Method for preparing membrane-electrode assembly, membrane-electrode assembly prepared therefrom, and fuel cell comprising same

一种膜电极组件、制造方法的技术,应用在燃料电池、电气元件、电池电极等方向,能够解决粘附、孔结构不稳定、性能下降等问题,达到提高性能、减少离聚物聚集和裂纹的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

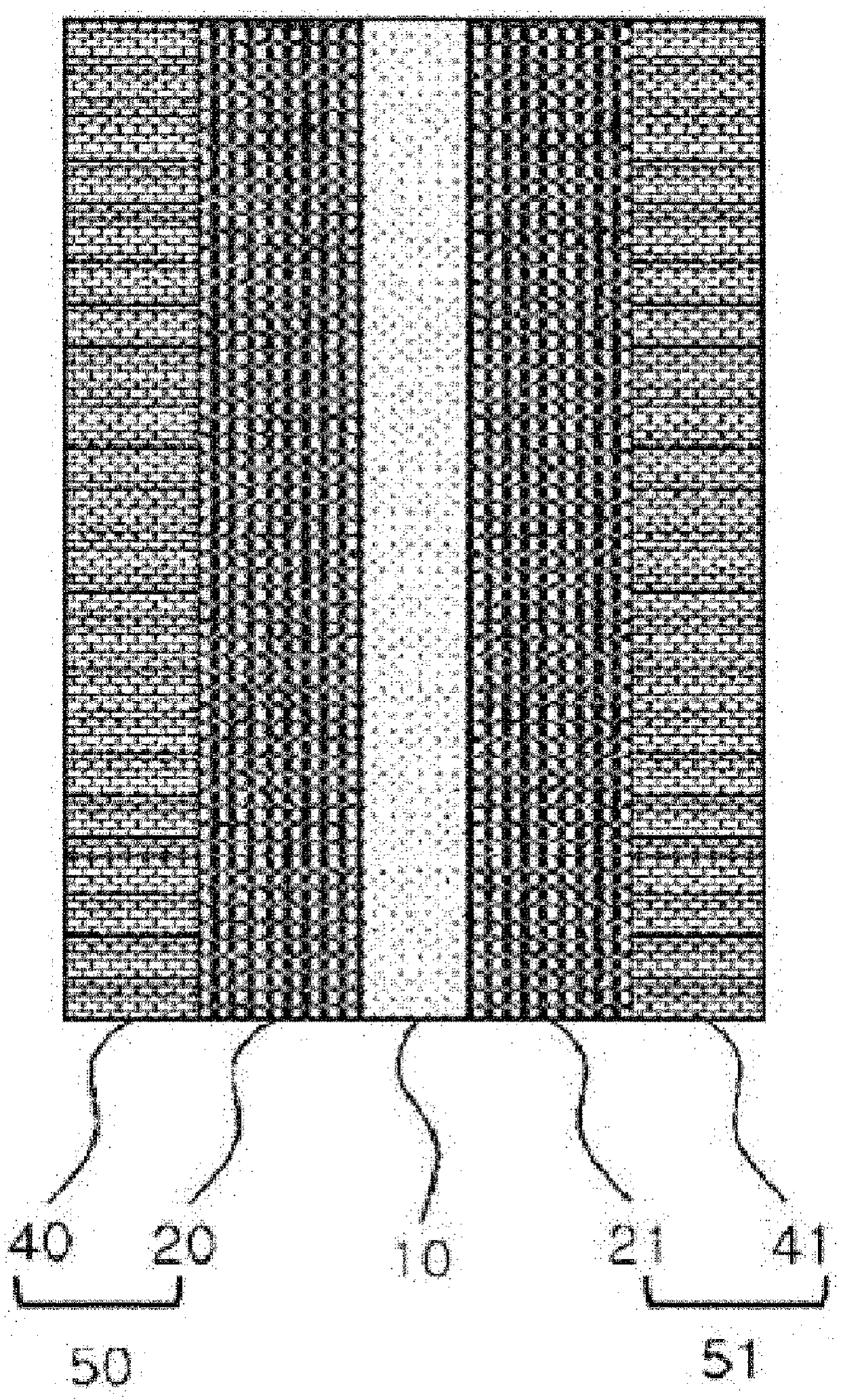

Image

Examples

Embodiment 1

[0086] Add 3M 825 ionomer to a 7:3 solution of water and 1-propanol. Thereafter, TEC 10F50E catalyst sold by Tanaka Co., Ltd. was added thereto at a mass ratio of ionomer and carbon (ionomer / carbon) of 0.9. The resultant was stirred at room temperature using a magnetic stirrer for 1 hour, then dispersed at room temperature for 1 hour using a bath-type ultrasonic homogenizer, and then dispersed for 15 minutes using a tip-type ultrasonic homogenizer after the temperature was lowered below 50°C. Then, the resultant was dried in an oven at 70° C. to obtain solid ionomer-dispersed catalyst particles.

[0087] After these particles were added to a solution mixed with 1-propanol and glycerin, the resultant was subjected to ultrasonic dispersion as described above to prepare an electrode slurry.

[0088] Using the prepared electrode slurry, the electrode catalyst layer was cast on the PTFE membrane using a scraper on the horizontal plate of the applicator in a clean bench, and then t...

Embodiment 2

[0090] An electrode was fabricated in the same manner as in Example 1 except that TEC 10F50E-HT catalyst sold by Tanaka Co., Ltd. was used as a catalyst.

experiment example 1

[0096] Membrane electrode assemblies using the electrode catalyst layers of Example 1 and Comparative Example 1 were evaluated. A sPEEK-based hydrocarbon membrane was used as the electrolyte membrane, 10BB manufactured by SGL Group was used as the gas diffusion layer (GDL), and its thickness ranged from 380 μm to 420 μm. The compressibility of the GDL was set at 25%, and glass fiber sheets were used to maintain the compressibility. The active area of the membrane electrode assembly was prepared to be 25 cm 2, for unit cell evaluation. As an anode and a cathode, electrodes of the same example were used for evaluation.

[0097] As an evaluation device, a PEMFC workstation device manufactured by Scribner Associates Inc. was used, and the cell temperature was kept at 70° C. and the humidity condition was kept at RH 50% for performance evaluation. The results are shown in Table 1 below and Figure 2 to Figure 6 shown.

[0098] [Table 1]

[0099]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com