Patents

Literature

51results about How to "Reduce crack phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

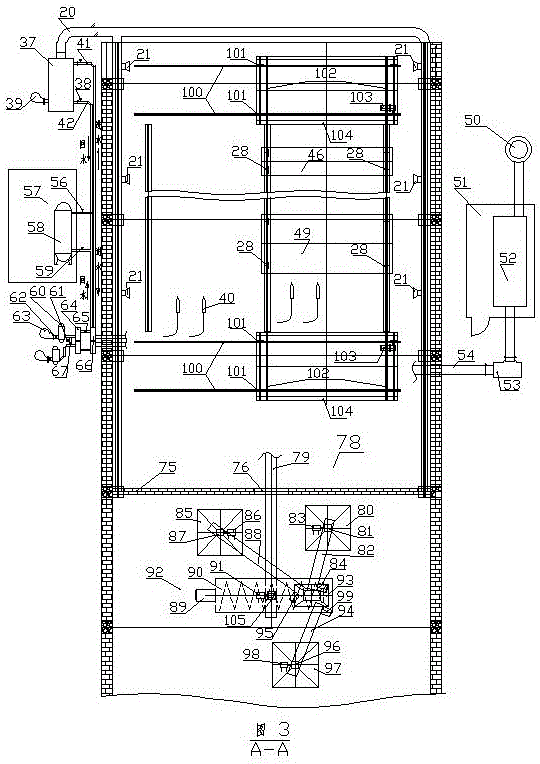

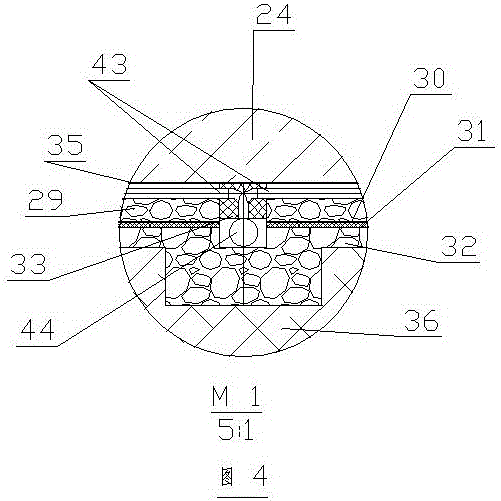

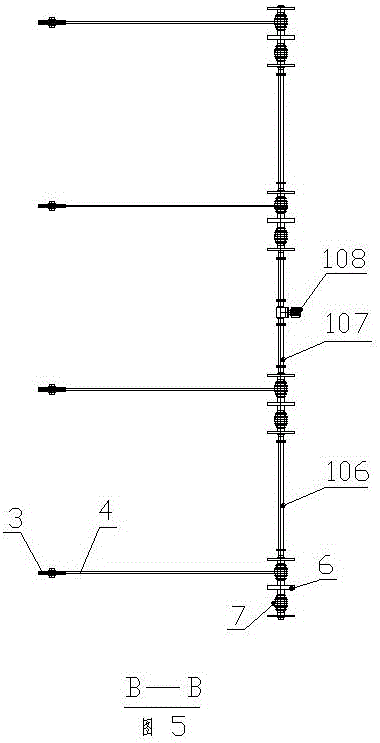

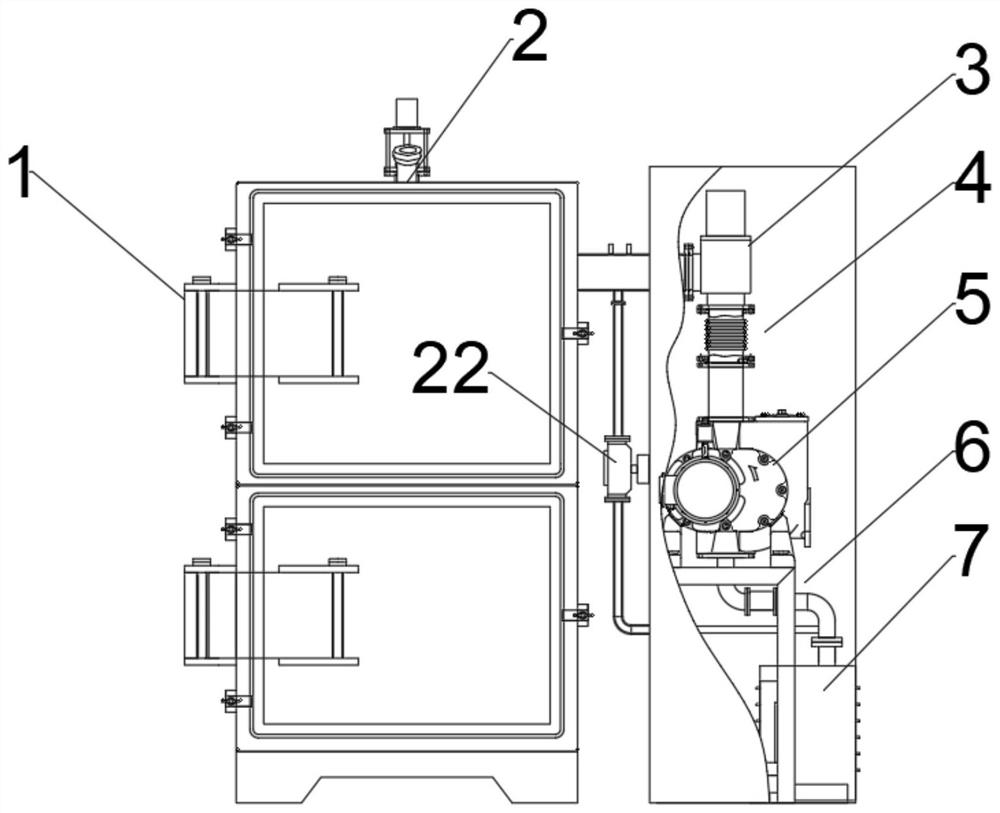

Process equipment for composting and rapid aerobic fermentation of sludge, and automatic control scheme for composting and rapid aerobic fermentation process

ActiveCN106396769AImproving the initial process conditions of aerobic fermentationImprove breathabilityBio-organic fraction processingEnergy inputAutomatic controlProcess equipment

The invention provides process equipment for composting and rapid aerobic fermentation of sludge and an automatic control scheme for a composting and rapid aerobic fermentation process, belonging to the technical field of composting and aerobic fermentation of sludge. The process equipment and automatic control scheme provide optimal initial process conditions for microbial propagation in composting and aerobic fermentation of sludge, enable composting and aerobic fermentation of sludge to rapidly enter a high-temperature fermentation period, accelerate the processes of fermentation and decomposition, shorten a fermentation period, reduce cost and exert beneficial effect on reduction, harmless treatment and stabilization of sludge. The process equipment comprises a solar photovoltaic power generation system, fermentation tanks with in-ground insulation and heating functions, a gas collecting cover having aeration and heating functions, used for collecting water vapor and stink produced in the process of fermentation and capable of moving up and down, a biological deodorizing system, an air supply and heating system for a workshop in winter, a travelling crane-like manipulator-operated material distribution machine, a composting heap turner, a data acquisition trolley, displace trolleys, a boiler system and an automatic control system for batching of raw and accessory materials and for process flow.

Owner:阮航 +2

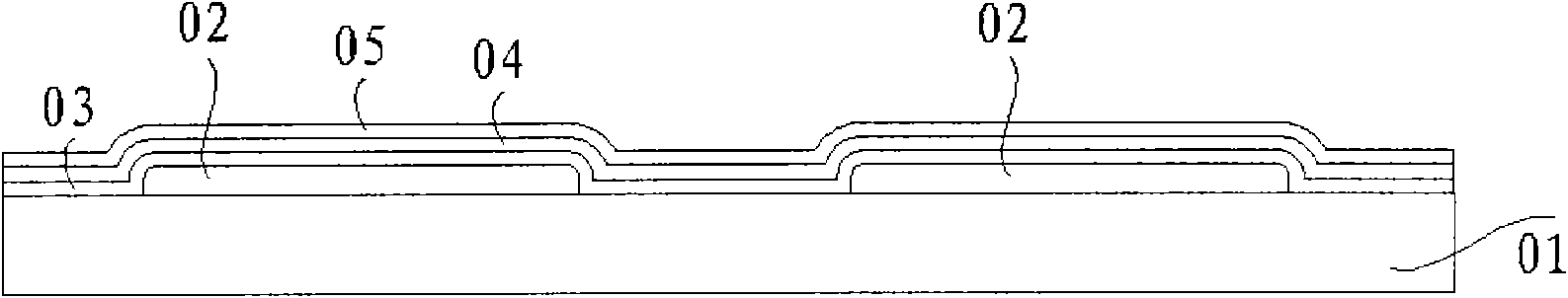

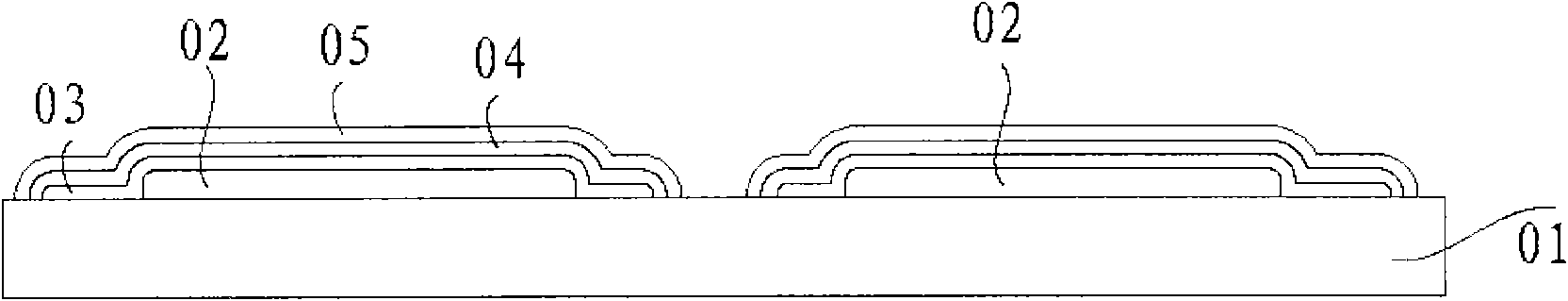

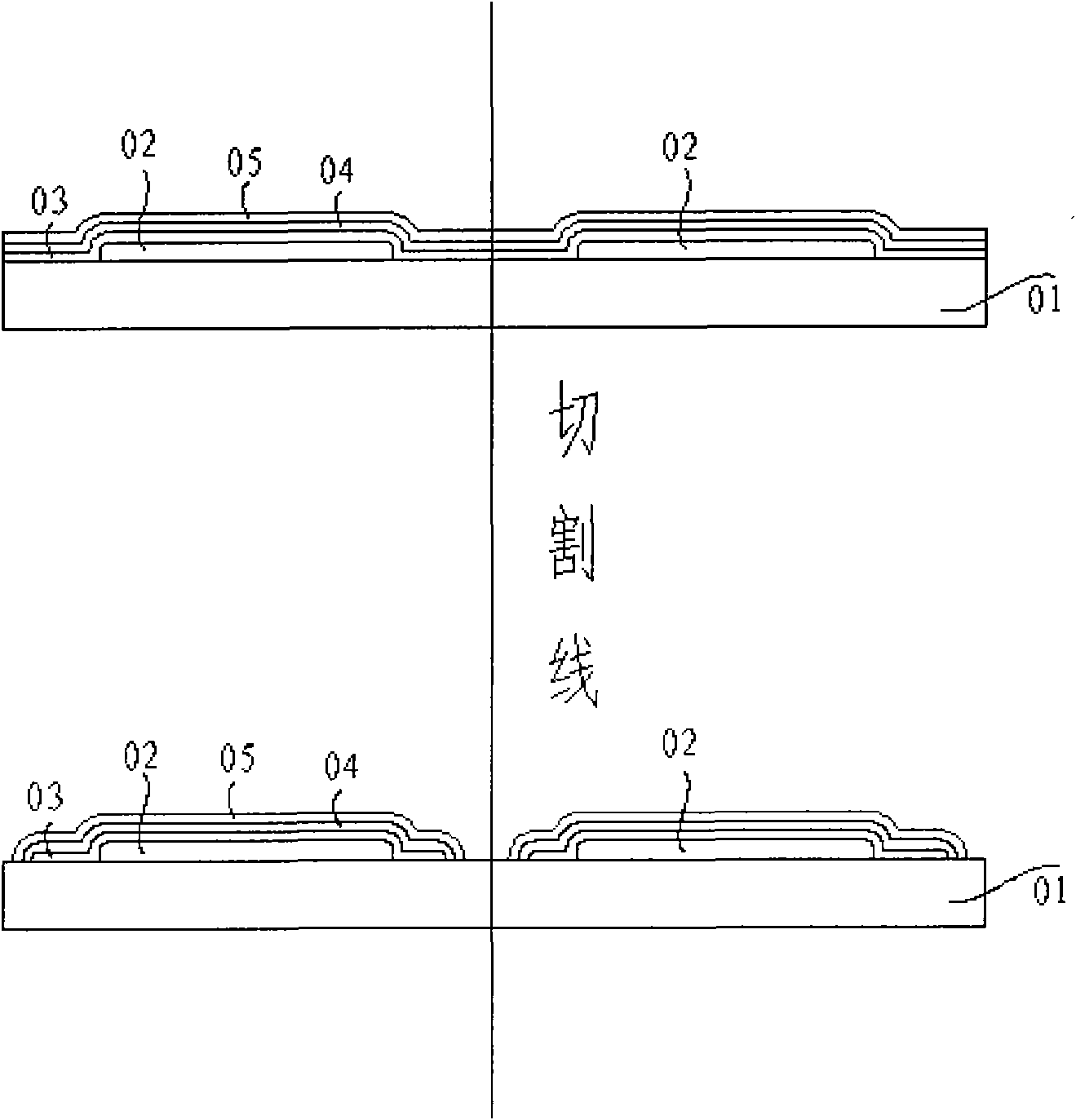

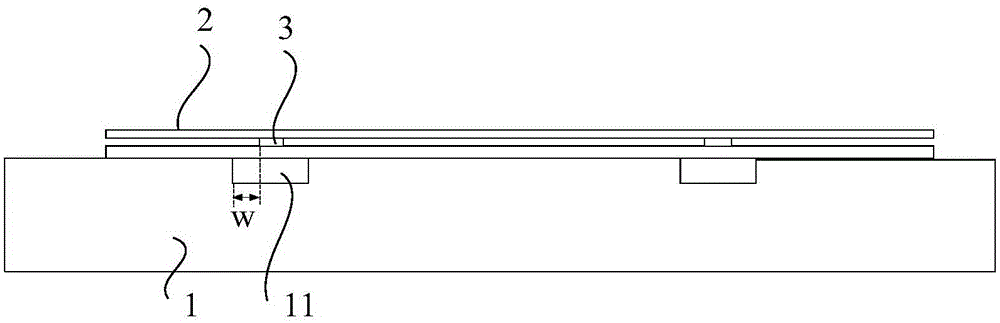

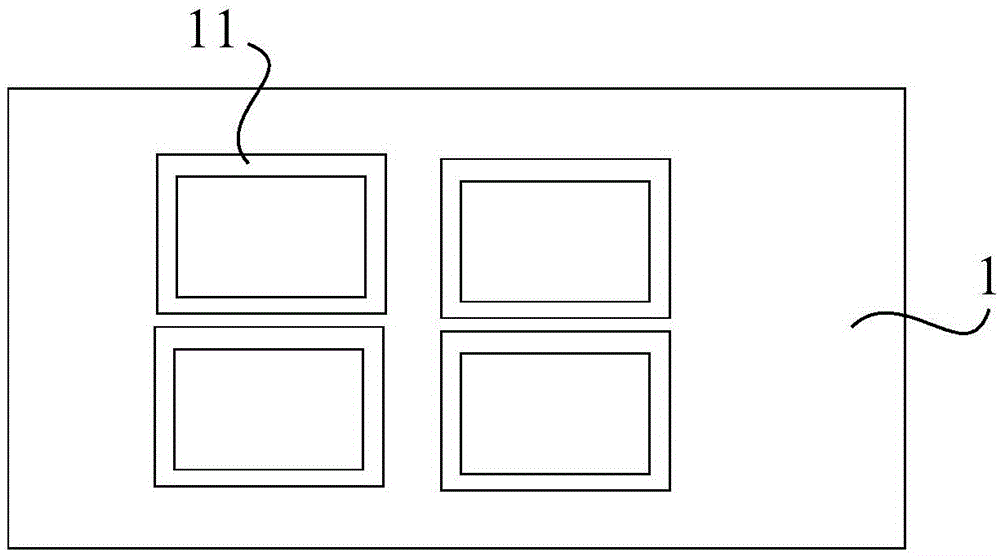

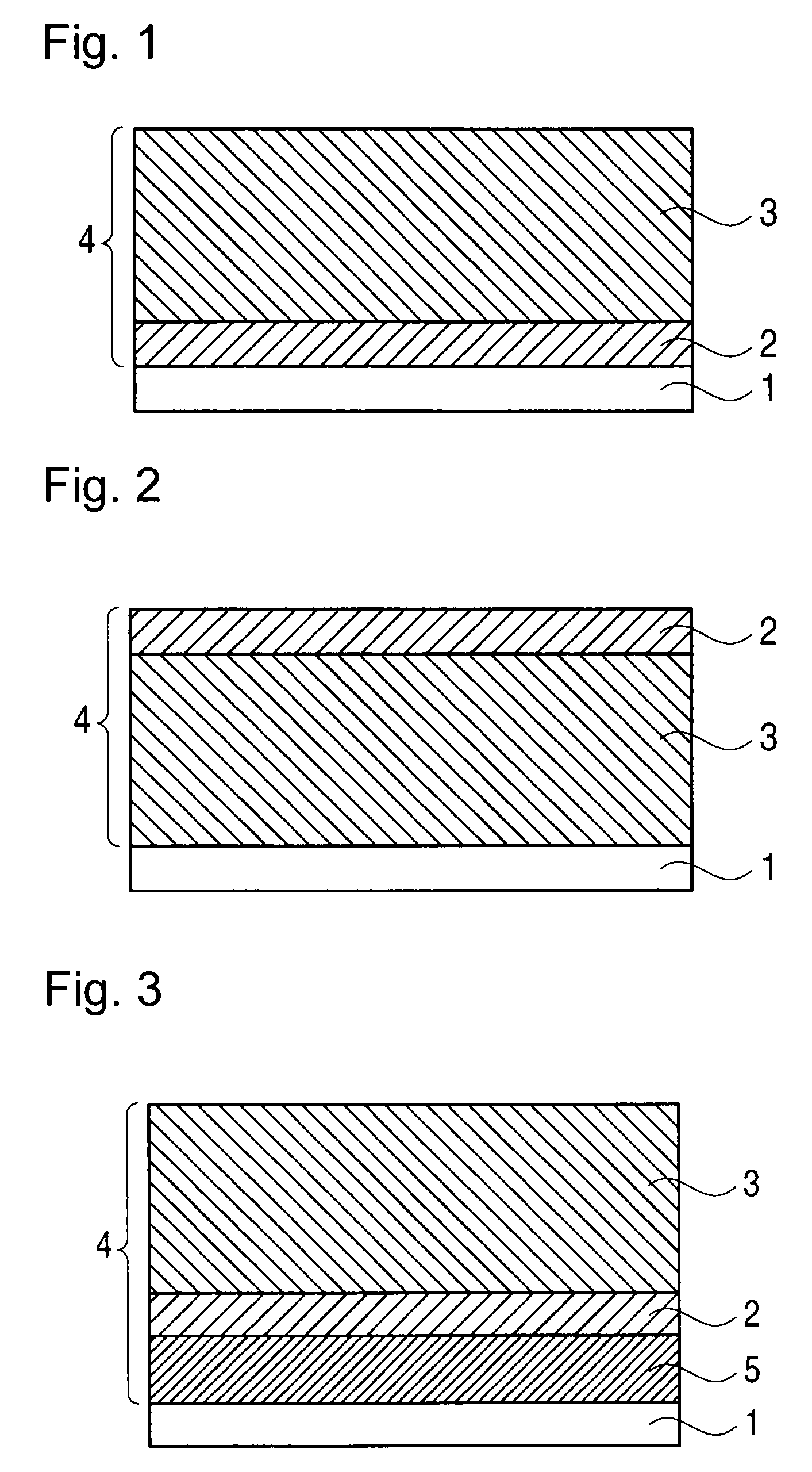

Film packaging method of organic light-emitting device

InactiveCN102610762AReduce crack phenomenonAvoid liftingSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmCrazing

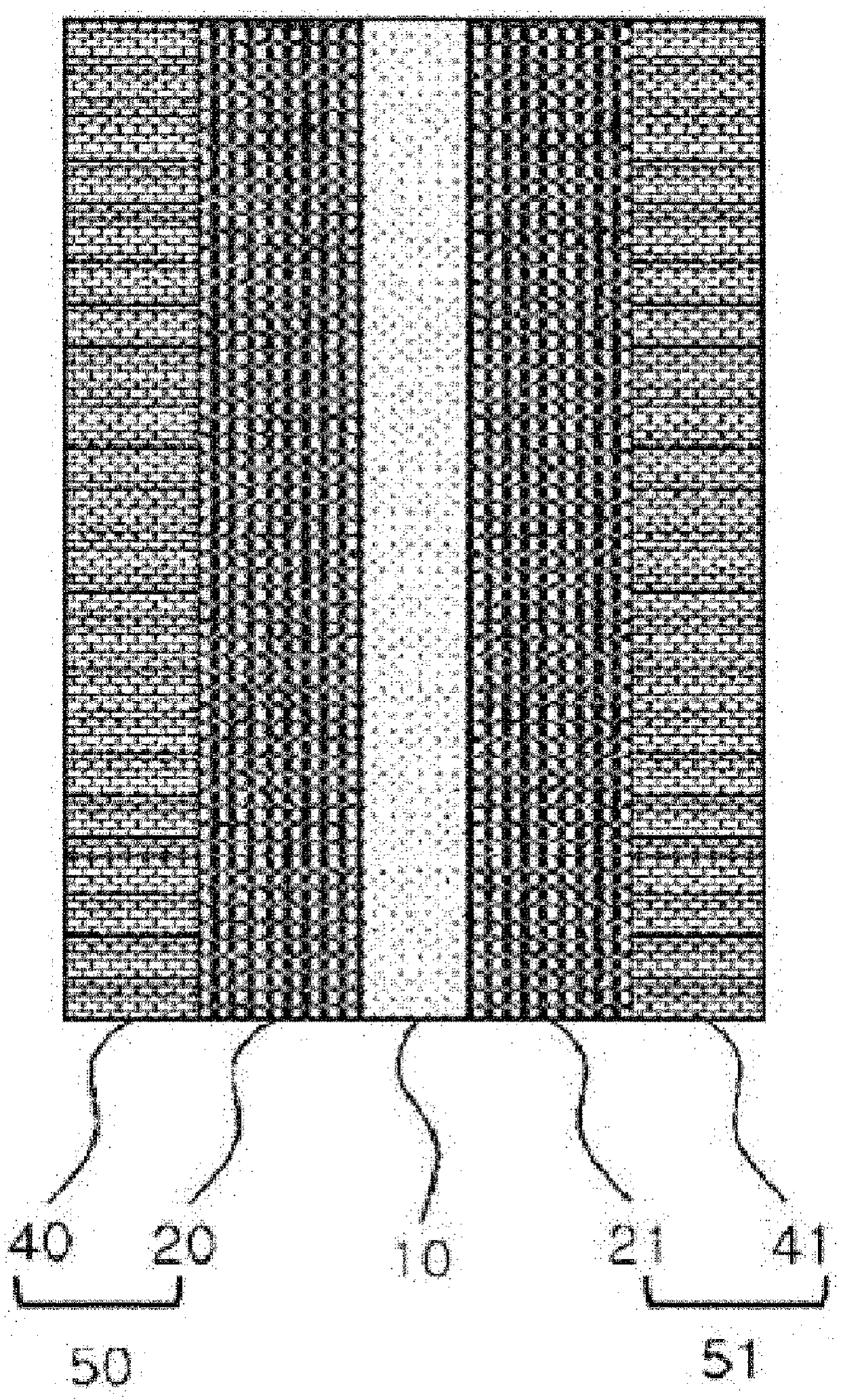

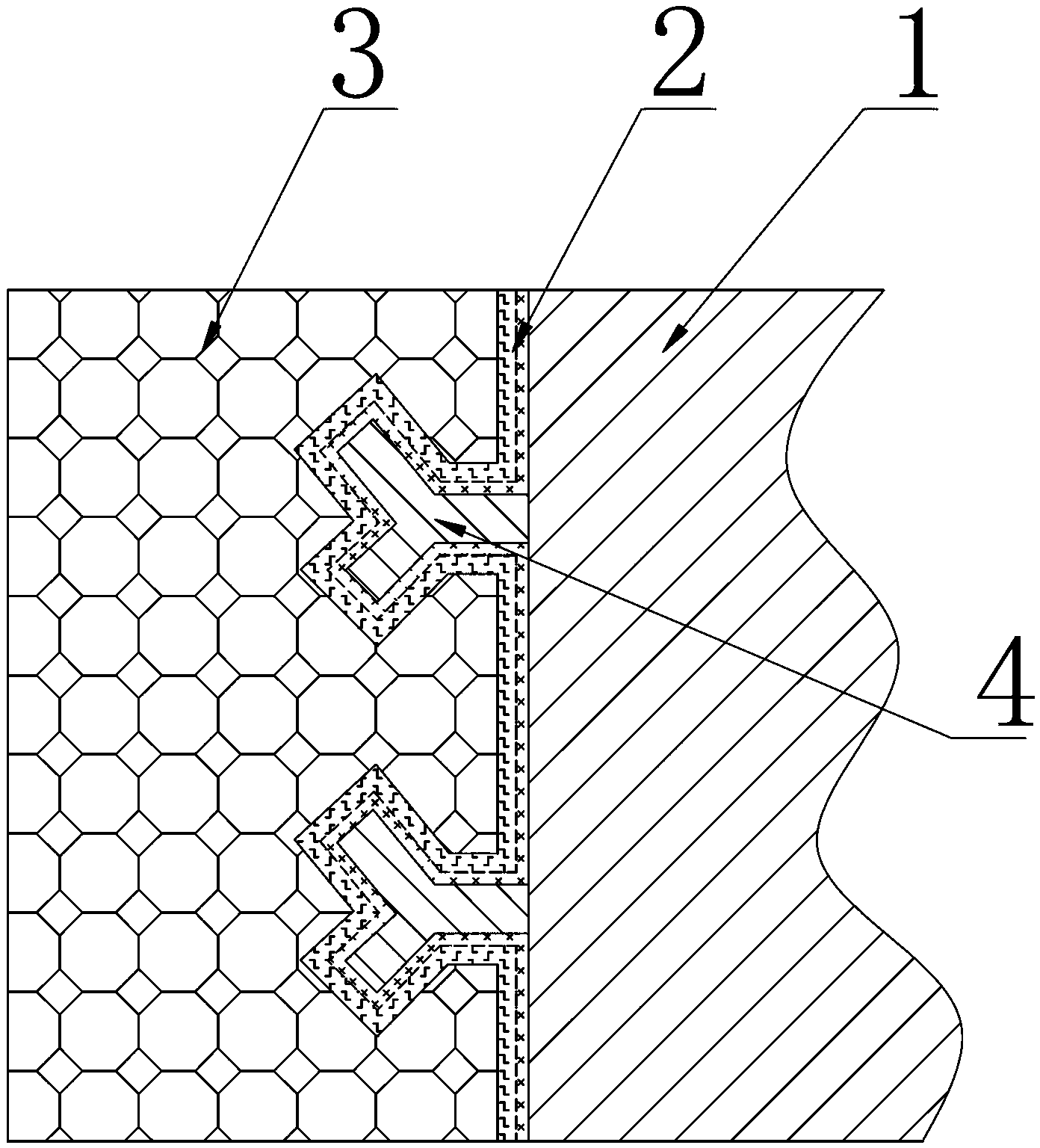

The invention provides a film packaging method of an organic light-emitting device, at least three film sealing layers are deposited on a baseboard from bottom to top, wherein inorganic material and organic material are alternatively deposited on each film sealing layer; a chemical vapor deposition method is preferentially carried out on the organic film sealing layer, and an iron beam sputtering method or an atomic layer deposition method or an magnetron sputtering deposition can be carried out on the inorganic film sealing layer; the early deposited film sealing layer is thinner than the film sealing layer deposited latter; different mask plates are adopted to deposit each film sealing layer, the geometry sizes of the patterns of the mask plates of the first layer, the second layer and the third layer increase sequentially. According to the film packaging method of the organic light-emitting device, the crack caused by plate breaking can be effectively reduced, the space between the sealing layer and the baseboard can be prevented from tilting resulting in air leakage during cutting, and the service life of the device can be effectively prolonged.

Owner:IRICO DISPLAY DEVICES

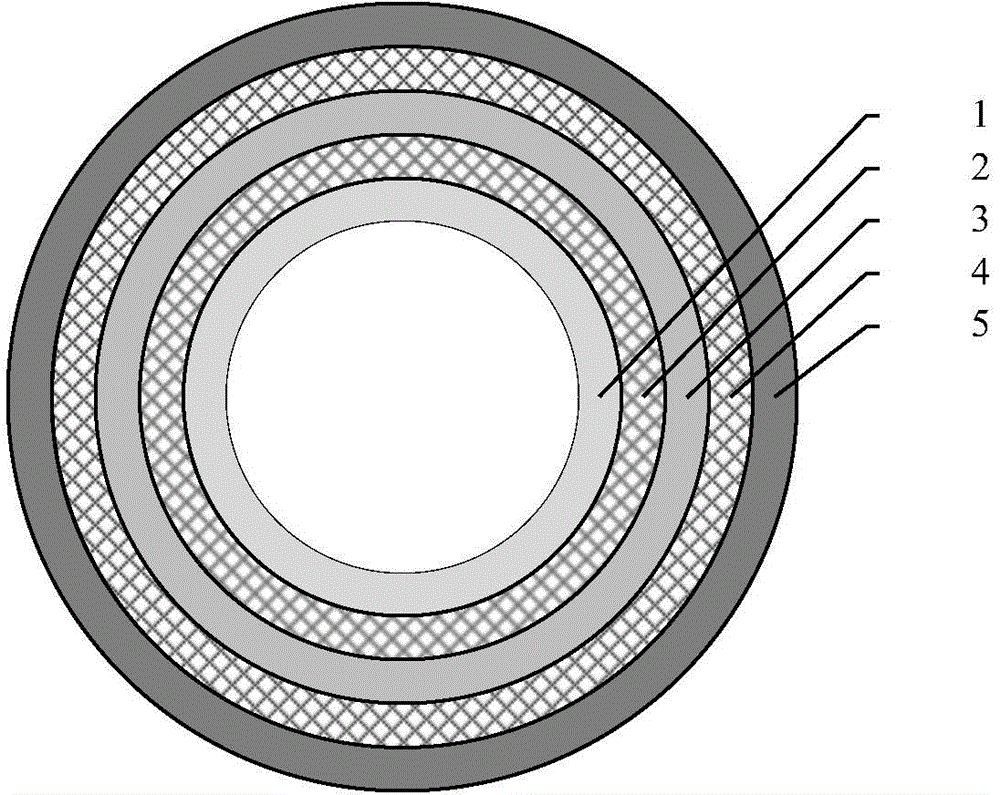

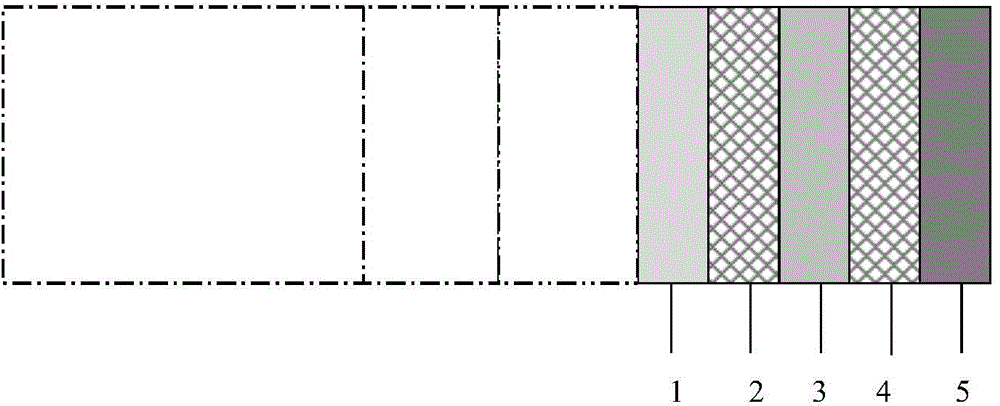

Hydraulic hose

ActiveCN105889659ADelay agingReduce crack phenomenonFlexible pipesActive agentButadiene-styrene rubber

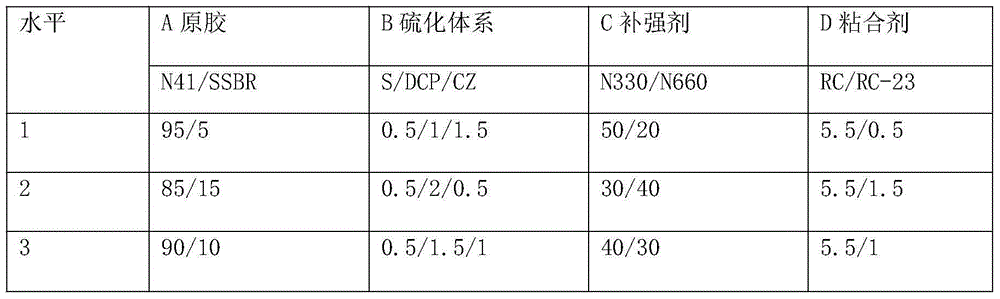

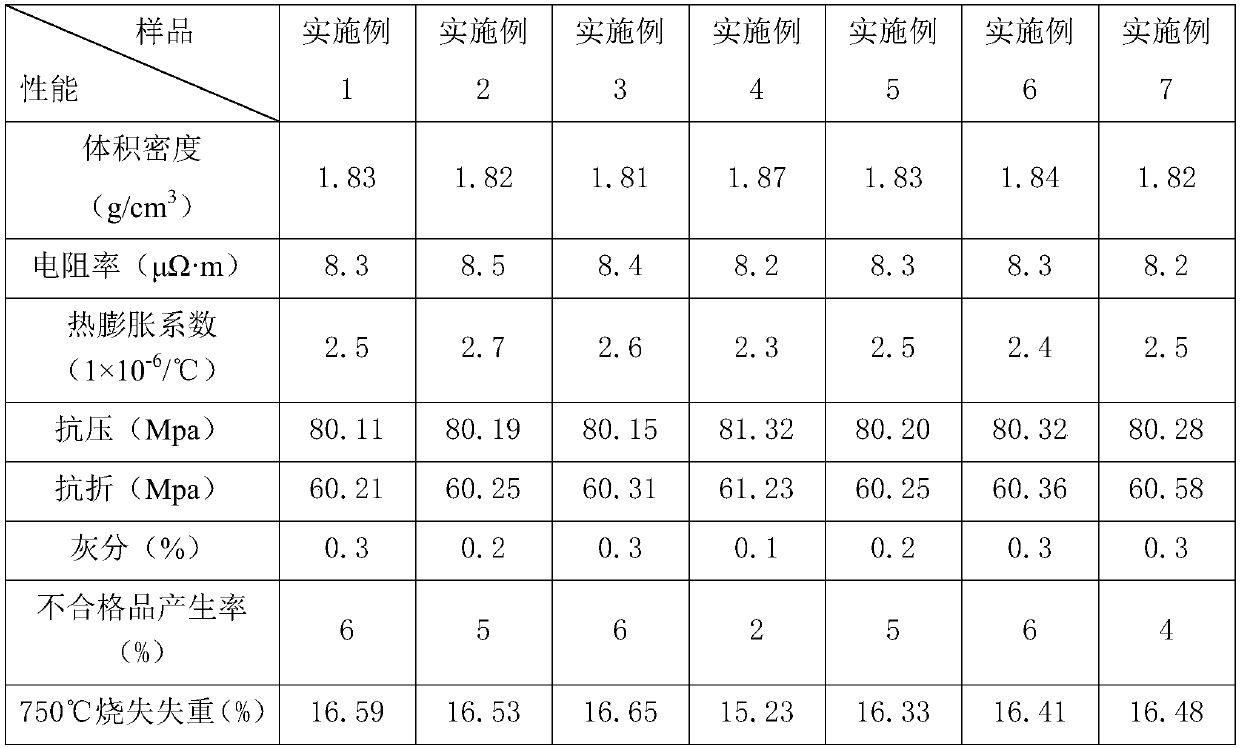

The invention belongs to the technical field of rubber hoses and relates to a hydraulic hose and a preparation method thereof. The hydraulic hose comprises an inner rubber layer, steel wire layers, a middle rubber layer and an outer rubber layer. An inner rubber sheet of the inner rubber layer is prepared from raw materials including, by weight, nitrile rubber N41, solution polymerized styrene-butadiene rubber, sulfur, a crosslinking agent, a promoter, a scorch retarder, an active agent, a bonding agent, a reinforcing agent, a filling agent, an anti-aging agent, a plasticizer and a processing aid. A middle rubber sheet of the middle rubber layer is prepared from raw materials including, by weight, nitrile rubber N41, solution polymerized styrene-butadiene rubber, sulfur, a promoter, an active agent, a bonding agent, a reinforcing agent, a filling agent, an anti-aging agent, a plasticizer and a processing aid. An outer rubber sheet of the outer rubber layer is prepared from raw materials including, by weight, nitrile rubber N41, rubber-plastic alloy, sulfur, a crosslinking agent, a promoter, an active agent, a bonding agent, a reinforcing agent, a filling agent, an anti-aging agent, a plasticizer and a processing aid. The hydraulic hose can be used within the temperature range from -45 DEG C to 150 DEG C.

Owner:河南汇龙液压科技股份有限公司

High-strength graphite product produced by adding pitch coke, and preparation method thereof

The invention belongs to the technical field of preparation of graphite products, and particularly relates to a high-strength graphite product produced by adding pitch coke, and a preparation method thereof, wherein the high-strength graphite product comprises an aggregate and a binder, the aggregate is pitch coke and calcined coke, the binder is coal tar pitch, and a mass ratio of the pitch coketo the calcined coke to the binder is 28-32%:48-52%:18-22%. According to the present invention, the strength of the graphite product is increased by adding pitch coke, wherein the pitch coke has highstrength, the crushed pitch coke and the calcined coke are used as the dry material so as to substantially improve the strength of the graphite product; and the raw materials of the graphite product contain the pitch, and the pitch can be carbonized and coked after roasting, such that only the strength of the graphite product added with the pitch coke can be increased while the change of other indexes cannot be affected, the occurrence of cracks and other unqualified products is low, and the high-temperature oxidation resistance is strong.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Silicon-and-magnesium-containing aluminum alloy sheet for air-conditioning radiator and preparation method of silicon-and-magnesium-containing aluminum alloy sheet

The invention relates to a silicon-and-magnesium-containing aluminum alloy sheet for an air-conditioning radiator. The silicon-and-magnesium-containing aluminum alloy sheet comprises the following chemical elements by mass percent: 0.25-0.35% of Si, 0.48-0.55 of Mg, 0.01-0.02 of Cr, 0. 05-0.15 of Fe, 0.01-0.03 of Ti, 0.01-0.03 of Cu, 0.005-0.02 of La, and the balance being Al. The aluminum alloy sheet provided by the invention has high strength and toughness, is added with lanthanum, the composition undercooling is carried out during gold casting, crystal grains are refined, a secondary crystal spacing is reduced, gas and inclusions in an alloy are reduced, and an inclusion tends to be nodulized, the surface tension of a melt can also be reduced, the mobility is increased, and ingots are favorably cast. According to a production method provided by the invention, the phenomena of layering, peeling, bubbling and cracking of aluminum alloy are reduced, and the yield is improved; a refining agent has a good refining effect, so that the pores and slag inclusion phenomena are obviously reduced.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

High-strength water-proof plaster block containing nonmetal nano material and preparation method thereof

The invention discloses a high-strength waterproof plaster brick with non-metal nanometer material and making method, which comprises the following steps: 1. adding 0.3-0.5% hydrogenous silicon oil into 35-40% water; 2. adding 0.005-0.01% ammonium chloride trimethyl octadecyl; 3. blending 45-50% hemi-hydrate plaster powder, 3-10% sepiolite powder and 3-5% metolline powder into liquid; 4. pouring the liquid into moulding box; stripping; culturing; obtaining the product. The invention makes the water adsorbing rate not more than 5% within 2 h and the conversion factor over 0.75, which improves the strength by 2-8 times and increases the toughness for frame-typed non-bearing wall.

Owner:李雨加 +1

High-strength steel automobile metal stamping part and preparing technology thereof

InactiveCN105970087AGuaranteed solid solution boron contentHigh strengthSolid state diffusion coatingUltimate tensile strengthWear resistance

The invention discloses a high-strength steel automobile hardware stamping part, which is composed of the following elements in mass percentage: C 0.17%, Si 0.50%, Mn 0.85%, B 0.002%, Al 0.04%, Ti 0.03%, Ni 0.03% , Mo 0.10%, P≤0.01%, S≤0.01%, N≤0.002%, the balance is Fe and unavoidable impurities, and its preparation process includes smelting, casting, processing, surface treatment, carburizing, quenching and tempering fire steps. The metal stamping parts prepared by the invention have good quality, high strength, good formability, good wear resistance, not easy to break, good safety performance, long service life and broad application prospects.

Owner:ANHUI HONGQIAO METAL MFG

High-strength low-temperature-resisting flux-cored wire for pipeline steel

InactiveCN107262962AIncrease the dislocation densityHigh strengthWelding/cutting media/materialsSoldering mediaArc stabilityLine tubing

The invention discloses a high-strength low-temperature-resisting flux-cored wire for pipeline steel, and the high-strength low-temperature-resisting flux-cored wire is composed of a flux core and a stainless steel skin wrapping the outer side of the flux core. The flux core comprises, by mass percent, C, Be, Si, Al, Mn, Ni, Cr, Cu, Ti, Sr, Mo, W, V, Nb, Zr, Nd, Sc, B, Ce, Eu, Y and the balance Fe and inevitable impurities. The provided high-strength low-temperature-resisting flux-cored wire for the pipeline steel is reasonable in formula, arc stability is good, welding line forming is attractive, a welding connector has high strength, low temperature resistance and good impact resistance, the bonding strength between the high-strength low-temperature-resisting flux-cored wire and base metal is high, and performance is stable.

Owner:安徽飞弧焊业股份有限公司

Anti-fatigue high toughness aluminum alloy welding wire for city rail train

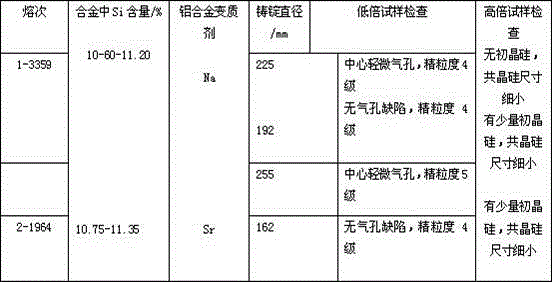

InactiveCN107081536AImprove refinementHigh strengthWelding/cutting media/materialsSoldering mediaArc stabilityWeld seam

The invention discloses an anti-fatigue high toughness aluminum alloy welding wire for a city rail train. The anti-fatigue high toughness aluminum alloy welding wire comprises the following mass fraction components of Mg, Si, Fe, Zn, Mn, Cr, Cu, Ti, Sr, Mo, W, V, Nb, Zr, Sc, Er, Ce, Y, Gd and the balance Al and inevitable impurities. The anti-fatigue high toughness aluminum alloy welding wire for the city rail train is reasonable in component, electrical arc stability is good at the time of welding, a formed welding seam is attractive, the strength of bonding of the welding wire with a parent metal is high, performance is stable, a welded joint has high strength and high toughness, and anti-fatigue performance is excellent.

Owner:安徽飞弧焊业股份有限公司

High-strength fracture prevention air conditioner radiator aluminum alloy sheet and molding technique thereof

InactiveCN106086554AHigh strengthImprove impact toughnessCorrosion preventionLaminated elementsSlagHigh intensity

The invention discloses a high-strength fracture prevention air conditioner radiator aluminum alloy sheet. The high-strength fracture prevention air conditioner radiator aluminum alloy sheet comprises the chemical elements of, by mass, 0.12-0.36 part of Cr, 0.15-0.30 part of Mg, 0.21-0.55 part of Cu, 1.22-1.77 parts of Zn, 0.11-0.18 part of Hg, 0.07-0.15 part of V, 0.15-0.28 part of Zr, 0.02-0.06 part of Nb, 0.01-0.03 part of Fe, 0.1-0.5 part of an aluminum alloy leavening agent, and the balance Al. Through addition of Nb and other elements, smell and impurities in alloy are reduced, mobility is improved, ingot formation through pouring is facilitated, and the technical performance is remarkably influenced. Grains of the aluminum alloy sheet are refined, high strength and impact toughness are achieved, the probability of cracks can be reduced through addition of Hg, and the aluminum alloy sheet has good corrosion resistance. By means of a production method, the phenomena of layering, peeling, bubbling and cracking of aluminum alloy are reduced, and the rate of finished products is increased. A refining agent is good in refining effect, so that the phenomena of pores and slag inclusion are reduced remarkably.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

Method for preparing membrane-electrode assembly, membrane-electrode assembly prepared therefrom, and fuel cell comprising same

ActiveCN109075348AGood dispersionReduce aggregationFinal product manufactureCell electrodesIonomerFuel cells

Owner:LG CHEM LTD

Method for fabricating refractory material prefabricated member expansion joint

InactiveCN102935659AEliminate expansion cracksReduce crack phenomenonCeramic shaping apparatusRefractoryExpansion joint

The invention relates to a method for fabricating a refractory material prefabricated member expansion joint. The method includes the following steps that at normal temperature, a grouting agent and 'Christmas sprayed snow' are sequentially and uniformly sprayed on outer surfaces of a metal structural part and an anchoring part of a prefabricated member to form a buffer layer, and then still standing is performed; the metal structural part with a solid buffer layer is fixedly placed in a mold, and stirred pug of refractory castable is poured in the mold; and a solidified fire-resistant prefabricated member is subjected to normal temperature life-preserving to enter into a drying process of 300 DEG C to 400 DEG C, a part of the buffer layer on the outer surfaces of the metal structural part and the anchoring part is decomposed into gas to be discharged, the rest part of the buffer layer is melted, and the melted buffer layer permeates into the refractory material through pores of the refractory castable to form the expansion joint. The method for fabricating the refractory material prefabricated member expansion joint has the advantages that the method is suitable for various metal structural parts with complicated surfaces, and the problem that expansion cracks occur when prior fire-resistant prefabricated members are dried and used is solved.

Owner:鞍山市和丰耐火材料有限公司

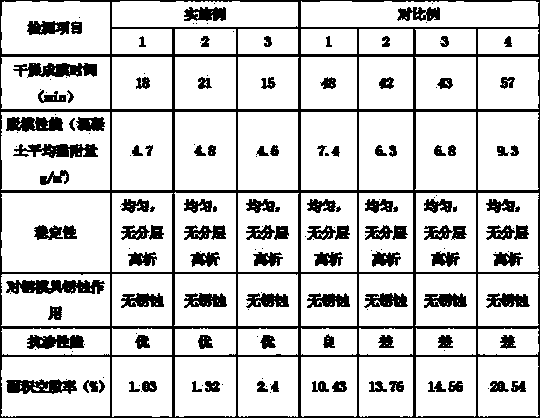

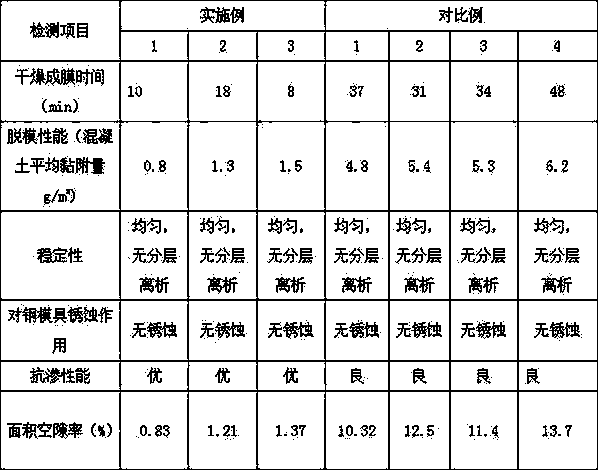

Concrete release agent and preparation method therefor

ActiveCN108913318ALow costEasy to operateCeramic shaping apparatusLubricant compositionSulfonateCarboxymethyl cellulose

The invention relates to a concrete release agent and a preparation method therefor. The concrete release agent disclosed by the invention is mainly prepared from the following raw materials in partsby weight: 5-10 parts of modified lignin, 22-35 parts of waste engine oil, 0.02-0.05 part of triethanolamine, 0.7-1 part of alkylphenol polyoxyethylene ether, 0.5-1.2 parts of sodium octadecyl sulfonate, 2-4 parts of sodium carboxymethyl cellulose and 55-78 parts of deionized water. The invention further discloses the preparation method for the concrete release agent. The concrete release agent disclosed by the invention is relatively low in cost and simple in synthesis equipment and operation and is in line with various indicators of release agent standards for concrete products JC / T 949-2005; and the concrete release agent can be spray-coated or roll-brushed, and gas-pore and crack phenomena of the concrete products can be effectively reduced. The modified lignin is applied to the concrete release agent, and resources can be fully utilized.

Owner:上海知碳电力工程有限公司

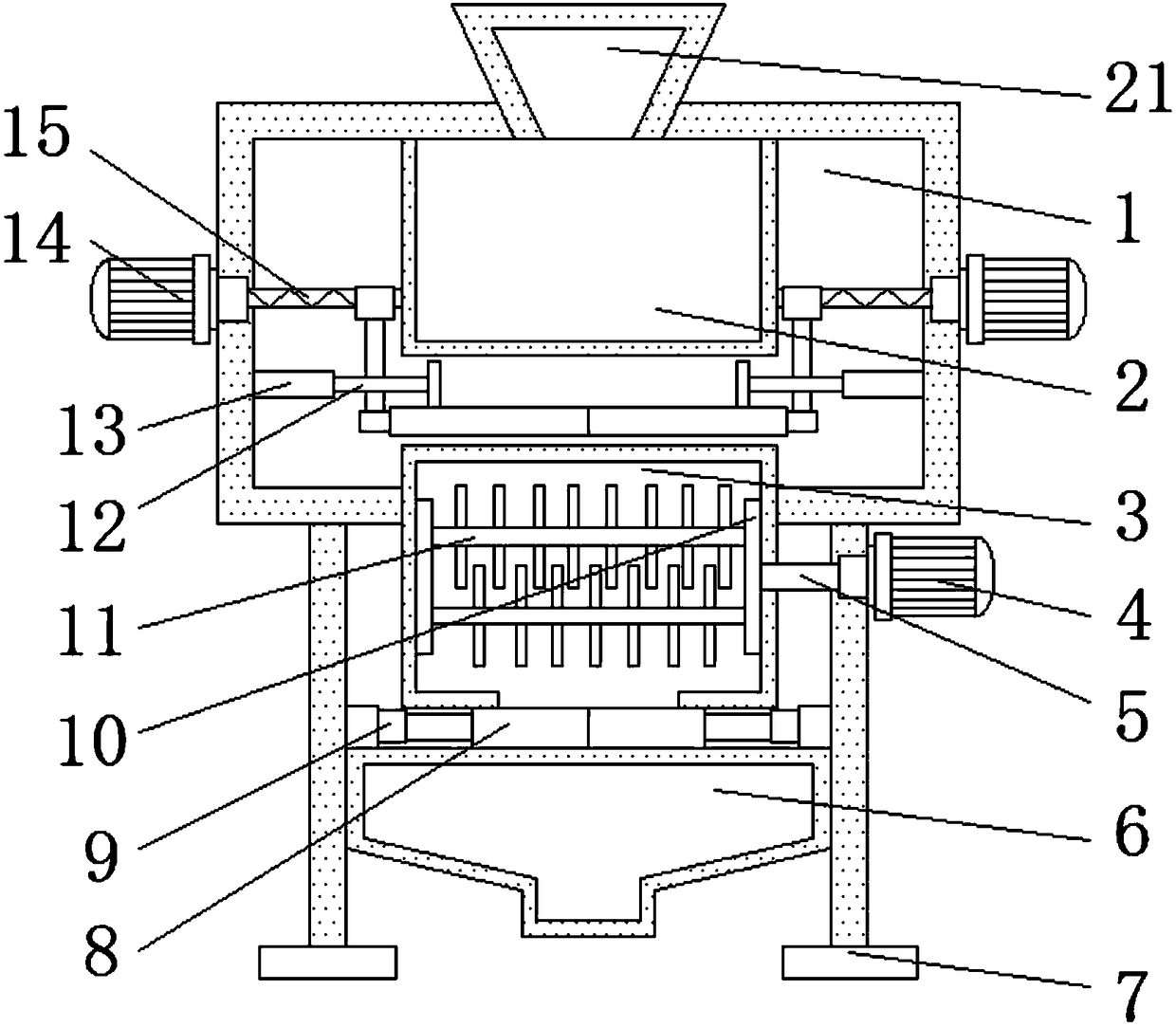

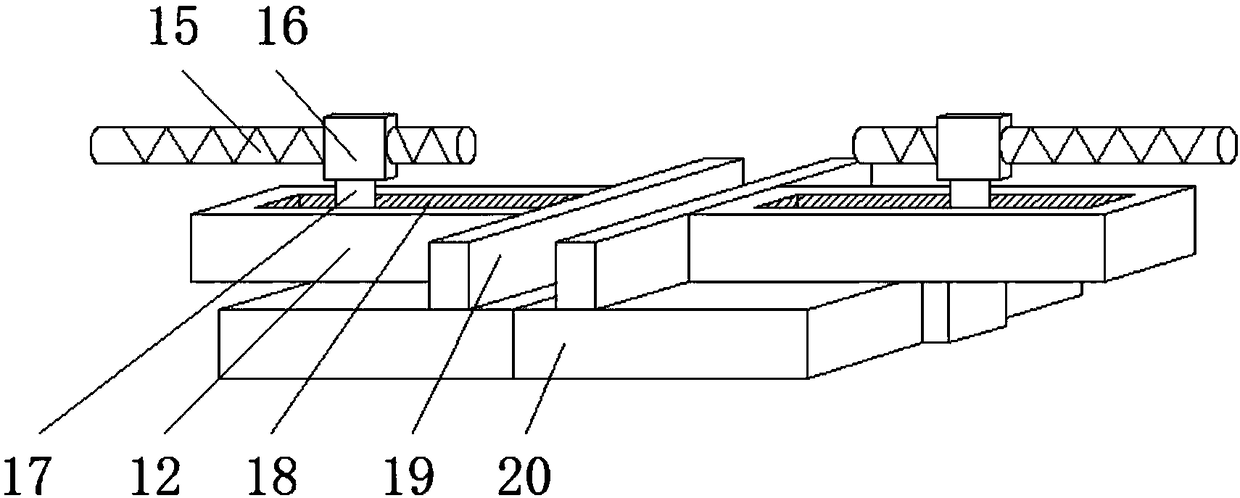

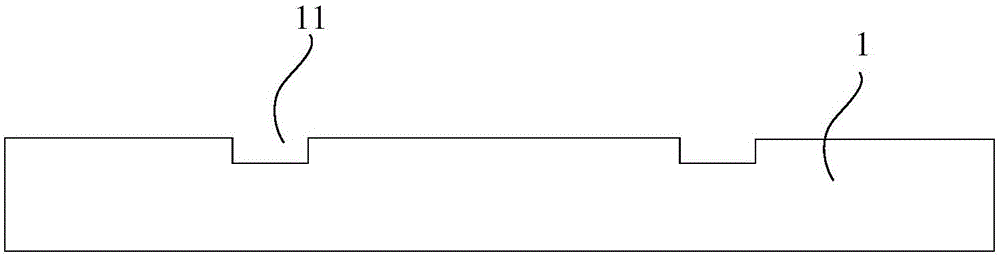

Pre-crushing device of high-purity quartz sand

The invention discloses a pre-crushing device of high-purity quartz sand. The pre-crushing device comprises a main body, wherein the main body is internally and fixedly connected with a feeding buffering chamber, a pre-crushing chamber and a discharging buffering chamber; the pre-crushing chamber is arranged in the feeding buffering chamber and the discharging buffering chamber; an outer side wallof the main body is fixedly connected with a first motor; an output end of the first motor is movably connected with a screw rod; a movable block is arranged on the outer surface of the screw rod; the lower surface of the movable block is fixedly connected with a vertical rod; a first movable door is fixedly connected with the lower end of the vertical rod; one side, close to the vertical rod, ofthe upper surface of the first movable door is in sliding connection with a connecting plate. The pre-crushing device disclosed by the invention is reasonable in design and simple to operate and canensure automatic assembly line production so that grains of quartz ores are more uniform; pre-treated materials can be added into a roller machine in an assembly line manner, abrasion, caused by relatively large grains, on a roller surface is alleviated and a crack phenomenon is reduced; the purity of a high-purity quartz sand product is easy to improve.

Owner:连云港格航工业设计有限公司

Pedestal of laser packaging equipment and laser packaging equipment

ActiveCN105070850AImprove yield rateReduce loss rateSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsMetal

The invention relates to the preparation technical field of display apparatuses and discloses a pedestal of laser packaging equipment and laser packaging equipment. The pedestal of the laser packaging equipment comprises a metal pedestal body; the metal pedestal body is used for supporting one side of a to-be-packaged substrate; and an insulation structure which is in one-to-one correspondence with a glass powder area of each sub-substrate in the to-be-packaged substrate is provided. According to the pedestal of the laser packaging equipment provided by the invention, the insulation structures are arranged on the metal pedestal body, so that the losing speed of heat which is transmitted to glass powder by the laser is reduced, rapid change in the temperature of the glass powder and the glass substrate is prevented, the crack is further reduced after the to-be-packaged substrate and the glass powder are packaged, and the packaging yield is improved.

Owner:BOE TECH GRP CO LTD

Environment-friendly wood-plastic material and preparation method thereof

The invention discloses an environment-friendly wood-plastic material and a preparation method thereof and relates to the technical field of wood-plastic materials. The environment-friendly wood-plastic material comprises the following raw materials in parts by weight: 30-40 parts of wood powder, 10-20 parts of plastic particles, 0.6-1.8 parts of dispersable adhesive powder, 1-5 parts of modifiednegative ion powder, 0.6-2 parts of cellulose, 3-6 parts of a filling agent, 2-6 parts of a compatilizer, 0.8-1.5 parts of a stabilizer and 0.3-1.2 parts of a lubricating agent. The preparation methodcomprises the following steps: (1) weighing raw materials; (2) mixing materials; (3) removing water vapor; (4) preparing the environment-friendly wood-plastic material. The wood-plastic material disclosed by the invention is resistant to chemical corrosion, impermeable, excellent in compactness, capable of reducing signs of mould and purifying the external environment, green and environment-friendly.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

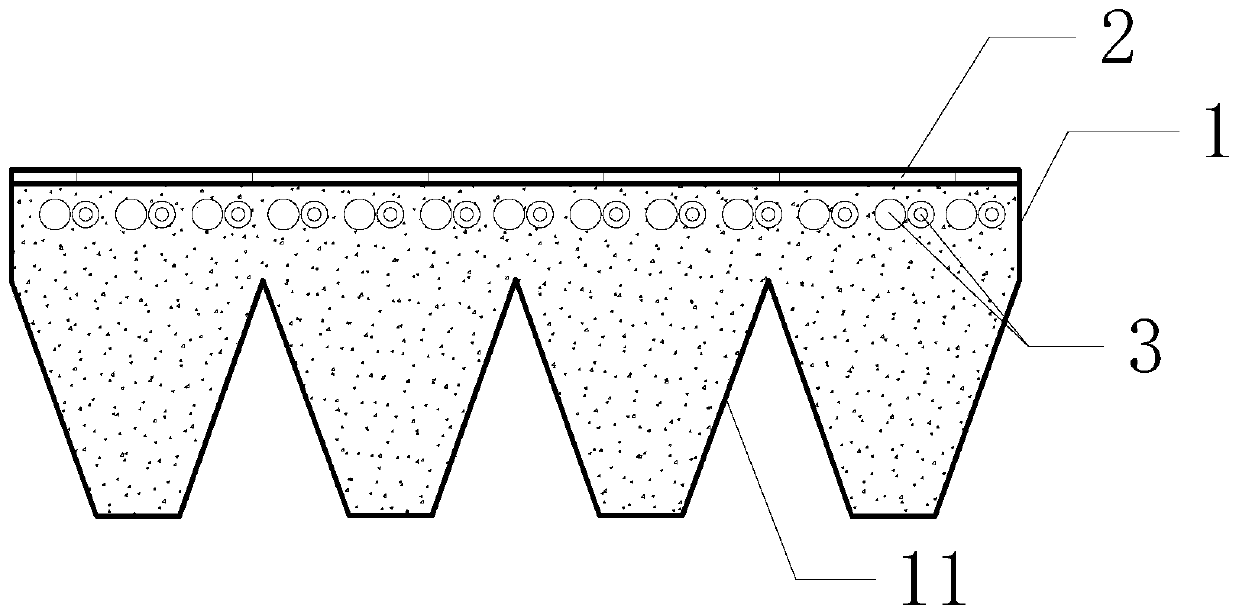

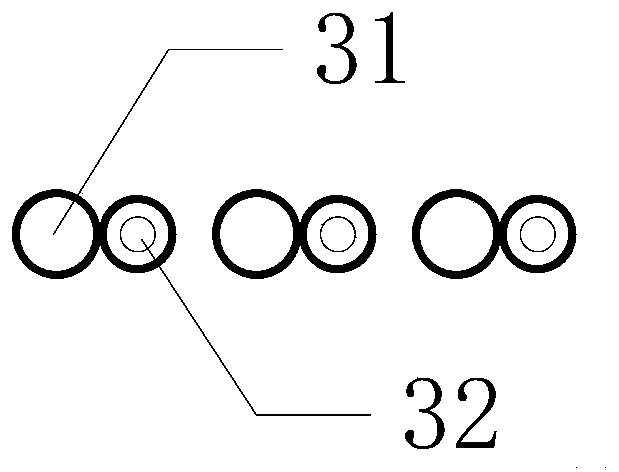

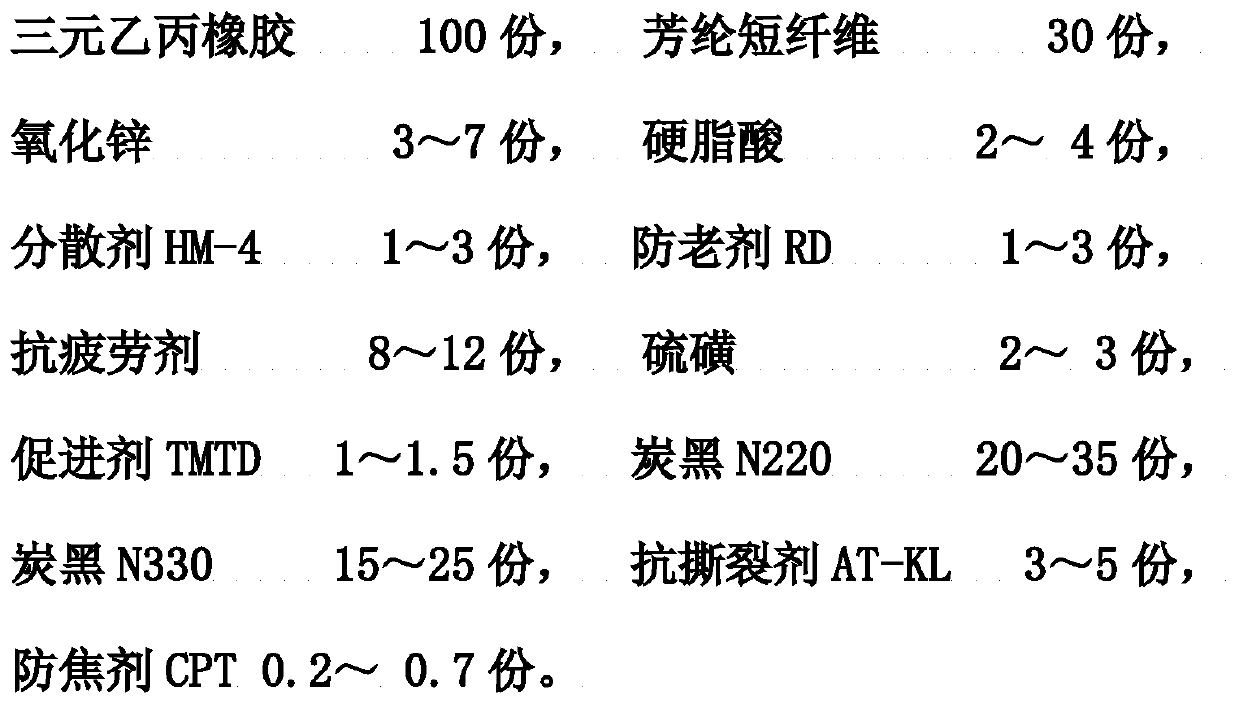

Noise-reducing and energy-saving EPDM polyrib belt

The invention relates to a noise-reducing and energy-saving EPDM polyrib belt which comprises a belt body made from an EPDM material. A group of trapezoidal wedges are arranged on the inner side of the belt body; a canvas layer vulcanized and adhered to the belt body is arranged on the outer side of the belt body, and the paving direction of the canvas layer is parallel to the transmission direction of the polyrib belt; a framework wound framework rope group along the transmission direction of the polyrib belt is arranged in the belt body, and the framework rope group is composed of an aramidfiber yarn and a hollow fiber yarn clinging to each other in parallel; the yarn diameter of the aramid fiber yarn is 0.7-0.9 mm, the yarn diameter of the hollow fiber yarn is 0.5-0.8 mm and the winding density of the framework rope group is 3-5 / cm. The noise-reducing and energy-saving EPDM polyrib belt not only has the characteristics of being long in service life and non-toxic and pollution-free, but also has the advantage of low noise in a using process.

Owner:台州格雷科胶带有限公司

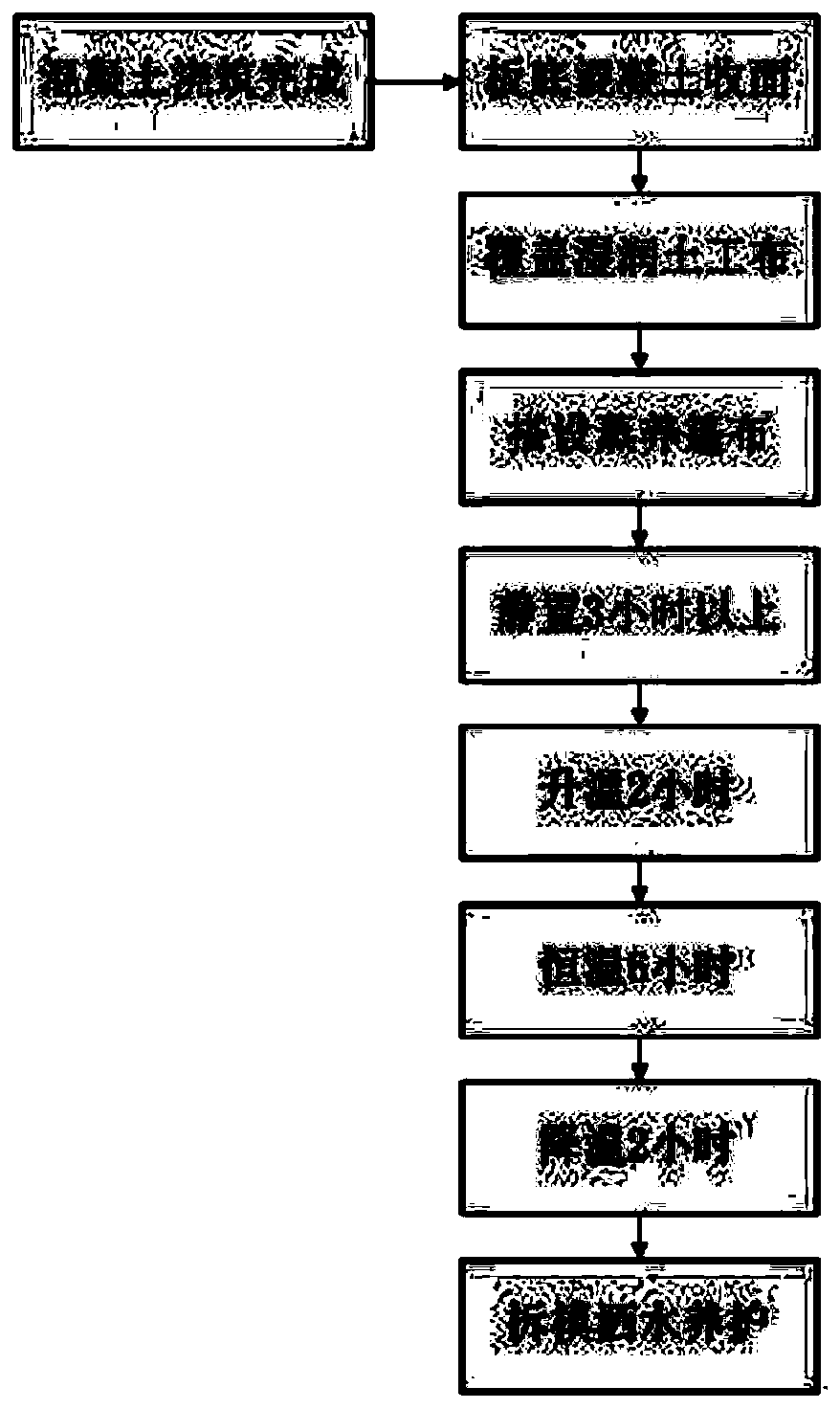

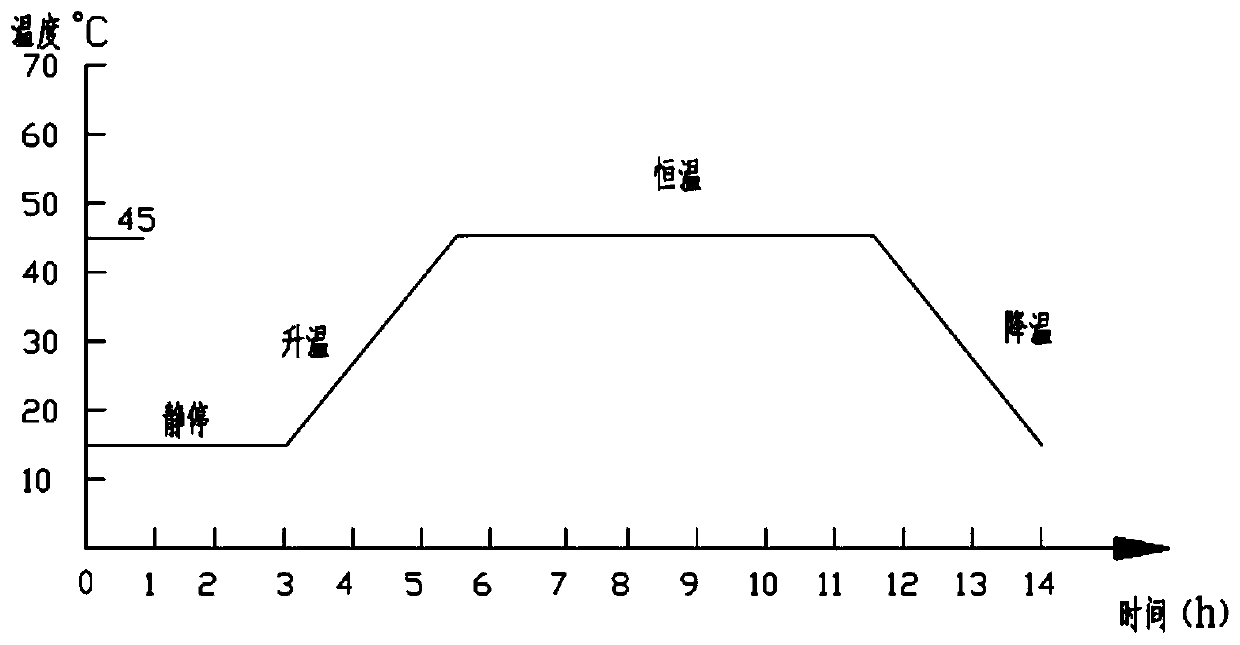

Concrete steam curing method in subway construction

The invention provides a concrete steam curing method in subway construction, which comprises the following steps: after concrete pouring of a station main body structure is completed, constructing acuring tarpaulin, performing standing treatment for 3-5 hours, and carrying out heating steam curing at a heating rate of 15 DEG C / h or below; increasing the temperature to 45 DEG C, and performing constant-temperature steam curing for more than 6 hours; and then cooling the concrete at the cooling speed not larger than 10 DEG C / h, wherein the temperature difference between the surface of the station body structure and the environment is below 15 DEG C. According to the method, by adjusting the construction process, the phenomena of concrete peeling and cracking are effectively reduced, and the appearance quality of concrete steam curing is improved; meanwhile, when the method is adopted for concrete steam curing, the curing work efficiency can be improved, the cost can be reduced, later maintenance can be omitted, waste of manpower and materials can be avoided, meanwhile, the construction progress can be accelerated, and the cost can be saved.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR

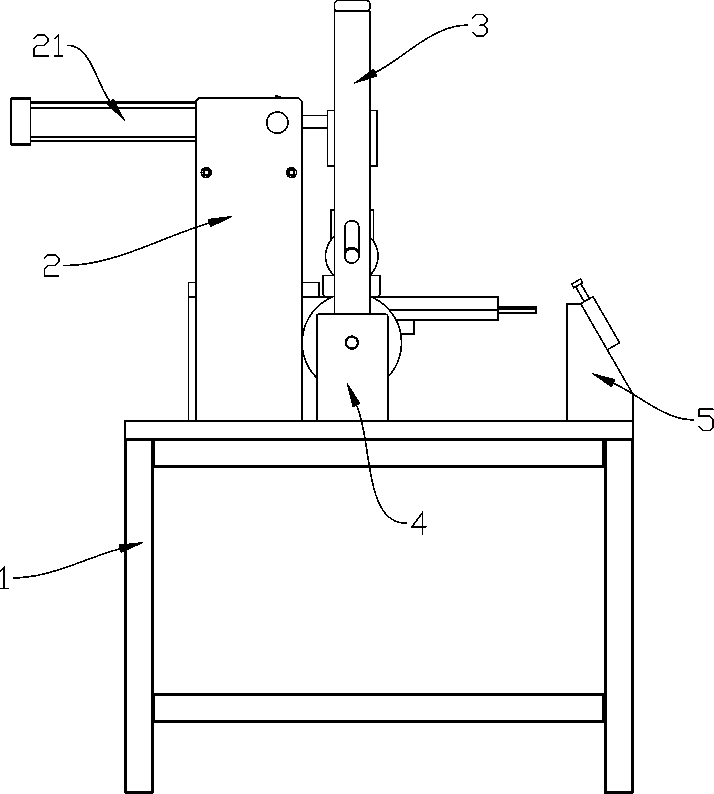

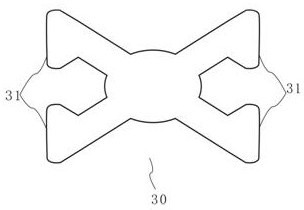

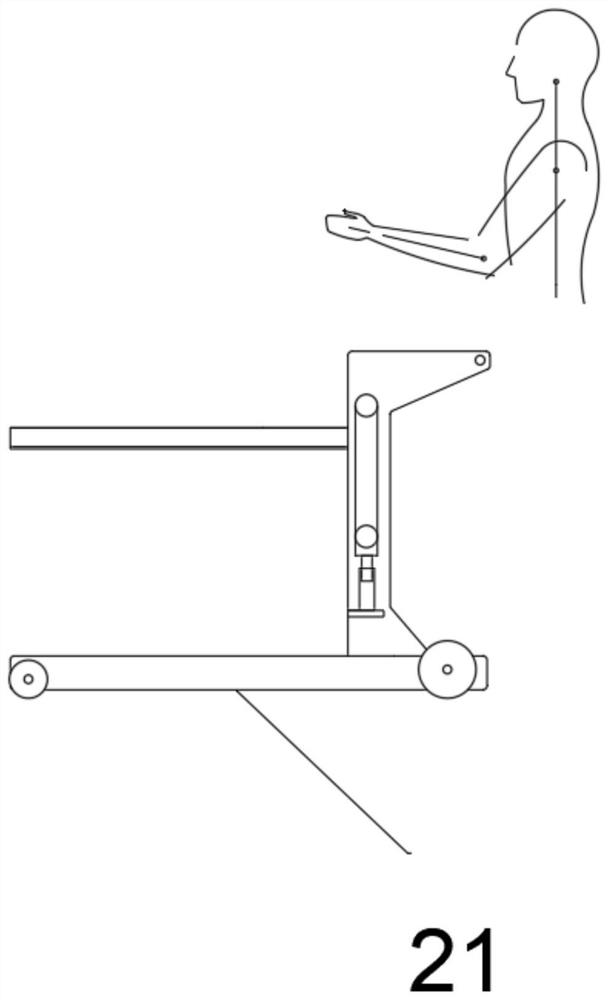

Profile bending device

ActiveCN110681744AImprove product qualityFixed support is firmMetal-working feeding devicesPositioning devicesPhysicsEngineering

The invention discloses a profile bending device. The profile bending device comprises a bottom plate, and a profile placing assembly, a positioning assembly, a bending assembly and a limiting assembly are arranged on the bottom plate. The profile placing assembly comprises a profile placing seat, an upper pad and a lower pad are arranged on the profile placing seat, and a flat shape profile placing cavity is formed between the upper pad and the lower pad; the positioning assembly comprises a positioning frame arranged on the bottom plate, and a first lower pressing member is arranged on the positioning frame; the bending assembly comprises a rotatable rotating frame, and a force member acting on a power member is arranged on the rotating frame; and a second lower pressing member is further arranged on the rotating frame. According to the profile bending device, fixing and supporting of profiles is firm, the deformation of the profiles is rare in the bending process, meanwhile, throughthe improvement of the upper pad or press block, the crack phenomenon of the profiles during the bending process is greatly reduced, and the bending quality of the profiles is high; and the bending device is accurate and stable in positioning, the bending precision is high, and the product quality is good.

Owner:NINGBO KENO ALUMINUM

Production method for refractory precast block

InactiveCN101554749AEliminate expansion cracksReduce crack phenomenonCeramic shaping apparatusRefractoryRejection rate

The invention relates to a production method for a refractory precast block. The refractory precast block is preset with a cushion layer between the outside surface of the steel structural component and external refractory material; the required condition of the cushion layer is to have certain strength during normal casting so as to ensure the formation of the self thickness space; low melting points, the cushion layer can be melted in the 100 to 250 DEG C to vacate the original thickness space used for being occupied by the expanded steel structural component. The cushion layer is a PVC foaming packing paper or a liquid PVC forming agent. The production method has the beneficial effects: (1) a familiar PVC forming material is used for replacing previous asphalt and kraft paper, thus greatly reducing the seaminess and rejection rate of the big-and-middle-sized refractory precast block; (2) the production method has low cost, is easy to operate and has little pollution.

Owner:鞍山市和丰耐火材料有限公司

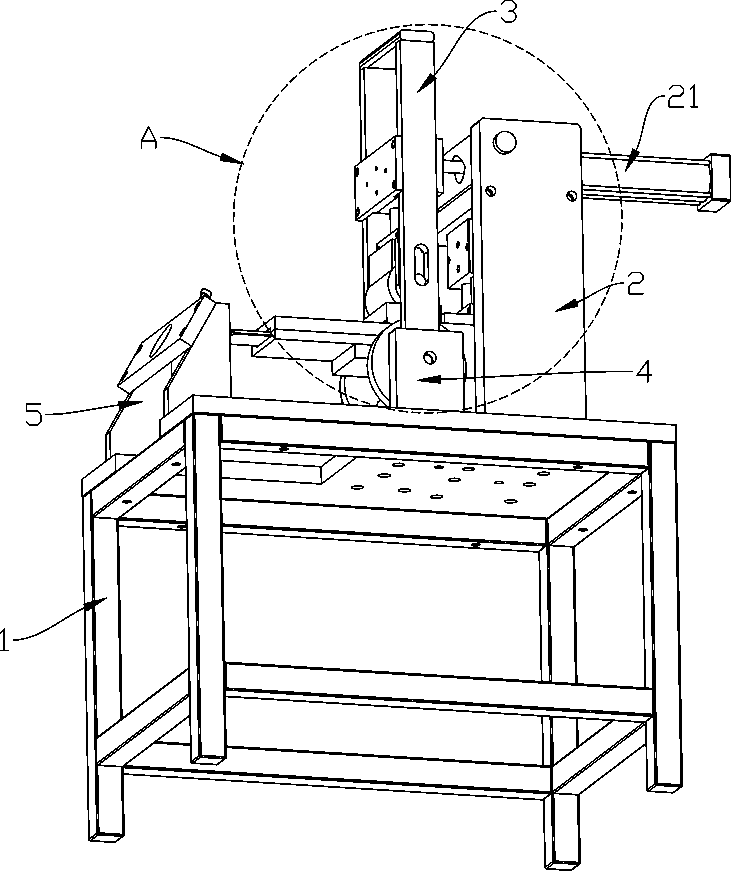

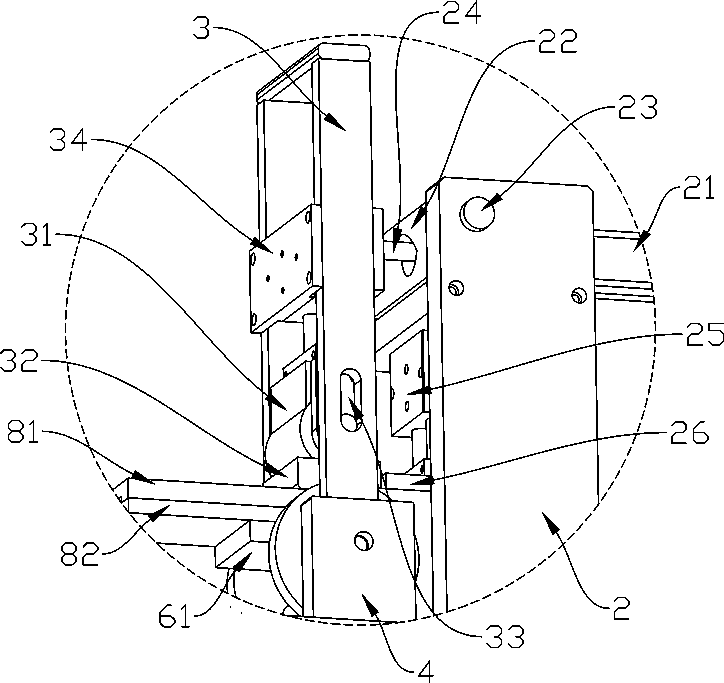

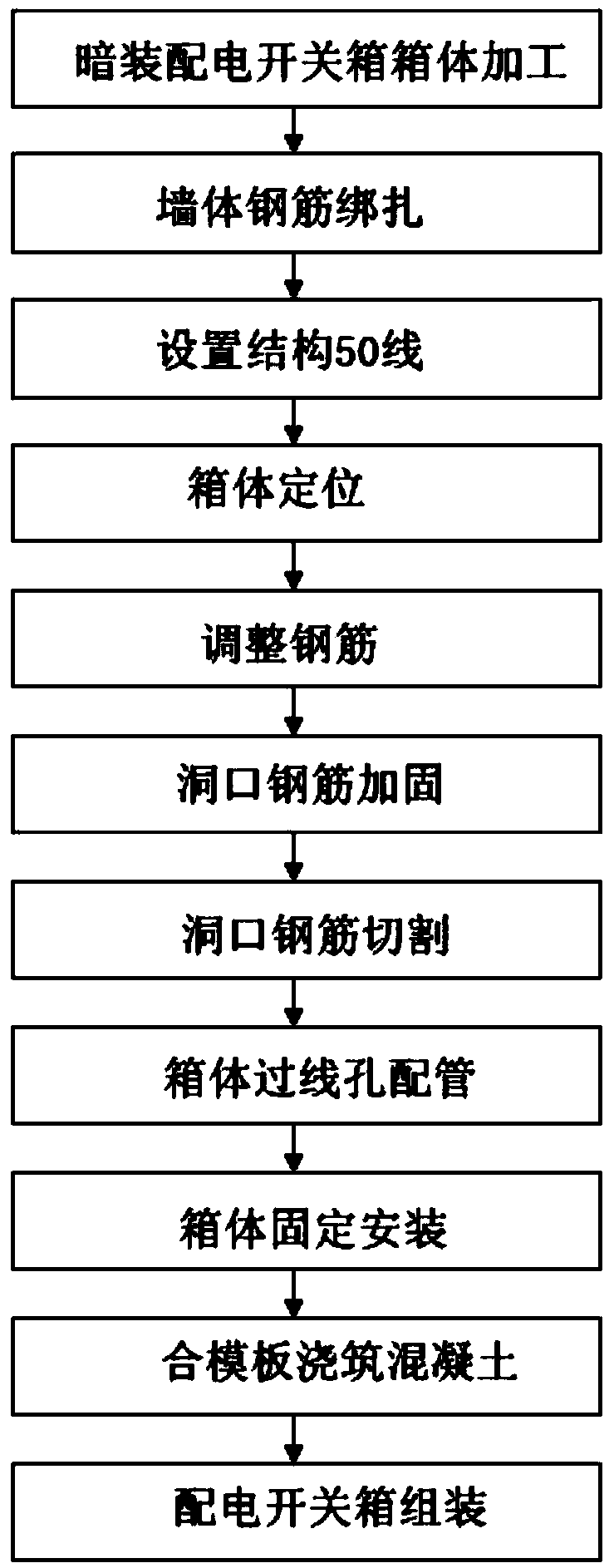

A Concrete Wall Direct Buried Power Distribution Switch Box Installation Construction Technology

The invention provides a mounting constructing technology for a concrete wall direct built distribution switch box. The mounting constructing technology comprises the following eleven steps: processing a hidden assembled distribution switch box body; binding wall reinforcing steel bars; arranging structural 50 wires; positioning the box body; adjusting the reinforcing steel bars; reinforcing entrance reinforcing steel bars; cutting the entrance reinforcing steel bars; arranging pipes for wire holes of the box body; fixedly mounting the box body; assembling the template and concreting; assembling the distribution switch box. According to the invention, the reserved holes of a civil engineering structure can be greatly reduced, the entrance template-removal construction can be reduced, the easily occurred hollow phenomenon of the surrounding walls of the traditional distribution switch box can be effectively overcome and the hole-blocking workload of civil construction and the wall cracks can be reduced, so that the construction technology is simplified, the promotion for the mounting positioning quality of the box body of the distribution switch box, the mounting and running stability of the electric equipment and the electricity utilization safety can be boosted, the construction efficiency can be further effectively increased and the labor intensity and the material loss in the construction can be reduced so that the cost is effectively saved and the construction cost is greatly lowered.

Owner:GUANGDONG WATER & ELECTRICITY EQUIP INSTALLATION CO LTD

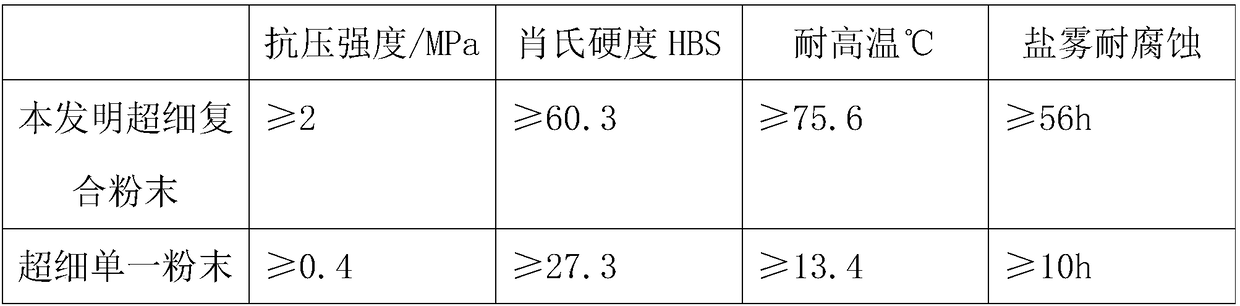

Production method of novel composite powder material containing superfine components

InactiveCN109047777AImprove scalabilityHigh degree of moldingTransportation and packagingMetal-working apparatusHigh energyFatty acid

The invention discloses a production method of a novel composite powder material containing superfine components. The production method of the novel composite powder material containing superfine components comprises the following concrete steps of (1) mixing glycerinum, fatty acid, ethylene oxide, hexadecanol, triethylamine alcohol and water, feeding into a high-temperature stirrer after preliminary mixing, heating for stirring, and obtaining a grinding agent; (2) feeding cobalt, titanium, tungsten carbide, chromium, copper and steel into a high-energy ball-milling machine for grinding, adding a dispersing agent and the grinding agent obtained in the step 1 during the grinding process, preventing the agglomeration of particles, changing the grinding environment, utilizing a cloth dust collector for recovering after finishing grinding, and obtaining metal composite powder; and (3) feeding the metal composite powder obtained in the step 2 into a reaction stirring tank, and stirring at high temperature. The hardness of superfine powder during use is increased, the crushing resistance is improved, the smoothness of the appearance is further improved due to heavy grinding and the use of the dispersing agent, and the occurrence of the phenomena of breakage and cracks after forming is reduced.

Owner:王玉环

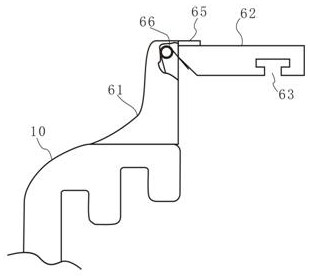

Aluminum alloy profile and manufacturing method thereof

InactiveCN112210743AEffective diffusionHigh bonding strengthMolten spray coatingFireproof doorsBoron nitrideSpray dried

The invention relates to the technical field of door and window aluminum profiles, and particularly discloses an aluminum alloy profile and a manufacturing method thereof. The method comprises castingand powder spraying of the aluminum alloy profile, wherein the powder spraying process specifically comprises the steps of: taking bentonite, adding water, stirring till the bentonite is completely expanded and completely dispersed in the water to form suspension liquid; adding recycled aluminum particles, continuously and completely stirring, adding a silver antibacterial agent and boron nitride, carrying out wet ball milling, and carrying out spray drying to obtain modified aluminum powder; taking nitrogen and oxygen as working gases, and spraying and depositing the working gases on the surface of the aluminum alloy profile under the carrying action of an ionic gas. According to the manufacturing method, the bonding strength of a coating and the surface of the aluminum alloy profile canbe enhanced, the oxidation resistance, aging resistance, toughness and corrosion resistance of a surface layer are remarkably improved, and meanwhile the aluminum profile is endowed with an excellentantibacterial performance.

Owner:美图(福建)铝业有限公司

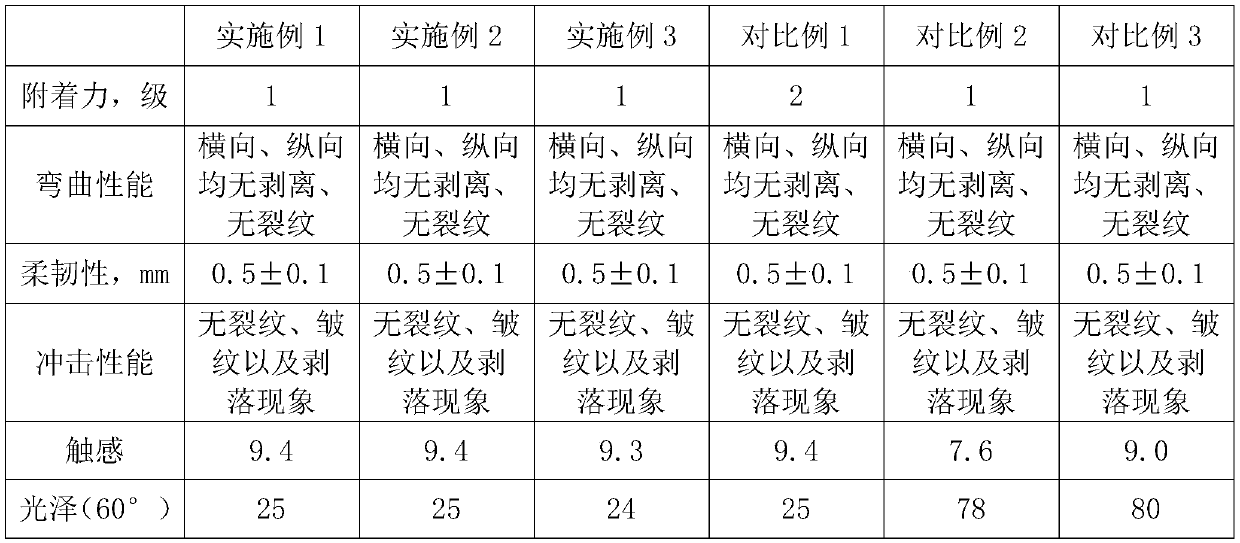

High-dispersibility water-based fluorocarbon coating

InactiveCN107384089AAvoid crackingImprove corrosion resistanceFireproof paintsAnti-corrosive paintsThermal isolationWater based

The invention discloses high-dispersibility water-based fluorocarbon coating, which is prepared from the following raw materials in parts by weight: 30 to 50 parts of polyamide resin, 15 to 35 parts of polyacrylic acid emulsion, 2 to 4 parts of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 5 to 15 parts of kieselguhr, 2 to 6 parts of talcum powder, 1 to 5 parts of white carbon black, 1 to 4 parts of gypsum powder, 2 to 7 parts of hollow glass micro beads, 2 to 6 parts of medical stone compounds, 1 to 5 parts of quartz sand, 1 to 4 parts of driers, 1 to 2 parts of disproportionated rosin, 2 to 4 parts of magnesium stearate, 0.4 to 1 part of N,N-dimethylethanolamine, 2 to 8 parts of montmorillonoid, 2 to 4 parts of fibroin, 1 to 4 parts of diluents and 40 to 80 parts of deionized water. The high-dispersibility water-based fluorocarbon paint has the advantages that the mechanical property, the heat resistance and the anti-corrosion performance are excellent; the thermal isolation and heat insulation effects are achieved; a coating film cannot easily crack; the uniformity is high; the weather-resistant performance is good; the attaching force is good; the anti-scratching and wear-resistant performance is good; the cost is low; environment pollution cannot be caused.

Owner:TIANCHANG JULONG TRAVEL PAINT

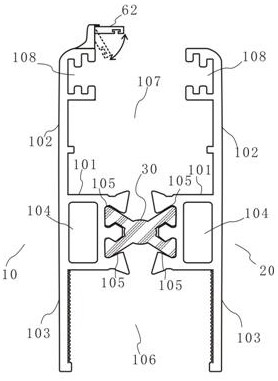

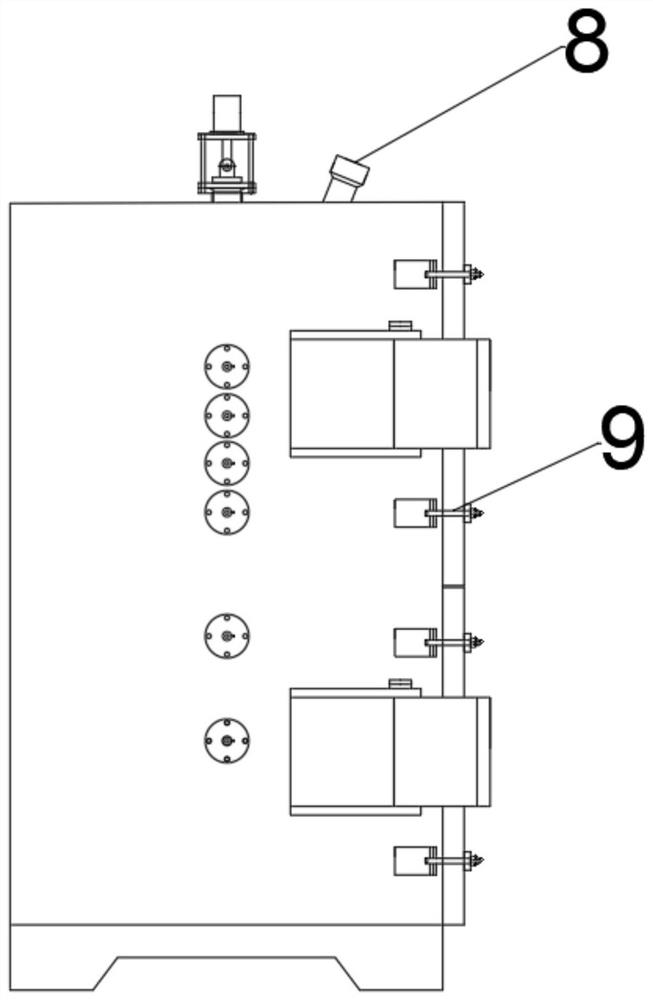

Advanced composite material experiment furnace

PendingCN111811274AReduce crack phenomenonMaintainance of heating chambersFurnace typesCrucibleAdvanced composite materials

The invention relates to the field of material industry, in particular to an advanced composite material experiment furnace. The furnace comprises an experiment furnace double-layer outer frame and amechanical pump, wherein heating cavities are formed inside the experiment furnace double-layer outer frame, and the heating cavities are composed of upper cavity heating belts and lower cavity heating belts; upper cavity heat preservation layers are arranged outside the upper cavity heating belts, and upper cavity crucibles are arranged inside the upper cavity heat preservation layers; lower cavity heat preservation materials are arranged outside the lower cavity heating belts, and lower cavity crucibles are arranged inside the lower cavity heating belts; and discharging pipelines are arranged at the bottoms of the upper cavity crucibles. According to the advanced composite material experiment furnace, the cavity at the upper portion cannot be oxidized by air during high-temperature smelting through a vacuum unit, and when a base material at the upper portion melts and flows into a reinforcement material, the composited material cannot generate bubbles and is more compact due to the action of high vacuum.

Owner:苏州东子云工业技术科技有限公司

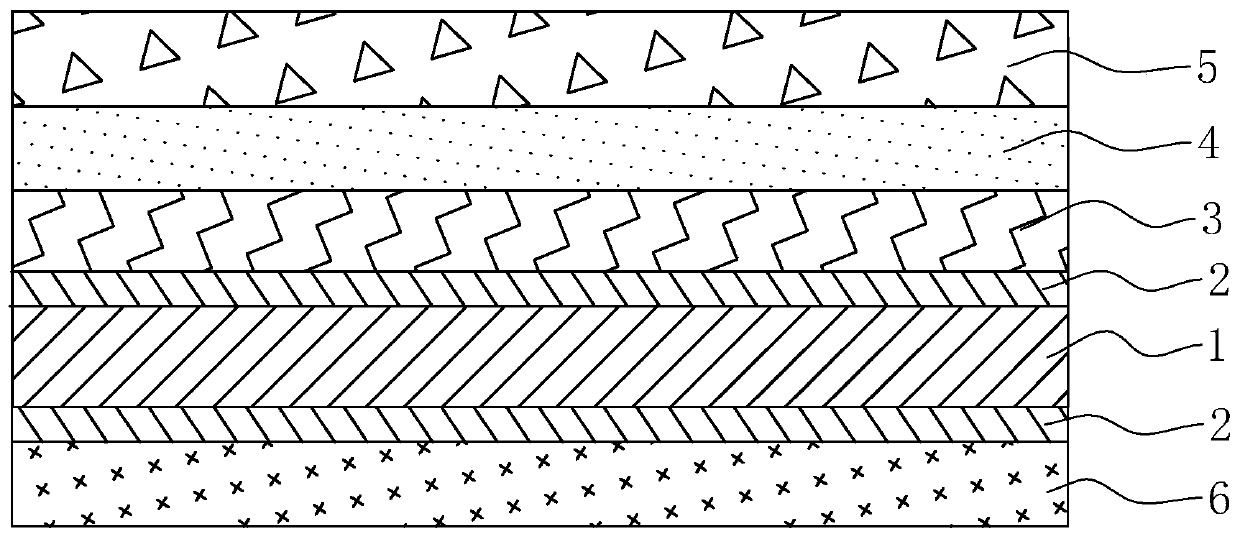

Stainless steel PCM (Pre-Coated Metal Steel) plate and production process thereof

InactiveCN110358417AGood flexibilityReduce coldnessAnti-corrosive paintsEpoxy resin coatingsCelluloseChemical treatment

The invention discloses a stainless steel PCM (Pre-Coated Metal Steel) plate and a production process thereof and relates to the technical field of metal plates for household electric appliance shells. According to the technical scheme, the stainless steel PCM plate is characterized by comprising a metal substrate, wherein a chemical treatment layer, a prime coat layer, a finish coat layer and a PE (Polyethylene) membrane layer are sequentially arranged on one side of the metal substrate; a back coat layer is arranged on the other side of the metal substrate; a finish coat comprises the following components in parts by weight: 40-50 parts of an aqueous polyester resin, 20-30 parts of an amino resin, 3-5 parts of triethanolamine, 25-35 parts of butyl acetate, 6-10 parts of cellulose acetatebutyrate, 10-15 parts of butyl cellosolve, 1-2 parts of a leveling agent, 2-3 parts of an organic silicon hand feeling agent and 1-2 parts of a matte agent. As the finish coat with the hand feeling agent and the matte agent is smeared on the metal substrate, the coldness and the metal feeling of the metal substrate can be degraded, the tough feeling of the PCM plate can be gentle, and the appearance attractiveness of the PCM plate can be improved.

Owner:杭州普络飞新材料科技有限公司

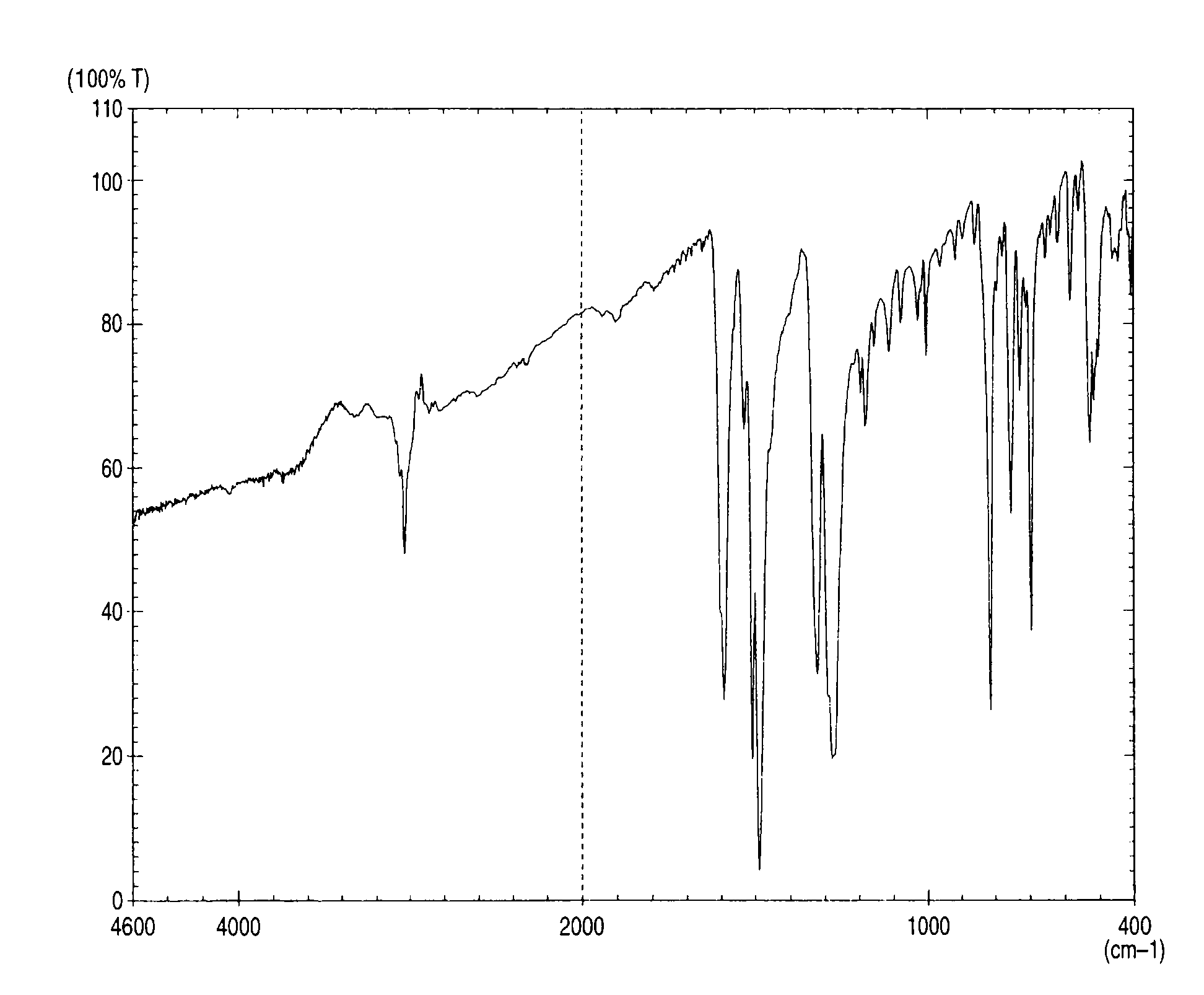

P-terphenyl compound mixture and electrophotographic photoreceptors made by using the same

ActiveUS8486594B2Improve solubilityImprove mobilityOrganic compound preparationElectrographic process apparatusBenzeneOrganic solvent

An object of the invention is to provide: a p-terphenyl compound mixture useful as a charge-transporting agent which has improved solubility in organic solvents to thereby diminish a cracking phenomenon, which poses problems concerning photoreceptor characteristics, and can realize an electrophotographic photoreceptor having high sensitivity and high durability; and an electrophotographic photoreceptor employing the compound mixture. The invention relates to: a p-terphenyl compound mixture which includes two symmetric p-terphenyl compounds respectively represented by the following general formula (1) and general formula (2) and an asymmetric p-terphenyl compound represented by the following general formula (3) which has both a group of substituents of the compound represented by general formula (1) and a group of substituents of the compound represented by general formula (2); and an electrophotographic photoreceptor containing the compound mixture.

Owner:HODOGOYA CHEMICAL CO LTD

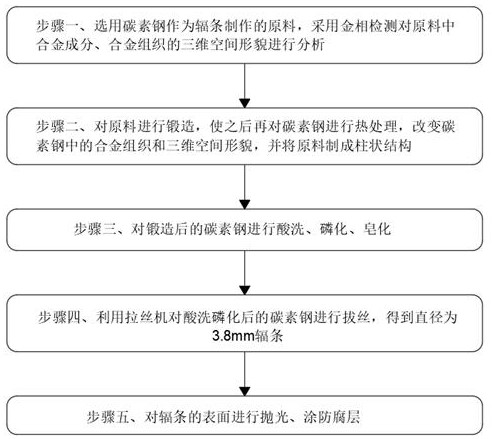

High-strength spoke manufacturing process

InactiveCN112296116AHigh strengthImprove plasticityMetallic material coating processesWheel manufactureUltimate tensile strengthCarbon steel

The invention discloses a high-strength spoke manufacturing process, and relates to the technical field of spoke manufacturing. The high-strength spoke manufacturing process comprises the following steps that step 1, carbon steel is selected as a raw material for spoke manufacturing, and metallographic detection is adopted to analyze alloy components in the raw material and the three-dimensional spatial morphology of alloy structures. According to the high-strength spoke manufacturing process, during use, a spoke is manufactured in a hot forging mode, chromium and carbon are added in the manufacturing process to improve the strength of the spoke, in addition, acid pickling, phosphorization and saponification are adopted to pretreat the spoke before the spoke is drawn and formed, the plasticity of the spoke in the drawing process can be further improved, so that the phenomenon that cracks occur on a spoke upset head and an elbow is reduced; and meanwhile, under the action of an anti-corrosion coating, the spoke can be prevented from rusting, and the storage time of the formed spoke is prolonged.

Owner:江苏华久辐条制造有限公司

Ferrous metal material

The invention discloses a ferrous metal material. The ferrous metal material comprises the following components in parts by weight: 2-5 parts of carbon, 70-80 parts of iron, 0.5-0.8 part of manganese, 0.3-0.6 part of cobalt, 0.2-0.5 part of magnesium and 0.12-0.35 part of tungsten. The ferrous metal material has the beneficial effects that by adjusting and controlling the composition radio and adding sequence of the elements in the alloy steel, cracking generated during a production process is reduced; the quality of the metal material is enhanced; the quality is good; the strength is high; shaping property is good; abrasion resistance is good; the material cannot be broken easily; safety is good; and the service life is long.

Owner:太仓源壬金属科技有限公司

Copper alloy material for automobile parts

The invention discloses a copper alloy material for automobile parts. Copper is used as a raw material, and the copper alloy material is prepared from the following components in parts by weight: 0.12 to 0.25 part of platinum, 0.8 to 1.5 part of aluminum, 1 to 3 parts of technetium, 0.22 to 0.34 part of chromium and 0.12 to 0.35 part of tungsten. The copper alloy material has the beneficial effects that the copper is used as the main raw material, and the composition ratio and the adding order of all elements in alloy steel are adjusted and controlled, so that the strengthening effect of an aluminum element is increased, the copper has good strength, the cracking phenomenon generated during production is reduced, and the quality of the copper is increased.

Owner:太仓源壬金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com