Hydraulic hose

A hydraulic hose and pipe body technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of fatigue resistance, pulse performance of the inner rubber, and aging resistance of the outer rubber without considering the adhesiveness of the middle rubber Sex and other issues, to achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

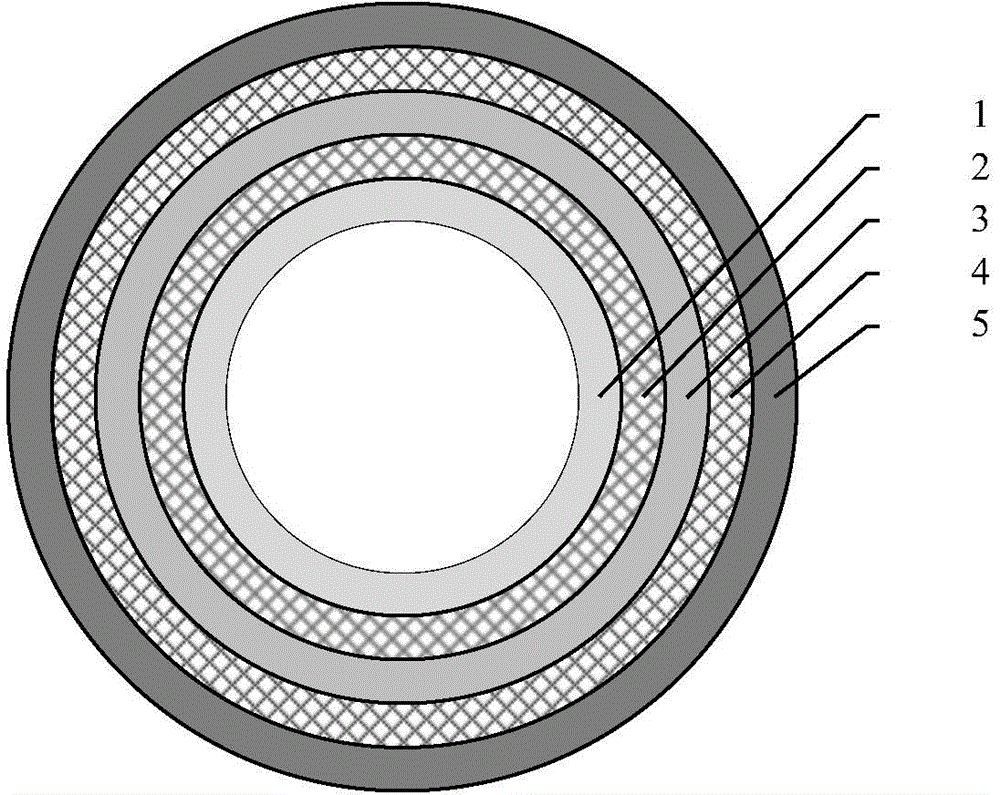

[0038] 1. The raw material composition of the inner rubber film of the inner rubber layer of the hydraulic hose is: raw rubber 100, vulcanization system 3.5-6, anti-scorch agent CTP0.5, nano-zinc oxide 6, high-activity magnesium oxide 3, adhesive 6.5-11 , Reinforcing agent 70, calcium fluoride 30, decaptyl 15, stearic acid 1. Experimentation is used to determine the raw material composition for optimum performance of the inner film.

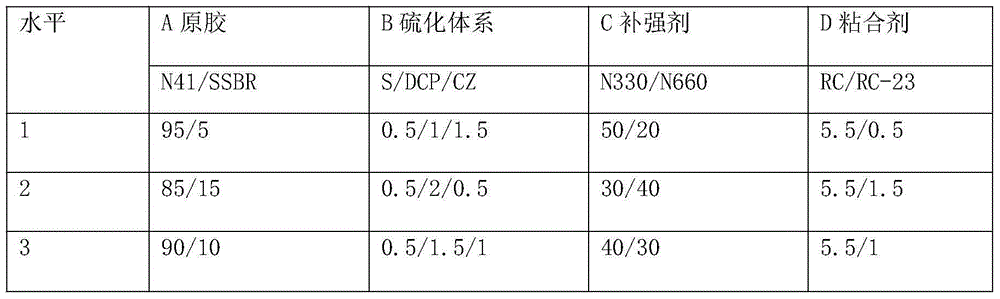

[0039] 2. First, use the orthogonal table to design, and see Table 1 for the determined four factors and three levels.

[0040] Table 1 Four factors and three levels

[0041]

[0042] 3. Next, experiments were carried out based on the raw material components of the 9 inner rubber sheets. The production equipment for preparing the inner rubber layer film included a kneader, a Φ150 filter, and a 24-inch open mill. The specific method steps included:

[0043] a. Put the original rubber into the kneader and knead for 3 minutes;

[0044] b. Put ...

Embodiment 2

[0061] 1. The raw material composition of the medium rubber film in the rubber layer of the hydraulic hose is: 100 raw rubber, 4.5-5 vulcanization system, 6 nano-zinc oxide, 6.5-11 adhesive, 50 reinforcing agent, 30 sepiolite, and anti-aging agent 5. 15 octadecyl esters, 1 stearic acid, and 8 petroleum resins. Experimentation is used to determine the raw material composition of medium film for optimum performance.

[0062] 2. First, use the orthogonal table to design, and see Table 3 for the determined four factors and three levels.

[0063] Table 3 Four factors and three levels

[0064]

[0065] 3. Next, experiment was carried out according to the raw material components of these 9 medium rubber films, wherein the production equipment for preparing the medium rubber film comprises a kneader, a Φ150 filter, and a 24-inch open mill. The specific method steps include:

[0066] a. Put the raw gum into the kneader and knead for 3 minutes;

[0067] b. Add active agent, accele...

Embodiment 3

[0079] 1. The raw material composition of the outer rubber film of the outer rubber layer of the hydraulic hose is: raw rubber 100, vulcanization system 3.5, nano-zinc oxide 8, high-activity magnesium oxide 4, adhesive 6.5-11, reinforcing agent 70, calcium fluoride 30, Antiaging agent 11, Decyl caprylate 20, Stearic acid 1. Experimentation is used to determine the raw material composition for optimum performance of the cover film.

[0080] 2. First, use the orthogonal table to design, and see Table 5 for the determined four factors and three levels.

[0081] Table 5 Four factors and three levels

[0082]

[0083] 3, then, carry out experiment according to these 9 outer rubber film raw material components, the experimental equipment and method steps of preparing outer rubber layer film are consistent with the experimental equipment and method of preparing middle rubber layer film in embodiment 2, detect experimental result, and For the evaluation of extreme difference, see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com