Patents

Literature

120results about How to "Reduce dust pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

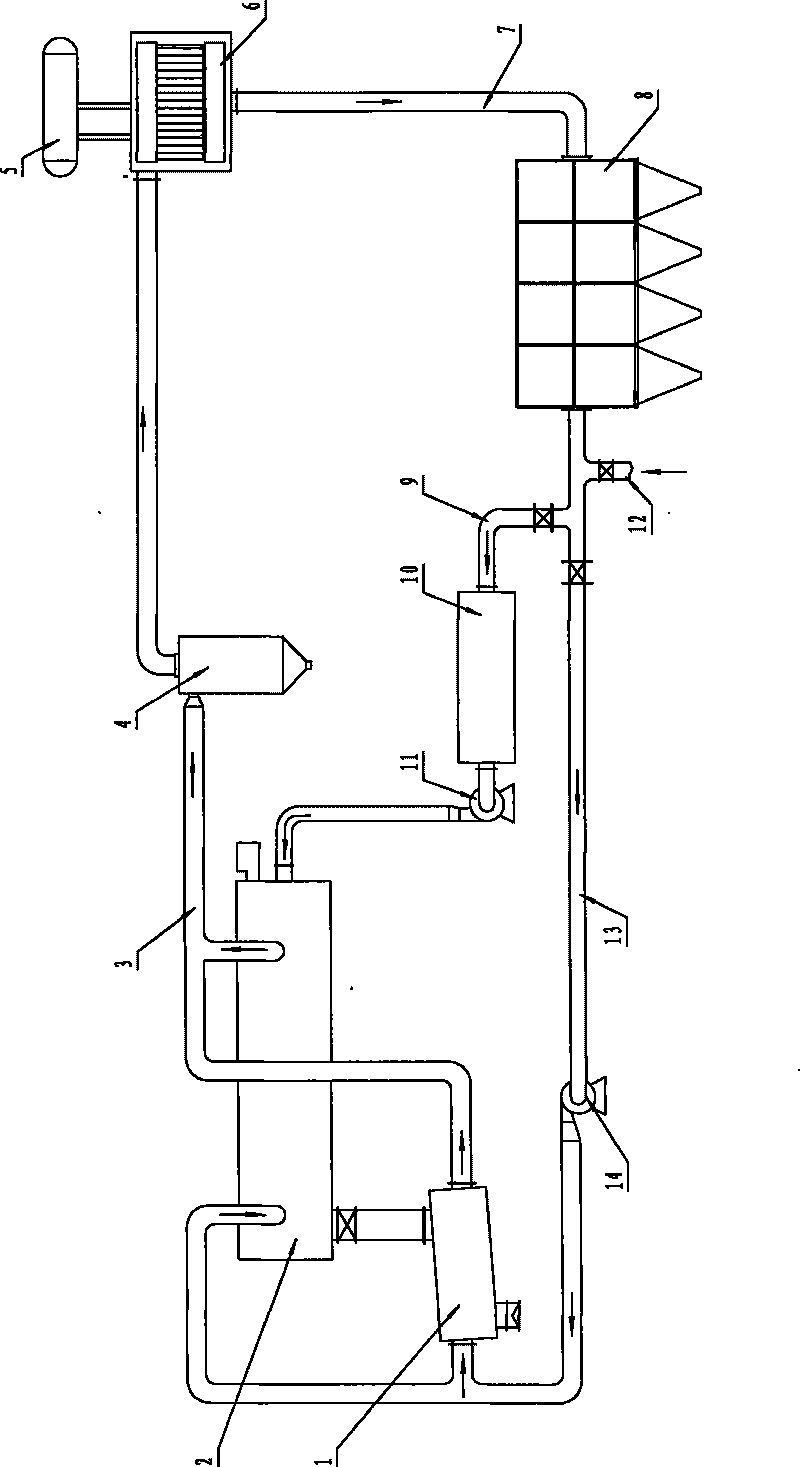

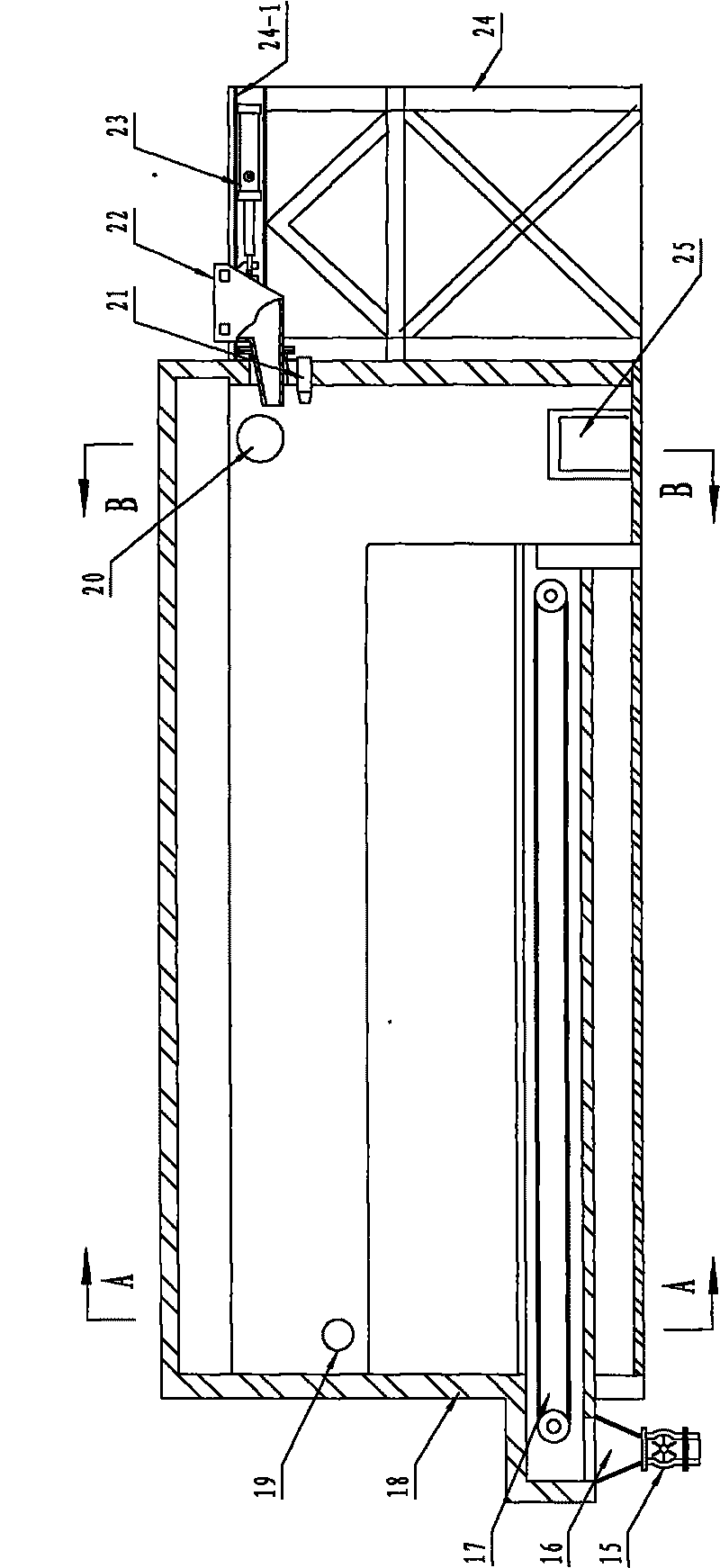

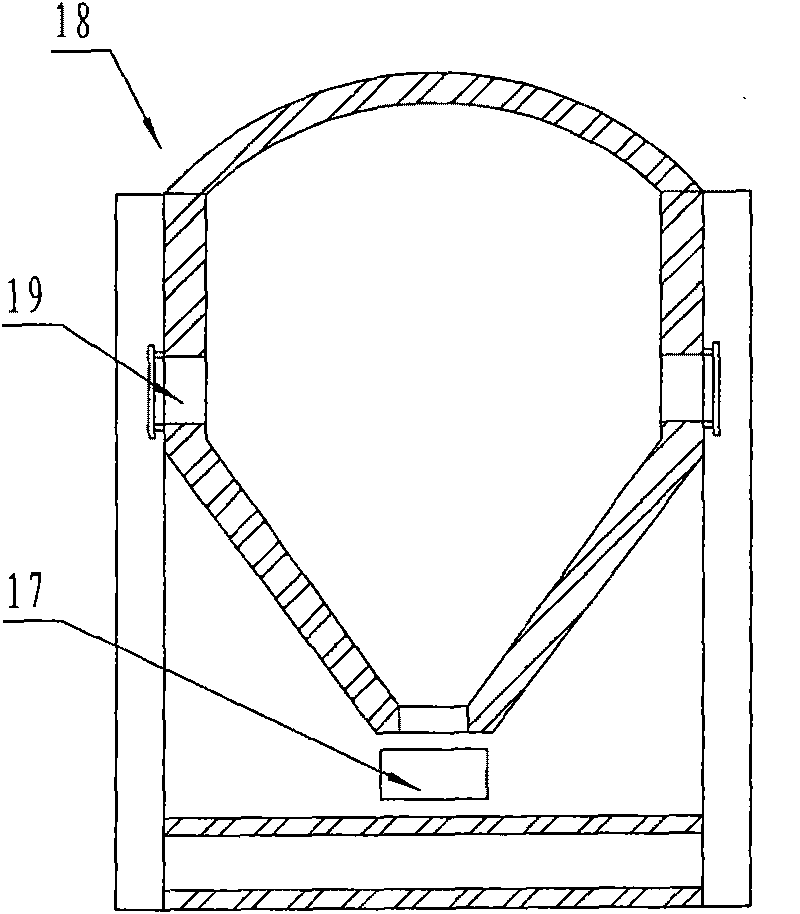

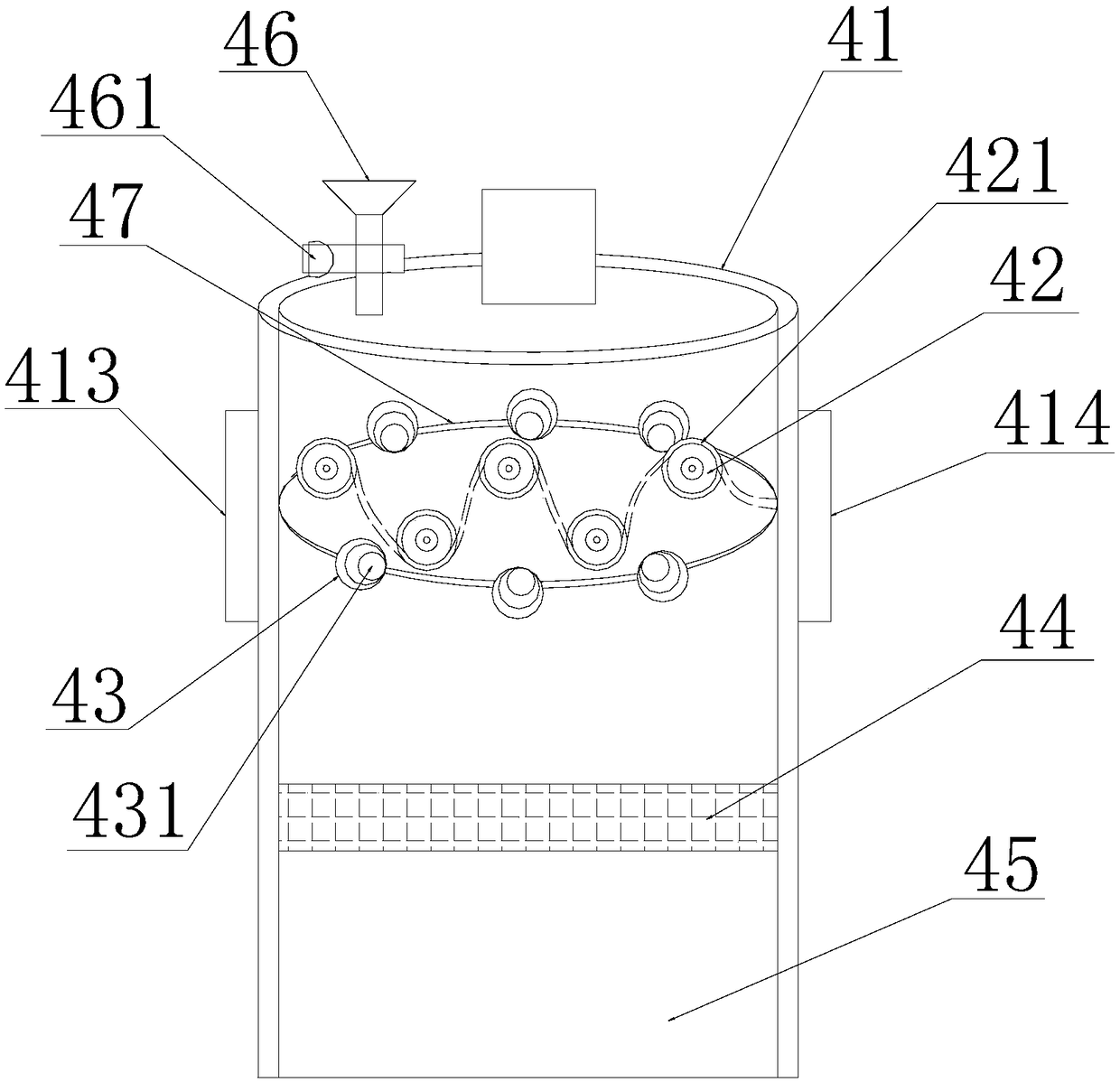

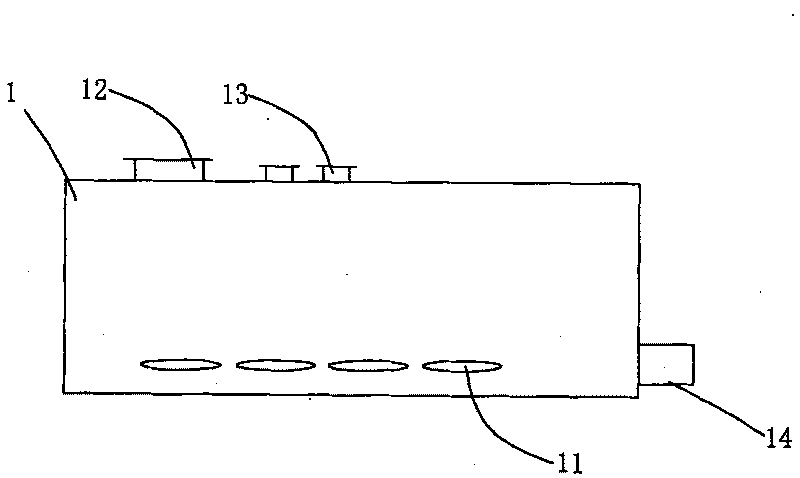

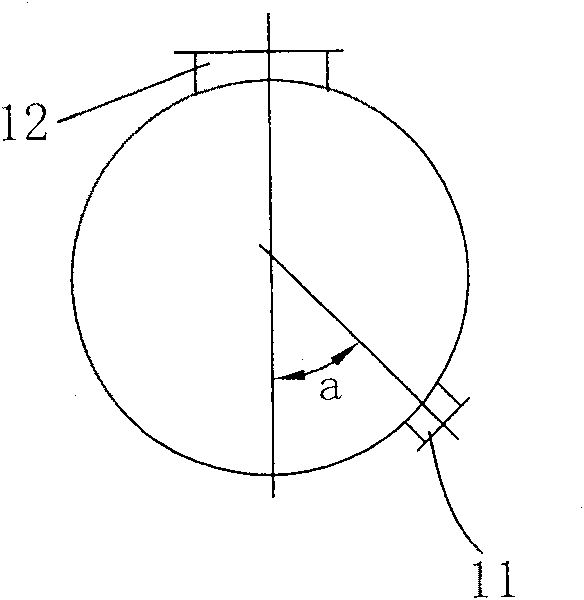

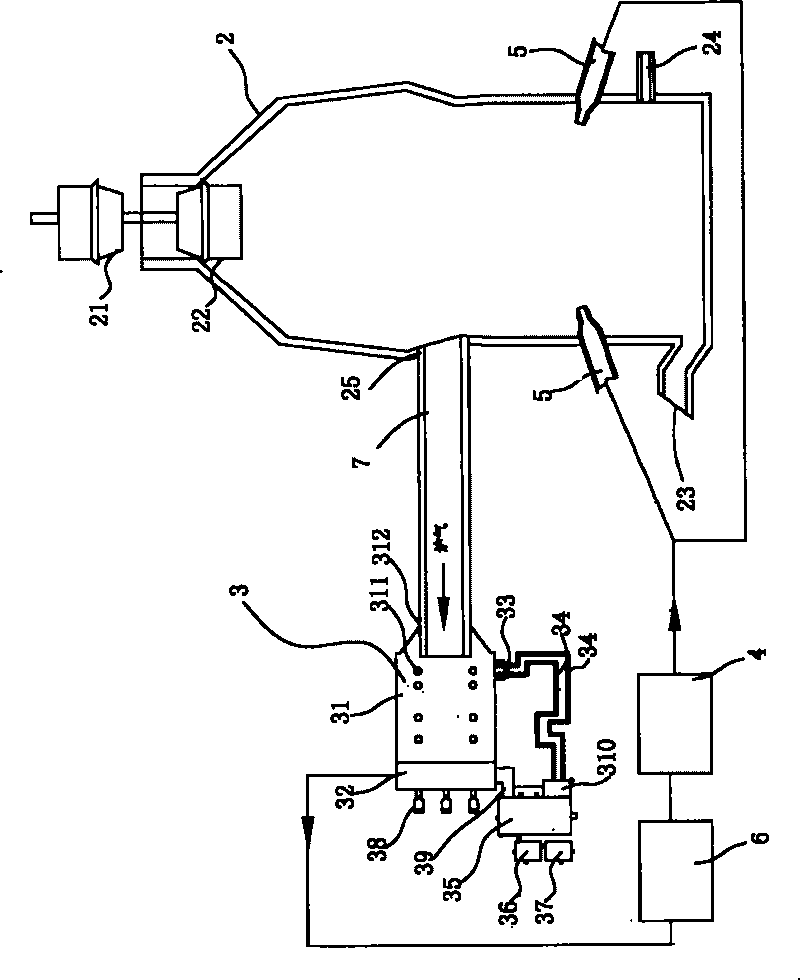

Process and device for processing liquid steel slag

ActiveCN101691620AImprove economic efficiencyReduce dust pollutionRecycling and recovery technologiesProcess efficiency improvementSlagLiquid steel

The invention provides a process and device for processing liquid steel slag, belonging to the technical field of the metallurgical equipment and aiming at solving the problems of liquid steel slag granulation and liquid steel slag sensible heat recovery. The process for processing the liquid steel slag comprises the following steps: a, granulating the liquid steel slag by quenching gas; b, cooling the high-temperature liquid solid steel slag; c, recovering liquid steel slag sensible heat; and d, reusing cooling gas. The invention also provides a device for processing liquid steel slag. The invention is mainly characterized in that firstly, the liquid steel slag is granulated in a sealed granulating tank, the liquid steel slag is small and uniform, the pure Fe in the liquid steel slag can not be oxidized and the economic benefit of the liquid steel slag processing process is improved; secondly, the liquid solid steel slag is cooled in a sealed cooling tank, less cooling gas leaks, the dust pollution is reduced, and less cooling gas is supplemented; and thirdly, the inert gas is used as the cooling gas in the granulating tank and the cooling tank, and the cooling gas inversely exchanges heat with the liquid steel slag, thus the efficiency of exchanging heat between the liquid steel slag and the cooling gas is improved, the temperature of the cooling gas at the outlet is increased, and the liquid steel slag sensible heat is recovered.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

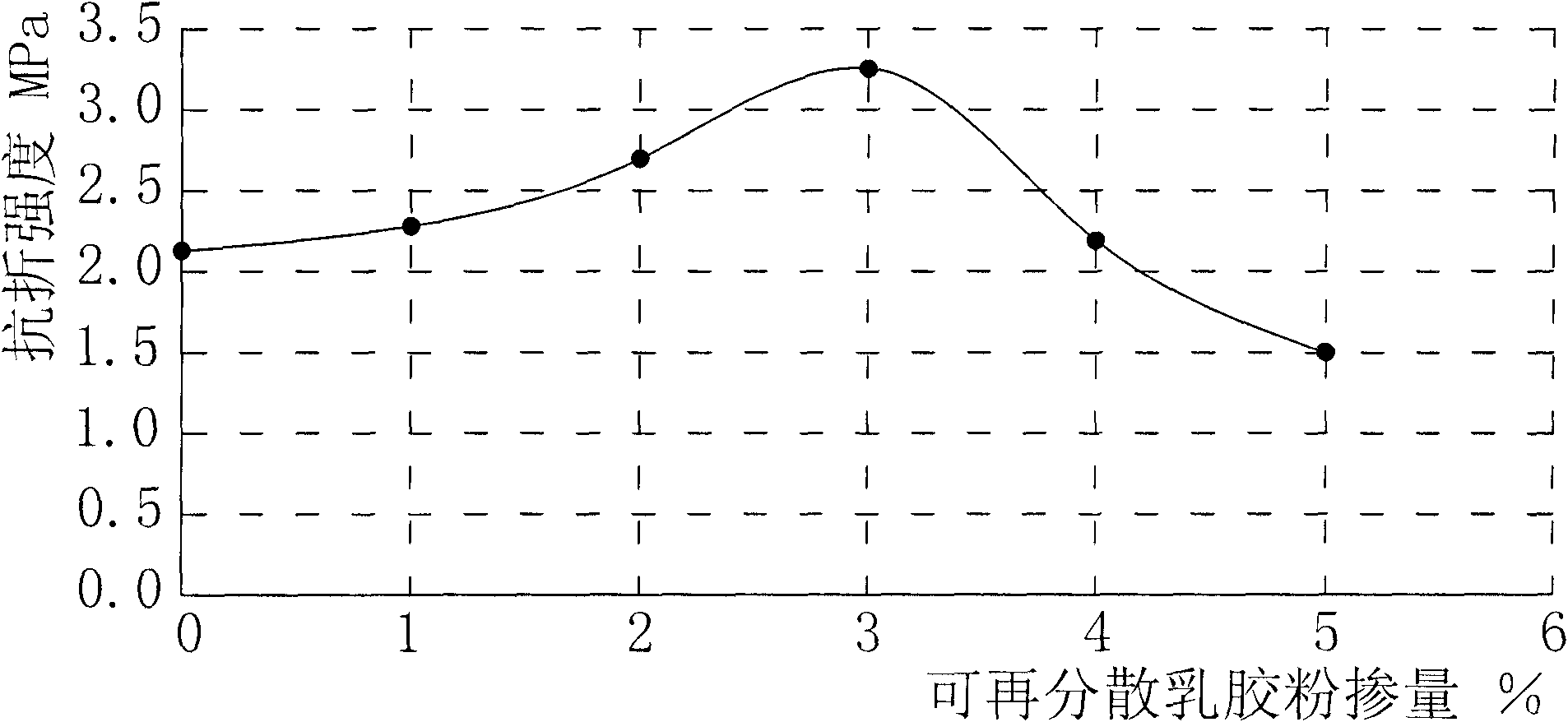

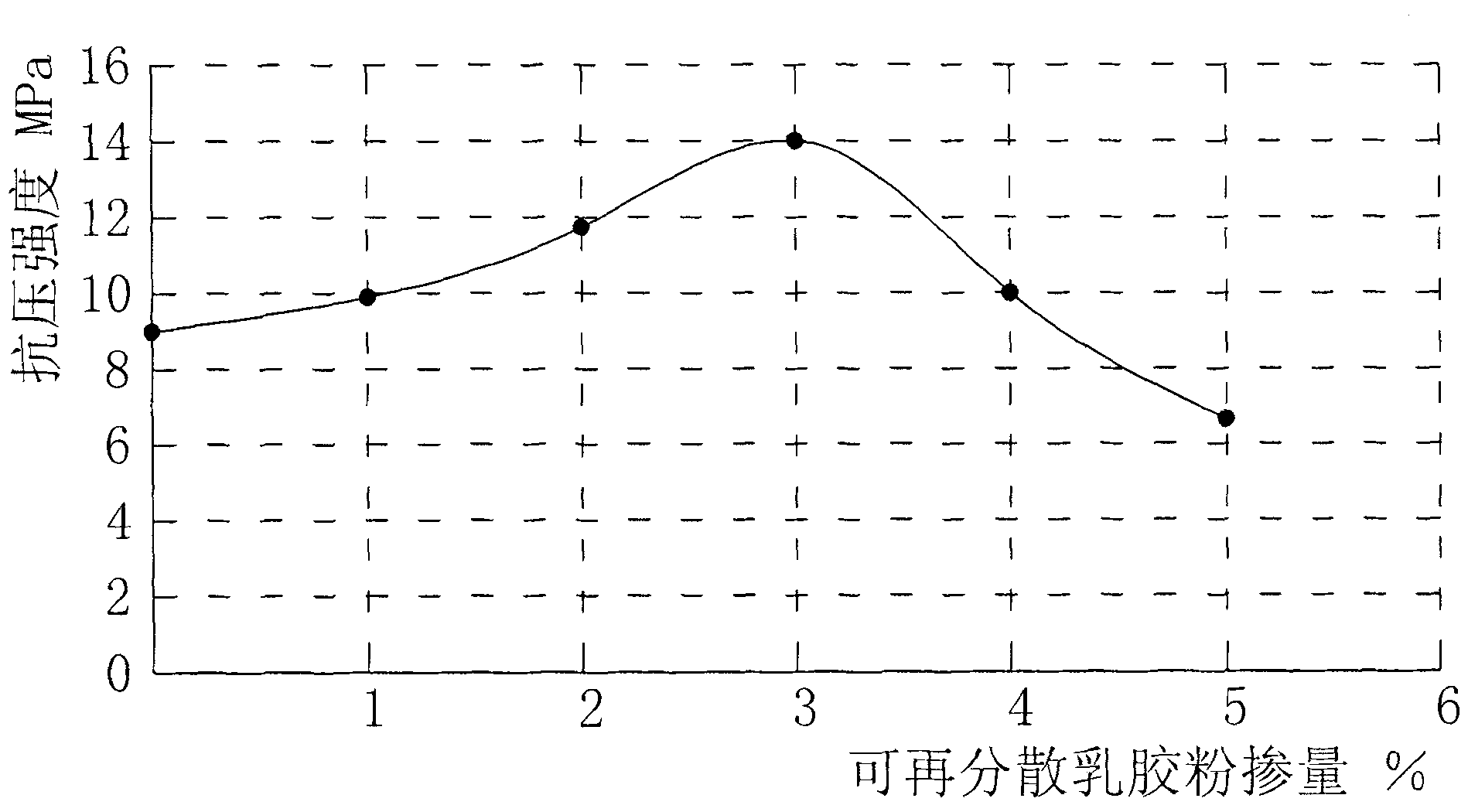

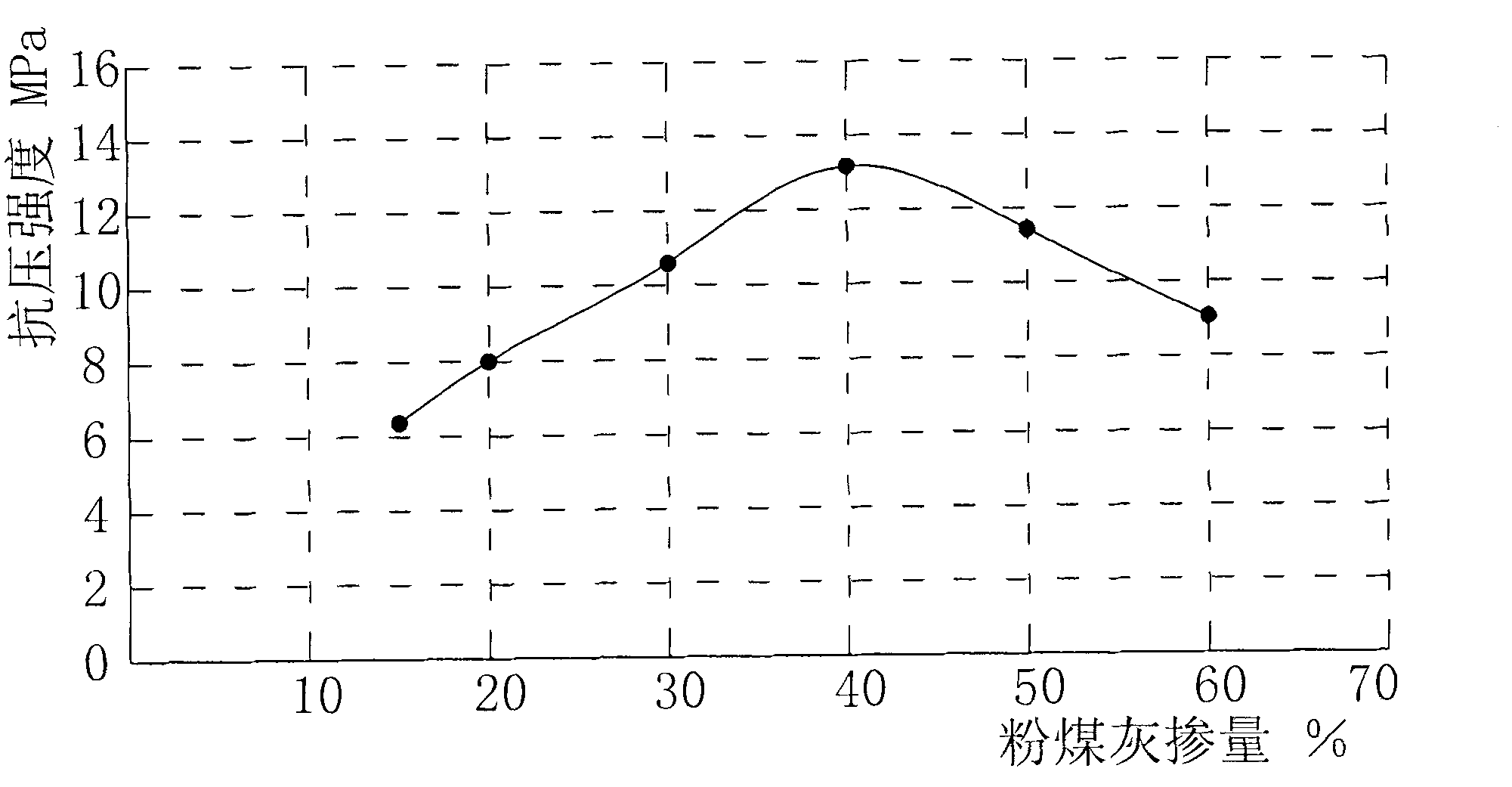

Light-weight dry-mixed masonry mortar

The invention discloses light-weight dry-mixed masonry mortar. The light-weight dry-mixed masonry mortar comprises the following components in percentage by weight: 200 to 300 percent of concrete, 80 to 120 percent of pulverized fuel ash, 400 to 1,400 percent of aerated concrete gains, 80 to 140 percent of vitrified beads, 0.8 to 1.6 percent of PP fibers, 2 to 12 percent of latex powder, and 3 to 15 percent of compound air entraining agent. The mortar has the advantages of avoiding field stirring and mixing, reducing construction dusts and noise pollution and reducing space occupation, along with precise mixing ratio, small concrete use amount, low cost, only need of adding water and mixing uniformly during construction, small material consumption and waste, convenient storage and transport and use, high binding strength, low shrinkage, high freezing resistance durability, low conductivity, good heat preservation, good workability, convenient construction, and the like; by substituting the aerated concrete gains for sand and using the pulverized fuel ash, the light-weight dry-mixed masonry mortar has the characteristics of industrial waste utilization, environmental protection, and low cost.

Owner:JIANGSU RONGNENG GROUP

Mining technology for gold ore

InactiveCN105649630AReduce noise and dust pollutionHigh recovery rateUnderground miningSurface miningGold oreMineralogy

The invention provides a mining technology for gold ore. The mining technology comprises a parameter determining step, wherein various parameters of a stope are determined according to the vein trend of the stope; a stope preparation cutting step, wherein according to the parameters, a haulage roadway, a stope preparation raise, connection roadways, a footwalling and a funnel of the stope are arranged; a chamber backstoping step, wherein a shallow hole backstoping mode is adopted, and backstoping is conducted in a layered mode from a footwalling roadway from bottom to top; a pillar recovery step, wherein a deep hole blasting recovery mode is adopted, through the raise and the connection roadways, upholes are drilled, blasting is conducted, ore is discharged through the chamber funnel, half of pillar studs is recovered, and bottom pillars are not recovered and serve as permanent losses to support chamber top and bottom plates. The ore recovery rate of a mine lot can be increased, the permanent losses in the mine lot can be effectively reduced, and resource waste and economic losses are reduced.

Owner:SHENYANG KUNYUAN TECH SERVICES LTD

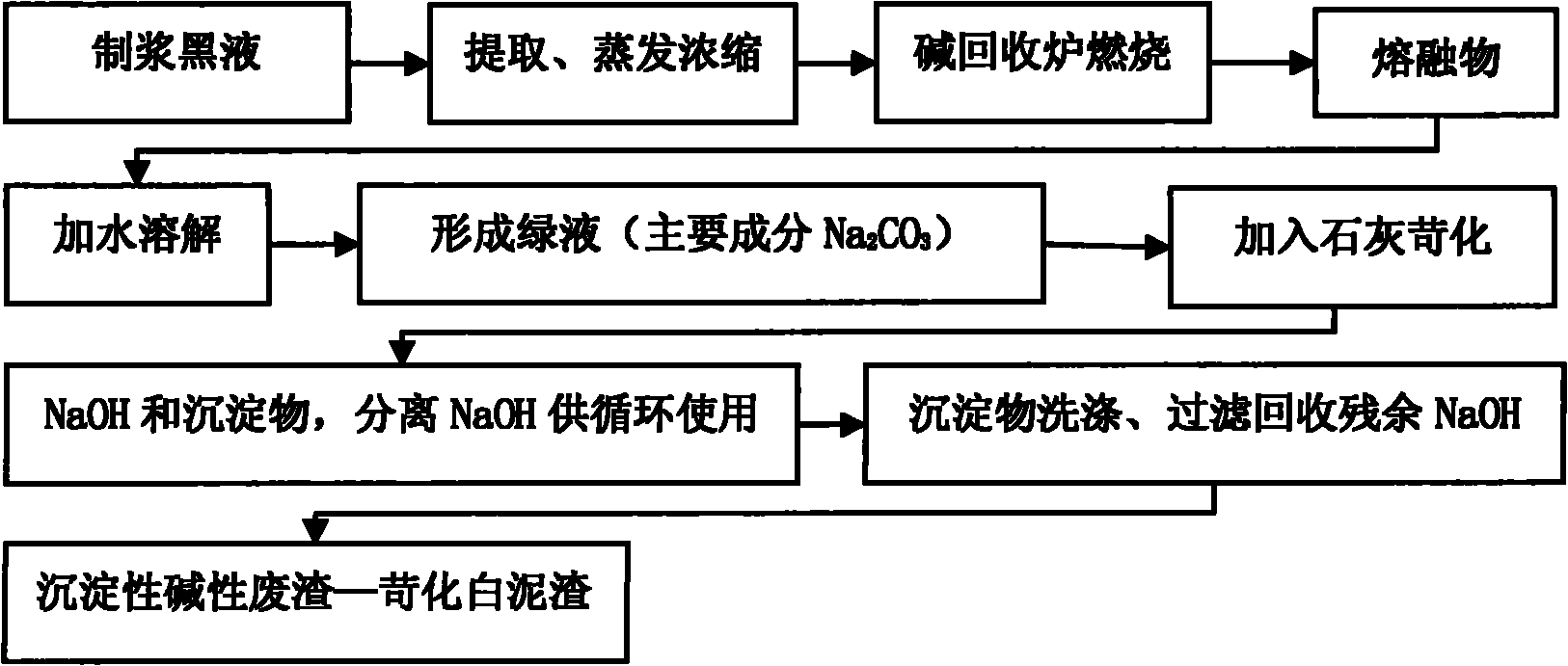

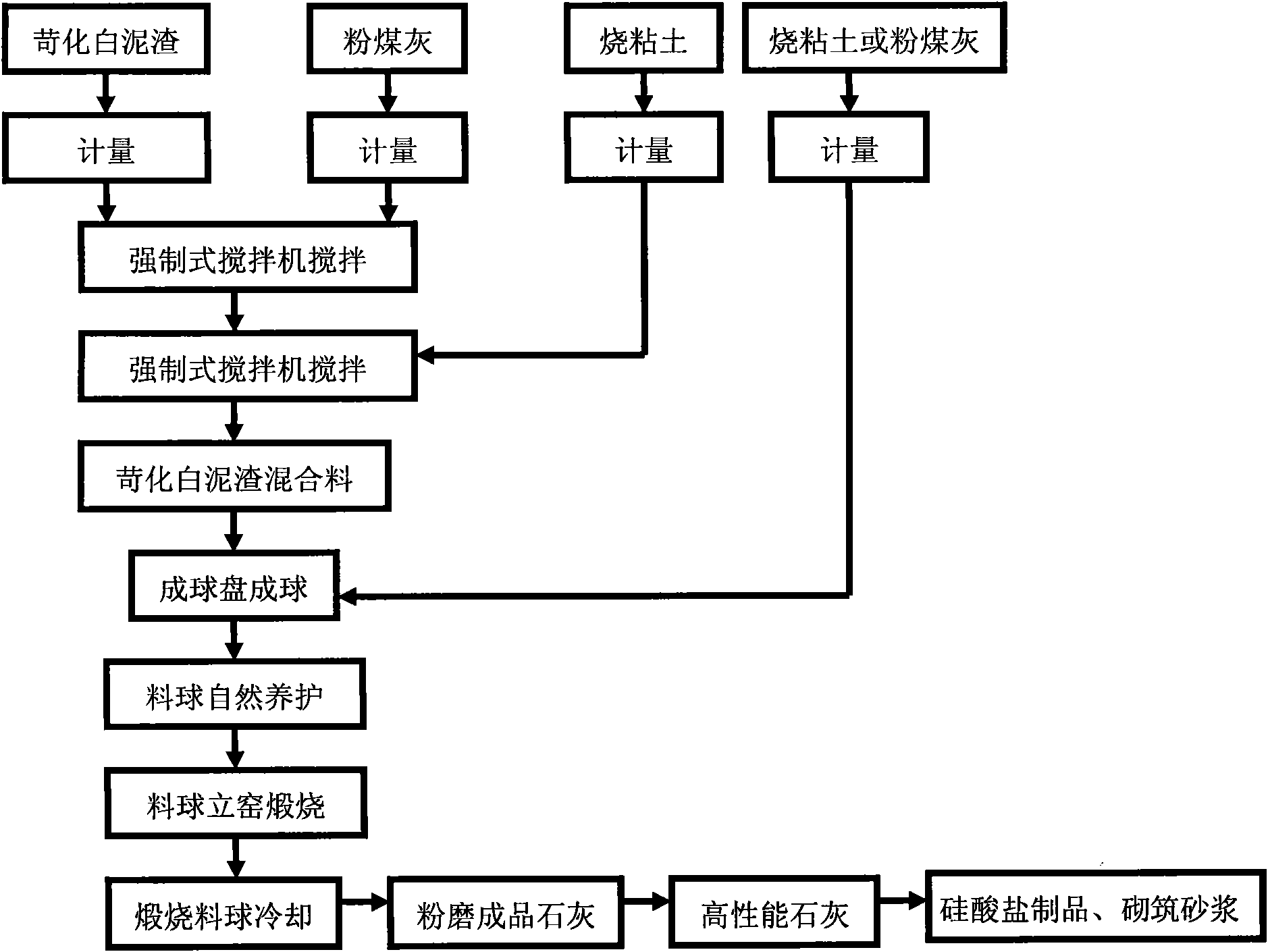

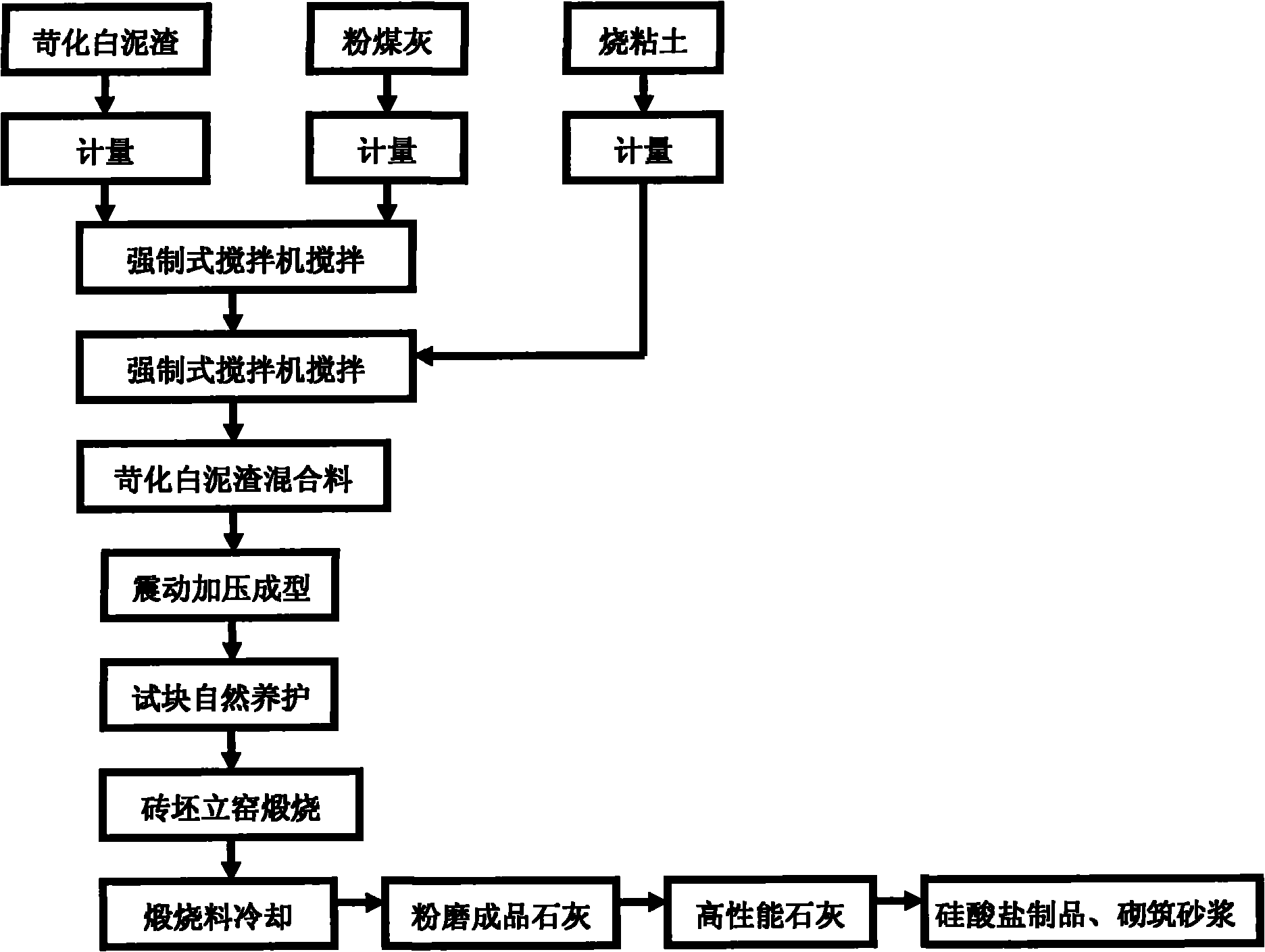

Method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge

InactiveCN102070309AReduce dust pollutionReduce moisture contentSolid waste managementPapermakingSludge

The invention discloses a method for preparing hydraulic calcium oxide through papermaking alkali recycling causticized white sludge. The method comprises the following steps: preparing a mixture: putting papermaking causticized white sludge and pulverized fuel ash into a forced type stirrer for stirring, and putting burnt clay into the forced type stirrer for evenly stirring to obtain the mixture; molding the mixture: molding by adopting a centrifugal rolling balling method or shaking pressurization method; naturally curing the mixture: putting the molded mixture balls into the natural environment with good ventilation conditions for stacking and curing, and putting adobes into the natural environment with good ventilation conditions for stacking and curing for 7-14 days until the quality of the adobes can not be further reduced and the primary compression strength of the adobes is more than 1MPa; and calcining the material: conveying the cured and dried material balls or adobes intoa shaft kiln for calcining and insulating, then naturally cooling to the room temperature, and milling the calcined products to be used for preparing silicate products. The invention reduces the dustpollution and solves the problem of treatment of pulverized fuel ash.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of brevibacillus brevis water dispersible granules

InactiveCN103563991AReduce dust pollutionReduce moisture contentBiocideFungicidesWater dispersibleChemistry

The invention relates to a formulation of water dispersible granules of a rice blast biocontrol bacteria brevibacillus brevis bactericide and a preparation method thereof. The solid water dispersible granules contain brevibacillus brevis TW strain raw powder (2*10<12> cfu / g) and auxiliaries, wherein the auxiliaries comprise a carrier, a dispersant, a wetting agent, a disintegrating agent, a light protecting agent and a binding agent; a processing method comprises the following steps: mixing the active ingredient and probes of the auxiliaries in a certain proportion, crushing with an air flow, granulating and drying. The obtained brevibacillus brevis water dispersible granules of 4*10<10> cfu / g have a better control effect against rice blast.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS +1

Building blasting integrated dust-removing method

InactiveCN101125335AReduce dust pollutionReduce blasting dust pollutionDirt cleaningNoise pollutionDust pollution

The present invention provides an integrated dust laying method of building blasting, which comprises: before blasting, the building to be demolished is processed by hydroscopic dust depressor solution; then foam is manufactured as much as possible in the blasting scale, which enables the building to be demolished to be surrounded by the foam; at the same time of blasting, active water spray is manufactured in the blasting space so as to further catch the dust. The integrated dust laying method of building blasting of the present invention uses an integrated method that combines the chemical method and the traditional physical method(watering) so as to reduce the dust in the blasting demolition, which reduces greatly dust pollution during the building blasting demolition, and also reduces noise pollution during blasting.

Owner:郑炳旭 +1

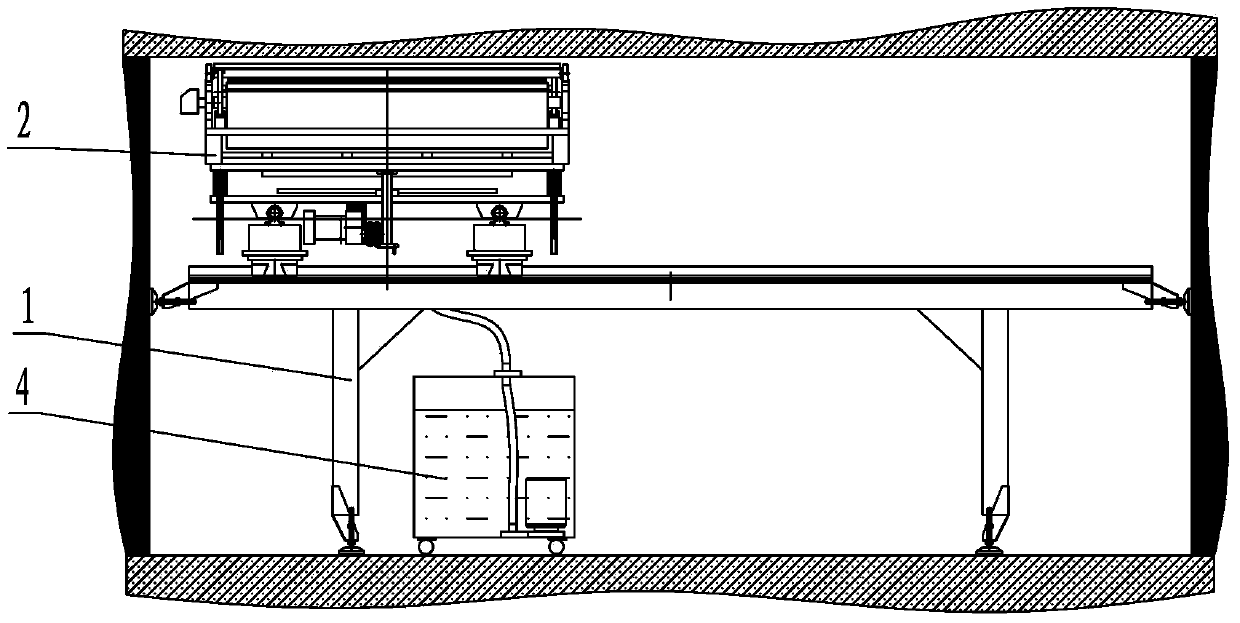

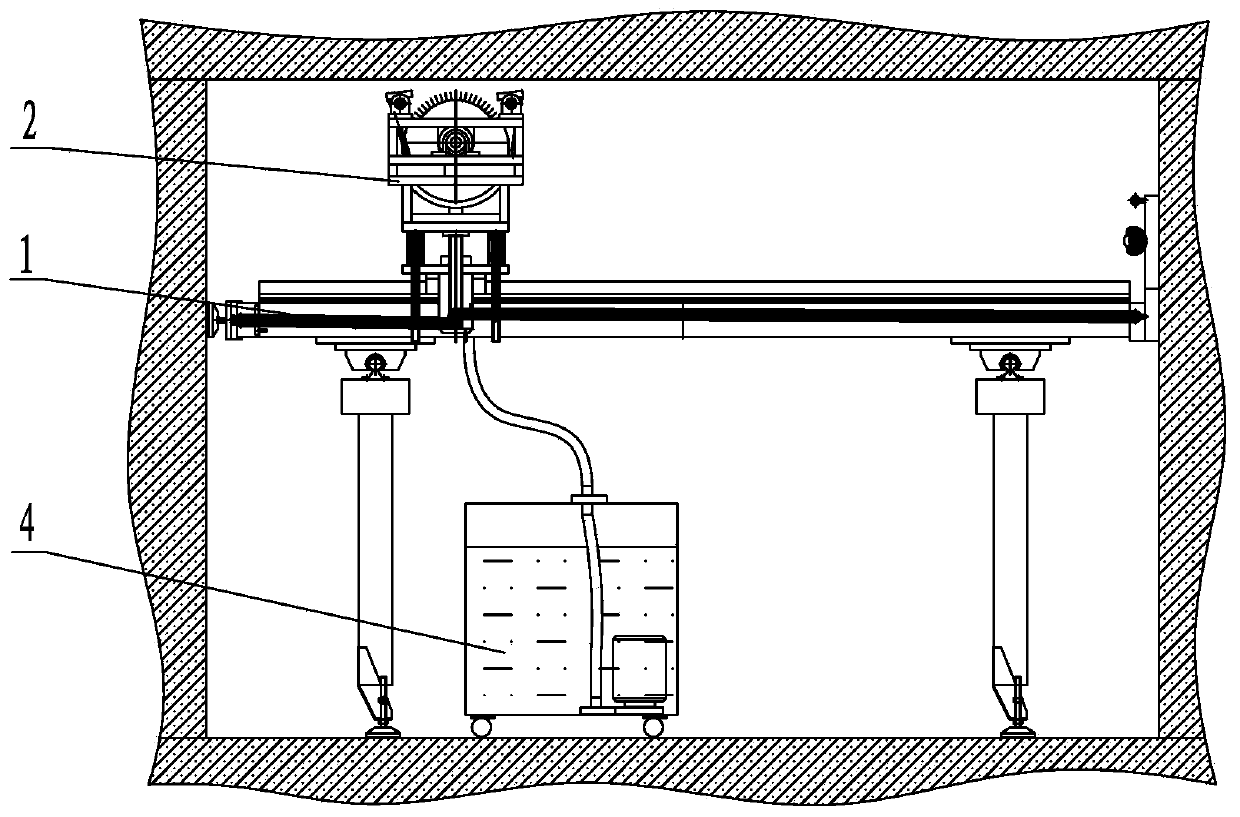

Module assembly-type wall surface and shed surface coating, screeding and polishing device

InactiveCN104047416AImprove adaptabilityImprove toleranceBuilding constructionsEngineeringUltimate tensile strength

The invention belongs to the field of building and relates to a wall surface and shed surface coating, screeding and polishing device, in particular to a module assembly-type wall surface and shed surface coating, screeding and polishing device. The module assembly-type wall surface and shed surface coating, screeding and polishing device aims to solve the problems that an existing wall wiping device cannot conduct coating, floating, polishing and dust collecting at the same time on a wall surface and a shed surface, operation is complex and inflexible, and the work intensity of operators is enhanced. A transversely-moving sliding rail unit is composed of two second rails arranged in parallel side by side and is installed on the upper face of a fixed sliding rail unit. A traveling lifting bracket mechanism is installed on the transversely-moving sliding rail unit. A splashing-type coating and screeding mechanism and a polishing and dust collecting mechanism are installed on the traveling lifting bracket mechanism in an alternate mode and can be connected with a material supplying and dust collecting mechanism in an alternate mode. The lower surface of a first rail of the fixed sliding rail unit is provided with a plurality of supporting uprights provided with adjusting supporting feet at the bottoms.

Owner:哈尔滨佳饰达科技开发有限公司

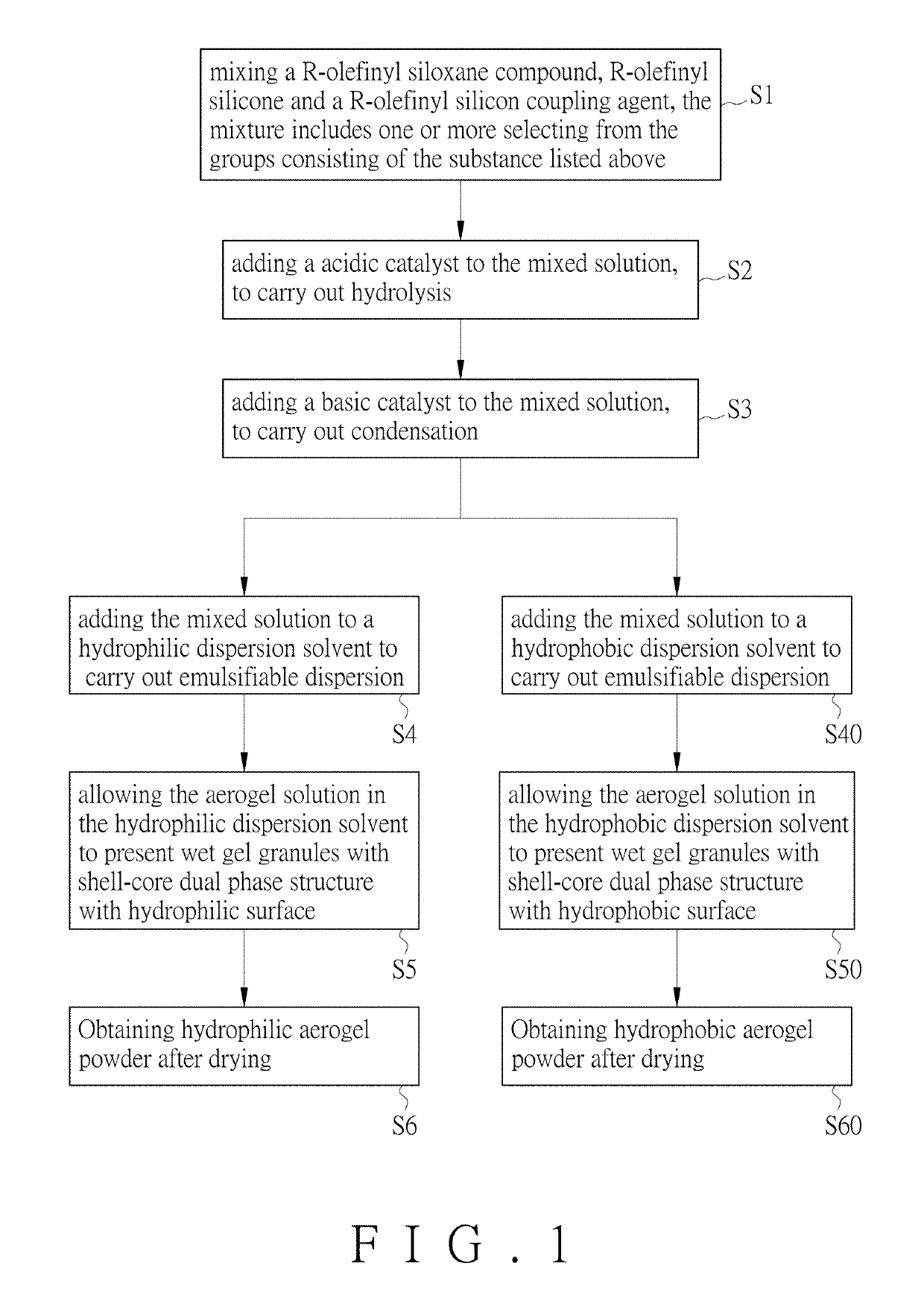

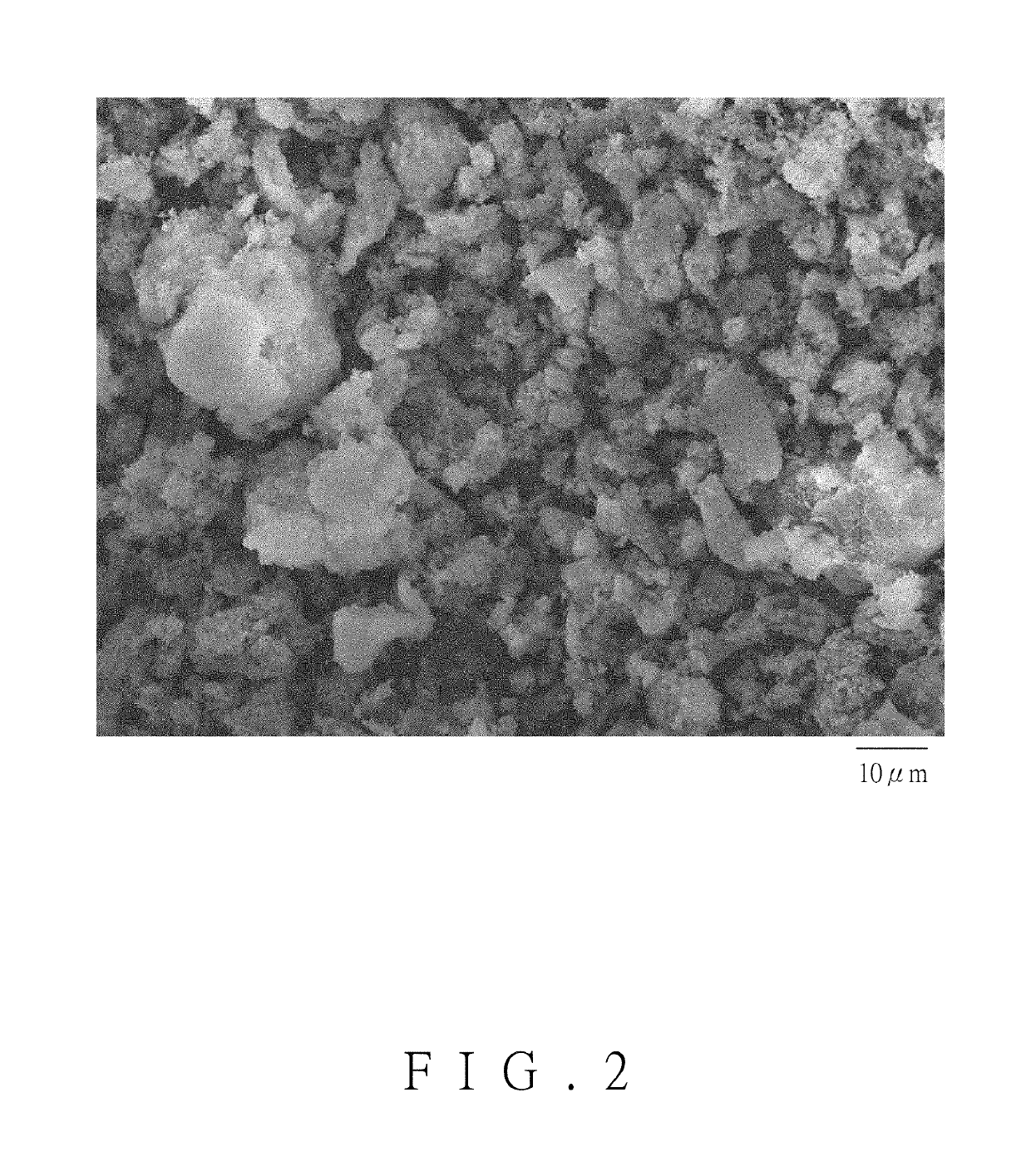

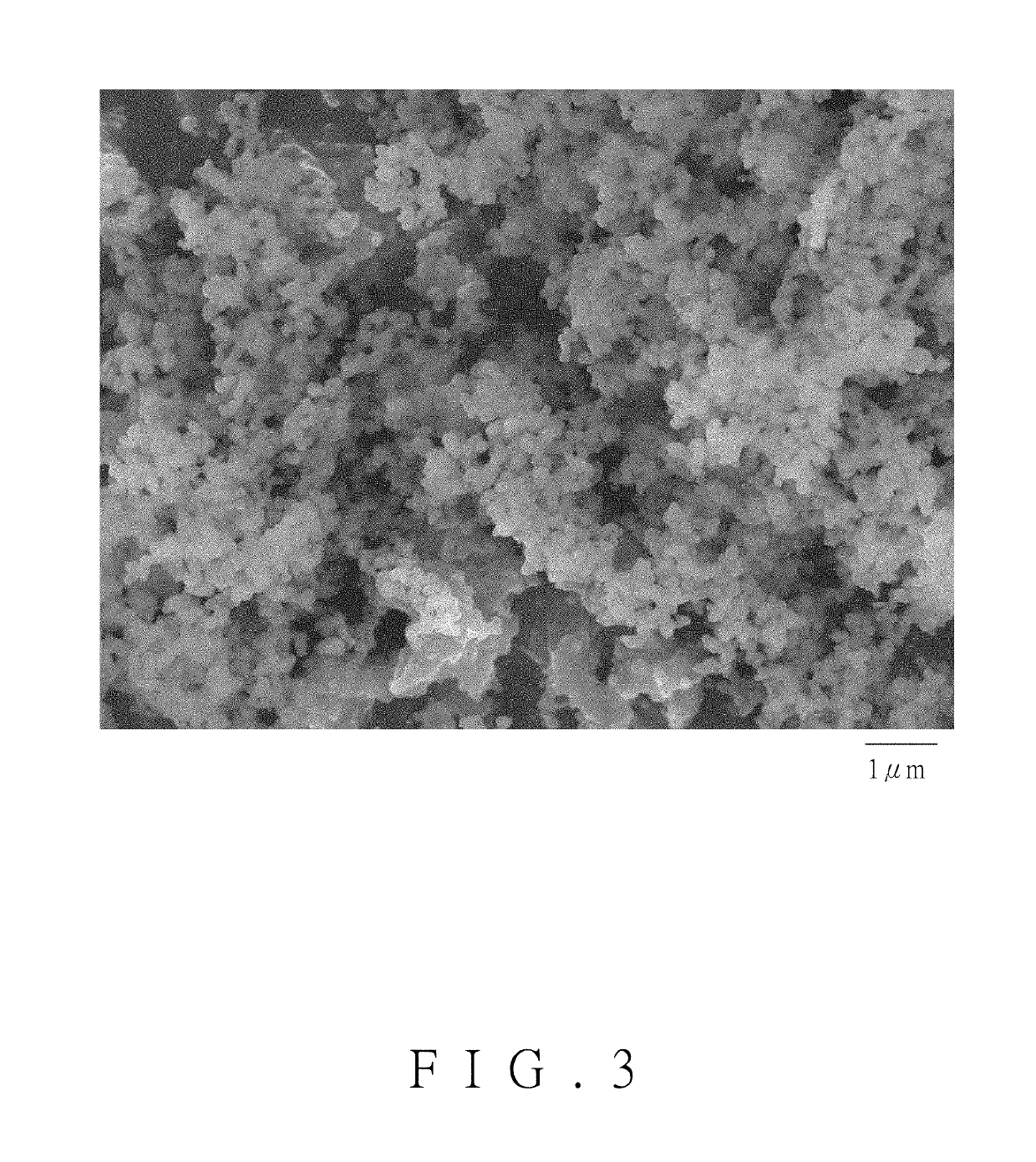

Wet gel granule of aerogel and preparation method thereof

ActiveUS20190160446A1Increase productivityUneven of contaminationAerogel preparationSilicon compoundsSolventHydrolysis

A wet gel granule of aerogel is prepared by the following steps: mixing step: mixing with an organic mixed solvent to form a mixed solution; hydrolysis step: adding an acid catalyst to the mixed solution for carrying out a hydrolysis reaction, and adding a dispersion solvent during the condensation reaction, and agitating to gel the mixed solution during agitation and produce multiple hydrophilic or hydrophobic wet gel granules of aerogel. The overall preparation speed can be shortened quickly and at the same time the hydrophilic or hydrophobic wet gel granules of aerogel wet glue particles are prepared to increase the production efficiency of the wet gel granules of aerogel.

Owner:TAIWAN AEROGEL TECH MATERIAL CO LTD

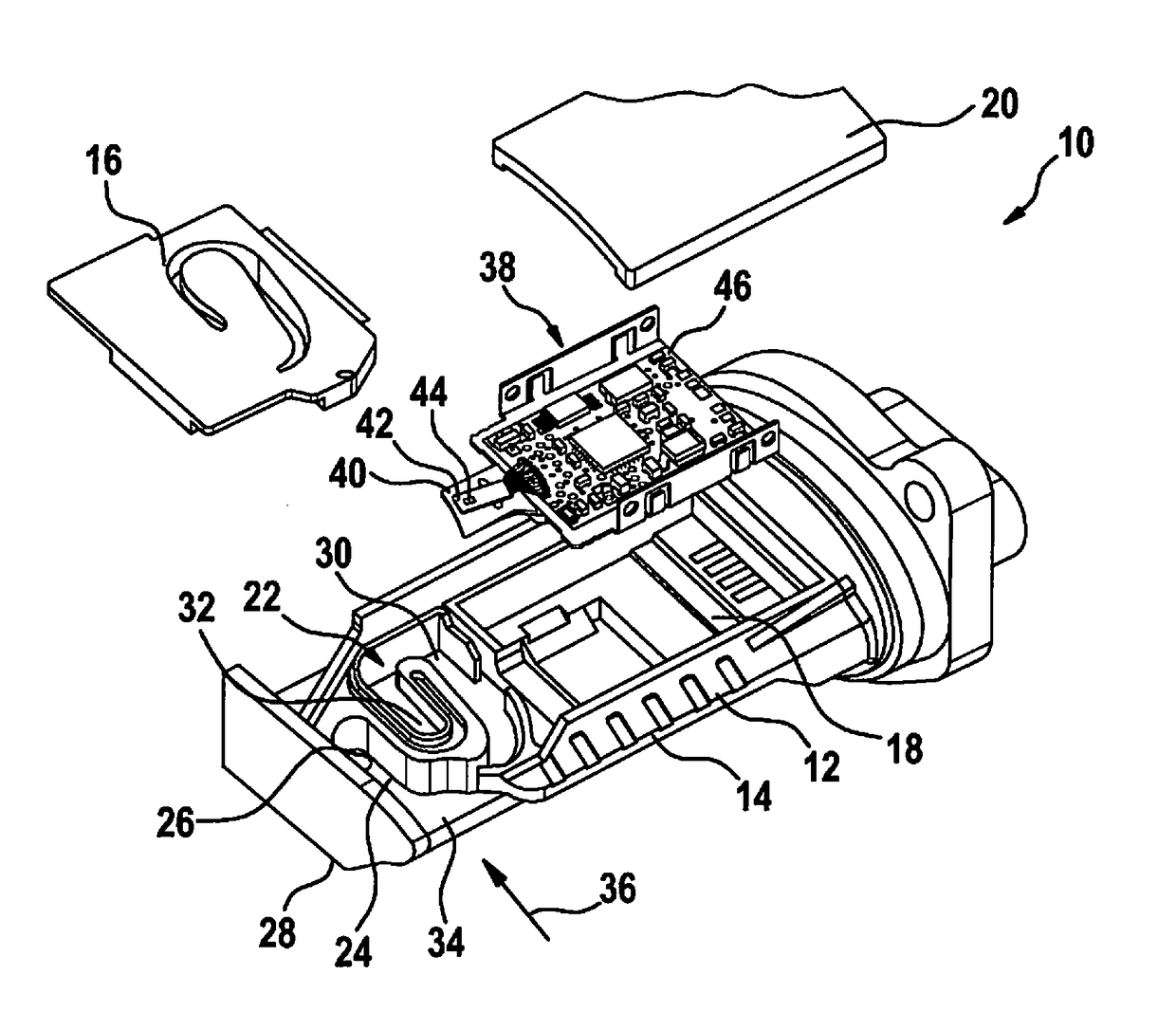

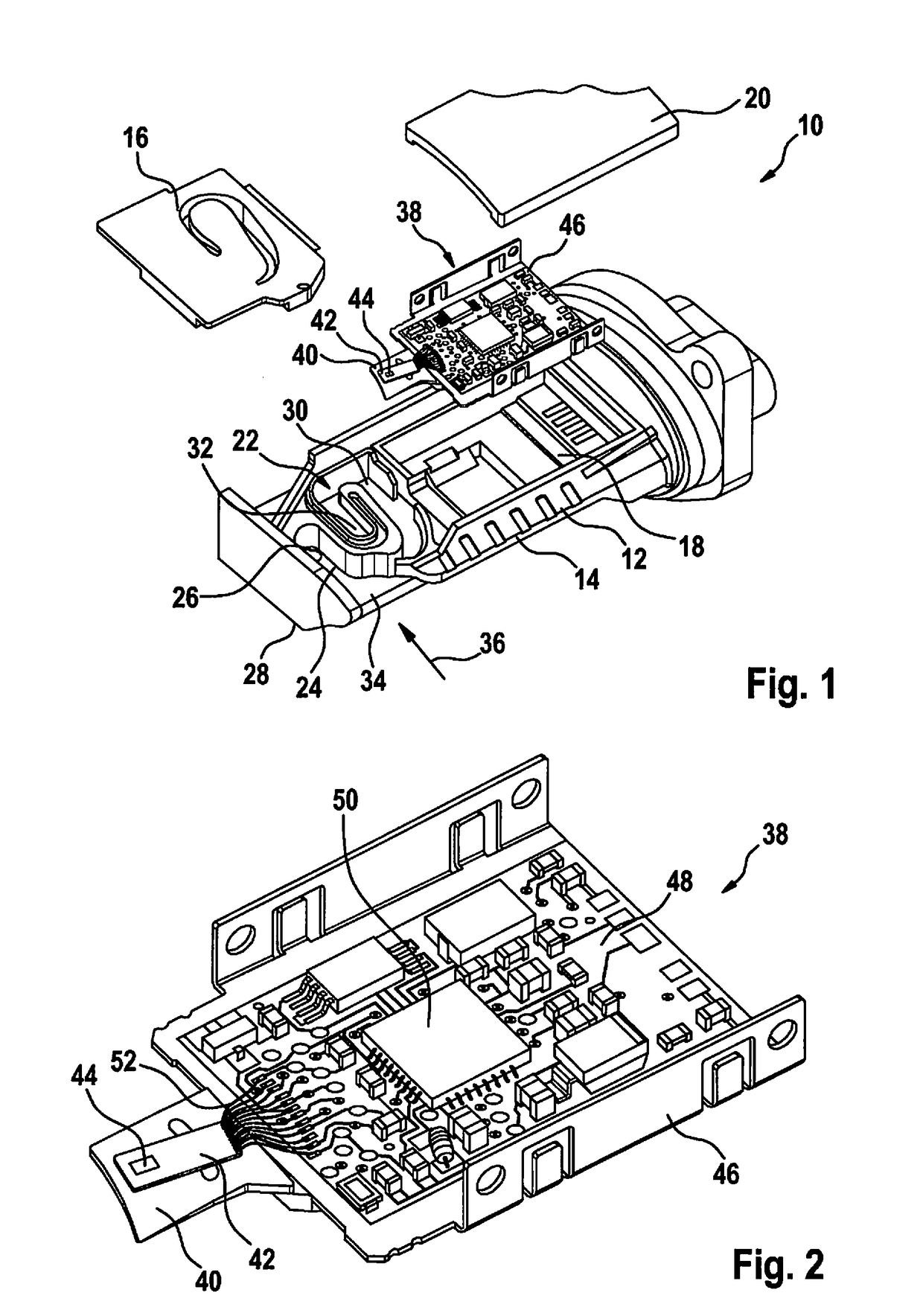

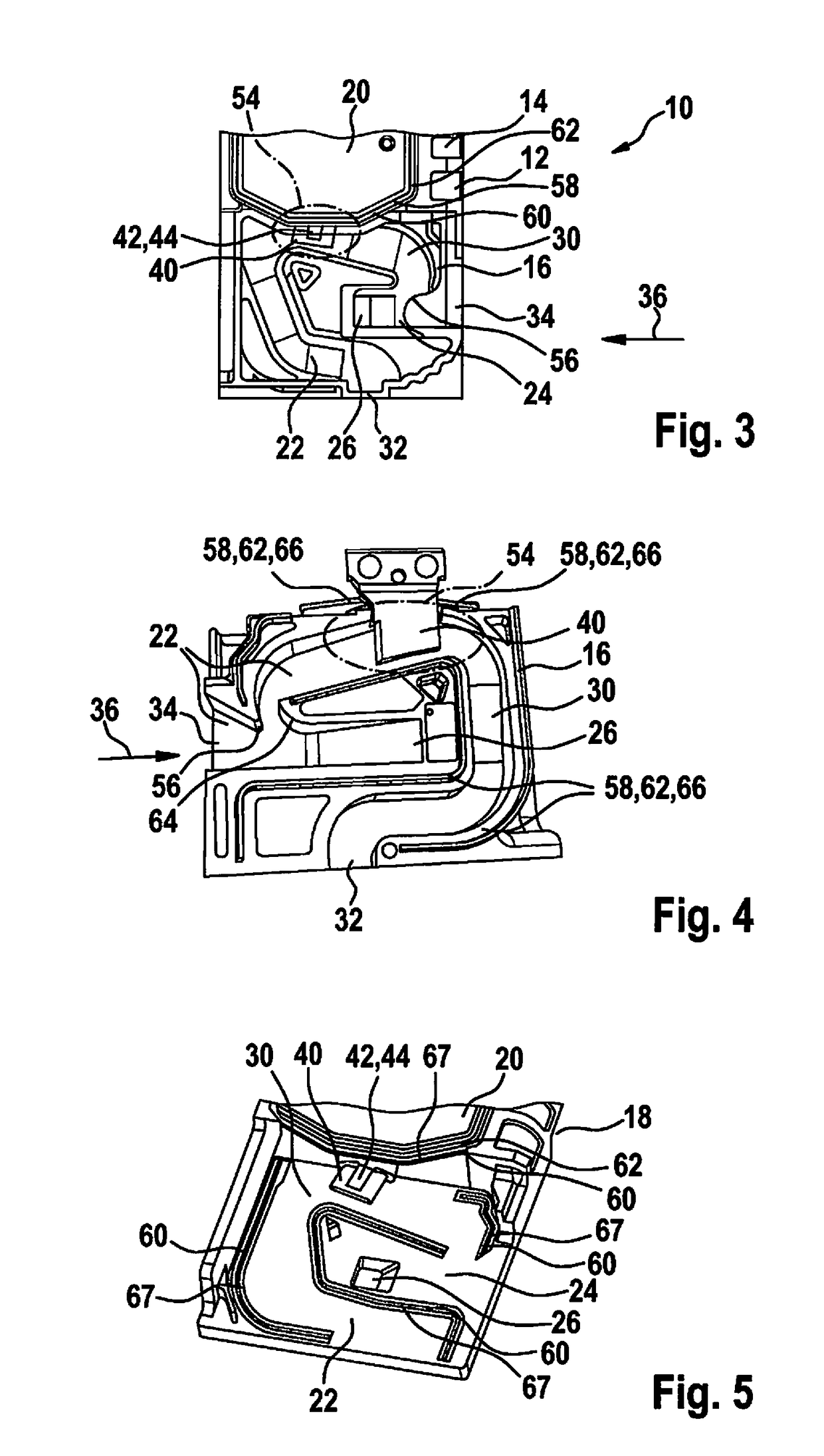

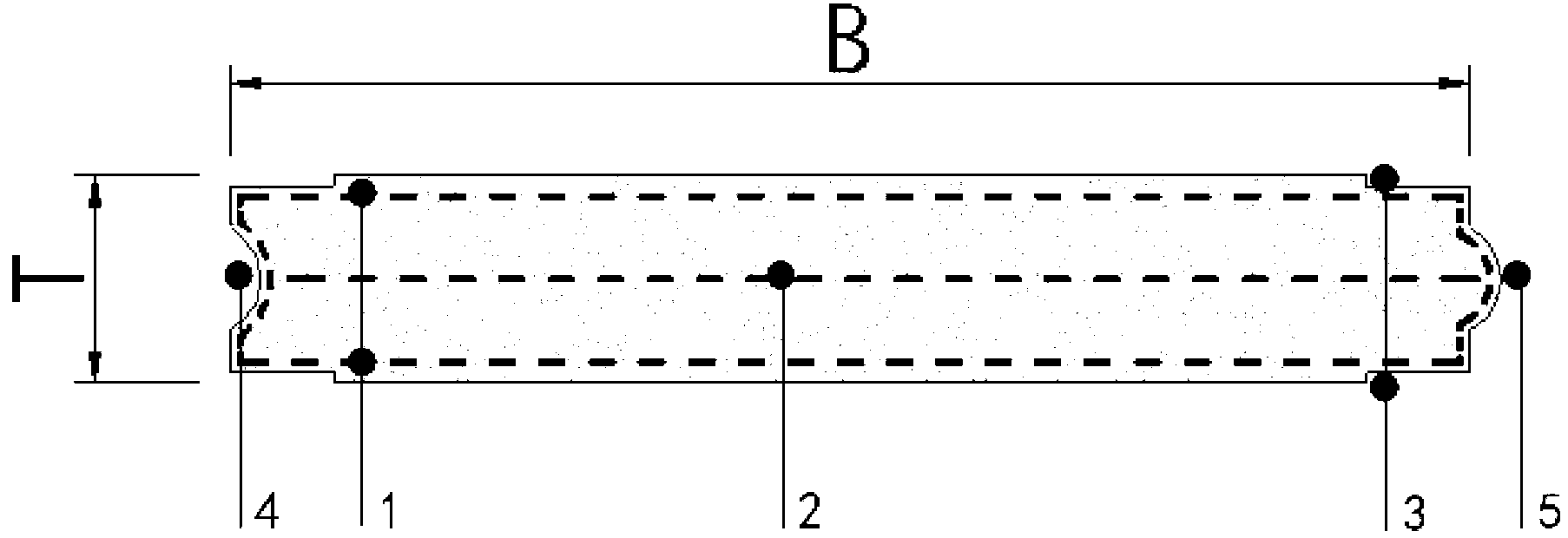

Sensor for determining at least one parameter of a fluid medium flowing through a measurement channel

ActiveUS20170328753A1Reduce dust pollutionLow costInternal-combustion engine testingVolume/mass flow measurementComputer moduleEngineering

A sensor is provided for determining at least one parameter of a fluid medium flowing through a measurement channel, in particular an intake air mass flow of an internal combustion engine. The sensor has a sensor housing, in particular a plug-in sensor that is inserted into or is insertable into a flow tube, in which sensor a measurement channel is fashioned, and has at least one sensor chip situated in the measurement channel for determining the parameter of the fluid medium. The sensor housing has an electronics compartment for accommodating an electronics module and has an electronics compartment cover for closing the electronics compartment. The electronics compartment cover has, at least in part, electrically conductive properties. For example, the electronics compartment cover is placed onto the electrical ground of the sensor and, viewed in projection, partly or completely covers the sensor chip.

Owner:ROBERT BOSCH GMBH

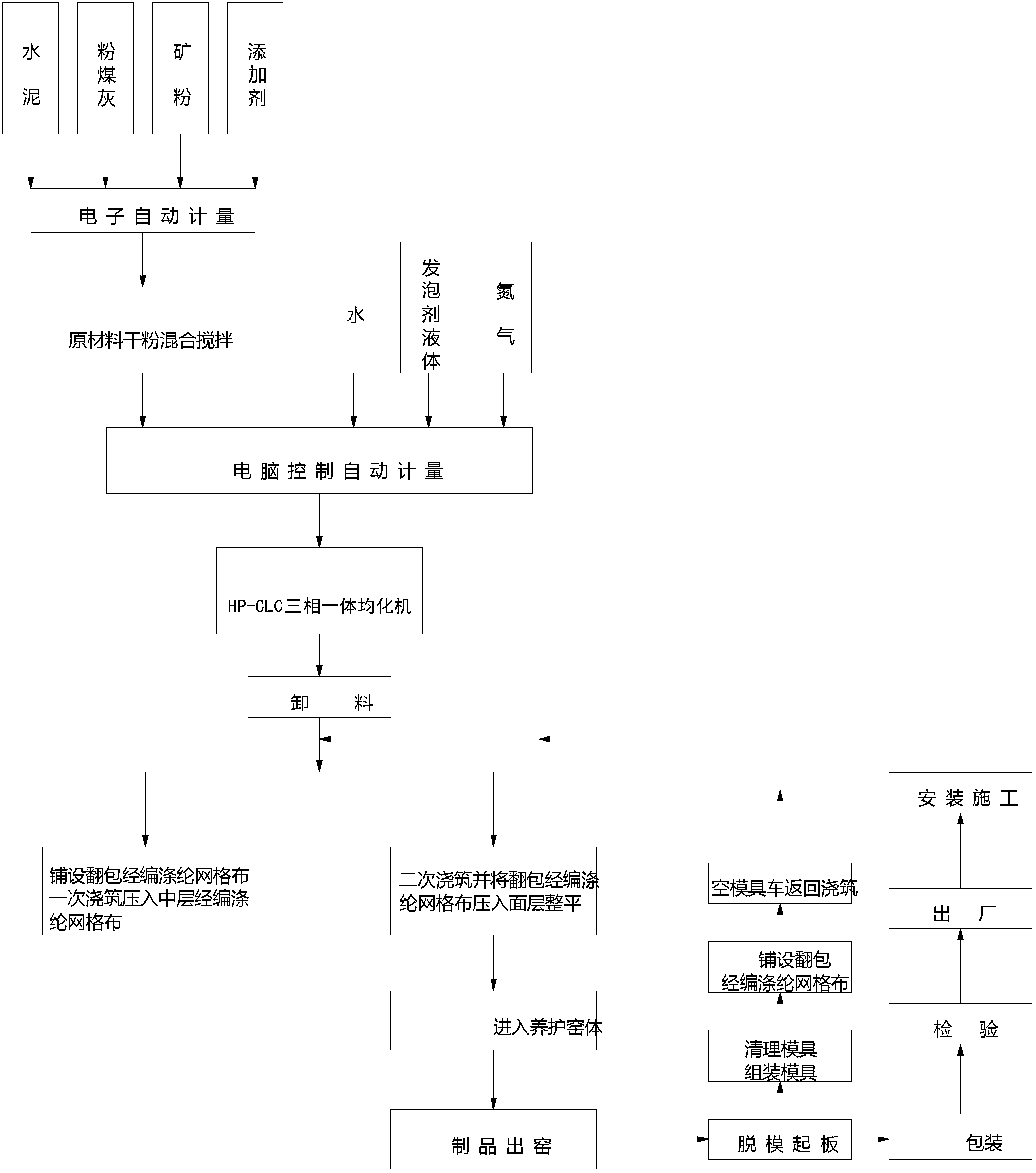

Energy-saving embedded type light inside and outside wall board

The invention relates to an HP-CLC energy-saving embedded type light inside and outside wall board and a manufacturing method of the wall board. The wall board is prepared from 30-60 parts by weight of inorganic gel material, 30-45 parts by weight of inorganic low-gel material, 15-30 parts by weight of inorganic heavy framework material, 0.3-0.4 part by weight of toughening fiber, 1-1.5 parts by weight of high-performance activating agent, 0.1-0.3 part of macromolecule initiating agent and 40-50 parts by weight of water. The physical foaming principle is adopted, namely, hollow foams formed by high polymer material are stirred and homogenized into slurry of the inorganic gel material, and the gas is not generated by chemical foaming, so that the produced concrete product has the characteristics of being diversified in varieties, high in yield, stable in performances and durable in weather fastness, having the rate of finished products reaching up to 100%, etc. Furthermore, all the raw materials used in the product can be directly used without additionally processing and grinding, thus having no limitation; and therefore, the cost is saved, and the defects such as environmental pollution and the like can be overcome.

Owner:陕西伟顺实业有限公司

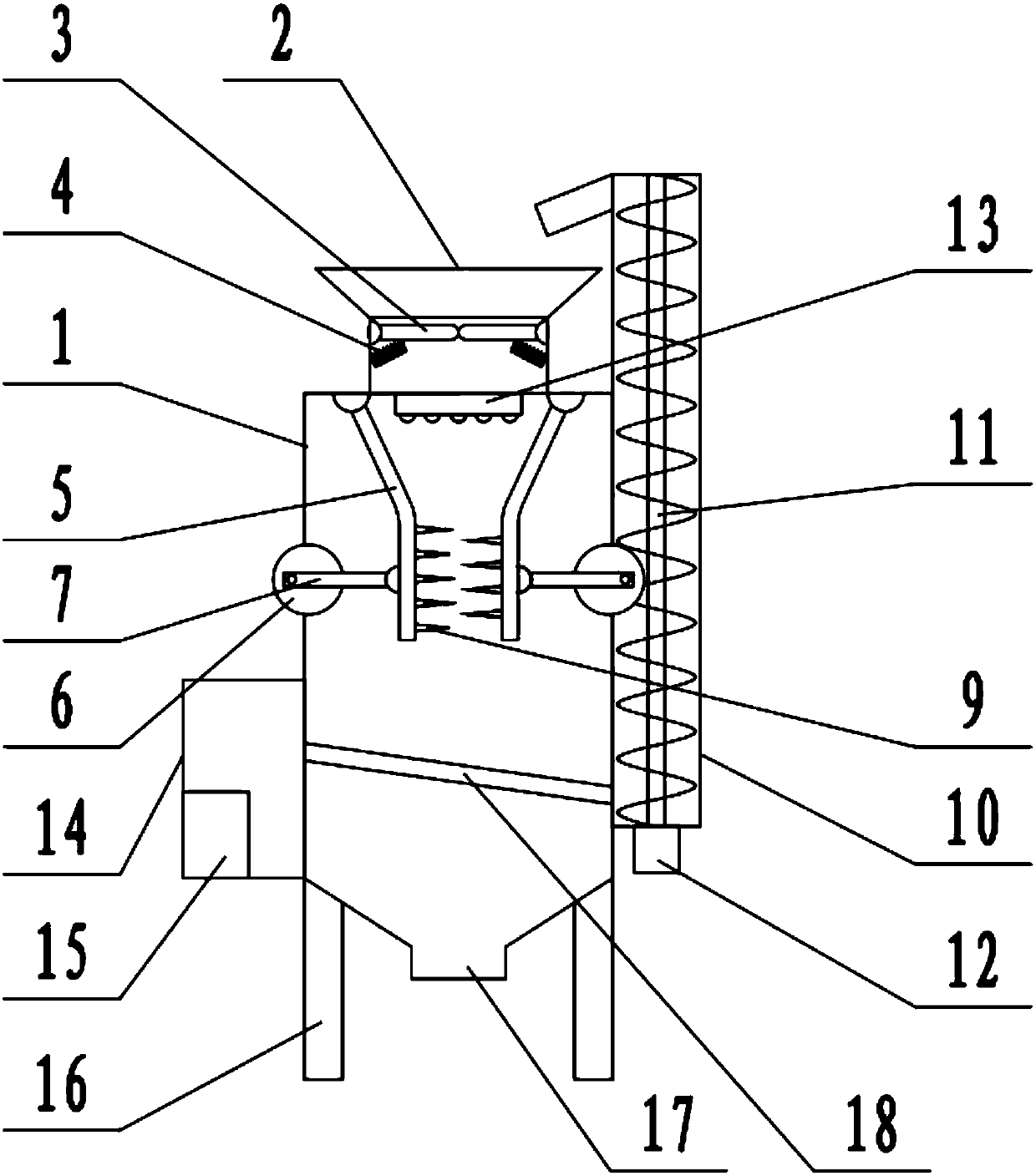

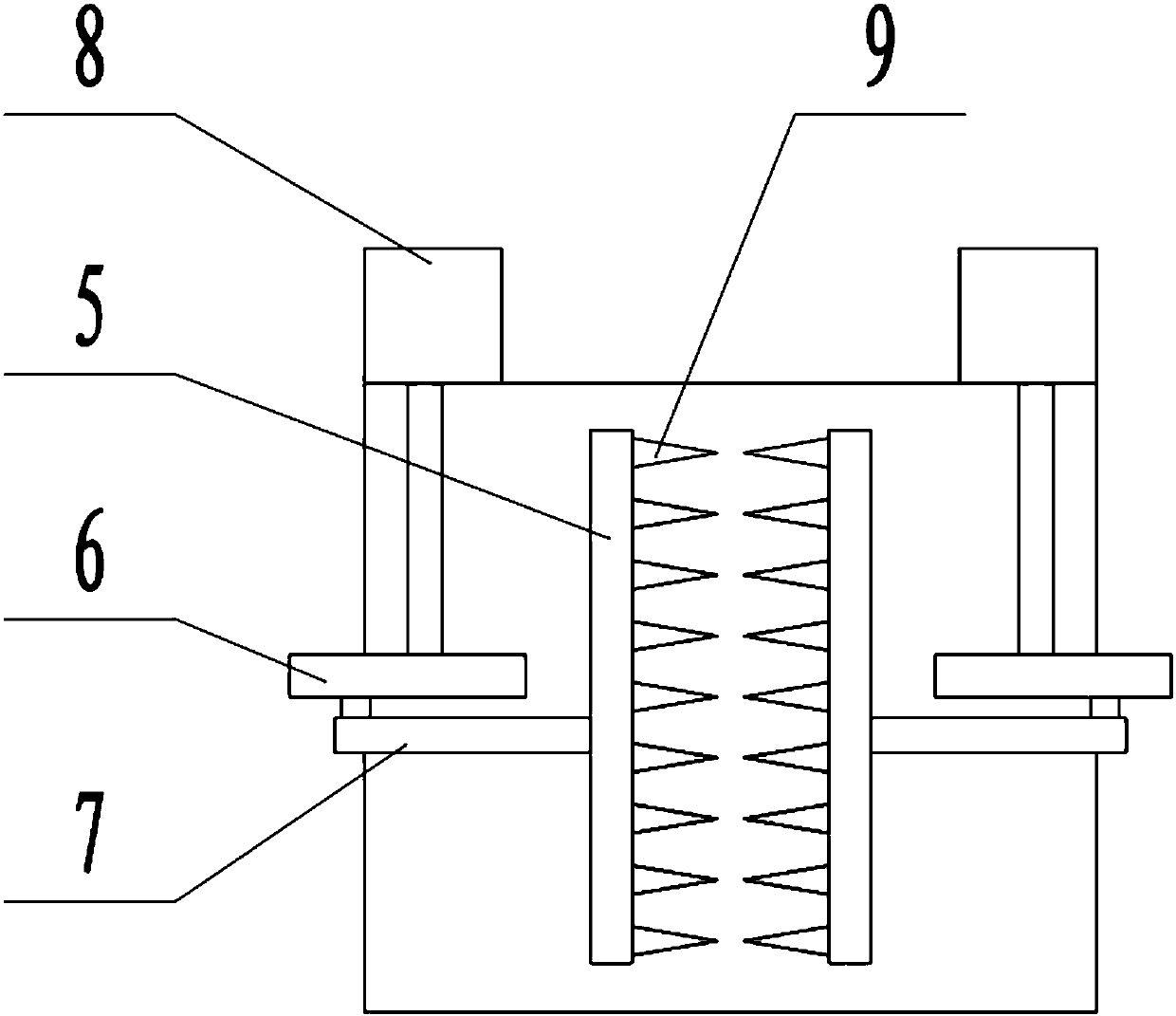

Circulating ore crusher

InactiveCN107866295AAvoid pollutionReduce dust pollutionUsing liquid separation agentGrain treatmentsElectric machineryEngineering

The invention discloses a circulating ore crusher. The circulating ore crusher comprises a shell, a feeding hole, a crushing plate, a supporting foot and a discharge opening, wherein the feeding holeis formed in the top of the shell; the crushing plate is arranged inside the shell; the outer side wall of the shell is fixedly connected with a crushing motor; a sieve plate is arranged below the crushing plate; the right side wall of the shell is fixedly connected with a circulating barrel; a screw rod is arranged inside the circulating barrel; the lower surface of the circulating barrel is fixedly connected with a circulating motor; the top of the circulating barrel is provided with a circulating discharge hole; the circulating discharge hole is positioned over the feeding hole; a water spray pipe is arranged inside the shell; the spray pipe is fixedly connected with the top of the shell. Ore to be crushed is put into the feeding hole, and a baffle plate is arranged on the inner wall ofthe feeding hole, so that dust is prevented from being discharged from the feeding hole, and pollution on the working environment is avoided; the ore is extruded and crushed by the crushing plate, and water is sprayed onto the ore in a crushing process, so that dust pollution is lowered greatly; the ore is crushed circularly by the circulating barrel, so that the crushing effect is enhanced.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

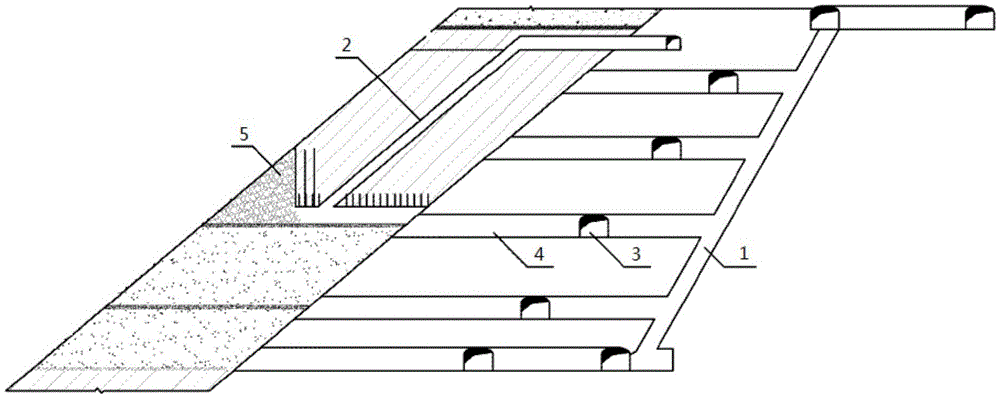

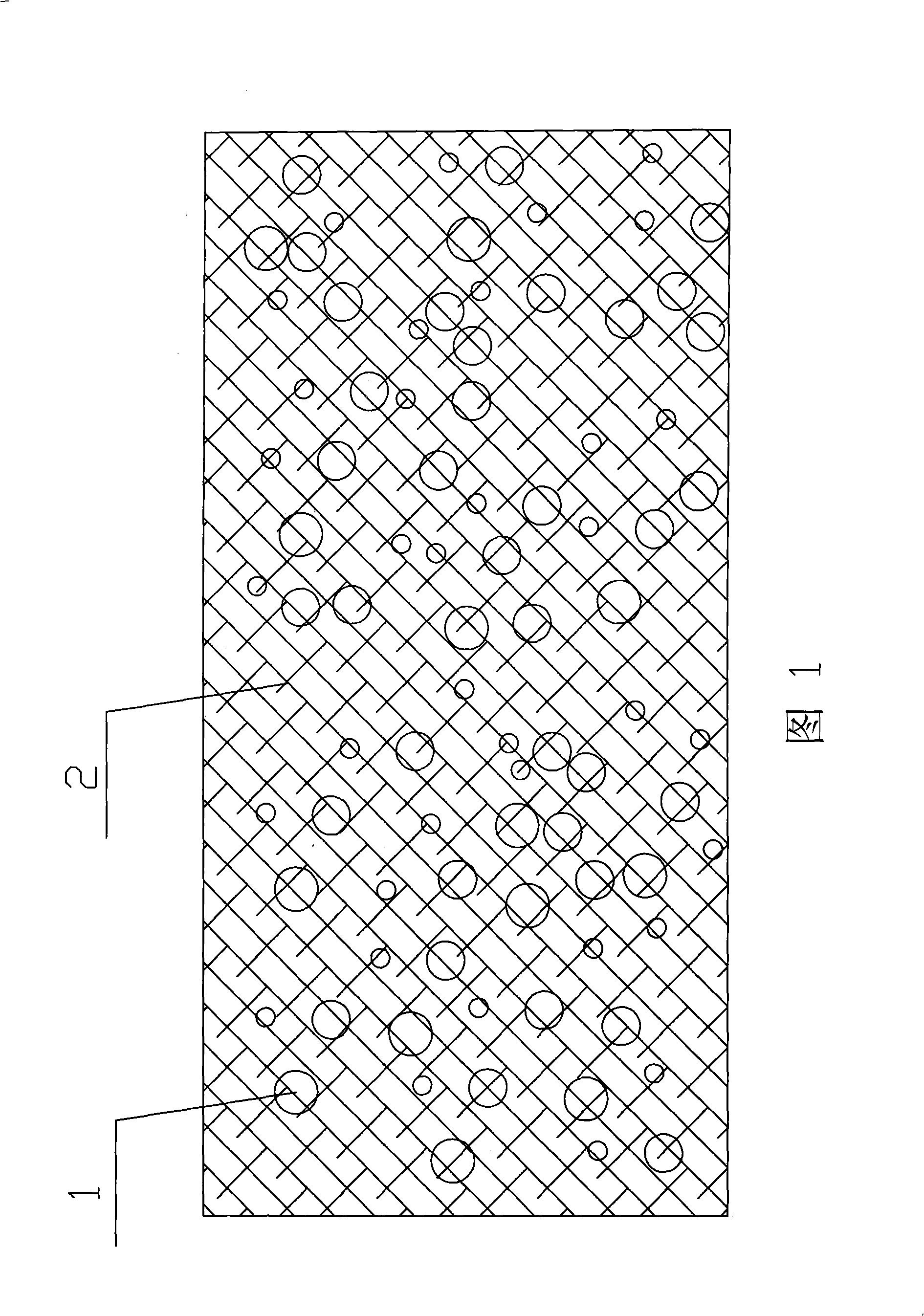

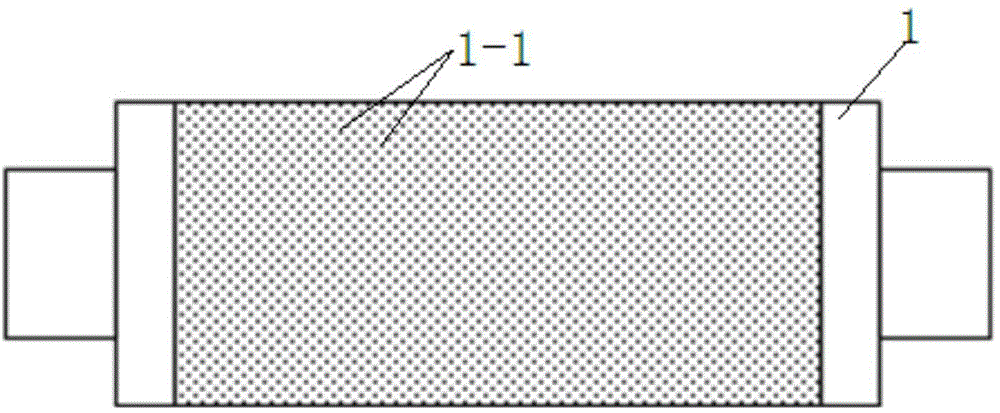

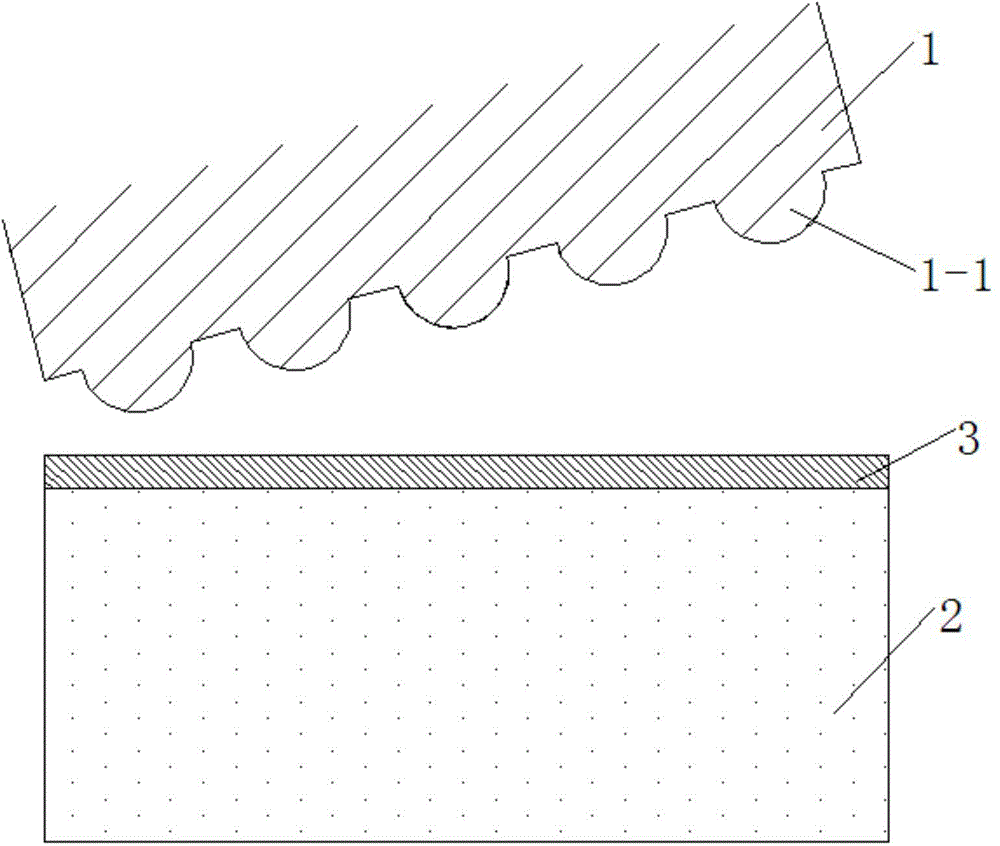

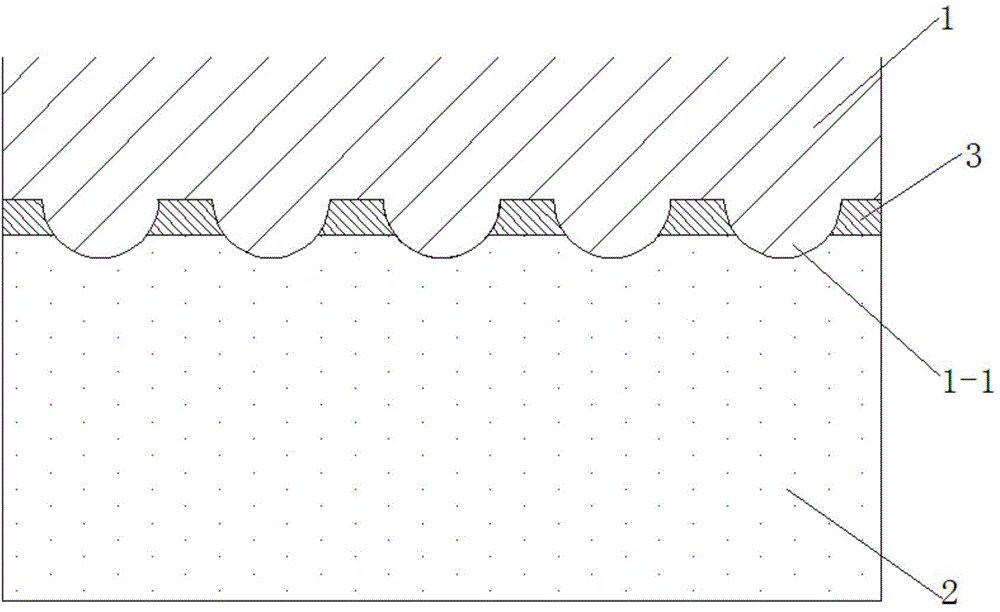

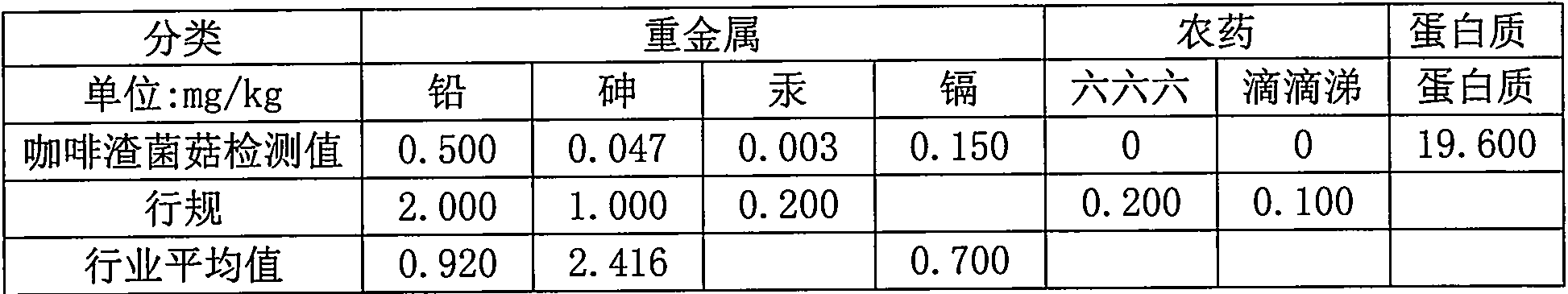

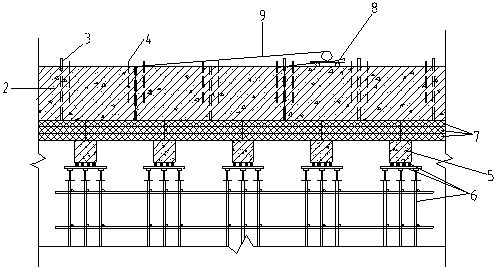

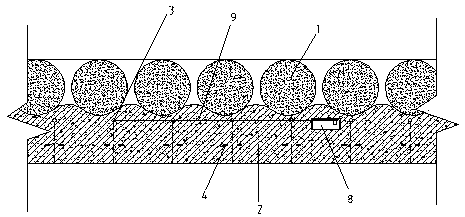

Carbon fiber autoclaved aerated concrete slab and application thereof

The invention relates to an autoclaved aerated concrete slab containing carbon fibers and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises building concrete structural slabs (1), wherein the concrete is autoclaved aerated concrete, and the concrete in the structural slabs is provided with carbon fibers (2). The product can be used as precast elements for buildings, such as floor slabs, roof slabs and wall slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

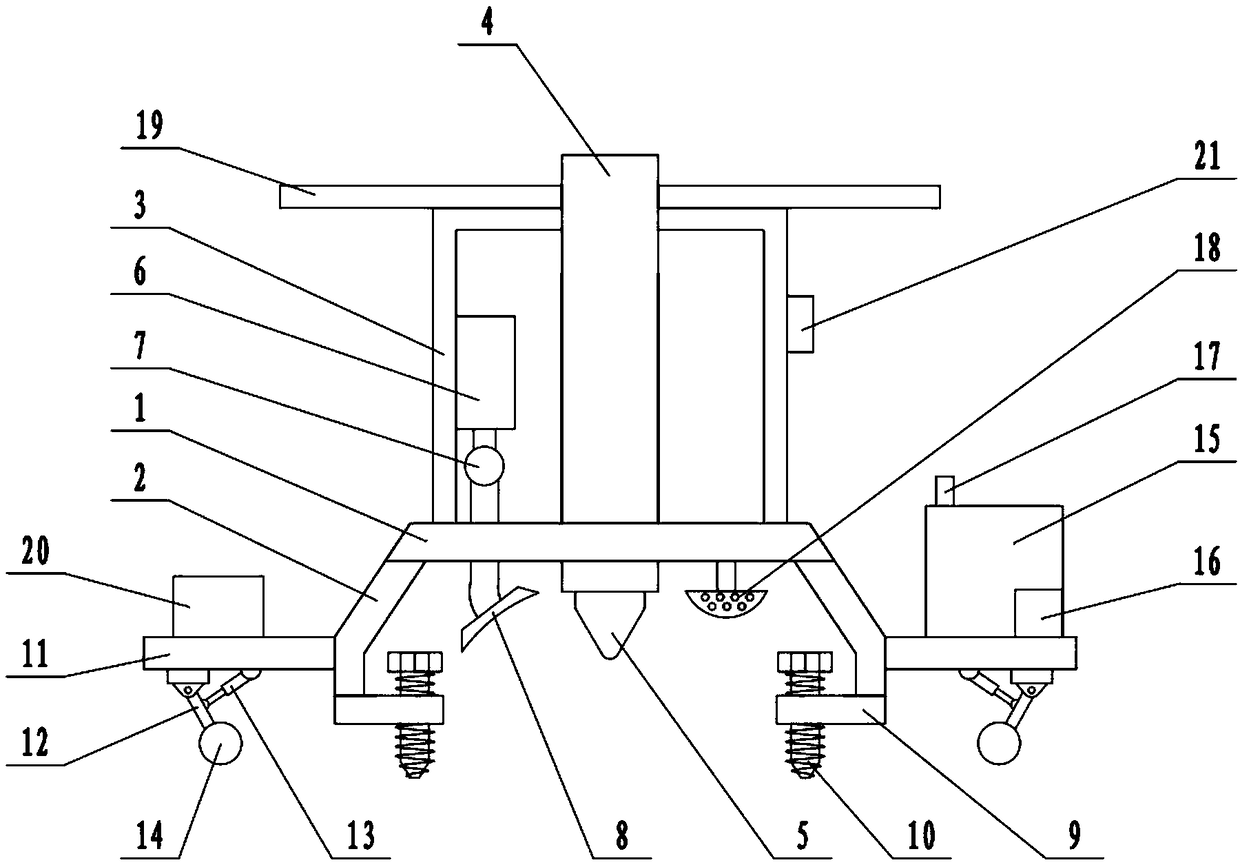

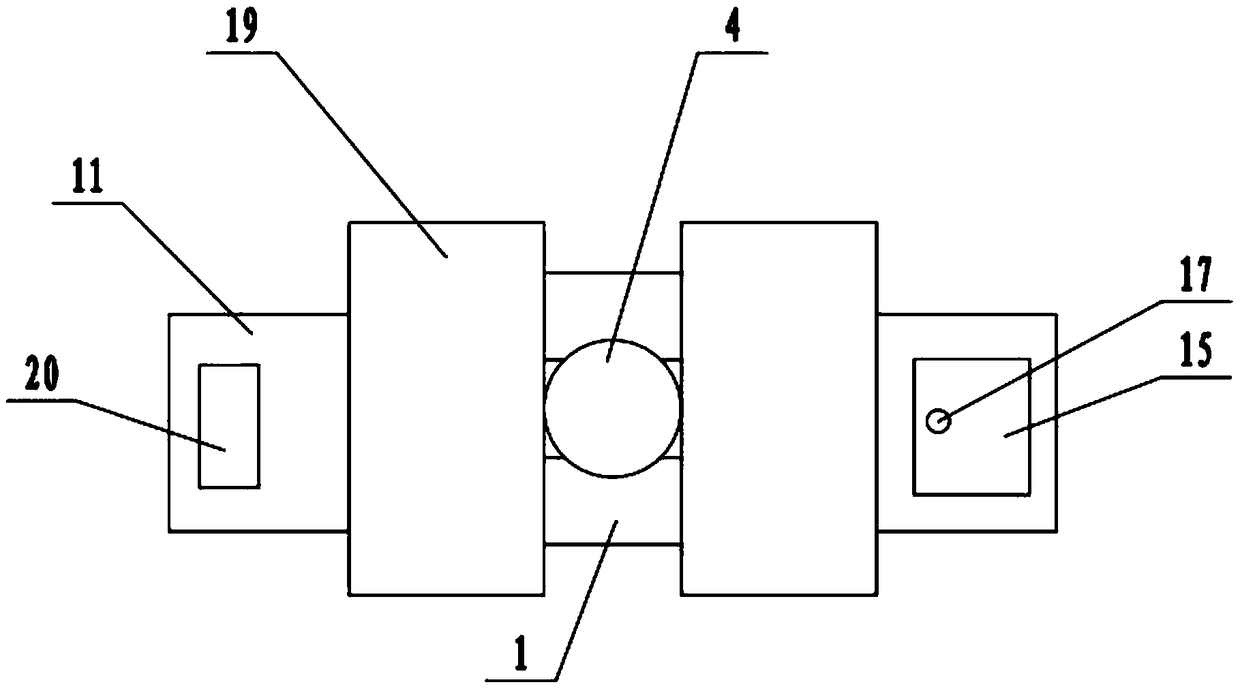

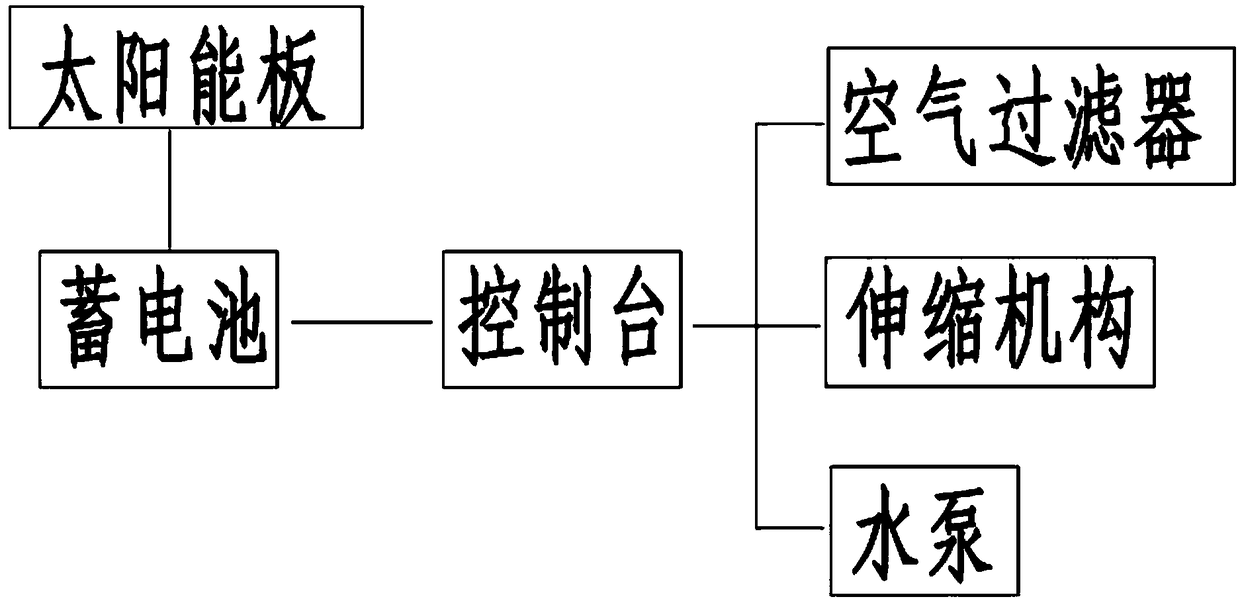

Minitype geophysical prospecting drilling machine dust-proof bracket convenient to move

InactiveCN108412443AImprove stabilityReduce dust pollutionEarth drilling toolsConstructionsFixed frameEngineering

The invention discloses a minitype geophysical prospecting drilling machine dust-proof bracket convenient to move. The bracket comprises a drilling machine platform, fixed frames, brackets, a drillingmachine and a drilling head, the left and right sides of the drilling machine platform are respectively fixedly connected with fixed frames, and the left and right sides of the drilling machine are respectively fixedly connected with the brackets; the lower ends of the brackets are fixedly connected with the drilling machine platform, the lower ends of the fixed frames are fixedly connected withsupporting blocks, and fixed bolts penetrate through the middles of the supporting blocks; the outer side walls of the fixed frames are fixedly connected with fixed blocks, the lower surfaces of the fixed blocks are hinged to connecting rods, and idler wheel groups are arranged on the lower ends of the connecting rods; the lower surfaces of the fixed blocks are further hinged to telescopic mechanisms, the supporting blocks are fixedly connected with the ground by utilizing the fixed bolts, the stability of the machine is improved, during the drilling operation, an exhaust fan is utilized to suck dusty gas into an air filter through an air suction hood, the air filter is utilized to filter the dusty gas, dust pollution is reduced, the telescopic mechanisms are used for controlling the idler wheel groups for lifting, and it is convenient to move the drilling machine.

Owner:GEOPHYSICAL SURVEY TEAM ANHUI PROVINCIAL BUREAU OF COAL GEOLOGY

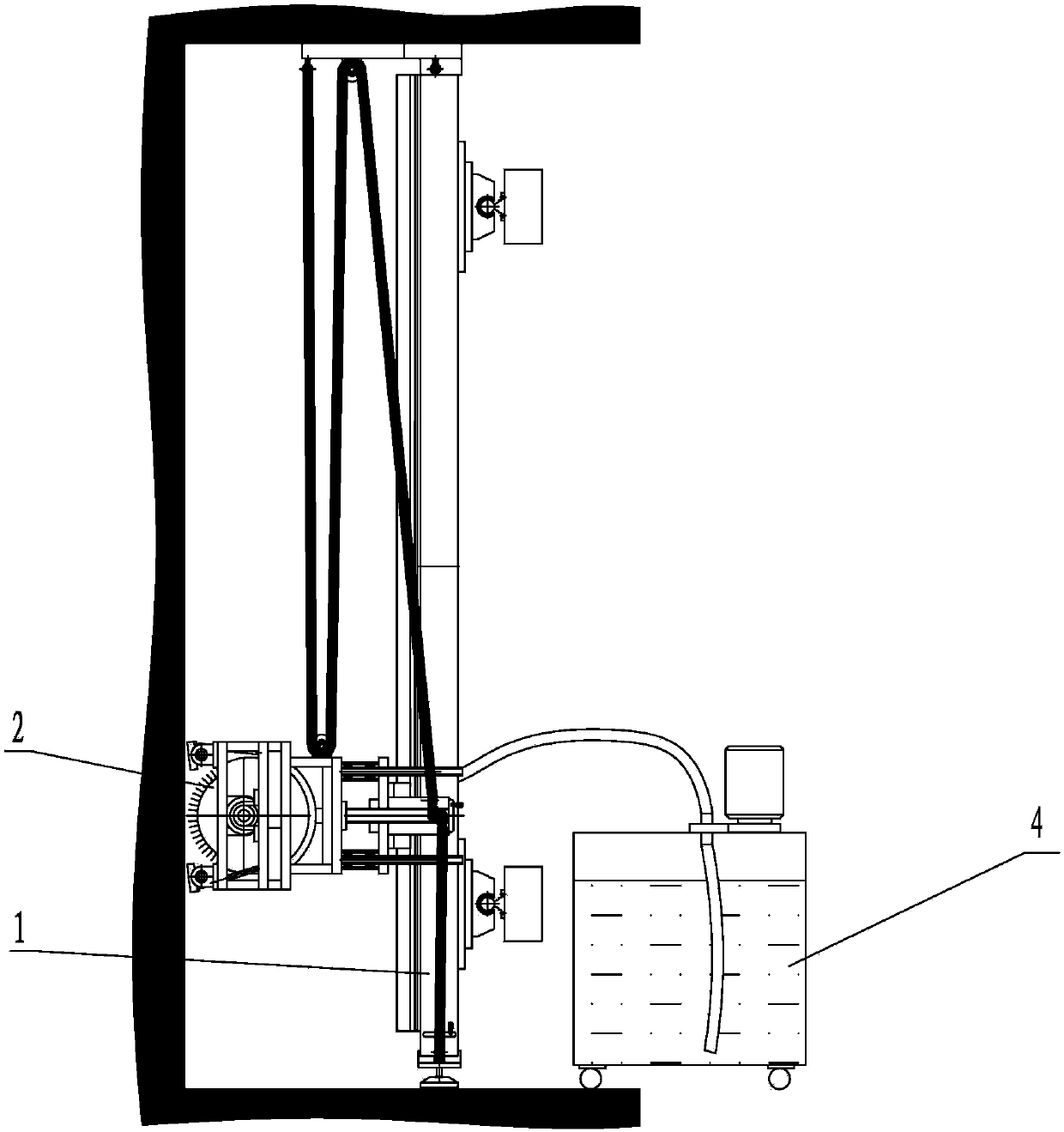

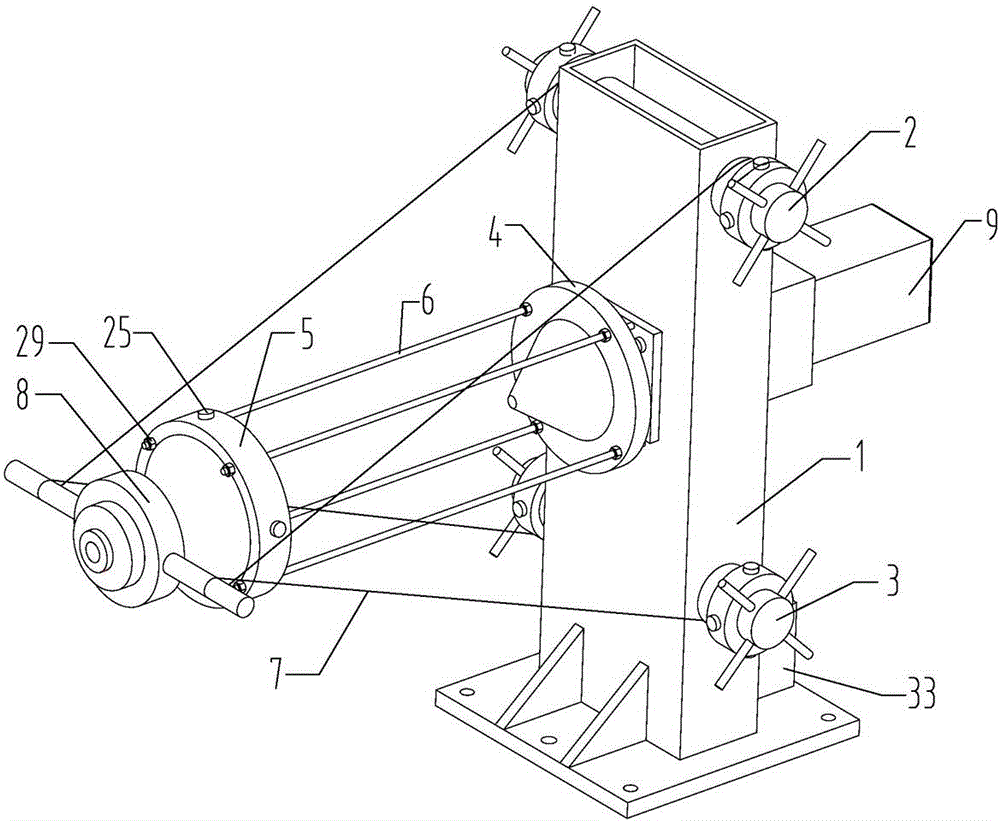

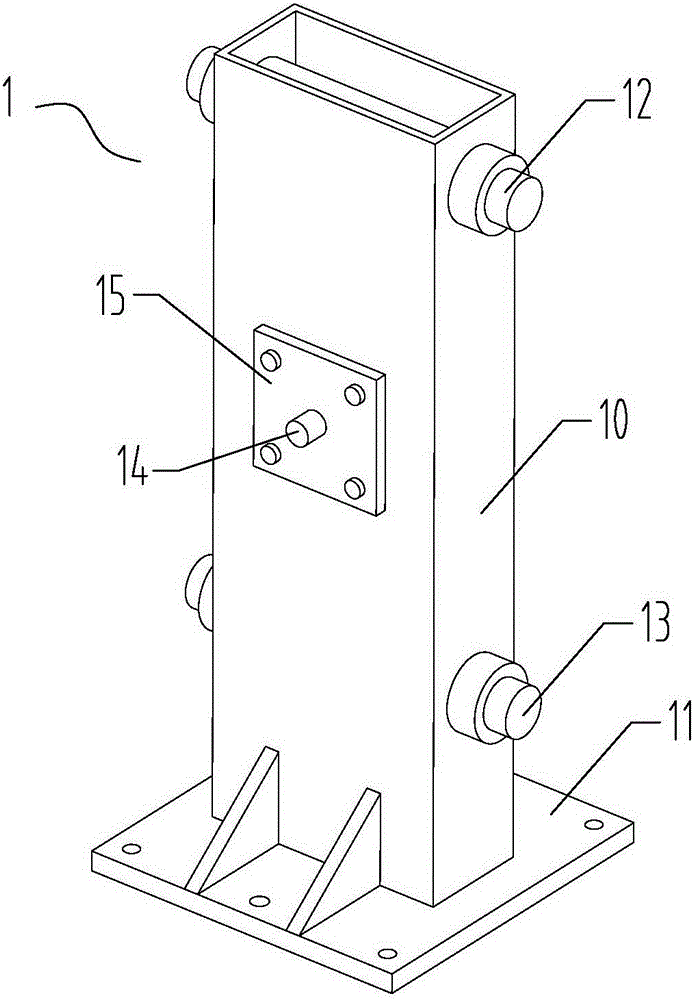

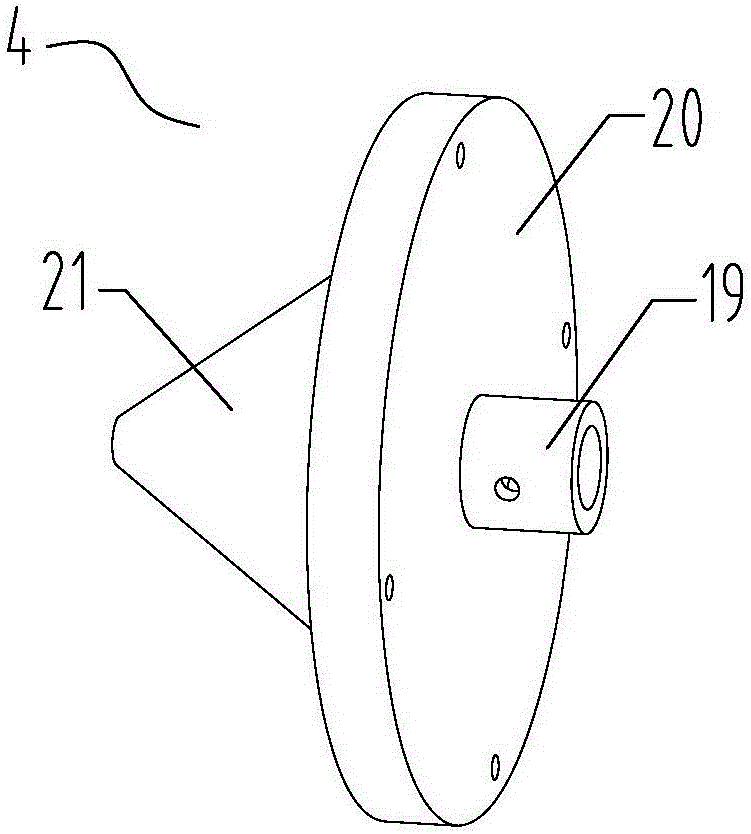

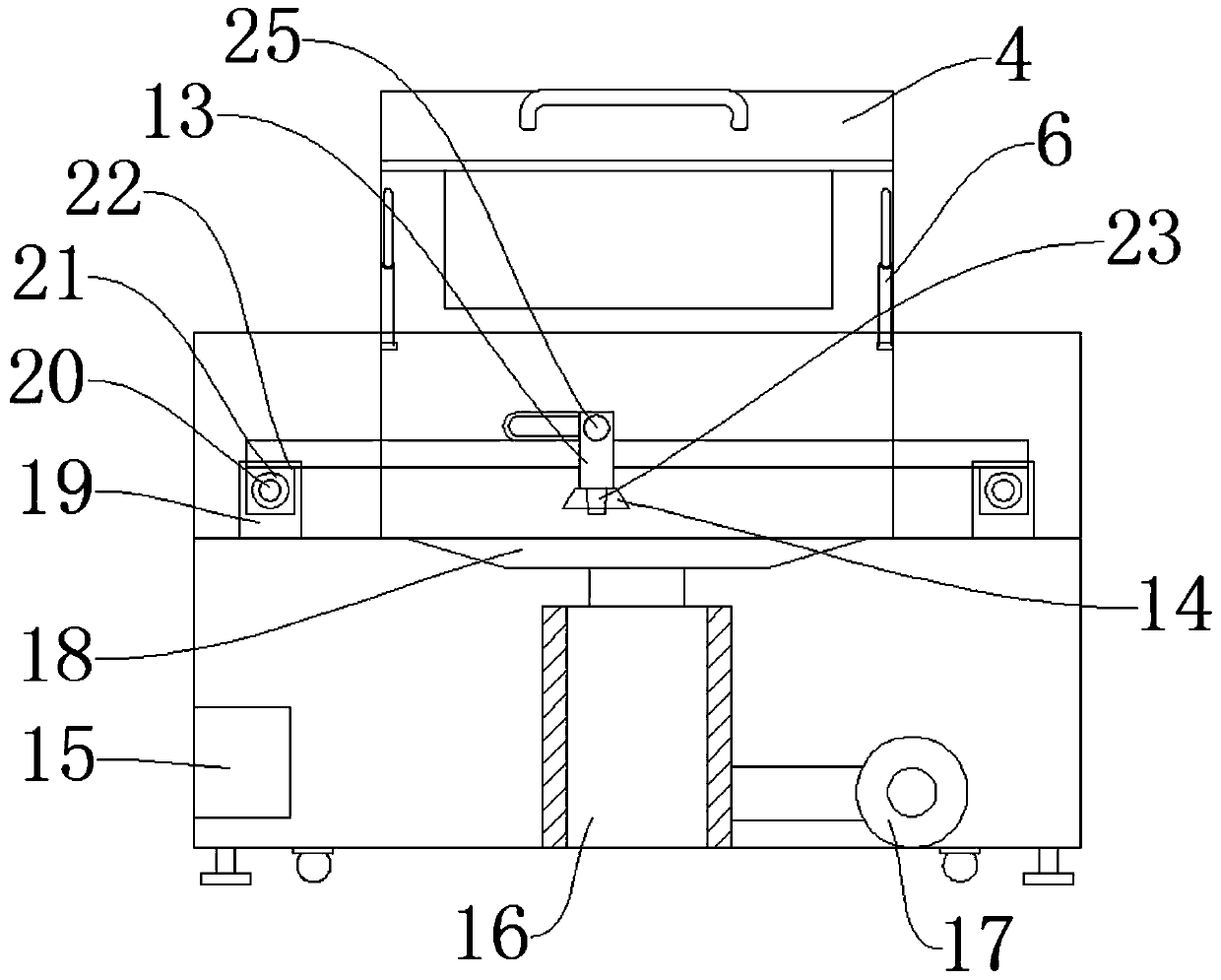

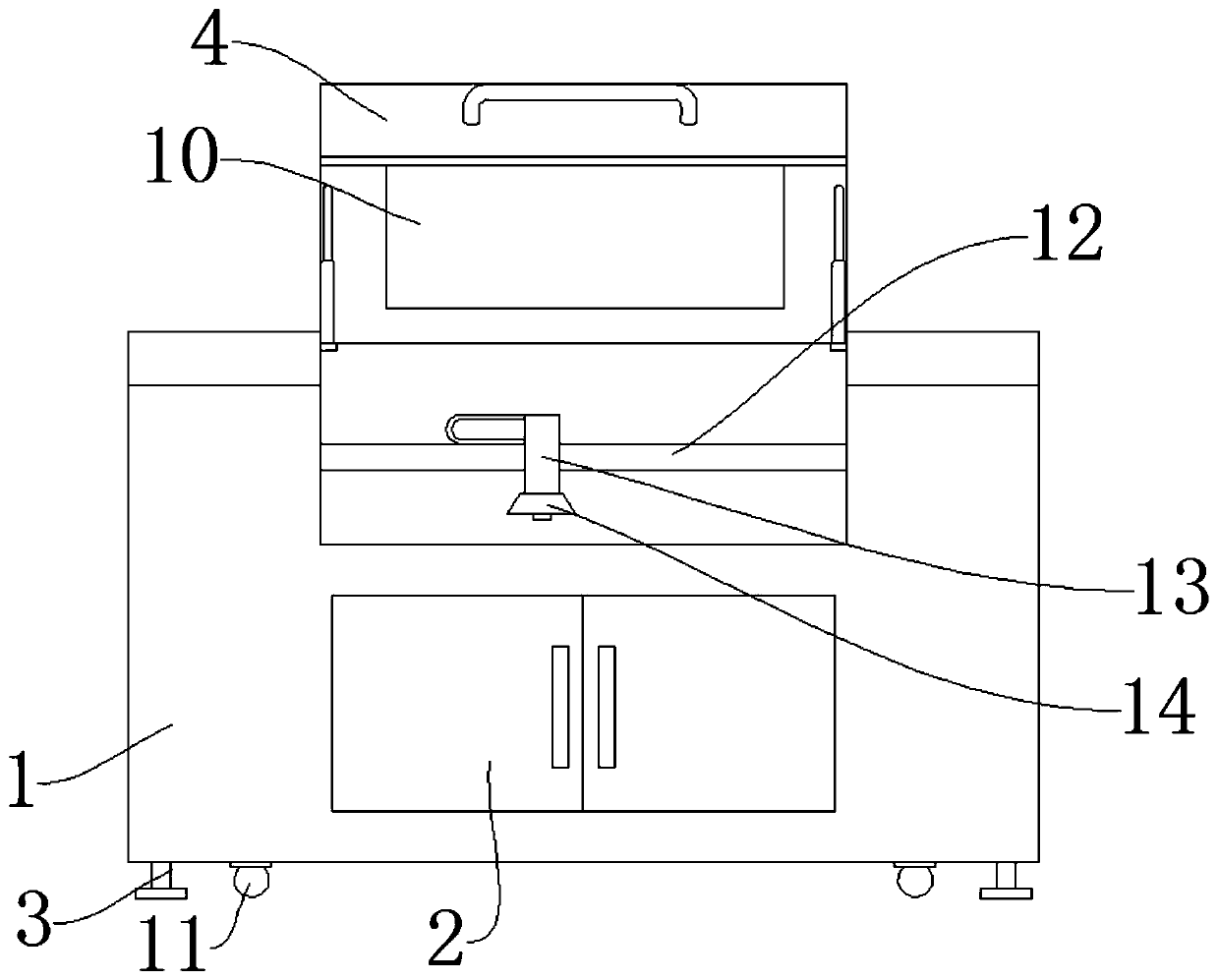

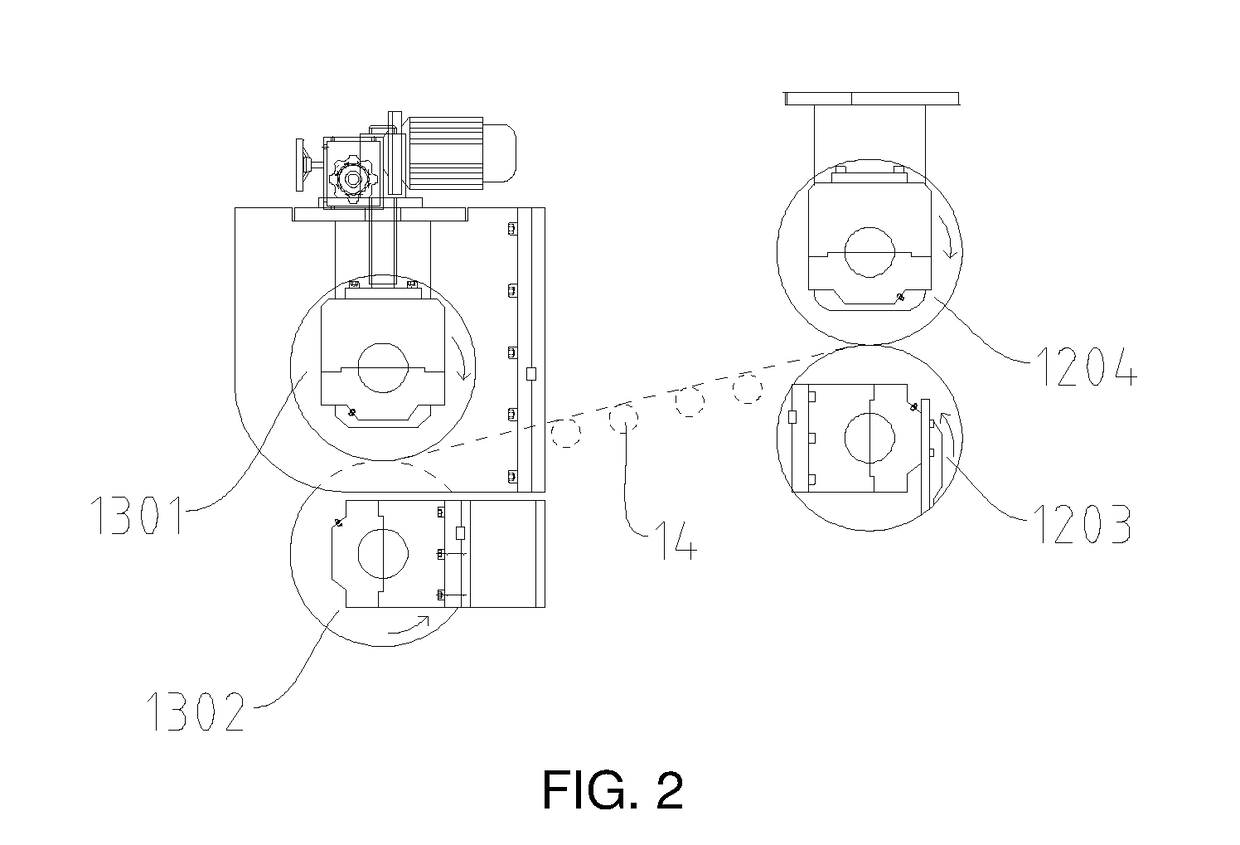

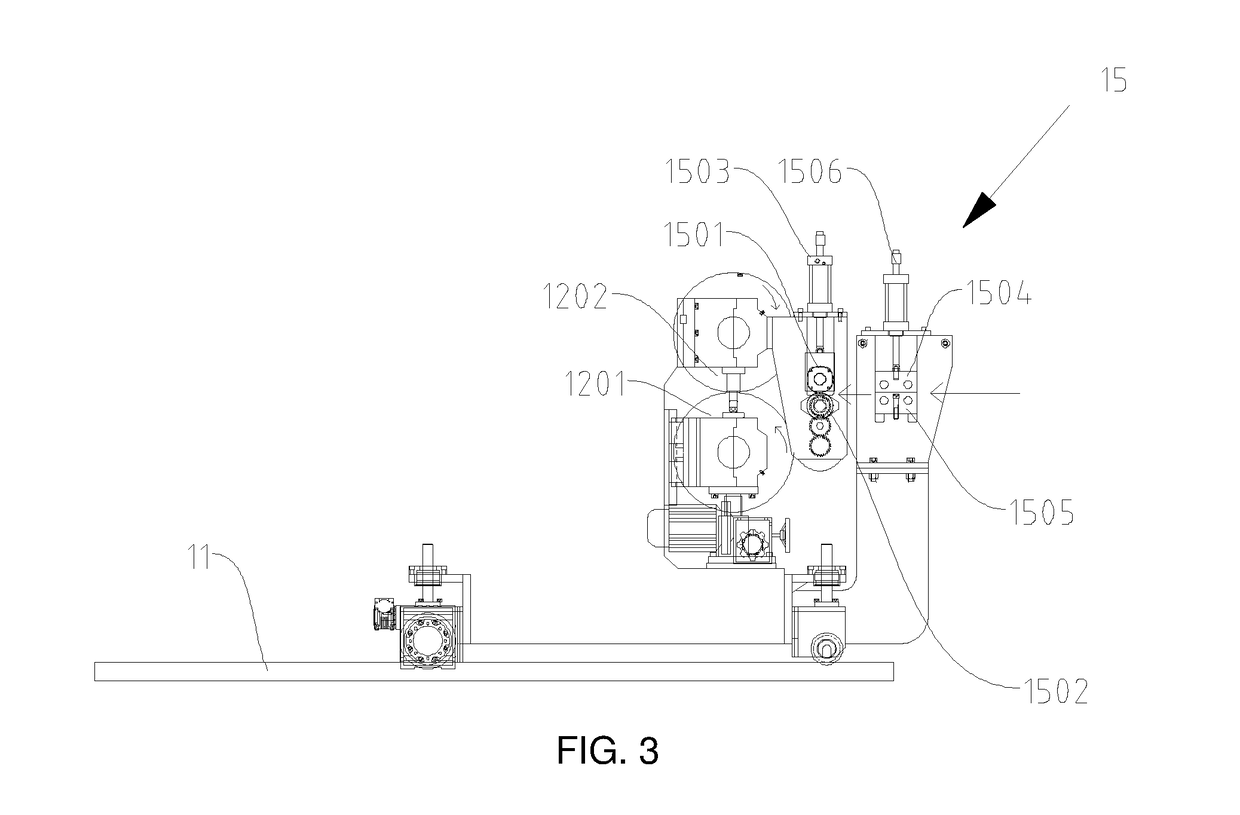

Derusting and lining pouring integrated machine for interior of centrifugal pipe

ActiveCN105773389AReduce noiseReduce dust pollutionEdge grinding machinesGrinding carriagesEngineeringCantilever

The invention provides a derusting and lining pouring integrated machine for the interior of a centrifugal pipe. The derusting and lining pouring integrated machine comprises a rack, upper reeling plates, lower reeling plates, a fixed end centering positioning conical plate, a cantilever end centering pressing buckle conical plate, tensioning rods, pulling ropes, a hanging bearing sleeve piece and a speed adjusting motor. An output shaft of the motor is connected with the fixed end centering positioning conical plate through a rotating transmission shaft assembly on the rack. The cantilever end centering pressing buckle conical plate and the fixed end centering positioning conical plate are opposite and connected together through the tensioning rods, the hanging bearing sleeve piece and the pulling ropes. The pulling ropes are wrapped on the upper reeling plates and the lower reeling plates through the hanging bearing sleeve piece. According to the derusting and lining pouring integrated machine for the interior of the centrifugal pipe, derusting and lining pouring can be both achieved, the occupied space is small, operation is easy and convenient, and the adaptability to the change of the pipe length and the lining thickness is high.

Owner:辽宁天和钢管防腐有限责任公司

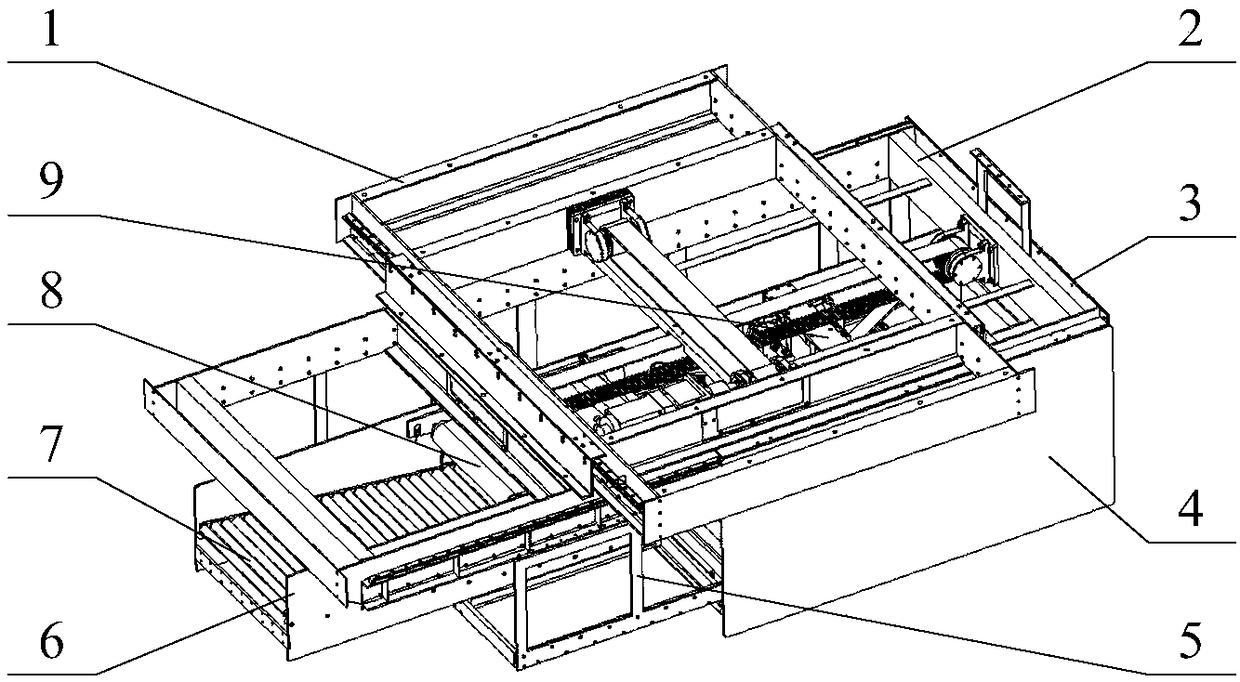

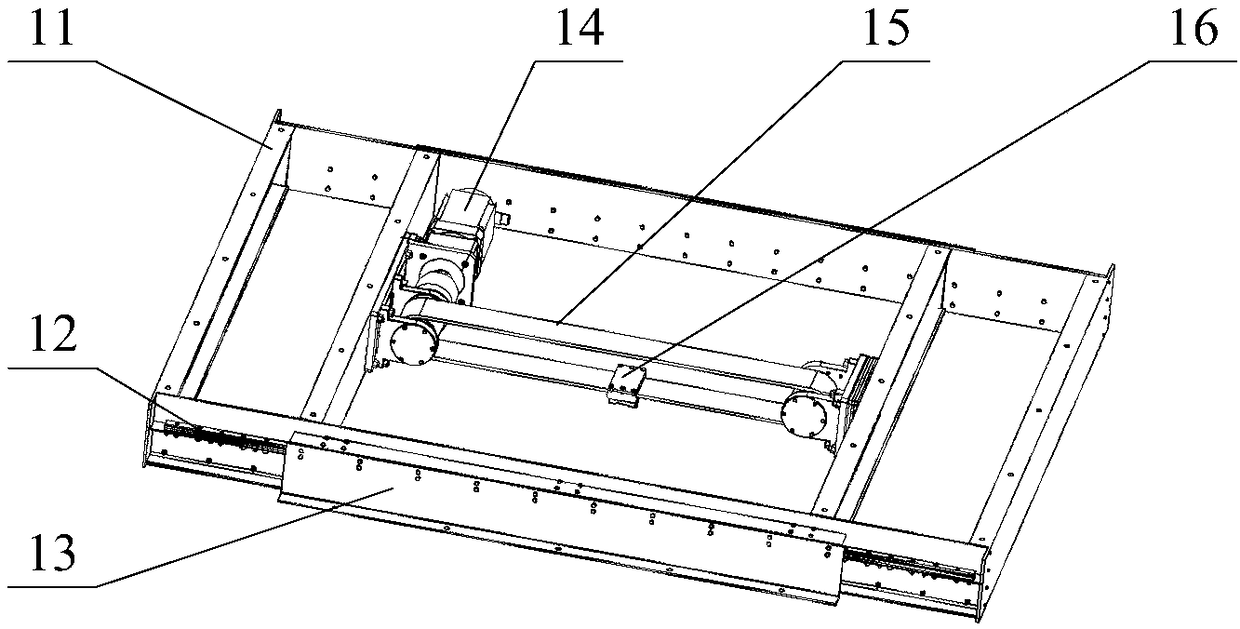

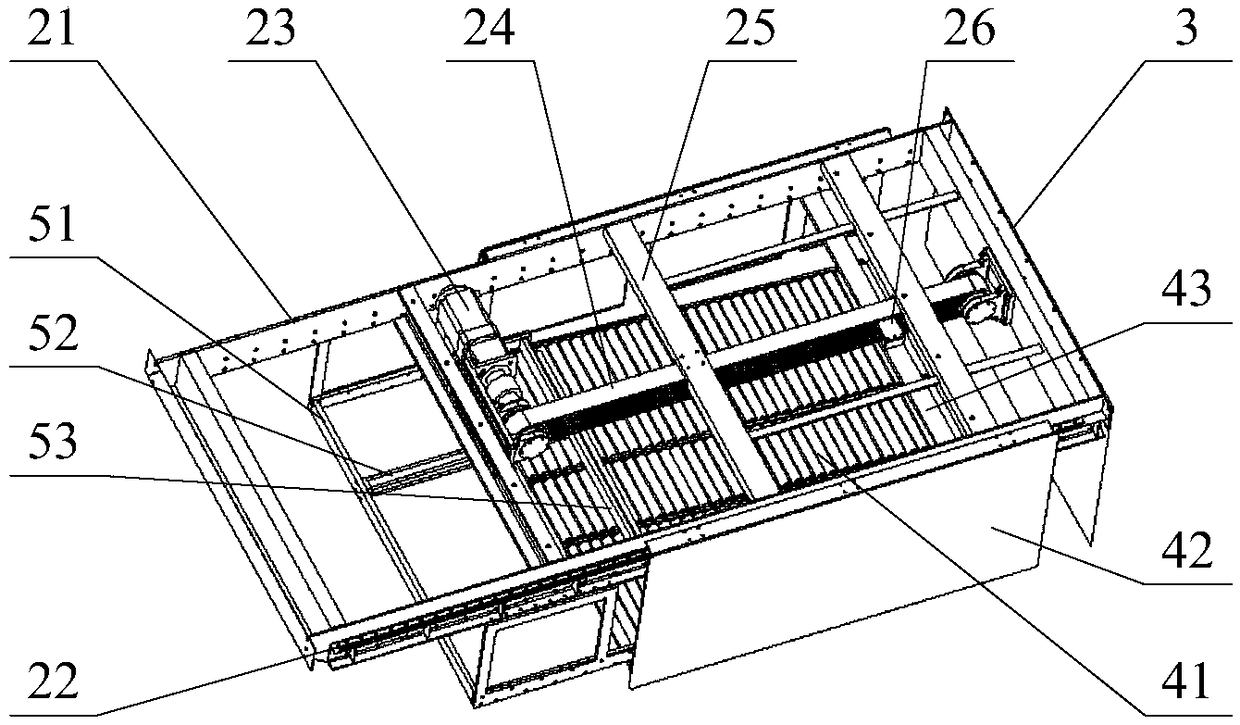

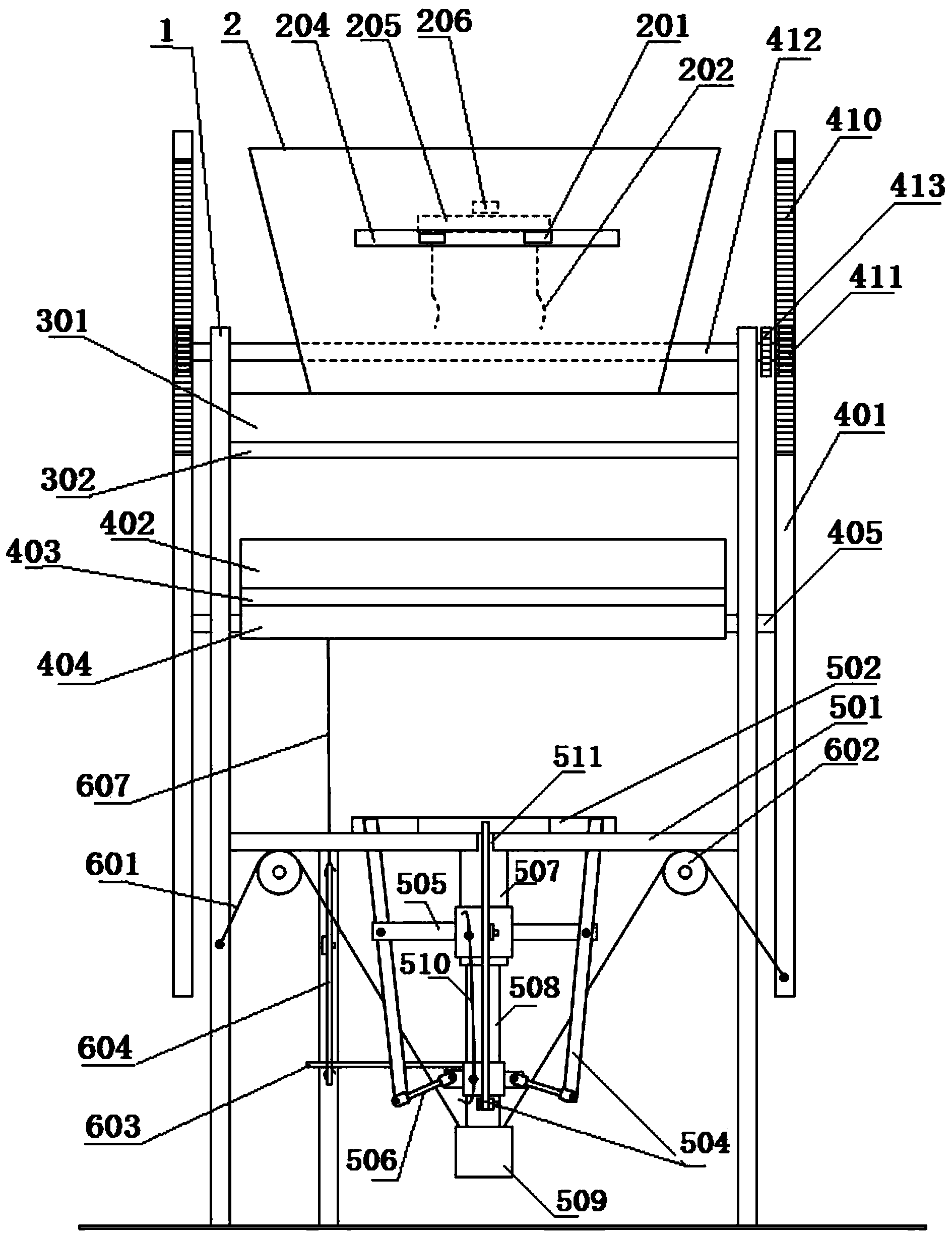

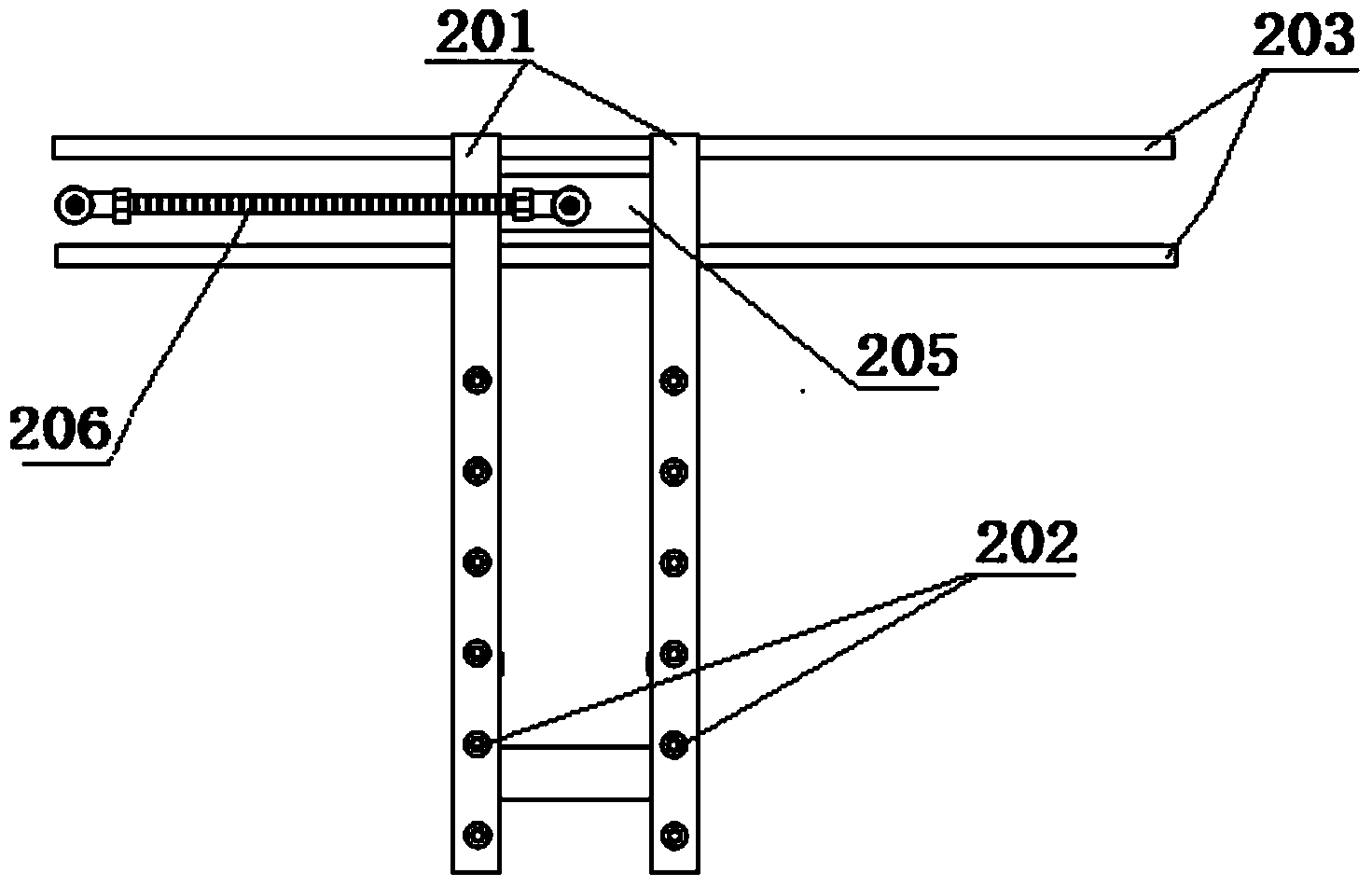

Automatic stacking device on bagged material loading machine

ActiveCN108177992AStable and stableSolve the problem of fully automatic loadingConveyorsStacking articlesEngineeringMechanical engineering

The invention provides an automatic stacking device on a bagged material loading machine. The automatic stacking device comprises a bag dropping platform, a dropped bag moving mechanism and a transverse moving mechanism, wherein the bag dropping platform is used for material grouping and bag dropping; the dropped bag moving mechanism is used for moving the bag dropping platform forward and backward; the transverse moving mechanism is used for transversely moving the dropped bag moving mechanism; a front-end positioning baffle plate and a bag pushing mechanism are connected with the front and rear ends of the dropped bag moving mechanism; a middle bridge connected with the transverse moving mechanism is arranged between the bag pushing mechanism and the dropped bag moving mechanism; and a bag stopping platform, a bag conveying mechanism and a bag placing mechanism are connected onto the middle bridge. The automatic stacking device provided by the invention has the beneficial effects that through the time sequence control of the bag conveying mechanism and the bag placing mechanism, the multi-form material stacking and grouping can be achieved; through the dropped bag moving mechanism and the bag dropping platform, the material stacking, dropping and arranging can be achieved; through the transverse moving mechanism, the front-end positioning baffle plate and the bag pushing mechanism, the material stacking and positioning can be achieved; and under the precise positioning control of the transverse moving mechanism, stacking groups which are subject to a plurality of stackingcycles along the compartment width direction can be orderly spliced, and then the automatic stacking and loading requirements between any material sizes and any compartments can be met.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD +1

Flame retardant high-heat-resistant polypropylene composite material for transparent electric cooker and preparing method and application of flame retardant high-heat-resistant polypropylene composite material

The invention discloses a flame retardant high-heat-resistant polypropylene composite material for a transparent electric cooker and a preparing method and application of the flame retardant high-heat-resistant polypropylene composite material. The composite material is composed of, by mass, 60-97% of high-crystallized homo-polypropylene, 1-20% of transparent padding master batch, 1.7-10% pf flame retardant master batch, 0.1-5% of scraping-resistant master batch, 0.1-2% of thermal oxidative aging resisting agent and 0.2-3% of addition agent. All the components are evenly mixed and added in a parallel double-screw extruding machine, blending and melt extrusion are carried out, and the composite material is obtained. The composite material is low in cost and excellent in comprehensive physical and mechanical property and can be used in the fields of small household appliances such as electric cookers, pressure cookers, induction cookers and soybean milk machines.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Highway slope protection ecological carpet preparation method

InactiveCN103174153AReduce the cost of protectionAvoid churnExcavationsNon-woven fabricsEnvironmental resource managementCarding

The invention discloses a highway slope protection ecological carpet preparation method. The preparation method comprises the following steps: A, utilizing polypropylene (PP) fibers and waste natural fibers as raw materials, adding other fibers, adopting an opener to respectively open the PP fibers, the waste natural fibers and other fibers, using a mixing cotton machine to mix after the opening, then adopting a carding machine for carding, and uniformly distributing the PP fibers, the waste natural fibers and other fibers; and B, utilizing a lapping machine to carry out cross lapping on the carded fibers so as to form a fibrous net, and carrying out post-processing on the fibrous net so as to form a highway slope protection ecological carpet. The method has the advantages that the preparation method is simple, the prepared ecological carpet can ensure the safety of highways and vehicles, and the protection cost of a hard material is lowered.

Owner:NANTONG UNIVERSITY

Method for restoring stannic chloride

InactiveCN102115157AReduce dust pollutionEliminate secondary pollutionStannous chlorideElectrolytic cellTin(II) chloride

The invention provides a method for restoring stannic chloride, which is characterized in that the method takes electricity as reducing agent. The method comprises the following specific steps of: adding diluted hydrochloric acid solution which is used for restoring stannic chloride generated by diazonium salt by means of stannous chloride into an electrolytic cell which is provided with a tail gas treatment system, a stirring system and two negative / positive metal electrodes, stirring and electrifying to 15-25A; slowly rising the temperature and reacting under the temperature of 30-75 DEG C; and detecting that no tetravalent tin is existed in the solution, and ending the reaction to obtain the diluted hydrochloric acid solution of the stannous chloride. By using the electricity as the reducing agent in the reaction, the method reduces the dust pollution during production process in a manufacturing shop, is more environment-friendly, is safer, and reaches the international standard. The method is more reasonable in a synthesis technology and low in cost, and the reaction yield is higher than 98%, so that the method is more suitable for the industrial production.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD

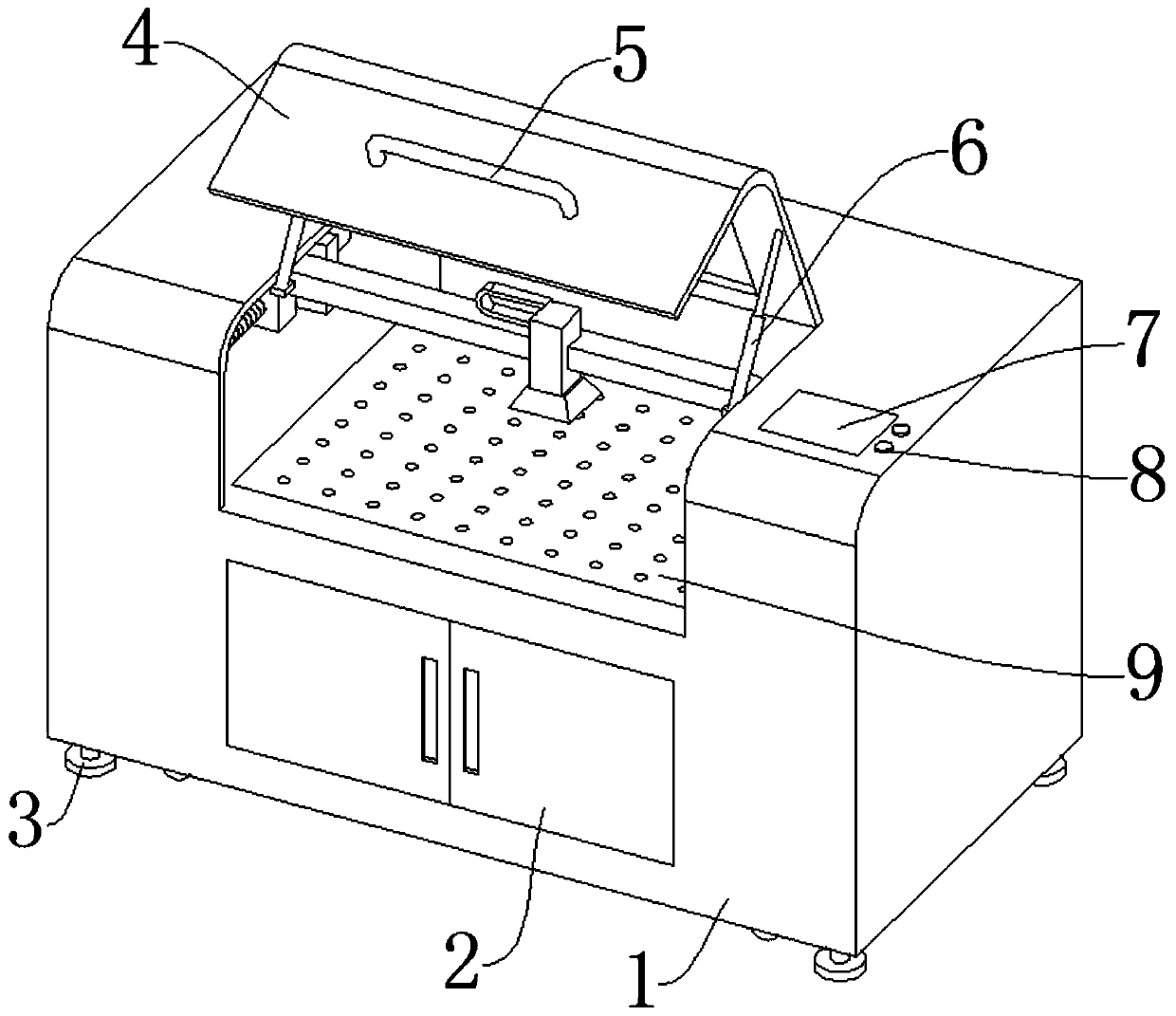

Laser cutting machine with safety protection device

InactiveCN109822234AReduce dust pollutionImprove the quality of the working environmentLaser beam welding apparatusOperations securityLaser cutting

The invention discloses a laser cutting machine with a safety protection device. The laser cutting machine comprises a box body, a safety cover, a dust hood and a filter screen. The filter screen is arranged on the inner side of the box body and is cylindrical. One side of the filter screen is provided with an exhaust fan. A flow guide cover is connected to the filter screen. A workbench is arranged above the flow guide cover, and through holes are uniformly distributed in the workbench. According to the laser cutting machine, suction force is generated through the operation of the exhaust fan; when a workpiece is cut by a cutting head, smoke in the cutting process is subjected to flow guide adsorption through the dust hood above the cutting head, the flow guide cover below the workbench is used for conducting flow guide adsorption on dust below the workpiece, and the dust enters the filter screen to be filtered, so that dust pollution in the cutting process is reduced, and the workingenvironment quality is improved; the box body is in a closed state through the safety cover, the cutting process is checked through a perspective window, splashing sparks in the cutting process are prevented from flying all around and scalding operators, and operation safety is improved.

Owner:孝感金致科技有限公司

Sandblasting-free, directly-coated and weathering-resistant steel and production method thereof

The invention discloses a sandblasting-free, directly-coated and weathering-resistant steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.04-0.12 percent of C, 0.20-0.50 percent of Si, 0.25-0.5 percent of Mn, less than or equal to 0.008 percent of S, less than or equal to 0.03 percent of P, 0.25-0.45 percent of Cu, 0.30-0.60 percent of Cu, 0.20-0.50 percent of Ni, 0.015-0.025 percent of TI, less than or equal to 0.03 percent of Als and the balance of iron and inevitable impurities. The protection method comprises the following steps: converter smelting, refining, continuous casting, heating, rolling, controlled cooling, reeling and finishing, wherein the controlled cooling is laminar flow cooling and adopts front section pulled cooling, and the concentration of Cl in laminar flow circulating cooling water is less than or equal to 100 mg / L; the reeling temperature is controlled to be 540-560 DEG C; a flatting roll is used for flatting, the surface textured roughness of the flatting roll Ra is 50-100 <mu>m, RPc is 45-70 pcs / cm, and the reduced quantity of the strip steel is 1-4 percent. The sandblasting-free, directly-coated and weathering-resistant steel has good weathering resistance, can be directly coated without a sand blasting pretreatment process, has a strong coating adhesion force and has low probability of falling off.

Owner:武汉钢铁有限公司

Uncoiling and wire drawing device

InactiveCN108994095AGuaranteed stabilityGuarantee processing qualityWire straightening devicesWire rodEngineering

The invention discloses an uncoiling and wire drawing device. The uncoiling and wire drawing device comprises a base, a feeding frame, an uncoiling mechanism, a wire drawing mechanism, a wire coilingmechanism and a control mechanism, wherein the uncoiling mechanism comprises a first uncoiling part, a longitudinal straightening part, a transverse straightening part and a material conveying part; the wire drawing mechanism comprises a wire drawing bin, wire drawing wheels, wire drawing liquid sprayers, a filter screen and a liquid collecting groove; and the wire coiling mechanism comprises a wire winding rotary shaft, a fixing seat and a wire winding motor. According to the uncoiling and wire drawing device, an upper positioning roller and a lower positioning roller are arranged to cooperate with each other, relative positions and rotating speed of the upper positioning roller and the lower positioning roller are adjusted according to the size of a wire rod, so that stability of the material feeding is guaranteed; the first uncoiling part, the longitudinal straightening part, the transverse straightening part and the material conveying part are arranged to cooperate with one another, the wire rod is straightened in all directions, and convenience is provided for subsequent processing; and the wire drawing wheels and the wire drawing liquid sprayers are arranged to cooperate witheach other, wire drawing operation is carried out on the wire rod in a closed environment, noise and dust pollution are reduced, the environment is protected, and the wire drawing effect is good.

Owner:XINCHANG HESHENGXIN BUSINESS CO LTD

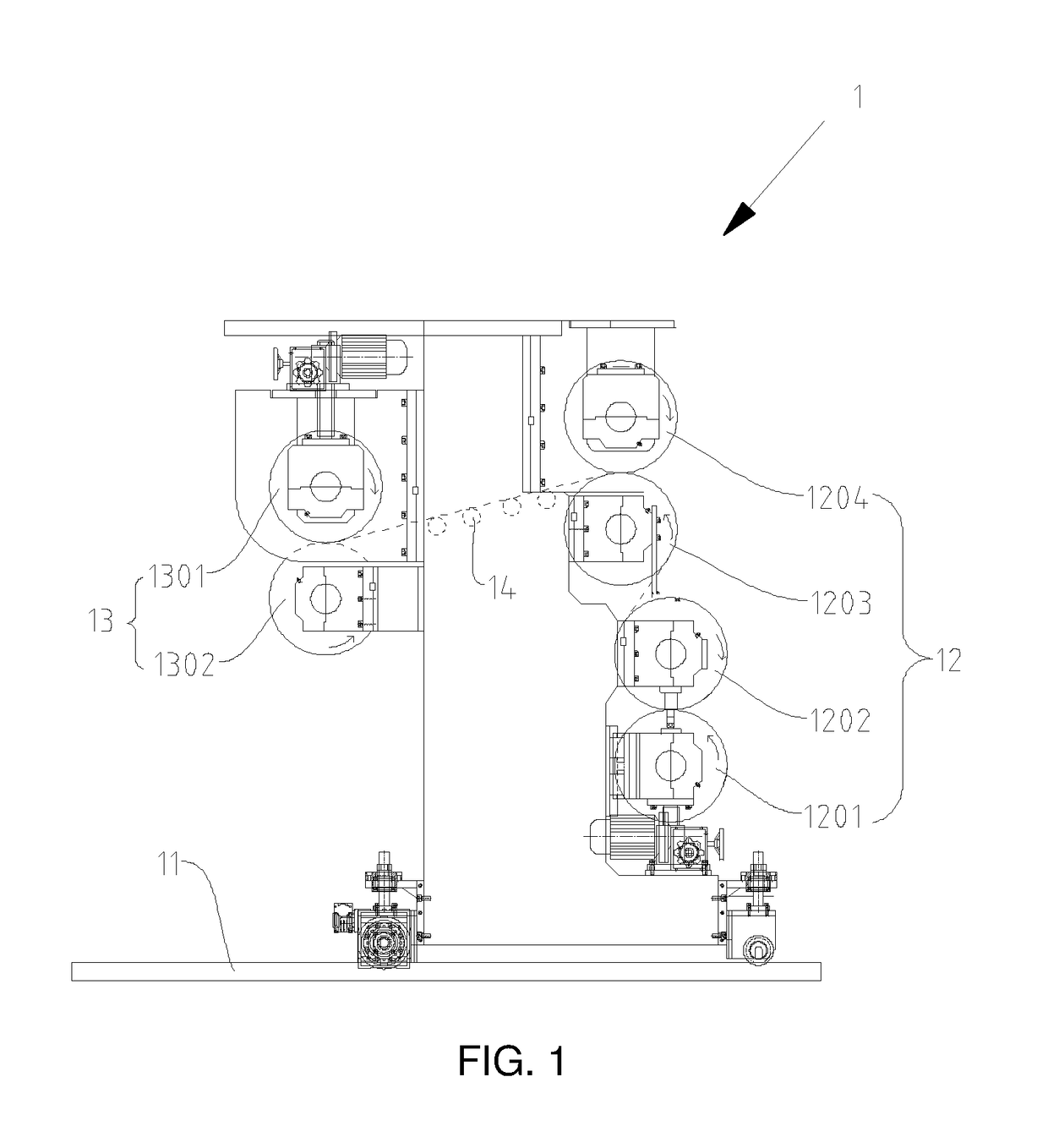

Calender, production line for foamed floor, and once-forming process for producing foamed floor

InactiveUS20190016024A1Improve embossing effectReduce the temperatureDomestic articlesFlooringProduction lineEngineering

A calender, comprising a base and a set of calendering rollers arranged on the base, wherein, the set of calendering rollers comprises a set of primary calendering rollers and a set of embossing rollers used for embossing a material to be processed; the set of primary calendering rollers and the set of embossing rollers are spaced apart for a distance to allow the material to be cooled before entering the set of embossing rollers from the set of primary calendering rollers. The calender can realize a better embossing effect, and integration production can be realized due to the use of the calender in a production of a foamed floor.

Owner:QINGDAO SANYI PLASTIC MACHINERY

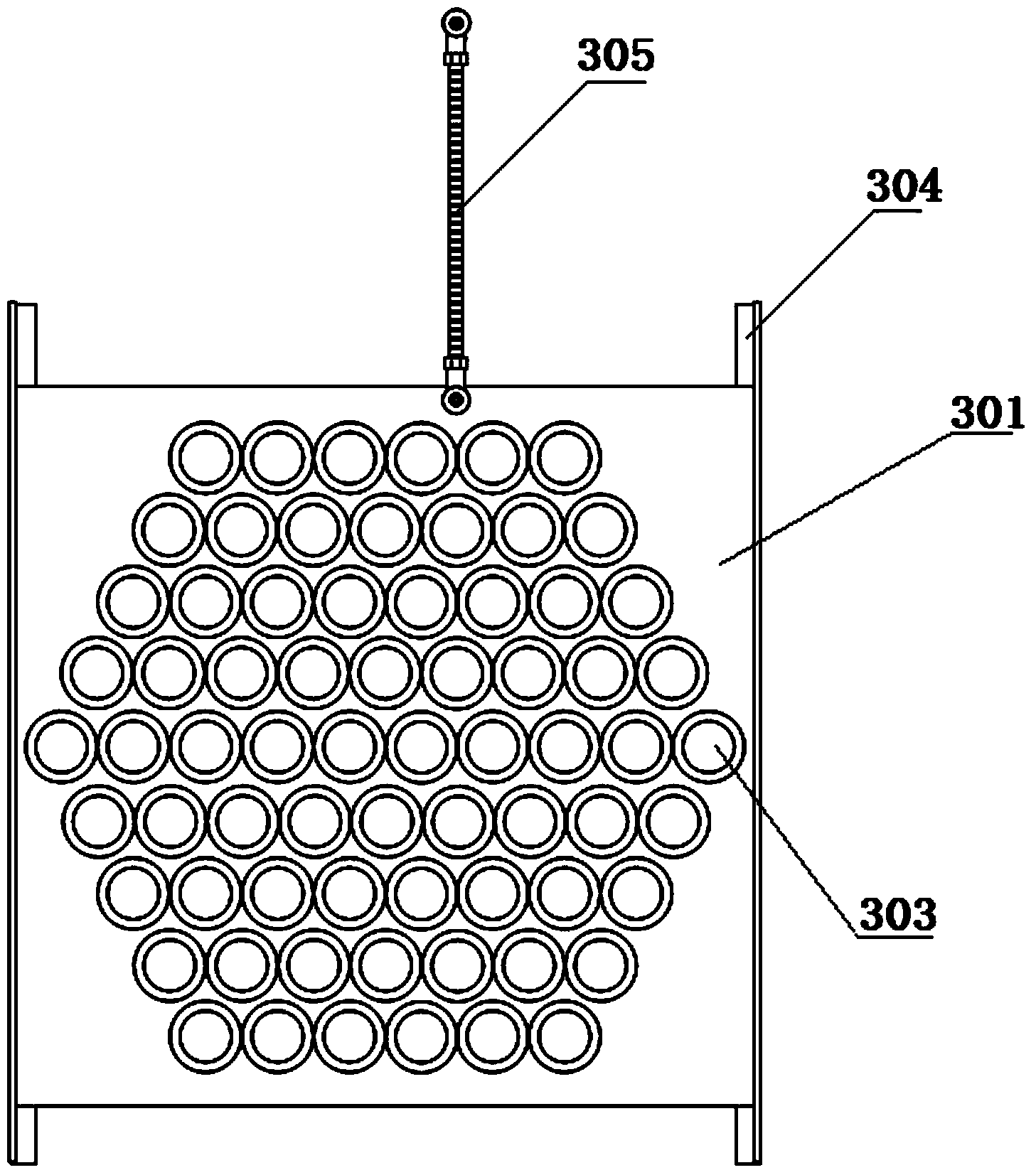

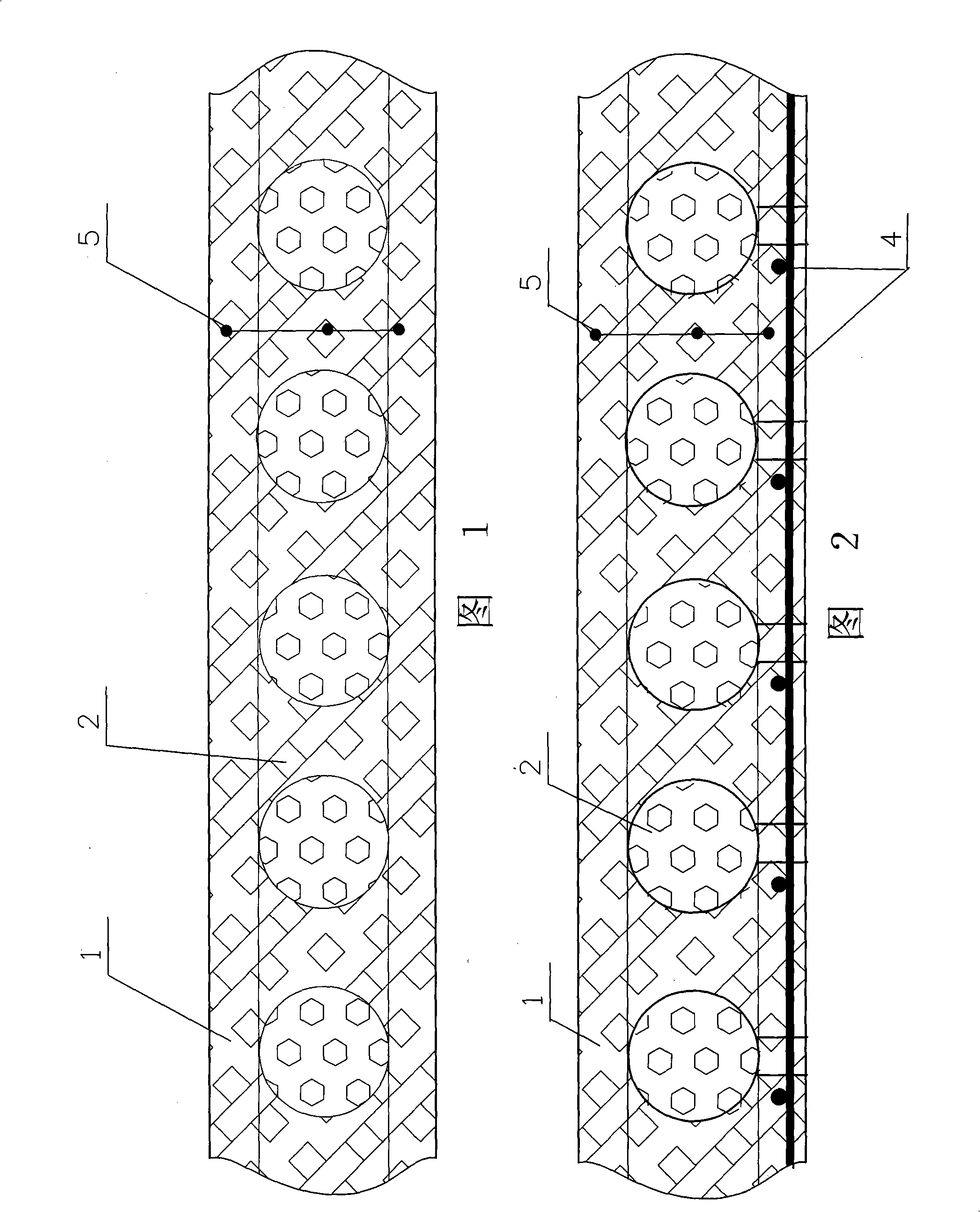

Vertical firework tube shaper

InactiveCN103968716AIncrease productivityEliminate jamming and confusionFireworksShortest distanceFireworks

The invention discloses a vertical firework tube shaper which comprises a hopper used for loading firework tubes, wherein a flexible neatening mechanism is arranged in the hopper, a guiding mechanism, a feeding mechanism and a shaping mechanism are arranged below the hopper from top to bottom in sequence, the firework tubes in the hopper swing in a reciprocating mode back and forth by short distance along with a guiding plate under the reciprocating neatening of the flexible neatening mechanism to generate vibration which enables the firework tubes to enter the guiding mechanism in a vertical mode, then point-to-point transferring is conducted on each vertical firework tube in a relay mode by the feeding mechanism, and the firework tubes are sent to the shaping mechanism to be shaped and bundled. The vertical firework tube shaper can operate without stop and work reliably and smoothly, and therefore production efficiency is improved greatly; due to the adoption of working mechanisms arranged according to the vertical firework tube principle, it is ensured that dust and noise pollution is far lower than that of other equipment.

Owner:周永录

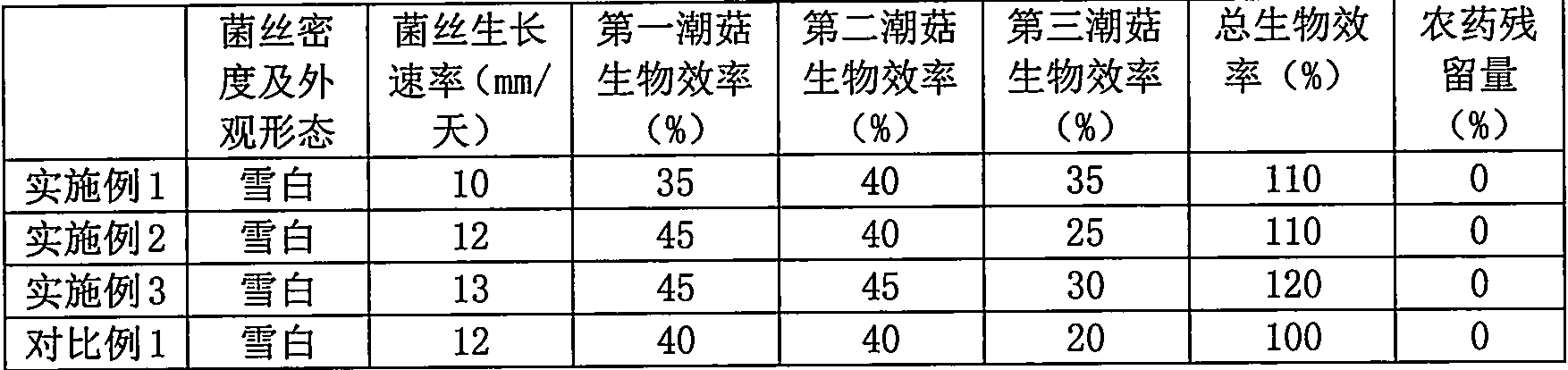

Mushroom culture medium prepared from coffee grounds

InactiveCN103553801AReduce wood consumptionReduce dust pollutionFertilizer mixturesCoffeaWater content

The invention discloses a mushroom culture medium prepared from coffee grounds. The mushroom culture medium comprises dry materials and water; by setting the weight of the dry materials to be 100 parts, the dry materials are composed of following components by weight percent: 20%-50% of the coffee grounds, 28%-58% of cotton seeds, 15%-20% of wheat bran, 1%-2% of gypsum and 1%-2% of lime. The mushroom culture medium is specifically prepared as follows: recycling and concentrating the waste coffee grounds and drying; crushing the coffee grounds until the diameter is 0.1cm-0.5cm; uniformly mixing the crushed coffee grounds with the cotton seeds, the wheat bran, the gypsum and the lime according to the weight ratio; adding water to enable the water content to be 60%-70% to prepare a primary material; and sterilizing the primary material for 1-1.5 hours under the conditions that the density is 1.5kg / cm<2> and the temperature is 121 DEG C and cooling. According to the mushroom culture medium prepared from the coffee grounds, the coffee grounds are used for replacing a sawdust part to provide necessary components including cellulose and the like; the growing of mushrooms is accelerated; the content of heavy metal of the mushrooms is reduced due to utilization of physical and chemical adsorption of the coffee grounds and no pesticide residue exists.

Owner:李洁

Chinese medicine preparation for treating cardiac and cerebral vascular diseases and its preparing process

InactiveCN1857607APromote absorptionRapid dissolutionUnknown materialsPill deliveryVascular diseaseAngina

The present invention relates to a kind of Chinese medicine preparation for treating cardiac and cerebral vascular diseases and its preparation process. The Chinese medicine preparation has the features of easy disintegration, easy absorption, fast acting, high bioavailability and high curative effect. The main Chinese medicinal materials include fleeceflower root, Chuanxiong rhizome, etc , which are extracted to obtain dry extractum, and the dry extractum is crushed into powder and added with pharmaceutically acceptable carrier or excipient to prepare capsule, soft capsule, granule, oral disintegrant tablet or dispersed tablet. The Chinese medicine preparation is used mainly for treating coronary heart disease, angina, atherosclerosis, hyperlipemia and cardiac and cerebral vascular diseases.

Owner:四川泰华堂制药有限公司

Autoclaved aerated concrete, steel reinforced concrete composite structure and application thereof

InactiveCN101294429AReduce weightReduce floor pressureConstruction materialFloorsFloor slabReinforced concrete

The invention relates to a composite structure of autoclaved aerated concrete and reinforced concrete and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises a building concrete structure member (1) containing reinforced steel bars, wherein the low stress part at the middle of the concrete structure member uses autoclaved aerated concrete (2). The product can be used as precast elements for buildings, such as floor slabs and roof slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

Zinc metallurgy apparatus and process

Owner:CHINA ENFI ENGINEERING CORPORATION

Foundation pit support breast beam wire saw cutting method

The invention relates to a foundation pit support breast beam wire saw cutting method which includes the steps: firstly, embedding steel bars into cast-in-place piles, daubing contact surfaces among the cast-in-place piles and a breast beam, and binding breast beam reinforcing steel bars; secondly, drawing cutting block diagrams; thirdly, pre-embedding PVC (polyvinyl chloride) sleeves, and avoiding blocking of the sleeves; fourthly, pre-embedding round steel lifting hooks on two sides of each concrete block to be cut; fifthly, constructing beam plate structures below a supporting beam and thebreast beam, and cutting parts of the pre-embedding PVC sleeves higher than beam surfaces; sixthly, arranging supporting systems at the bottom of the supporting beam; seventhly, arranging sleepers onthe supporting beam; eighthly, fixing a wire saw machine on the breast beam; ninthly, enabling a diamond wire saw to wound the pre-embedding PVC sleeves, and connecting the diamond wire saw with the wire saw machine to cut concrete blocks; tenthly, hosting the cut concrete blocks by the round steel lifting hooks to off-site place to be crushed. According to the method, noise and dust pollution aredecreased, the cut concrete blocks are transferred to off-site place to be crushed, and inside cleaning cost and time are reduced.

Owner:CHINA MCC20 GRP CORP

Calcium stearate preparation technology

InactiveCN103880632AReduce liquidityHigh densityOrganic compound preparationCarboxylic acid salt preparationCalcium hydroxideDistilled water

The invention discloses a calcium stearate preparation technology. The technology comprises the following steps: 1, adding 40-45 parts ofstearic acid, 10-15 parts of calcium hydroxide, 1-5 parts of zinc oxide and 20-30 parts of distilled water into a reaction kettle, and uniformly stirring; 2, heating the reaction kettle to 90DEG C while starting a vacuum system; 3, sampling, analyzing free acids and calcium hydroxide, and ending the reaction if continuous three-time detection results show that the content of calcium hydroxide is zero and the content of the free acids is smaller than 0.5%; and 4, separating the obtained product from raw materials, and drying the product until the water content is smaller than 2% in order to obtain the calcium stearate product. The product prepared in the invention has the advantages of large density, reduced fluidity, unlikely suspension in air, and reduction of the dust pollution.

Owner:QINGDAO SHUAIWANG OIL CHEM

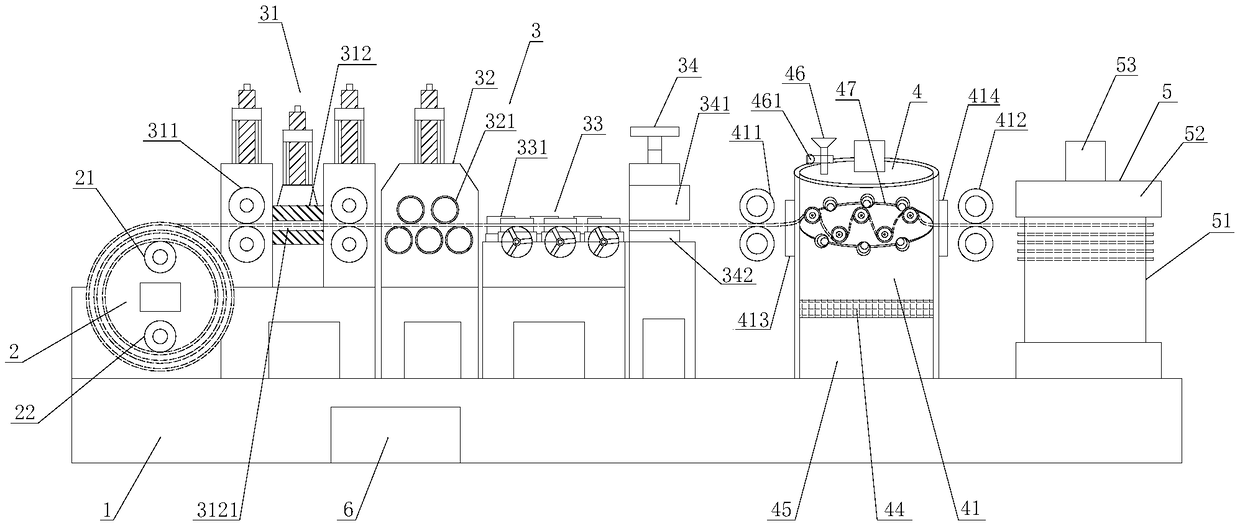

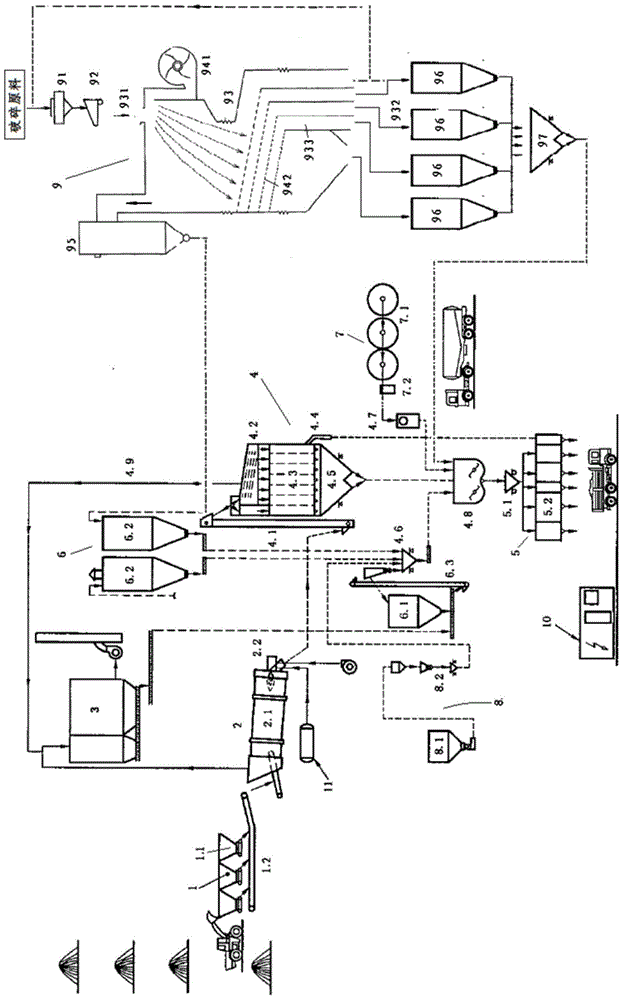

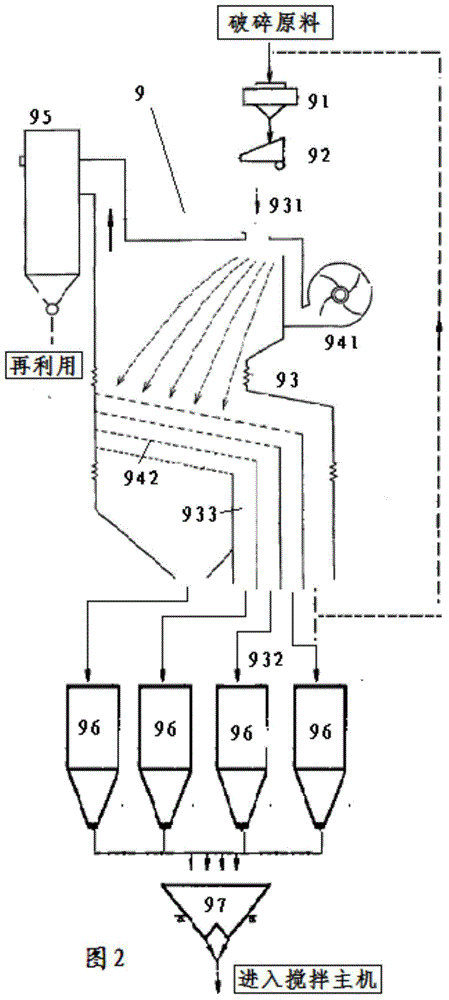

Production equipment for high-quality asphalt mixture and production method thereof

ActiveCN104894946AReduce energy consumptionReduce dust pollutionRoads maintainenceAir separationAsphalt

The invention relates to the field of asphalt mixture production, and specifically relates to production equipment for a high-quality asphalt mixture and a production method thereof. The production equipment for the high-quality asphalt mixture comprises an intermittent asphalt mixture stirring system and a fine aggregate treatment system, wherein the fine aggregate treatment system comprises an air separation device, a negative pressure dust removal and recovery device, a fine aggregate storage device, and a fine aggregate metering and conveying device. According to the production equipment for a high-quality asphalt mixture and the production method provided by the invention, by adding the fine aggregate treatment system, fine aggregates can be independently broken and sieved, and stored and metered, and directly poured in an asphalt stirring main machine without the need of further heating of a drying drum to carry out asphalt mixture production; compared with the previous production equipment for an asphalt mixture, because fine aggregate grading is strictly ensured, the structure is capable of greatly improving the asphalt mixture, reducing energy consumption, and meeting the production needs of the high-quality asphalt mixture.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com