Perovskite-type substance La<1-x>Sr<x>CrO<3>, heat-engine plant denitration composite catalyst, and preparation methods of perovskite-type substance La<1-x>Sr<x>CrO<3> and heat-engine plant denitration composite catalyst

A composite catalyst and perovskite-type technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as unfavorable industrial production and complicated processes, Achieve high plasticity, improve extrusion molding process, and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of active liquid is to adopt ammonium metavanadate, ammonium tungstate to dissolve in oxalic acid solution to obtain active liquid, the concentration (mass ratio) of oxalic acid solution is 10%, the quality of ammonium metavanadate, ammonium tungstate and oxalic acid solution The ratio is 10:16:55.

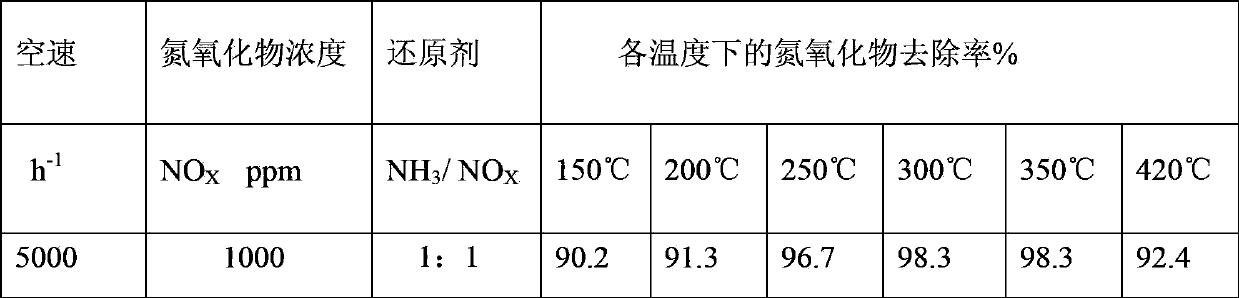

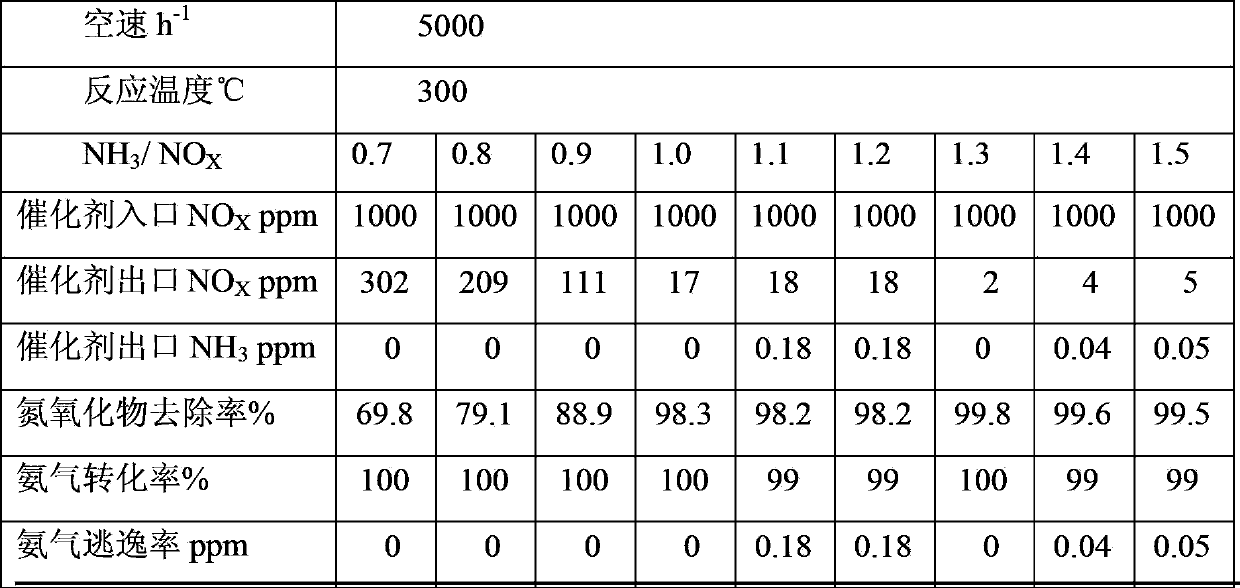

[0050] According to the flue gas composition of the simulated thermal power plant, the flue gas composition is 1000ppm of nitric oxide, 700-1500ppm of ammonia, and 5-7% of nitrogen. The denitrification catalyst sample prepared by the above method is tested for the purification effect of simulated exhaust gas.

[0051] Utilize the method of the present invention to obtain a typical example: a kind of anatase titanium dioxide prepared according to the above method is a denitration catalyst as a raw material, and the prepared denitration catalyst has a product size of 40mm × 40mm × 40mm, and a pore density of 3 pores / cm 2 , pitch 7.4mm. According to the i...

Embodiment 1

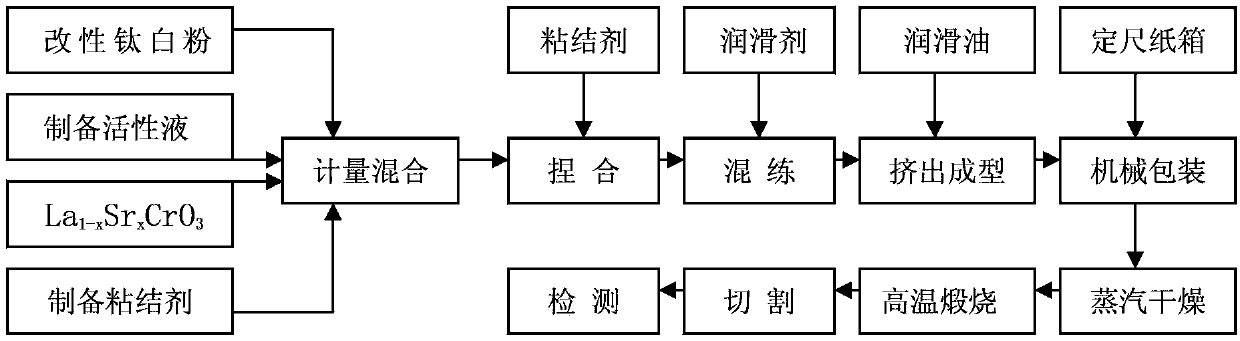

[0059] The method for preparing a thermal power plant denitrification composite catalyst with anatase titanium dioxide as a substrate comprises the following sequential steps:

[0060] Step 1: preparing modified titanium dioxide, comprising the following steps:

[0061] Anatase titanium dioxide is added to water to prepare a suspension with a concentration of 1% by weight; sodium hexametaphosphate is added to the suspension as a dispersant, and the amount of sodium hexametaphosphate added is 0.1% of the weight of titanium dioxide. After 10 minutes, the mixed slurry was obtained; then the mixed slurry was heated to 60°C, and sodium silicate solution was added dropwise to the mixed slurry, wherein sodium silicate was used as the precursor of nano-scale silicon dioxide, and the dropping amount of sodium silicate 0.1% of the weight of titanium dioxide, then drop dilute sulfuric acid into the mixed slurry, adjust the pH value of the mixed slurry to 8, and then age the mixed slurry ...

Embodiment 2

[0079] The method for preparing a thermal power plant denitrification composite catalyst with anatase titanium dioxide as a substrate comprises the following sequential steps:

[0080] Step 1: preparing modified titanium dioxide, comprising the following steps:

[0081] Anatase titanium dioxide is added to water to prepare a suspension with a concentration of 5% by weight; sodium hexametaphosphate is added to the suspension as a dispersant, and the amount of sodium hexametaphosphate added is 0.25% of the weight of titanium dioxide. After 15 minutes, the mixed slurry was obtained; then the mixed slurry was heated to 75°C, and sodium silicate solution was added dropwise to the mixed slurry, wherein sodium silicate was used as the precursor of nano-scale silicon dioxide, and the amount of sodium silicate added 0.3% of the weight of titanium dioxide, then drop dilute sulfuric acid into the mixed slurry, adjust the pH value of the mixed slurry to 9, and then age the mixed slurry fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com