Anti-oxidation spraying device and method for anode carbon block for aluminum electrolysis

A technology of anode carbon block and spraying device, which is applied to the device and coating of surface coating liquid, which can solve the problems of affecting the economic benefits of aluminum electrolysis plants, the inability to popularize and apply on a large scale, and the effect is not obvious, so as to reduce labor costs. Intensive and repetitive mechanical labor, improving the quality of the working environment, and improving the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

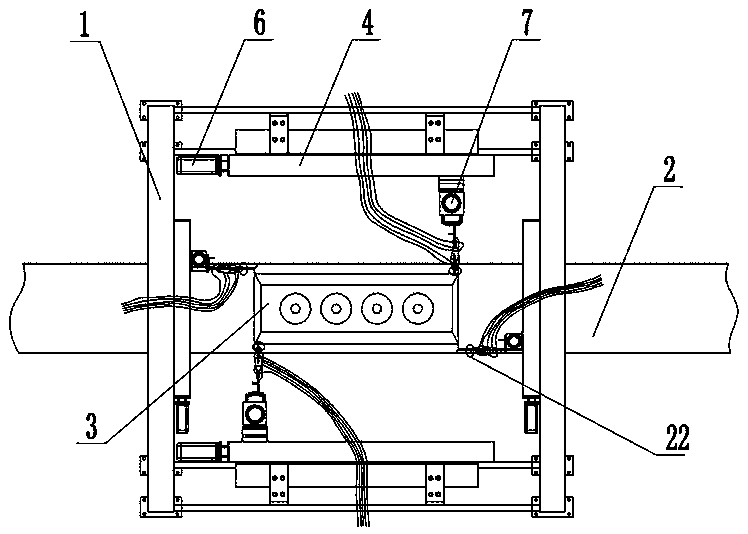

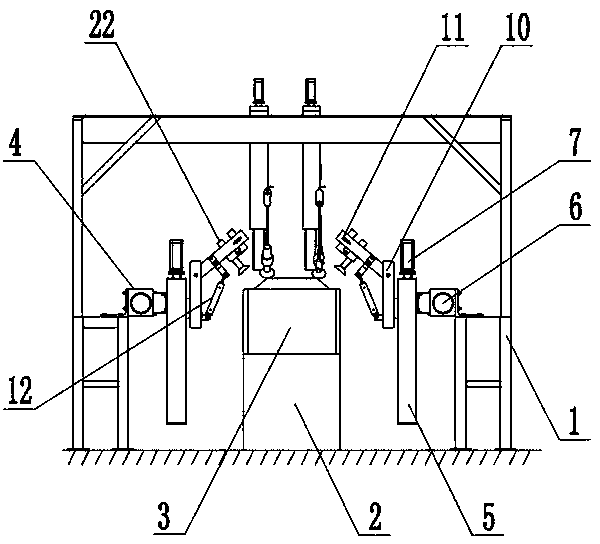

[0034] Embodiment one: see figure 1 , figure 2 , Figure 4-Figure 6 , Figure 9 and Figure 10 , an anti-oxidation spraying device for anode carbon blocks for aluminum electrolysis in the present invention, comprising a support frame 1 and a carbon block working platform 2 arranged on the lower side of the support frame 1, and the four sides inside the support frame 1 are provided with spraying units, so The spraying unit described above includes arc spraying equipment and a moving mechanism connecting the arc spraying equipment and the support frame 1, the described arc spraying equipment includes a spray gun 22, a wire feeder, a dedicated power supply, a control device and a compressed air supply system, and the moving The mechanism includes a horizontal sliding table 4 fixed on the support frame 1, a vertical sliding table 5, a traverse motor 6 and a lifting motor 7 respectively arranged at the ends of the horizontal sliding table 4 and the longitudinal sliding table 5,...

Embodiment 2

[0035] Embodiment two: see figure 1 , figure 2 , Figure 4-Figure 6 , Figure 9 and Figure 10 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that an adjustment mechanism is also provided between the spray bracket 10 and the spray gun 22, and the adjustment mechanism includes The spraying fixed plate 11 of fixed spray gun 22 and the electric push rod 12 that two ends are respectively with one end of spraying fixed plate 11 and spraying support 10 hinged, the other end of spraying fixed plate 11 is hinged with spraying support 10.

Embodiment 3

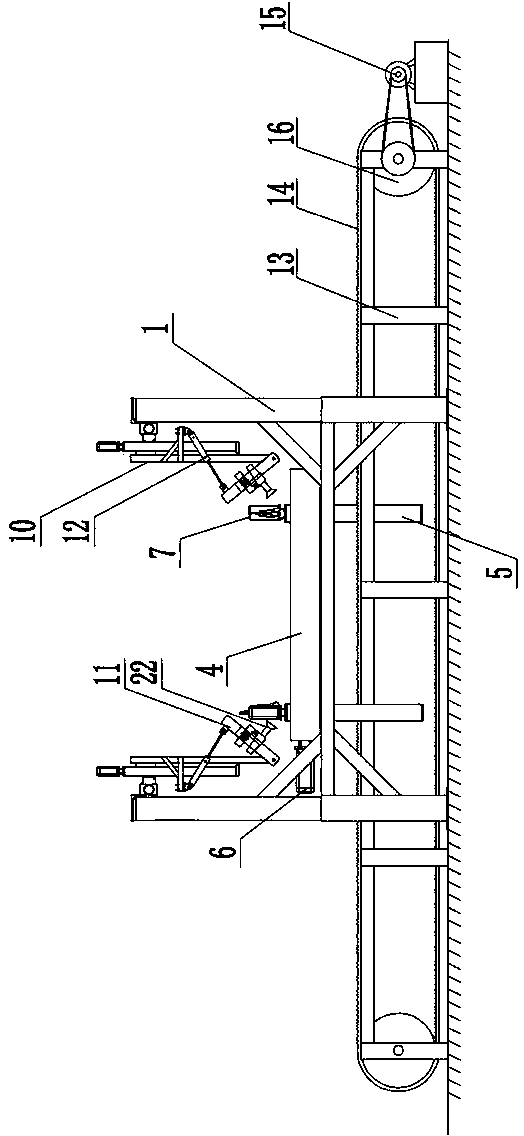

[0036] Embodiment three: see Figure 3-Figure 6 , Figure 9 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the carbon block working platform is an automatic feeding mechanism that runs through the front and rear end faces of the support frame 1, and the automatic feeding The mechanism includes a feeding support 13, a feeding conveying belt 14, a conveying roller 16 and a drive motor 15 that drives the conveying roller 16 to run.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com