Patents

Literature

125results about How to "Improve the degree of adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

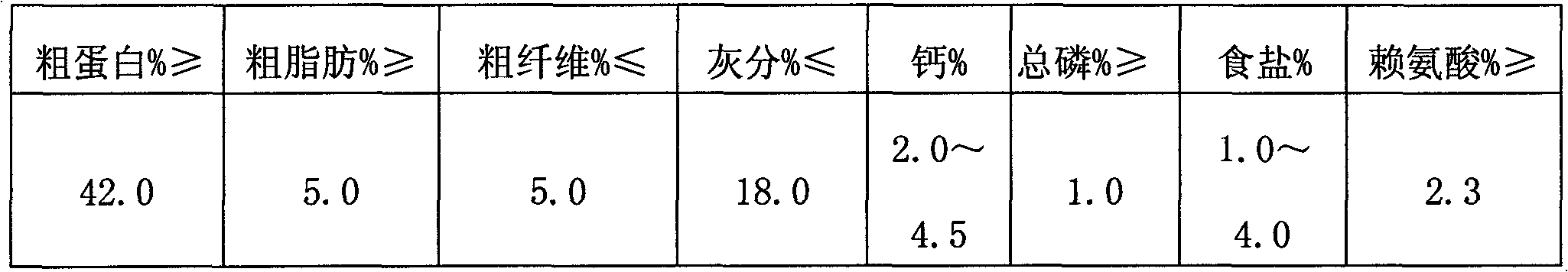

Health-care compound feed for prawns and production method thereof

InactiveCN102178078AGuaranteed FreshnessGood digestion and absorption rateFood processingClimate change adaptationAnimal sciencePrawn

The invention discloses a health-care compound feed for prawns and a production method thereof. The invention aims to provide a health-care compound feed for prawns, which can improve immunity in the prawns, utilization rate of feed and water quality, and a production method thereof. The formula of the raw material comprises the following components in part by weigh: 1 to 6 parts of imported white fish meal, 20 to 25 parts of steamed fish meal imported from Taiwan, 2 to 8 parts of steamed fish meal made in China, 18 to 22 parts of high-gluten wheat flour, 15 to 22 parts of peeled soybean pulp, 8 to 15 parts of peanut cakes, 2 to 6 parts of defatted shrimp meal, 1 to 3 parts of beer yeast cream, 1 to 3 parts of soyabean lecithin oil, 0.5 to 2 parts of refined fish oil, 0.5 to 2 parts of monocalcium phosphate and 1 to 4 parts of additive premix. The production method comprises: crushing, primary material mixing, secondary material mixing, hardening and tempering, granulating, braising, aging, drying, cooking, sieving and packaging. The invention can improve the breeding yield of pawns, reduce discharge pollution, improve water environment and the like.

Owner:深圳市澳华集团股份有限公司

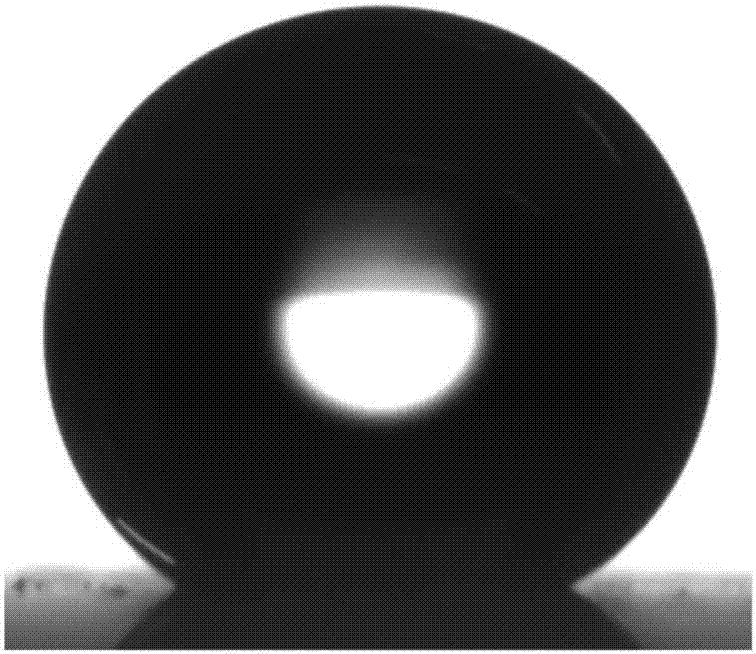

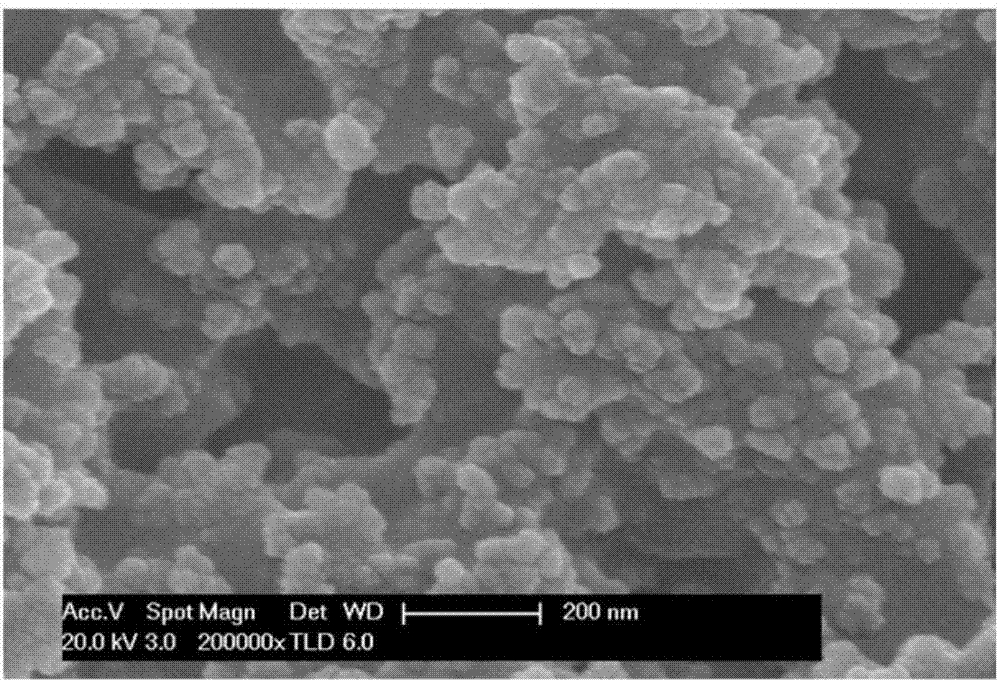

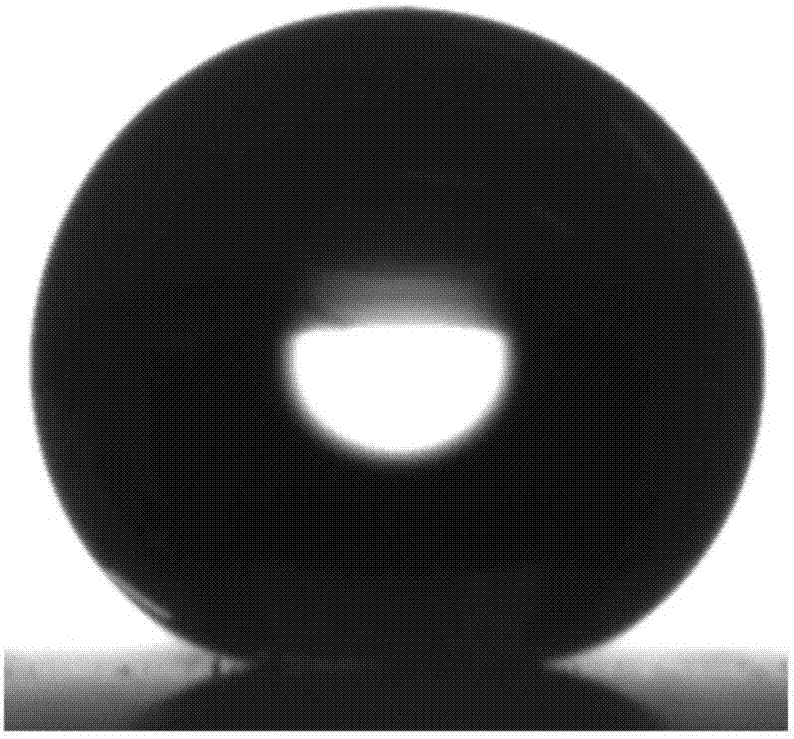

Durable super-hydrophobic coating and preparation method thereof

ActiveCN107384055AAvoid reunionGuaranteed numberAntifouling/underwater paintsPretreated surfacesMicro nanoOrganic solvent

The invention relates to a durable super-hydrophobic coating and a preparation method thereof. The preparation method comprises the following steps: 1) hybrid paint preparation: under low-speed mechanical stirring condition, adding micro nano particles, hydrophobic resin and a curing agent in a volatile organic solvent successively, performing high speed stirring and then ultrasonic dispersion to obtain the hybrid paint; 2) coating semi-solidification: coating the surface of a base material with the hybrid paint and performing semi-solidification; and 3) complete solidification: immersing the semi-solidified coating in a mixed immersion solution of the curing agent and the volatile organic solvent, taking the coating out, and drying the coating to obtain the durable super-hydrophobic coating having good wear resistance. The preparation method has no special requirement for a substrate material and its shape, the coating is suitable for various common base material surfaces such as metal, glass, timber and concrete, the equipment is simple, operation is easy, the cost is low, large-area construction is realized, and the coating has large application value on super-hydrophobic fields of self-cleaning, anticorrosion, mildew resistance, ice and frost resistance, and oil-water separation.

Owner:SOUTHEAST UNIV

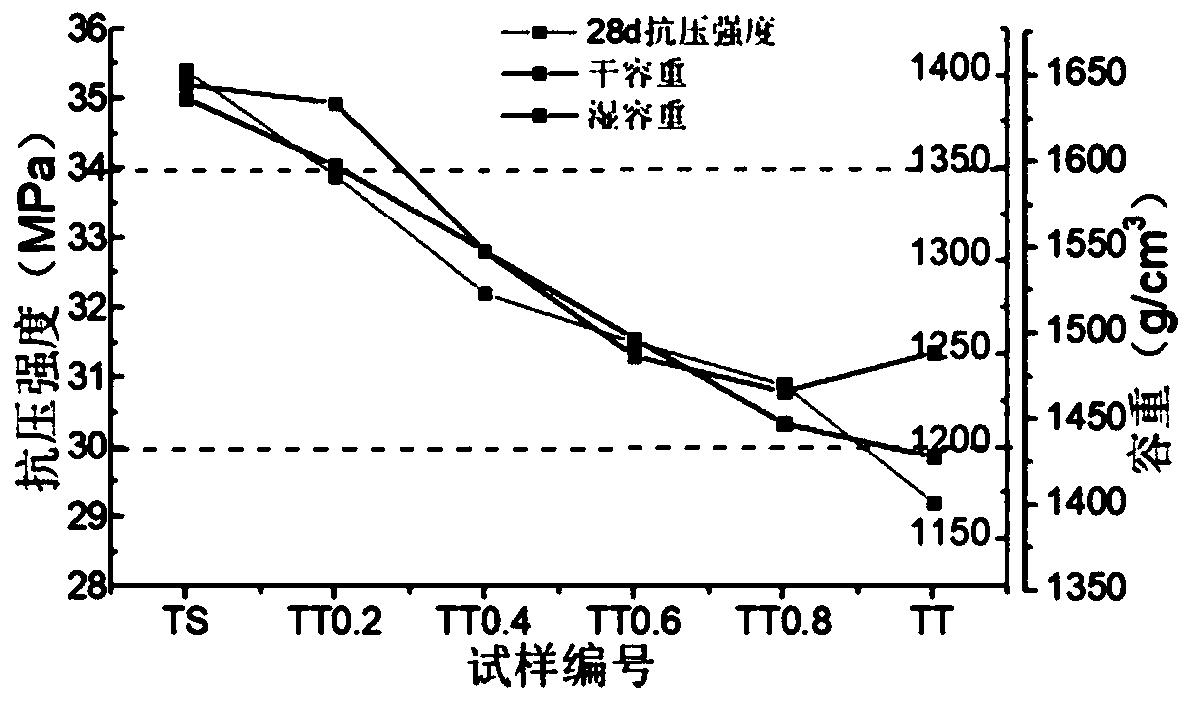

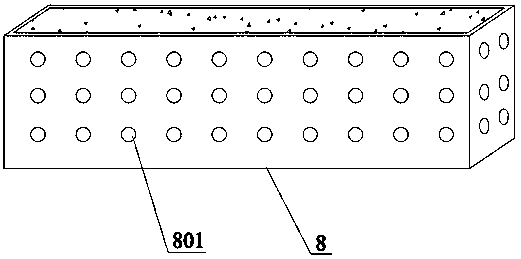

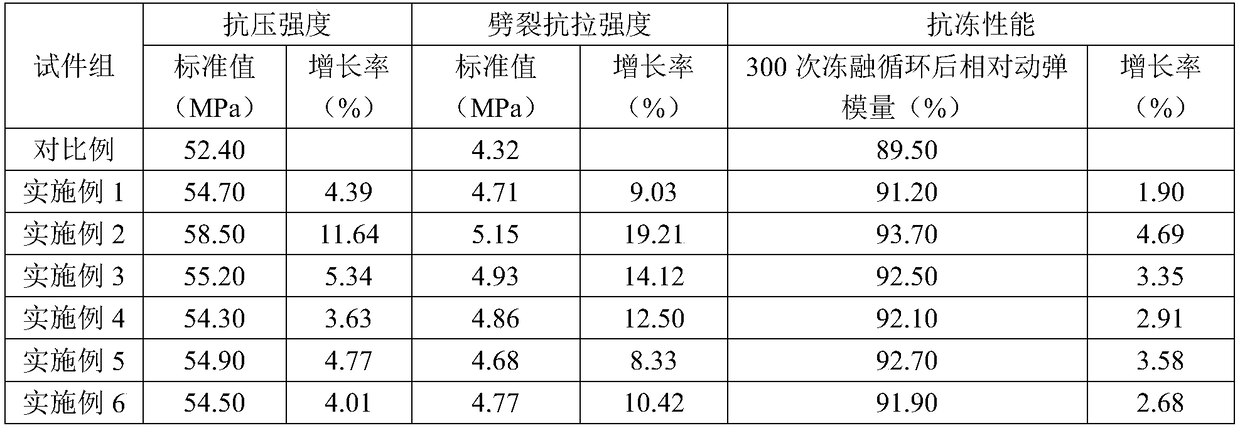

Core-shell type sulphoaluminate cement-based high-strength lightweight aggregate and preparation method thereof

ActiveCN110526609A3d excellent compressive strengthFully adsorbedPortland cementExpanded clay aggregate

The invention relates to a core-shell type sulphoaluminate cement-based high-strength lightweight aggregate and a preparation method thereof. With the high-strength lightweight aggregate, a lightweight and high-strength spherical fly ash ceramsite is used as a core; and a sulphoaluminate cement-based cementitious material is coated onto the surface of the fly ash ceramsite to form a shell layer with a porous structure. According to the invention, a proper cementitious material is selected to be coated onto the fly ash ceramsite to prepare the core-shell type sulphoaluminate cement-based high-strength lightweight aggregate, so the bearing capacity of a light aggregate is reinforced, and the strength of light aggregate concrete is improved; meanwhile, by using of ordinary portland cement, fly ash and silica fume as additives, the defects like over-rapid setting time and later-stage strength shrinkage of sulphoaluminate cement are improved, and the bonding strength of a core material anda shell material is reinforced, so the overall strength of core-shell type lightweight aggregate concrete is significantly improved, and the light aggregate concrete can be more extensively applied.

Owner:WUHAN UNIV OF TECH

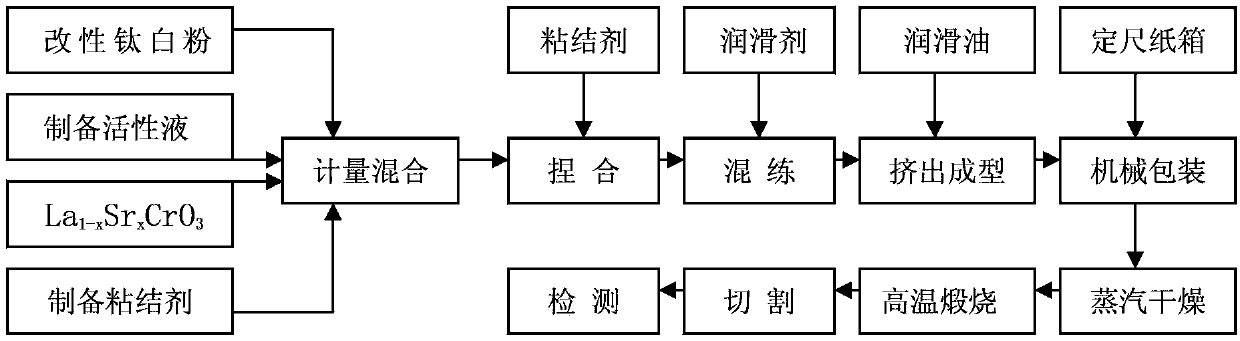

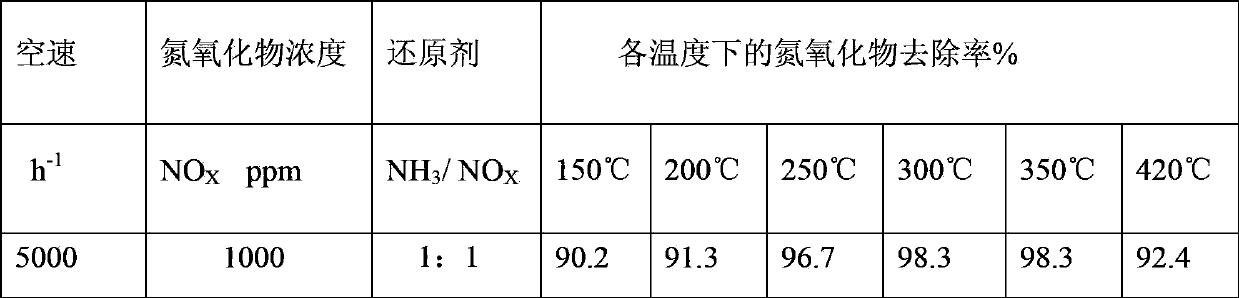

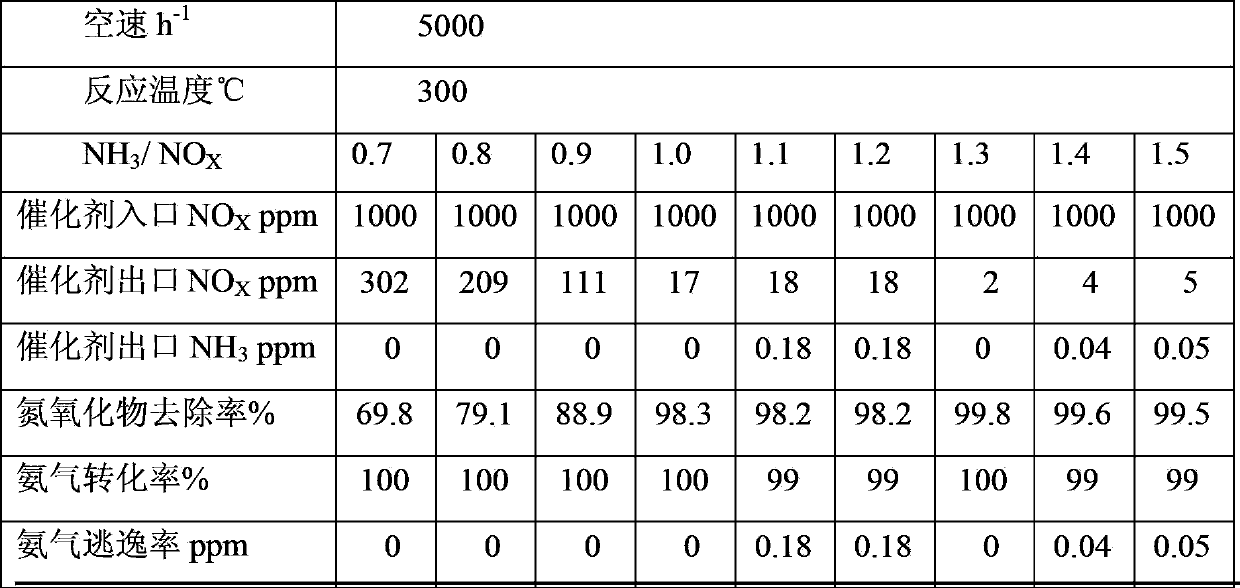

Perovskite-type substance La<1-x>Sr<x>CrO<3>, heat-engine plant denitration composite catalyst, and preparation methods of perovskite-type substance La<1-x>Sr<x>CrO<3> and heat-engine plant denitration composite catalyst

InactiveCN103861581AImprove performanceUltra-fine crystal shape lowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPhosphateHoneycomb like

The invention discloses perovskite-type substance La<1-x>SrCrO<3>, a heat-engine plant denitration composite catalyst, and preparation methods of the perovskite-type substance La<1-x>SrCrO<3> and the heat-engine plant denitration composite catalyst, and belongs to the technical field of flue gas denitrification catalyst. The preparation method of the perovskite-type substance La<1-x>SrCrO<3> is used for solving a problem that existing preparation method of the perovskite-type substance is complex. According to the preparation method of the perovskite-type substance La<1-x>SrCrO<3>, lanthanum nitrate, strontium nitrate, and chromium nitrate are taken as raw material precursors, and are dissolved in water, and then are subjected to high-temperature roasting so as to obtain finished products. The preparation methods of the heat-engine plant denitration composite catalyst is used for solving a problem of existing denitration catalyst that ammonia is released in denitration processes. According to the preparation methods of the heat-engine plant denitration composite catalyst, a titanium dioxide mixture, an active liquid, water, glycerin, ethylene glycol, glass fiber, and aluminium dihydrogen phosphate are subjected to kneading so as to obtain ceramic clay; the ceramic clay is subjected to vacuum extrusion so as to obtain honeycomb ceramic blank; and the honeycomb ceramic blank is subjected to steam drying and roasting so as to obtain products. The heat-engine plant denitration composite catalyst is high in denitration rate, and is capable of solving a problem of ammonia escaping.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH +1

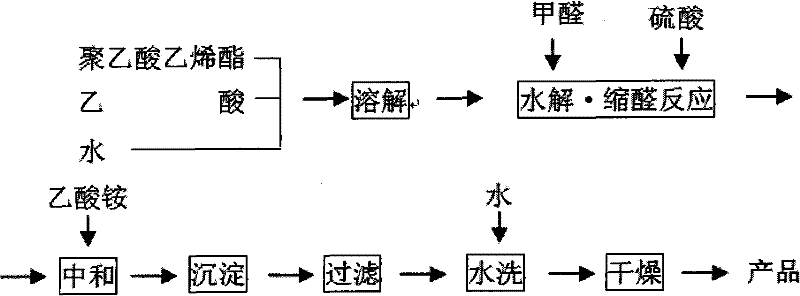

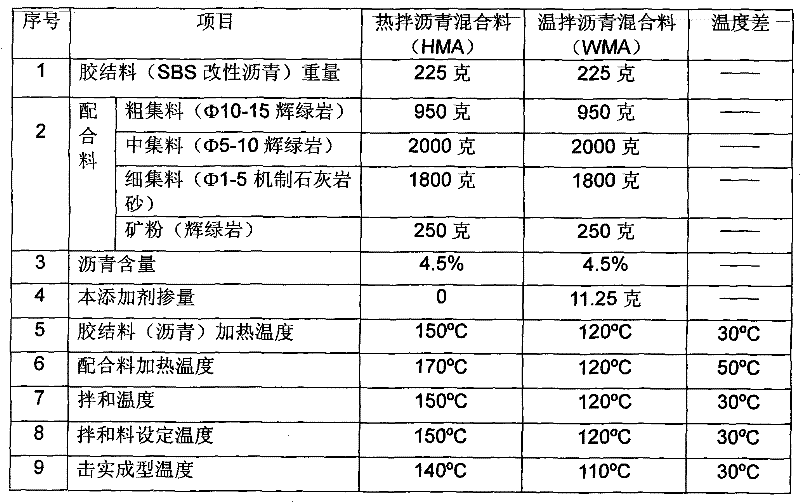

Anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application

InactiveCN102234432AImprove the degree of adhesionLower working conditionsClimate change adaptationBuilding insulationsPolyvinyl alcoholFatty acid

The invention, belonging to the field of construction engineering, relates to an anti-stripping warm mix asphalt additive agent comprising surfactant, its preparation method and application. The anti-stripping warm mix asphalt additive agent disclosed in the invention comprises polyvinyl acetal, polyacrylamide, fatty acid anhydride ester surfactant, polyoxyethylene acid ester surfactant and water. The warm mix asphalt additive agent disclosed in the invention can enhance the bonding of stone, rock flour and asphalt, so as to get the purposes of high strength and preventing stripping. The requirements of the technical characteristics of the warm mix asphalt is realized by spraying the additive agent with the content of 5-6% of the weight of the asphalt when the temperature of the asphalt reaches 120-130 DEG C, and then carrying out blending and operation as routine asphalt. The warm mix asphalt additive agent disclosed in the invention has no substances which are harmful to the human body and environment, with being environmentally friendly, and is an excellent product with energy saving and emission reduction.

Owner:SHANGHAI YITAI ENERGY TECH

Fiber-broken stone synchronous-sealing pavement maintenance method

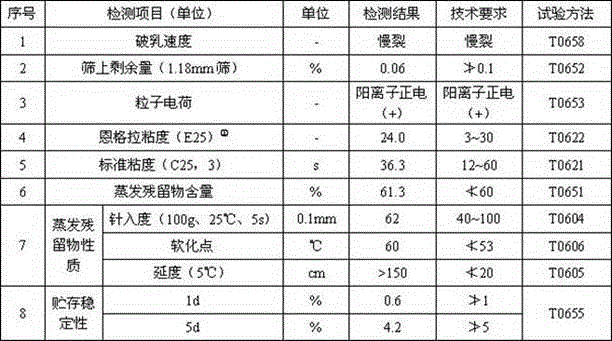

InactiveCN105908589AImprove skid resistanceGood water sealing effectIn situ pavingsRoads maintainenceFiberChipseal

The invention relates to a fiber-broken stone synchronous-sealing pavement maintenance method, relates to the pavement maintenance method, and is suitable for preventive maintenance treatment for roads. The method includes the steps: 1) spraying modified emulsified asphalt; 2) synchronously spreading fibers and broken stone aggregates; 3) adopting a 16 T-or-more rubber wheel road roller for rolling the pavement obtained in the step 2) for 2-3 times with the rolling speed of 2-3.5 km / h, and followed by cleaning and recycling loose aggregates with an aggregate recycling device; and 4) after determining that the pavement obtained in the step 3) basically has no loose aggregates, spraying the modified emulsified asphalt, and closing traffic for 2 h-6 h, and then allowing vehicles to pass through. The water sealing performance and the anti-abrasion performance of the pavement can meet the preventive maintenance requirements of all kinds of roads, and the anti-sliding performance is excellent.

Owner:江苏燕宁新材料科技发展有限公司

Strong combination method of metal material and plastic material

The invention discloses a treatment method of forming nano holes on the surface of an aluminum alloy and a strong combination method of a metal material and a plastic material. The treatment method comprises the following steps of: S1, selecting a workpiece and mounting the workpiece on a rack, S2, performing preliminary treatment: washing the workpiece with water, removing dust or residual fragments after machining from the surface of the workpiece, S3, performing hole preforming treatment-chemical corrosion, S4, performing hole forming treatment-electrolysis, S5, performing post treatment, and S6, performing soaking treatment to accomplish an entire experiment. The chemical corrosion is adopted during the hole preforming treatment; electrochemical corrosion is adopted during the hole forming treatment; the method is applicable to aluminum alloy materials with different strength; for example, uniform nanoscale holes are formed on the surface of a harder aluminum alloy AL6061-T6; the soaking treatment is performed after the hole forming treatment; the aluminum alloy materials are soaked in an amine compound; and the bonding degree between the aluminum alloy materials and a glue solution can be increased.

Owner:中山美力特环保科技有限公司

Anti-cracking, wear-resistant and seepage-proof compound mortar and preparation method thereof

The invention discloses anti-cracking, wear-resistant and seepage-proof compound mortar. The anti-cracking, wear-resistant and seepage-proof compound mortar is prepared from raw materials in parts by weight as follows: 20-30 parts of long and short reinforcing fiber, 15-20 parts of a waterproof additive, 10-20 parts of gelatine powder, 10-16 parts of a composite aid, 10-14 parts of glass beads, 65-75 parts of Portland cement, 55-65 parts of fine sand, 35-45 parts of composite filling sand, 1-2 parts of triethanolamine and 1-3 parts of sodium tripolyphosphate. The compound mortar has excellent anti-cracking, wear-resistant and efflorescence preventing properties and has better water resistance, seepage-proof property and adhesion force, relatively excellent impact resistance and thermal insulation and sound insulation effects and a certain pollutant air absorption function; besides, according to the provided preparation method, the material cost is lower, raw materials are easy to obtain, the process is simple, and the compound mortar has higher practical value and excellent application prospects.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

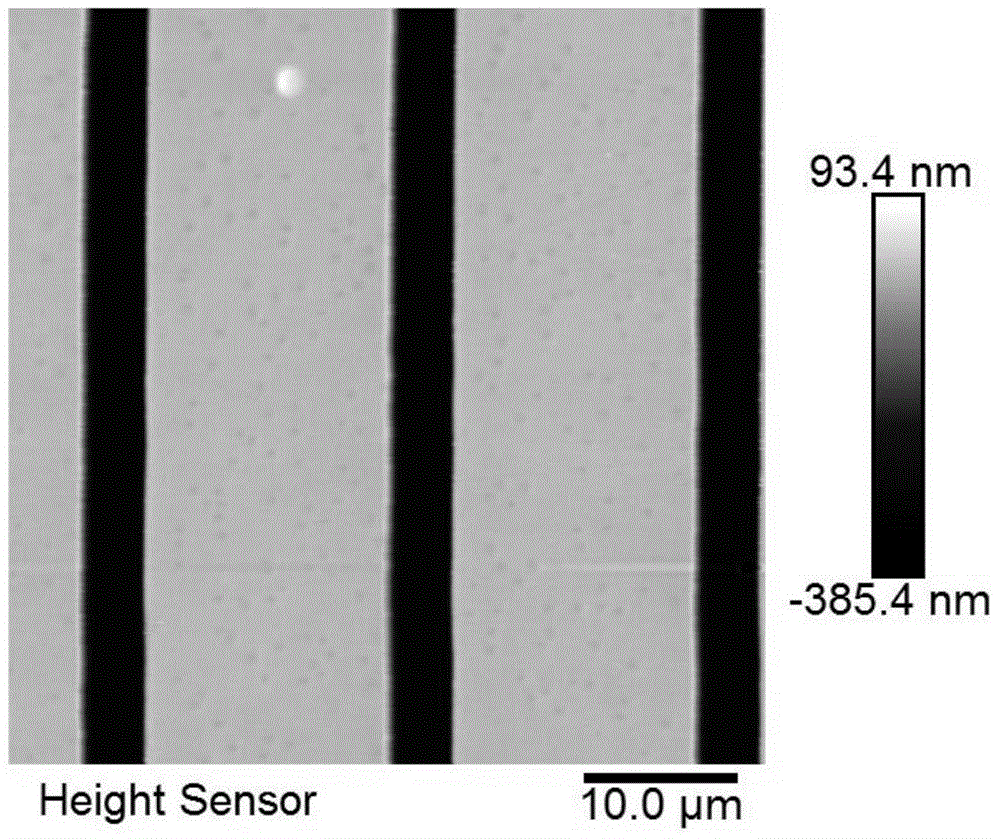

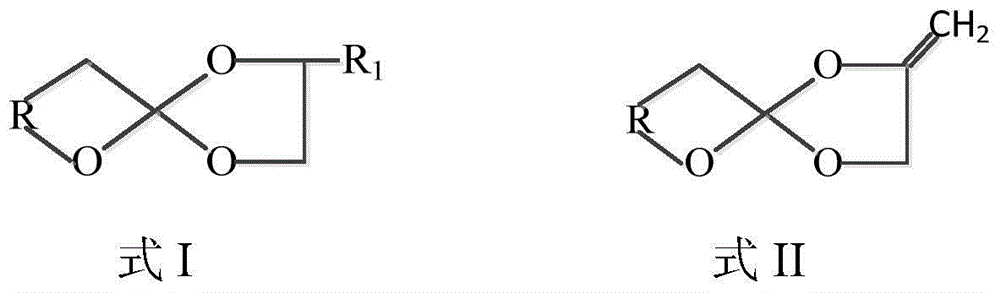

Expansion polymerization imprinting glue for nano-imprinting

ActiveCN104932197AAdjustable volume changeSmall volume shrinkagePhotosensitive materials for photomechanical apparatusMicro nanoPolymer science

The invention discloses an expansion polymerization imprinting glue for nano-imprinting. Raw materials required for the preparation of the expansion polymerization imprinting glue comprise a low polymer and an expansion monomer. Compared with the prior art, after the expansion polymerization imprinting glue for nano-imprinting is introduced in the expansion monomer, the expansion monomer can be polymerized with the low polymer, the volume change of the impressing glue after polymerization can be adjusted, and thus the volume shrinkage after the imprinting glue is cured is reduced or even eliminated; and the imprinting glue with zero curing shrinkage or volume expansion can be obtained by adjusting the content of the expansion monomer. The imprinting glue can effectively reduce the residual stress in a micro-nano figure, and the generation of figure defects in the nano-imprinting demolding process caused by the residual stress is reduced while accurate figure copying is realized.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Method of utilizing polydopamine modified aluminum nitride microspheres to prepare thermal radiation film

InactiveCN109824936AGood thermal conductivityImprove thermal conductivityFilm structureCHLORIDE HEXAHYDRATE

The invention relates to a method of utilizing polydopamine modified aluminum nitride microspheres to prepare a thermal radiation film and belongs to the technical field of thermal radiation materials. Aluminum nitride microspheres are prepared by utilizing aluminum chloride hexahydrate to react with epoxy propane and calcining at high temperature in an ammonia gas atmosphere after reaction, and aluminum nitride enables atom crystals to be of a tetrahedral structure, has good heat conducting performance itself and is prepared to be microspherical particles to be filled in a thermal radiation film structure, so that thermal radiation ability of the thermal radiation film is further improved. A polydopamine film is grafted on the aluminum nitride microspheres to modify the surfaces of the same, bonding strength between the aluminum nitride microspheres and other molecules in the thermal radiation film is improved, groups in an organic compound are utilized to generate chemical bonding force to improve mechanical strength of the thermal radiation film, and toughness of the thermal radiation film is improved.

Owner:徐扣华

Crack filler

ActiveCN106190003AGood wear resistanceLow costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCalcium carbonateALUMINUM STEARATES

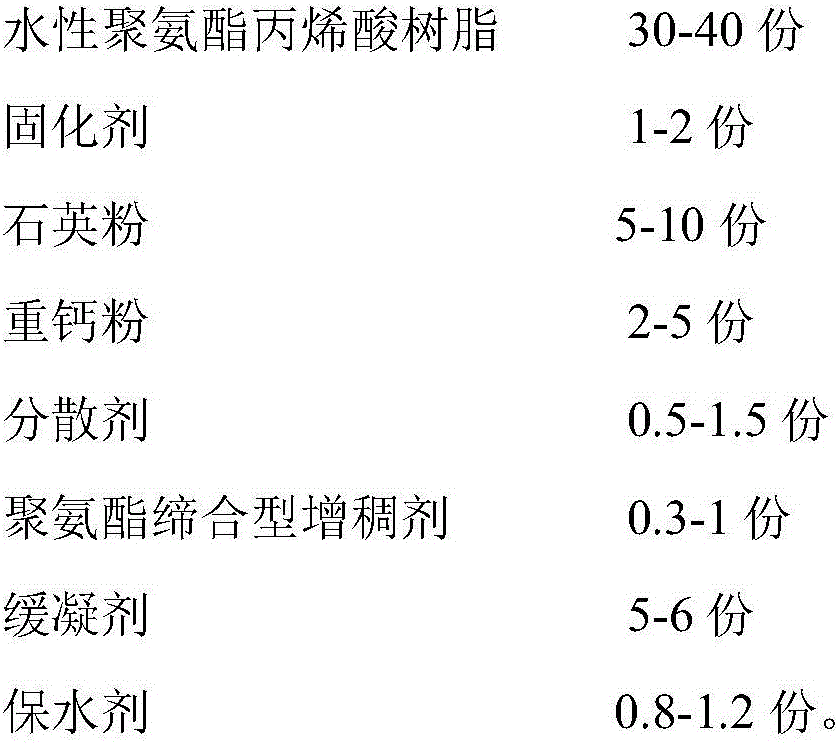

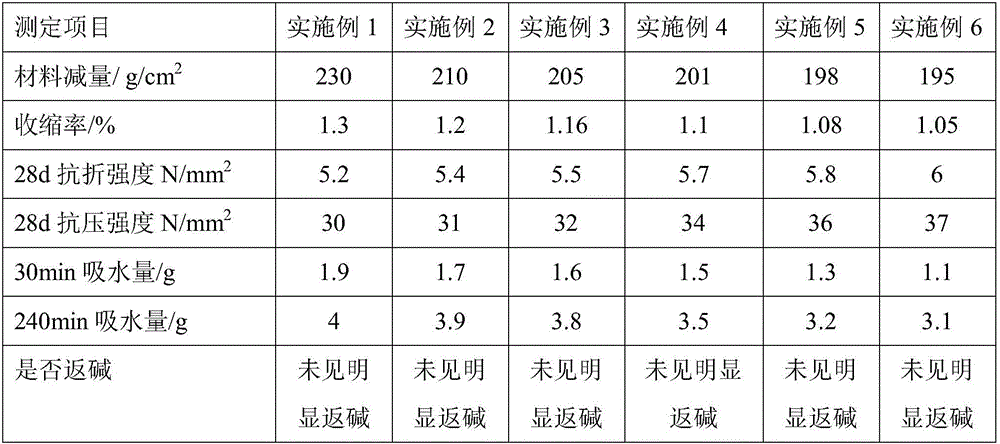

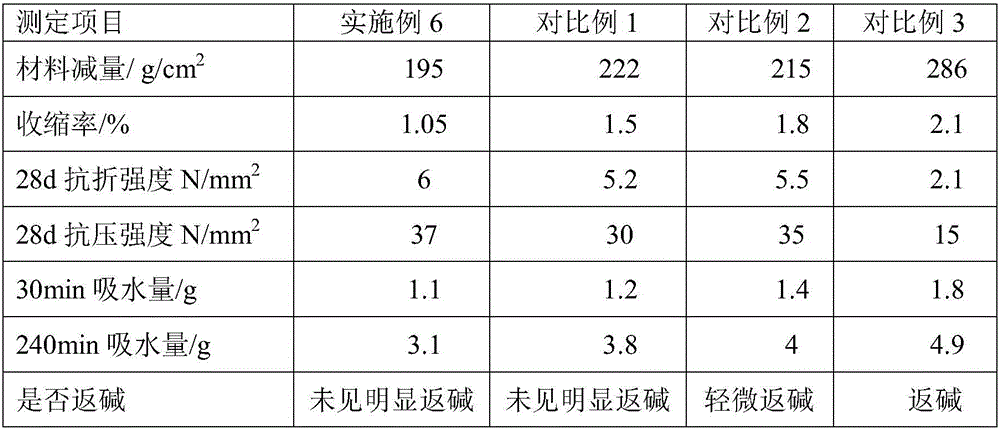

The invention discloses crack filler. The crack filler is prepared from components in parts by weight as follows: 30-40 parts of waterborne polyurethane-acrylic resin, 1-2 parts of a curing agent, 5-10 parts of quartz powder, 2-5 parts of ground calcium carbonate, 0.5-1.5 parts of a dispersing agent, 0.3-1 part of a polyurethane associative thickener, 5-6 parts of a retarder and 0.8-1.2 parts of a water-retaining agent. The crack filler is enabled to have good abrasion resistance, hydrophobicity and weather fastness due to addition of the waterborne polyurethane-acrylic resin; the crack filler has good viscosity, and the bonding degree of the crack filler can be increased; the crack filler is uniformly mixed and avoids caking; aluminum stearate can exist in a film form, and the crack filler is less affected by water; the easy-to-clean performance of the crack filler can be improved by means of organic bentonite.

Owner:苏州大乘环保新材有限公司

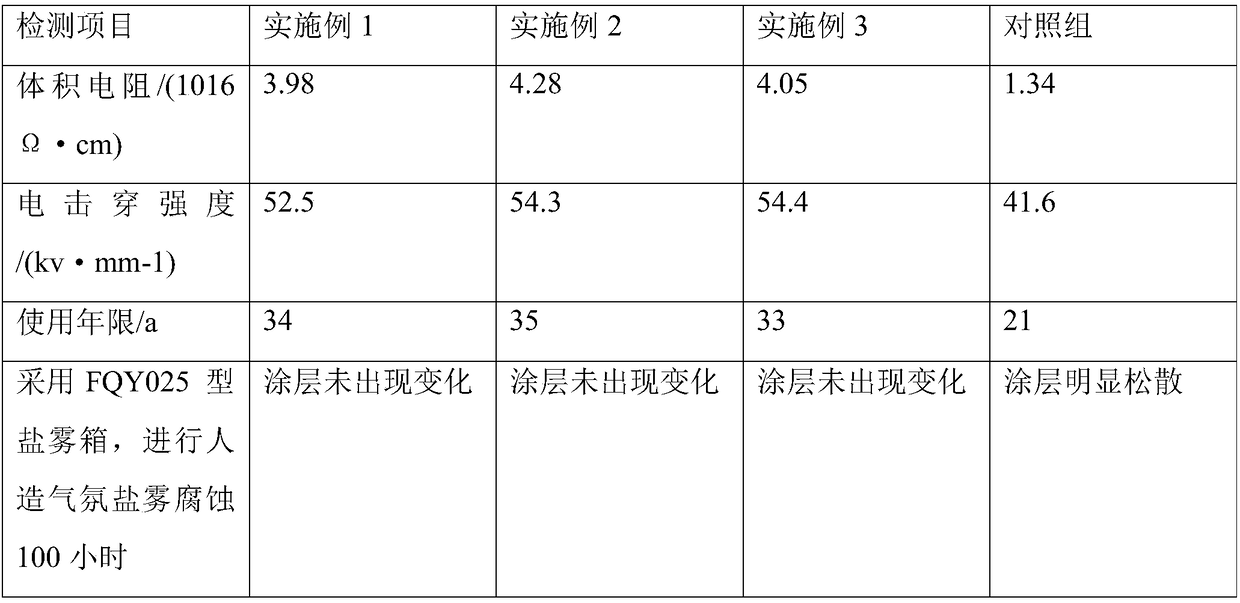

High-voltage insulation bus and coating process

InactiveCN109355008AGuaranteed anti-corrosionEnsure insulationPlastic/resin/waxes insulatorsInsulated cablesAlkali freeInsulation layer

The invention discloses a high-voltage insulation bus and a coating process. The high-voltage insulation bus comprises a bus body, the bus body is coated with an anticorrosive layer and an insulationlayer, the anticorrosive layer is positioned on the bottom layer of the bus body, the insulation layer is positioned on the outer layer of the bus body, the anticorrosive layer is coated with organicsilicon coatings, and the insulation layer comprises, by weight, 60-75 parts of organic silicon resin, 40-45 parts of polyacrylate rubber, 5-7 parts of titanate coupling agents, 3-4 parts of zirconiumoxide, 20-24 parts of silicon dioxide, 3-7 parts of naphthenic oil, 4-6 parts of calcium stearate, 3-4 parts of alunite, 5-7 parts of vinyl trimethoxysilane, 2-6 parts of alkali-free glass fibers and9-17 parts of ethylene-propylene-diene monomer glue. A coating structure of the bus can effectively decrease electrical short circuit of the bus body, and the insulating property and the anticorrosive property of the bus are greatly improved, so that the service life of the bus is prolonged.

Owner:镇江朝阳机电科技有限公司

Fireproof coal ash heat insulation material and preparation method thereof

The invention discloses a fireproof coal ash heat insulation material which comprises, by weight, 15-25 parts of compressed coal ash, 20-40 parts of acidified coal ash, 10-14 parts of water glass, 12-18 parts of adsorption filling soil, 5-7 parts of coupling agents, 15-25 parts of adhesives, 9-13 parts of glass beads, 8-16 parts of reinforced fibers and 7-11 parts of flame-retardant additives. The coal ash is comprehensively recycled, resources are saved, environments are protected, waste is sufficiently used, the prepared heat insulation material is low in specific gravity, high in strength, good in heat insulation performance, excellent in high-temperature resistance and flame resistance and good in stability. Besides, the preparation method is low in material cost and simple and clear in process and has a high practical value and a good application prospect, and raw materials are easily obtained.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Industrial sewage treatment adsorbent

InactiveCN106830163AEasy to passImprove adsorption capacityWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationAdhesiveSorbent

The invention discloses an industrial sewage treatment adsorbent. The industrial sewage treatment adsorbent comprises the following raw materials in parts by weight: 30-40 parts of attapulgite, 30-40 parts of argil, 20-30 parts of expanded graphite cyclodextrin compound, 10-18 parts of bamboo charcoal, 10-20 parts of carbon nanotube, 5-10 parts of retinervus luffae fructus, 8-18 parts of adhesive, 20-35 parts of flocculant and 3-5 parts of oxidizing bactericide. According to the invention, industrial sewage treatment is performed by means of the attapulgite clay; and the industrial sewage treatment adsorbent can adsorb wastewater containing heavy metal, is high in effect and low in cost, and achieves considerable economic benefits.

Owner:安徽其霖环境工程技术有限公司

Synthetic rice applicable to diabetic patient and processing method thereof

InactiveCN107041511AImprove eating effectIncrease the degree of staple foodEdible oils/fatsFood ingredient functionsBiotechnologyBanana powder

The invention discloses a processing method of synthetic rice applicable to a diabetic patient. The processing method comprises the following steps: firstly, preparing a first raw material group, namely mashed potatoes, a second group of raw materials, namely rice flour, corn flour and soybean flour, a third group of raw materials, namely Chinese chestnut powder, Chinese yam powder and banana powder and a fourth group of raw materials, namely propolis liquid, royal jelly, custard apples, edible oil, potato starch and water; secondly, uniformly mixing the fourth group of raw materials, adding into the third group of raw materials, and uniformly mixing; thirdly, uniformly mixing the first raw material group and the second group of raw materials, then uniformly mixing with the material obtained in the step 2, and extruding into a rice-like synthetic rice primary product applicable to the diabetic patient; and fourthly, drying to obtain the synthetic rice applicable to the diabetic patient, namely firstly carrying out hot air drying at the temperature of 50-110 DEG C, then blowing with hot air at the temperature of 15-35 DEG C, then carrying out microwave drying at the power of 200-400W, then carrying out hot air drying at the temperature of 30-50 DEG C, and finally carrying out hot air drying for 1-2 minutes at the temperature of 10-20 DEG C.

Owner:钟静涛

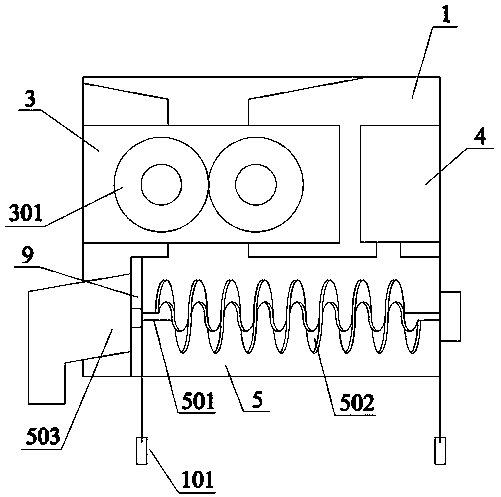

Ecological treatment system and ecological treatment method for gravel yard

InactiveCN109821868AImproves fertility and porosityFacilitate ecological governanceSpadesSoil lifting machinesIrrigationEcosystem

Disclosed are an ecological treatment system and an ecological treatment method for a gravel yard. The ecological treatment system comprises a soil treatment module and a planting restoration module.The soil treatment module comprises a crushing cavity, an improved matrix cavity and a mixing cavity. The planting restoration module comprises an irrigating and seeding device, a soil turning and impurity removing device and a plurality of planting troughs. The irrigating and seeding device comprises a rotating cavity, and the rotating cavity is divided into a seed storage cavity and an irrigation cavity by a partition plate. A plurality of rows of sowing devices are arranged on the outer side the seed storage cavity, and a plurality of rows of spraying heads are arranged on the outer side ofthe irrigation cavity. The soil turning and impurity removing device disposed below the irrigating and seeding device comprises a long rotating shaft and a plurality of rows of hook teeth disposed onthe long rotating shaft. Through holes are uniformly formed in the periphery of each planting trough, and gravel soil improved by the soil treatment module is paved in the troughs. The method combining physical improvement with biological improvement is adopted to fundamentally solve the problems of excessive gravel, hardening, poor water storage capacity and low nutrition of the soil of the gravel yard, and accordingly, the original ecosystem of the gravel yard is restored.

Owner:洛阳智昊工程科技有限公司

Potato rice and processing method thereof

InactiveCN107095218AImprove eating effectIncrease the degree of staple foodFood scienceBanana powderPotato starch

The invention discloses a processing method of potato rice. The method comprises the following steps of 1, taking the raw materials in parts by weight (the first group of raw materials comprise 30 to 60 parts of potato powder; the second group of raw materials comprise 3 to 6 parts of rice powder, 10 to 20 parts of corn powder and 15 to 25 parts of soybean powder; the third group of raw materials comprise 5 to 10 parts of Chinese chestnut powder, 15 to 20 parts of yam powder and 20 to 30 parts of banana powder; the fourth group of raw materials comprise 3 to 5 parts of edible oil, 5 to 10 parts of potato starch and 80 to 100 parts of water); 2, after uniformly mixing the four groups of raw materials, adding the raw materials into the third group of raw materials; performing the uniform mixing; 3, uniformly mixing the first group and second group of raw materials; uniformly mixing the raw materials with substances obtained in the second step; extruding the materials into rice-shaped potato rice primary products; performing extrusion forming by a single-screw-rod extruding machine, wherein the first stage machine tube temperature of a single screw rod is 50 to 70 DEG C; the temperature of the second stage machine tube is 60 to 80 DEG C; the temperature of the third stage machine tube is 70 to 100 DEG C; the machine tube temperature of the fourth stage machine tube is 90 to 120 DEG C; the temperature of the fifth stage machine tube is 80 to 95 DEG C; 4, performing drying to obtain the potato rice.

Owner:钟静涛

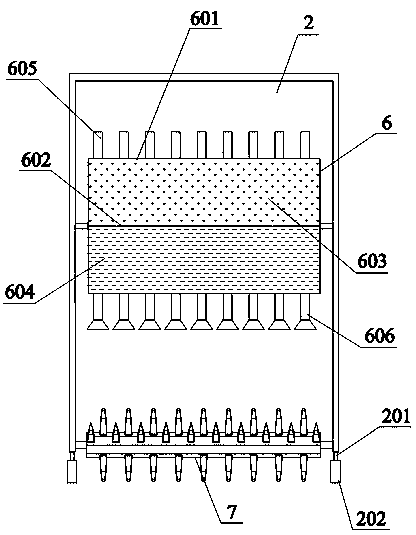

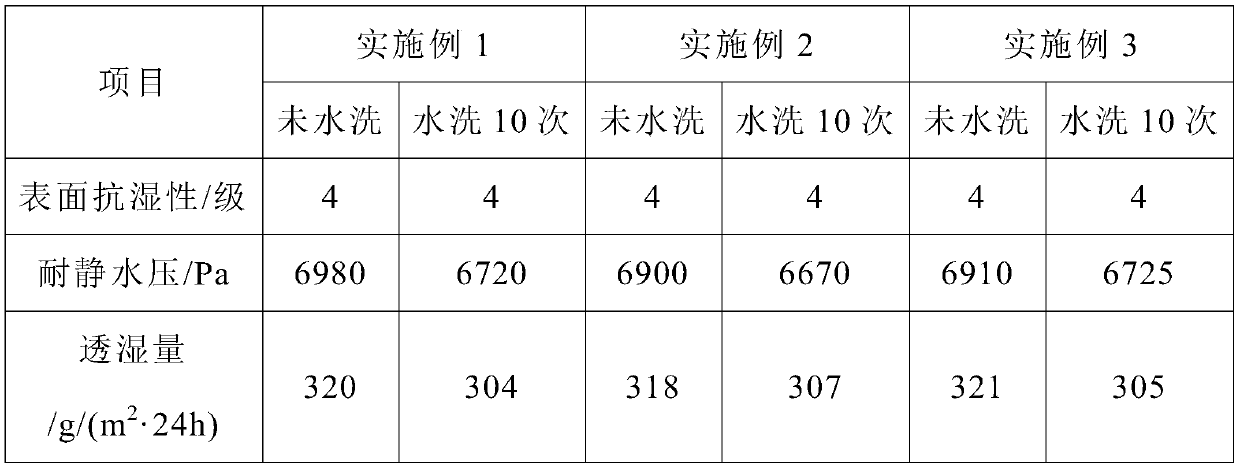

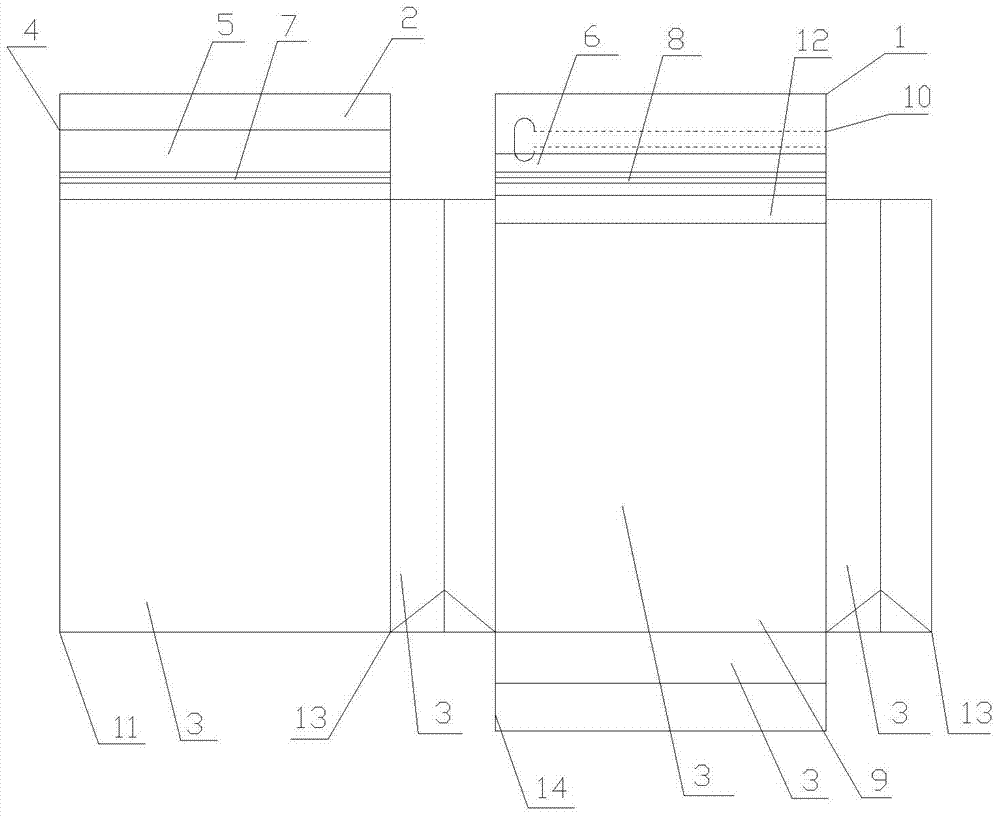

Washable waterproof moisture-permeable foam adhesive laminated fabric and preparation method thereof

ActiveCN111516311AImprove wrinkle resistanceGood quality and stabilityLamination ancillary operationsNon-macromolecular adhesive additivesFoaming agentAdhesive

The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The laminated fabric comprises a modified fabric, a foam adhesive anda waterproof film from bottom to top, the modified fabric is prepared from a cotton fabric, sodium hydroxide, oxalic acid, a first modifier and a second modifier; wherein the foam glue is obtained byfoaming a foaming agent; the waterproof membrane is prepared from a pretreatment membrane, polydimethylsiloxane and cyclohexane; the pretreatment film comprises a first waterproof layer and a second waterproof layer from bottom to top. The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The preparation method is simple in process operation and reasonable in component proportion, the waterproof film with hydrophobic, waterproof and moisture-permeable performance is attached to the surface of the modified fabric through a foam glue attaching method, and the prepared attached fabric has excellent waterproof and moisture-permeable performance, high hydrophobic performance, excellent washing resistance and high practicability.

Owner:东莞市听雨轩服装有限公司

Method for preparing red bean paste stuffing with tender taste

The invention discloses a method for preparing a red bean paste stuffing with a tender taste. The method comprises the following steps: (1) selecting raw materials; (2) performing screening to remove impurities; (3) performing cleaning and soaking; (4) performing cooking treatment; (5) performing peeling to take paste; (6) squeezing wet bean paste; (7) preparing semi-product bean paste A; (8) preparing semi-product bean paste B; and (9) preparing end-product bean paste. The prepared red bean paste stuffing has not only a favorable sand feeling but also excellent tenderness, and is unique in taste and strong in market competitiveness.

Owner:BENGBU JINWANG FOOD

Complex fertilizer for increasing oil tea yield

InactiveCN107840751AGood sustained release effectImprove fertilizer efficiencyCalcareous fertilisersMagnesium fertilisersAmmonium hydroxideNitrogen fertilizer

The invention discloses a complex fertilizer for increasing oil tea yield. The complex fertilizer comprises the following raw materials in parts by weight: 70-80 parts of a main material, 30-50 partsof fermented castor seed oil, 10-20 parts of soybean meal, 4-12 parts of diatomite, 4-10 parts of radish sprout, 6-12 parts of coconut shell flour, 4-12 parts of oat bran, 1-2 parts of trace element,2-4 parts of pectin, 2-8 parts of vermiculite powder, 1-8 parts of coal slag, and 1-3 parts of perlite; and the main material comprises the following components in parts by weight: 50-65 parts of a composite nitrogenous fertilizer, 4-18 parts of a calcium magnesium phosphate fertilizer, and 2-8 parts of potassium nitrate. A method for preparing the composite nitrogenous fertilizer comprises the following steps: calcining Chinese medical stone powder, under a stirring state, adding ammonium hydroxide, then placing the materials in a polyvinyl alcohol aqueous solution, uniformly stirring the materials, then adding urea and carboxymethylcellulose sodium, heating the materials and stirring the materials, and performing spray drying to obtain the composite nitrogenous fertilizer.

Owner:安庆市望马楼生态农业发展有限公司

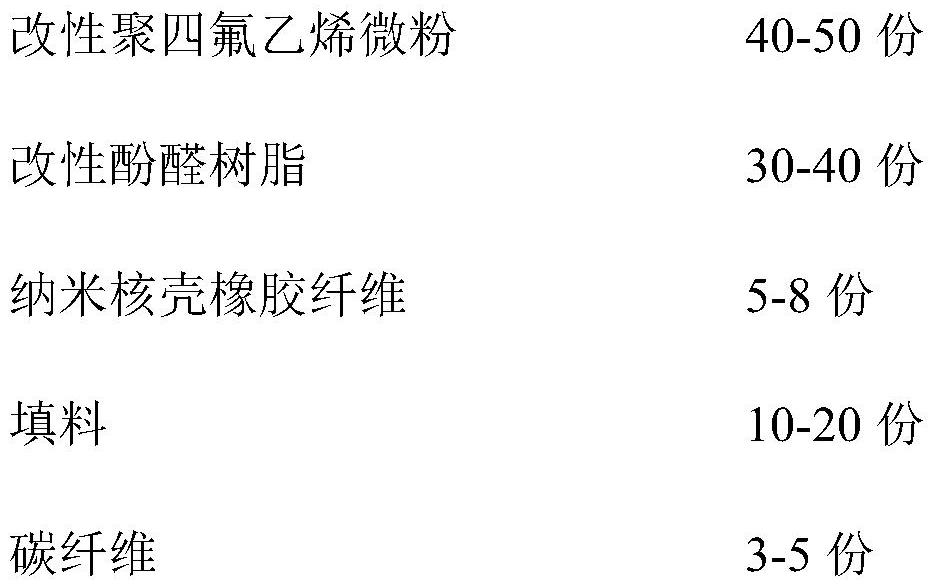

Thermosetting corrosion-resistant and wear-resistant coating material as well as preparation method and use method thereof

ActiveCN112143301AExcellent resistance to hydrochloric acidStrong pressure resistanceUnspecified rubber coatingsPretreated surfacesCorrosion resistantPolytetrafluoroethylene

The invention discloses a thermosetting corrosion-resistant and wear-resistant coating material as well as preparation and use methods thereof, and belongs to the field of corrosion protection. The coating material comprises polytetrafluoroethylene, phenolic resin, a filler and a coupling agent, the filler comprises silicon dioxide, and the coupling agent is a fluorine-containing coupling agent and / or an epoxypropoxy-containing coupling agent; and the coupling agent is attached to the periphery of the filler, and the coupling agent distributed on the periphery of the filler accounts for 35-80%of the total amount of the coupling agent. The coating material is prepared through coating raw material pretreatment, coating material preparation, coating material coating and drying. The coating material provided by the invention has excellent high-temperature resistance, acid resistance, alkali resistance and wear resistance, can effectively resist chloride ion erosion, and effectively protects the service safety of a matrix material.

Owner:北京博研中能科技有限公司

Manufacturing method of industry and mining drum screen with high wear resistance and high screening rate

ActiveCN106182843AAvoid easy cloggingIncrease elasticitySievingScreeningPolyurethane elastomerHigh resistance

The invention discloses a manufacturing method of an industry and mining drum screen with high wear resistance and high screening rate. The manufacturing method comprises the steps of firstly, prefabricating a screen plane forming die, spraying a release agent in the inner cavity of the forming die, and paving the forming die with twisted steel; then, preparing a polyurethane elastomer, preheating the forming die to 100-120 DEG C, pouring the polyurethane elastomer into the forming die, and demolding after gelling to form a planar screen; curling the planar screen and heating to 100-120 DEG C, and smearing the polyurethane elastomer to an abutted surface of the drum screen to reinforce and bond at the temperature; and then, vulcanizing the drum screen at the temperature of 100-120 DEG C, and preserving the heat for 16-24h to obtain a product. The industry and mining drum screen with high wear resistance and high screening rate is integrally molded, the traditional rubber punched screen plates, the rubber molded outlet type screen plates and the traditional pourable polyurethane screen plates are effectively avoided, so that the problem of screening rate reduction caused by manufacturing the traditional screen part by part is avoided.

Owner:LUOYANG CHENGCHUANG WEAR RESISTANT MATERIALS

Preparation method of papermaking retention agent

InactiveCN109763376AHigh retention performanceImprove adsorption capacityNon-macromolecular organic additionVegetable material additionFiberPartial hydrolysis

The invention relates to a preparation method of a papermaking retention agent, and belongs to the technical field of papermaking assistants. According to the preparation method, cellulose, hemicellulose, lignin and other components are extracted from maize leaves and bagasse, the fiber surfaces are partially hydrolyzed to form complexing adsorption and ionic bond adsorption with iron ions which are added later and form adsorption effects of covalent bonds, intermolecular force and other chemical bonding force with starch, thus bonding degree between all molecules of the retention agent is increased, and the retention effect is improved; and according to the preparation method, the starch is introduced into the retention agent and subjected to oxidation modification and carboxyl modification, thus oxhydryl groups on the surface of the starch are substituted by carboxyl groups, starch molecules are easily combined with fine fibers in wood pulp through a reaction between carboxyl and oxhydryl to generate covalent bonds, firm absorption combination is achieved, thus the retention effect of the retention agent is enhanced, adsorption to the plant fibers and bonding to the external finefibers and the wood pulp are promoted, the retention effect of the retention agent is enhanced, and thus the papermaking retention agent has wide application prospects.

Owner:常州麒通国际贸易有限公司

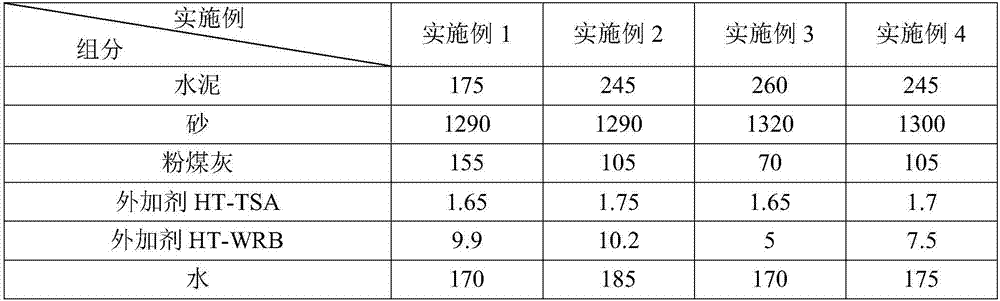

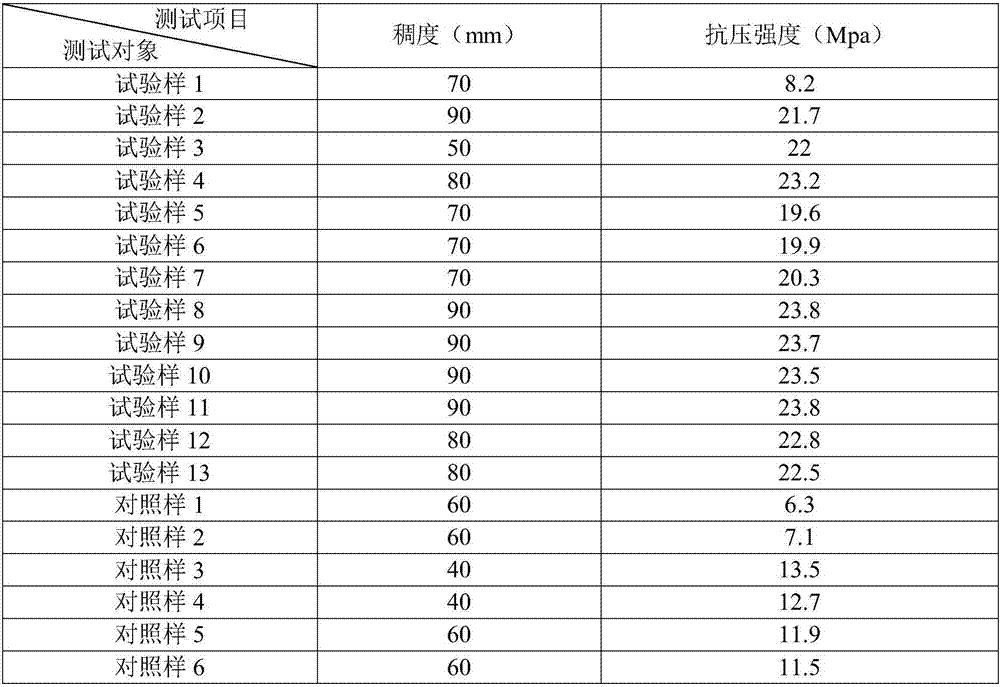

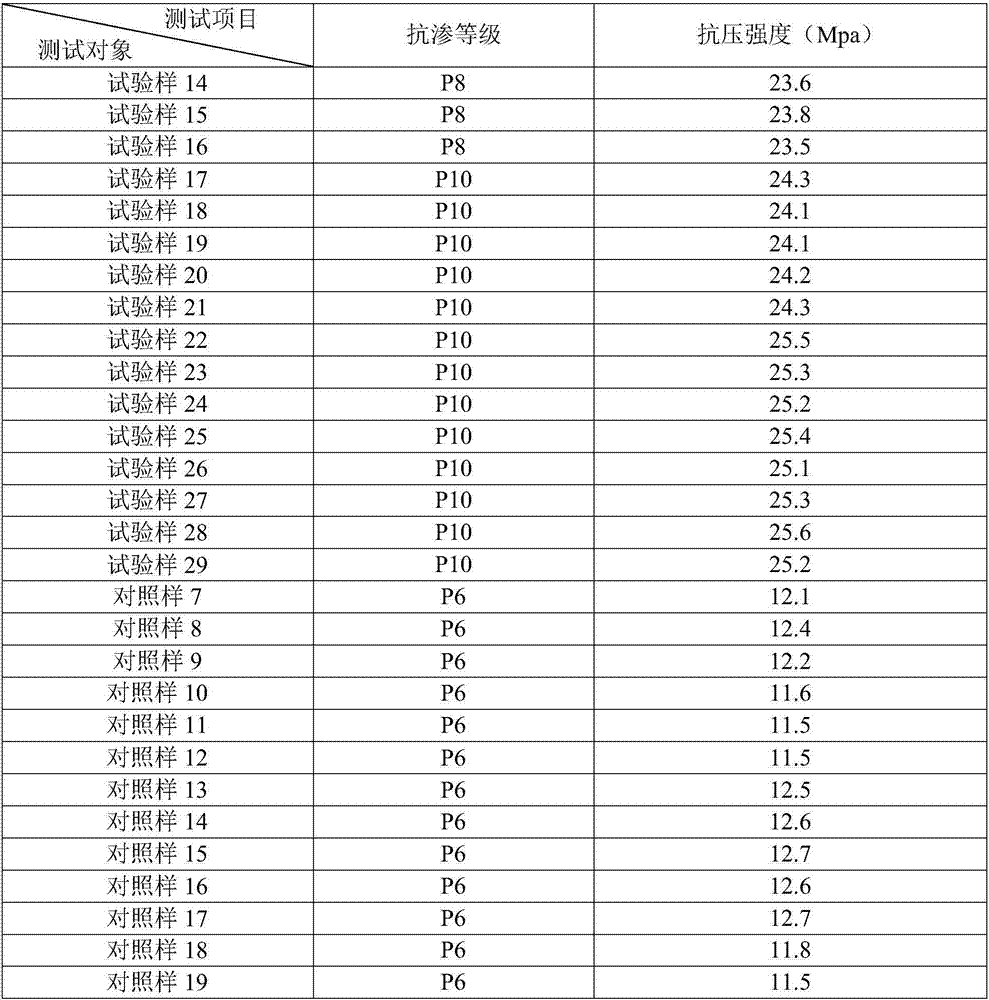

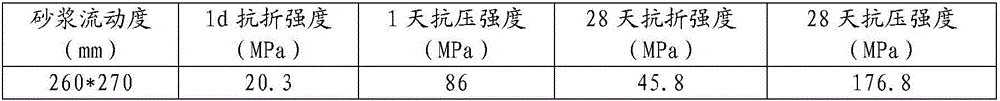

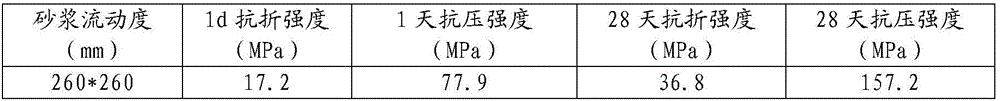

Mortar

The invention discloses a mortar which contains the following components in parts by weight: 170-260 parts of cement, 1290-1320 parts of sand, 76.65-166.95 parts of mixed material and 170-185 parts of water; the fineness modulus of the sand is 2.5-2.7; the mixing ratio of cement to sand to mixed material to water is 1:(5.08-7.37):(0.27-0.89):(0.65-0.97); the mixed material contains at least one of coal ash, additive HT-TSA and additive HT-WRB. The mortar has the advantages of excellent liquidity and higher pressing resistance after final setting.

Owner:广州超力混凝土有限公司

Organic light emitting device and preparation method thereof

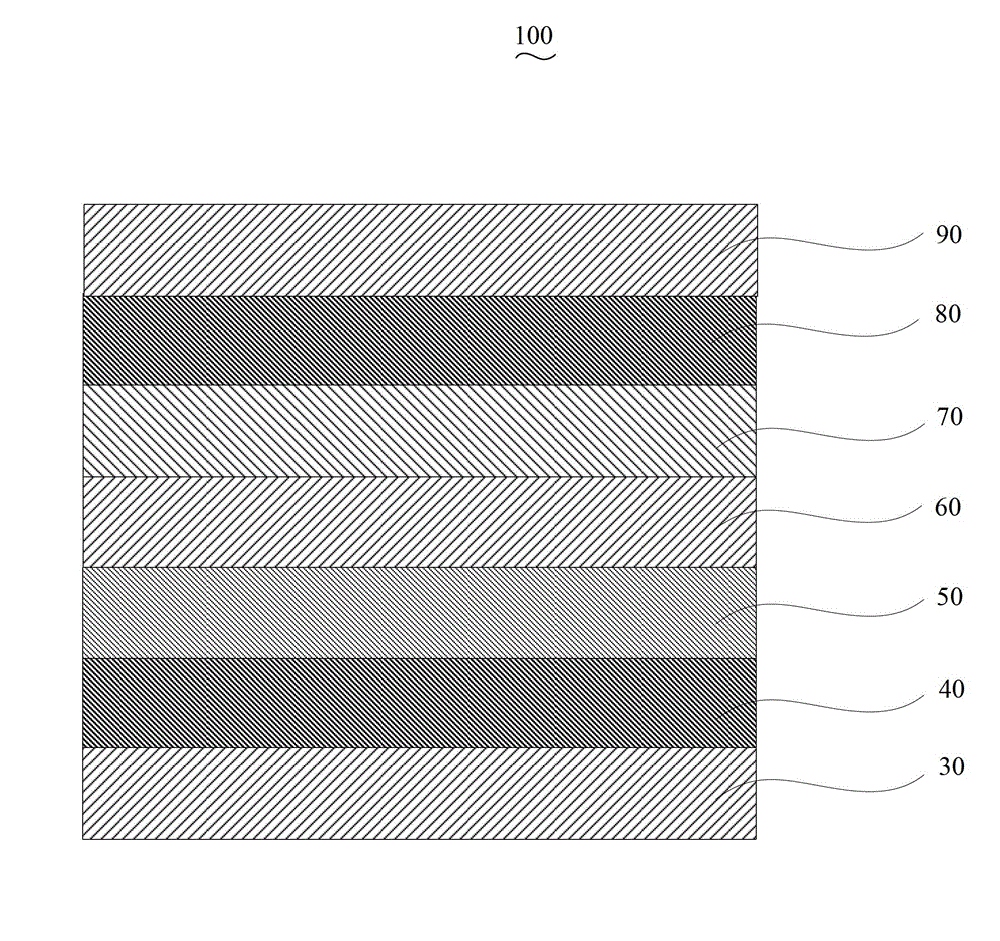

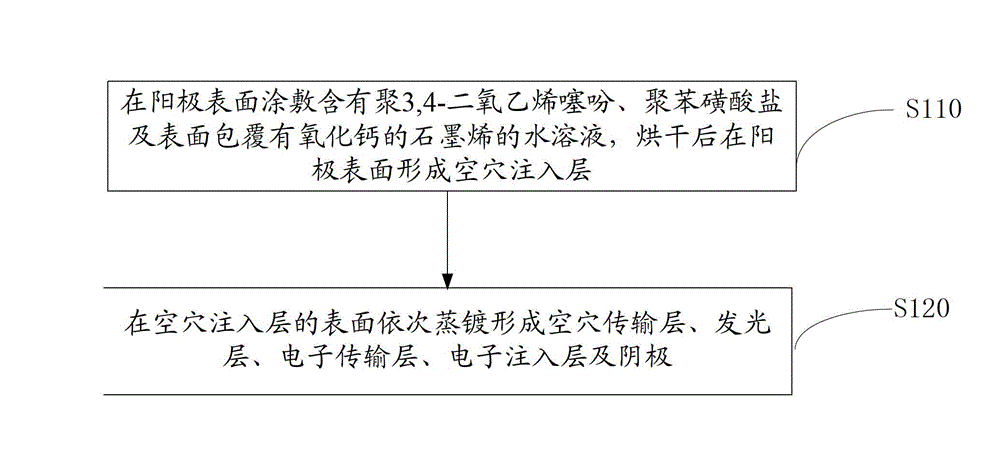

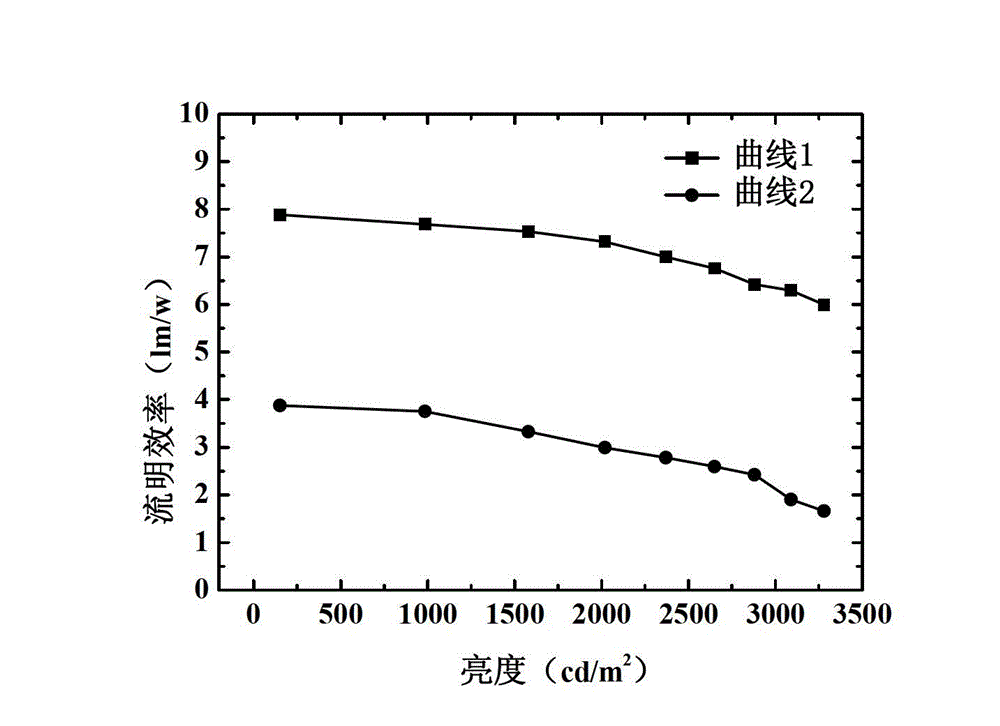

InactiveCN104037341AImproved hole injection performanceIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic light emitting device

An organic light emitting device comprises an anode, a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode which are sequentially stacked. The materials of the hole injection layer include poly(3,4-ethoxylene dioxy thiophene), polystyrene sulfonate, and grapheme coated with calcium oxide, wherein the mass ratio of polystyrene sulfonate to poly(3,4-ethoxylene dioxy thiophene) is 1:2 to 1:6, and the mass ratio of grapheme coated with calcium oxide to poly(3,4-ethoxylene dioxy thiophene) is 1:100 to 1:10. The light emitting efficiency of the organic light emitting device is high. The invention further provides a preparation method of the organic light emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Recycled concrete with added polypropylene fibers and preparation method of recycled concrete

The invention discloses recycled concrete with added polypropylene fibers. The polypropylene fibers are added to concrete in a ratio, and the effect of fine distribution of reinforcement can be realized; furthermore, the polypropylene fibers can be blended with a cement material very well, so that fine distribution effect is realized; on the basis of the characteristics of a large number and a large specific surface area of the polypropylene fibers, the polypropylene fibers can be uniformly distributed in concrete to form a three-dimension space net structure, the aggregate supporting effect is realized, therefore, anti-cracking performance of the concrete is improved, sedimentation of coarse and fine aggregate is prevented, pore channels in the concrete are reduced, and the polypropylenefibers can inhibit crack propagation of the concrete. Mechanical properties and durability of the concrete can be affected by addition of recycled coarse aggregate, and due to the fact that the polypropylene fibers can change the pore structure in the recycled concrete, the polypropylene fibers produce beneficial effects on strength and durability of the recycled concrete.

Owner:CHANGAN UNIV

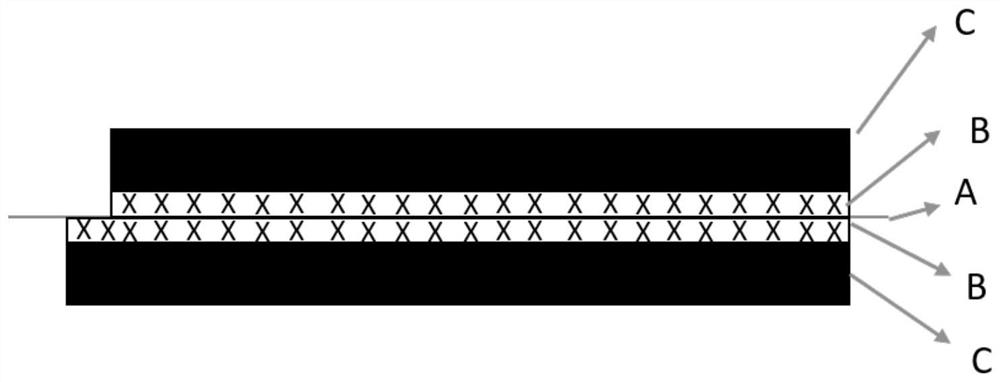

High-workability high-toughness concrete and preparation method thereof

ActiveCN106348685AImprove work performanceHigh workability and high toughnessFiberUltimate tensile strength

The invention discloses a high-workability high-toughness concrete and a preparation method thereof, belonging to the technical field of construction materials. The invention aims to solve the problems of low toughness and poor workability in the existing ultrahigh-performance concrete. The high-workability high-toughness concrete is prepared from cement, high-strength fibers, a nano material, medium sand, an additive and water according a certain proportion at normal temperature. A calcium silicate hydrate gel solution water reducing agent introduced as the additive effectively increases the early strength of the high-workability high-toughness concrete, enhances the binding degree between the fibers and mortar matrix and enhances the binding effects, thereby effectively enhancing the concrete ductility. Besides, the high-toughness concrete has the characteristics of lower nano material doping amount and low water consumption, thereby being beneficial to enhancing the concrete strength. The additive has the advantages of controllable doping amount and favorable adaptability to the nano material, so the concrete has the advantages of low viscosity, low isolation tendency, favorable flowability, favorable stability and favorable plasticity.

Owner:SHANGHAI CONSTRUCTION GROUP

Production technology of easily-tearing packaging bag

ActiveCN104118136AImprove the degree of adhesionReduce manufacturing costBox making operationsPaper-makingHot stampingFiber

The invention provides a production technology of an easily-tearing packaging bag. The technology comprises the following steps that (1) plant fiber paper is arranged in a covering mode; (2) cooling is carried out; (3) printing is carried out; (4) film covering is carried out; (5) oil coating is carried out; (6) hot stamping is carried out; (7) the packaging bag is packaged; (8) mounting is carried out; (9) sealed edge folding is carried out; (10) line cutting is carried out; and (11) after an object is contained in an unsealed packaging bag, the back face of a convex strip paper is sealed on the inner side of the back face of the bag body in a hot-seal mode, the top end of a bag body is subjected to hot sealing, and the temperature of hot sealing is 120-180 DEG C. According to the production technology, a flat-pressing technology is used, production cost can be lowered, subsection cooling is set, so that buffering cooling effect is achieved first, time is saved, efficiency is improved, the bonding degree of the plant fiber paper and a PE film is improved, cost can be lowered by room temperature cooling, the defective rate of products is lowered, the cost of raw materials is saved, namely cost increasing caused by tone-determining layout page using is avoided, cost increasing caused by hard plastic pulling strip using is avoided, and accordingly resource waste and environment pollution are reduced.

Owner:江苏华港医药包装有限公司

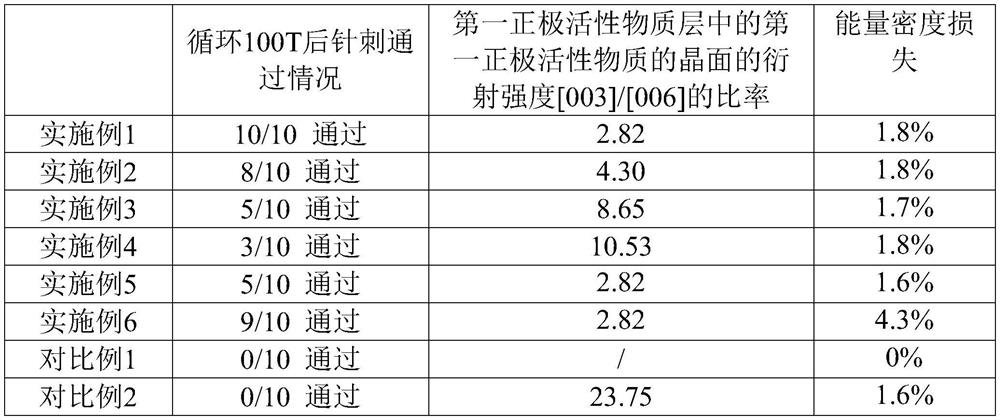

Positive pole piece and preparation method and application thereof

ActiveCN111900343AImprove acupuncture pass rateImprove securitySecondary cellsPositive electrodesEngineeringPole piece

The invention provides a positive pole piece and a preparation method and application thereof. The surface of the positive electrode current collector is coated with the lithium cobalt oxide positiveelectrode active material containing small particles as the first positive electrode active material layer in a double-layer coating manner, and the use of the first positive electrode active materiallayer can effectively improve the needling passing rate of the high-voltage system battery cell; the double-layer coating method is simple in process, secondary coating is not needed, and the production time can be saved; according to the method, on the premise that the needling safety is greatly improved, the energy density loss is smaller than 2%.

Owner:ZHUHAI COSMX BATTERY CO LTD

High-strength regenerated concrete doped with waste cable and preparation method thereof

The invention discloses high-strength regenerated concrete doped with a waste cable. Every cubic meter of regenerated concrete is prepared from the following raw materials by weight: 168-180 kg of water, 300kg-330kg of cement, 63-70kg of ultrafine mineral powder, 63-70kg of coal ash, 860-900kg of fine aggregates, 560-600kg of regenerated coarse aggregates, 560-600 kg of natural coarse aggregates,4.3-9.4 kg of water reducer, 85.2-141g of air entraining agent and 4.3-7.1kg of waste cable. A preparation method comprises the following steps: sequentially pouring 50% of the total tap water, the regenerated coarse aggregates, the natural coarse aggregates, the fine aggregates and the waste cable into a concrete stirrer; pouring the ultrafine mineral powder and the coal ash into the stirrer; adding the cement; dissolving the air entraining agent and the water reducer into the rest of the 50% of tap water, and pouring into the stirrer; and unloading the stirred novel concrete onto a steel plate, and stirring to obtain the regenerated concrete.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com