Preparation method of Cu-Cr-Zr wear-resistant alloy wire

A cu-cr-zr, wear-resistant alloy technology, applied in the field of wire manufacturing, can solve the problems of inability to achieve rapid solidification, coarse grains, poor composition uniformity, etc., to achieve increased nucleation rate, small deformation resistance, and suppression The effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

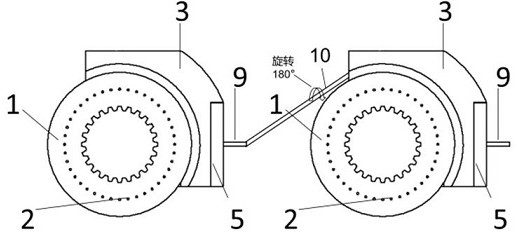

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of Cu-Cr-Zr wear-resistant alloy wire, comprising the following steps:

[0051] S1. Powder metallurgy: first make Cu-Cr and Cr-Zr alloys into powders with a diameter of 50-300 μm, the powders are prepared by atomization, the atomization GMR is 0.9, the atomization distance is 6m, and the atomization gas is liquid Nitrogen, atomization temperature is 1.1T m , get 50 ~ 300μm powder;

[0052] Then dry press or sinter the powder prepared above to make a block material, and finally break the block material into 1-10mm particles for use;

[0053] S2. Melting: Melt 50% of the ingot raw material into an alloy solution under vacuum conditions, the melting temperature is 1200°C, and the vacuum degree is kept at 10 -2 MPa, after complete melting, keep the temperature at 1200°C, turn to VOC furnace for refining to remove impurities and gases, then add particles prepared by 50% S1 into the melting furnace, keep the temperature at 1180°C, refine and further rem...

Embodiment 2

[0062] A preparation method of Cu-Cr-Zr wear-resistant alloy wire, comprising the following steps:

[0063] S1. Powder metallurgy: first make the Cu-Cr-Zr alloy into a powder with a diameter of 50-300 μm, the powder is prepared by the rotary ionization method, using argon as the arcing gas, and the flow rate is 5m 3 / h, nitrogen is the protective gas, the flow rate is 6m 3 / h, the rotation speed of the alloy rod is 12000rpm, and the ionization working voltage is 9kV.

[0064] Then dry press or sinter the powder to make a block material, and finally break the block material into 1-10mm particles for use;

[0065] S2. Melting: Melt 70% of the ingot raw material into an alloy solution under vacuum conditions, the melting temperature is 1300°C, and the vacuum degree is kept at 10 -4 MPa, after complete melting, keep the temperature at 1250°C, turn to VOC furnace for refining to remove impurities and gases, then add particles prepared by 30% S1 into the melting furnace, keep the ...

Embodiment 3

[0074] A preparation method of Cu-Cr-Zr wear-resistant alloy wire, comprising the following steps:

[0075] S1. Powder metallurgy: first make the Cu-Cr-Zr alloy into a powder with a diameter of 50-300 μm, the powder is prepared by ball mill grinding, the speed of the ball mill is controlled at 150r / min, the forward and reverse time is 10min, and the powder mixing time is 4h , to obtain a powder of 50-300 μm;

[0076] Then dry press or sinter the powder to make a block material, and finally break the block material into 1-10mm particles for use;

[0077] S2. Melting: Melt 90% of the ingot raw materials into an alloy solution under vacuum conditions, the melting temperature is 1370°C, and the vacuum degree is kept at 10 -5 MPa, after complete melting, keep the temperature at 1300°C, turn to VOC furnace for refining to remove impurities and gases, then add particles prepared by 10% S1 into the melting furnace, keep the temperature at 1280°C, refine and further remove impurities ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com