A method for simultaneously improving the oxidation and corrosion resistance of ndfeb powders and magnets

An anti-oxidation and magnet technology, applied in the direction of magnets, magnetic objects, magnetic materials, etc., can solve the problems of less powder, easy to cause pollution, high cost of raw material preparation, etc., to reduce energy loss, lower heat preservation temperature, and good protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Take about 50g of NdFeB magnetic powder, mix it with Zn particles with a mass of 100g and a diameter of about 3mm, and put it into a heat treatment furnace;

[0029] 2) Set the speed of the heat treatment furnace to 4r / min, and the vacuum in the furnace is greater than 10 -3 When Pa is filled with Ar until the pressure is 60kPa;

[0030] 3) Turn on the heat treatment furnace for heating, the heating temperature is 350°C, and the holding time is 6h;

[0031] 4) Take out the powder after the heat treatment, use a sieve to separate the NdFeB powder from the Zn particles, and collect the obtained powder;

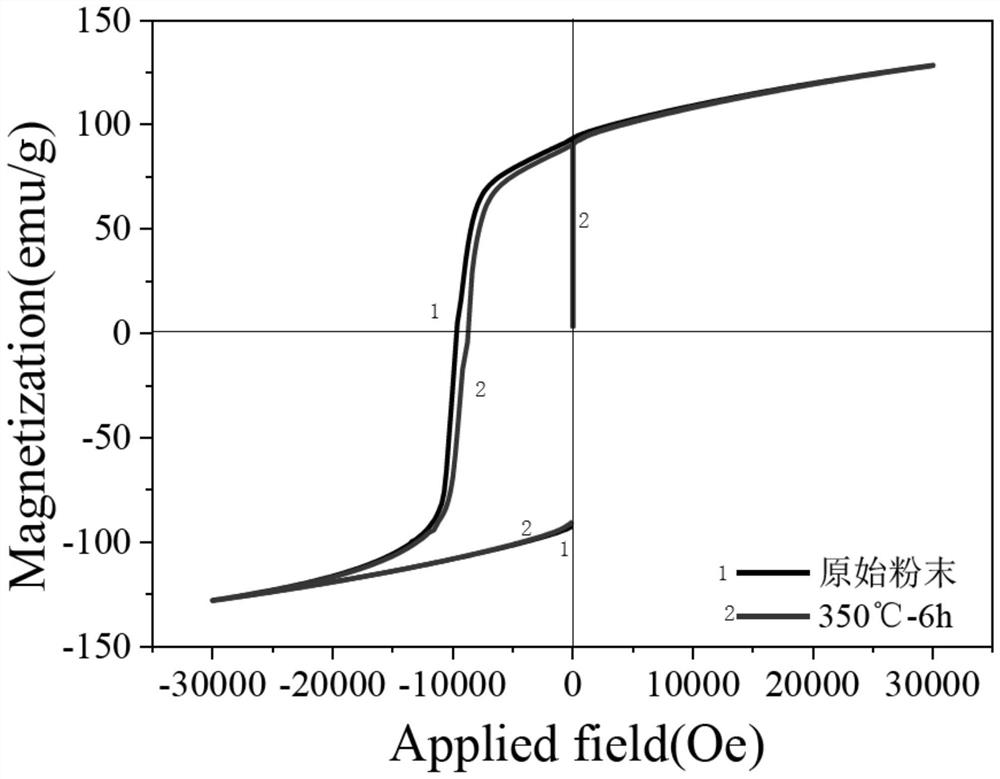

[0032] 5) Use VSM to test the performance of the powder before and after coating:

[0033] Table 1 Powder magnetic properties before and after Zn coating

[0034] Powder type Coercivity / Oe Remanence / emu·g -1

Powder before coating 10125 93.54 coated powder 9843 93.05

[0035] After coating the powder, the coercive force is reduc...

Embodiment 2

[0042] 1) Take about 10 pieces of NdFeB magnets, the total mass of which is about 30g, and uniformly mix with Cu particles with a mass of about 60g and a diameter of about 3mm, and place them in a heat treatment furnace;

[0043] 2) Set the speed of the heat treatment furnace to 4r / min, and the vacuum in the furnace is greater than 10 -3 Pa filled with Ar until the air pressure is 70kPa;

[0044] 3) Turn on the heat treatment furnace for heating, the heating temperature is 600°C, and the holding time is 3h;

[0045] 4) Take out the magnet after the heat treatment, and mix the magnet with 60g of Al quick-setting sheets with a length and width of 10mm and a thickness of about 0.5mm, and put them back into the heat treatment furnace after mixing evenly;

[0046] 5) The speed of the heat treatment furnace remains unchanged, and the vacuum degree in the furnace is greater than 10 -3 When Pa is filled with Ar until the air pressure is 65kPa;

[0047] 6) Turn on the heat treatment...

Embodiment 3

[0057] 1) Take 10 sintered NdFeB magnets with a total weight of about 30g.

[0058] 2) Take an AlZn alloy quick-setting sheet with a mass of 90 g, a length of about 6 mm, and a thickness of about 0.5 mm, and mix the magnet and the quick-setting sheet evenly into a heat treatment furnace;

[0059] 3) Set the speed of the heat treatment furnace to 5r / min, and the vacuum in the furnace is greater than 10- 3 When Pa is filled with Ar until the air pressure is 80kPa;

[0060] 4) Turn on the heat treatment furnace for heating, the heating temperature is 200°C, and the holding time is 5h;

[0061] 5) After the heat treatment, the magnet is taken out, and the magnet is separated from the quick-setting sheet.

[0062] 6) Use the BH permanent magnet measurement system to test the magnetic properties of the processed magnet;

[0063] Table 5 Energy table of magnets before and after coating AlZn alloy

[0064] Magnet type Coercivity / kOe Remanence / kG Magnet before wr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com