Patents

Literature

189results about How to "Improve the quality of the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

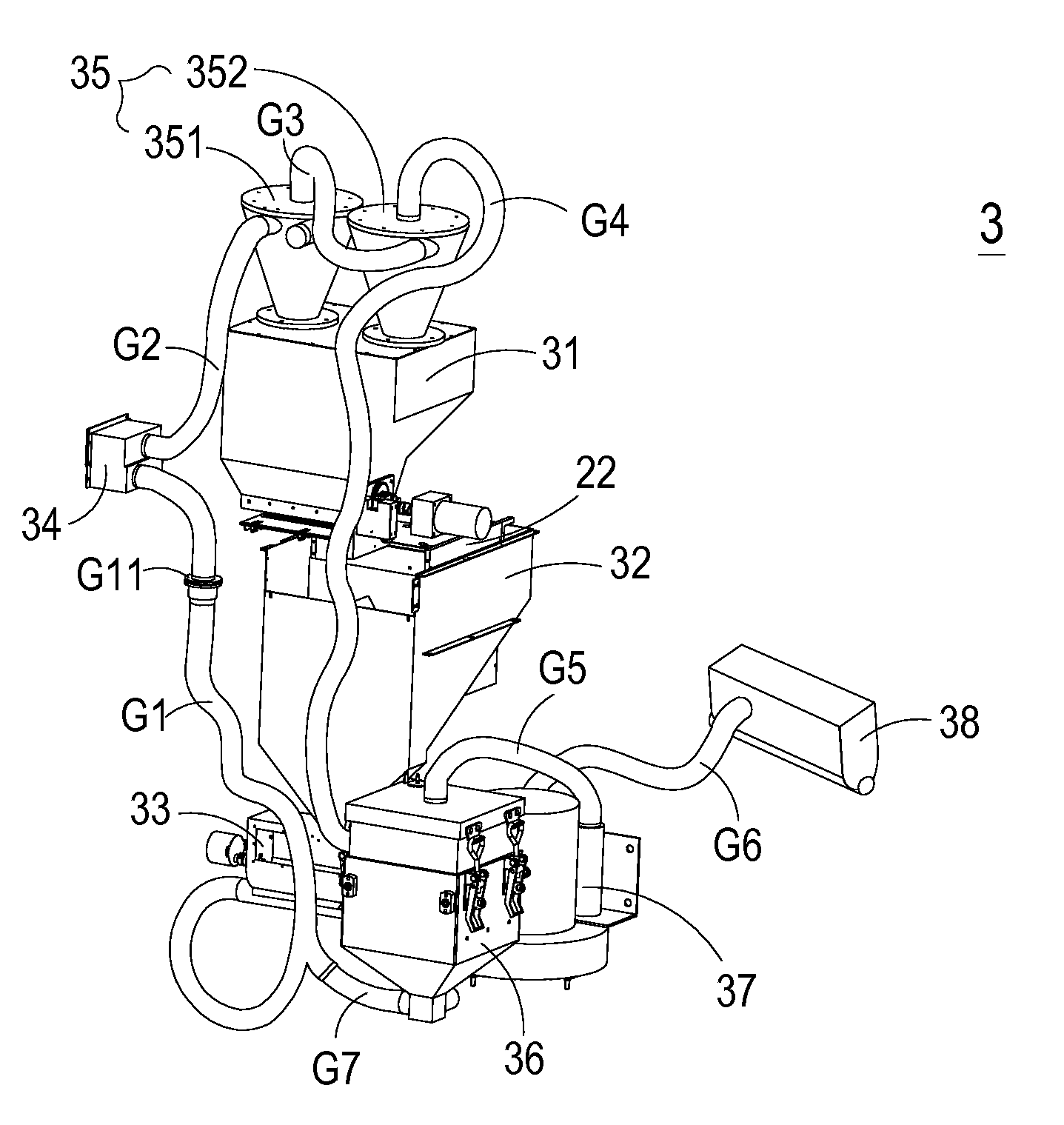

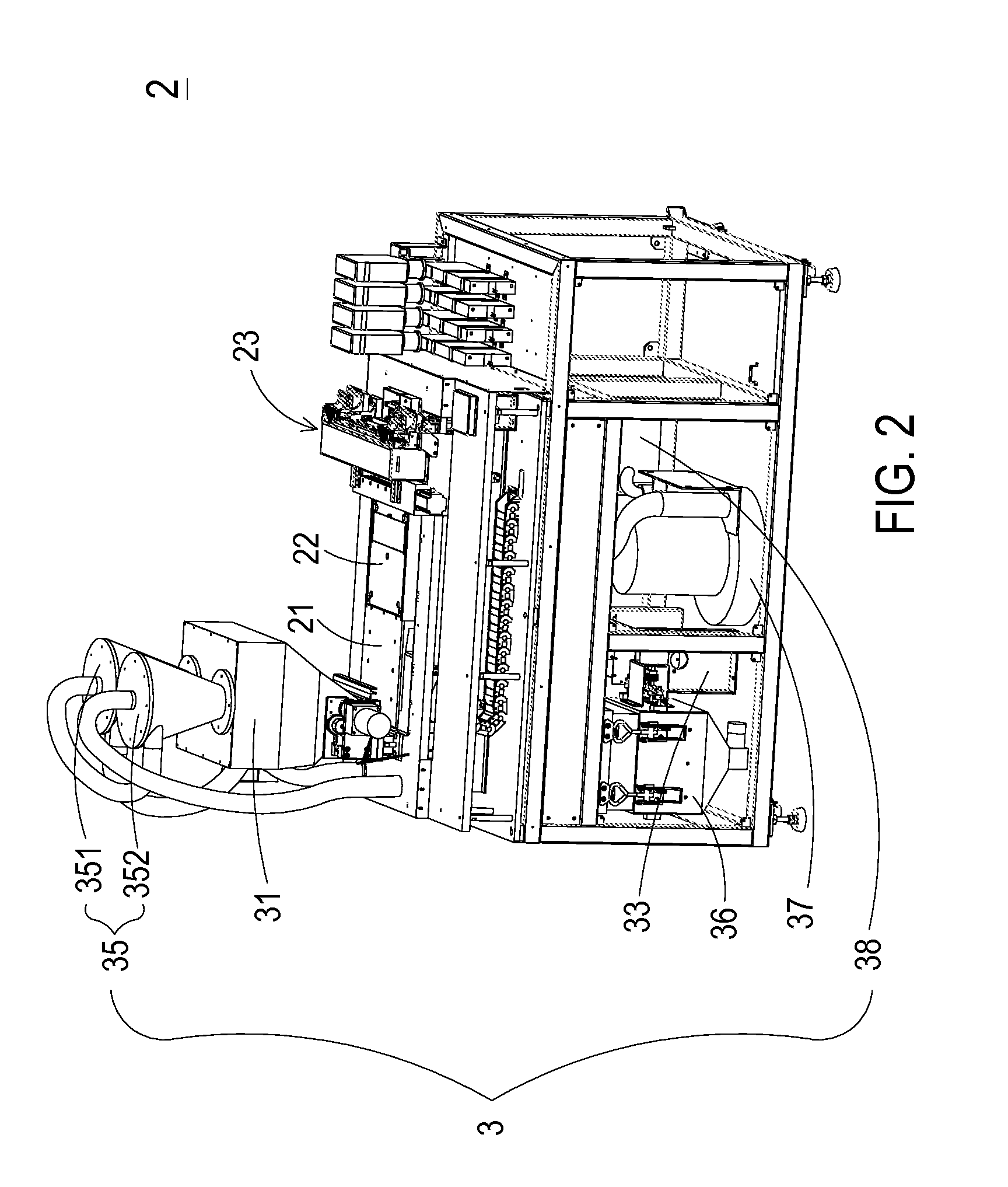

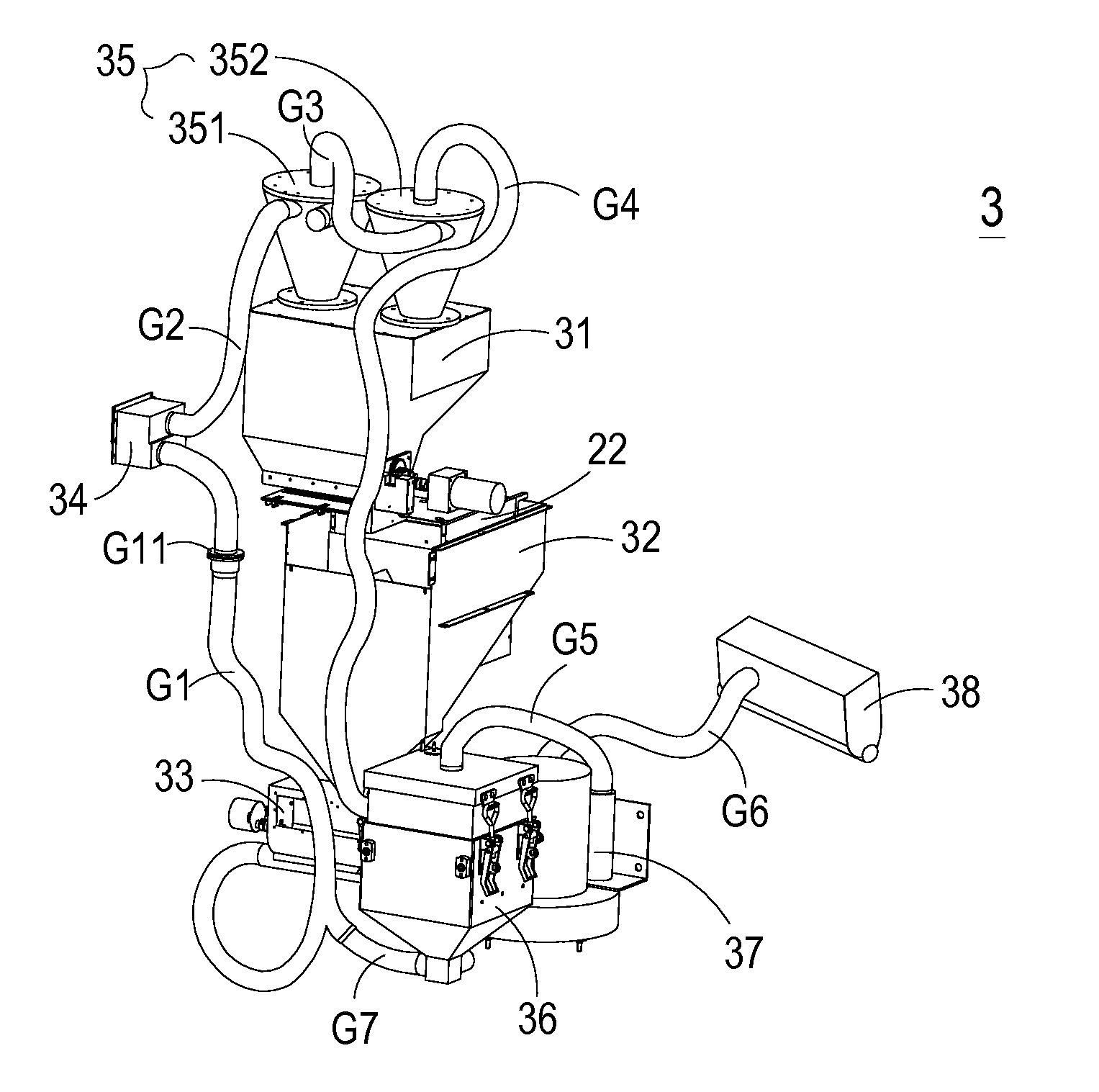

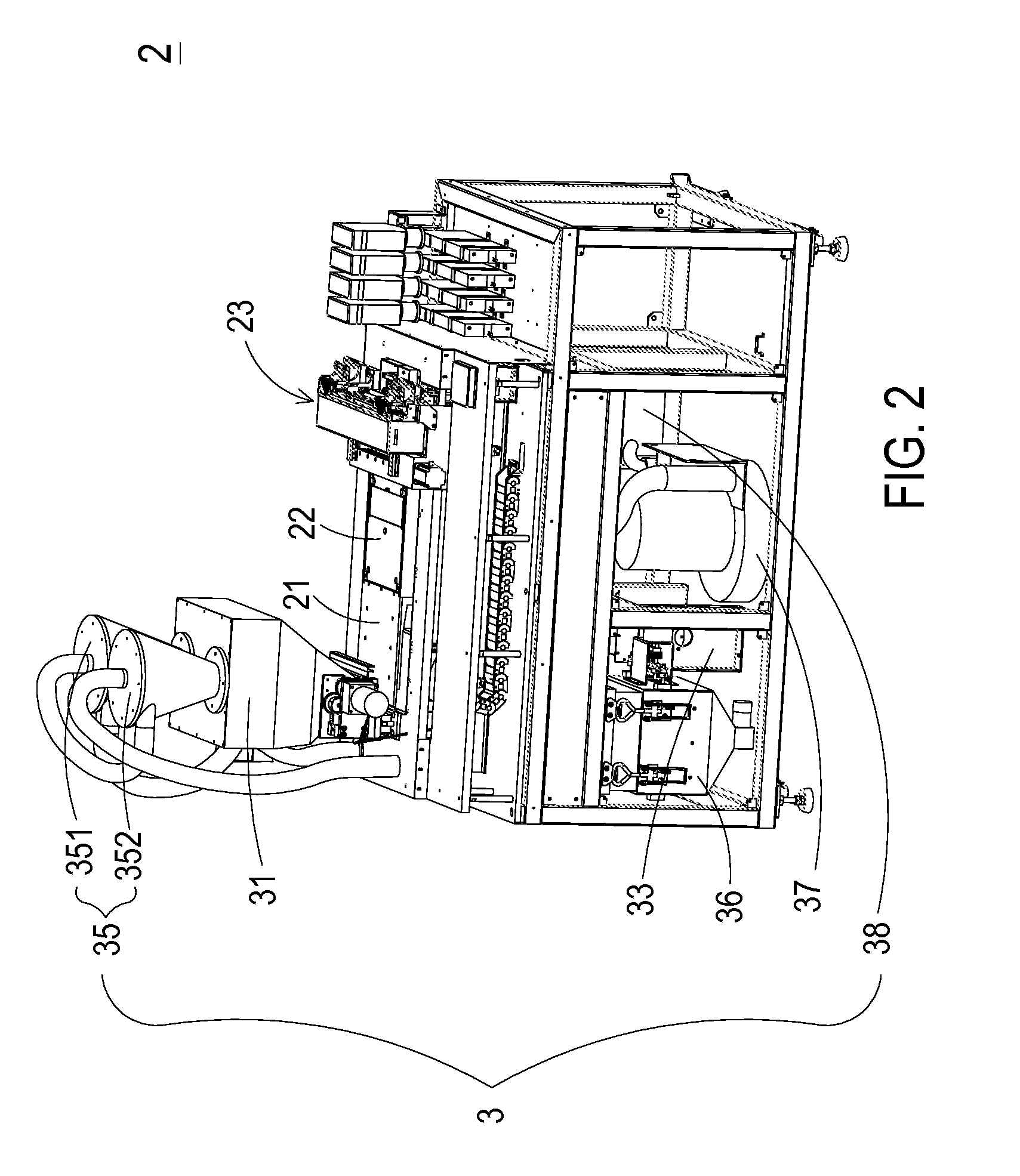

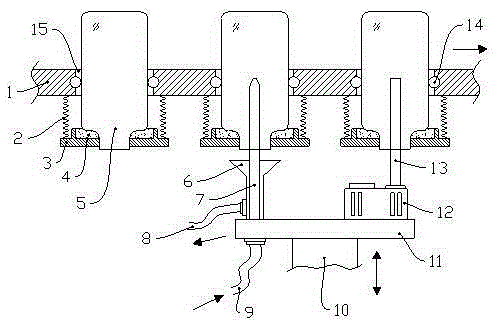

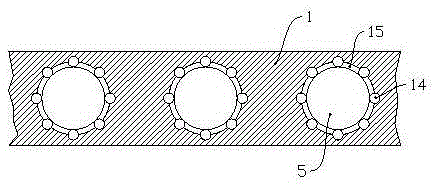

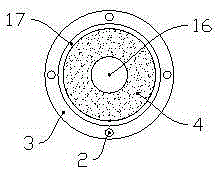

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Infrared radiation ceramic glaze layer with bacteriostasis function and its prepn process

The present invention relates to an infrared radiant ceramic glazed layer and its preparation method. The main composition of said glazed layer in includes potash feldspar, SiO2, CaCo3, ZnO, talcum, ZrSiO4, clay BaCO3, opaque frit, colouring agent and infrared radiannt ceramic powder. The invention adopts ceramic processing technique, and makes said materials into the invented infrared radiat ceramic glazed layer with the obvious bacteria-inhibiting action for mould, Gram-positive bacterium and Gram-negative bacteruim, and its bacteria-inhibiting rate is up to 91.87%-100%. It can be used in building ceramics, specially used in the places of kitchen, toilet, hospital, infant school and others, so that it possesses strong practicability.

Owner:WUHAN UNIV OF TECH

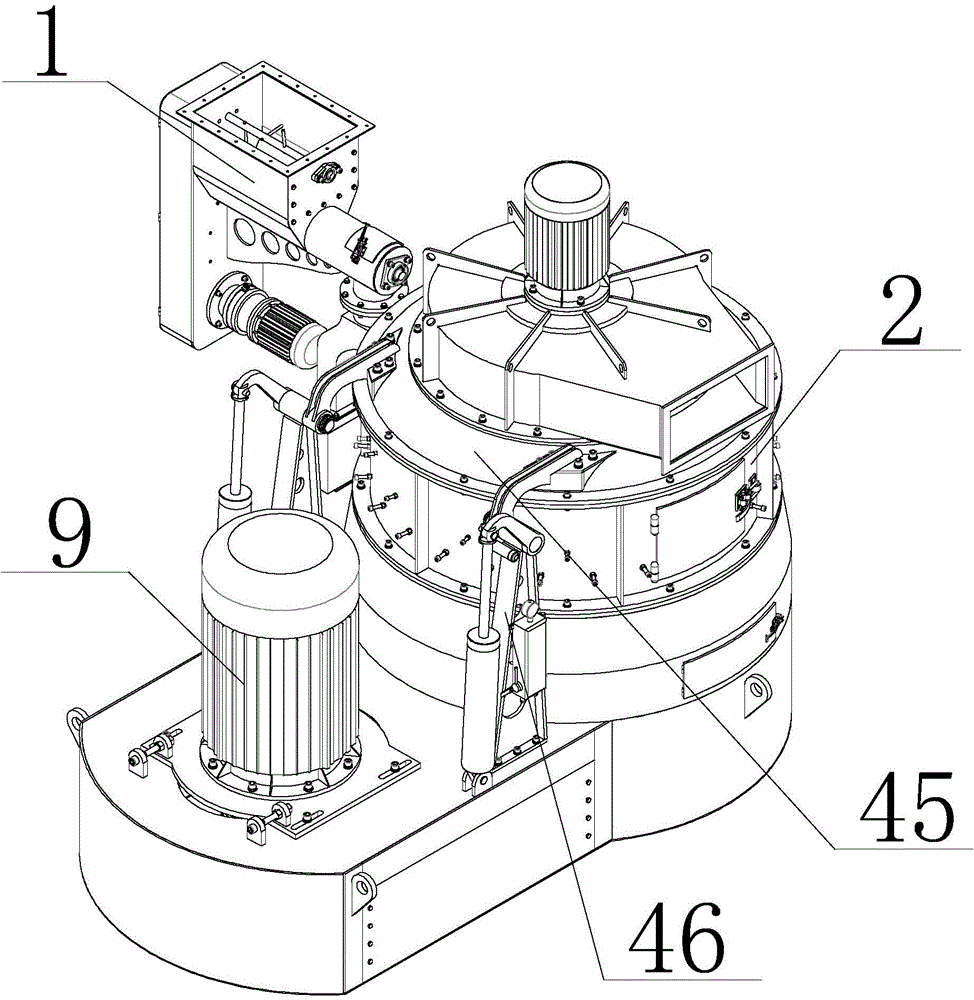

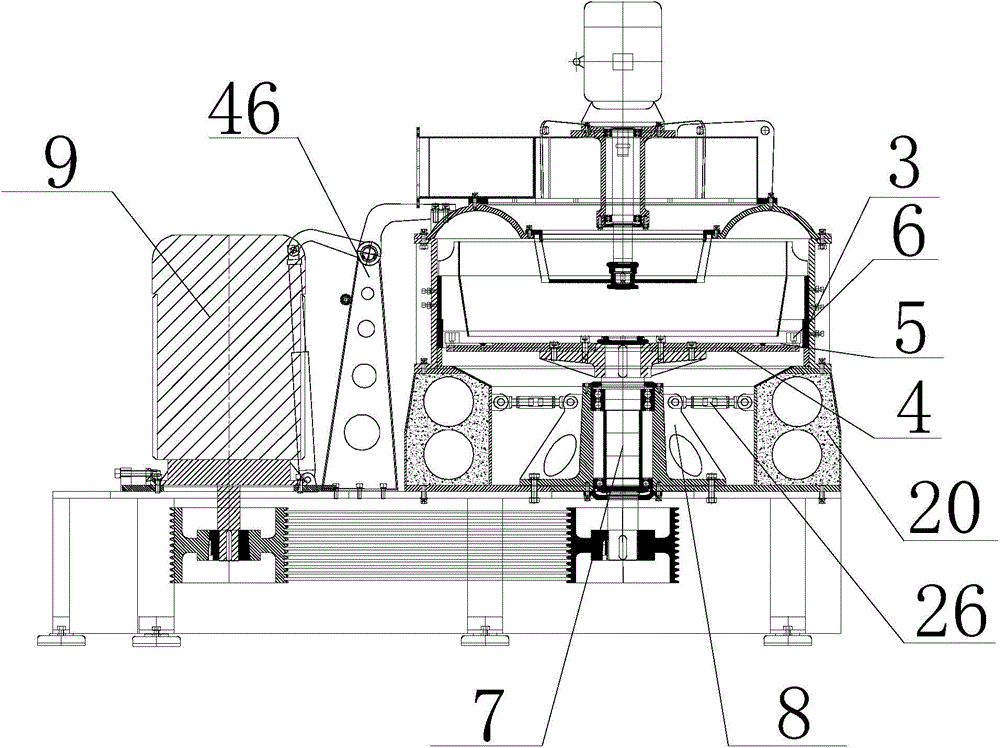

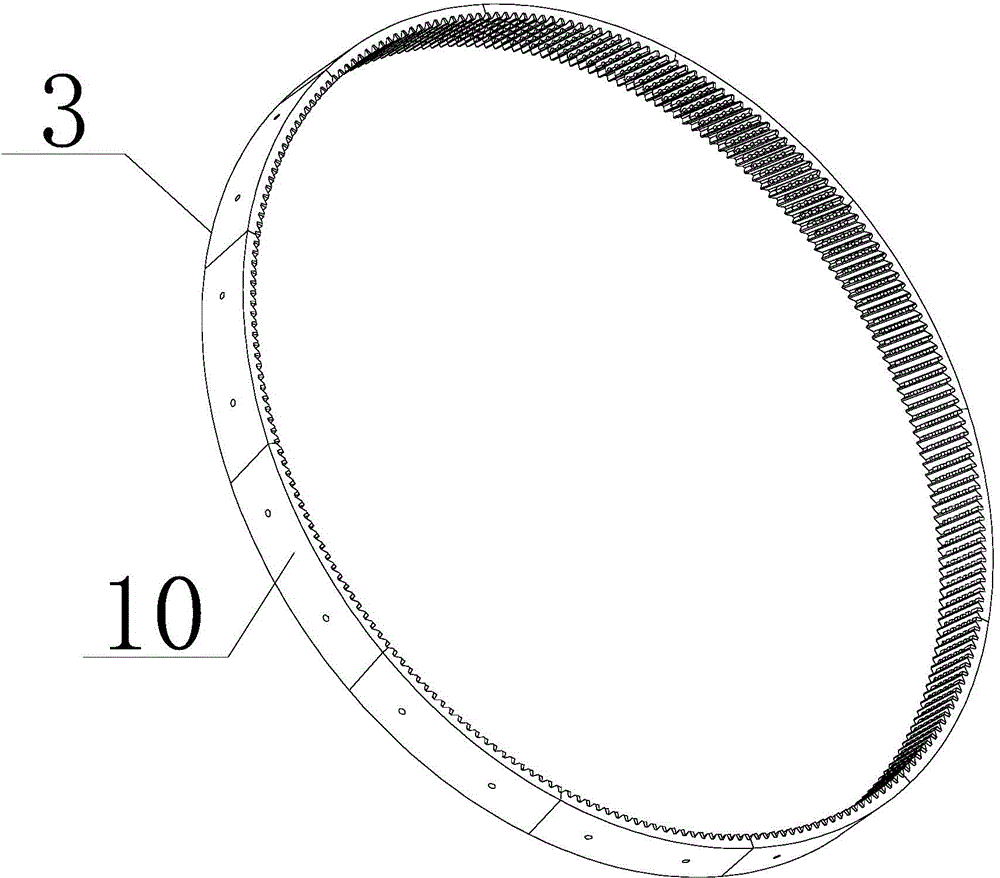

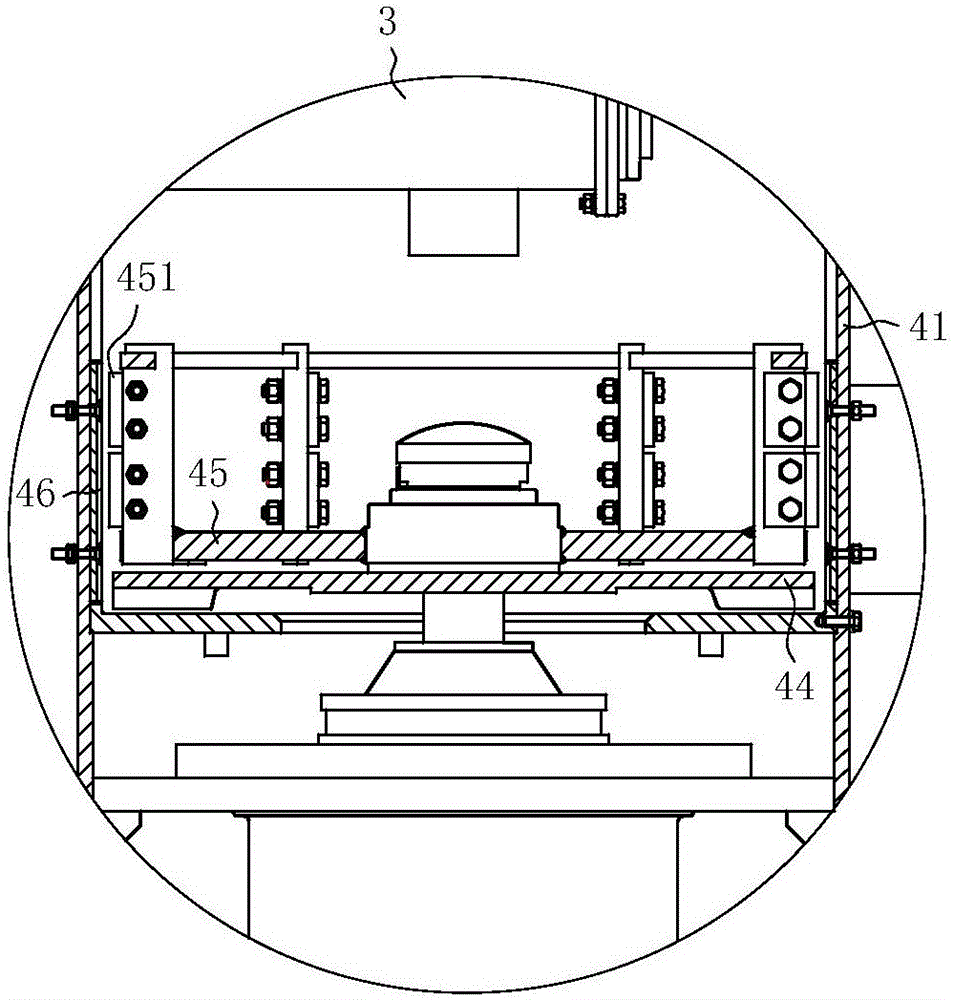

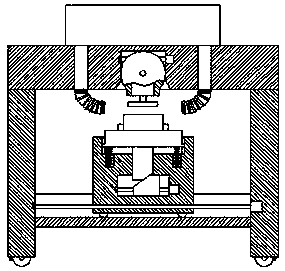

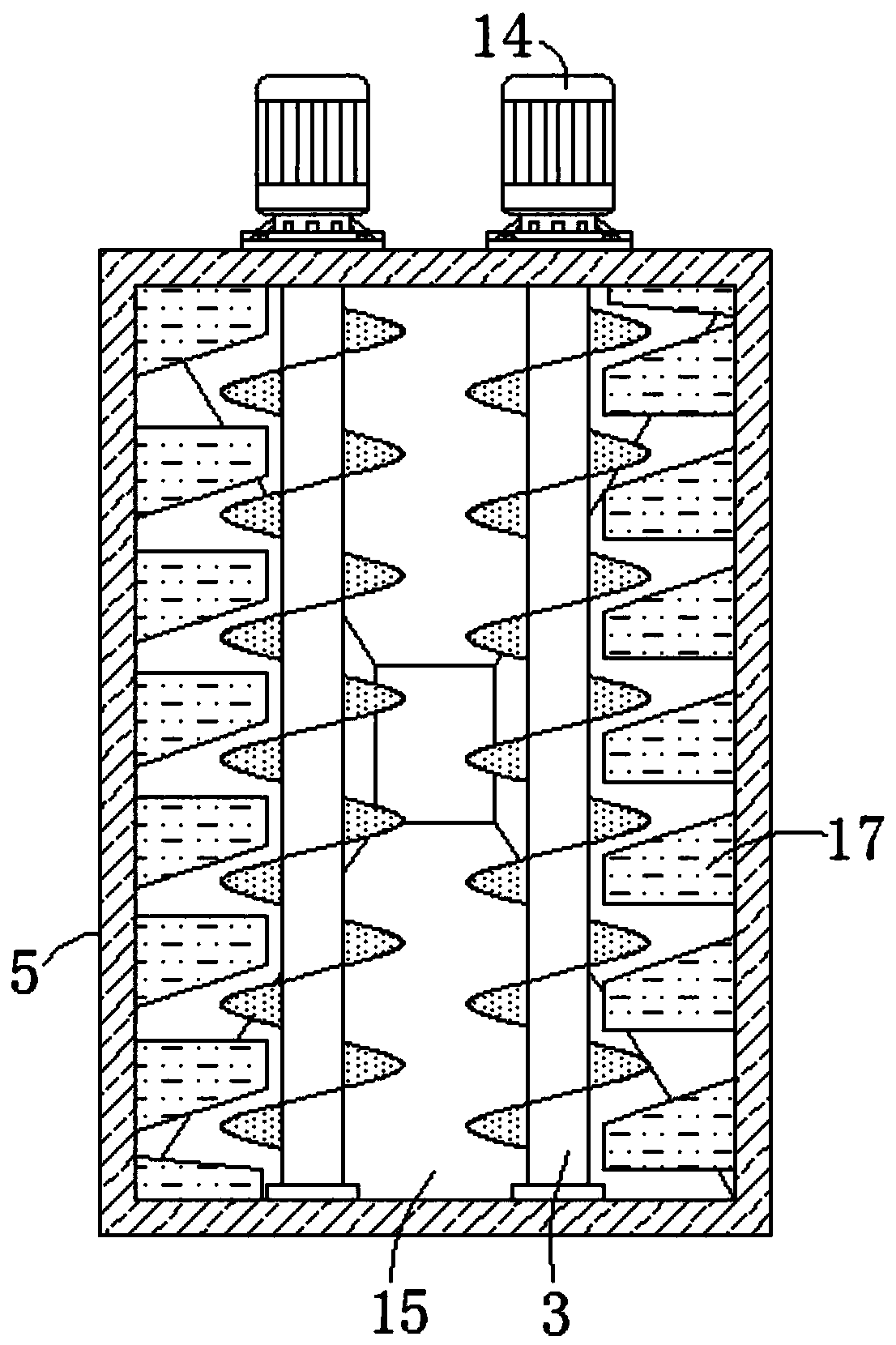

Ultrafine pulverizer

The invention discloses an ultrafine pulverizer. A gear ring of a pulverizing mechanism of the ultrafine pulverizer is formed by connecting and splicing a plurality of identical gear ring arc sections end to end; inclined teeth inclining towards the axial direction of the gear ring are arranged in the arc sections of the gear ring; alloy strips are arranged on the inclined teeth by oxygen welding; a plurality of grooves are formed in the alloy strips; a dentoid structure is arranged on one side, facing to the gear ring, of each hammerhead; the dentoid structures are inclined teeth inclining towards the normal direction of a wearproof tray; and the inclination directions of the inclined teeth on the hammerheads are opposite to those of the inclined teeth on the gear ring. According to the ultrafine pulverizer, with the adoption of the inclined tooth structures of the gear ring and the hammerheads, the impact of a high-speed air flow on materials in the pulverizer is improved, and the collision and the friction among materials are increased, so that the pulverizing efficiency and effect are improved effectively; the yield by the pulverizer is increased; the abrasion performances of the hammerheads and the gear ring are improved with the adoption of the alloy materials; the service life of the hammerheads and the gear ring is further prolonged; and the maintenance cost is reduced.

Owner:MEISHAN LIDAHUARUI MACHINERY CO LTD

Energy-saving environment friendly production method of concrete lining segment

ActiveCN102528917AGuaranteed lossReduce lossCeramic shaping apparatusProcess engineeringEnvironmental geology

The invention discloses an energy-saving environment friendly production method of a concrete lining segment. The energy-saving environment friendly production method comprises the following step of: carrying out dry-wet-heat curing on concrete after pouring, wherein the dry-wet-heat curing is finished in a sealed curing kiln and comprises four stages of static curing, heating, constant temperature keeping and temperature reducing. According to the energy-saving environment friendly production method of the concrete lining segment, disclosed by the invention, all procedures are connected closely and smoothly, wherein the dry-wet-heat curing directly ensures large shortening of curing time because of creation of a technical method, and compared with a traditional steam curing of keeping the constant temperature for 4h and total curing time of 8-10h, the energy-saving environment friendly production method disclosed by the invention has the advantage that the speed is largely accelerated, in addition, standing temperature reduction ensures that segment concrete is secondarily cured and is fully reduced in temperature, thus a quality defect due to an inner stress is avoided, the quality of products is improved, and good support is provided for long-term safe usage of the concrete lining segment.

Owner:中铁八局集团第七工程有限公司

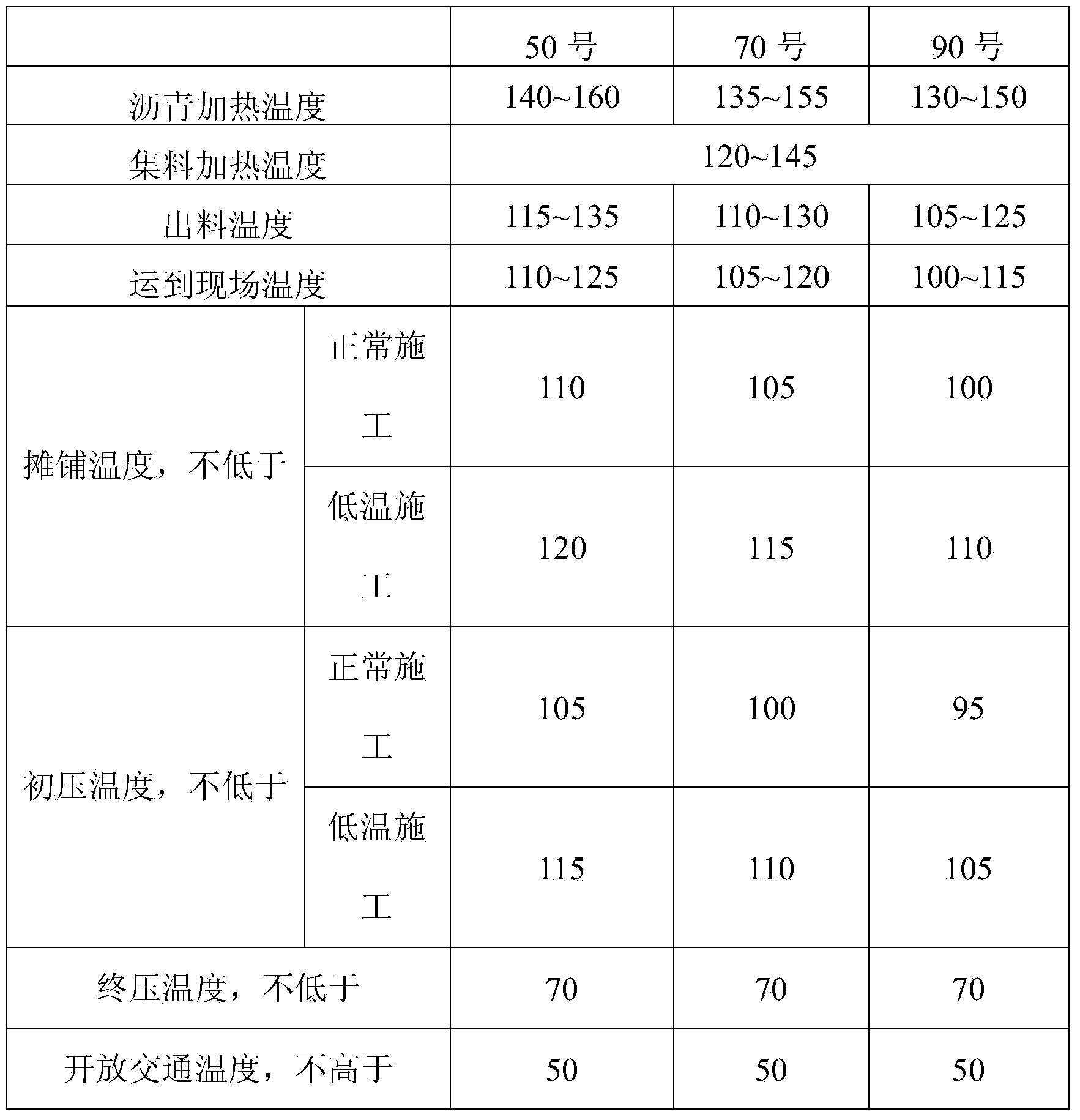

Construction method of warm mix asphalt concrete pavement of municipal road

InactiveCN103911930AImprove performanceEase of constructionIn situ pavingsClimate change adaptationWorking environmentRoad surface

The invention discloses a construction method of a warm mix asphalt concrete pavement of a municipal road. The construction method comprises the following steps: 1, reforming and adjusting the traditional mixing equipment; 2, determining the construction temperature of a warm mix mixture; 3, mixing the mixture; 4, transporting the warm mix mixture to the construction position; 5, paving the warm mix mixture; 6, compacting the paved warm mix asphalt mixture. Compared with the prior art, the construction method has the beneficial effects that the mixing cost and production consumption of the asphalt mixture are lowered, the ageing is alleviated, the pavement performance is improved, the emissions of harmful gas and dust are reduced, the environmental pollution is lowered, and the working environment quality of a worker is improved.

Owner:成张佳宁

Tunnel construction method with shield methodand new Austrian tunneling method being combined

ActiveCN105863651AAddress riskSolve the costUnderground chambersTunnel liningShield tunnelingRapid construction

The invention discloses a tunnel construction method with a shield method and a new Austrian tunneling method being combined. The tunnel construction method comprises the following steps: S1, excavating a tunnel; S2, carrying out preliminary bracing construction; S3, pushing a shield tunneling machine ahead for an excavation length; S4, repeating the step from S1 to the step S3, carrying out tunnel excavation cycle operation till the tunnel runs through, wherein pavement of waterproof boards in the tunnel and secondary lining construction are carried out in the tunnel excavation process. According to the tunnel construction method disclosed by the invention, the new Austrian tunneling method construction and the shield mehtodconstruction are beneficially combined to realize safe and fast construction of the tunnel, and meanwhile, the tunnel construction cost is controlled to be within an economic and reasonable range. Due to the adoption of fully-mechanized operation, the manual operation intensity is greatly reduced, the safety of a tunnel operation environment is guaranteed powerfully, and the quality of the operation environment is remarkably improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

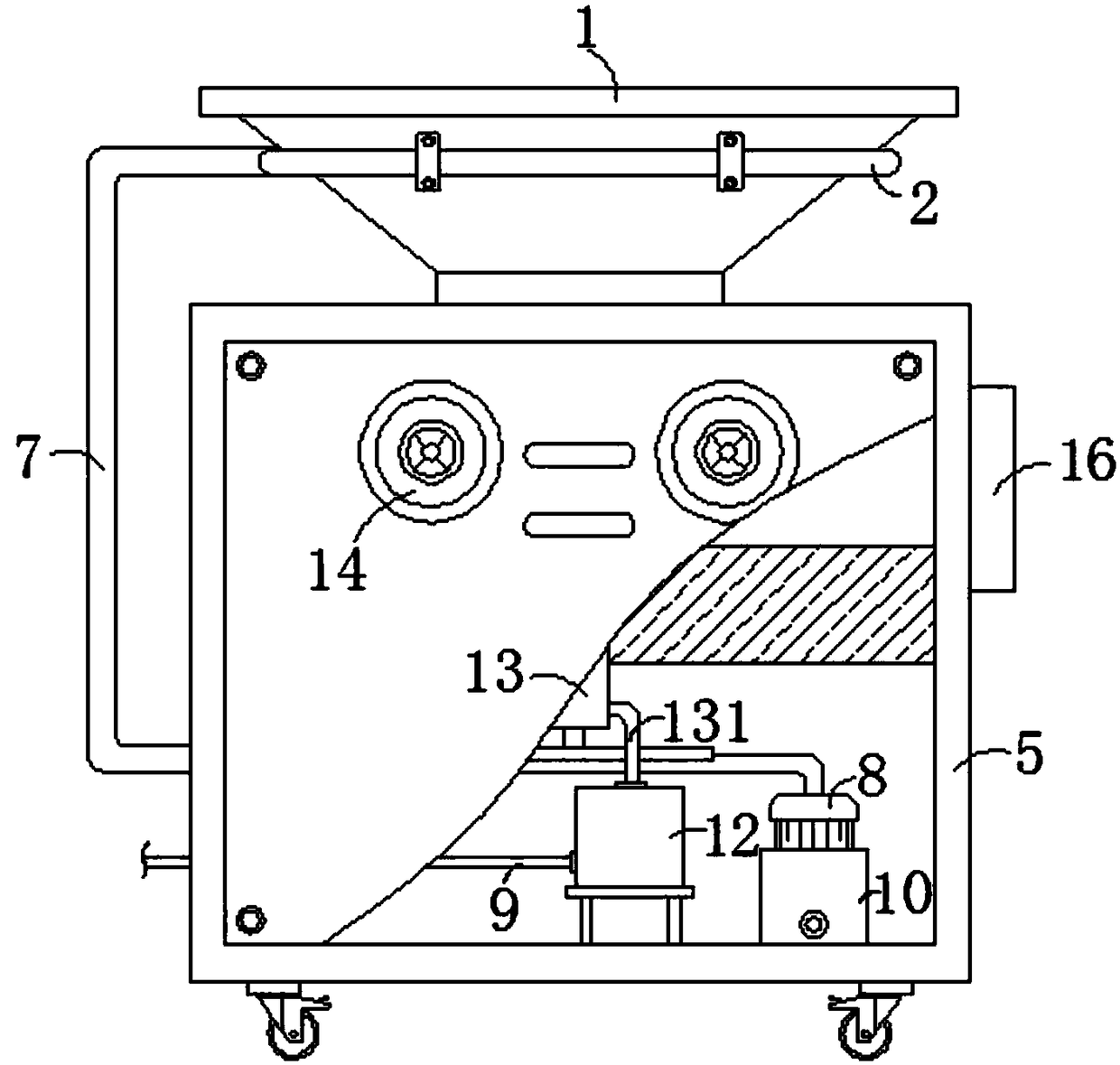

Powder recycling system

ActiveUS9586365B2More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

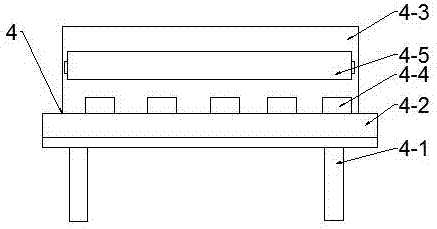

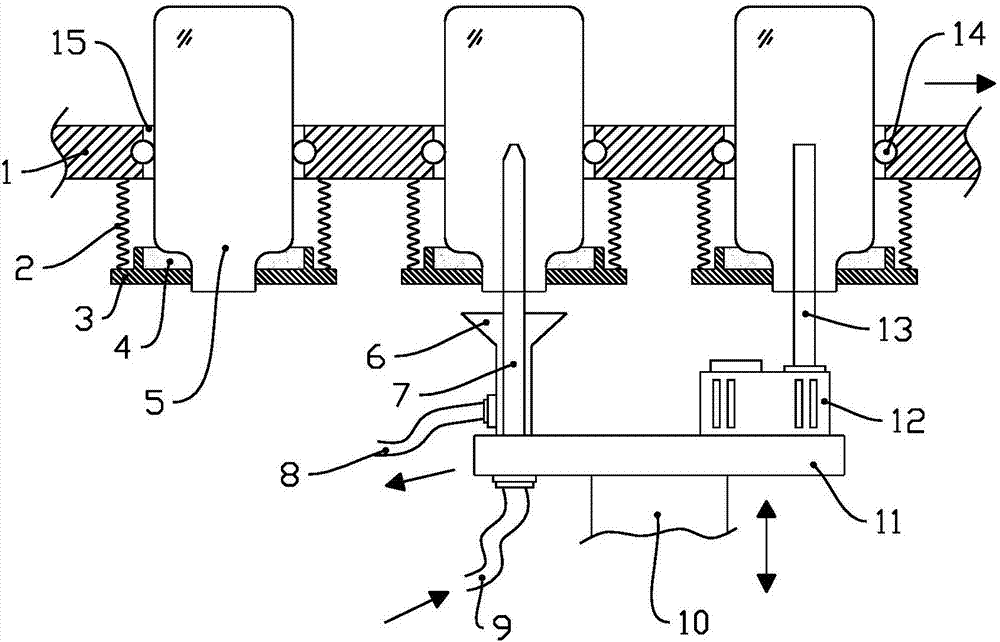

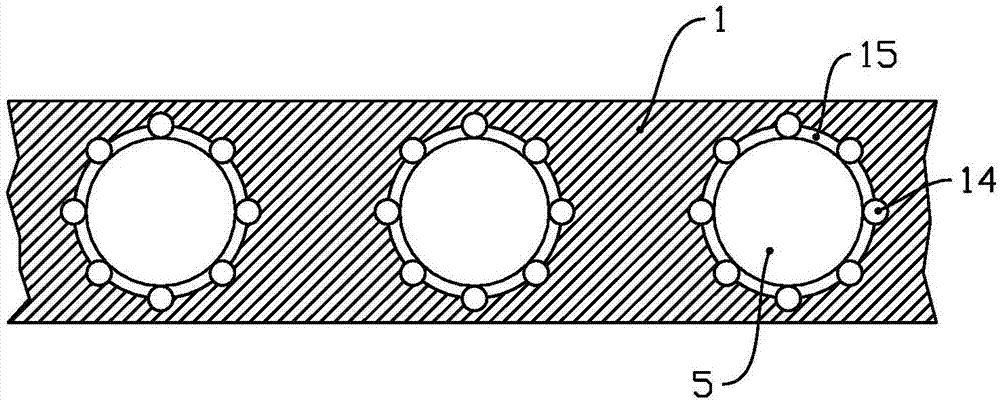

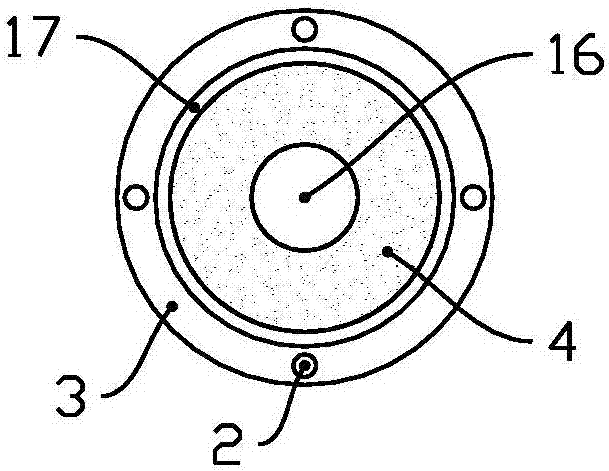

Cleaning and drying device for machining fire extinguisher bottles

InactiveCN105300060AEasy to cleanImprove drying effectDrying gas arrangementsDrying solid materialsRainwater harvestingFire extinguisher

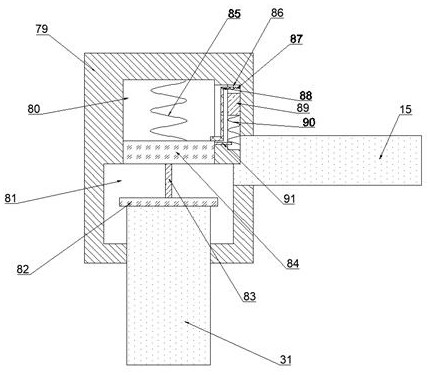

The invention discloses a cleaning and drying device for machining fire extinguisher bottles. The cleaning and drying device comprises a conveying device, a power device and a dryer. A plurality of first circular notches are evenly formed in the conveying device, supporting plates are arranged below the first circular notches respectively, and second circular notches are formed in the middle portions of the supporting plates. A protective pad is arranged on the inner side of a top flange of each supporting plate. A plurality of first springs are arranged on the outer side of each flange. An installation plate is arranged below the conveying device. The power device is arranged at the bottom of the installation plate. A water spraying pipe is arranged on the left side of the top of the installation plate. A rainwater collecting hopper is sleeved with the portion, on the outer side of the water spraying pipe, of the installation plate. The dryer is arranged on the right side of the top of the installation plate and provided with a drying pipe. According to the cleaning and drying device, elastic buffer conveying is carried out on the to-be-processed fire extinguisher bottles; as bottle bodies vertically and elastically vibrate when cleaning and drying are carried out, the cleaning effect and the drying effect on the bottle bodies are easily improved, and the working efficiency is improved.

Owner:JIANGSU KUAIDA FIRE EQUIP TRADING CO LTD

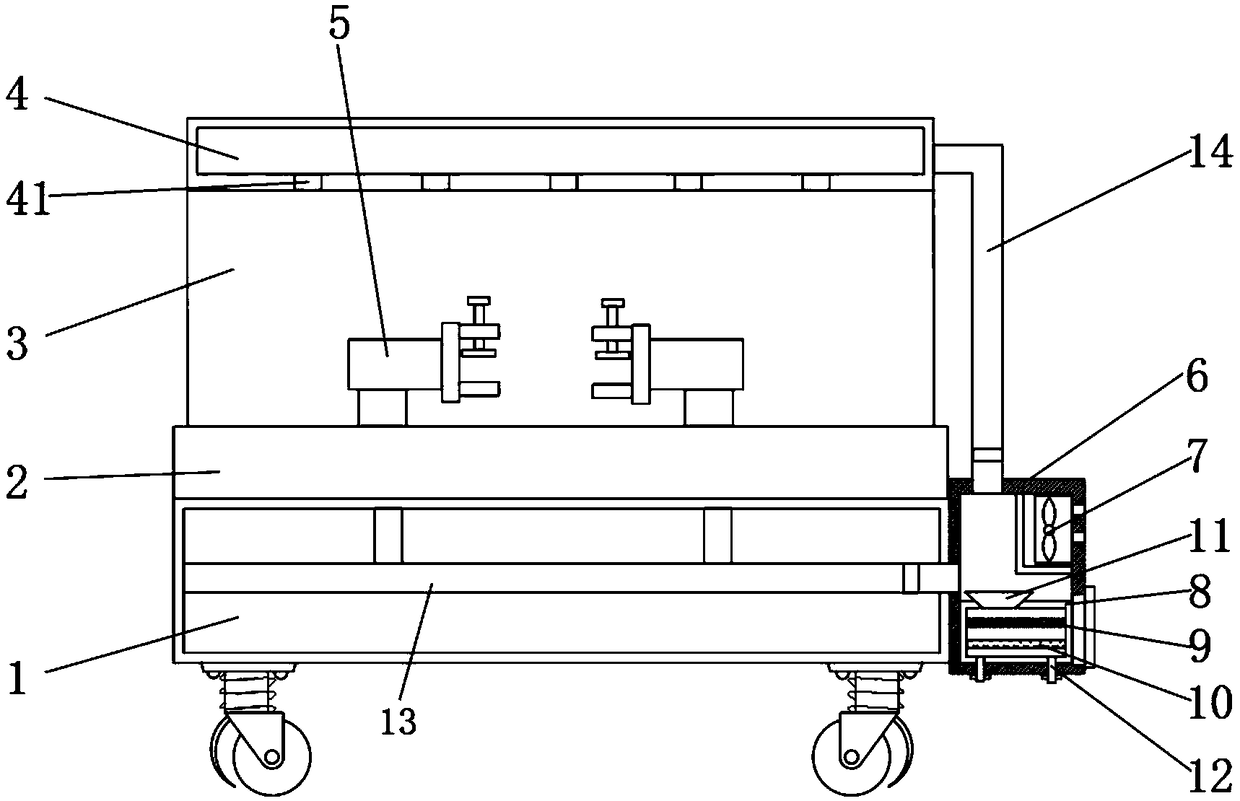

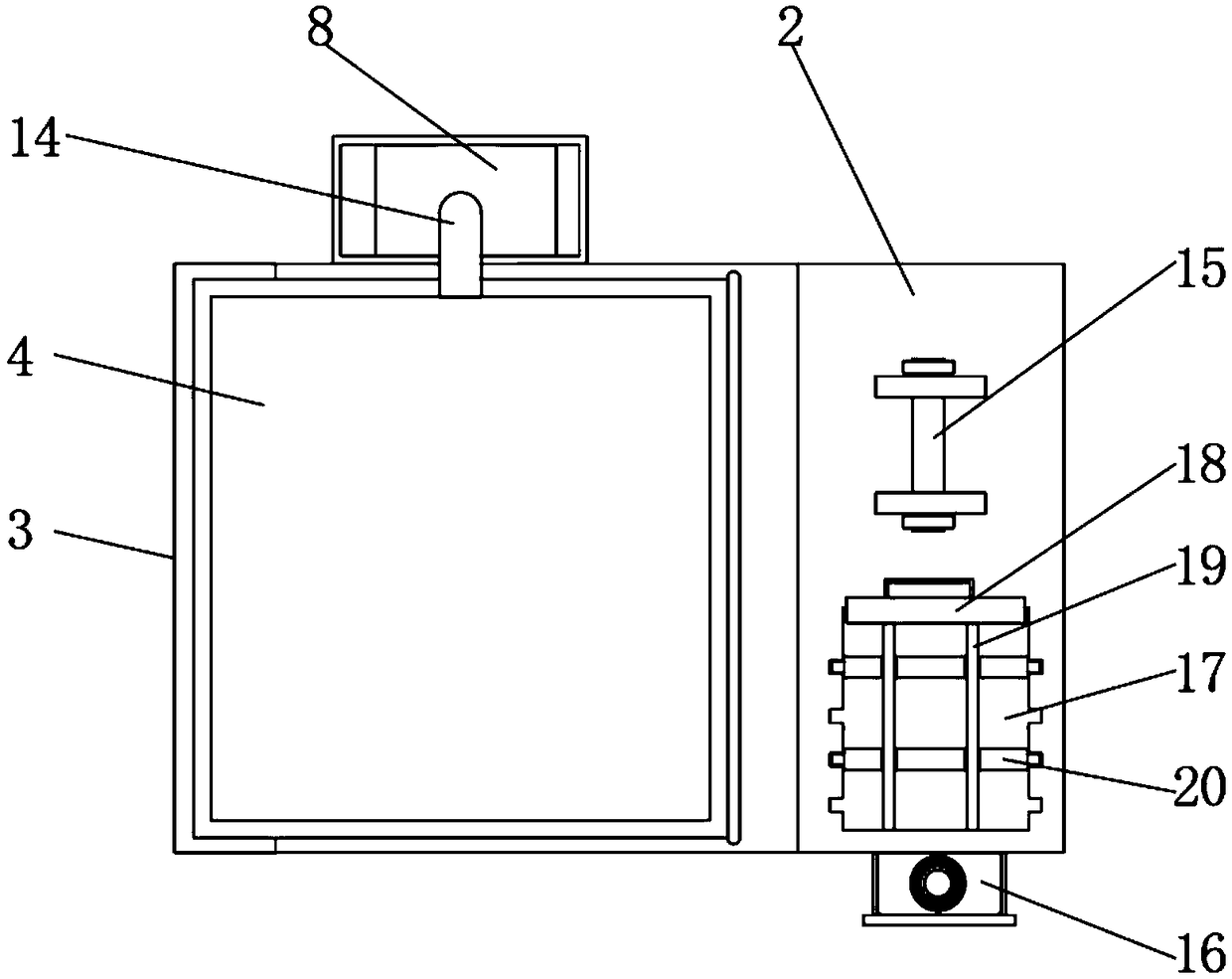

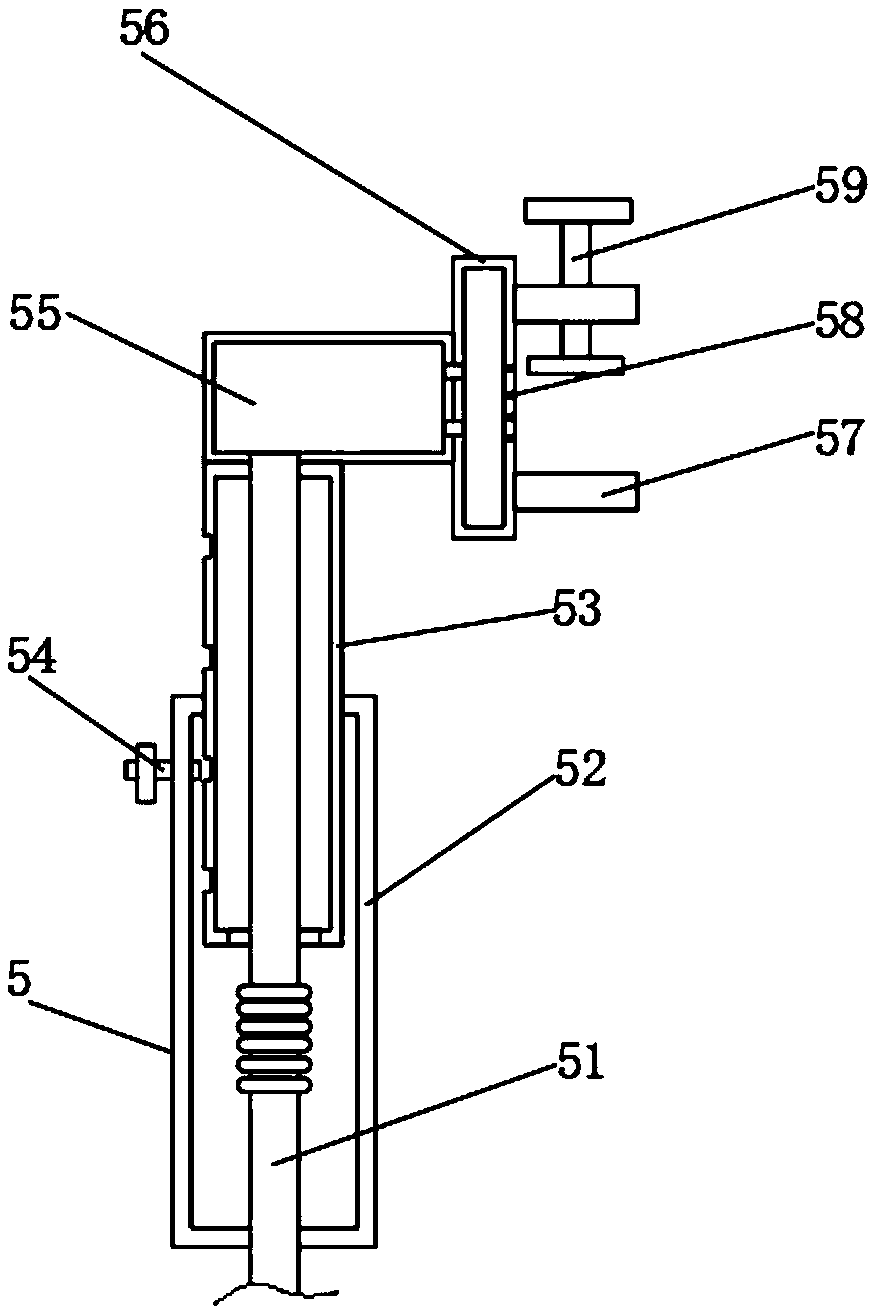

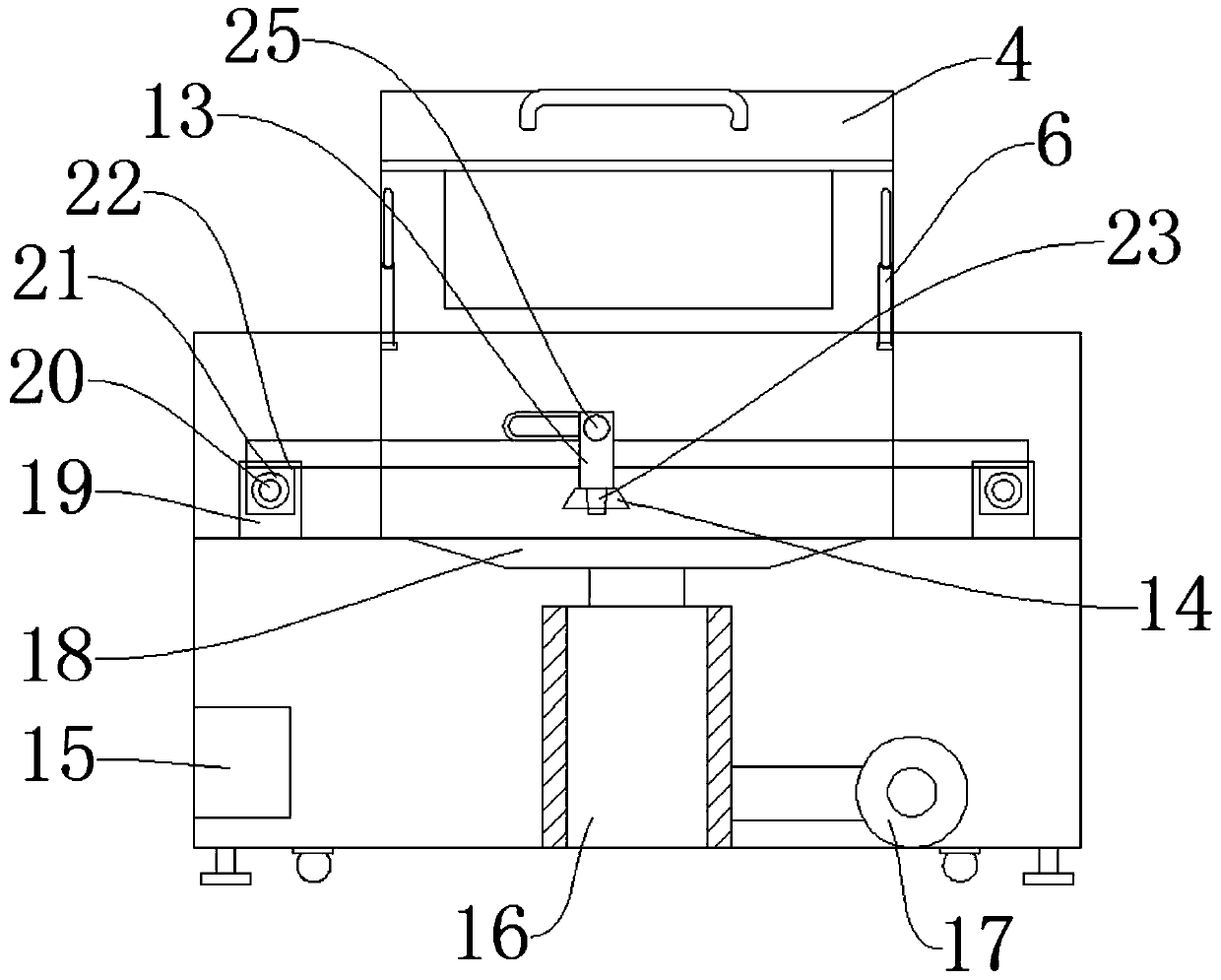

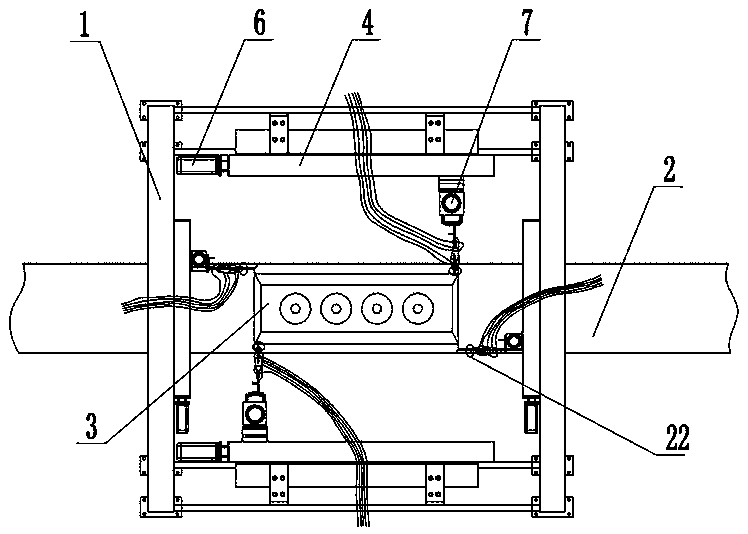

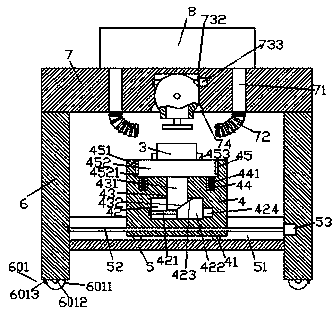

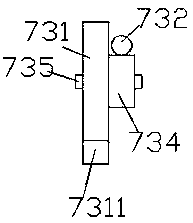

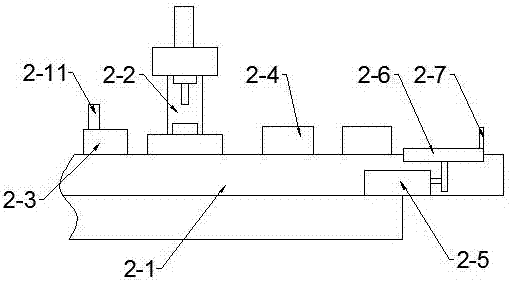

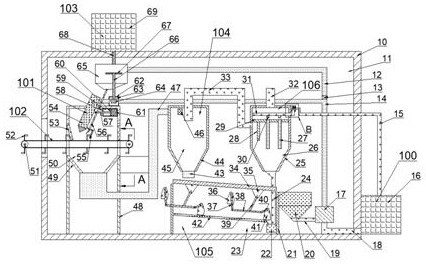

Electronic assembly welding table for integration tools

InactiveCN108907391AGuaranteed stabilityImprove the quality of the working environmentMetal working apparatusSoldering auxillary devicesToxic gasWorking environment

The invention discloses an electronic assembly welding table for integration tools, and belongs to the technical field of electronics. The electronic assembly welding table comprises a base, fixing assemblies of the same structure are symmetrically arranged on the left side and the right side of the top of the base, a shell is arranged in the middle of the right side of the base, a purifying box is arranged at the bottom of an inner cavity of the shell, a solder roller is arranged on the right side of the top of a placing plate, an electric soldering iron frame is arranged on the left side ofthe placing plate, according to the welding table, an exhaust fan is started and exhausts air in a hollow block and an adsorption plate through a first exhaust pipe and an exhaust hose, negative pressure is produced at an air suction hole, toxic gas enters the air suction hole during welding of soldering wires and enters the shell through the exhaust hose and the first exhaust pipe, gas is purified by a ceramic filter net and an active carbon adsorption net through a gas collection hopper to filter away toxic matter in gas, and the working environment quality is effectively improved.

Owner:扬州华青电子有限公司

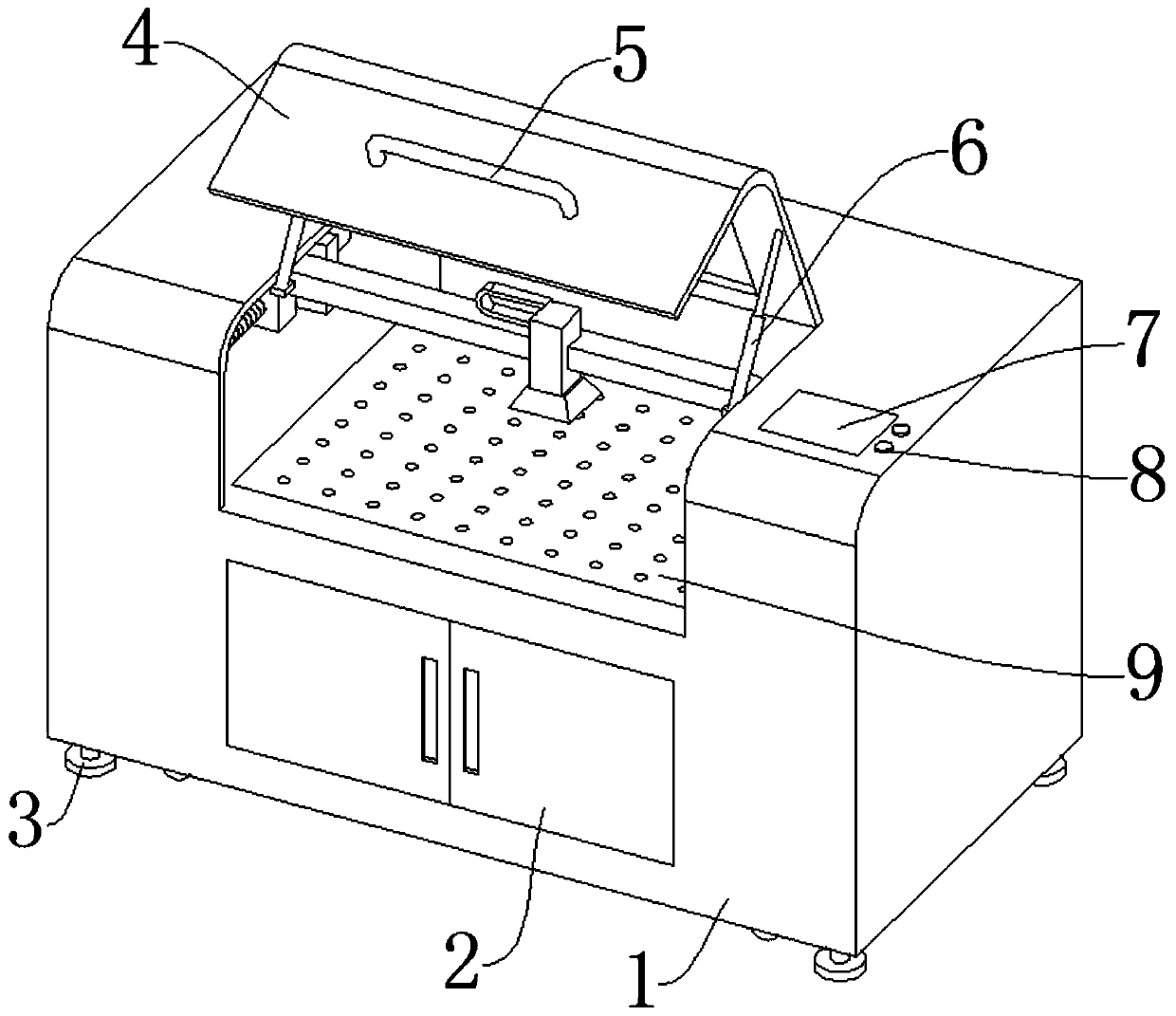

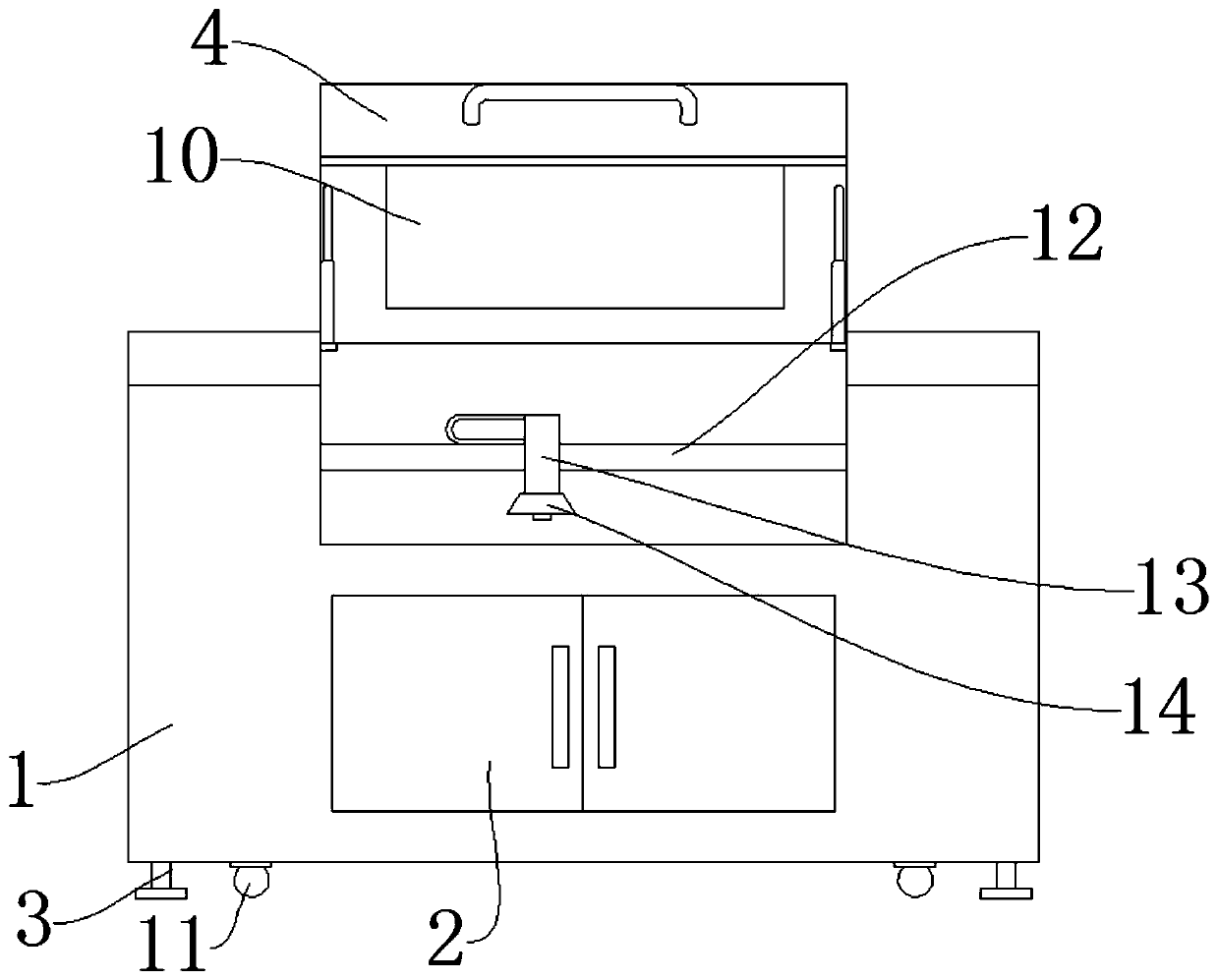

Laser cutting machine with safety protection device

InactiveCN109822234AReduce dust pollutionImprove the quality of the working environmentLaser beam welding apparatusOperations securityLaser cutting

The invention discloses a laser cutting machine with a safety protection device. The laser cutting machine comprises a box body, a safety cover, a dust hood and a filter screen. The filter screen is arranged on the inner side of the box body and is cylindrical. One side of the filter screen is provided with an exhaust fan. A flow guide cover is connected to the filter screen. A workbench is arranged above the flow guide cover, and through holes are uniformly distributed in the workbench. According to the laser cutting machine, suction force is generated through the operation of the exhaust fan; when a workpiece is cut by a cutting head, smoke in the cutting process is subjected to flow guide adsorption through the dust hood above the cutting head, the flow guide cover below the workbench is used for conducting flow guide adsorption on dust below the workpiece, and the dust enters the filter screen to be filtered, so that dust pollution in the cutting process is reduced, and the workingenvironment quality is improved; the box body is in a closed state through the safety cover, the cutting process is checked through a perspective window, splashing sparks in the cutting process are prevented from flying all around and scalding operators, and operation safety is improved.

Owner:孝感金致科技有限公司

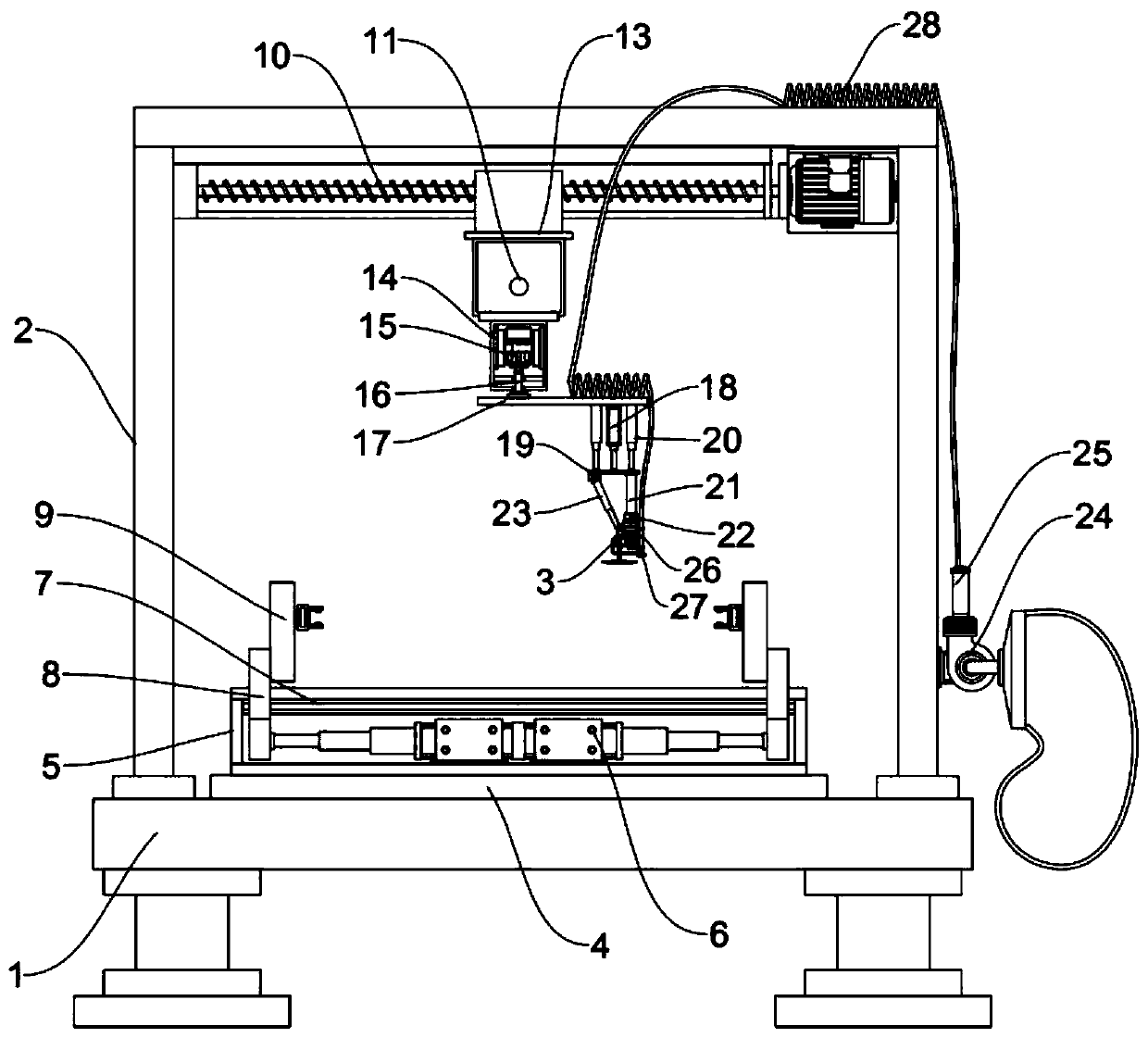

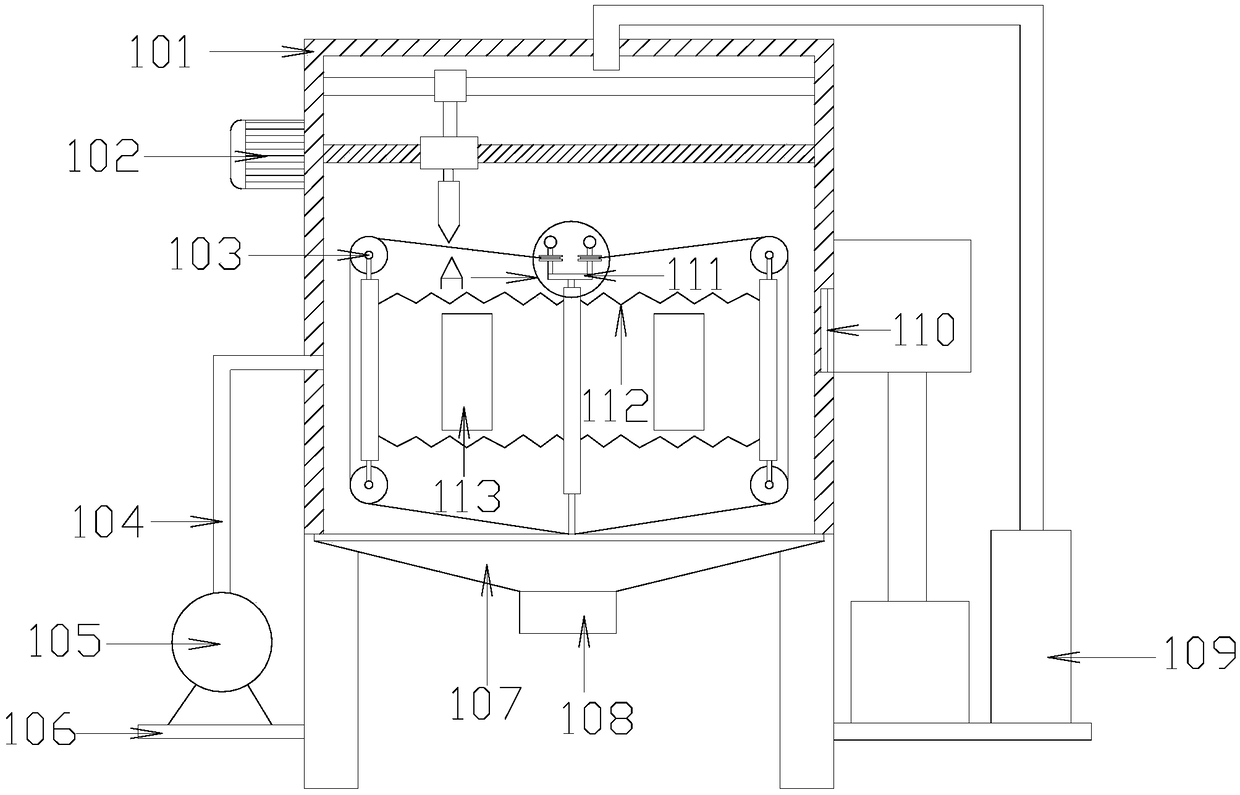

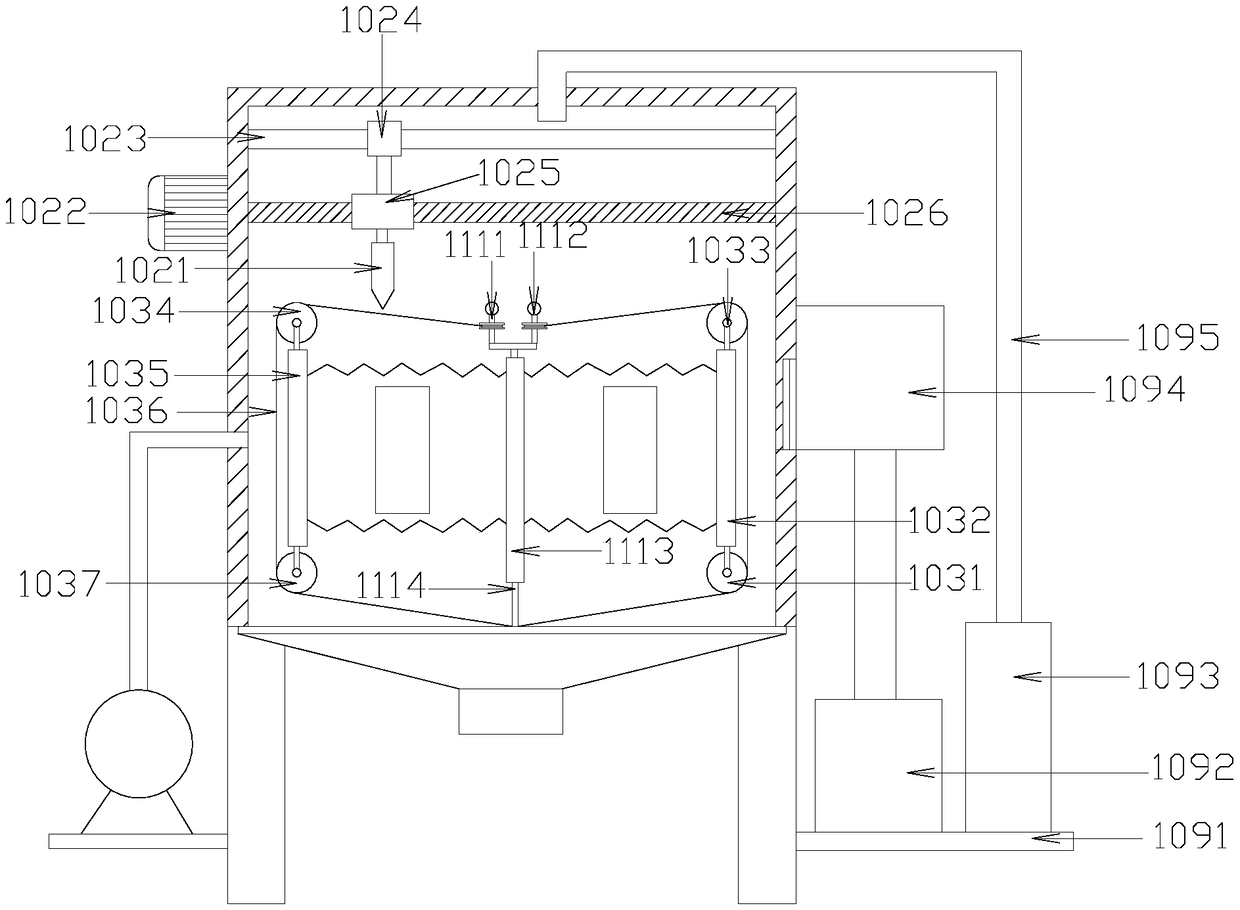

Small polishing rust-removal device special for kitchen hardware

InactiveCN111070060AImprove the quality of the working environmentSimple structureGrinding machinesGrinding work supportsPolishingEngineering

The invention discloses a small polishing rust-removal device special for kitchen hardware. The small polishing rust-removal device comprises an operating table, a supporting frame and a polishing machine head, the supporting frame is mounted on the operating table, the polishing machine head is mounted on the supporting frame, the operating table is provided with a clamping fixing mechanism, an adjustable polishing mechanism is arranged on the supporting frame and connected with the polishing machine head, and the operating table is provided with a centrifugal dust removal mechanism. By arranging the clamping fixing mechanism on the operating table, to-be-polished hardware workpieces are clamped, meanwhile, the angle of the polishing machine head is correspondingly adjusted through cooperation of the adjustable polishing mechanism to polish different parts of the to-be-polished workpieces, chippings and powder generated in the polishing process are collected and treated through cooperation of the centrifugal dust removal mechanism, thus the effect environmental quality is improved, the structure is simple, and controllability is high.

Owner:蒋德明

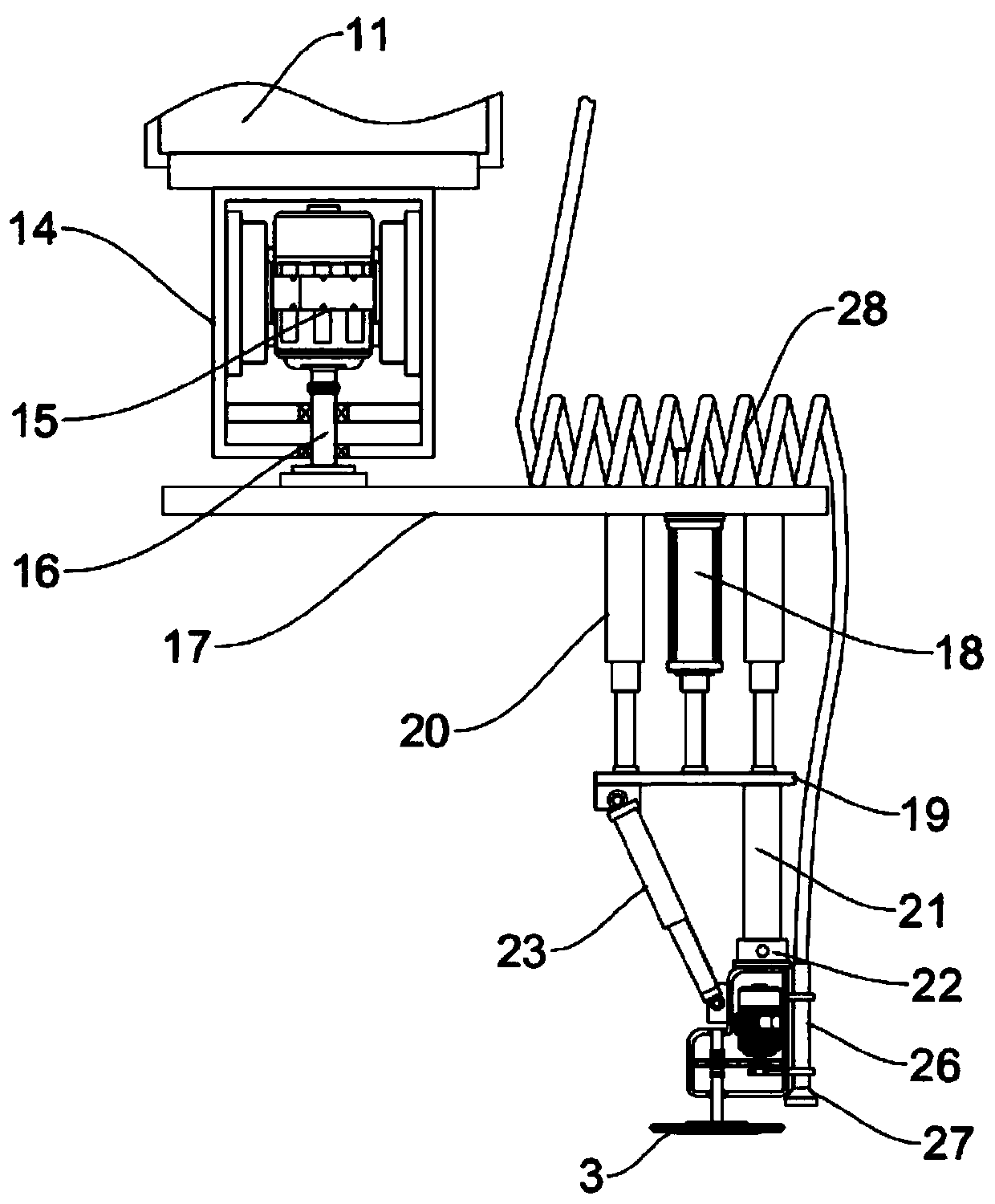

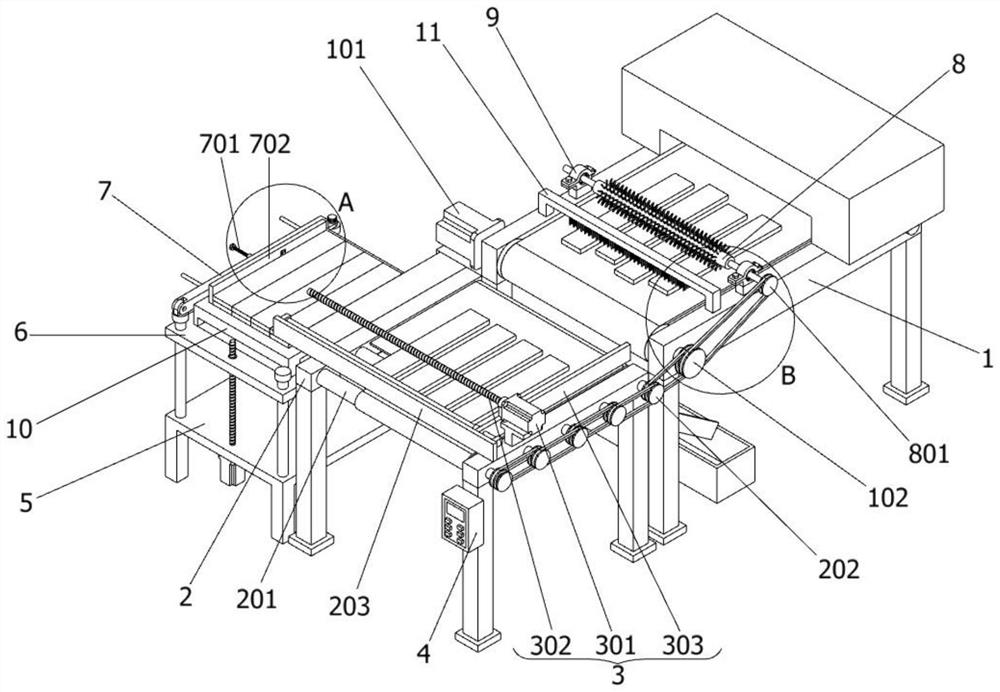

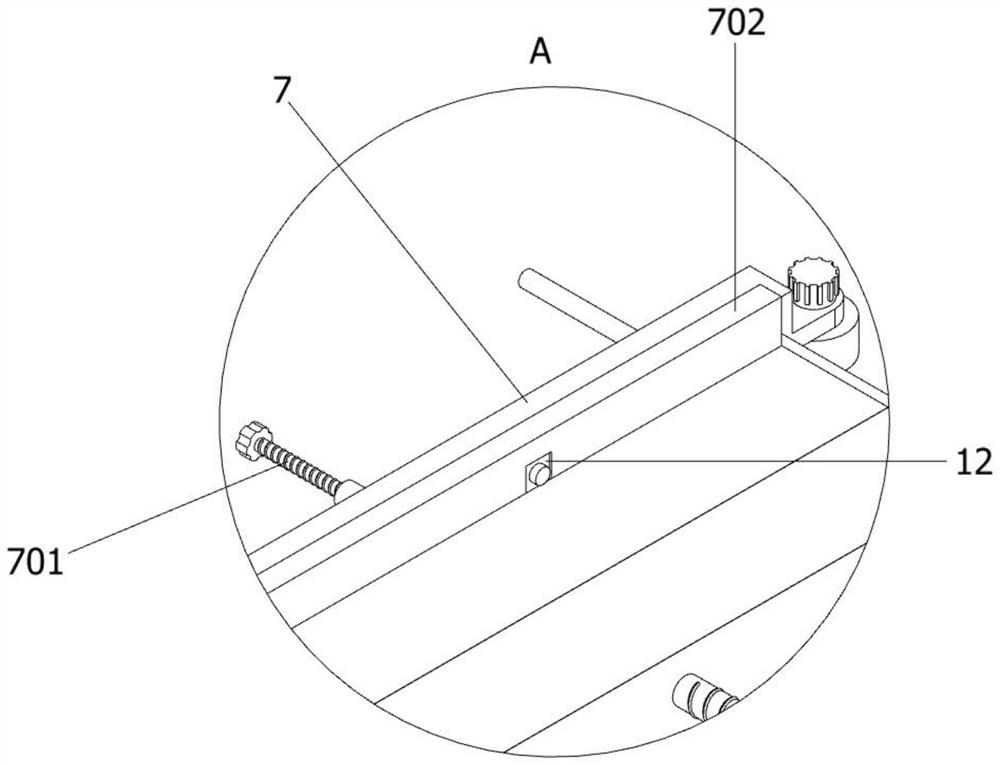

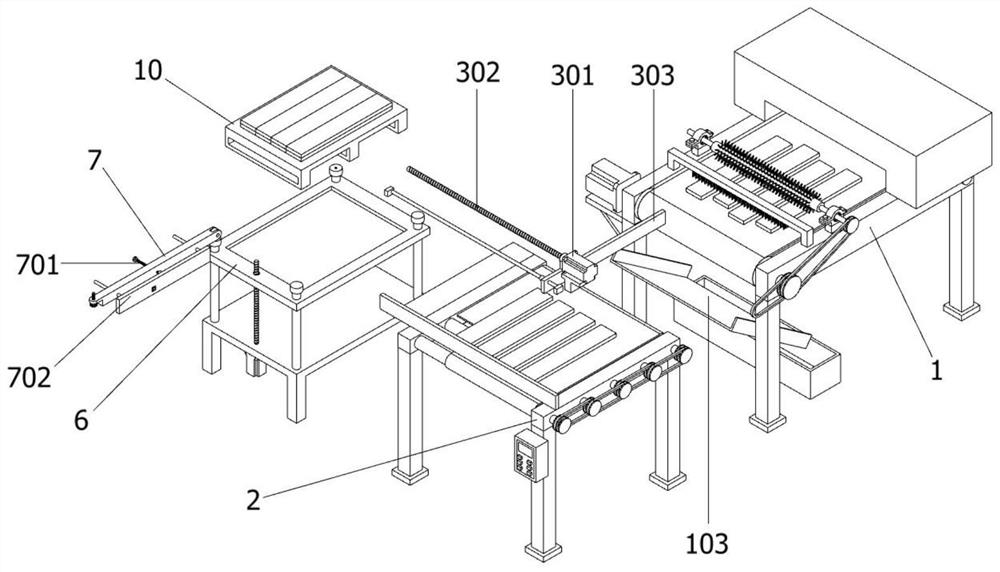

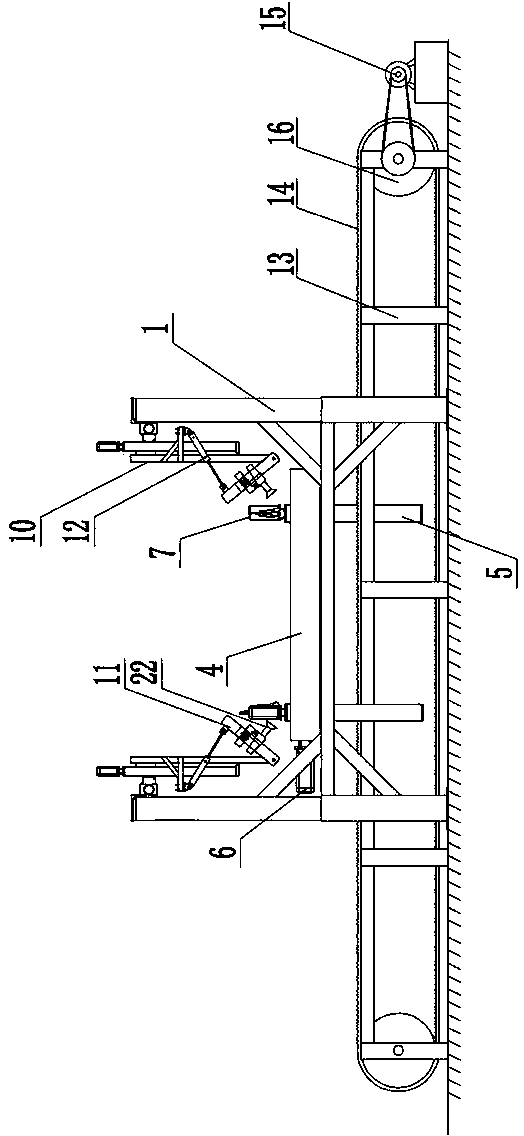

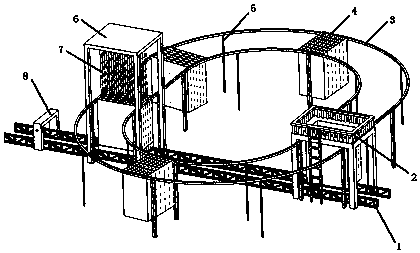

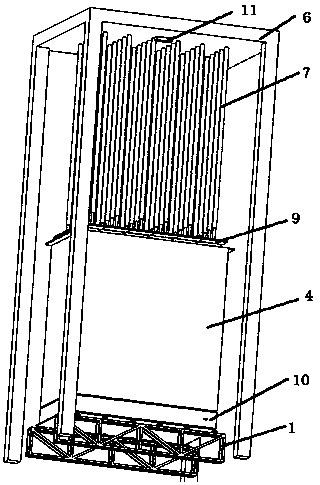

Automatic stacking device based on wooden floor stacking

InactiveCN111807064AImprove efficiencyImprove convenienceConveyorsCleaning using toolsElectric machineryStructural engineering

The invention provides an automatic stacking device based on wooden floor stacking, belongs to the technical field of floor stacking devices, and aims to solve the problems that when wooden floors arestacked in the prior art, due to manual operation, the labor loss of workers is increased, and time is consumed. The automatic stacking device comprises a conveying rack, and an alignment mechanism is arranged on the front side of the conveying rack. According to the automatic stacking device, the machined wooden floors are conveyed forwards to the alignment mechanism through a conveying belt onthe conveying rack, so that the alignment operation of the front end faces of four wooden floors is achieved; and then the four wooden floors are pushed leftwards to a tray through a pushing mechanism, and then a controller sends a pulse signal to a stepping motor through a control switch, so that a lifting mechanism drives the tray to move downwards by the distance equal to the thickness of one wood floor, then manual stacking is not needed when the wood floors are stacked, the labor loss of workers is reduced, time is saved, and then the efficiency and convenience during stacking of the woodfloors are improved.

Owner:赵纪彩

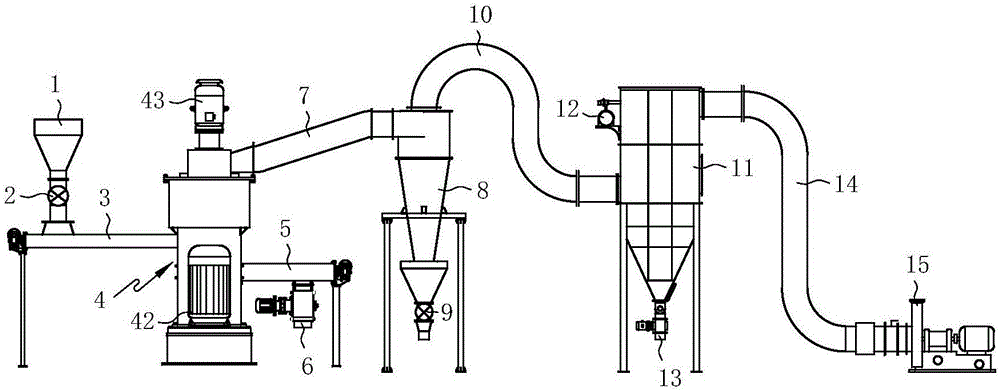

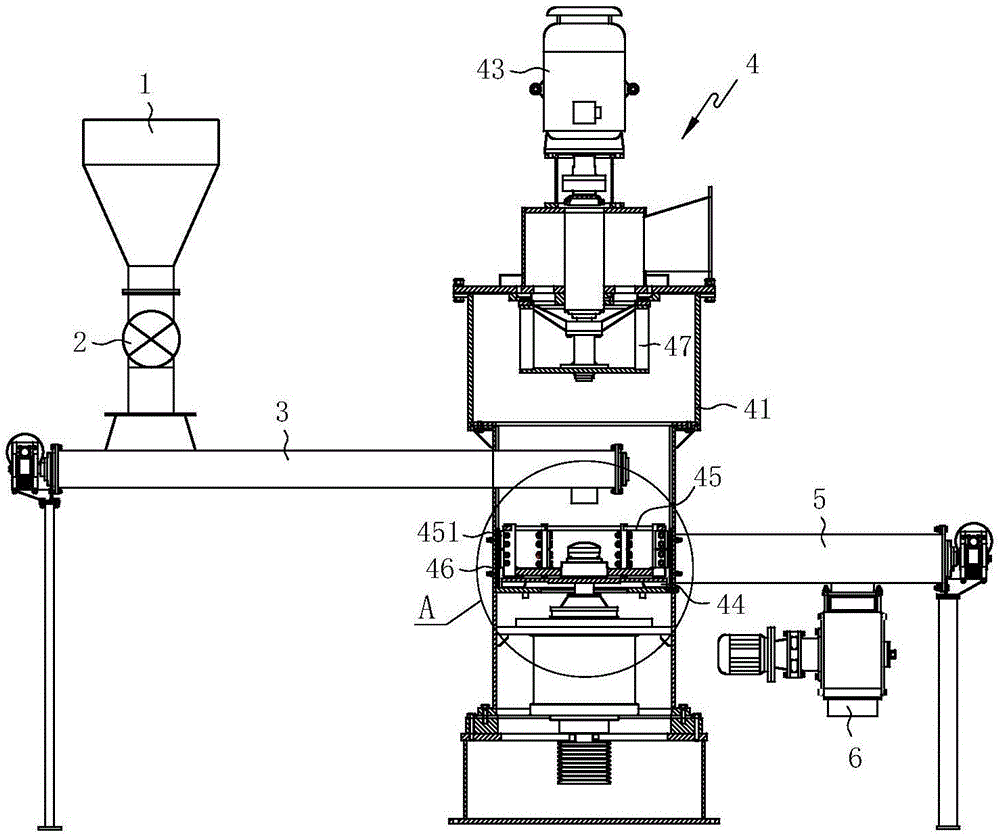

Crushing and shaping integrated production line

The invention discloses a crushing and shaping integrated production line and relates to the technical field of powder equipment. The crushing and shaping integrated production line comprises a crushing and shaping integrated machine; a crushing and shaping device and a grading device are mounted in a cylinder body of the crushing and shaping integrated machine; the crushing and shaping device comprises a wind wheel, a crushing disc and a shaping hammerhead which is fixedly arranged on the inner wall, corresponding to the crushing disc, of the cylinder body; the grading device comprises an impeller; a material inlet is formed in the cylinder body between the crushing disc and the impeller; a fine powder outlet is formed in the cylinder body between the impeller and a second power device; a coarse powder material outlet is formed in a position, corresponding to the crushing disc, on the cylinder body. The crushing and shaping integrated production line disclosed by the invention has the advantages that crushing, shaping and grading functions are simultaneously achieved; the whole crushing and shaking process is carried out in one closed equipment so that material overturning is avoided and material pollution caused by mixing other materials in the material in the overturning process is completely eliminated; product quality is improved; the crushing efficiency is enhanced.

Owner:WEIFANG ZHENGYUAN POWDER ENG EQUIP

Quartz mineral purification flotation agent

ActiveCN106076650AGood effect of removing impuritiesWide effect of removing impuritiesFlotationSolubilityDissolution

The invention relates to a quartz mineral purification flotation agent. The quartz mineral purification flotation agent comprises, by percentage, 20% to 30% of mixed amine, 30% to 40% of petroleum sodium sulfonate, 5% to 10% of hydroximic acid and 30% to 40% of industrial alcohol; and in each ton of quartz sand, 0.5 kg to 1.5 kg of flotation agent is contained. The quartz mineral purification flotation agent has the beneficial effects that a floating agent mixture is stable in property, selectivity is good, the impurity removal effect is obviously superior to that of products of the same type, water solubility is good, environment temperature adaptation is high, mixing and mutual dissolution in any proportion to water can be achieved at the environment temperature, the adaptation of a reagent is wide, the good impurity removal purification effect is achieved, the purification efficiency is high, the use amount is small, in each ton of quartz sand, the use number of purification flotation agent ranges from 0.5 kg to 1.5 kg, the mineral separation cost is greatly reduced, no pungent smell exists, the work environment quality of production operators is obviously improved, and the use number of flotation agents is small.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

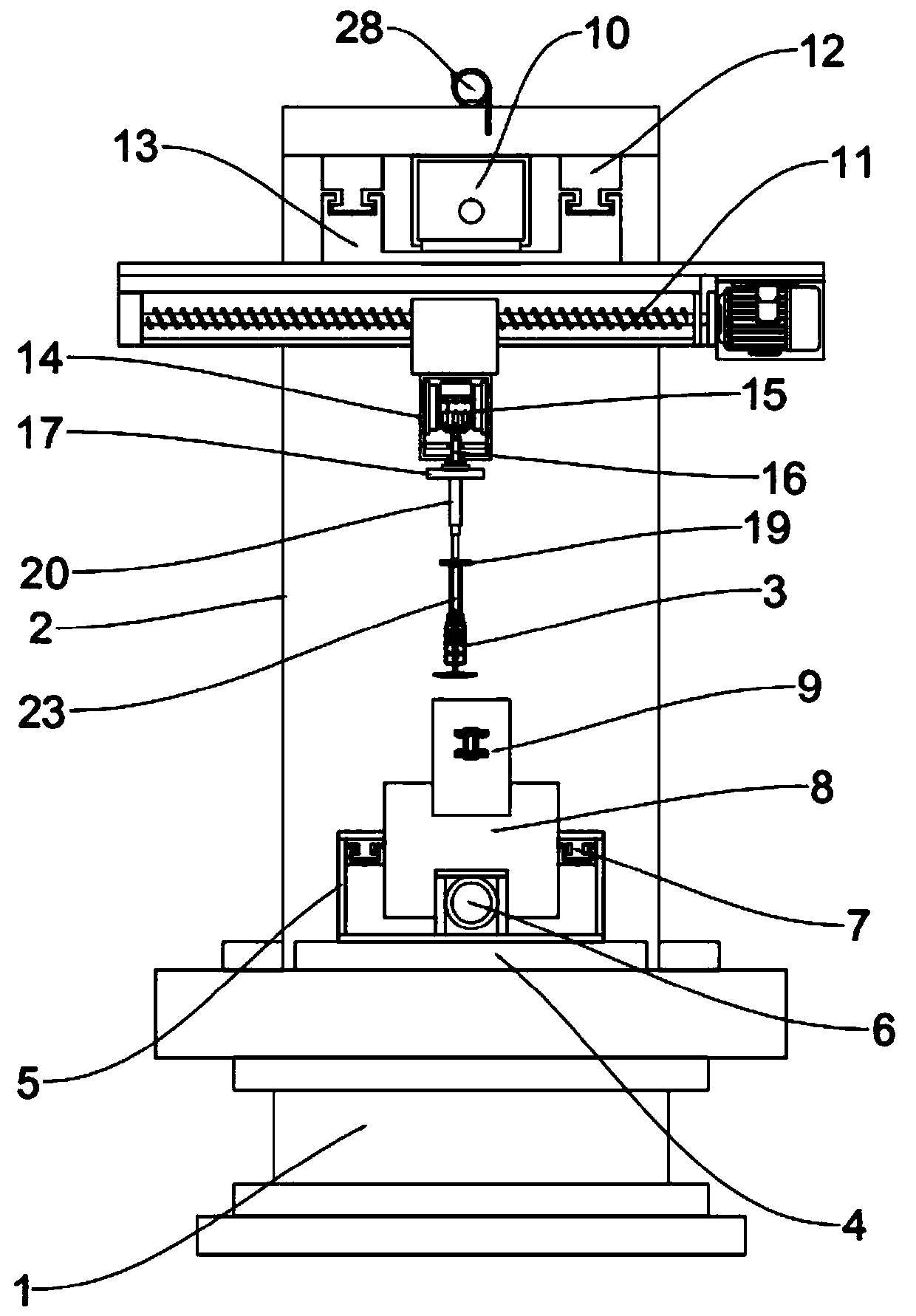

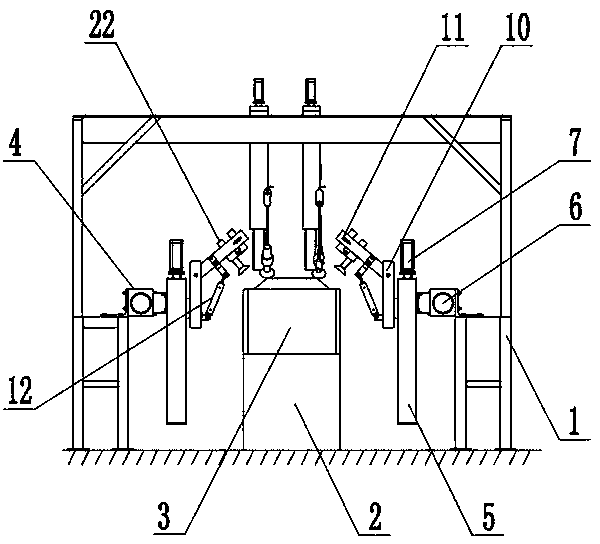

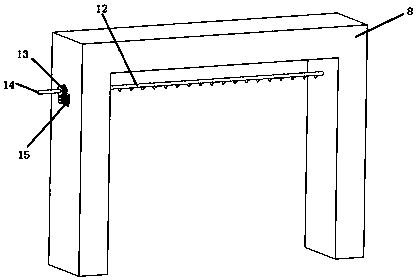

Anti-oxidation spraying device and method for anode carbon block for aluminum electrolysis

InactiveCN103480539AReduce labor intensityReduced mechanical propertiesLiquid surface applicatorsCoatingsElectrolysisAluminum coating

The invention belongs to the technical field of anti-oxidation spraying equipment, and discloses an anti-oxidation spraying device and method for an anode carbon block for the aluminum electrolysis. The anti-oxidation spraying device for the anode carbon block for the aluminum electrolysis comprises a supporting framework and a carbon block work platform arranged at the lower side of the supporting framework, spraying units are arranged on the four side faces of the supporting framework, each spraying unit comprises a spraying device body and a moving mechanism which connects a spraying gun of the spraying device body and the supporting framework, a transverse sliding table and a longitudinal sliding table of each moving mechanism are provided with patches, a driving lug is provided with a proximity switch matched with the patches, a PLC system is used for controlling forward and backward rotation of lifting motors and transversely-moving motors and controlling the limit motions of the proximity switch and the patches, and accordingly the longitudinal sliding tables and spraying supports are adjusted to carry out spraying in an S shape. The anti-oxidation spraying device and method for the anode carbon block for the aluminum electrolysis achieve the technical purpose of automatic electric arc spraying of aluminum coatings for the anode carbon block, improve work efficiency, save expenses, and avoid damage to the human body by smoke dust, harmful gas, noise and the like caused by electric arc spraying.

Owner:ZHENGZHOU LIGHT METAL TECH

Construction decorative stone grinding device

InactiveCN108788986AReduce labor intensityImprove work efficiencyGrinding carriagesGrinding work supportsAutomatic controlArchitectural engineering

The invention discloses a construction decorative stone grinding device which comprises a cross beam and supporting columns fixed to bottoms of two sides of the cross beam. A supporting rack is fixedly arranged between the supporting columns below the cross beam; a first sliding groove is formed in the supporting rack; a first threaded rod extending left and right is arranged in the first slidinggroove; a sliding block is in threaded fit connection to the first threaded rod; the upper part of the sliding block is located out of the top surface of the supporting rack; a sliding cavity is formed in the sliding block; an embedding groove is formed in the top surface of the sliding block; a communicating groove in the sliding block communicates longitudinally between the middle position of the inner bottom surface of the embedding groove and the middle position of the inner top surface of the sliding cavity; a second threaded rod extending left and right is arranged in the sliding cavity;a push block is arranged on the second threaded rod; and a first bevel is arranged above the left side of the push block. The construction decorative stone grinding device disclosed by the inventionis simple in structure, low in manufacturing cost and maintenance cost, can be automatically controlled to lift to grind stones, can adjust the angle of a polishing head automatically, and also has the function of preventing flying dust from polluting the environment.

Owner:宁波育闪科技有限公司

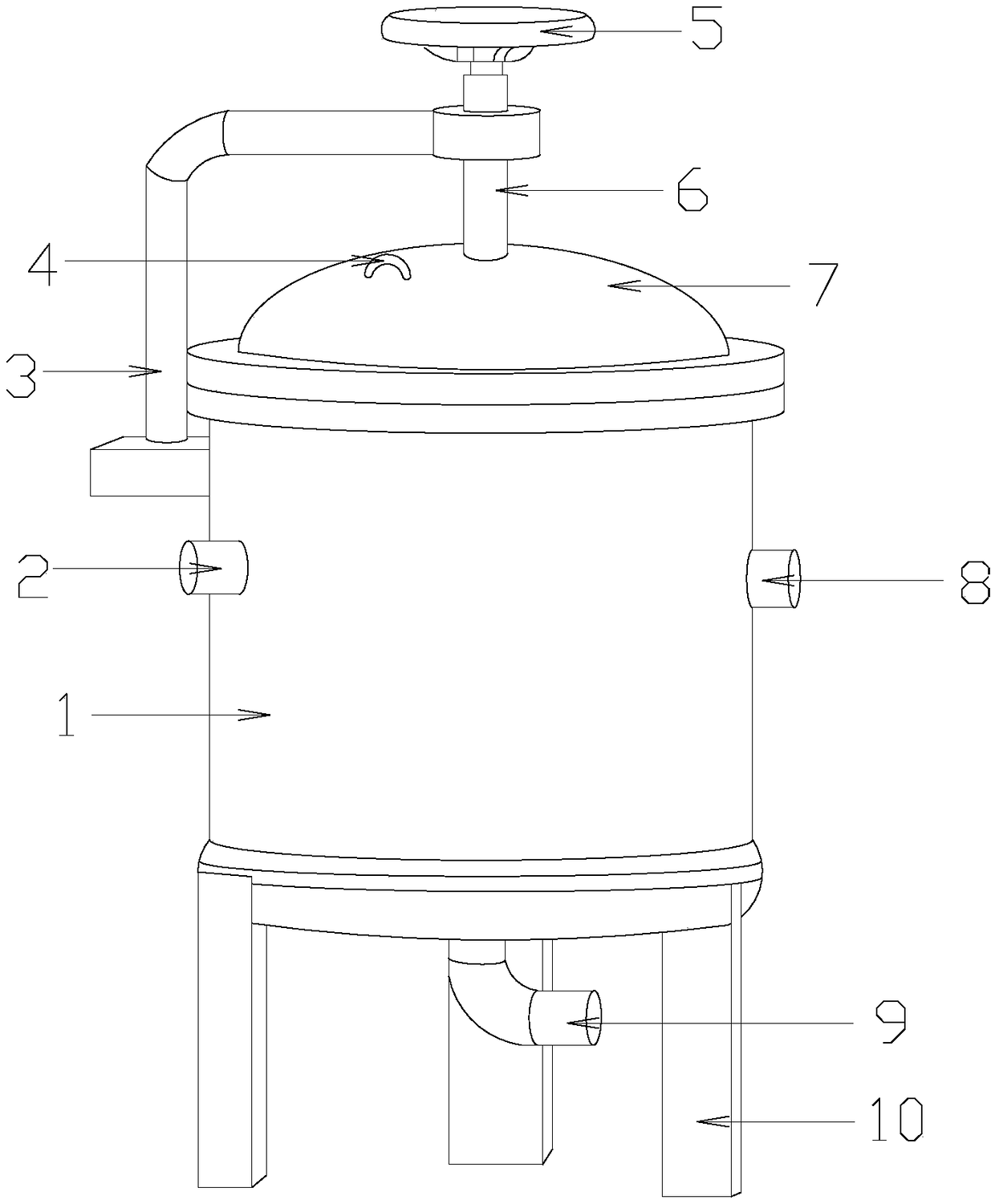

Irrigation-fed filter

InactiveCN108704371AGuaranteed continuityIndependent replacementFiltration circuitsInlet channelWorking environment

The invention discloses an irrigation-fed filter. The irrigation-fed filter structurally comprises an automatic effective filter mechanism, an air inlet channel, a rotary arm, a handle, a hand wheel,a lifting rod, a sealing cover, an air outlet channel, a sewage discharge channel and more than two supporting racks, wherein the supporting racks are separately welded to the surface of the bottom ofthe automatic effective filter mechanism; the upper end of the sewage discharge channel is fixedly welded to the bottom end of the automatic effective filter mechanism, and the inside of the sewage discharge channel communicates with the automatic effective filter mechanism; and the size of the air inlet channel is consistent to that of the air outlet channel. The irrigation-fed filter extends out through a lifting cylinder, a scraper blade is in contact with a second filter screen, a third filter screen and a fourth filter screen, a lead screw drives the scraper blade to move back and forthto scrape impurities to one side with a sealing door, in an impurity cleaning process, the sealing door is open, the impurities are driven by the scraper blade to enter an impurity transition box, andthen flow into an impurity collecting box through a connecting tube, gas discharged from a gas discharge tube enters a container filter, and therefore, the quality of a working environment of a useris improved.

Owner:章帆

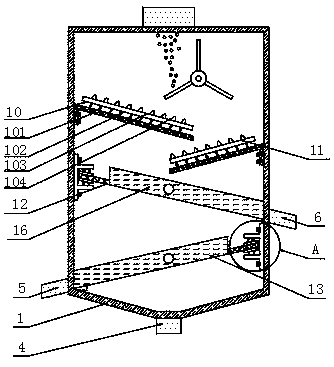

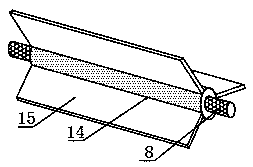

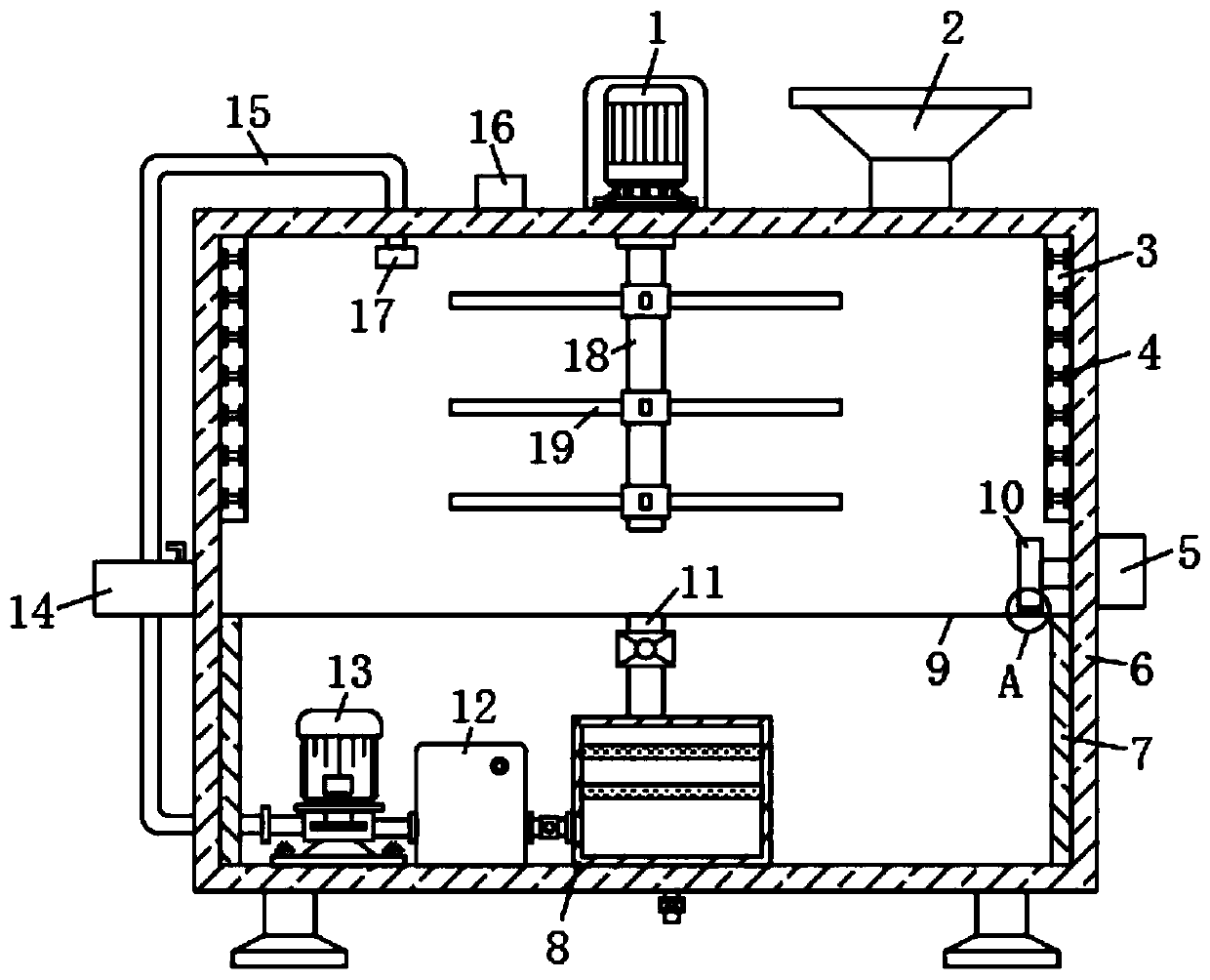

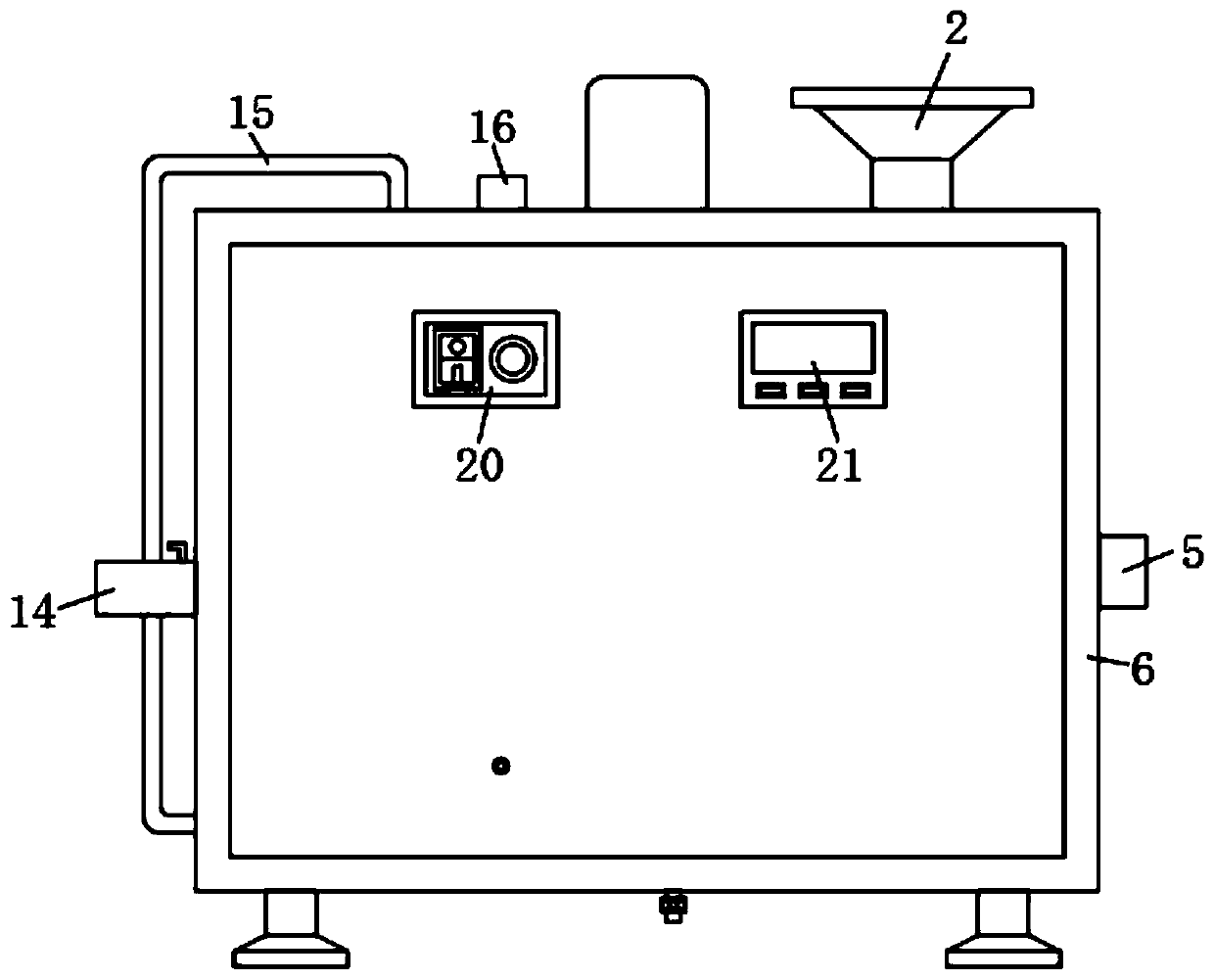

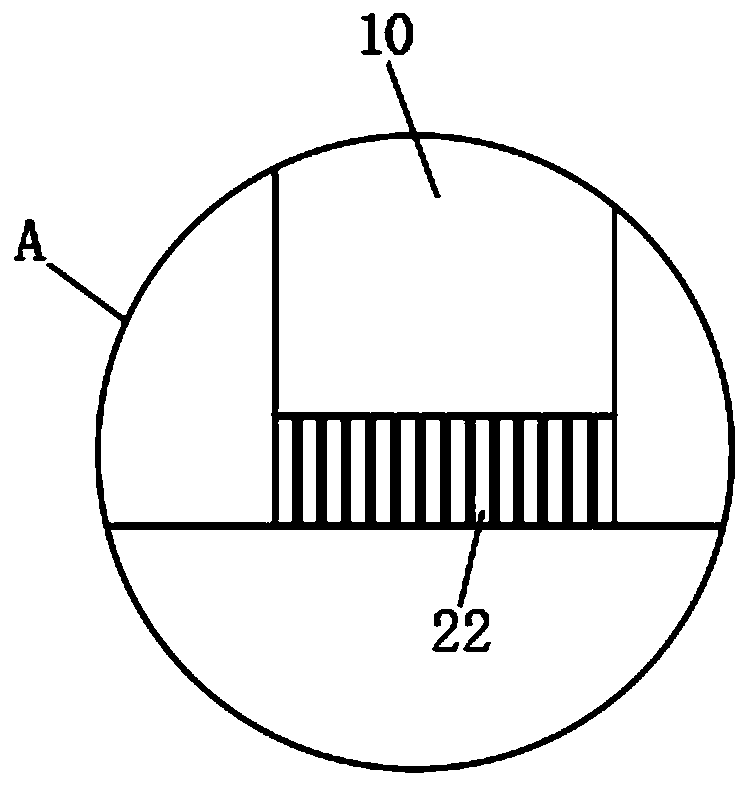

Graded screening device for sand and gravel on construction site

InactiveCN108889609AImprove the quality of the working environmentReduce labor intensitySievingGas current separationWind drivenWorking environment

The invention discloses a graded screening device for sand and gravel on a construction site, Include filter box, the upper surface of the screening box is provided with a feeding port, A No. I discharge port is arranged in the middle of the lower surface of the screening box, and support legs are fixedly installed at four corner positions of the lower surface of the screening box. The double evacuation mechanism is provided in the invention, which not only can disperse the falling sand and gravel during screening, but also slows down the falling speed of the sand and gravel, and improves screening efficiency. A rotating rod and a movable blade are arranged, and the movable blade is driven to rotate by the gravity of sand and gravel to generate wind-driven dust, and the dust is purified byan adsorption mechanism, thereby improving the working environment quality of the construction personnel; A pull mechanism is provided, which facilitates the worker to drive the screen to move left and right, facilitates the removal of larger grains of sand and gravel blocked on the screen, and accelerates the screening speed of the sand and gravel. The screening device has high screening efficiency, simple operation, and is convenient to be widely popularized to the market.

Owner:刘黄莹

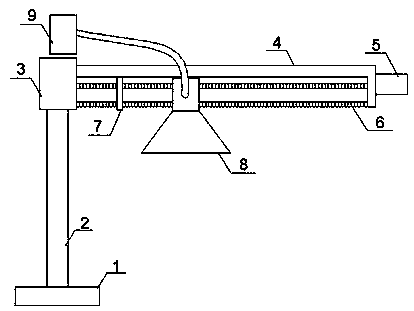

Flexible vehicle fitting dust removing device

InactiveCN108746139AEasy to useImprove dust removal efficiencyDirt cleaningGrinding/polishing safety devicesEngineeringBreathing

The invention discloses a flexible vehicle fitting dust removing device. The flexible vehicle fitting dust removing device comprises a base, a support column, a rotating column, a support rod, a ballscrew module, a slide rail, a baffle plate, a dust sucking cover and a dust sucker; the support column is fixedly mounted on the upper plane of the base through a bolt; the rotating column is rotationally mounted on the support column; the support rod is fixedly mounted on the rotating column; the slide rail is fixedly mounted on the support rod; the baffle plate is fixedly mounted on the slide rail; the ball screw module is arranged on the support rod; the dust sucking cover is fixedly mounted on a ball nut of the ball screw module, and is slidingly connected with the slide rail; and the dustsucker communicates with the dust sucking cover through a ventilation pipe. The flexible vehicle fitting dust removing device has the advantages of convenience to use, improvement of the dust removing efficiency, improvement of the worker operation environment quality and the like.

Owner:来安县劲松车辆零部件有限公司

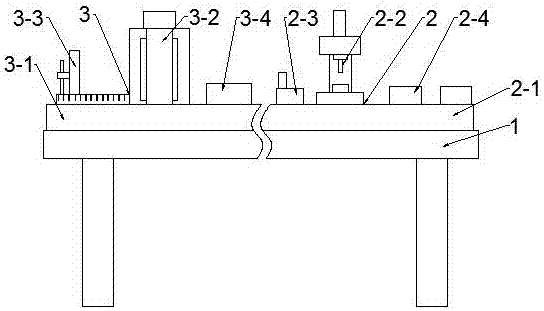

Grounded flat iron processing and manufacturing platform

ActiveCN107123914APrevent overshootPrevent problems such as slantingContact member manufacturingConnection contact member materialState of artEngineering

The invention discloses a grounded flat iron processing and manufacturing platform, which is used for solving the technical problems of low flat iron manufacturing mechanization degree, poor manufacturing quality, low work efficiency and the like in the prior art. The grounded flat iron processing and manufacturing platform comprises an operation platform and a spraying brushing mechanism, wherein a hole punching mechanism and a bending mechanism are arranged on the operation platform; the hole punching mechanism comprises a base, a hole punching machine, a support block and a positioning block are arranged at the upper part of the base; the support block is positioned at one side of the hole punching machine; the positioning block is positioned at the other side of the hole punching machine; the bending mechanism comprises a support seat; a bending machine, a positioning plate and a fixing plate are arranged on the support seat; the positioning plate is positioned at one side of the bending machine; the fixing plate is positioned at the other side of the bending machine; the spraying brushing mechanism comprises a spraying and brushing support frame; a fixing seat and a support plate are arranged on the spraying and brushing support frame; paint blocking plates are arranged on the fixing seat at intervals; a cover plate is arranged on the support plate. The fast and precise hole punching bending can be realized; the phase color mark can be formed in one step; the manufacturing time can be reduced from the original 50 minutes to 5 minutes; the work efficiency is improved by 10 times and the quality of the workpiece is ensured.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +2

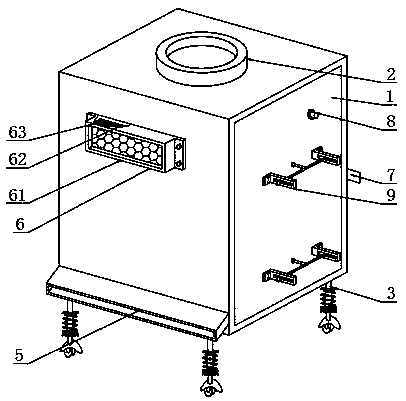

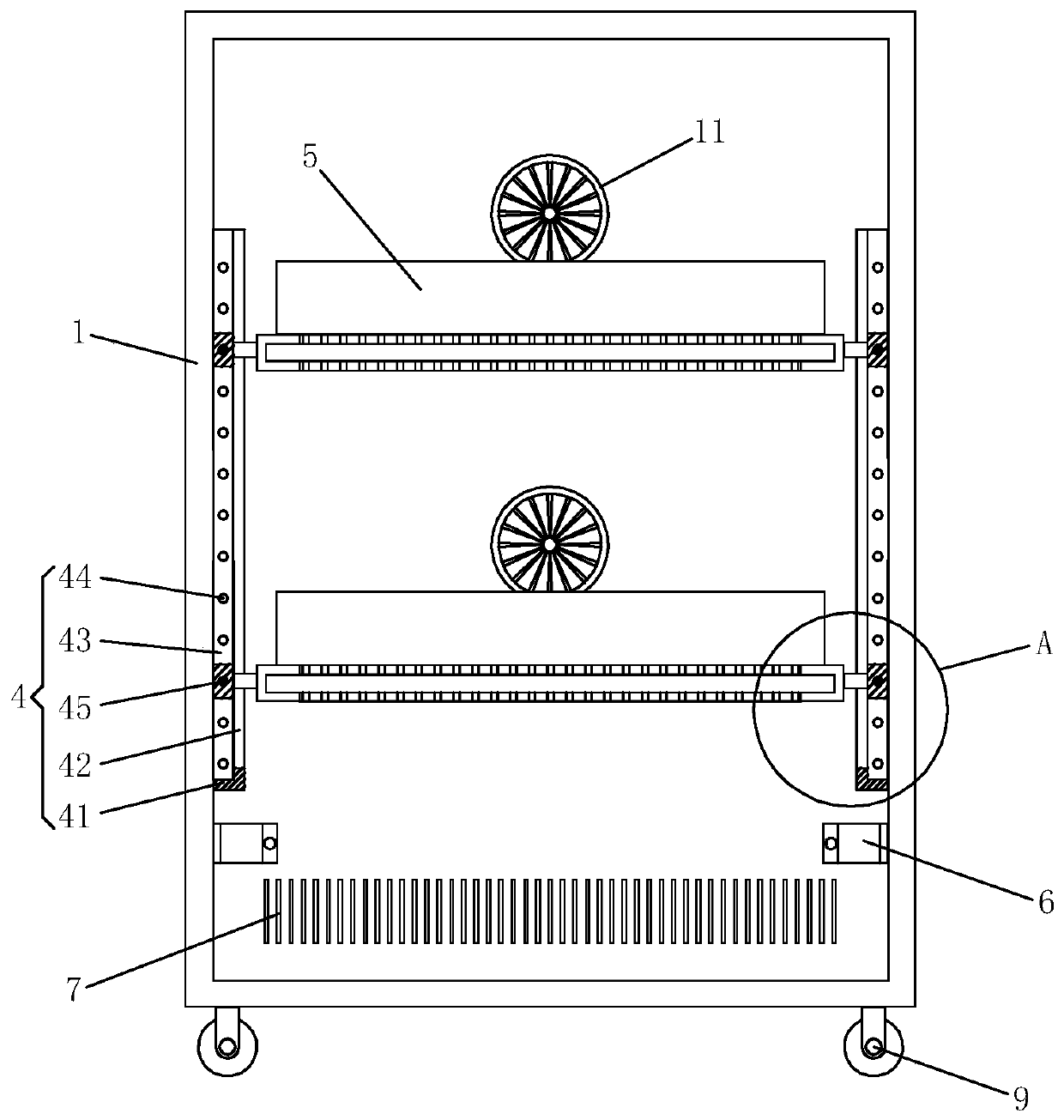

Stable big data server

ActiveCN110769650AHeight adjustableAchieve dustproof effectServersCasings/cabinets/drawers detailsMechanical engineeringServer

The invention relates to the technical field of servers, in particular to a stable big data server. The stable big data server comprises a server. The bottom of the server is installed on the inner wall of a machine shell through a ventilation structure. A door body is rotationally arranged on one side of the machine shell through hinges. A handle is fixedly mounted on the outer side of the door body. Rollers are fixedly installed at the bottom of the machine shell. Wire fixing structures are fixedly installed on the inner walls of the two sides of the interior of the machine shell and locatedbelow the ventilation structures. A heat dissipation groove is fixedly formed in the inner side of the lower portion of the back face of the machine shell. A dustproof structure is fixedly installedbelow the back surface of the shell and is positioned on the outer side of the heat dissipation groove. A first heat dissipation structure is fixedly installed on the surface of the inner wall of theback face of the machine shell, a second heat dissipation structure is fixedly installed on the surface of the inner side of the door body, and the second heat dissipation structure and the first heatdissipation structure are the same in structure. The stable big data server is very good in heat dissipation effect, high in stability, good in buffering and damping effect and worthy of popularization.

Owner:温州大卖客网络科技有限公司

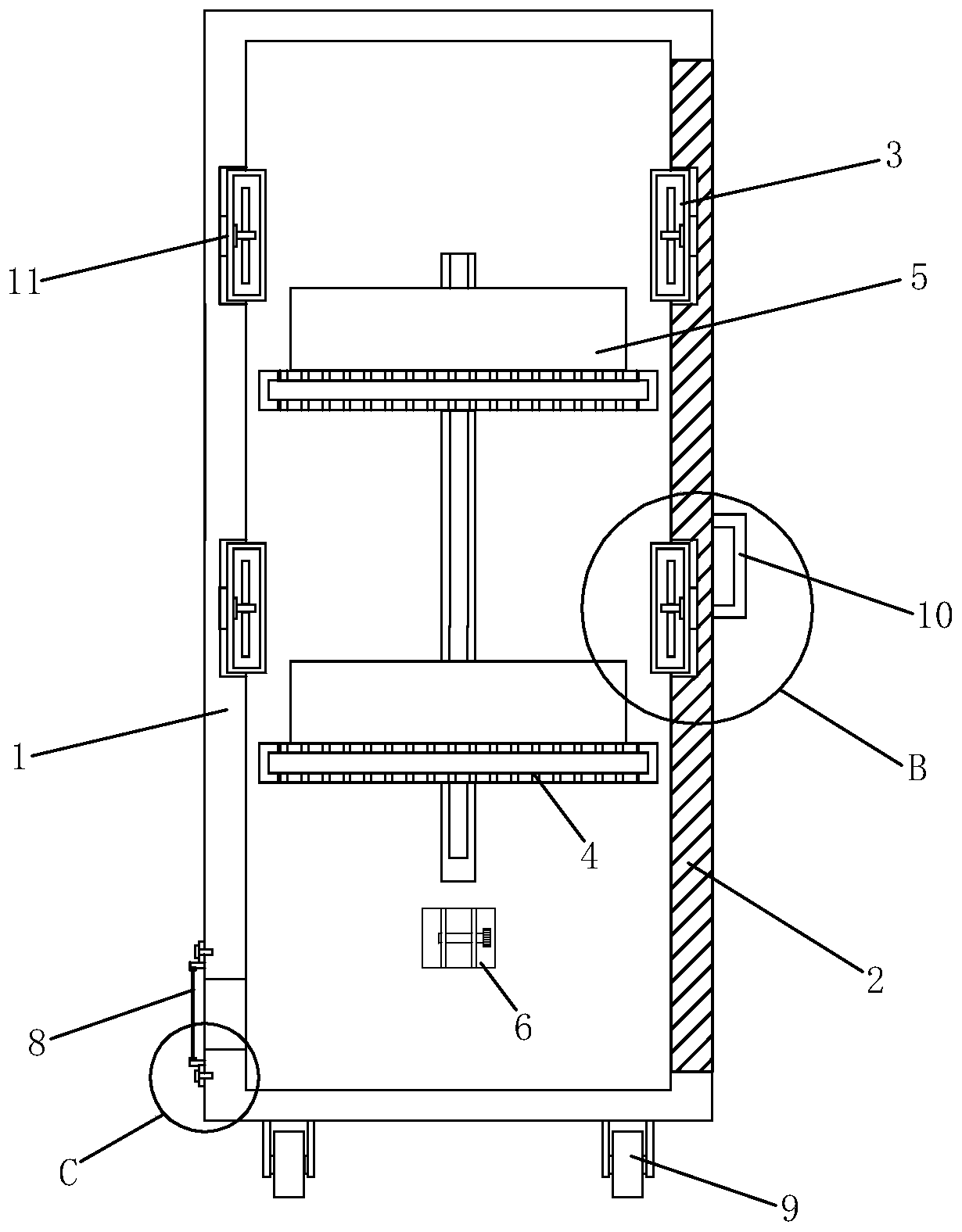

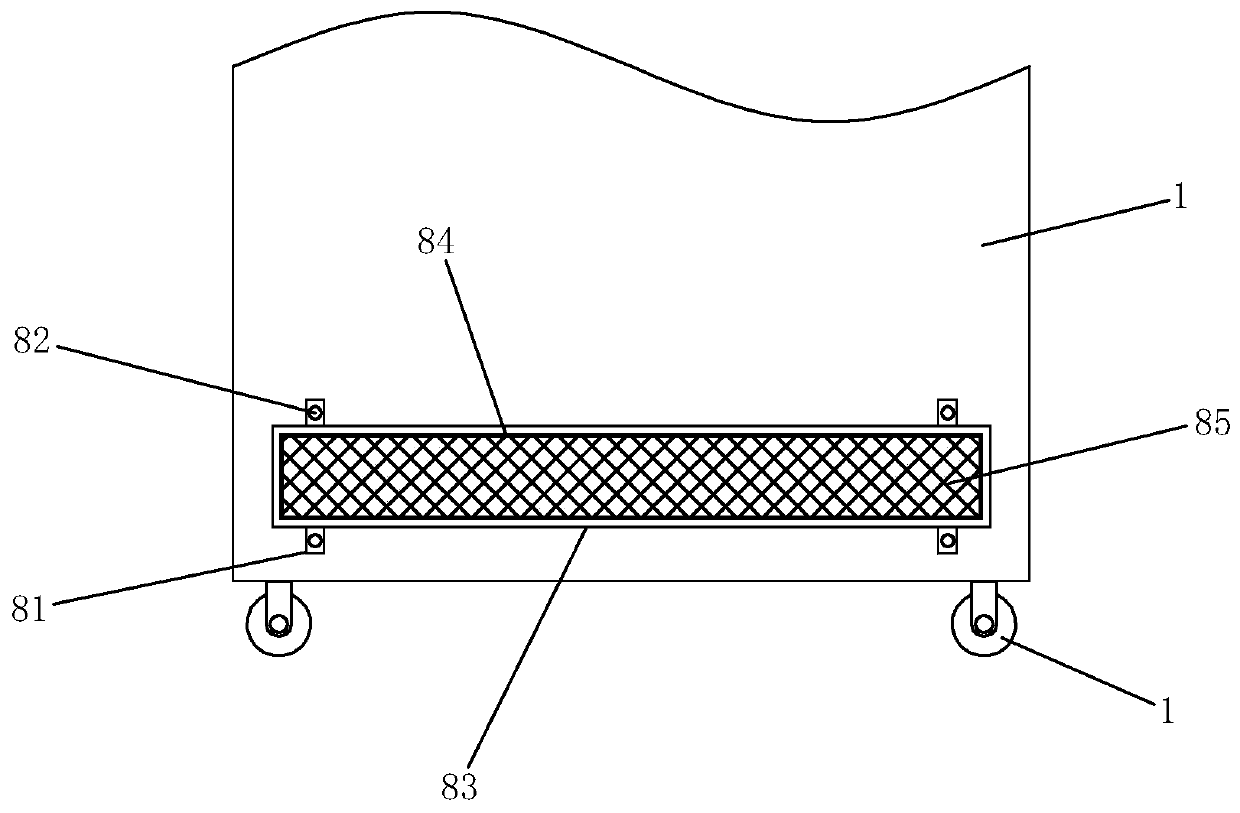

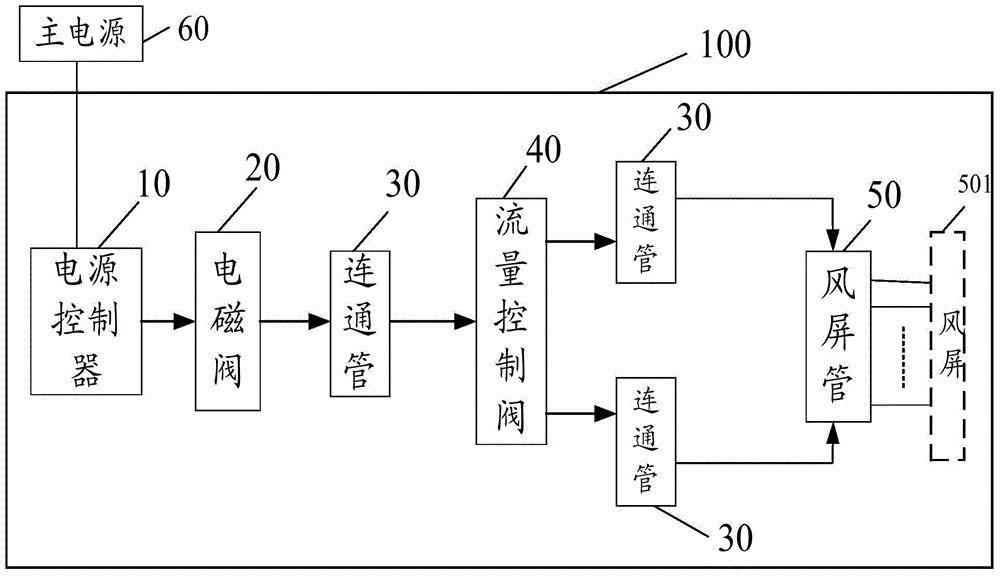

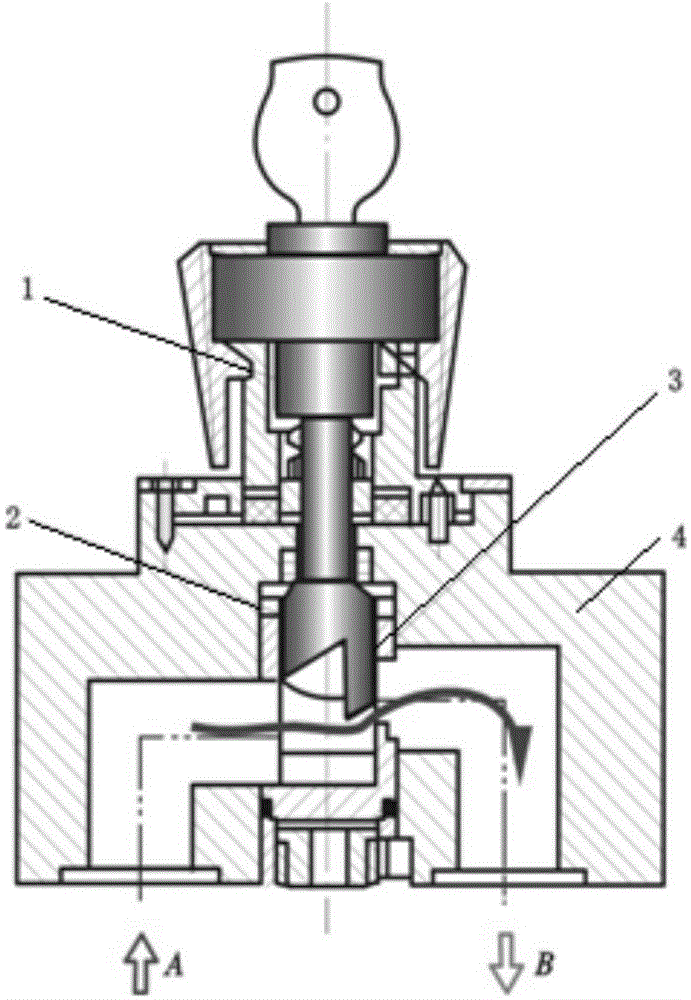

Shielding device for atomized cutting fluid

ActiveCN103551911AReduce development costsLow retrofit costMaintainance and safety accessoriesProduct gasMachining process

The invention discloses a shielding device for an atomized cutting fluid. The shielding device is mounted on numerical control machine tool equipment, and comprises a solenoid valve, a flow control valve, a wind shield pipe, a power supply controller and atomized water adsorption equipment, wherein one end of the solenoid valve is connected with the power supply controller, and the other end thereof is connected to a gas inlet of the flow control valve through a communicating pipe; the solenoid valve is used for controlling the opening or closing of compressed gas; one end of a gas outlet of the flow control valve is respectively connected with two ends of the wind shield pipe through communicating pipes; the flow control valve is used for adjusting the flow rate and the shunting of the compressed gas; a wind outlet is formed in the wind shield pipe; compressed gas forms an invisible wind shield at the wind outlet; the atomized water adsorption equipment is arranged at the top of a machine tool, and is used for adsorbing the atomized cutting fluid sprayed from the top of the machine tool. According to the shielding device, the problem that the cutting fluid, produced during the machining process of a conventional numerical control machine tool, is easy to destroy the environment quality of a production workshop and also brings severe harm to the health condition of operators is solved.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

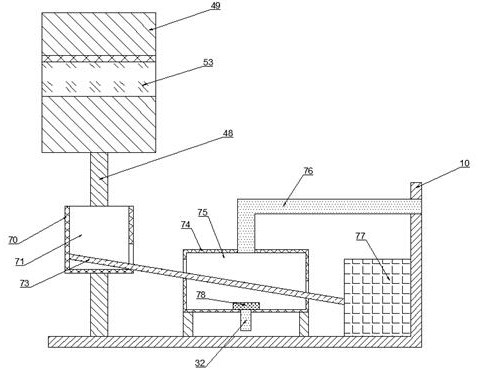

Cleaning and drying device for steel cylinder processing

InactiveCN107442536AEasy to cleanImprove drying effectDrying solid materials with heatHollow article cleaningElastic vibrationPulp and paper industry

The invention discloses a cleaning and drying device for steel cylinder processing. The cleaning and drying device comprises a conveying device, a power device and a drying machine; a plurality of first circular notches are uniformly formed in the conveying device; each first circular notch is provided with a supporting plate below; second circular notches are formed in the middle parts of the supporting plates; protective pads are arranged on the inner sides of flanges at the tops of the supporting plates; a plurality of first springs are arranged on the outer sides of the flanges; a mounting plate is arranged below the conveying device; the power device is arranged at the bottom of the mounting plate; a water spraying pipe is arranged on the left side of the top of the mounting plate; a rainwater collecting hopper is connected to the position, on the outer side of the water spraying pipe, of the mounting plate in a sleeving mode; the drying machine is arranged on the right side of the top of the mounting plate; and a drying pipe is arranged on the drying machine. According to the cleaning and drying device, cylinder bodies of fire extinguishers to be treated are subjected to elastic buffer conveying, the cylinder bodies are subjected to vertical elastic vibration in the cleaning and drying process, and therefore the cleaning and drying effects of the cylinder bodies can be improved, and the working efficiency can be improved.

Owner:刘操

New energy environment-friendly power battery aluminum shell cleaning equipment

InactiveCN111001619AAffect nestingAffect waste dischargeHollow article cleaningSound producing devicesPower batteryElectric machine

The invention discloses new energy environment-friendly power battery aluminum shell cleaning equipment, which comprises a case, and is characterized in that a motor is mounted in the middle of the upper surface of the case; a feeding hopper is arranged on the side, which is close to the motor, of the upper surface of the case; an exhaust port is formed in the side, which is opposite to the feeding hopper, of the upper surface of the case; a cleaning box is mounted in the case; heating layers are arranged on two sides of the inner wall of the upper half section of the cleaning box; and a stirring roller rotationally connected with the motor is mounted in the middle of the top end in the cleaning box. The equipment is provided with an electric telescopic rod, a push plate and a brush strip,so that the cleaning of the bottom in the cleaning box is realized, the pipeline is prevented from being blocked to affect the discharge of materials and waste, and the processing efficiency of the equipment is improved; and the equipment is provided with a silencing plate composed of a vacuum layer, a honeycomb plate, a foam layer and an inverted horn, and sound absorption and noise reduction are achieved by means of the principle that sound is amplified in the forward direction and silenced in the reverse direction in the horn, so that the working environment quality of workers is improved,and the workers are facilitated to work.

Owner:浙江郡琳新材料科技有限公司

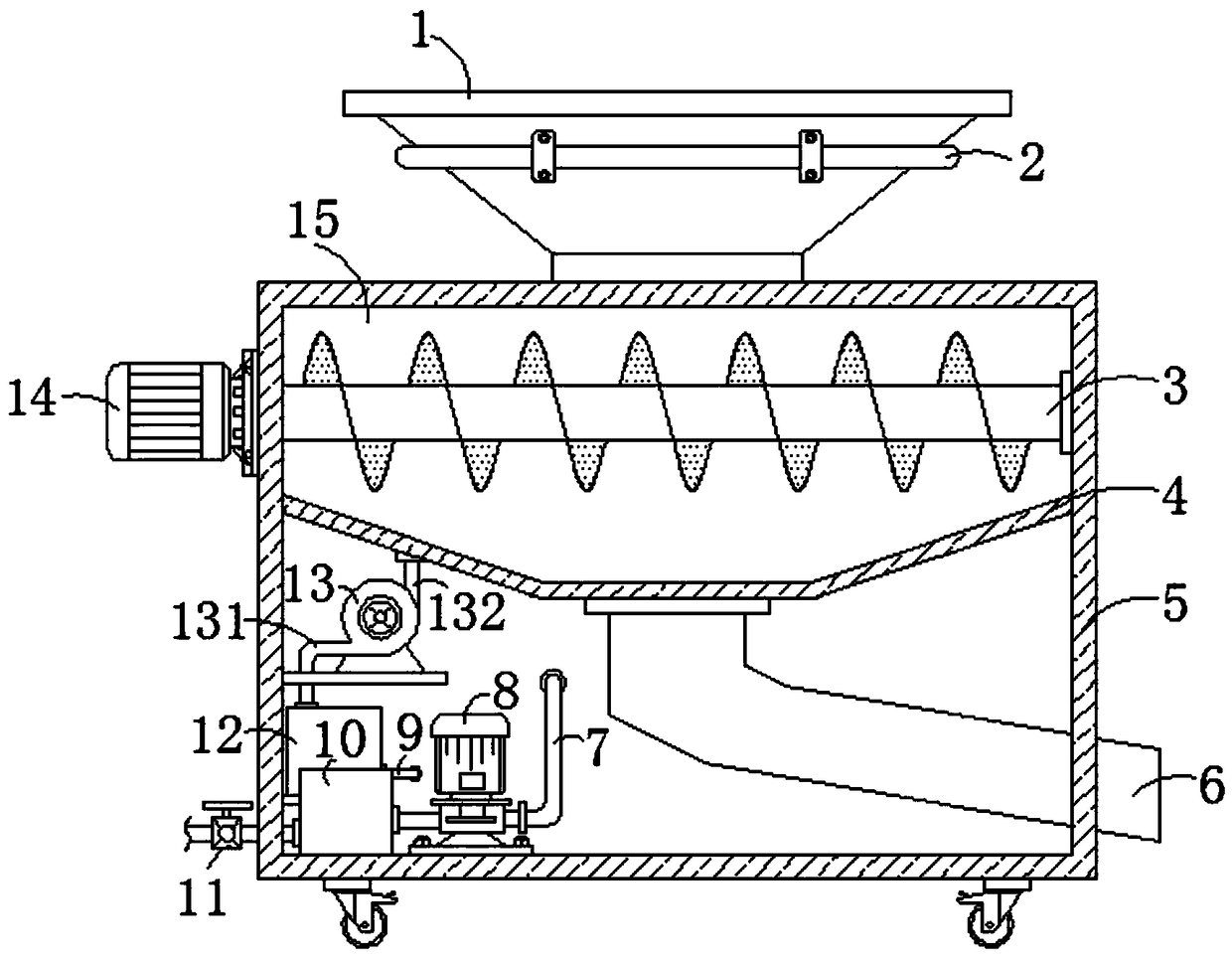

Meat smashing machine for food processing workshop

InactiveCN108435298AAvoid pollutionImprove the quality of the working environmentDispersed particle filtrationTransportation and packagingWorking environmentSpray nozzle

The invention discloses a meat smashing machine for food processing workshop. The meat smashing machine comprises a machine cabinet. A feeding hopper is arranged in the middle position of the upper surface of the machine cabinet. A partition plate is installed in the middle position in the machine cabinet. A smashing chamber is arranged above the partition plate. A feeding pipeline is connected tothe bottom end of the partition plate. Two smashing rollers are symmetrically installed in the smashing chamber. Stationary cutters matched with the two smashing rollers are installed on the two sides of the inner wall of the smashing chamber correspondingly. An induced draft fan is fixed to one side in the machine cabinet through a support. According to the meat smashing machine, the induced draft fan and an air purification box are arranged, waste gas is purified, the situation that waste gas is exhausted and pollutes air is prevented, the working environment quality of workers is improved,the working efficiency of workers is ensured, a spraying pipe, a spraying nozzle and a water pump are arranged, the smashing machine can be cleared conveniently, meat scraps are prevented from adhering to the inner wall of the machine cabinet, the situation that bacteria breed in the smashing machine is avoided, and safety of meat food is ensured.

Owner:浙江长兴好方向食品有限公司

Efficient shot blasting equipment for removing rust and burrs of steel part

InactiveCN112497083AImprove reuse rateSimple stepsBlast gunsAbrasive feedersWorking environmentProcess engineering

The invention discloses efficient shot blasting equipment for removing rust and burrs of a steel part. The efficient shot blasting equipment for removing the rust and the burrs of the steel part comprises a shot blasting box and a pneumatic mechanism arranged on the right side of the shot blasting box, wherein a working cavity is formed in the shot blasting box. According to the efficient shot blasting equipment for removing the rust and the burrs of the steel part provided by the invention, a mode of directly adding dry ice fragment spraying on the rear side of a metal ball jet flow is used,rust removal and burr removal are integrated into one procedure, and traditional cleaning, drying and other procedures are not needed after dry ice spraying, so that the steps are greatly simplified,dry ice can be directly gasified after being used, and whether residues exist or not does not need to be manually detected; coarse and fine particles are separated in a vibration mode in subsequent separation equipment, so that the reuse rate of metal balls in a shot blasting machine is increased, rust, burrs and dust are collected in a unified mode, the cleaning cost is reduced, and the working environment quality is improved; and meanwhile, automation of the treatment process is achieved, so that the treatment efficiency is greatly improved, and labor force is saved.

Owner:石家庄闻索科技有限公司

Novel rapid building block core filling device

PendingCN107891520AImprove the quality of the working environmentContinuous and efficient productionCeramic shaping plantsAuxillary shaping apparatusConstruction engineeringWorking environment

The invention discloses a novel rapid building block core filling device and belongs to the technical field of building block processing. The filling can be applied to other fields after being subjected to simple modification, for solving the problems that the conventional manual building block core filling efficiency is low, the operating environment is poor, the time and labor are consumed, theproduction cost is increased, and continuous and high-efficiency production is not facilitated. The novel rapid building block core filling device disclosed by the invention comprises a rack, a powerdevice, a transfer device, a rapid filling device, a cleaning device and a detection device, and is characterized in that a transport device on the rack drives a mold to move forwards by virtue of chain drive, and the rapid filling device, the high-pressure cleaning device and the detection device are arranged on the rack. The novel rapid building block core filling device disclosed by the invention is simple in structure, ingenious in design, low in cost and high in reliability, full-automatic, high-efficiency and high-quality filling is realized, and the core filling efficiency in the production process is increased. Meanwhile, the labor intensity of the staff is reduced, and the operating environment quality of the staff is improved.

Owner:UNIV OF JINAN

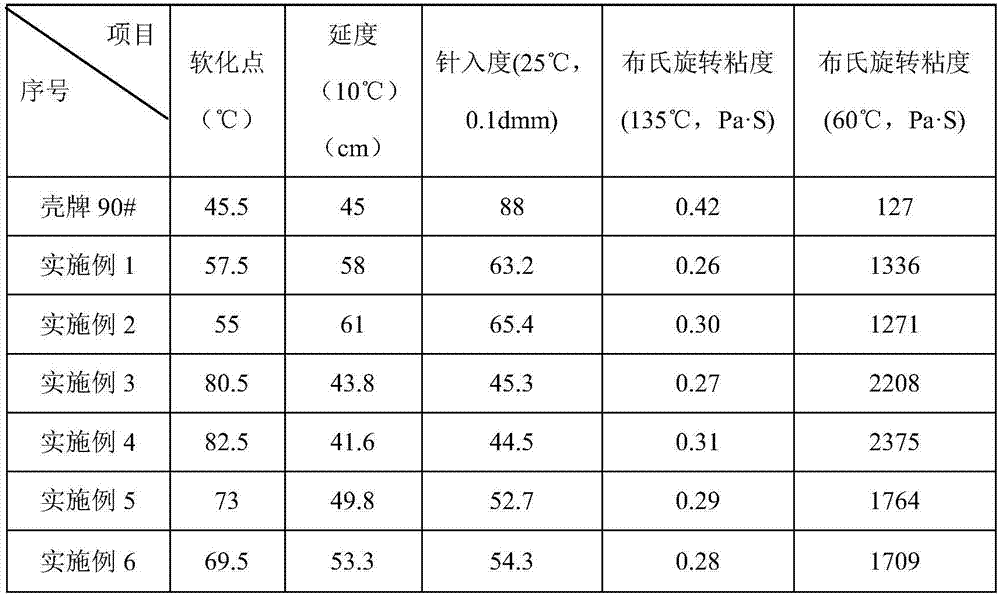

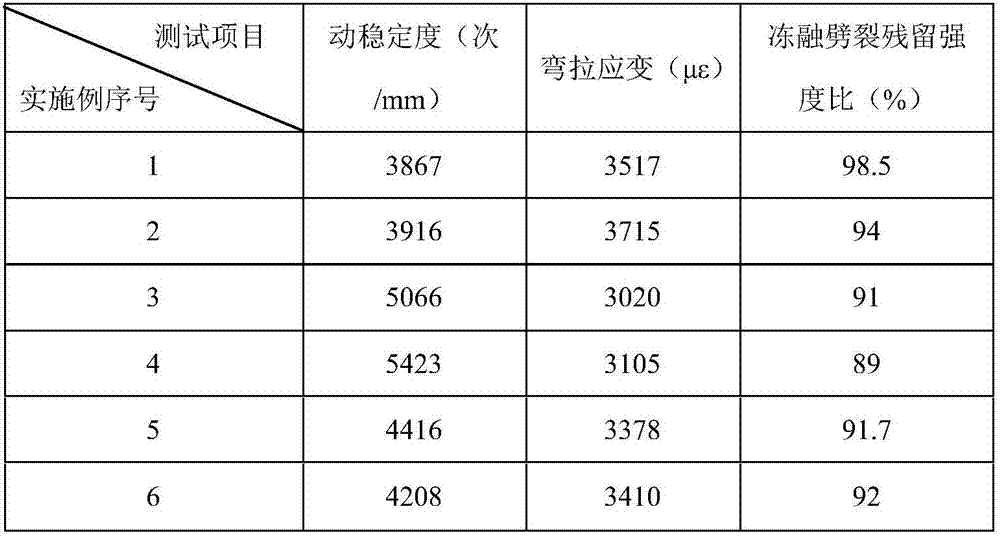

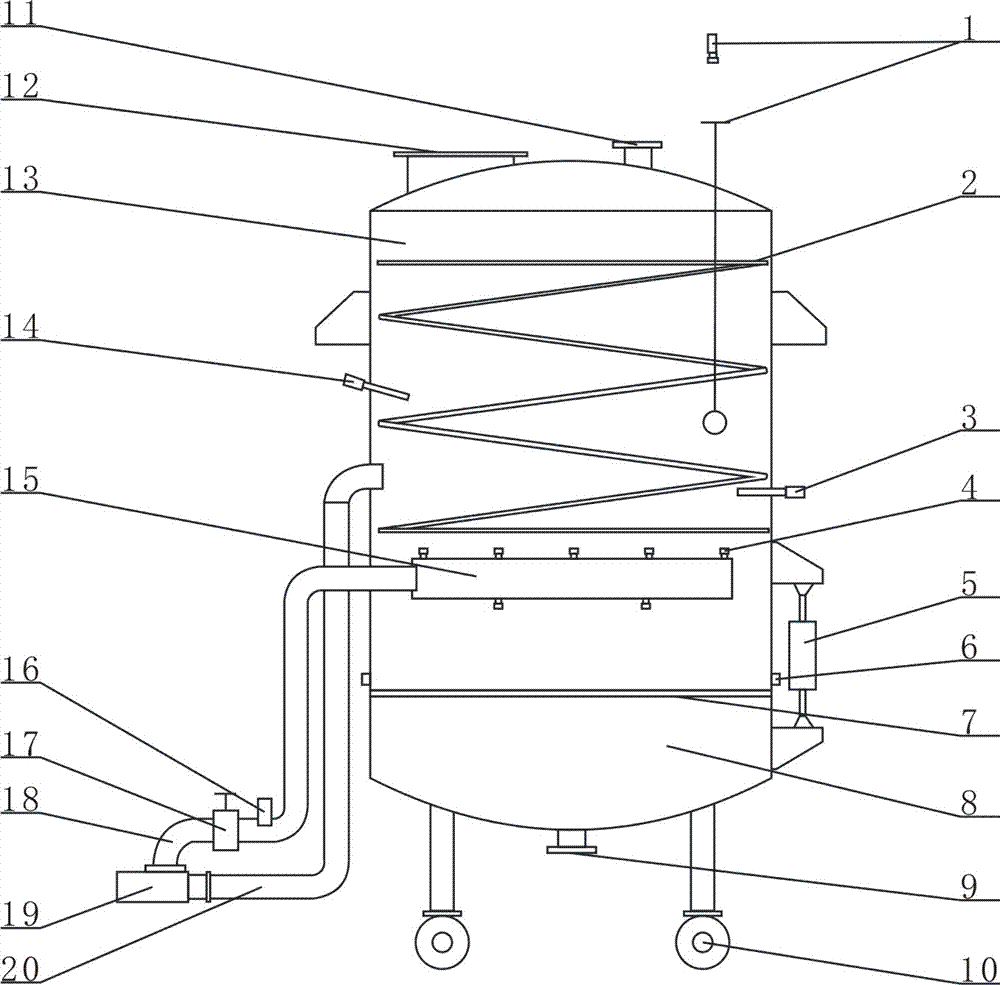

Preparation method of asphalt concrete warm mixing rutting and cracking resisting agent

The invention relates to a preparation method of an asphalt concrete warm mixing rutting and cracking resisting agent. The preparation method concretely comprises the following steps: fully mixing wax, resin and a cross-linking agent in a reaction kettle to obtain a modifying mixture; and adding a surfactant, a plasticizer and assistant to the modifying mixture, carrying out melt blending, and granulating the mixture through a granulating tower or a rotary belt condensation granulator to obtain the warm mixing rutting and cracking resisting agent. Compared with the prior art, the preparation method disclosed in the invention has the advantages of simplicity in operation, easiness in industrial generation, facilitation of reduction of the mixing temperature and the compacting temperature of asphalt concrete, reduction of the discharge of harmful gases, improvement of the moisture resistance, and high-temperature viscosity reducing and low-temperature viscosity increasing effects on asphalt; and the prepared warm mixing rutting and cracking resisting agent obviously improves the softening point, the ductility and the 60 DEG C viscosity of the asphalt, reduces the mixing and lying temperature, and improves the rutting resistance, the low-temperature cracking resistance and the water damage resistance of the asphalt concrete.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com