Movable ceiling tile combined house whose door and window positions can be artitrarily set

A technology for ceiling boards and combined houses, which is applied in the field of prefabricated houses, which can solve the problems of poor heat preservation, high manufacturing precision requirements, and large steel consumption, so as to improve overall stability, reduce wood consumption, and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

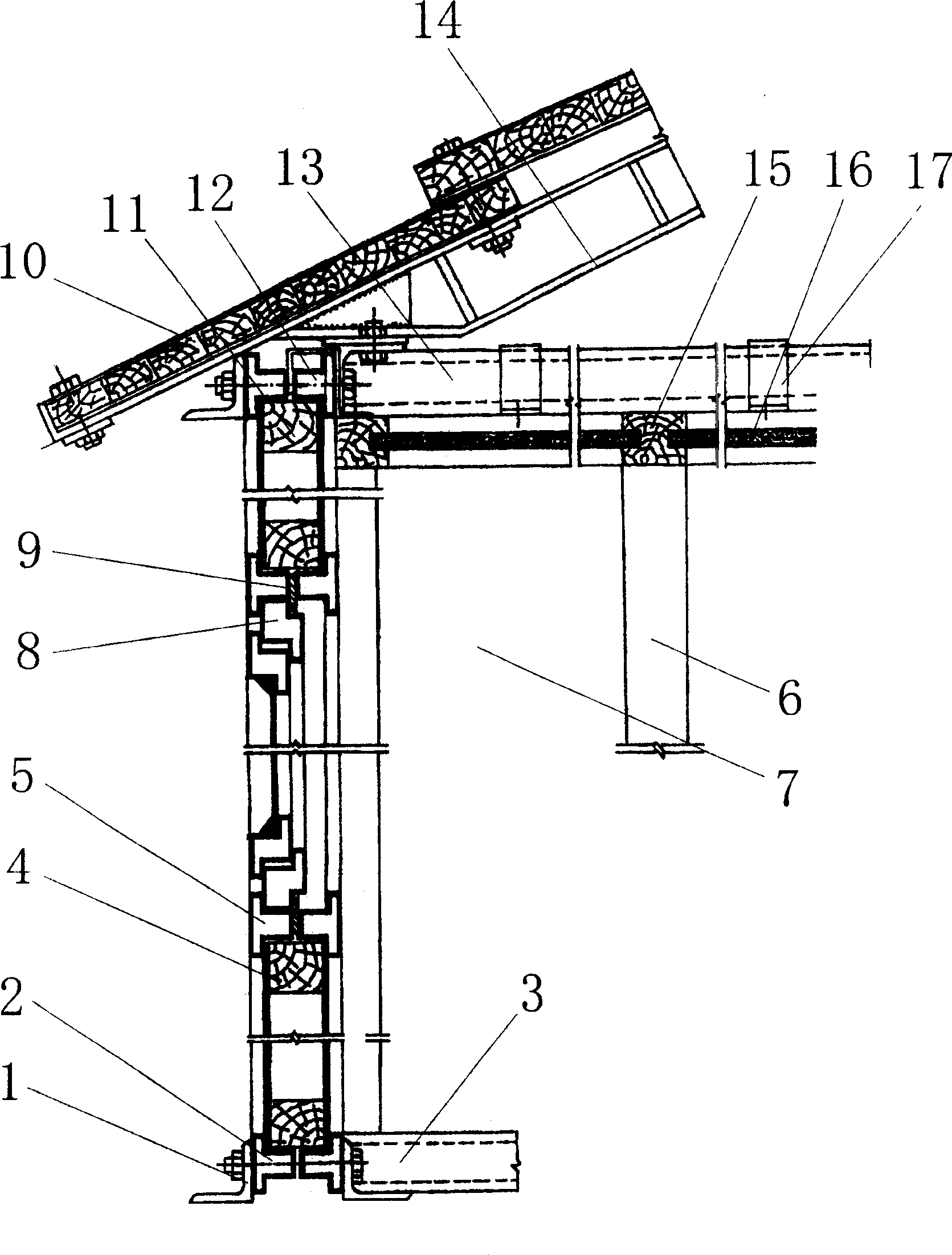

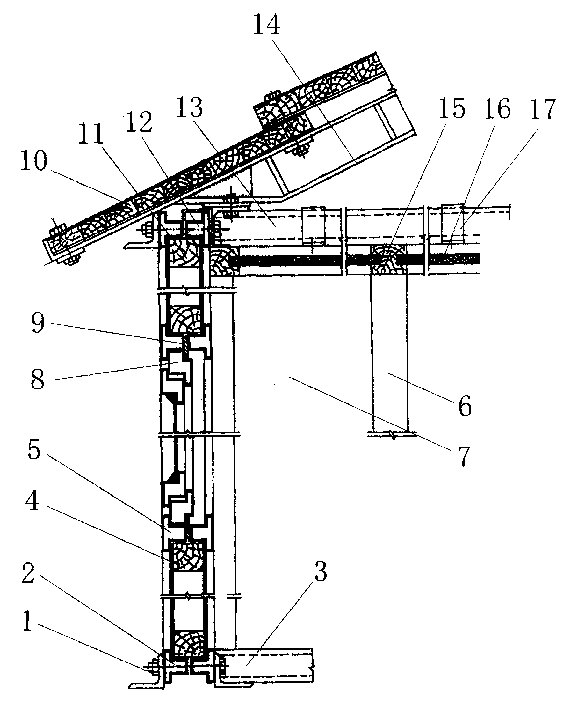

[0007] As shown in the figure, the corner column 1, the upper longitudinal ring beam 12, the lower longitudinal ring beam 2, the upper horizontal ring beam 13, the lower horizontal ring beam 3, the middle horizontal frame 5 and the middle column 6 are all made of commercial fasting steel window materials. Symmetrical tailor welding, leaving a gap in the middle, the upper and lower tenoned central column 6 is stuck between the upper longitudinal ring beam 12 and the lower longitudinal ring beam 2, except for the corner column 1 at the four corners of the outer wall, the rest are used by the central column 6. A closed groove with gaps is formed between the corner column 1, the upper longitudinal beam 12, and the lower longitudinal beam 2, and the wall panels 7 are all inserted into the groove. When installing the window 8, use a The middle horizontal frame 5, the upper half wall panel 11, the window 8 and the window wall panel 4 are replaced. The middle horizontal frame 5, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com