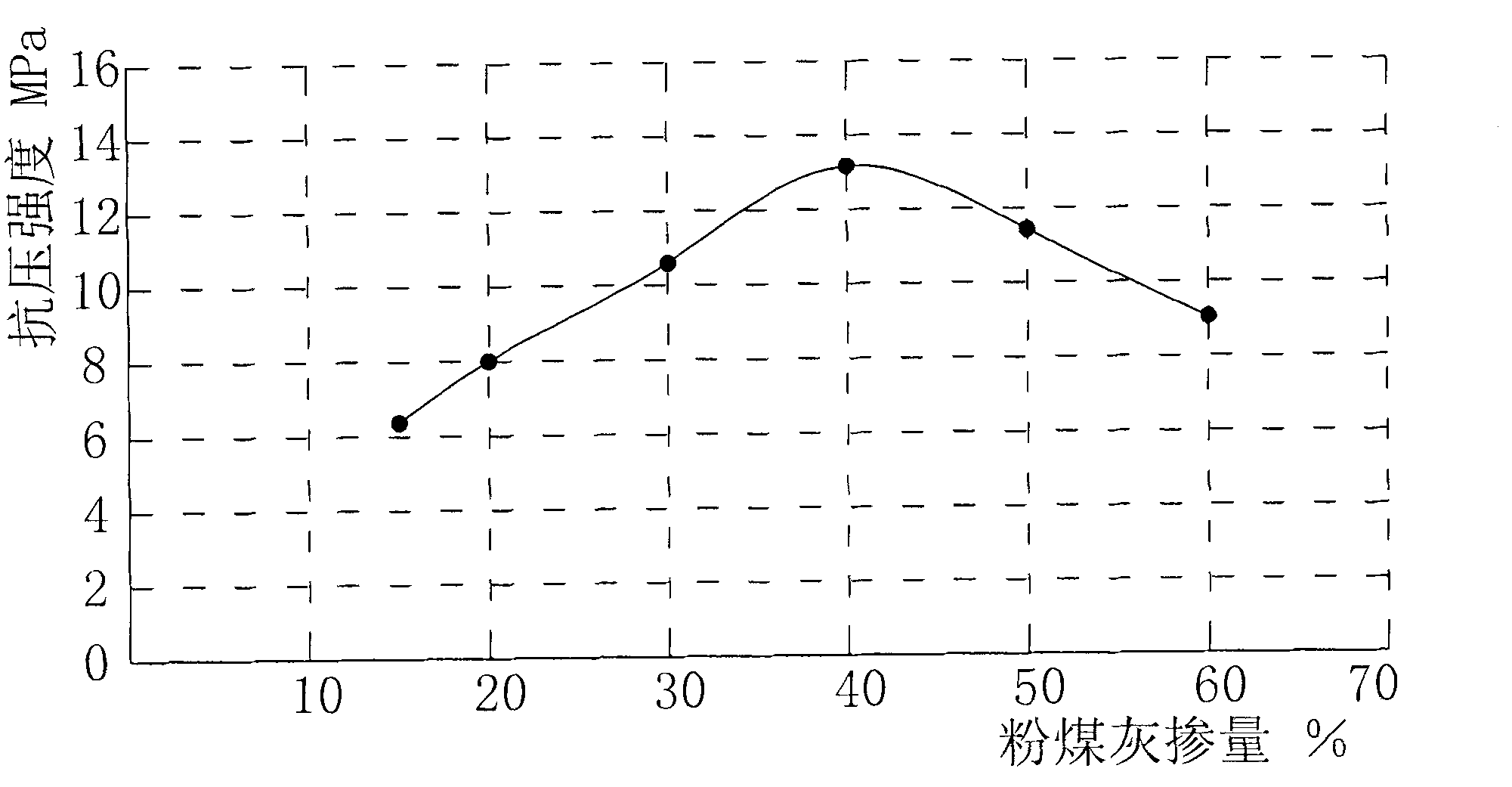

[0025] The redispersible latex powder used is water-soluble, and can be well dispersed under general stirring, and is dissolved in alkali to make the solution viscous. It forms a latex in water, which is very good for various substances. Adhesion, improve the workability of mortar, have obvious thickening effect on mortar, can obviously improve the water retention of fresh mortar and reduce the water absorption of hardened mortar. Due to its plasticizing effect on the mortar, the water-cement ratio can be reduced while maintaining the original fluidity, so that the mechanical properties can be improved and improved. With the increase of the content of dispersible polymer powder, the consistency of thermal insulation masonry mortar decreases, the viscosity increases, the layering degree decreases, and the cohesion and water retent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com