Patents

Literature

45results about How to "Lower the holding temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

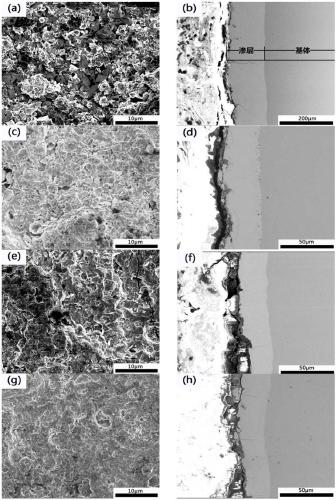

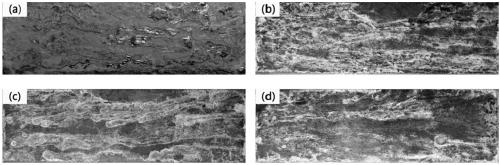

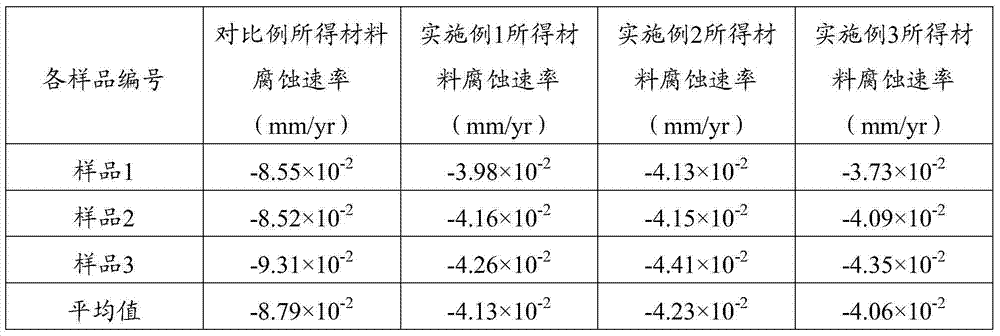

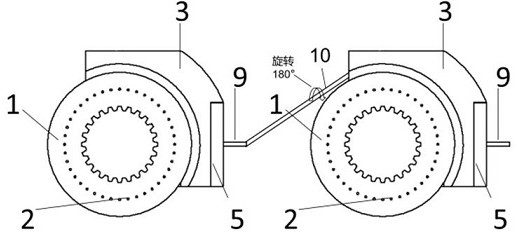

Preparation method of Zn-Al-Ni anticorrosion functional impregnation layer

ActiveCN109136828AImprove compactnessHigh surface hardnessSolid state diffusion coatingMechanical energyRare earth

The invention discloses a preparation method of a Zn-Al-Ni anticorrosion functional impregnation layer, in which such elements as Al and Ni are added into a zinc impregnation agent to change the organizational structure of the conventional zinc and aluminum impregnation layer prepared through mechanical energy aided impregnation. An impregnation agent is prepared according to the following ratio (based on a total number of 100 parts): 20-50 parts of zinc powders (an impregnation supplying agent), 5-25 parts of aluminum powders (an impregnation supplying agent), 0.5-5 parts of nickel powders (an impregnation supplying agent), 0.1-2 parts of ammonia chloride (an activating agent), 0.1-2 parts of rare earth (a catalyst), and of the balance of Al2O3 powders (a filler). The preparation method of the Zn-Al-Ni anticorrosion functional impregnation layer comprises the following steps: uniformly mixing the zinc powders, the aluminum powders, the nickel powders, the rare earth and the Al2O3 powders according to the ratio, and weighing the mixture for later use; and carrying out heat preservation for 3-5 hours under the following technical parameters: a heat preservation temperature of 450 DEG C, and an impregnation furnace rotation speed ranging from 5r / min to 7r / min. The preparation method provided by the invention has the advantages that a high quality of the impregnation layer is ensured through adopted particle diameters of the powders in the impregnation layer formula, and the prepared Zn-Al-Ni impregnation layer achieves low thickness, high surface compactness, high rigidity and excellent anticorrosion performance.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

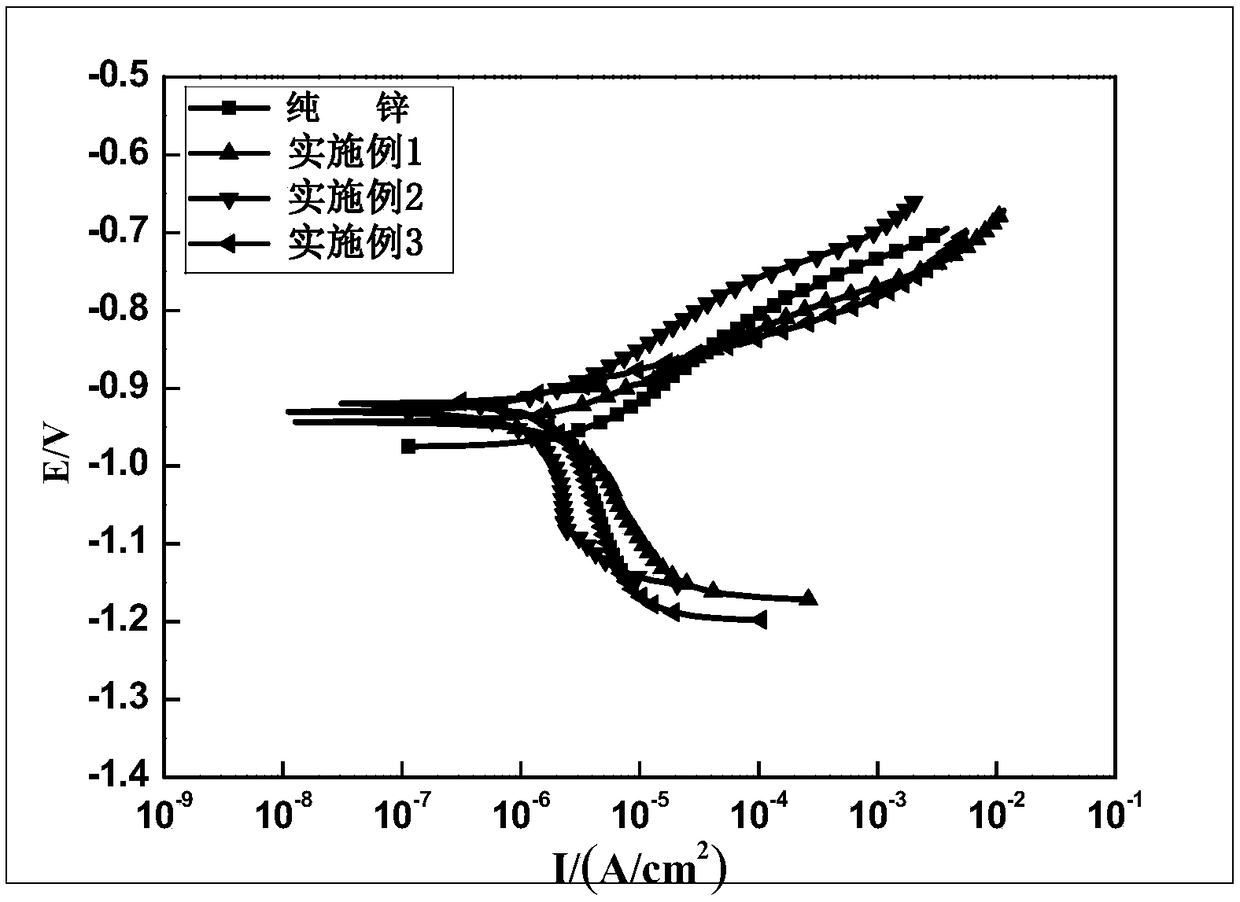

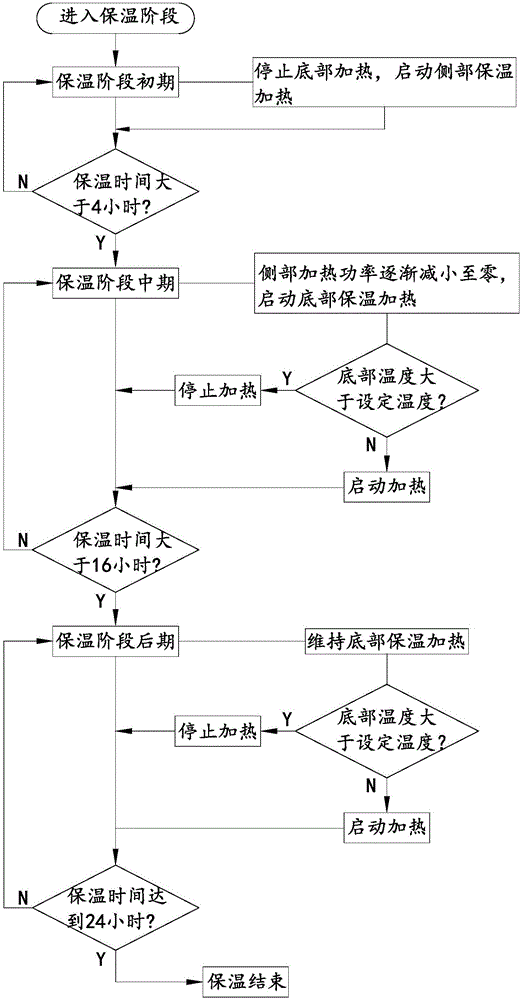

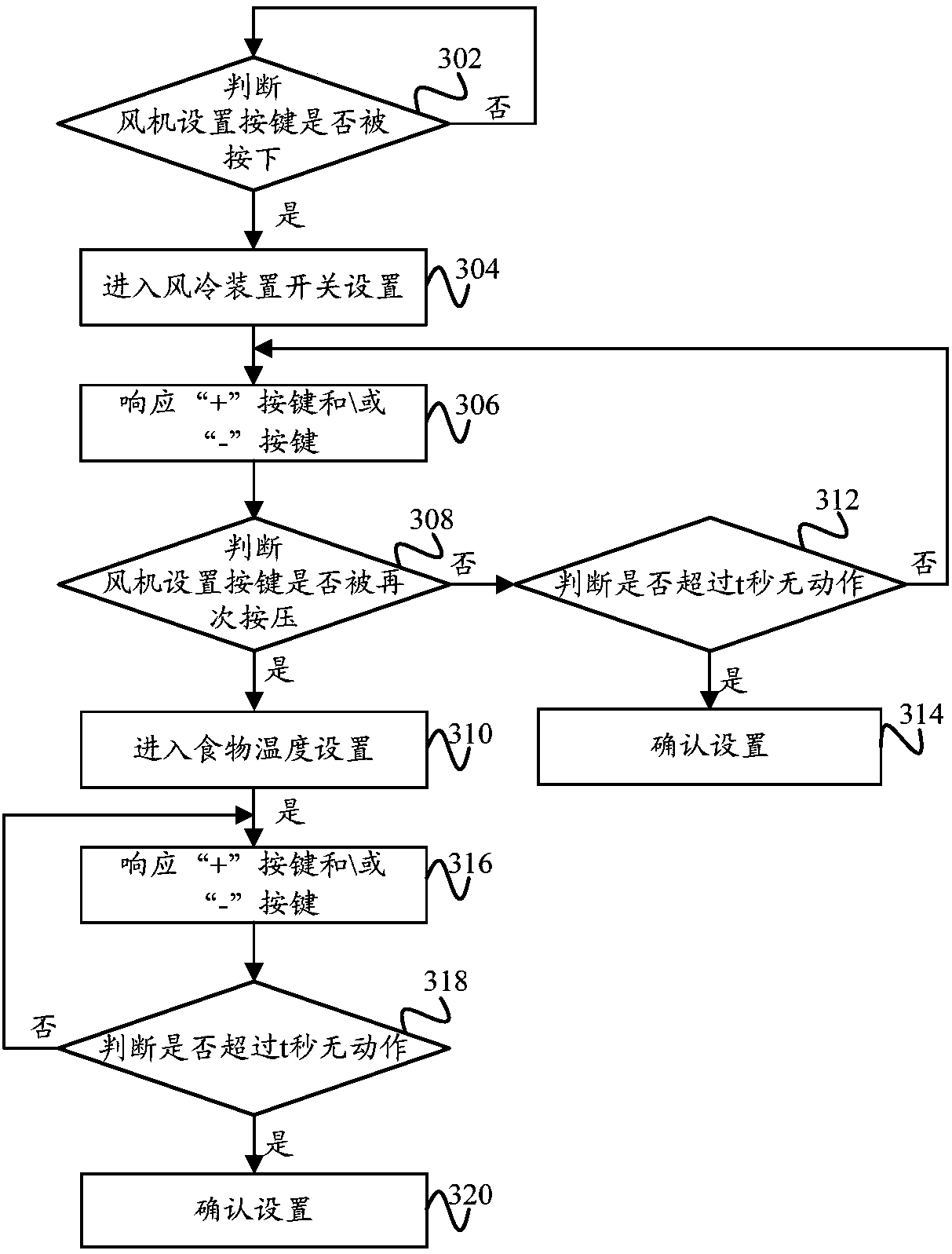

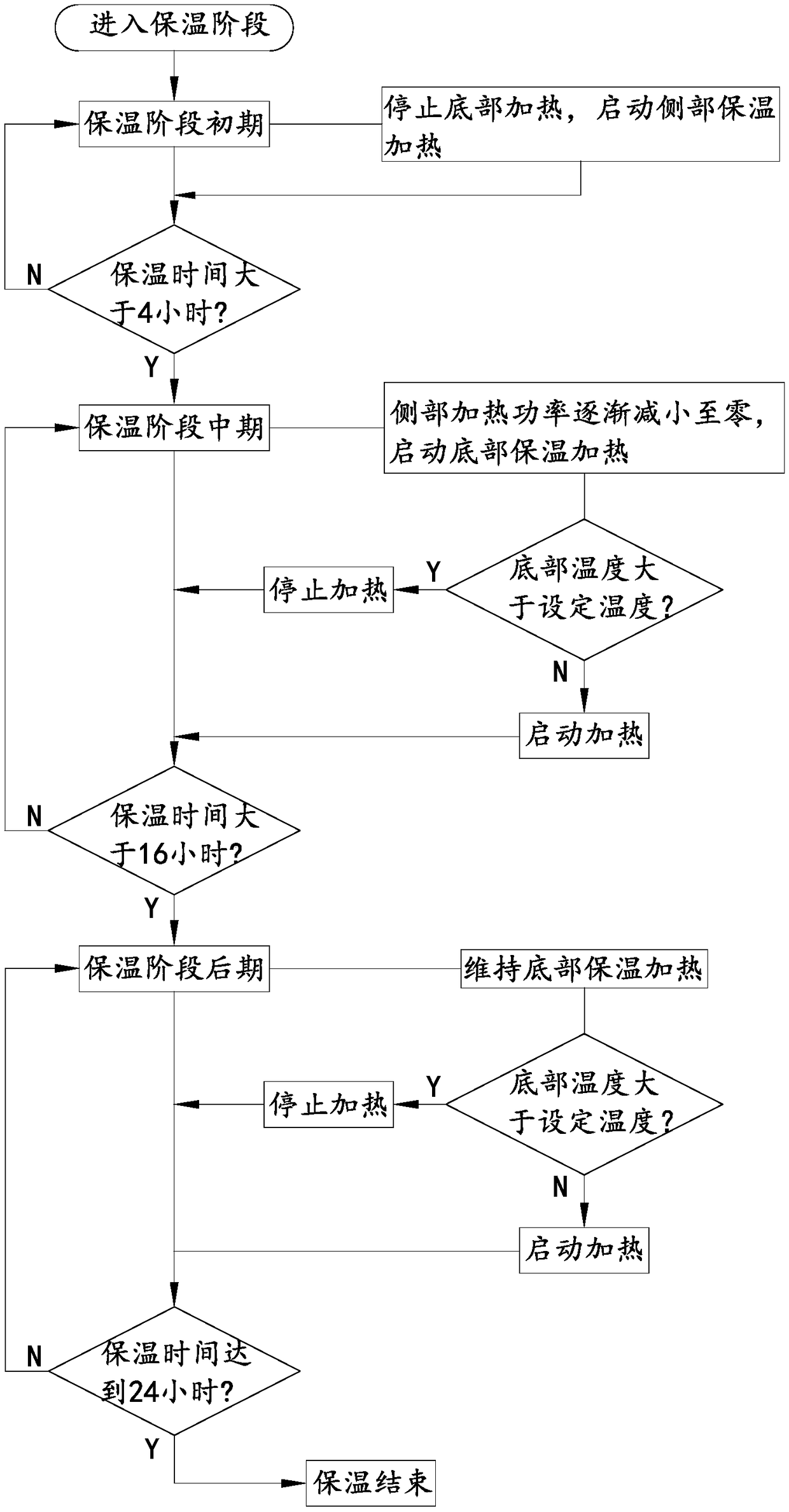

Heat preservation control method for electric rice cooker

ActiveCN106510481AAvoid hardening and yellowingConsistent tasteTemperature control using electric meansWarming devicesEngineeringCooker

The invention discloses a heat preservation control method for an electric rice cooker, belongs to the technical field of kitchen cooking, and solves the problem of food hardening and yellowing caused by long-time heat preservation of an existing electric rice cooker. The electric rice cooker comprises a control unit, a heating apparatus and an inner pot, wherein the heating apparatus comprises a bottom heater for heating the bottom of the inner pot and a side heater for heating the side part of the inner pot. According to the heat preservation control method, the control unit controls the bottom heater and the side heater to alternately perform heat-preservation heating according to a set heat preservation temperature after the electric rice cooker enters a heat preservation stage. The heat preservation control method is used for the electric rice cooker to perform food cooking such as rice cooking, congee cooking and the like.

Owner:JOYOUNG CO LTD

Anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application

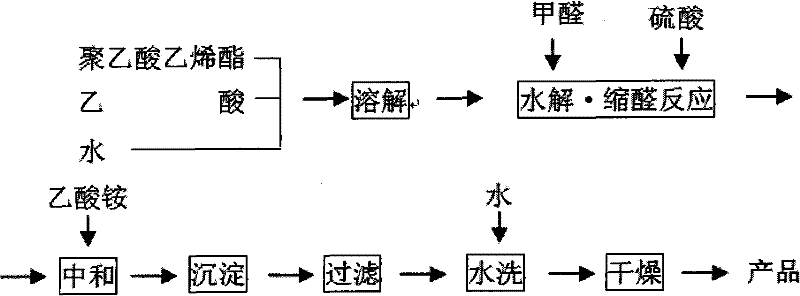

InactiveCN102234432AImprove the degree of adhesionLower working conditionsClimate change adaptationBuilding insulationsPolyvinyl alcoholFatty acid

The invention, belonging to the field of construction engineering, relates to an anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application. The anti-stripping warm mix asphalt additive agent disclosed in the invention comprises polyvinyl acetal, polyacrylamide, fatty acid anhydride ester surfactant, polyoxyethylene acid ester surfactant and water. The warm mix asphalt additive agent disclosed in the invention can enhance the bonding of stone, rock flour and asphalt, so as to get the purposes of high strength and preventing stripping. The requirements of the technical characteristics of the warm mix asphalt is realized by spraying the additive agent with the content of 5-6% of the weight of the asphalt when the temperature of the asphalt reaches 120-130 DEG C, and then carrying out blending and operation as routine asphalt. The warm mix asphalt additive agent disclosed in the invention has no substances which are harmful to the human body and environment, with being environmentally friendly, and is an excellent product with energy saving and emission reduction.

Owner:SHANGHAI YITAI ENERGY TECH

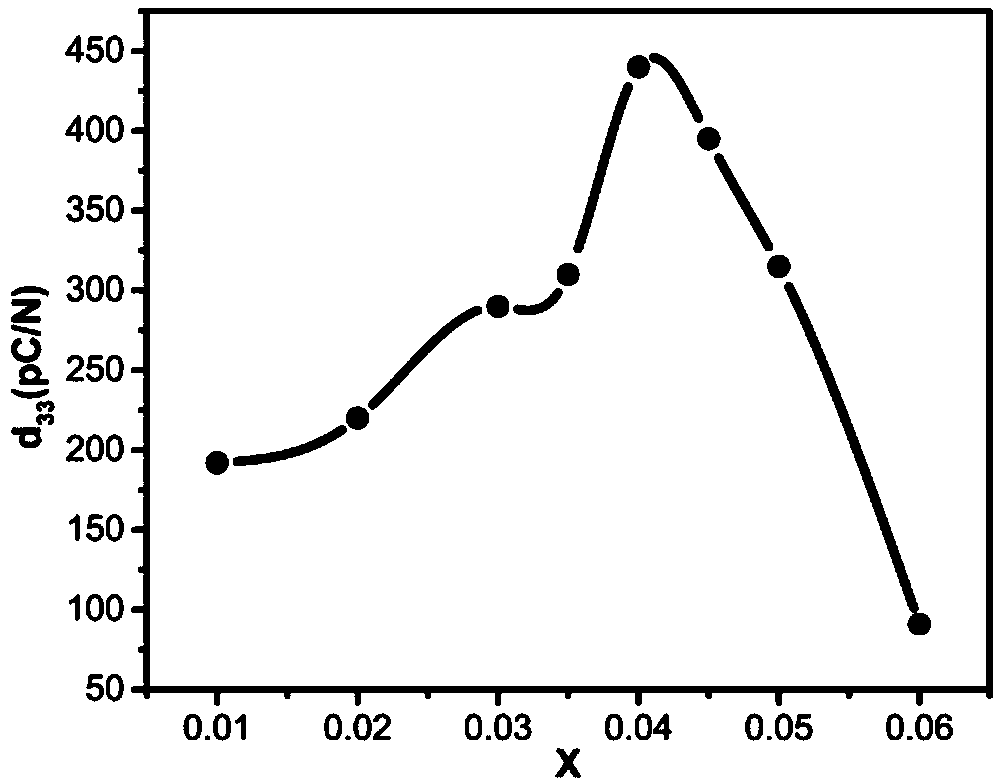

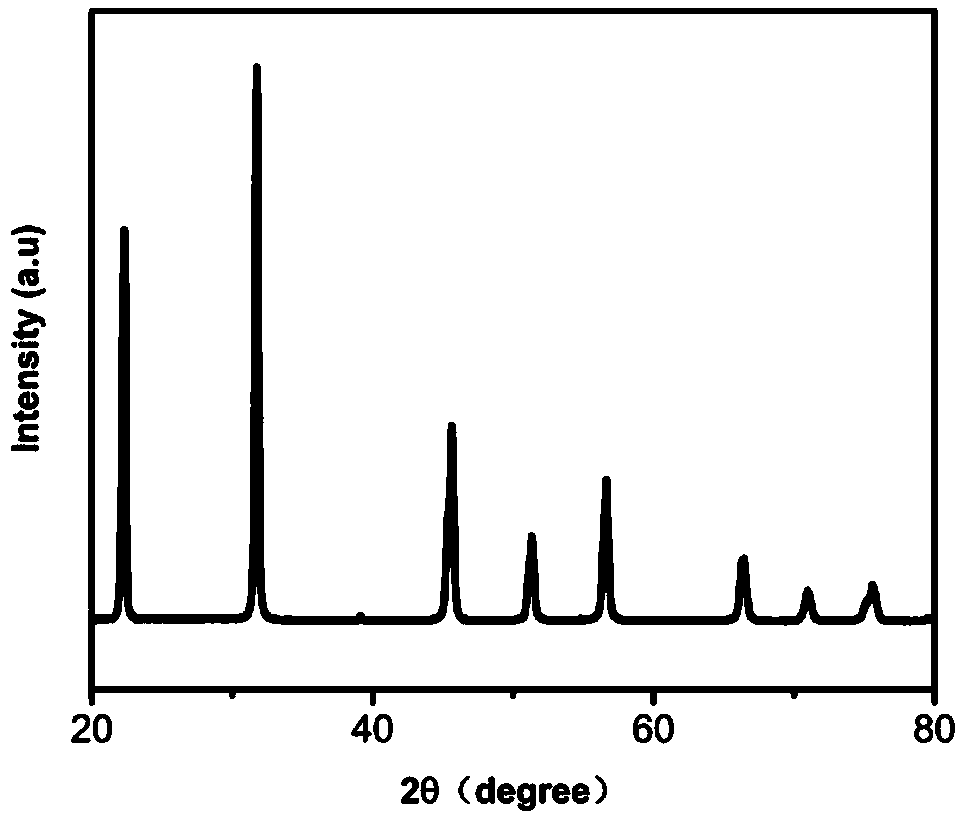

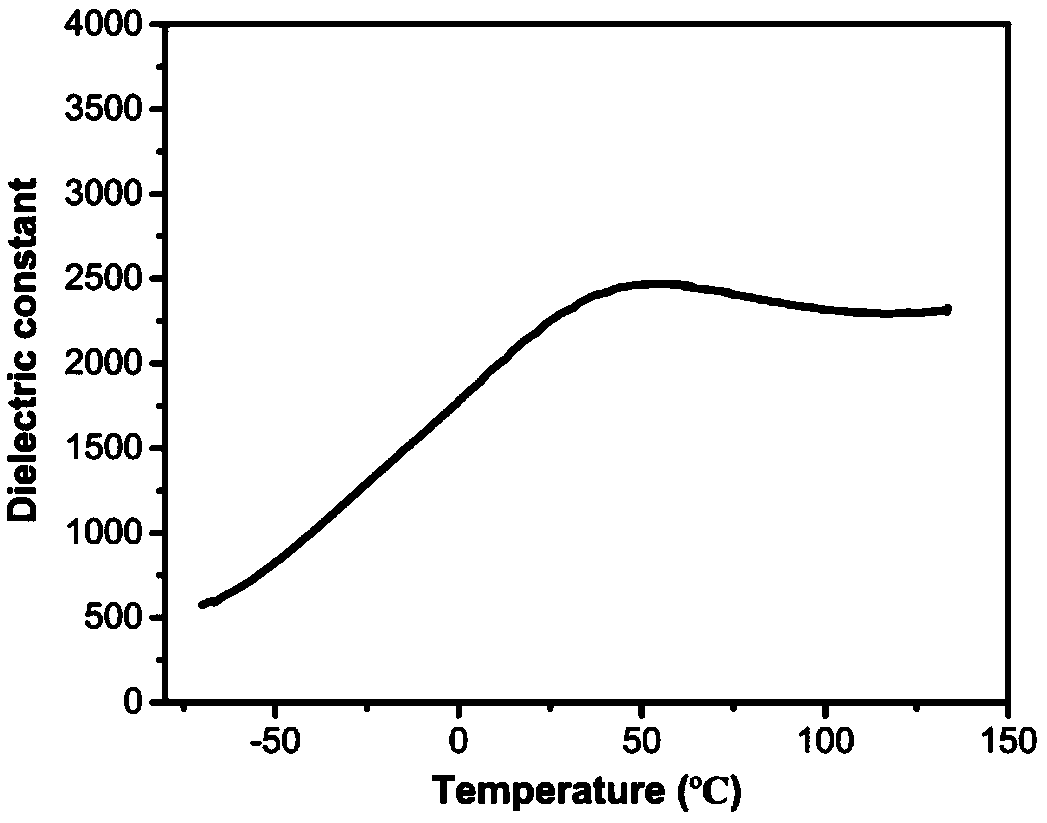

Lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and preparation method thereof

ActiveCN109608195ALower the holding temperatureHigh piezoelectric coefficientChemical compositionHigh pressure

The invention relates to a lead-free piezoelectric ceramic material with high piezoelectricity and high electrogenerated strain and a preparation method thereof. The chemical composition of the material accords with the chemical general formula (1-x)(K0.5Na0.5)0.98Ag0.02(Nb0.96Sb0.04) O3-x (Bi0.5Na0.5) ZrO3, wherein x represents the percentage of (Bi0.5Na0.5) ZrO3 in the potassium-sodium niobate-based lead-free piezoelectric ceramic, and x is more than or equal to 0.01 and less than or equal to 0.06. Compared with the prior art, the preparation method has the advantages of simplicity, good stability and low cost. The lead-free piezoelectric ceramic material obtained by the preparation method has excellent piezoelectric performance and electrogenerated strain, the d33 reaches 440 pC / N, thed33* reaches 553 pm / V, good temperature stability is shown, and the lead-free piezoelectric ceramic material can be used for piezoelectric sensors, piezoelectric motors and high-precision displacementcontrollers, the material has good application prospect.

Owner:TONGJI UNIV

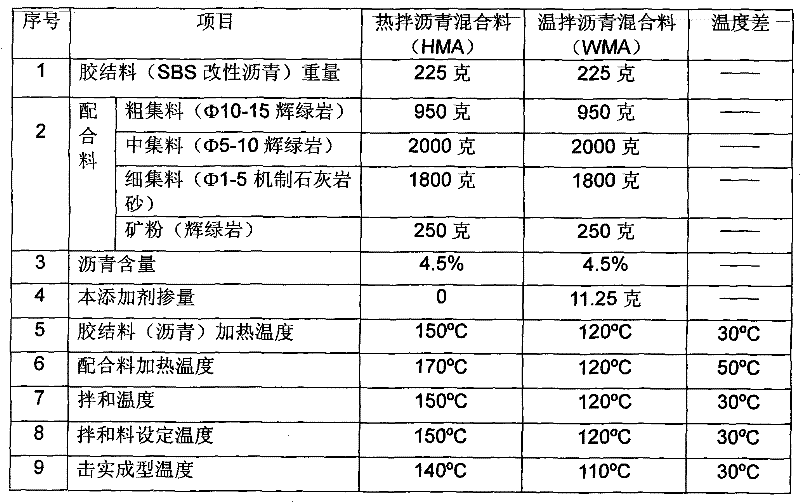

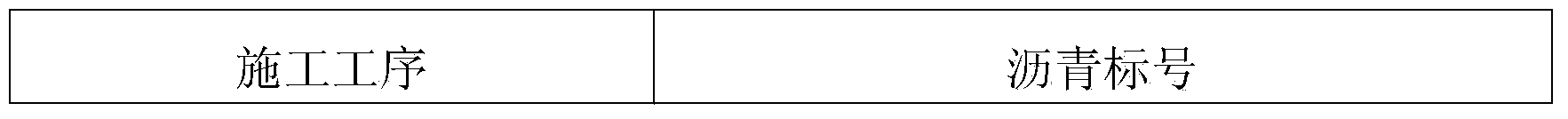

Construction method of warm mix asphalt concrete pavement of municipal road

InactiveCN103911930AImprove performanceEase of constructionIn situ pavingsClimate change adaptationWorking environmentRoad surface

The invention discloses a construction method of a warm mix asphalt concrete pavement of a municipal road. The construction method comprises the following steps: 1, reforming and adjusting the traditional mixing equipment; 2, determining the construction temperature of a warm mix mixture; 3, mixing the mixture; 4, transporting the warm mix mixture to the construction position; 5, paving the warm mix mixture; 6, compacting the paved warm mix asphalt mixture. Compared with the prior art, the construction method has the beneficial effects that the mixing cost and production consumption of the asphalt mixture are lowered, the ageing is alleviated, the pavement performance is improved, the emissions of harmful gas and dust are reduced, the environmental pollution is lowered, and the working environment quality of a worker is improved.

Owner:成张佳宁

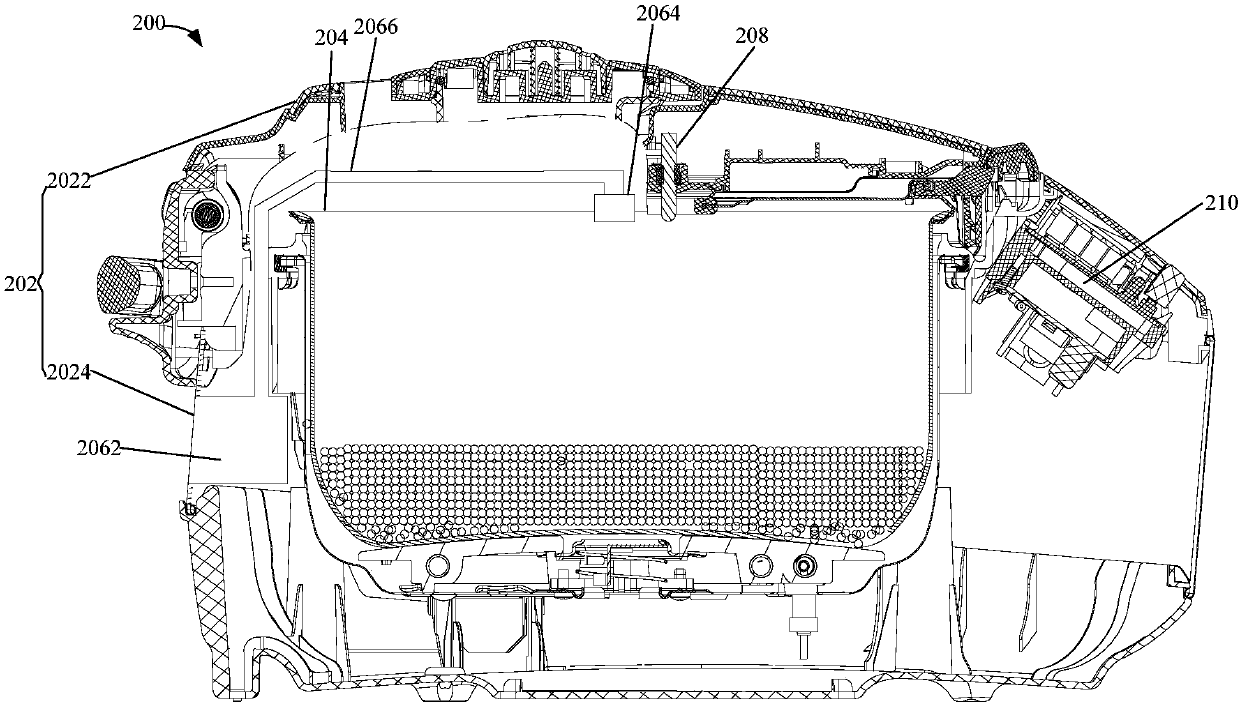

Control panel and control method of cooking utensil and cooking utensil

ActiveCN107865578AMeet the needs of useImprove user experiencePressure-cookersVessels with intergral heatingKey pressingEngineering

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

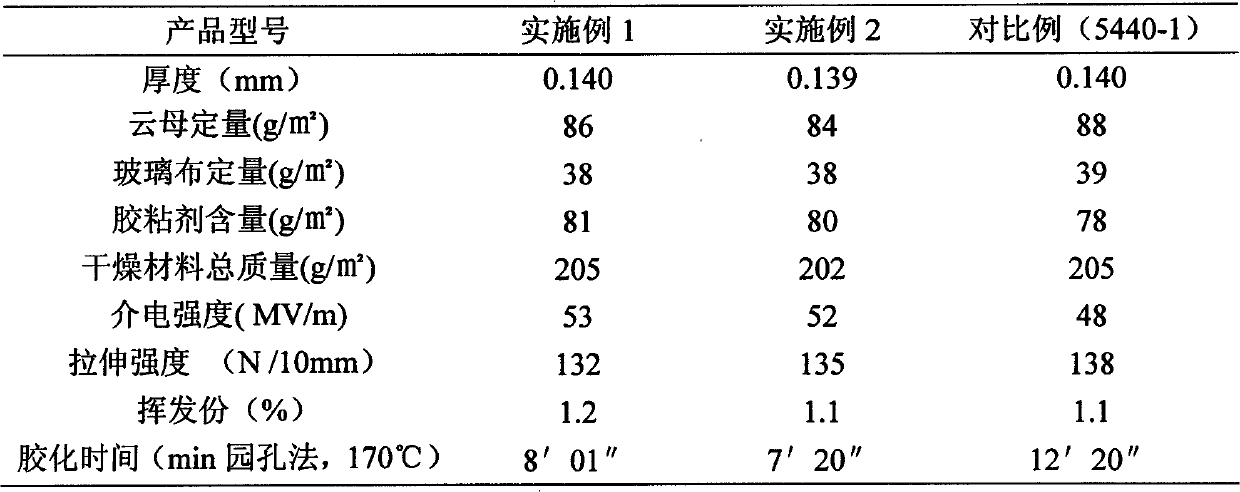

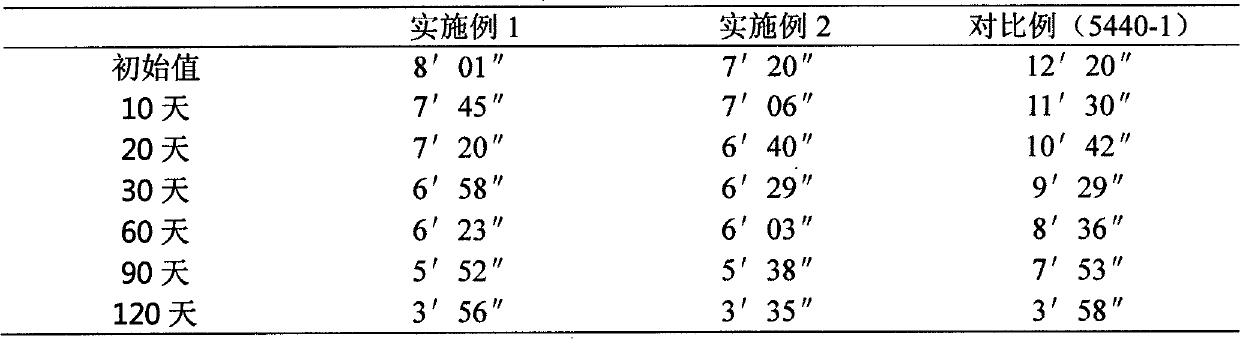

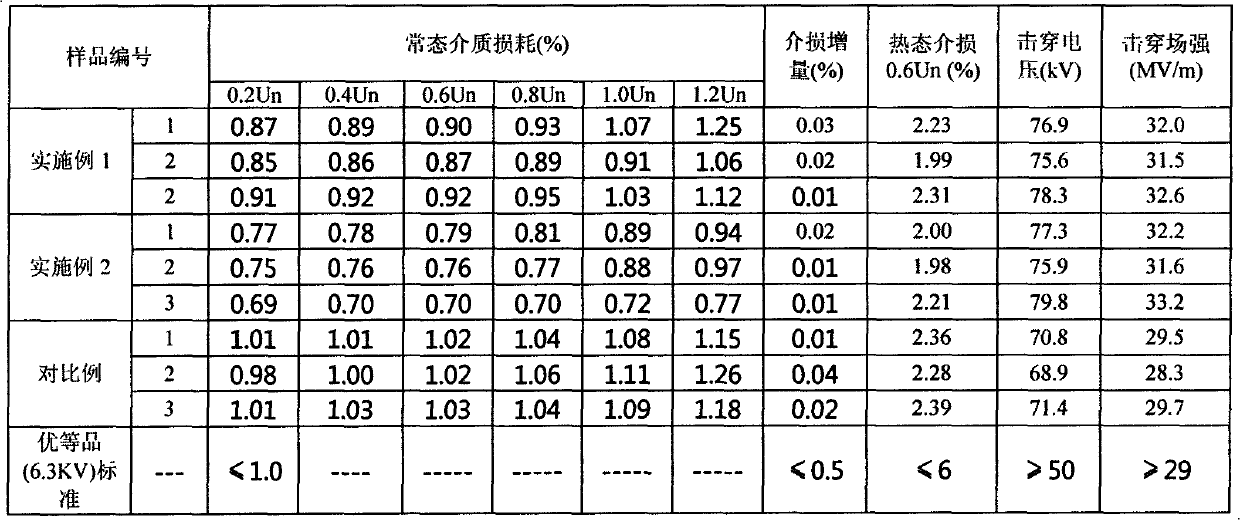

Resin-rich epoxy glass powder mica tape

ActiveCN102324268AImprove cured product performanceExcellent electrical performance indicatorsWindings insulation materialMicaMicaHolding time

A resin-rich epoxy glass powder mica tape consists of two layers of electrical alkali-free glass cloth, a mica layer and adhesive, wherein the mica layer is arranged between the two layers of electrical alkali-free glass cloth, and the adhesive is used for bonding the two layers of electrical alkali-free glass cloth and the mica layer together. The mica tape has the characteristics of decreasing the preserved molding temperature, shortening the molding temperature preservation time, greatly increasing the processing efficiency by 30 to 50 percent, shortening the motor production period, reducing energy consumption, and the like, and can better meet the requirement of the resin-rich molding production technique for large high-voltage motors and generators.

Owner:浙江荣泰电工器材股份有限公司

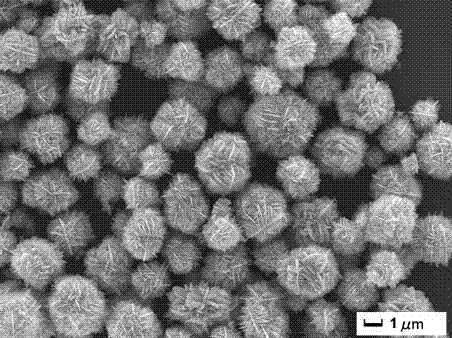

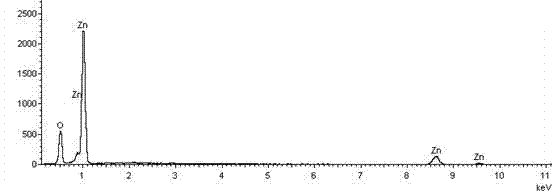

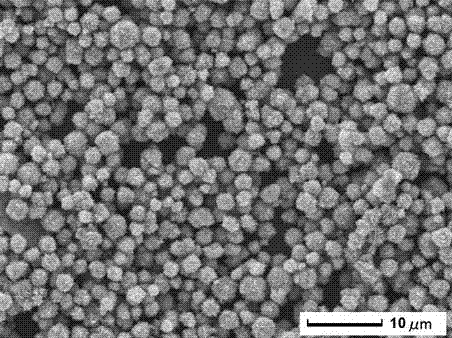

Method for preparing zinc oxide micron sphere

InactiveCN102249286AHigh yieldLower the holding temperatureZinc oxides/hydroxidesPhysical chemistrySemiconductor

Owner:JIANGSU UNIV

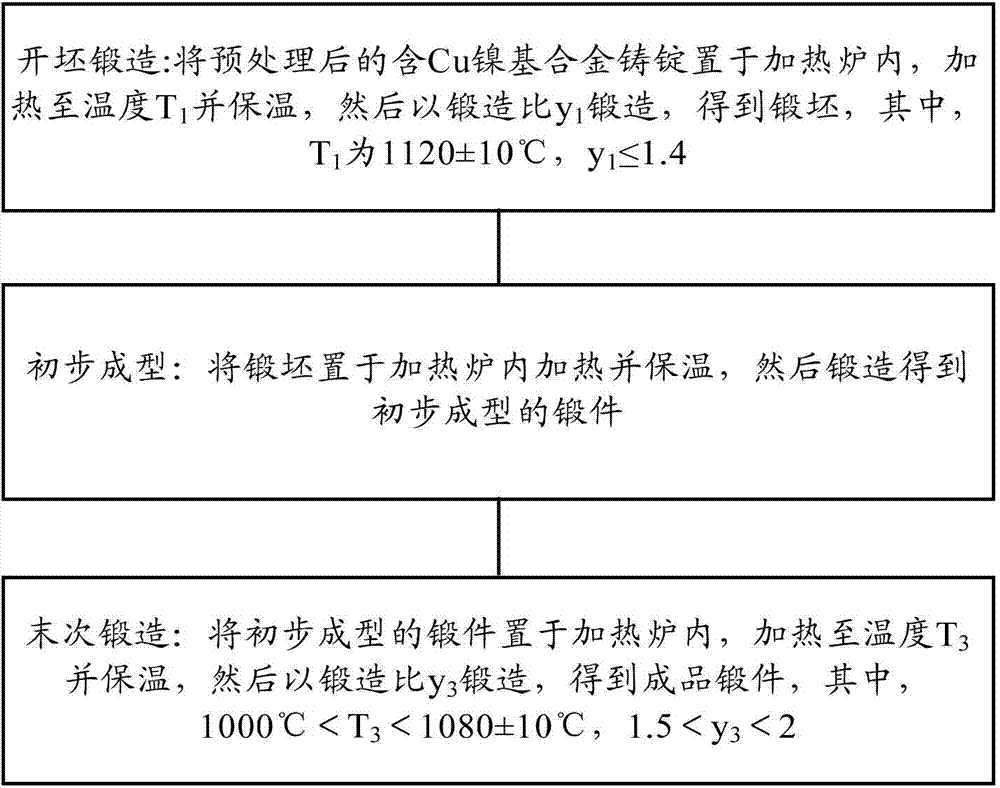

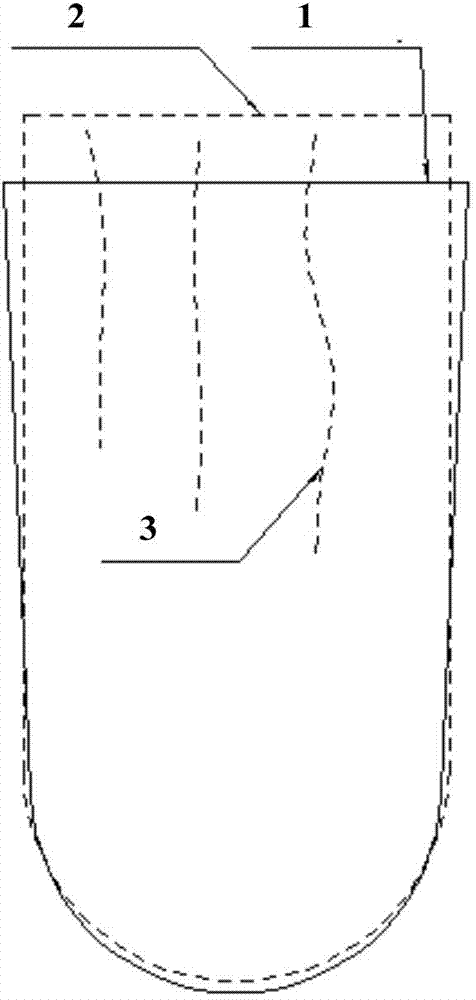

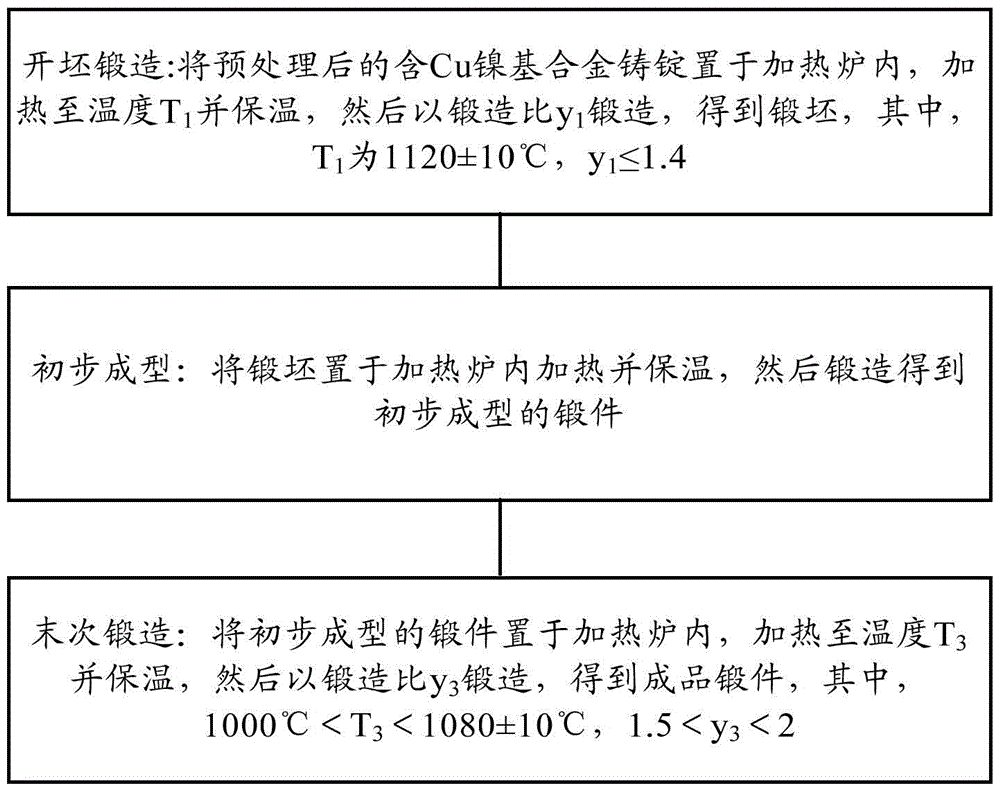

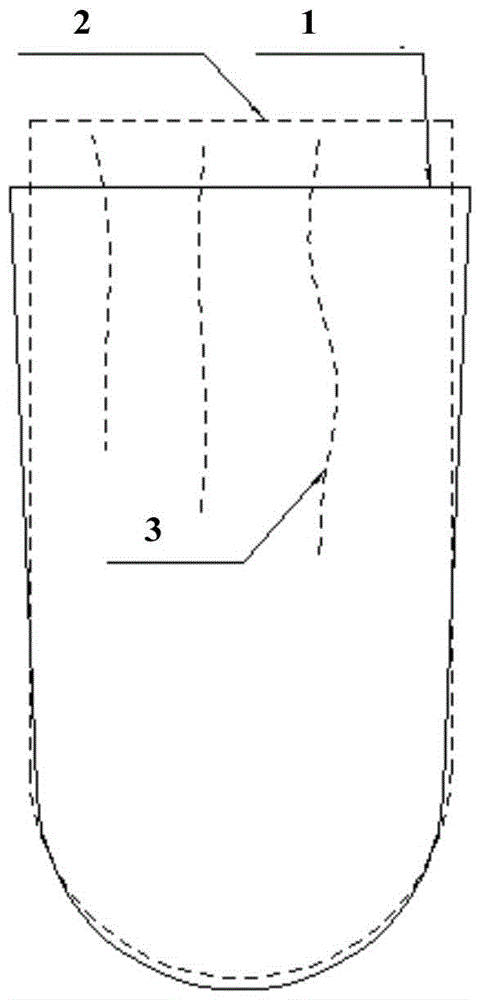

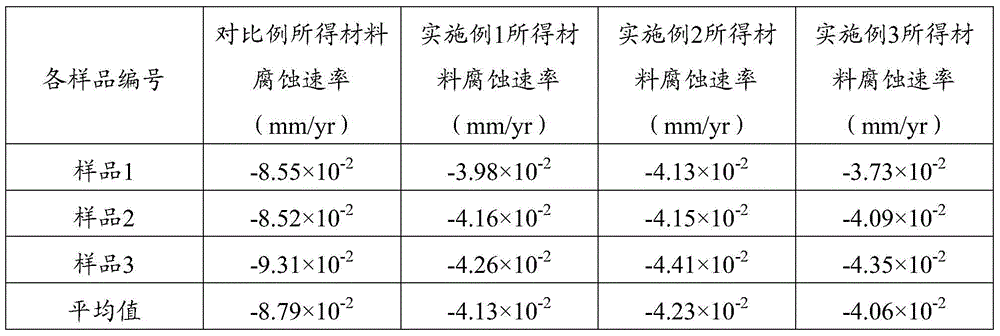

Forging method of nickel base alloy containing copper and nickel base alloy containing copper

ActiveCN104741494AImprove plasticityLower the holding temperatureMetal-working apparatusPre treatmentHeating furnace

The invention provides a forging method of nickel base alloy containing copper and the nickel base alloy containing copper and belongs to the technical field of forging technologies. The forging method overcomes the defects that because copper is added to the nickel base alloy, the hot working character is poor, and forge cracking is caused, and the yield can be effectively improved. The forging method comprises the steps of conducting billet forging, wherein preprocessed nickel base alloy ingots containing copper are placed in a heating furnace, the nickel base alloy ingots containing copper are heated to the temperature T1, the temperature T1 is kept, forging is conducted according to the forging ratio y1, so that forging stocks are obtained, the temperature T1 is 1120+ / -10 DEG C, and y1 is smaller than or equal to 1.4; conducting initial forming, wherein the forging stocks are arranged in the heating furnace to be heated, the temperature is kept, and forged pieces which are initially formed are obtained through forging; conducting final forging, wherein the initially formed forged pieces are arranged in the heating furnace to be heated to the temperature T3, the temperature T3 is kept, forging is conducted according to the forging ratio y3, so that finished forged pieces are obtained, the temperature T3 is higher than 1000 DEG C and lower than 1080+ / -10 DEG C, and y3 is larger than 1.5 and smaller than 2. The forging method can be used for forging of the nickel base alloy containing copper.

Owner:ENN ENVIROTECH CO LTD

Preparation method of Cu-Cr-Zr wear-resistant alloy wire

ActiveCN112845652ASmall sizeIncrease nucleation rateFurnace typesHeat treatment furnacesRefining (metallurgy)Ingot

The invention discloses a preparation method of a Cu-Cr-Zr wear-resistant alloy wire. The method comprises the following steps: S1, powder metallurgy: firstly, preparing a Cu-Cr alloy or Cr-Zr alloy or Cu-Cr-Zr alloy or a combined alloy thereof into powder with the diameter of 50-300 [mu]m, then, carrying out dry pressing or sintering on the powder to prepare a block material, and finally, crushing the block material into particles with the size of 1-10 mm for later use; and S2, smelting: firstly, smelting 50-90% of cast ingot raw materials into an alloy solution under a vacuum condition at the smelting temperature of 1,200to 1,370 DEG C, keeping the vacuum degree at 10<-2> to 10<-5>MPa, keeping the temperature at 1,200 to 1,300 DEG C after complete smelting, and refining to remove impurities and gas. According to the process, the wear-resistant alloy wire with higher tensile strength, better wear resistance, better corrosion resistance and higher conductivity can be prepared, it can be seen from the microscopic structure of the product that the second phase is distributed in a dispersed mode, and the wear resistance and the mechanical property of the material are well improved.

Owner:SUQIAN COLLEGE

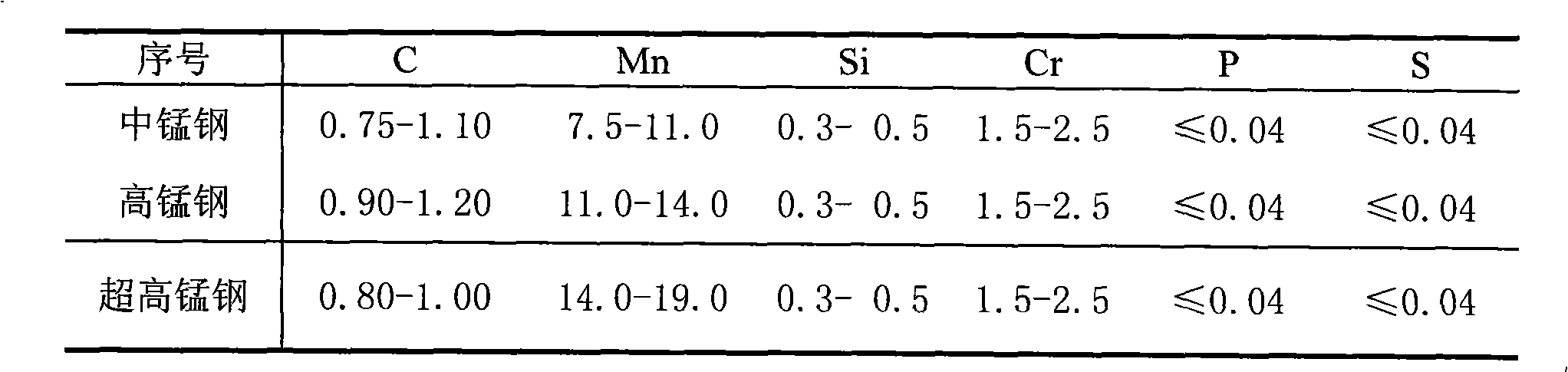

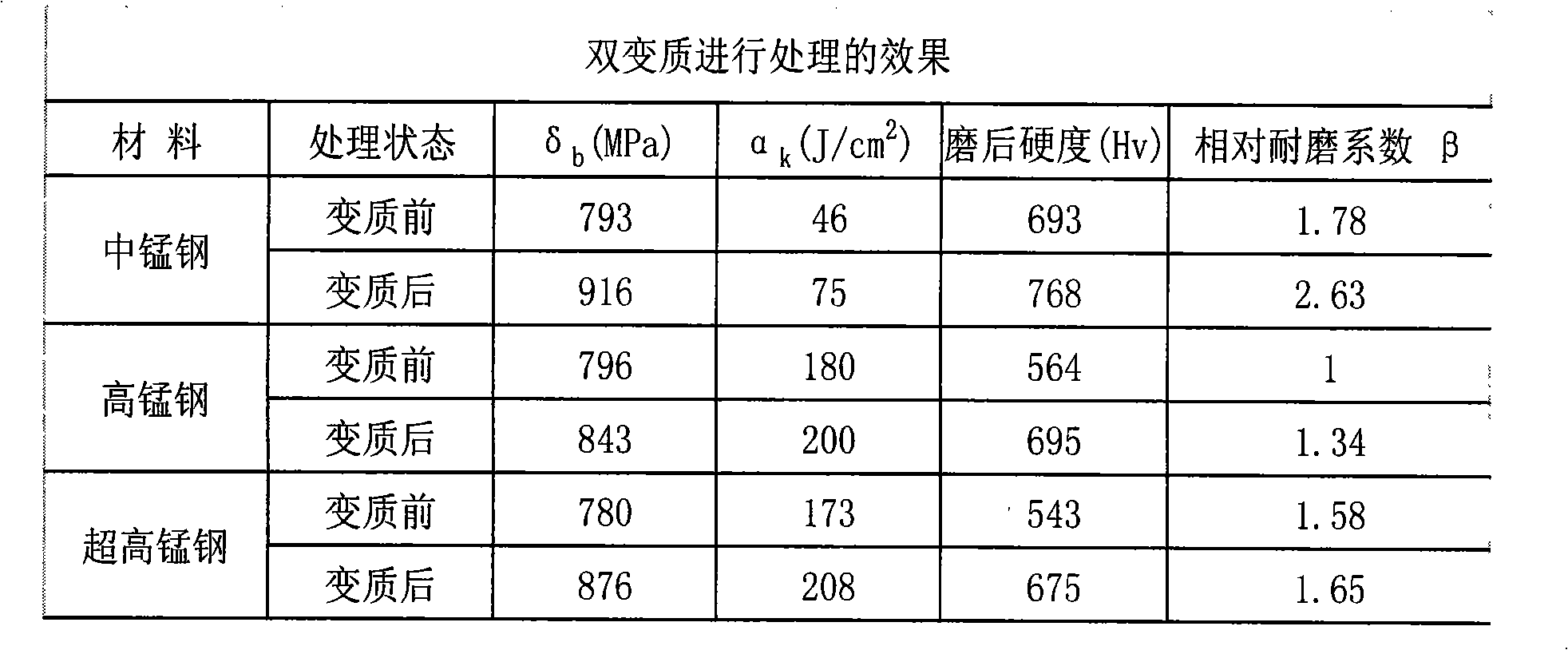

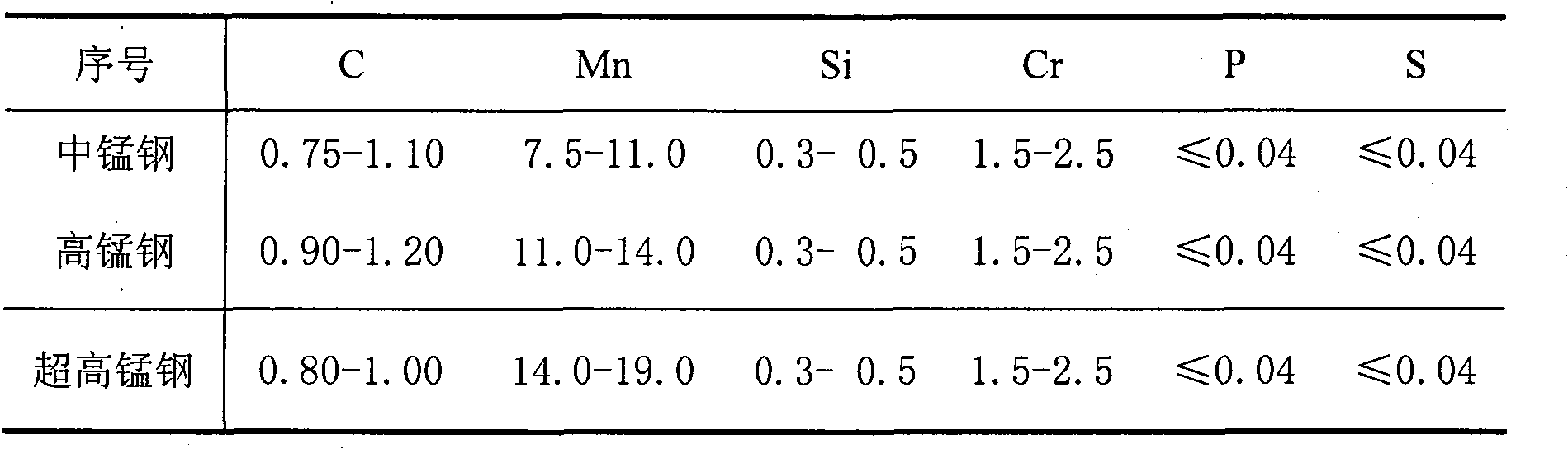

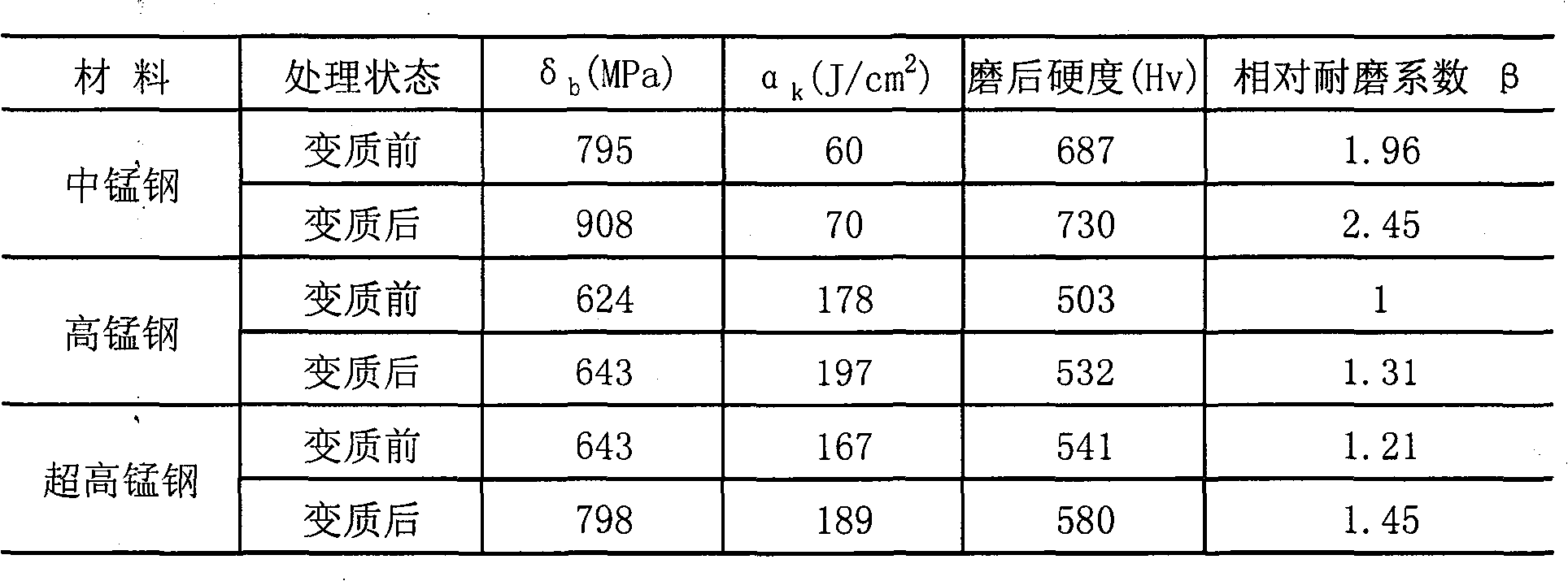

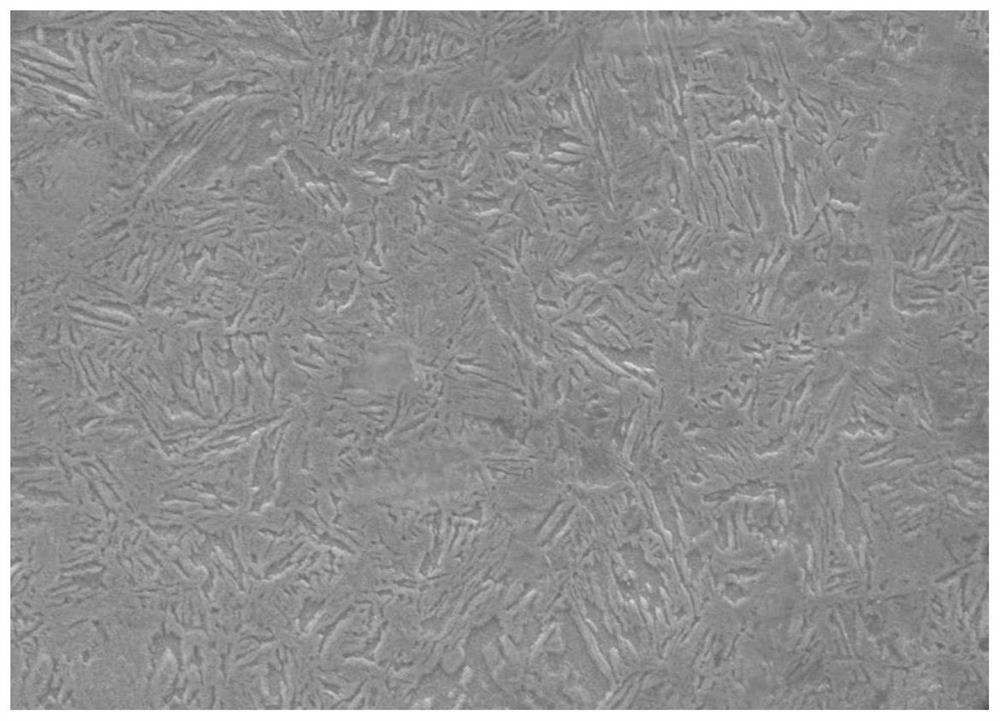

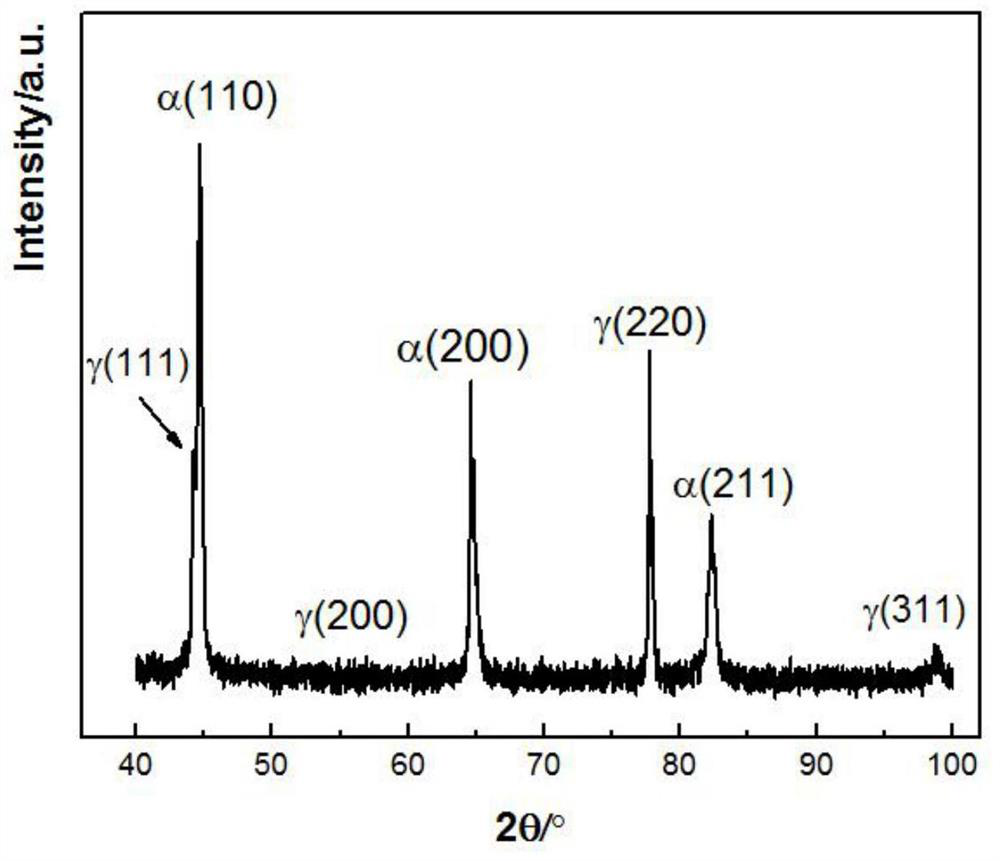

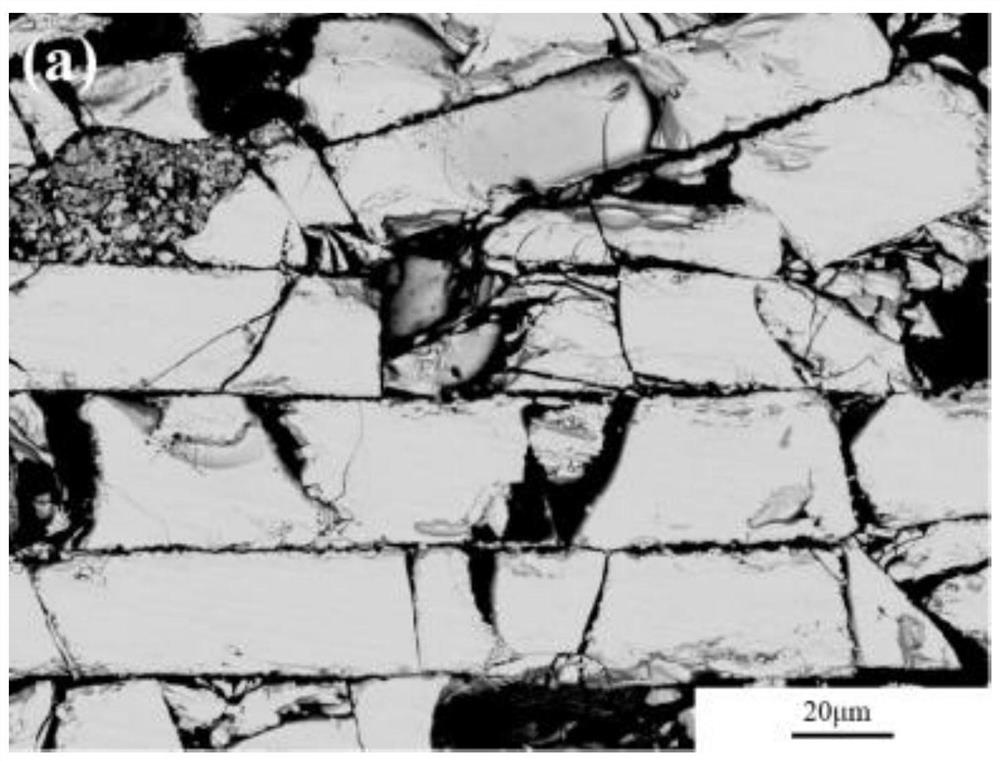

Double- modification method for advanced austenitic manganese steel

The invention discloses an advanced double-modification method for austenitic manganese steel. The method comprises the following steps that: after ferromanganese is added to molten steel for the fine adjustment of manganese content, Re-containing rare earth alloy accounting for 0.067-0.081 percent of the weight of the molten steel and vanadium slag accounting for 2.0-2.5 percent of the weight of the molten steel are orderly added to a molten pool; aluminum accounting for 0.15-0.20 percent of the weight of the molten steel is added in before the tapping of the molten steel; calcium silicon accounting for 0.04-0.06 percent of the weight of the molten steel, Re-containing rare earth alloy accounting for 0.133-0.169 percent of the weight of the molten steel, ferrotitanium accounting for 0.02-0.03 percent of the weight of the molten steel, as well as zinc accounting for 0.006-0.008 percent of the weight of the molten steel are added to a steel ladle outside a furnace. The comprehensive mechanical property and wear resistance of austenitic manganese steel are improved through double modification.

Owner:铜陵市大明玛钢有限责任公司

Volatile insulation box for cooling and insulation of cold fresh product

InactiveCN105947415AIncrease manufacturing costLong holding timeDomestic cooling apparatusLighting and heating apparatusEngineeringNatural environment

The invention provides a volatile insulation box for cooling and insulation of a cold fresh product. The volatile insulation box comprises a box body and a box cover, wherein the box body and the box cover can be formed only by water-absorbing and water-volatilizing foam for one-time use, or by combining a vacuum box body and a vacuum box cover for repeat use; the vacuum box body comprises a box body vacuum inner container and a layer of water-absorbing and water-volatilizing foam coating the box body vacuum inner container; and the vacuum box cover comprises a box cover vacuum inner container and a layer of water-absorbing and water-volatilizing foam coating the cover vacuum inner container. Before use, the volatile insulation box is immersed in cold water, and thus a proper amount of water is absorbed by the foam; after the volatile insulation box is filled with the cold fresh product, the box cover is closed; the water absorbed in the foam can be volatilized in a natural environment; in the water volatilizing process, heat of the foam is absorbed, the temperature of the foam is lowered, and then the volatile insulation box is cooled; if the water is volatilized thoroughly, the cooling function of the foam is converted into the insulation function; and as the effects of cooling, insulation and prolonging of an insulation period are achieved, the volatile insulation box can be widely used.

Owner:徐一凡

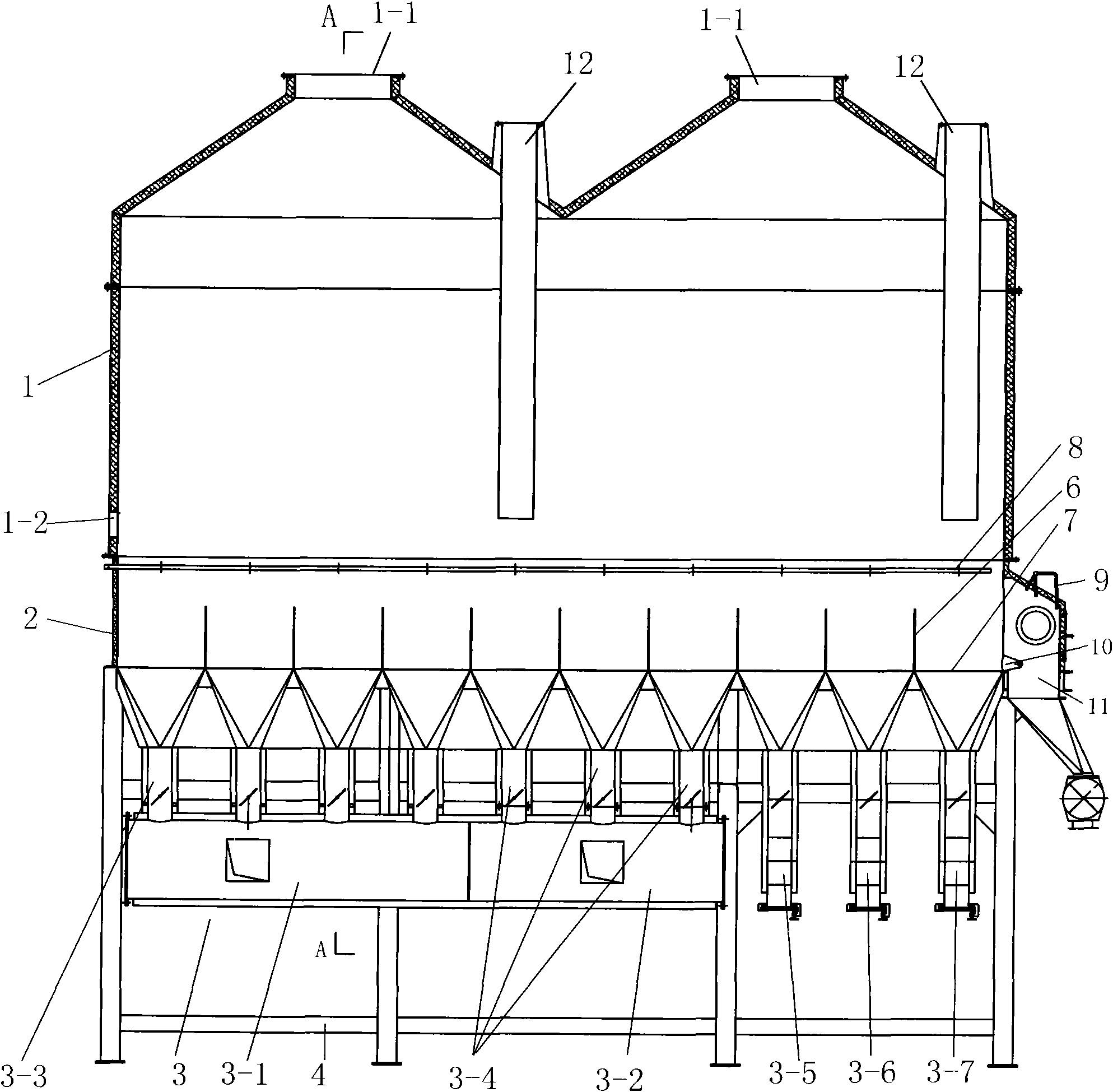

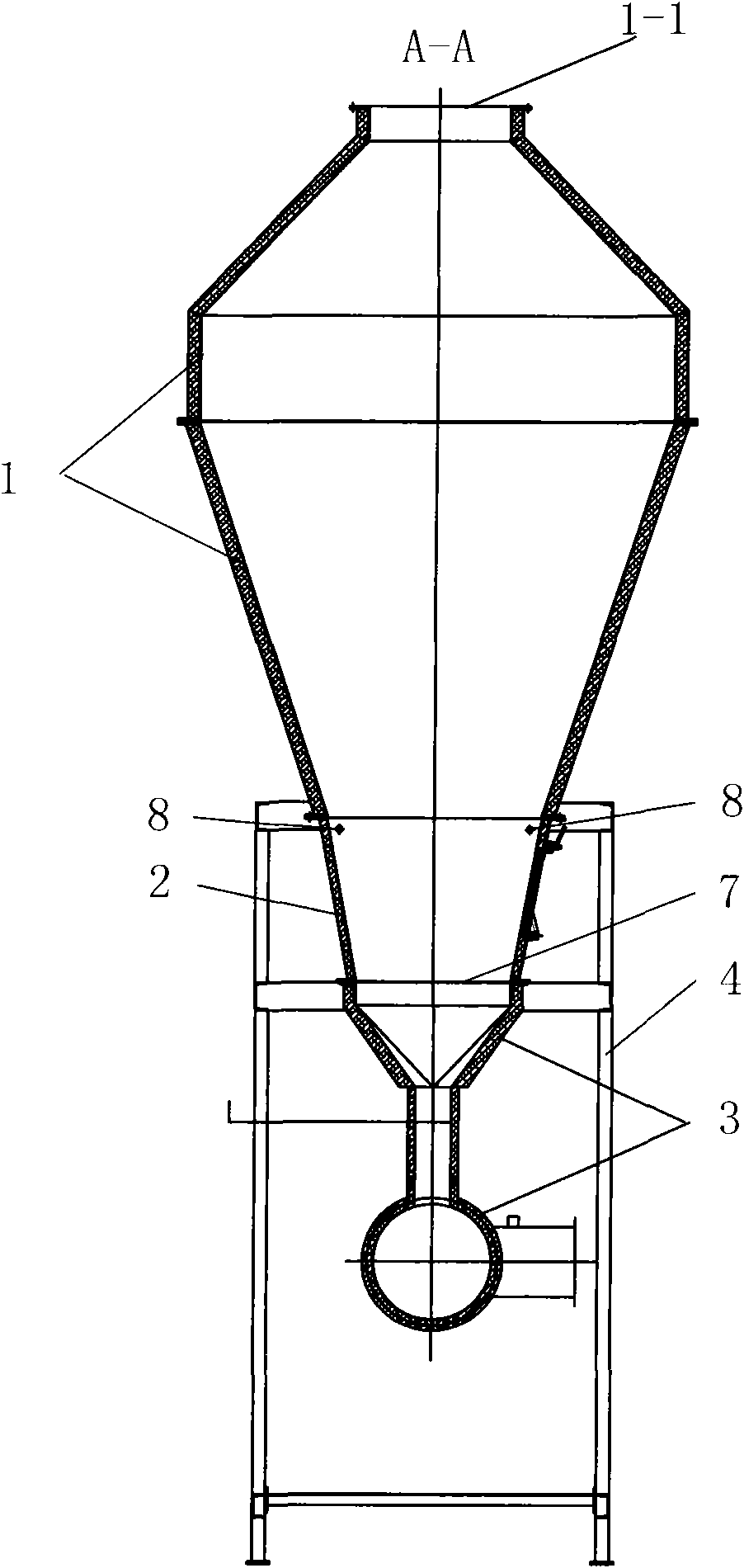

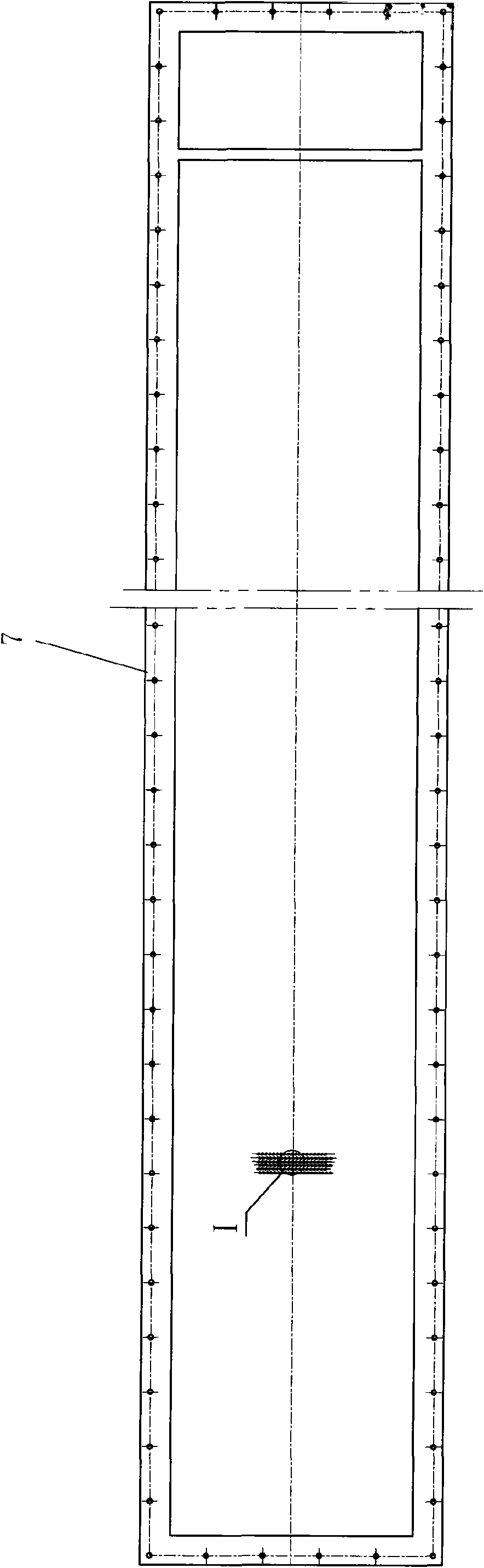

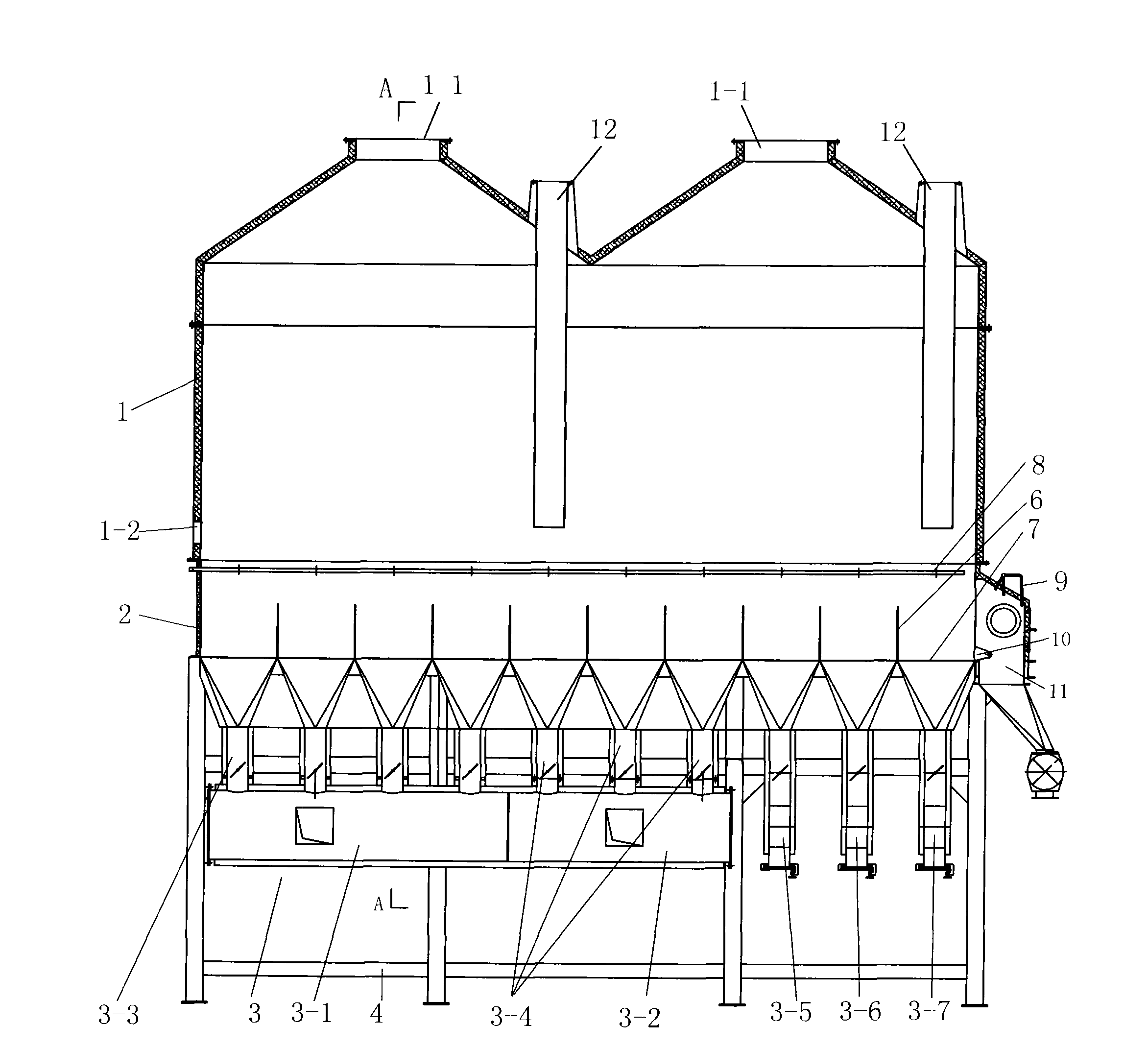

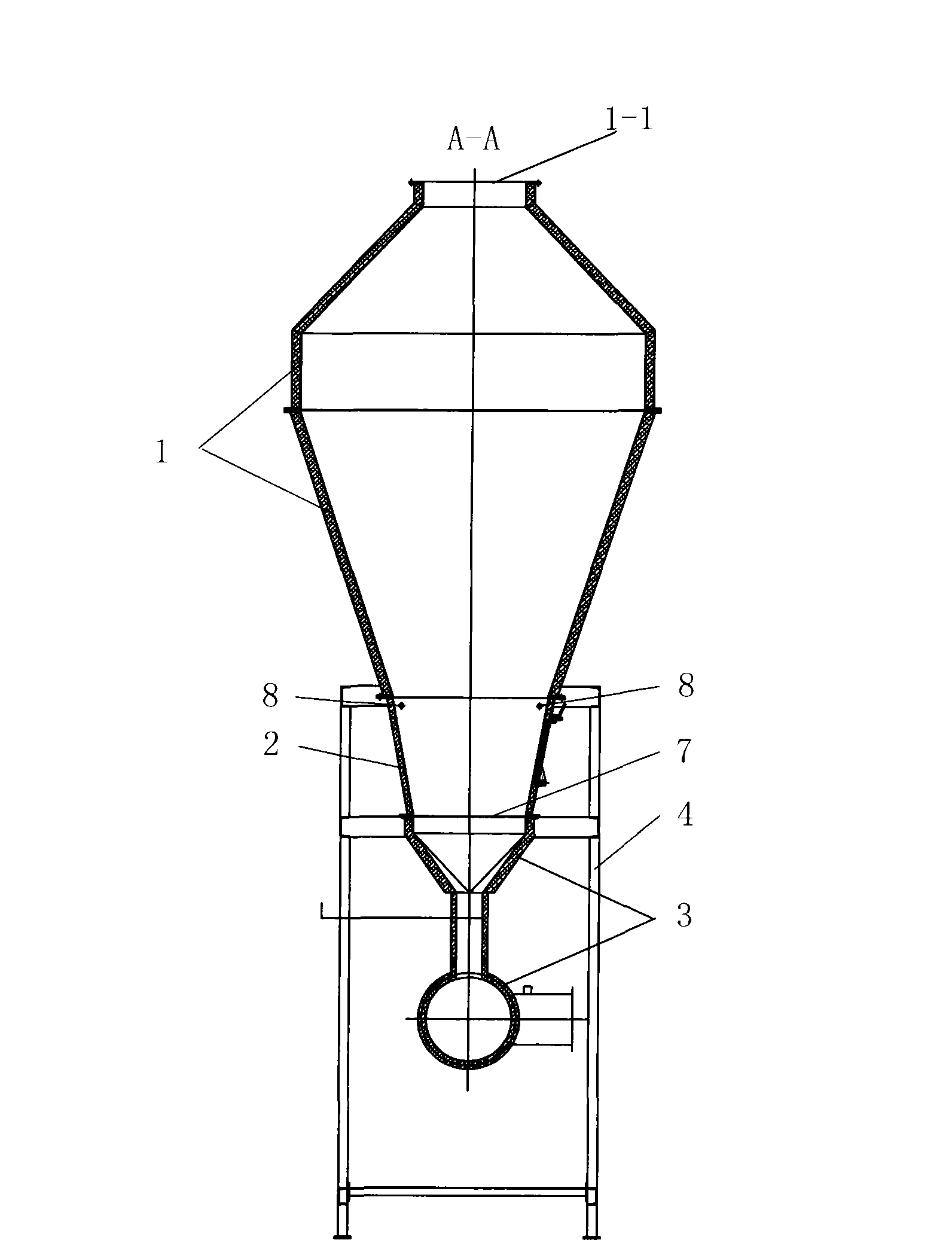

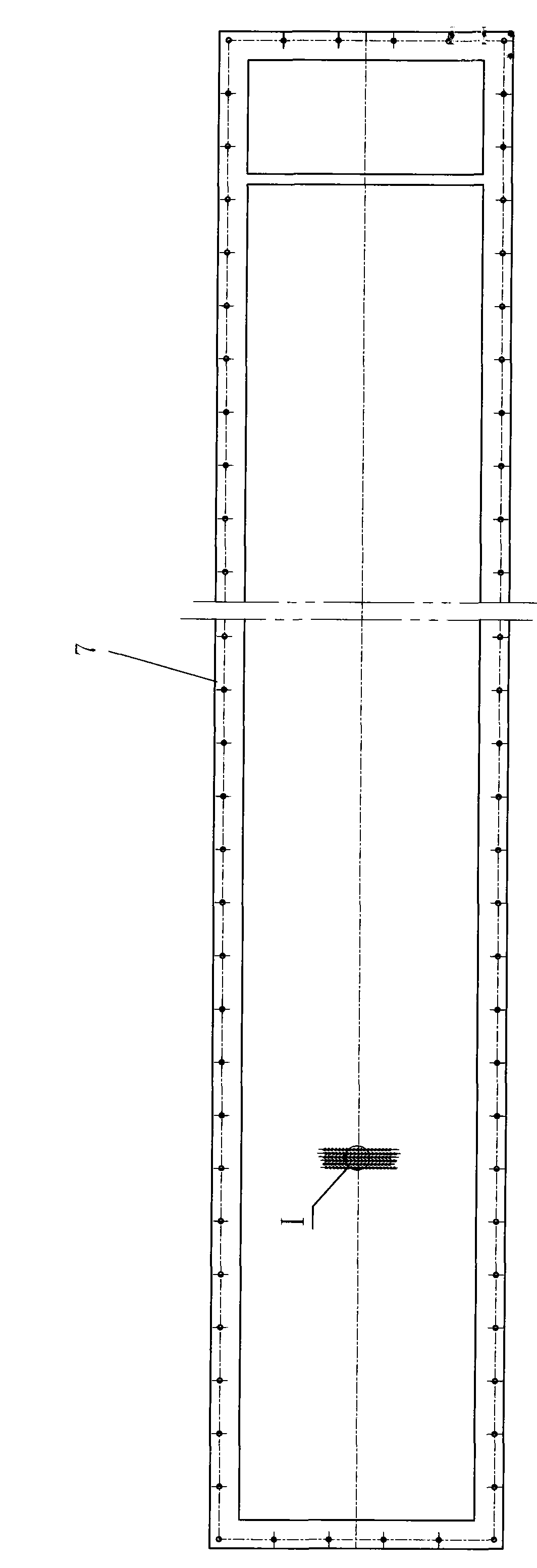

Boiling fluidization drying apparatus

InactiveCN101566422AIncrease or extend drying dwell timeAvoid meltingDrying solid materials with heatDrying gas arrangementsEngineeringFine powder

A boiling fluidization drying apparatus comprises an upper bed body, a middle bed body and a frame. An air outlet is arranged on the top face of the upper bed body. A feed port and a discharge chamber are respectively arranged at the front face and the back face at the lower portion of the upper bed body. A fine powder reflux pipe inserted from the top face is arranged in the upper bed body. The middle bed body is divided into a plurality of drying chambers along the front-and-back direction by a baffle plate. An opening is arranged at the lower portion of the baffle plate. An air duct is formed. A hole plate is arranged at the connection of the middle bed body and the lower bed body. The lower bed body is a wind division apparatus. The wind holes on the hole plate are fishscale holes and arranged in a row orderly. The direction of the air outlets of the wind hole in the same row is consistent. The hole rows are arranged at intervals at the back left portion and the back right portion of the air outlet. An included angle exists between the projection of the air outlet of the wind hole on the hole plate and the central line of the hole plates at the front-and-back direction. The invention has good drying effect and is especially suitable for drying the thermal sensitivity materials.

Owner:陆文光

A method of cooking and pulping Dalong bamboo pre-impregnated with propylene glycol organic solvent

ActiveCN105155323BReduce the maximum holding temperatureEasy to removePulping with organic solventsNon-woody plant/crop pulpLiquid wasteDistillation

Belonging to the technical field of pulping, the invention relates to a method of cooking pulping by preimpregnation of dendrocalamus giganteus in a propylene glycol organic solvent. The method includes: firstly splitting dendrocalamus giganteus into bamboo segments that are 2cm-3cm long and have a width of less than 3cm to serve as the pulping raw materials; adding the pulping raw materials into a propylene glycol analytically pure reagent to conduct preimpregnation, and then performing separation to obtain an impregnated material; adding a pulping agent into the impregnated material, then putting the mixture into a chain oil bath cooking pan, and separating the slurry and the waste liquid at the end of cooking; washing the separated slurry and then subjecting the slurry to screening in a pulp screener to obtain clean dendrocalamus giganteus paper pulp; adding cold water into the waste liquid to carry out dilution standing and centrifugal separation, performing microfiltration with a microfiltration membrane, conducting ultrafiltration with an ultrafiltration membrane, implementing reduced pressure distillation to remove water, and then using the obtained solution to replace the propylene glycol analytically pure reagent to serve as the preimpregnation reagent. The paper pulp prepared by the method has the advantages of high yield, high viscosity, high whiteness and good strength.

Owner:KUNMING UNIV OF SCI & TECH

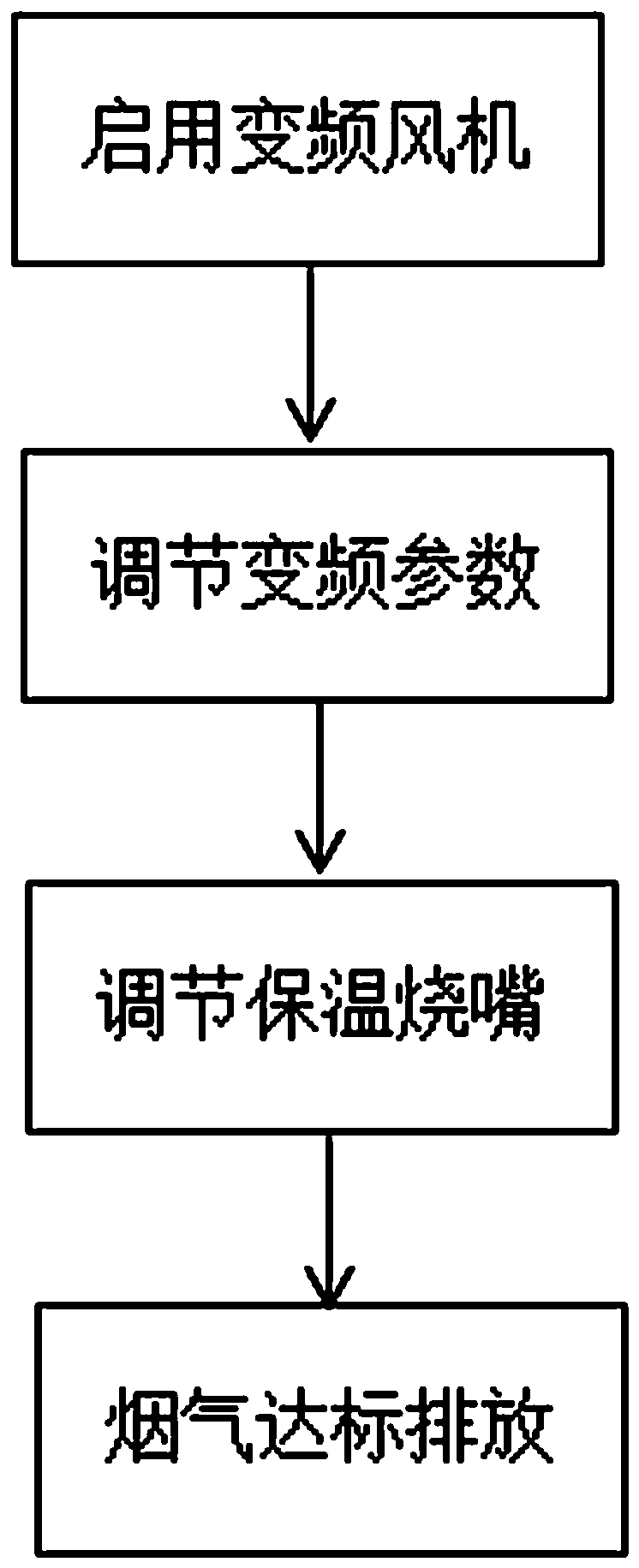

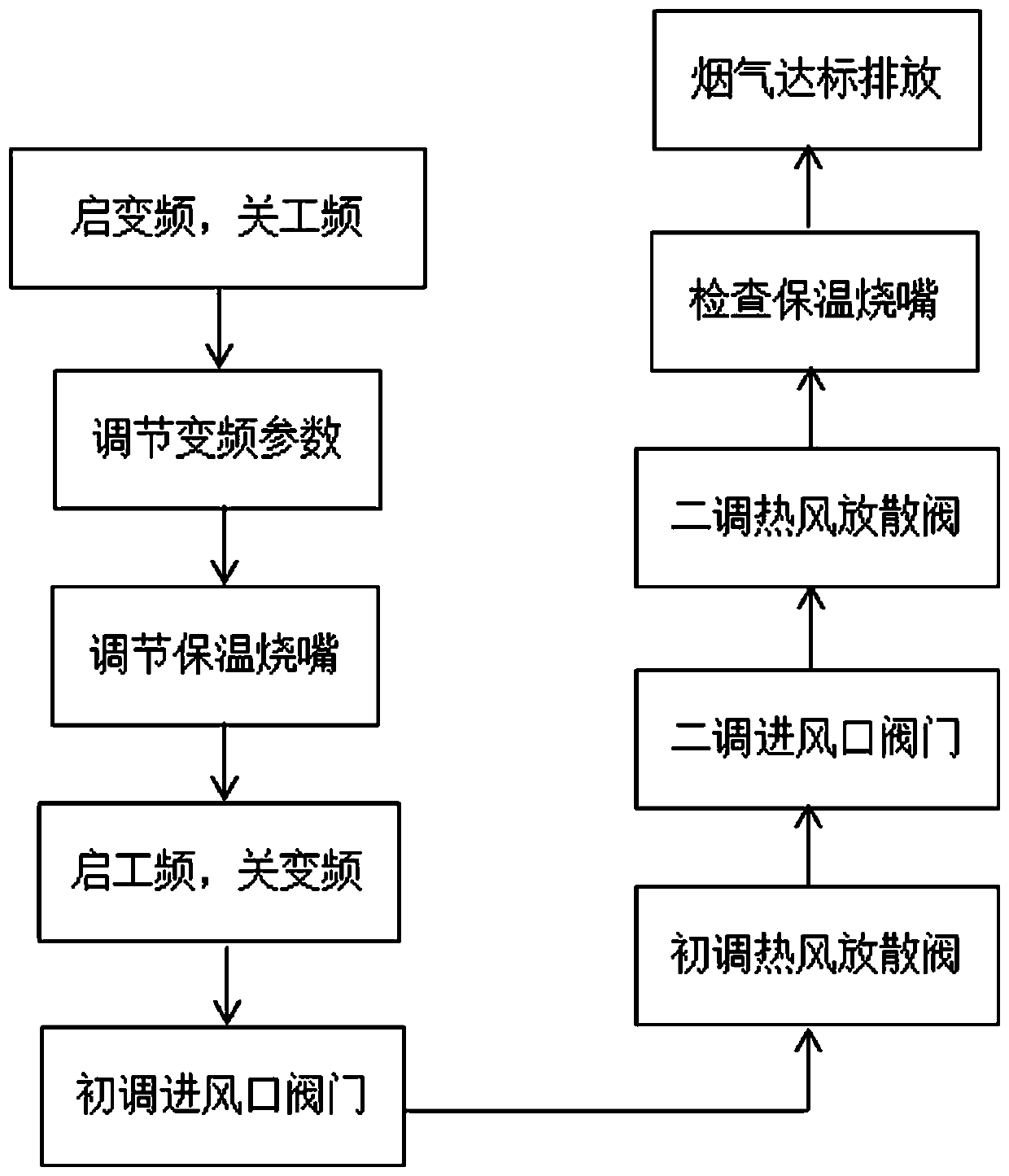

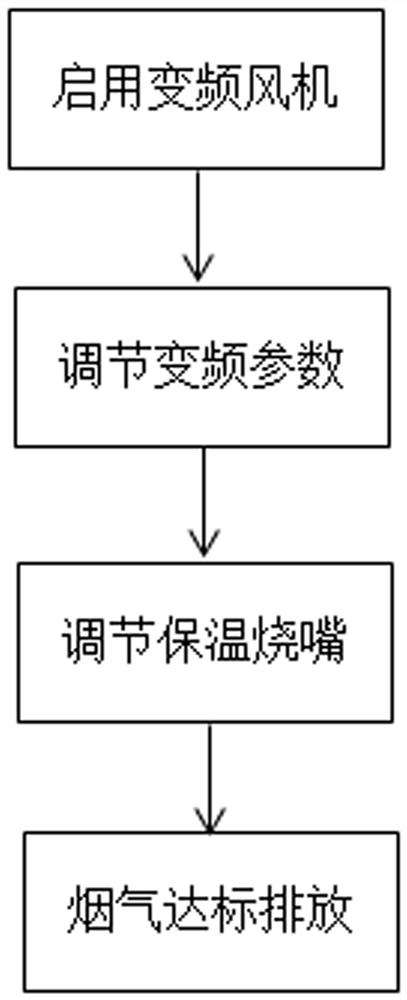

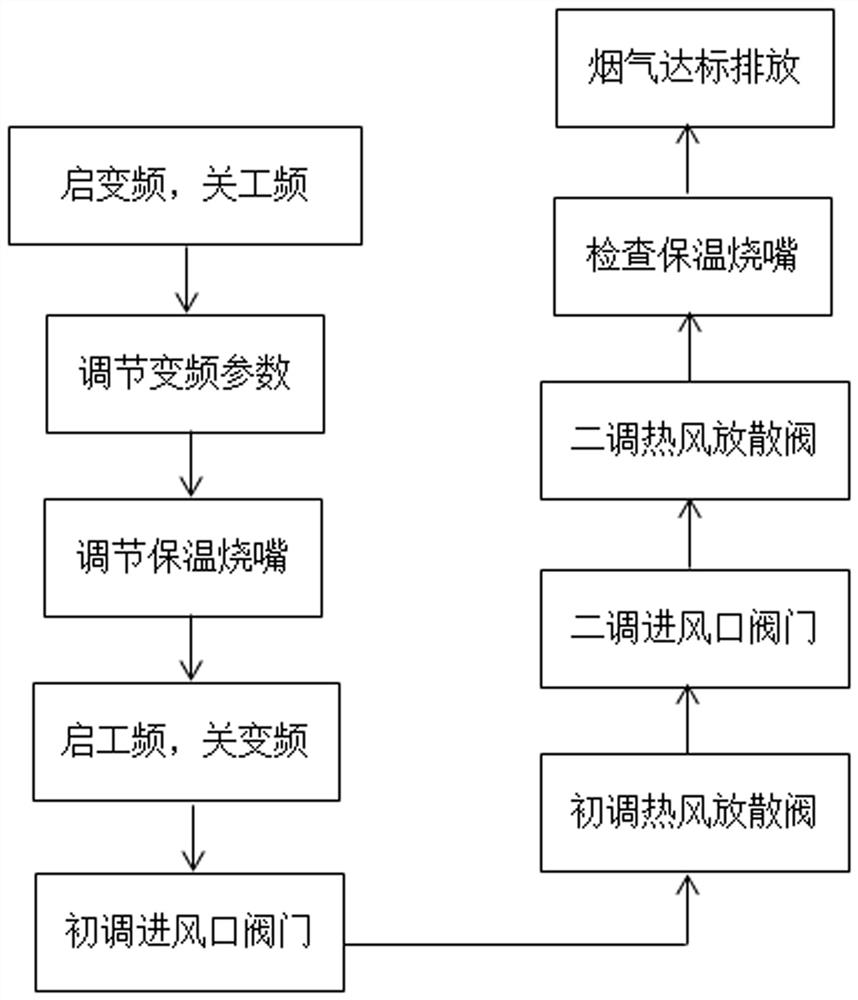

Method for ultralow dust emission of heating furnace in low-temperature heat preservation state

ActiveCN111521029AAchieve ultra-low emissionsLower the holding temperatureControl devices for furnacesWaste heat treatmentThermodynamicsCombustion

The invention relates to a method for ultralow dust emission of a heating furnace in a low-temperature heat preservation state. The method comprises the following specific steps of additionally arranging a variable-frequency fan on the heating furnace, and starting the variable-frequency fan in the low-temperature heat preservation state; adjusting the frequency of the fan to be below 33 Hz, and reducing the rotating speed of the fan to 950 rpm; reducing the jet velocity of a burner by over 20 percent, and enabling the burner to be in an oxygen-deficient combustion state; and after the parameters are adjusted, reducing the dust concentration by 0.5-1 mg / Nm<3>, reducing the oxygen content in flue gas to be below 19 percent, and performing flue gas emission of the heating furnace in the low-temperature heat preservation state. The method for the ultralow dust emission of the heating furnace in the low-temperature heat preservation state has the advantages that the method is convenient tooperate and control, the ultralow dust emission of the heating furnace in the low-temperature heat preservation state is realized, the heat preservation temperature of the heating furnace is reduced,and the method is environmental-friendly and energy-saving.

Owner:NANJING IRON & STEEL CO LTD

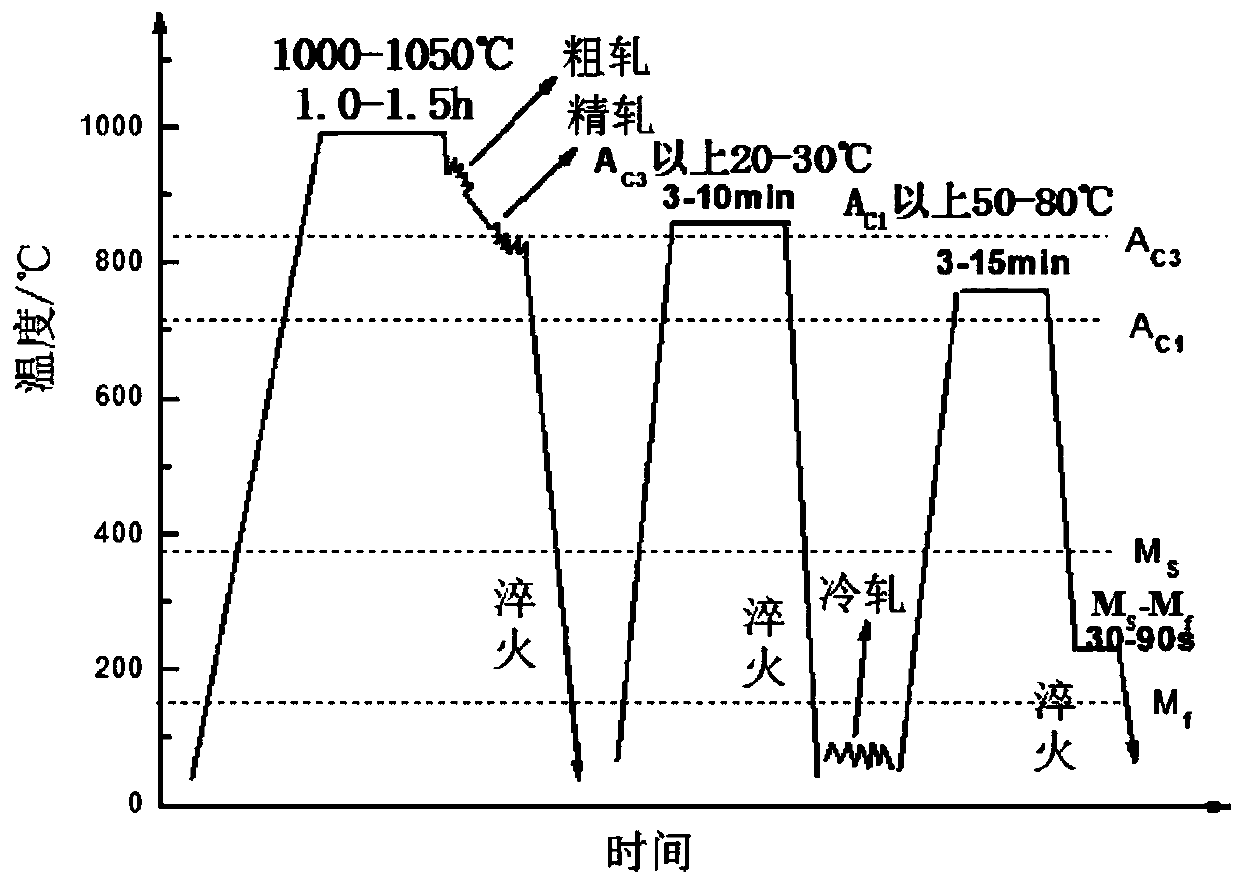

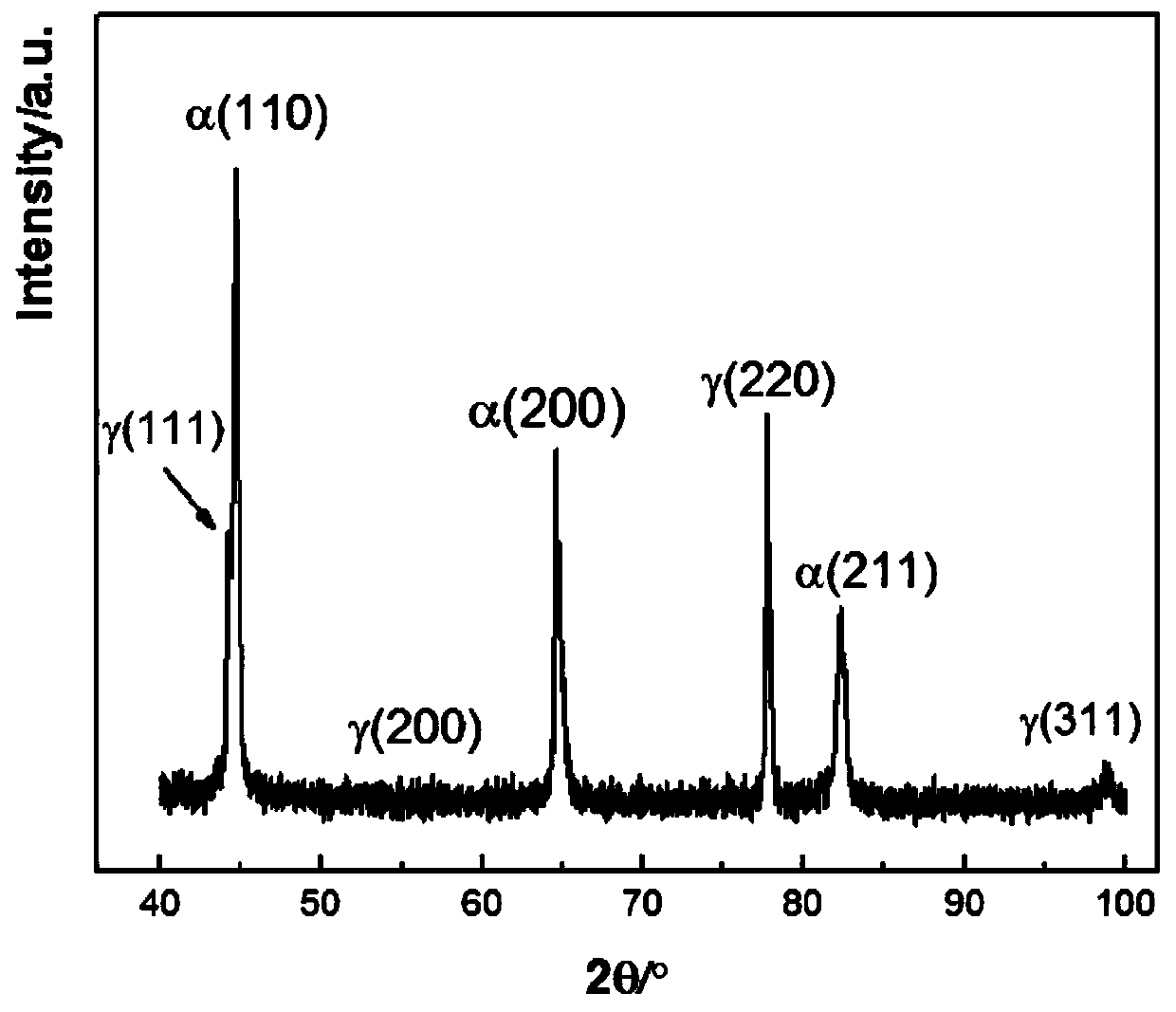

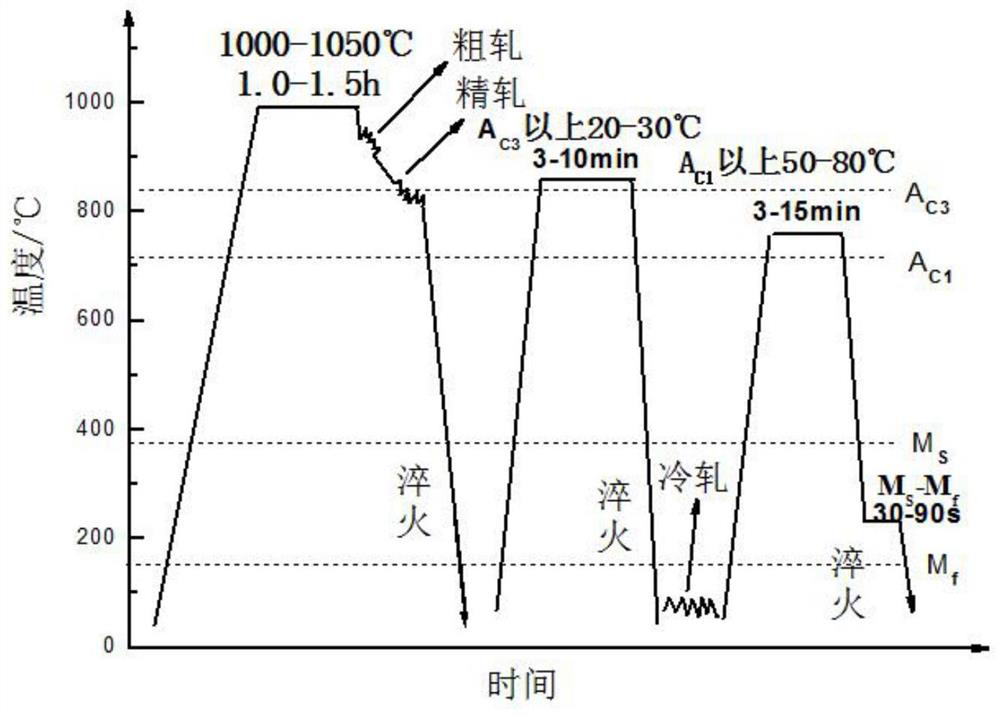

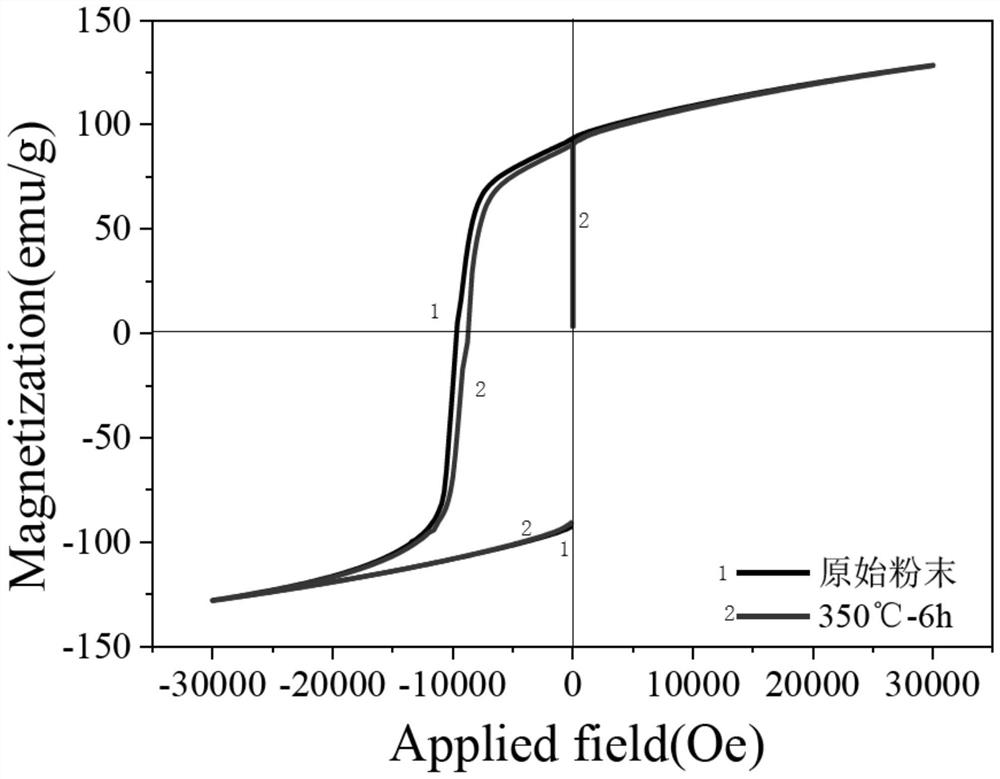

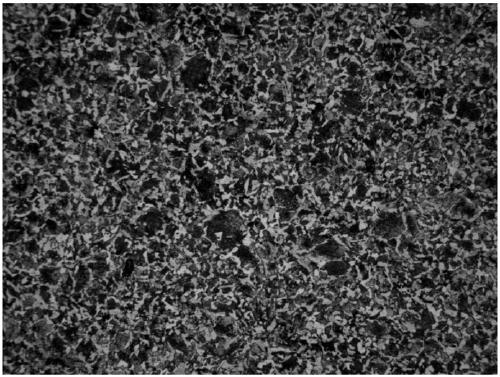

Preparation method of 1300MPa-grade rare earth reverse transformation Q & P steel

The invention discloses a preparation method of 1300MPa-grade rare earth reverse transformation Q & P steel. The steel comprises the following chemical components in percentage by mass: 0.12%-0.18% ofC, 2.0%-3.0% of Mn, 0.8%-1.2% of Si, 0.6%-1.0% of Al, 0.05%-0.08% of V, 0.001%-0.003% of B, 0.02% or below of P, 0.01% or below of S and the balance of Fe and inevitable impurities. According to thecomponent design, a certain amount of mixed rare earth iron alloy is added, smelting is conducted to obtain a casting blank. A reverse transformation process is combined with a Q & P process, so thatthe austenite stability is improved. The Si content is low, so that the surface quality and the hot rolling performance are guaranteed. The hardenability is improved through the Al and the B, a certain amount of the V is added, a dispersedly-distributed second phase is introduced, and the work hardening capacity of ferrite is enhanced through matching of the V and the Si. By adding the proper amount of the rare earth, the modification effect is achieved, grains are refined, and the comprehensive mechanical property of the steel plate is improved. According to the steel plate produced by the method, the microstructure is martensite, ferrite, retained austenite and the dispersedly-distributed second phase, the tensile strength is larger than 1300 MPa, the percentage elongation after fractureis larger than 15%, and the steel plate has good strength and plasticity matching.

Owner:SHANDONG JIANZHU UNIV

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144BLow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

Owner:CCCC FIRST HIGHWAY CONSULTANTS

A method for ultra-low dust emission of heating furnace under low temperature and heat preservation state

ActiveCN111521029BAchieve ultra-low emissionsLower the holding temperatureControl devices for furnacesWaste heat treatmentThermodynamicsCombustion

The invention relates to a method for ultra-low dust emission of a heating furnace in a low temperature heat preservation state. The specific steps include adding a variable frequency fan on the heating furnace, and turning on the variable frequency fan in a low temperature heat preservation state; adjusting the frequency of the fan to below 33 Hz, The fan speed is reduced to 950rpm; the injection speed of the burner is reduced by more than 20%, and the burner is in a state of oxygen-deficient combustion; after adjusting the above parameters, the dust concentration drops by 0.5~1 mg / Nm 3 , the oxygen content in the flue gas is reduced to less than 19%, and the flue gas emission of the heating furnace under low temperature heat preservation can be carried out. The advantages of the invention are that it is easy to operate and control, realizes ultra-low dust emission of the heating furnace in a low-temperature heat preservation state, reduces the heat preservation temperature of the heating furnace itself, and is environmentally friendly and energy-saving.

Owner:NANJING IRON & STEEL CO LTD

Novel composite modifier for austenitic manganese steel

InactiveCN101289723BControl crystallizationEnhance the ability to resist "recession"Melting tankRare earth

The invention discloses a novel composite modifier for austenitic manganese steel, comprising rare earth alloy, ferrotitanium, calcium silicon and aluminum, wherein the dosage of the Re-containing rare earth alloy accounts for 0.20-0.25 percent of the weight of molten steel; the dosage of the ferrotitanium accounts for 0.02-0.03 percent of the weight of the molten steel; the dosage of the calciumsilicon accounts for 0.20-0.25 percent of the weight of the molten steel; and the dosage of the aluminum accounts for 0.15-0.20 percent of the weight of the molten steel. Treatment inside a furnace is carried out in the alloying adjustment stage for the composition of the molten steel after ferromanganese is added for the fine adjustment of the manganese content of the molten steel; one third of the rare earth alloy is added to a molten pool, and the aluminum is added before the tapping of the molten steel. Treatment outside the furnace is to add the calcium silicon, two thirds of the rare earth alloy and the ferrotitanium to a steel ladle. The adoption of the Re-Ca-Ti-Al multi-element composite modifier prolongs the effective time of the modification process of the molten steel and guarantees good modification effect.

Owner:铜陵市大明玛钢有限责任公司

Dyeing Process of Cotton Knitted Fabric Containing Lycra

ActiveCN104074045BWill not harmShort processBleaching apparatusDyeing processAfter treatmentEngineering

The invention discloses a dyeing process of Lycra cotton-containing knitted fabrics and mainly aims at solving the problems of large amount of water and coal consumption, and long time and high power consumption of a traditional process. The dyeing process comprises a presetting step, a hemming step, a pretreatment step, a dyeing step, an after-treatment step and an after-finishing step, which are orderly implemented; the presetting step comprises the procedure of adding auxiliaries to a rolling liquid system of a setter; the pretreatment step comprises the procedures of heating a bathtub and then preserving heat, and then washing by use of overflowing water. The dyeing process is characterized in that the tea saponin is used for bleaching instead of the hydrogen peroxide; as the tea saponin does not damage equipment, the tea saponin can be added in the presetting step for bleaching, and the operation of removing the hydrogen peroxide in the pretreatment step is avoided, so that the flow is shortened and the process is simplified, and the heat preserving temperature in the pretreatment step is also reduced. More importantly, the water consumption, coal demand and power consumption of the dyeing process are all reduced and the purpose of saving energy sources is realized, and the time taken by the process is reduced.

Owner:JIHUA 3543 KNITTING CLOTHING

A heat preservation control method for an electric rice cooker

ActiveCN106510481BAvoid hardening and yellowingConsistent tasteTemperature control using electric meansWarming devicesEngineeringControl unit

The invention discloses a heat preservation control method for an electric rice cooker, belongs to the technical field of kitchen cooking, and solves the problem of food hardening and yellowing caused by long-time heat preservation of an existing electric rice cooker. The electric rice cooker comprises a control unit, a heating apparatus and an inner pot, wherein the heating apparatus comprises a bottom heater for heating the bottom of the inner pot and a side heater for heating the side part of the inner pot. According to the heat preservation control method, the control unit controls the bottom heater and the side heater to alternately perform heat-preservation heating according to a set heat preservation temperature after the electric rice cooker enters a heat preservation stage. The heat preservation control method is used for the electric rice cooker to perform food cooking such as rice cooking, congee cooking and the like.

Owner:JOYOUNG CO LTD

Boiling fluidization drying apparatus

InactiveCN101566422BIncrease or extend drying dwell timeLower the holding temperatureDrying solid materials with heatHearth type furnacesFine powderAirflow

A boiling fluidization drying apparatus comprises an upper bed body, a middle bed body and a frame. An air outlet is arranged on the top face of the upper bed body. A feed port and a discharge chamberare respectively arranged at the front face and the back face at the lower portion of the upper bed body. A fine powder reflux pipe inserted from the top face is arranged in the upper bed body. The middle bed body is divided into a plurality of drying chambers along the front-and-back direction by a baffle plate. An opening is arranged at the lower portion of the baffle plate. An air duct is formed. A hole plate is arranged at the connection of the middle bed body and the lower bed body. The lower bed body is a wind division apparatus. The wind holes on the hole plate are fishscale holes andarranged in a row orderly. The direction of the air outlets of the wind hole in the same row is consistent. The hole rows are arranged at intervals at the back left portion and the back right portionof the air outlet. An included angle exists between the projection of the air outlet of the wind hole on the hole plate and the central line of the hole plates at the front-and-back direction. The invention has good drying effect and is especially suitable for drying the thermal sensitivity materials.

Owner:陆文光

A kind of forging method of Cu-containing nickel-based alloy and Cu-containing nickel-based alloy

ActiveCN104741494BImprove plasticityAvoid defects such as cracking and scrappingMetal-working apparatusIngotHeating furnace

The invention provides a forging method of nickel base alloy containing copper and the nickel base alloy containing copper and belongs to the technical field of forging technologies. The forging method overcomes the defects that because copper is added to the nickel base alloy, the hot working character is poor, and forge cracking is caused, and the yield can be effectively improved. The forging method comprises the steps of conducting billet forging, wherein preprocessed nickel base alloy ingots containing copper are placed in a heating furnace, the nickel base alloy ingots containing copper are heated to the temperature T1, the temperature T1 is kept, forging is conducted according to the forging ratio y1, so that forging stocks are obtained, the temperature T1 is 1120+ / -10 DEG C, and y1 is smaller than or equal to 1.4; conducting initial forming, wherein the forging stocks are arranged in the heating furnace to be heated, the temperature is kept, and forged pieces which are initially formed are obtained through forging; conducting final forging, wherein the initially formed forged pieces are arranged in the heating furnace to be heated to the temperature T3, the temperature T3 is kept, forging is conducted according to the forging ratio y3, so that finished forged pieces are obtained, the temperature T3 is higher than 1000 DEG C and lower than 1080+ / -10 DEG C, and y3 is larger than 1.5 and smaller than 2. The forging method can be used for forging of the nickel base alloy containing copper.

Owner:ENN ENVIROTECH CO LTD

A kind of preparation method of 1300mpa grade rare earth reverse transformation q&p steel

The invention discloses a preparation method of 1300MPa grade rare earth reverse transformation Q&P steel. Its chemical composition by mass percentage is: C: 0.12‑0.18%, Mn: 2.0‑3.0%, Si: 0.8‑1.2%, Al: 0.6‑1.0%, V: 0.05‑0.08%, B: 0.001‑0.003%, P<0.02%, S<0.01%, the balance is Fe and unavoidable impurities. According to the composition design of the present invention, a certain amount of mixed rare earth ferroalloy is added, smelted and made into cast slabs. Combine the reverse transformation process with the Q&P process to increase the stability of austenite. Low Si content ensures surface quality and hot rolling performance, and improves hardenability through Al and B, adding a certain amount of V to introduce a dispersed second phase, V and Si are combined to enhance the work hardening ability of ferrite. By adding a suitable content of rare earth, it plays a role in modification, refines the crystal grains, and improves the comprehensive mechanical properties of the steel plate. The steel plate produced by the invention has a microstructure of martensite, ferrite, retained austenite and dispersed second phases. The tensile strength is greater than 1300MPa, and the elongation after fracture is greater than 15%. It has a good combination of strength and plasticity.

Owner:SHANDONG JIANZHU UNIV

A method for simultaneously improving the oxidation and corrosion resistance of ndfeb powders and magnets

ActiveCN111243846BCoated evenlyIncrease contentPermanent magnetsMagnetic materialsOxidation resistantAlloy coating

Owner:BEIJING UNIV OF TECH

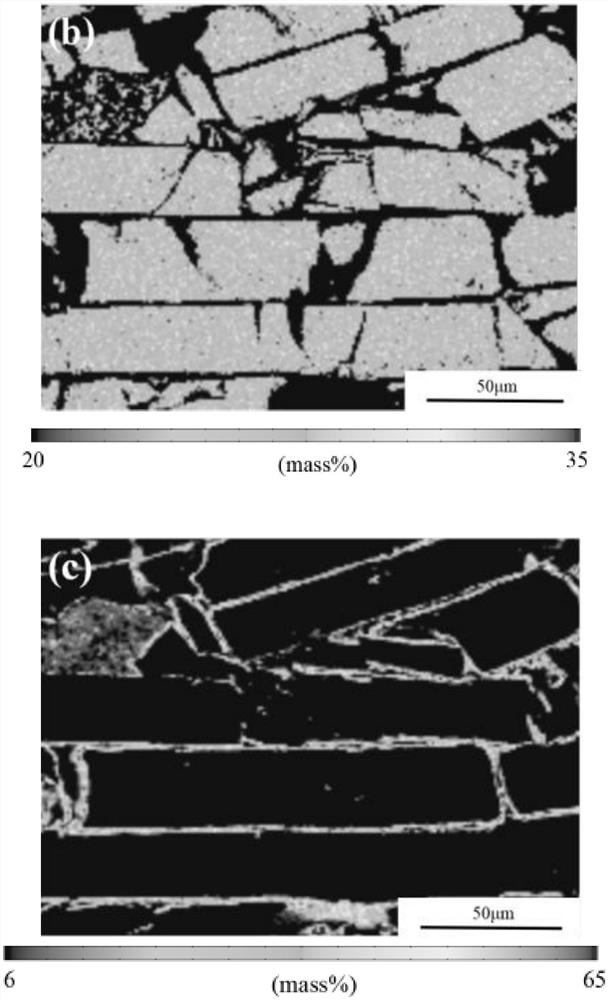

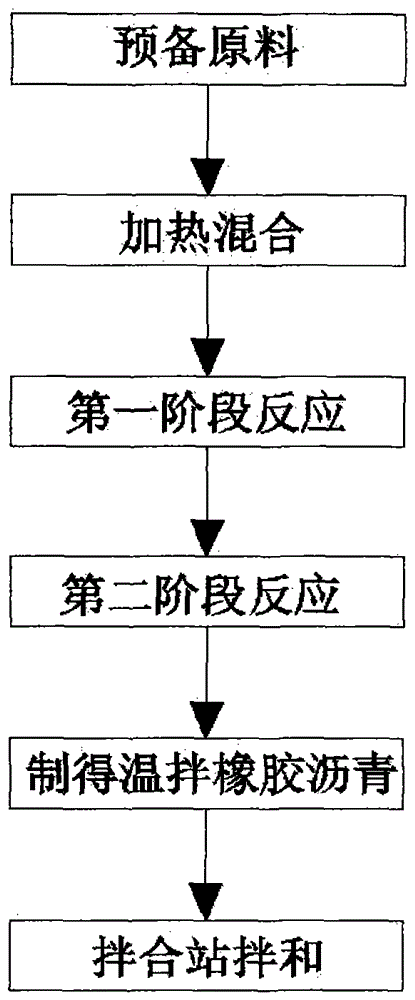

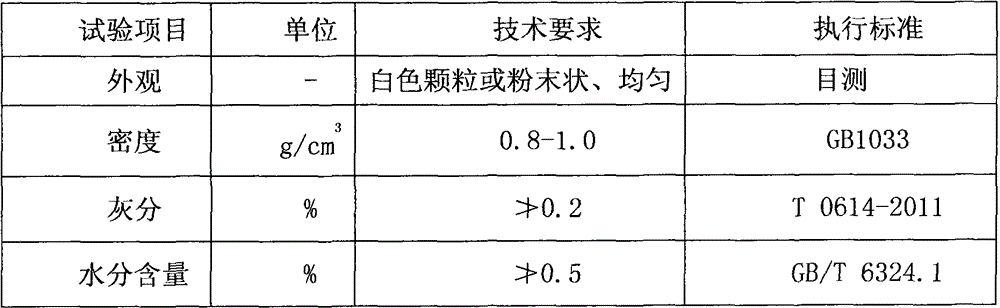

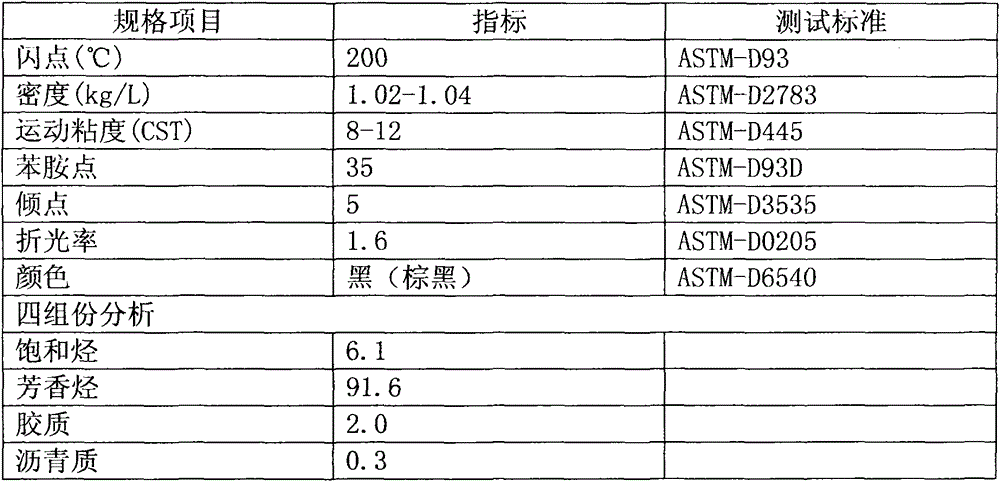

Two-stage warm-mix rubber asphalt method and its products

ActiveCN103923472BLow reaction temperatureReduce consumptionClimate change adaptationBuilding insulationsEngineeringPollution

The present invention discloses a two-stage type rubber asphalt warm mix method, which comprises: 1) preparing raw material; 2) carrying out heating mixing; 3) adding an oil produced from a crude oil vacuum distillation tower, and carrying out a first stage reaction; and 4) adding a RH asphalt warm mix modifier to carry out a second stage reaction, and carrying out a viscosity reduction treatment. The invention further discloses a product prepared by performing the preparation method. According to the present invention, the method has characteristics of simple process, easy achievement and high efficiency; under the premise of assurance of the road performance, the two auxiliary agents are adopted to modify the rubber asphalt at two stages so as to effectively reduce the reaction temperature of the rubber asphalt, reduce the fuel consumption, reduce the emissions of harmful gases and dust, reduce the environmental pollution and improve the construction environment; and the product provided by the present invention has characteristics of low viscosity, low reaction temperature, asphalt pavement construction season prolonging, asphalt mixing material aging reducing, road performance improving, effective reduction of fuel energy consumption required by the mixing material production process, energy source saving and mixing cost reducing.

Owner:北京嘉格伟业筑路科技有限公司 +2

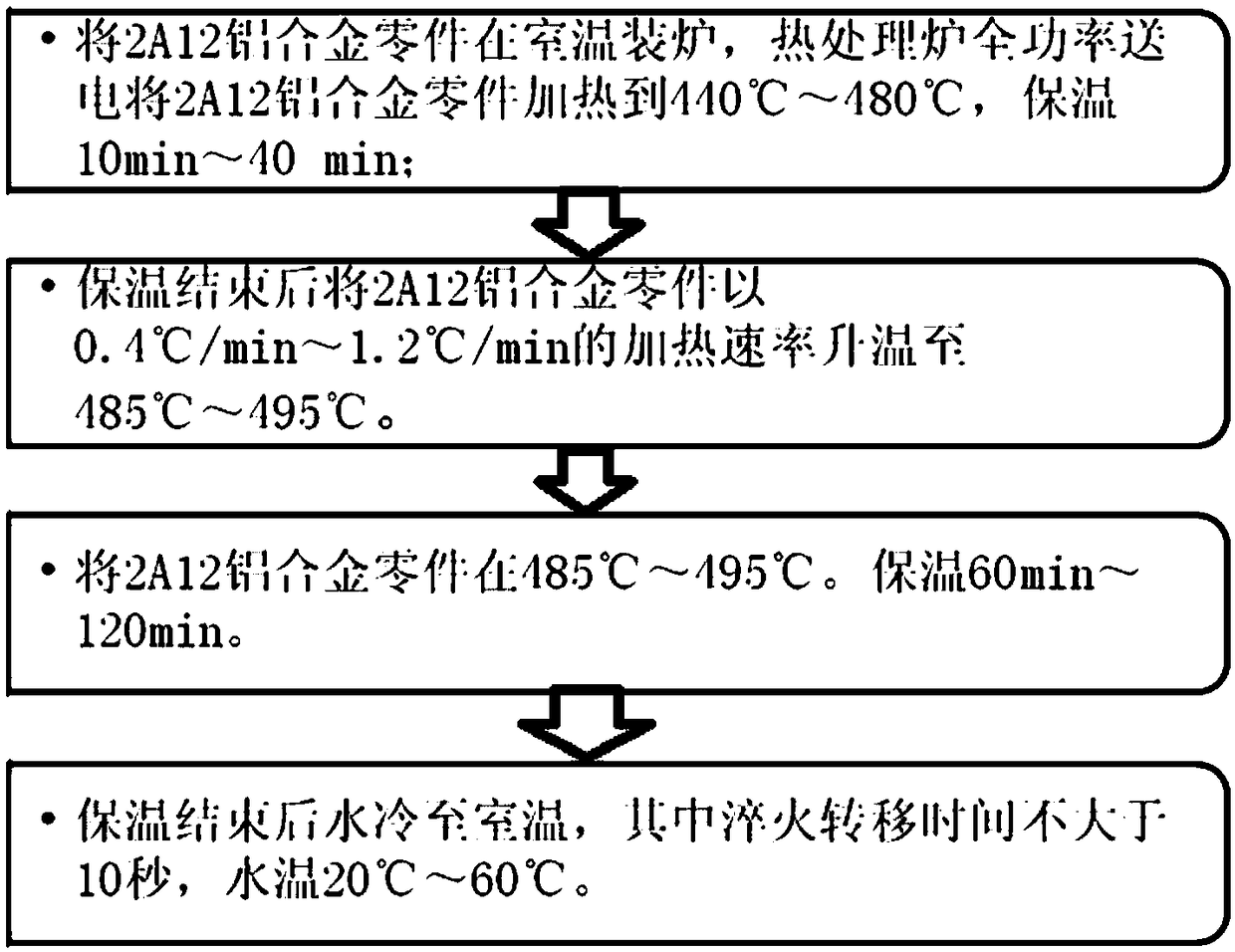

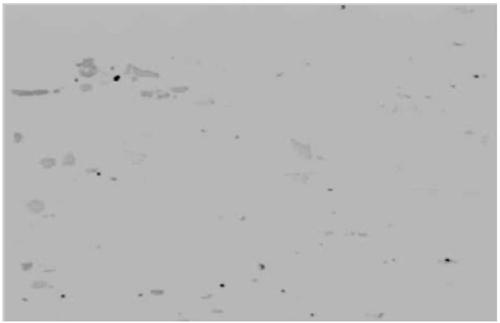

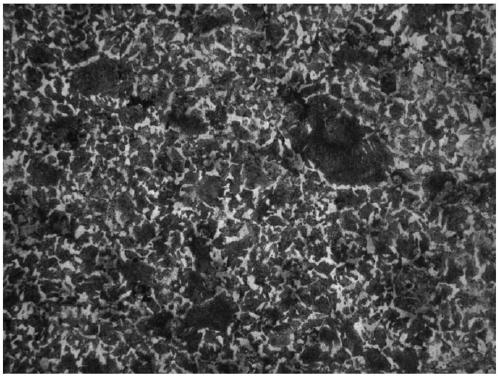

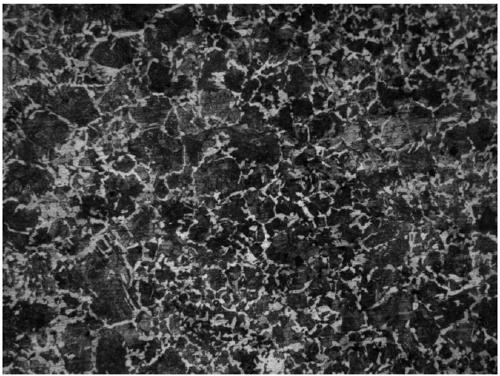

Heat treatment method for preventing 2A12 aluminum alloy parts from solid solution overburning

ActiveCN109023181AEliminate internal stressRaise the solution temperatureRoom temperatureWater cooling

The invention provides a heat treatment method for preventing 2A12 aluminum alloy parts from solid solution overburning. The heat treatment method comprises the following steps of heating the 2A12 aluminum alloy parts to 440-480 DEG C, and keeping the temperature for 10-40 minutes; then heating to 485-495 DEG C at a heating rate of 0.4-1.2 DEG C per minute, and keeping the temperature for 60-120 minutes; and finally, using water to cool the aluminum alloy parts to room temperature, wherein transfer time of entering water is not more than 10 seconds and the water temperature is 20-60 DEG C. Theheat treatment method for preventing the 2A12 aluminum alloy parts from solid solution overburning has simple operation, not only can prevent the 2A12 aluminum alloy parts from solid solution overburning, but also can reduce energy consumption and improve the performance of 2A12 aluminum alloy products.

Owner:西安长峰机电研究所

Low-temperature normalizing heat treatment method for No.45 steel

InactiveCN109022707ALower the holding temperatureImprove performanceHeat treatment bathsMaterials scienceHeat treated

The invention discloses a low-temperature normalizing heat treatment method for No.45 steel, and relates to the technical field of heat treatment. The low-temperature normalizing heat treatment methodincludes the steps of salt bath liquid preheating, workpiece salt bath heat preservation, ultrasonic treatment, air cooling and the like. According to the method, an ultrasonic field with a certain vibrational frequency and power is introduced in the normalizing heat preservation process of the No.45 steel, the normalizing heat preservation temperature can be lowered, heat preservation time required in the austenitizing process is greatly shortened, normalizing efficiency is improved, normalizing heat treatment tissue is improved, and the overall performance of the No.45 steel is also improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

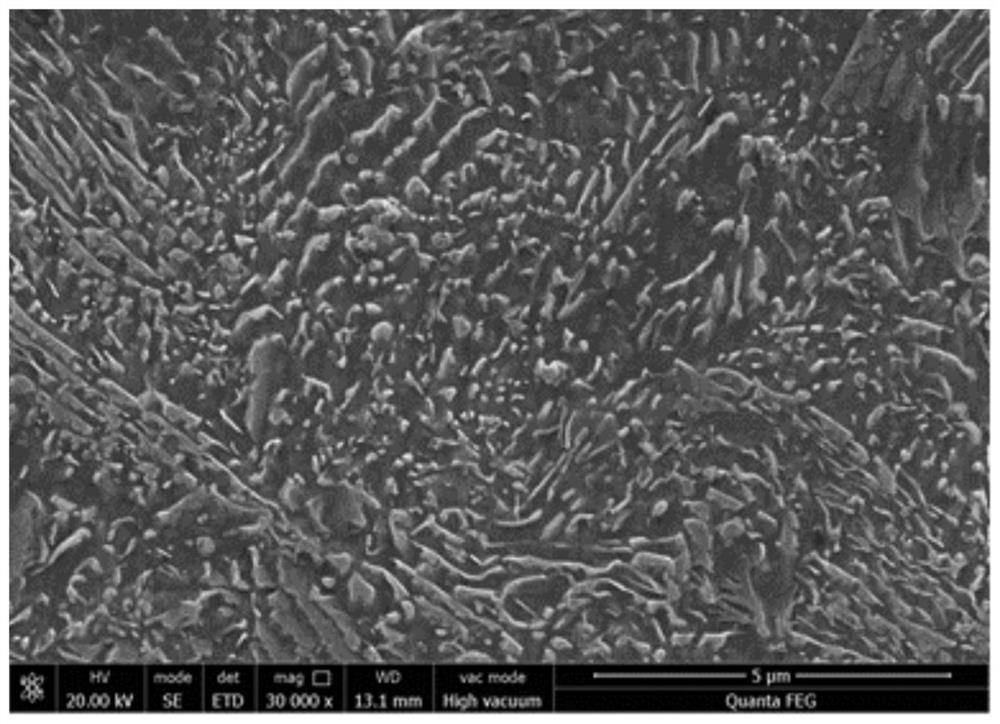

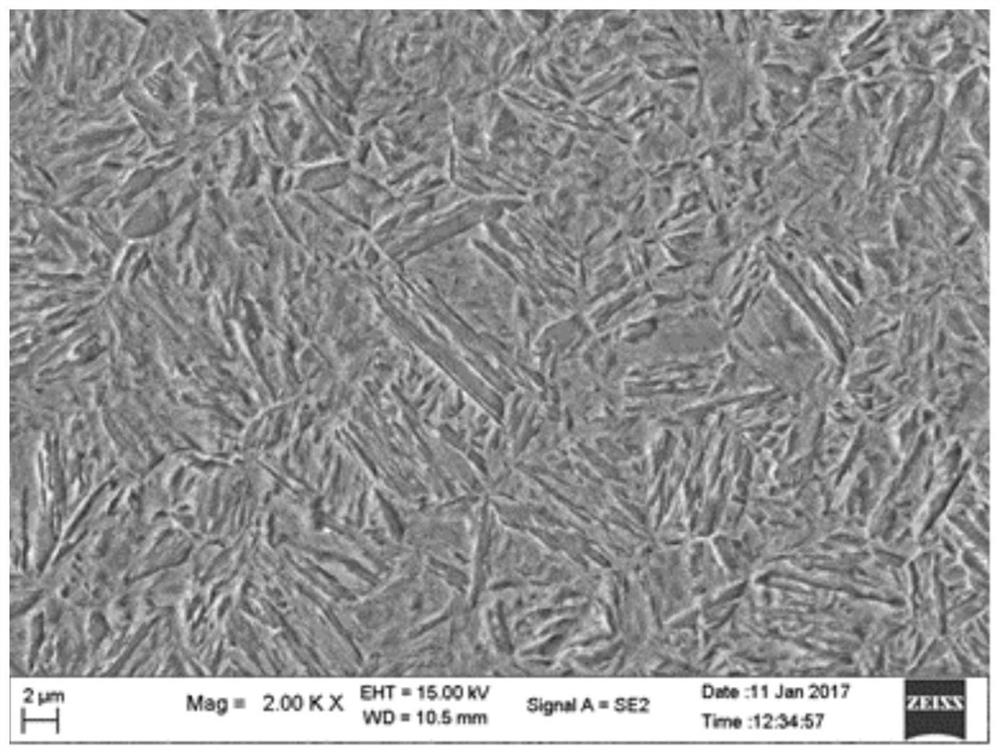

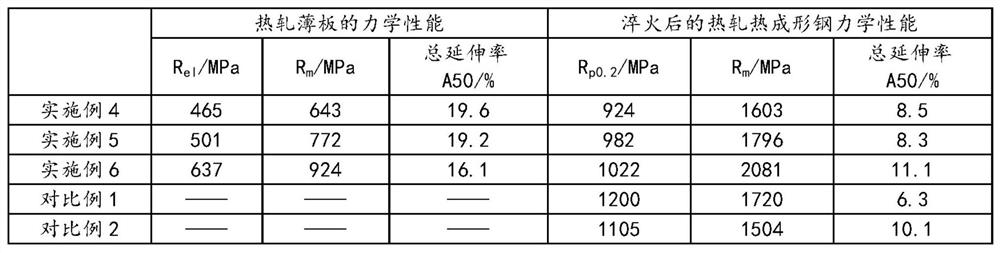

A kind of hot-rolled hot-formed steel and its preparation method

The invention specifically relates to a hot-rolled hot-formed steel and a preparation method thereof, belonging to the technical field of high-strength steel for automobiles. The chemical composition of the hot-rolled hot-formed steel is calculated by mass fraction: C: 0.18%-0.50%, Si: 0.3 %‑1.7%, Mn: 1.0%‑4.0%, Alt: 0.02%‑0.09%, Cr: 0.8%‑2.5%, P≤0.015%, S≤0.015%, B: 0.001‑0.012%, Mo: 0.03% ‑0.20%, Ti: 0.01%‑0.07%, Nb: 0.02%‑0.12%, and the rest are Fe and unavoidable impurity elements; the mechanical properties of the hot-rolled hot-formed steel provided by the embodiments of the present invention are: Rp0.2= 900MPa-1100MPa, Rm=1500MPa-2200MPa, A50=6%-12%; the yield strength of the hot-rolled sheet before thermoforming is 400MPa-700MPa, the tensile strength is 600MPa-1000MPa, and the elongation A50=15%-20%.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com