Connection-type golf nail

A golf nail and connection technology, which is applied to golf balls, golf clothes, golf accessories, etc., can solve the problems of large wood consumption and large processing volume, and achieve the effects of saving wood consumption, improving utilization rate, and reducing electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

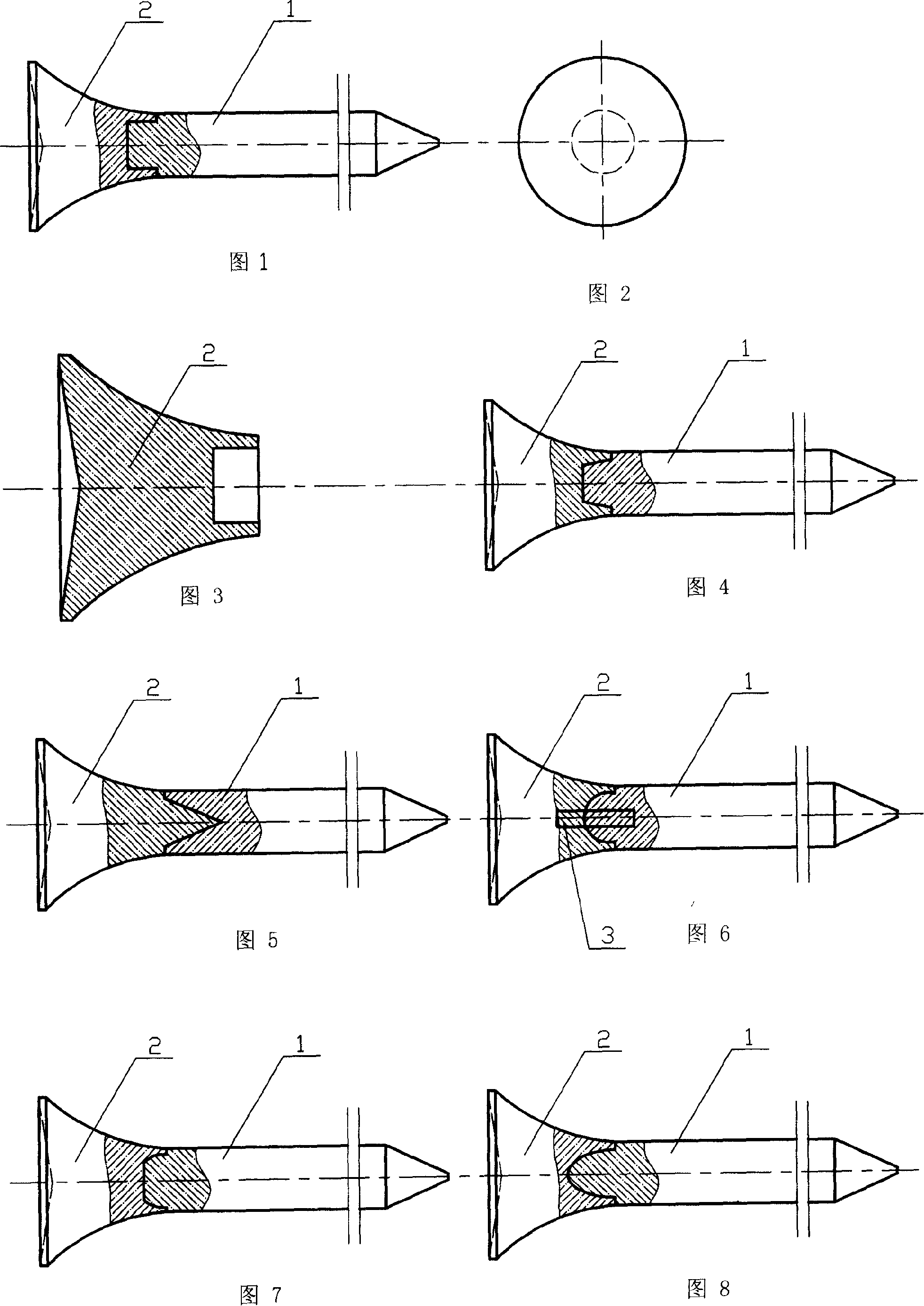

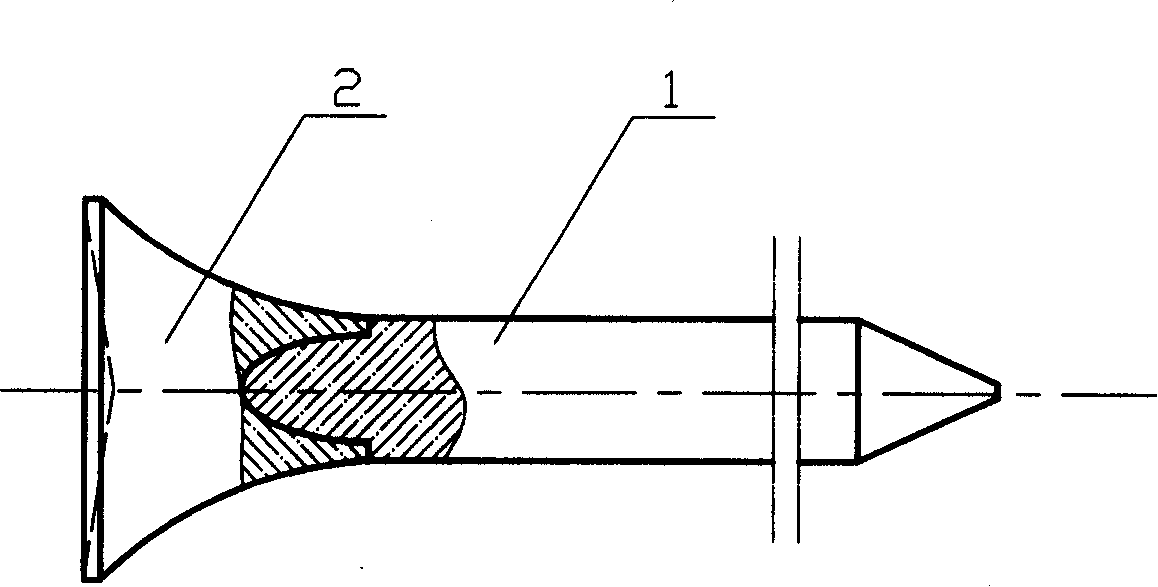

[0033] Connecting golf nails, its composition includes: the product is made of wood, including a nail tail 1, the upper end of the nail tail is inlaid and connected with the nail seat 2 through a connection port and glued and fixed with wood adhesive. The length of the nail seat is generally 16MM, the diameter of the nail seat is 11MM, the diameter of the rod part of the nail tail is 4MM, and the length of the tail vertebra is still 7.795. The total length is determined according to international standards. The length of the recessed end adopts a dynamic fit or a transition fit with a small gap in the radial direction, and the upper end of the nail tail has a positioning shoulder. When assembling, apply glue first and then connect.

[0034] The mating surface of the connection port can be a regular or irregular curved surface, such as a spherical crown or a spherical strip or an ellipsoid or a parabolic curved surface, and can also be processed into other irregular curved surf...

Embodiment 2

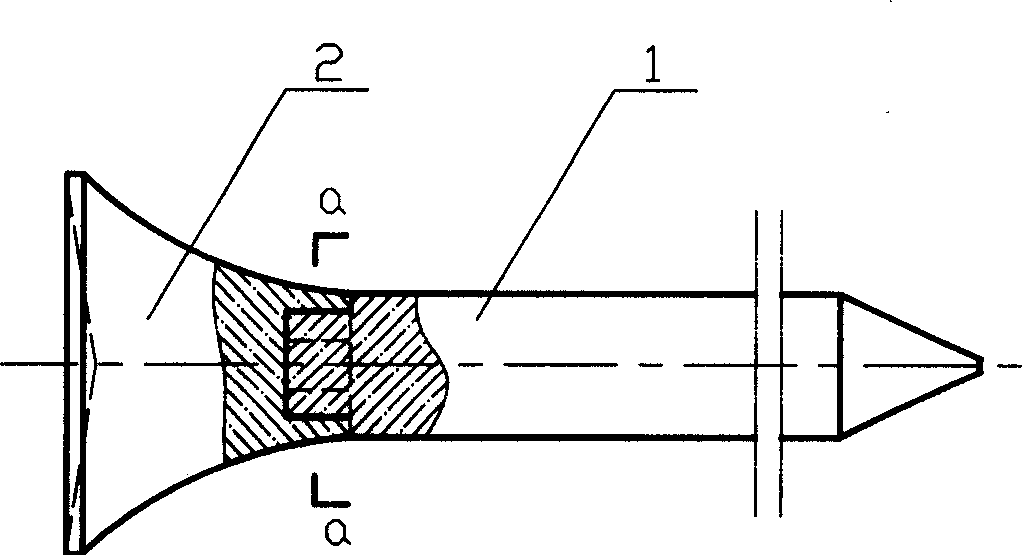

[0036] The connected golf nail comprises: a nail tail 1, the upper end of the nail tail is inlaid and connected with the nail seat 2 through a connection port and glued and fixed with wood adhesive. The mating surface of the connection port is a tongue-and-groove surface formed by a combination of a plane and a regular curved surface, such as a cylinder, a truncated cone, or a cone, and an irregular curved surface can also be used. Among them, the cylindrical mating surface can adopt transition fit. In addition, details of other parts can be referred to Embodiment 1.

Embodiment 3

[0038] The connected golf nail comprises: a nail tail 1, the upper end of the nail tail is inlaid and connected with the nail seat 2 through a connection port and glued and fixed with wood adhesive. The mating surface of the connection port is a tongue-and-groove surface formed by combining planes, such as a polygonal or cross-shaped surface such as a triangle, a quadrangle, or a hexagon. Easy to process by hand, temporary patch on site. The connecting parts can be transition fit or interference fit, and details of other parts can be referred to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com