Crack filler

A pointing agent and curing agent technology, applied in the field of pointing agents, can solve the problems of poor waterproofness, non-application, peeling, peeling, etc., and achieve good viscosity, good wear resistance, and uniform mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

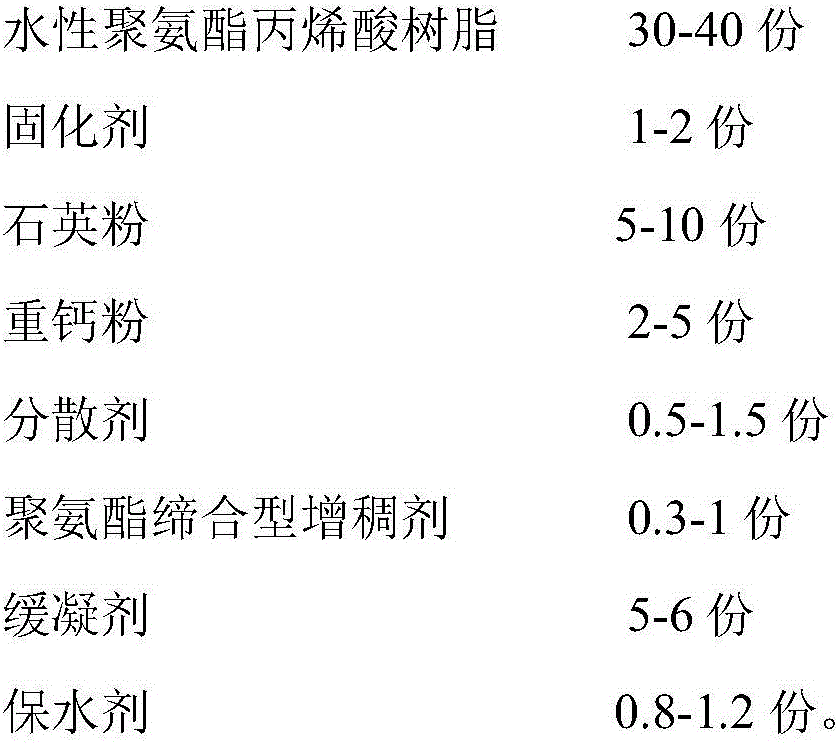

[0030] Step 1: Weigh 30 parts of water-based polyurethane acrylic resin, 1 part of aluminum sulfate, 5 parts of quartz powder, 2 parts of heavy calcium powder, 0.5 part of sodium p-allyloxybenzene sulfonate, polyurethane associative type 0.3 parts of thickener, 5 parts of sodium dipolyphosphate, 0.8 parts of hydroxypropyl methylcellulose;

[0031] Step 2: First, add aluminum sulfate, quartz powder, heavy calcium powder, and water-based polyurethane acrylic resin into the mixer and stir until uniform;

[0032] Step 3: add p-allyloxybenzene sodium sulfonate and sodium dipolyphosphate to mixer and continue to stir;

[0033] Step 4: Finally, add polyurethane associative thickener and hydroxypropyl methylcellulose into the mixer and continue stirring. The stirring speed of the mixer is controlled at 1000r / min, and the material is discharged after stirring for 20 minutes.

Embodiment 2

[0035]Step 1: Weigh 32 parts of water-based polyurethane acrylic resin, 1.2 parts of organic bentonite, 6 parts of quartz powder, 3 parts of heavy calcium powder, 0.7 parts of sodium p-methallyloxybenzene sulfonate, polyurethane association Type thickener 0.5 parts, sodium hydroxycarboxylate gluconate 5 parts, methyl cellulose 0.9 parts, aluminum stearate 1 part, nano silver 1 part, glass fiber 1 part;

[0036] Step 2: First, add organic bentonite, quartz powder, heavy calcium powder, and water-based polyurethane acrylic resin into the mixer and stir until uniform;

[0037] Step 3: Add p-methallyloxybenzene sodium sulfonate and sodium hydroxycarboxylate gluconate to the mixer and continue stirring;

[0038] Step 4: Finally, add polyurethane associative thickener, methyl cellulose, aluminum stearate, nano-silver and glass fiber to the mixer and continue stirring. The stirring speed of the mixer is controlled at 1050r / min, and the mixture is stirred for 20 minutes. material.

Embodiment 3

[0040] Step 1: Weigh 34 parts of water-based polyurethane acrylic resin, 1.4 parts of aluminum sulfate, 7 parts of quartz powder, 3.5 parts of heavy calcium powder, 0.9 parts of sodium p-allyloxybenzene sulfonate, polyurethane associative type 0.6 parts of thickener, 5.4 parts of titanium white slag, 1 part of hydroxypropyl methylcellulose, 1.3 parts of aluminum stearate, 1.3 parts of nano silver, 1.6 parts of boron fiber;

[0041] Step 2: First, add aluminum sulfate, quartz powder, heavy calcium powder, and water-based polyurethane acrylic resin into the mixer and stir until uniform;

[0042] Step 3: Add p-allyloxybenzene sodium sulfonate and titanium white slag to the mixer and continue stirring;

[0043] Step 4: Finally, add polyurethane associative thickener, hydroxypropyl methylcellulose, aluminum stearate, nano-silver and boron fiber to the mixer and continue stirring. The stirring speed of the mixer is controlled at 1050r / min, stirring 20 minutes to discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com