Mushroom culture medium prepared from coffee grounds

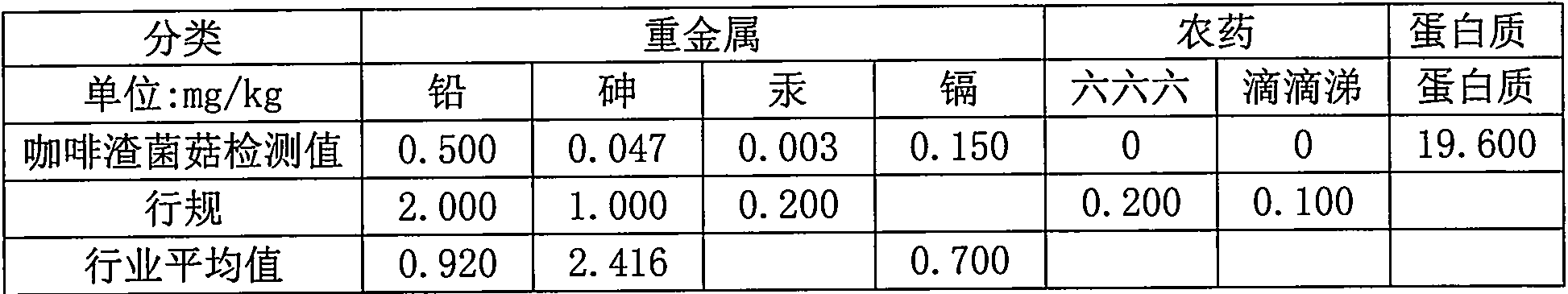

A technology for mushroom culture medium and coffee grounds, which is applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of not realizing the full utilization of coffee grounds, high cost, low commercial value, etc. The effect of reducing pesticide residues and heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

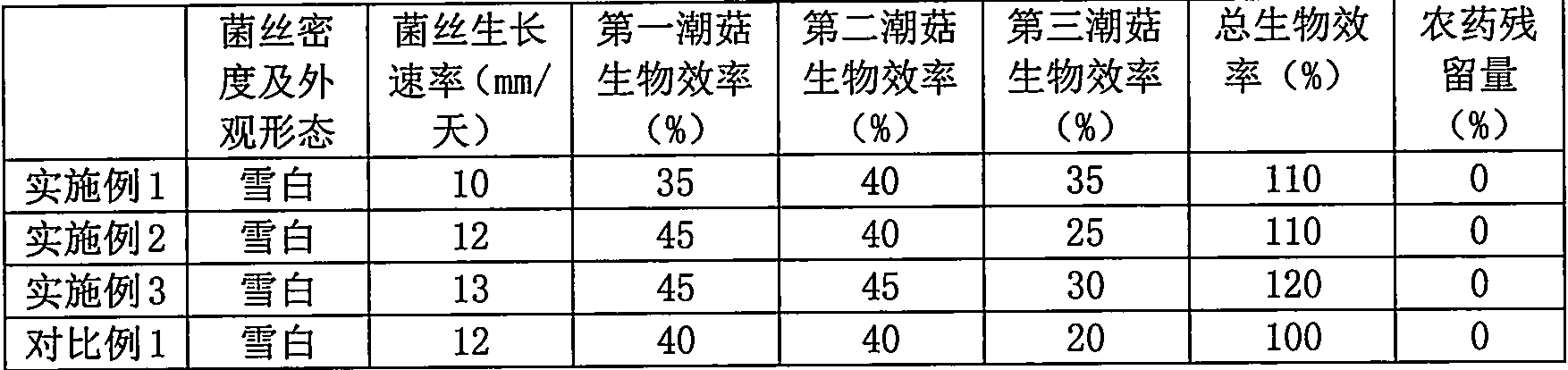

Examples

Embodiment 1

[0025] Example 1 relates to mushroom culture medium prepared from coffee grounds. Concrete preparation process is as follows:

[0026] A. Recycle and concentrate the discarded coffee grounds, and expose them to the sun to a moisture content of 10%;

[0027] B. Then use drying equipment to roast the exposed coffee grounds for 2.5 hours at 150°C;

[0028] C. Finally, grind the roasted coffee grounds to a diameter of 0.2 cm and set aside;

[0029] D, the coffee grounds after pulverizing and cotton seed, bran, gypsum, lime are mixed uniformly by the weight ratio described in Table 1, add water and make water content be 65%, make the initial material of mushroom culture medium;

[0030] E, every 1100 grams of the mushroom culture medium initial material is packed into the space bag plastic bag, through 1.5kg / cm 2 , sterilized at 121°C for 1.2 hours, and cooled to obtain the mushroom culture medium;

[0031] F. Insert the mushroom hyphae into the above-mentioned mushroom medium,...

Embodiment 4

[0046] This example relates to a mushroom culture medium prepared from coffee grounds. Concrete preparation process is as follows:

[0047] A. Recycle and concentrate the discarded coffee grounds, and expose them to the sun to a moisture content of 15%;

[0048] B. Then use drying equipment to roast the exposed coffee grounds for 4 hours at 200°C;

[0049] C. Finally, crush the roasted coffee grounds to a diameter of 0.5 cm and set aside;

[0050] D, the coffee grounds after pulverizing and cotton seed, bran, gypsum, lime are mixed uniformly by the weight proportion described in Table 1, add water and make water content be 70%, make mushroom culture medium raw material;

[0051] E, every 1100 grams of the mushroom culture medium initial material is packed into the space bag plastic bag, through 1.5kg / cm2 , sterilized at 121°C for 1.5 hours, and cooled to obtain the mushroom culture medium;

[0052] F. Insert the mushroom hyphae into the above-mentioned mushroom medium, plac...

Embodiment 5

[0055] This example relates to a mushroom culture medium prepared from coffee grounds. Concrete preparation process is as follows:

[0056] A. Recycle and concentrate the discarded coffee grounds, and expose them to the sun to a moisture content of 5%;

[0057] B. Then use the drying equipment to roast the exposed coffee grounds for 1 hour at 120°C;

[0058] C. Finally, crush the roasted coffee grounds to a diameter of 0.1 cm and set aside;

[0059] D, mix the coffee grounds after pulverizing with cottonseed, bran, gypsum, lime according to the weight ratio described in Table 1, add water so that the water content is 60%, and make the initial material of the mushroom culture medium;

[0060] E, every 1100 grams of the mushroom culture medium initial material is packed into the space bag plastic bag, through 1.5kg / cm 2 , sterilized at 121°C for 1 hour, and cooled to obtain the mushroom culture medium;

[0061] F. Insert the mushroom hyphae into the above-mentioned mushroom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com