Patents

Literature

58 results about "Fracture prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Since you probably spend most of your time in your home, a key part of fracture prevention is to make it safer. Some things that can help: Keep rooms free of clutter. Put carpet or plastic runners on polished floors. Get throw rugs, electric cords, and phone lines off the floor.

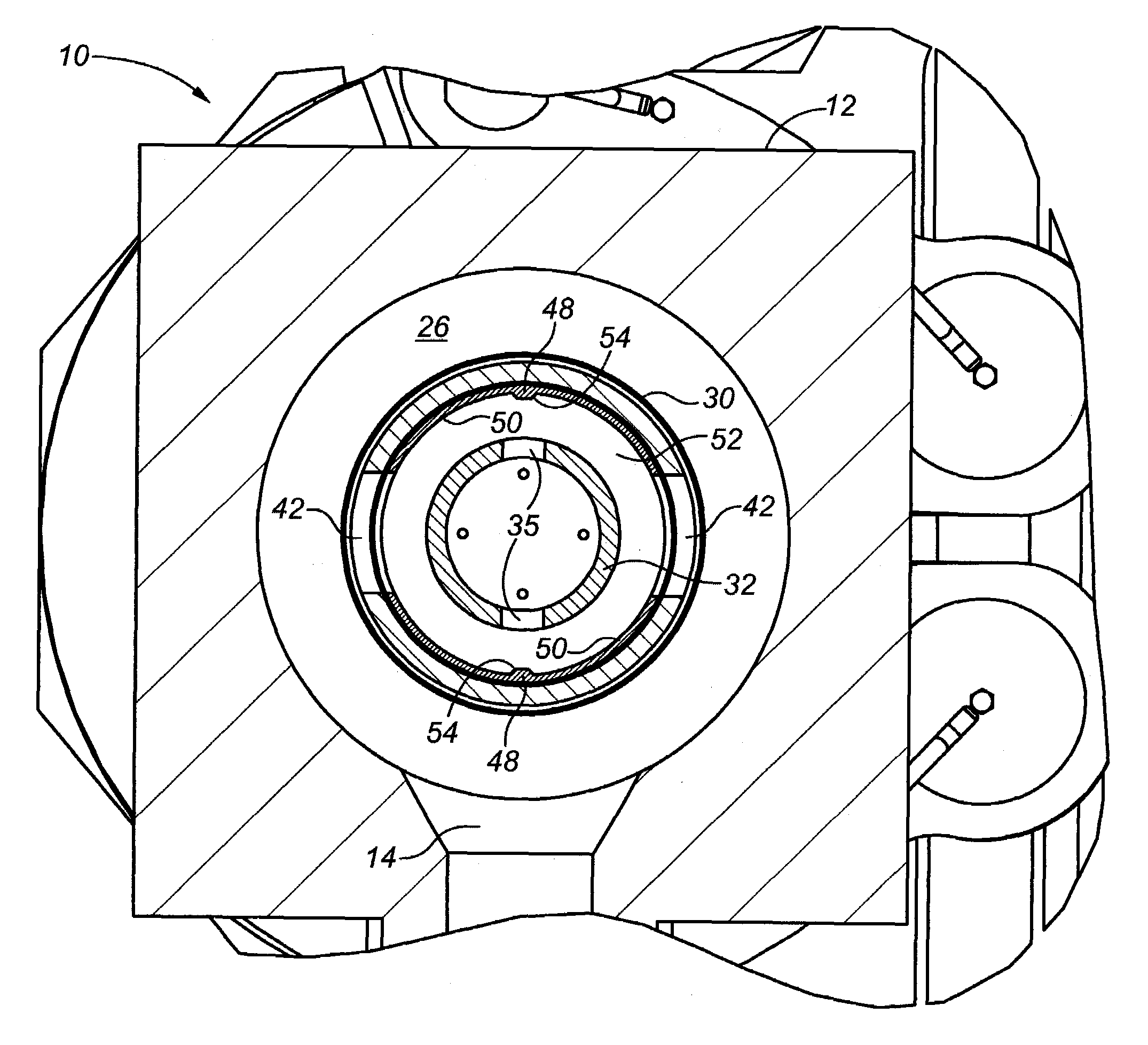

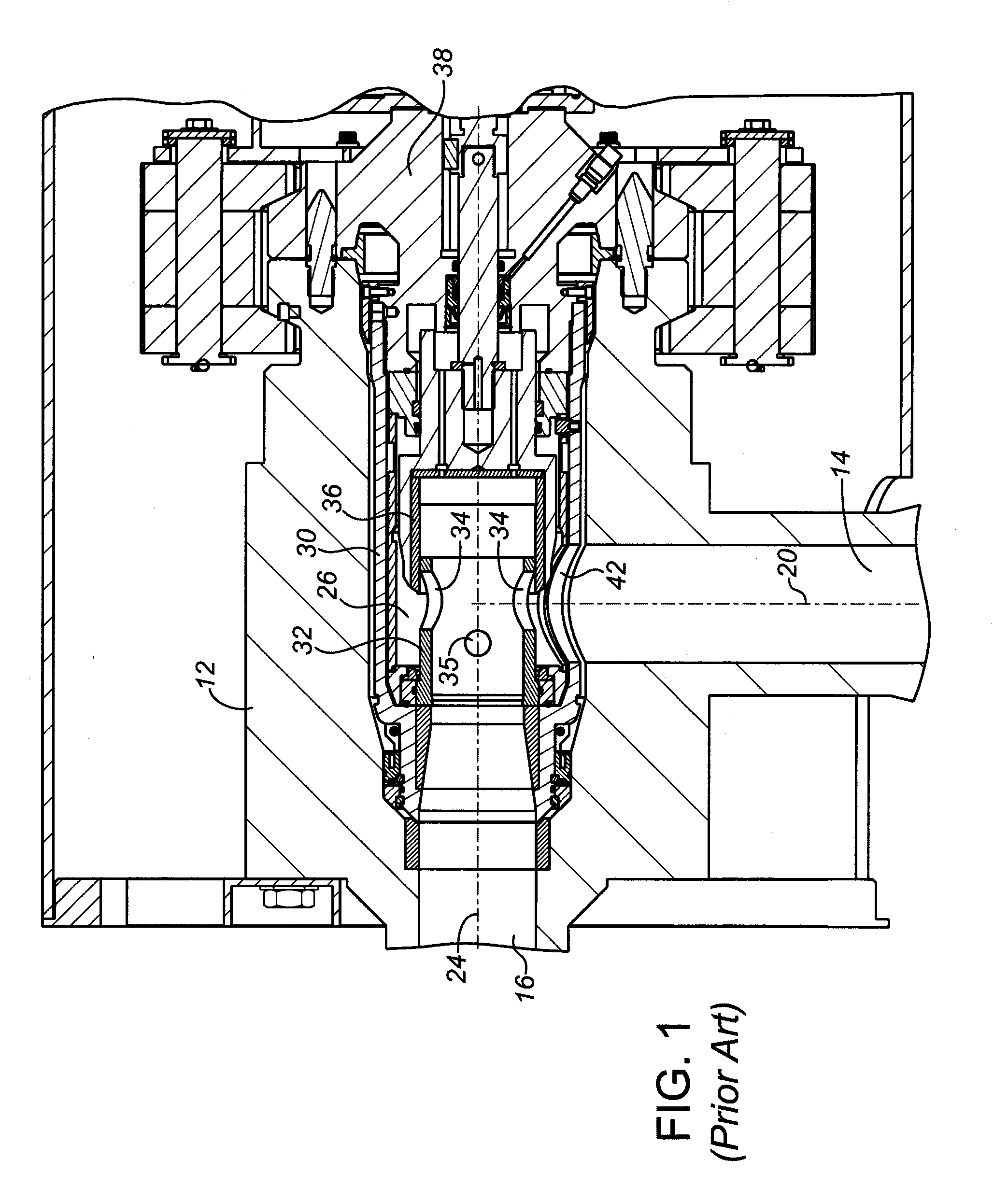

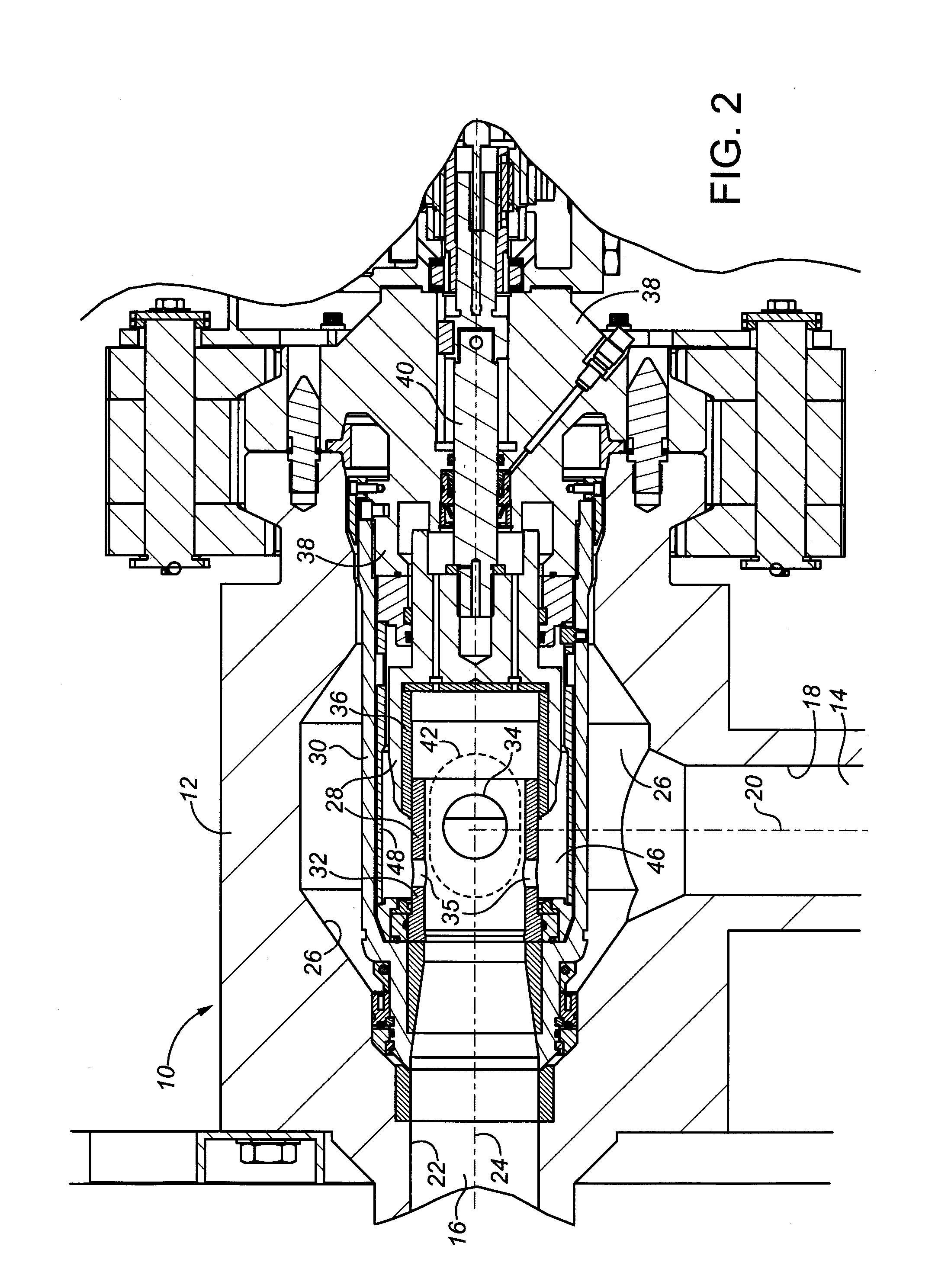

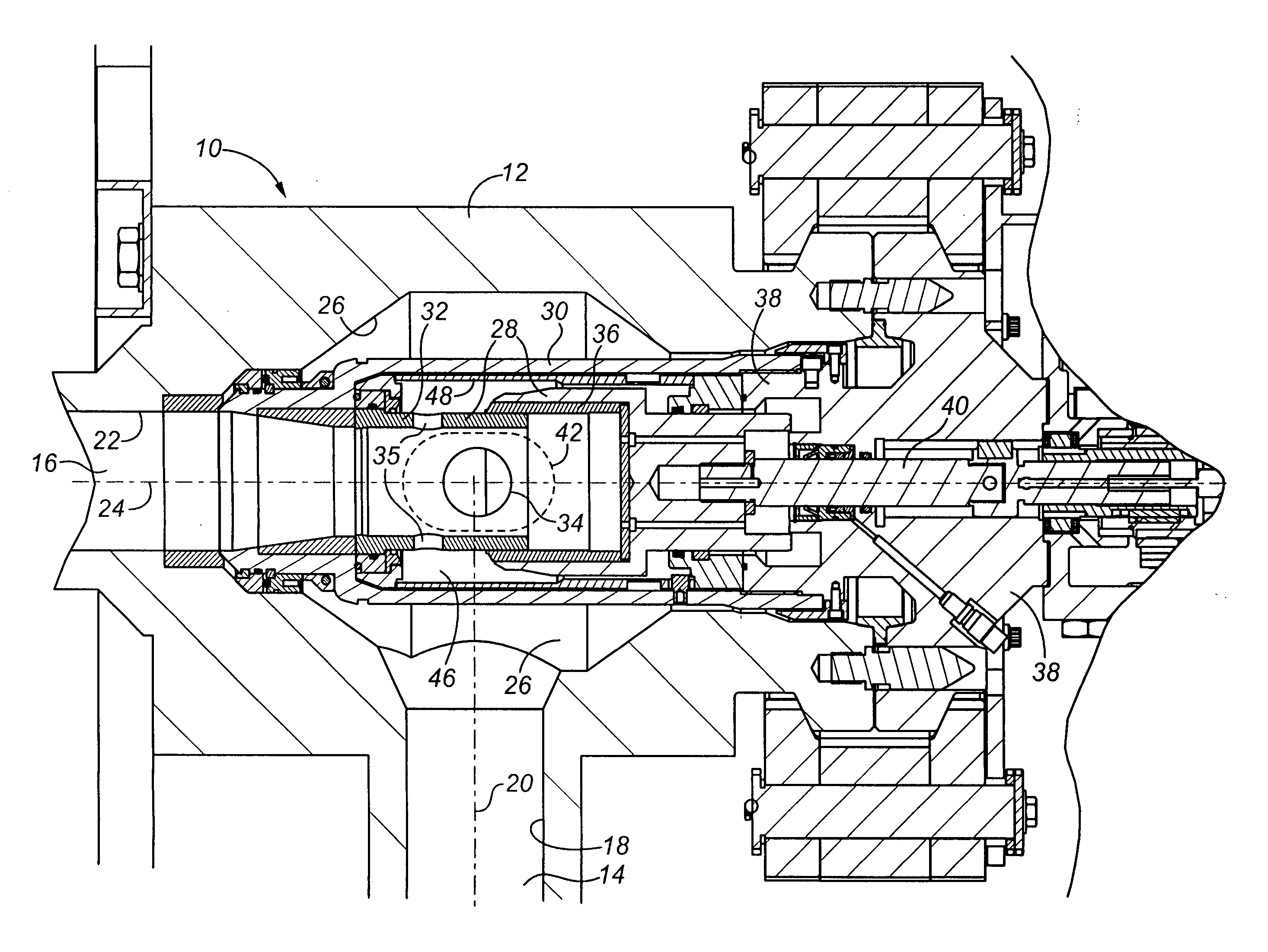

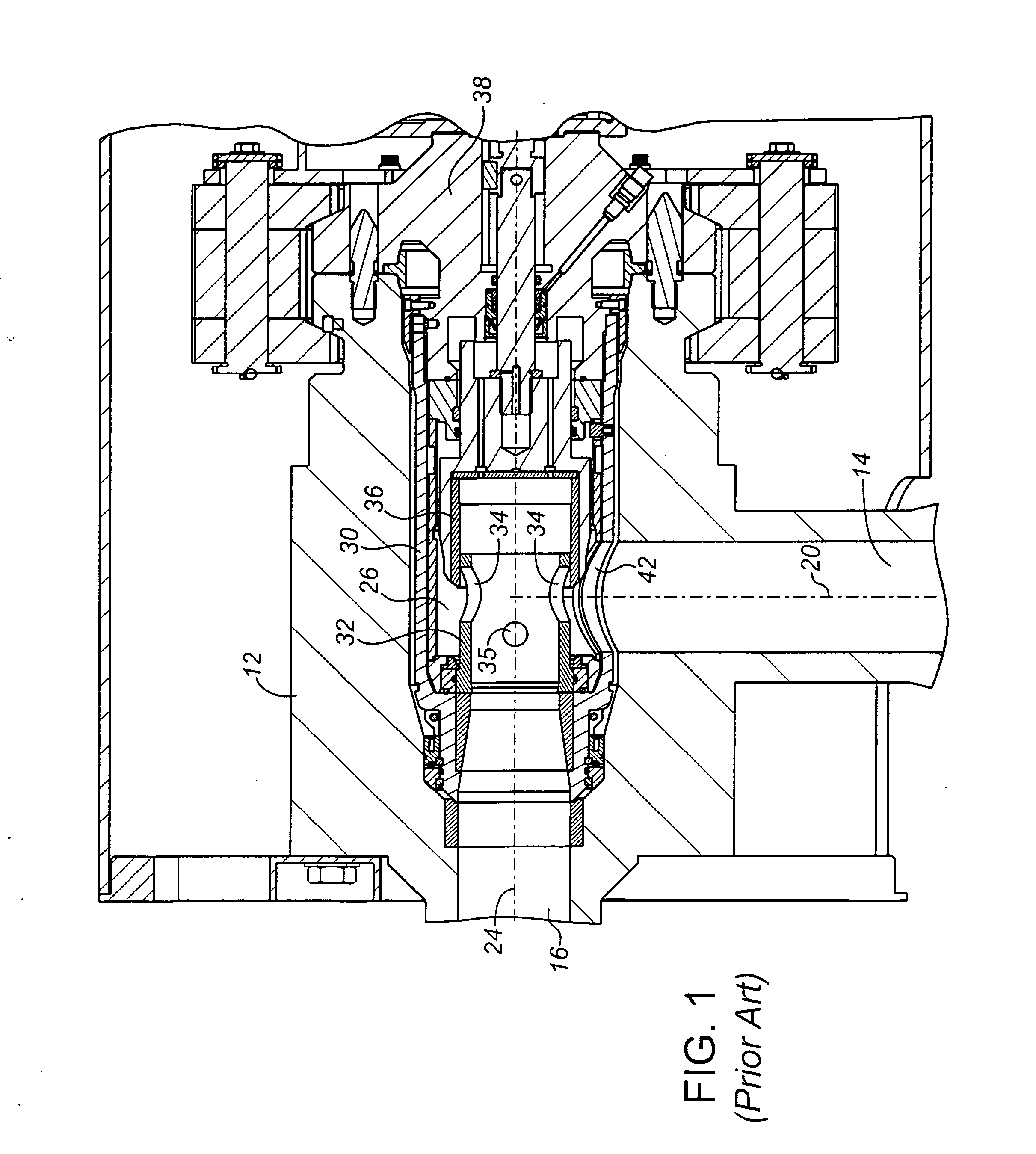

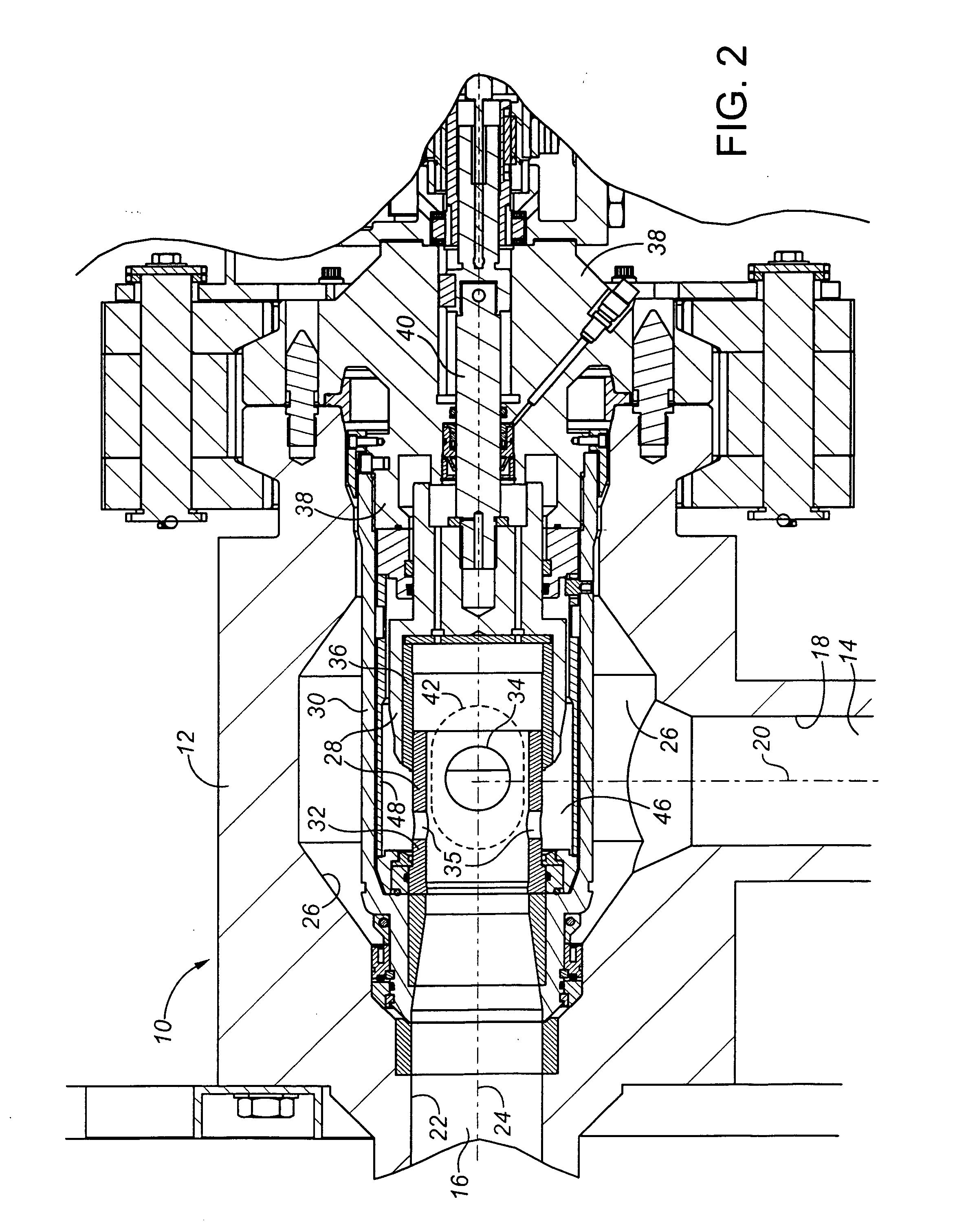

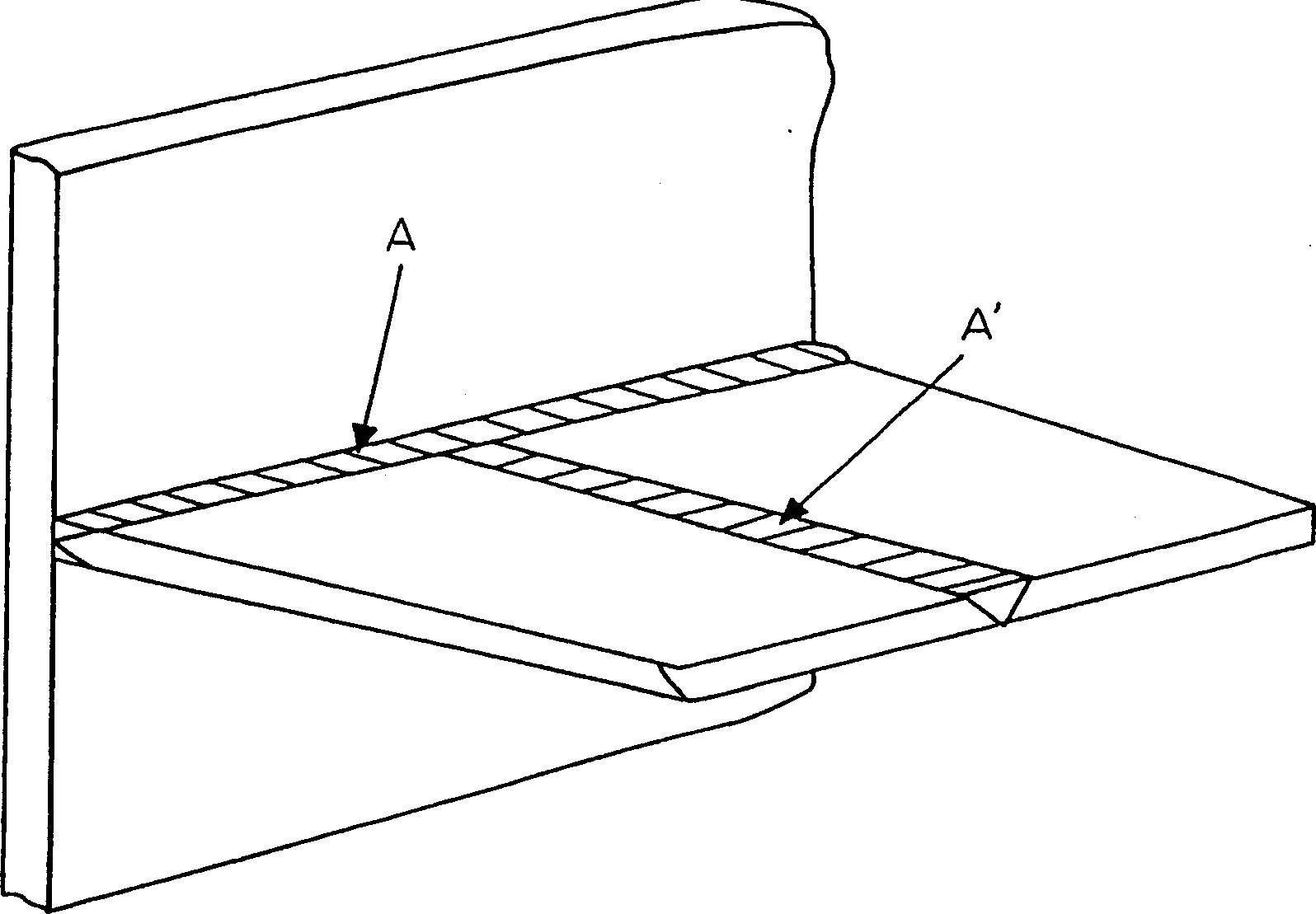

Choke valve flow trim for fracture prevention

ActiveUS7426938B2Large resistanceAvoid direct impactValve members for absorbing fluid energyPipe elementsFracture preventionStreamflow

A choke valve having flow trim components, namely a tubular cage and a flow collar or plug, and related components, designed and arranged for reduced fracturing. The invention includes a protective tubular sleeve, or insert cartridge in which the side ports are located to overlap with the intersection of axes of the inlet and outlet bores, but to avoid direct impingement of fluid along the axis of the inlet bore. In the cage, at least a pair of main flow ports are located to overlap with the intersection of the axes of the inlet and outlet bores, and are aligned with the side ports of the tubular sleeve or cartridge to communicate directly with the side ports. In this manner fluid may enter the choke valve through the inlet bore and pass through the main flow ports at reduced pressure and continue out through the outlet bore, without direct impingement on the side wall of the flow trim components.

Owner:MASTER FLO VALVE

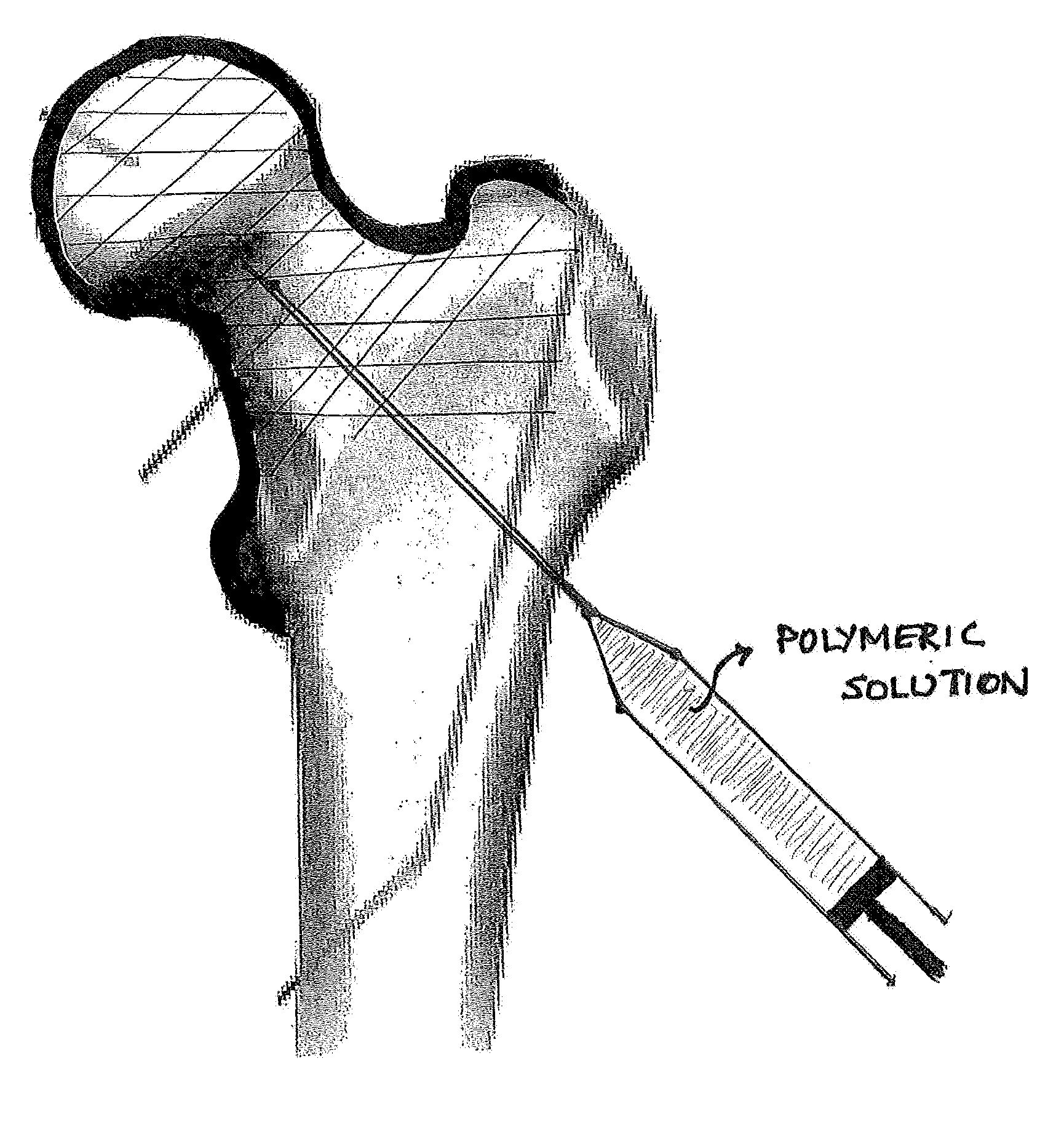

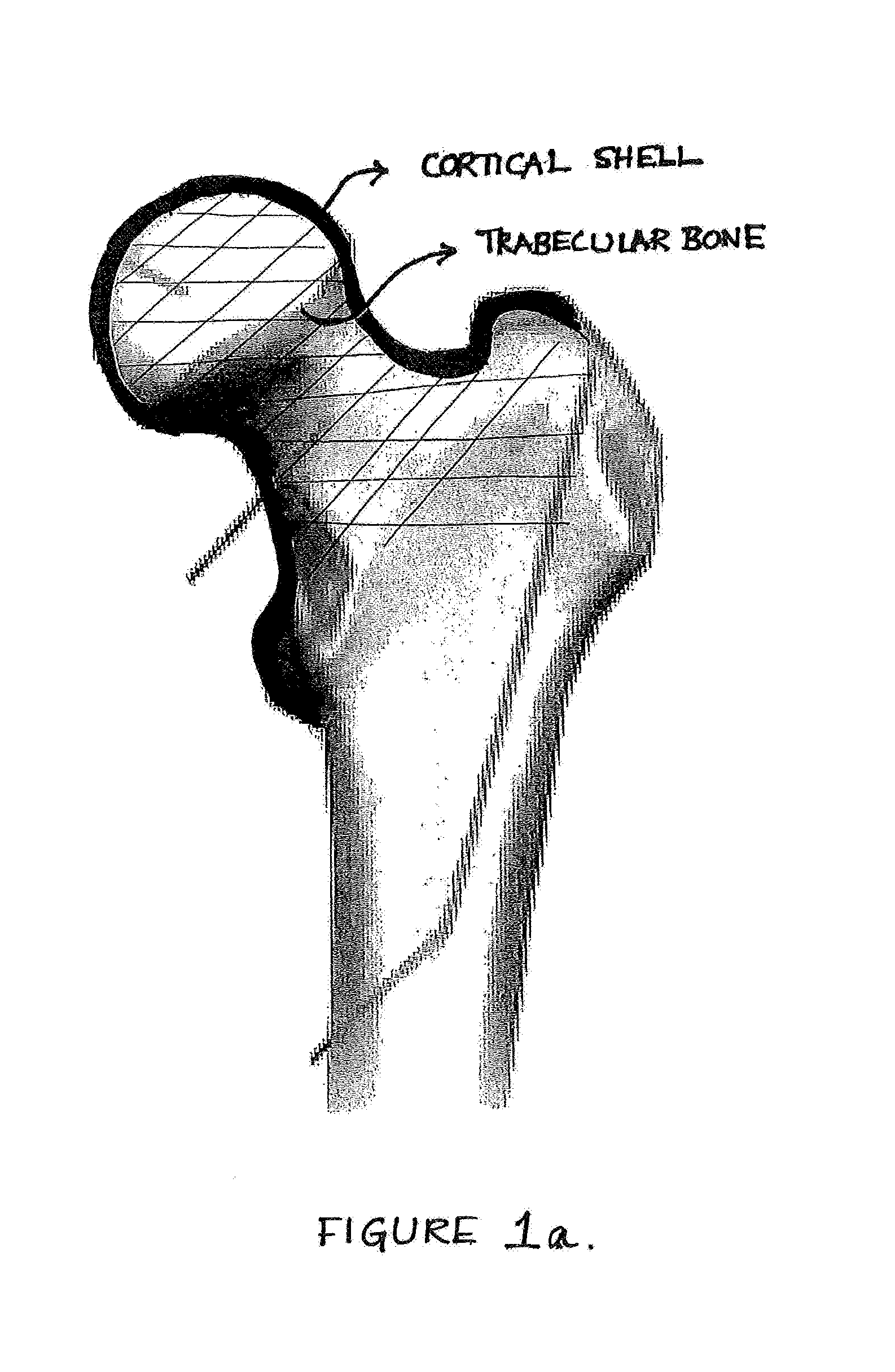

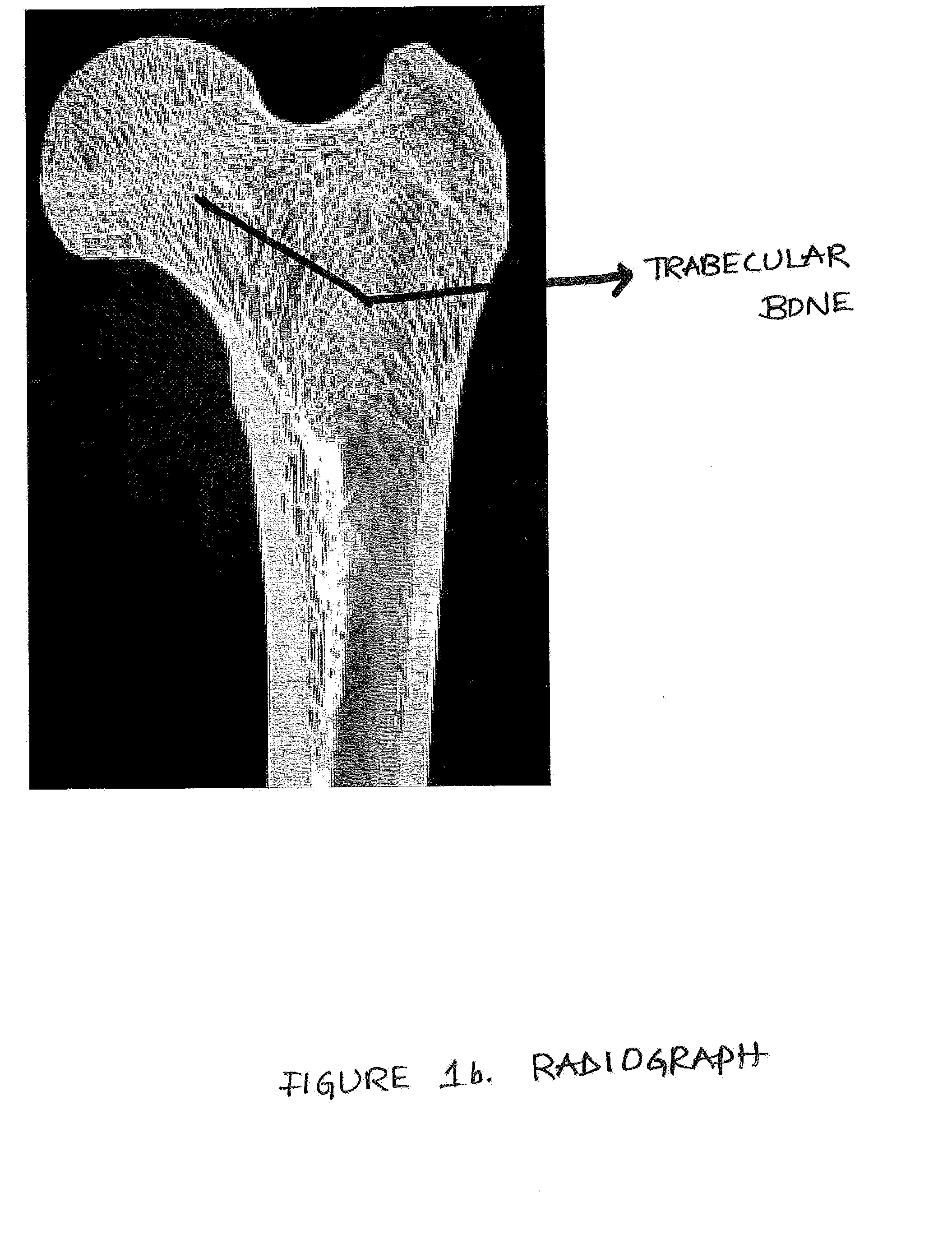

Device, Composition and Method for Prevention of Bone Fracture and Pain

InactiveUS20140194887A1Low viscosityStrong bonesDiagnosticsPharmaceutical delivery mechanismCross-linkBone structure

Methods, apparatus, compositions for reinforcing bone structures are disclosed as well as a reinforced bone structure itself. By injecting a low viscosity polymeric solution into a trabecular bone region at least partly surrounded by cortical bone allowing it to cross-link in-situ, a non-degradable gel can effectively reinforce the region by retaining fluid in the constrained space within the cortical shell. Due to the low viscosity of the pre-cross-linked aqueous polymeric solution, the entire site could be filled effectively and consistently. Additionally, by injecting a low viscosity pre-cursor, the solution fills the natural intra-trabecular spaces without substantial alteration of the trabecular structure at the site.

Owner:SHENOY VIVEK

Choke valve flow trim for fracture prevention

ActiveUS20060163517A1Reduce flow rateReduce kinetic energyOperating means/releasing devices for valvesValve members for absorbing fluid energyFracture preventionStreamflow

A choke valve having flow trim components, namely a tubular cage and a flow collar or plug, and related components, designed and arranged for reduced fracturing. The invention includes a protective tubular sleeve, or insert cartridge in which the side ports are located to overlap with the intersection of axes of the inlet and outlet bores, but to avoid direct impingement of fluid along the axis of the inlet bore. In the cage, at least a pair of main flow ports are located to overlap with the intersection of the axes of the inlet and outlet bores, and are aligned with the side ports of the tubular sleeve or cartridge to communicate directly with the side ports. In this manner fluid may enter the choke valve through the inlet bore and pass through the main flow ports at reduced pressure and continue out through the outlet bore, without direct impingement on the side wall of the flow trim components.

Owner:MASTER FLO VALVE

Corrosion-resistant fracture-prevention plastic woven bag and preparation method thereof

InactiveCN105176056AImprove corrosion resistanceAvoid breakingConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberLinear low-density polyethylene

A corrosion-resistant fracture-prevention plastic woven bag is characterized by being prepared from, by weight, 40% of waste polyolefin plastic, 40% of polyurethane waste materials, 2% of nano silicon carbide, 5% of metallocene polyethylene, 5% of linear low-density polyethylene, 0.5% of antioxidants, 0.5% of hindered amine light stabilizers, 0.5% of nano titanium carbide, 0.5% of fire retardants, 0.5% of lubricating agents, 1% of calcium stearate, 0.5% of tributyl citrate, 0.5% of vital gluten, 1% of tert-butyl mercaptan, 1% of ash calcium powder, 1% of lignin, and 0.5% of carbon fibers. According to the corrosion-resistant fracture-prevention plastic woven bag, the formula is simple, the cost is low, the made plastic woven bag has good corrosion resistance, breakage of silk threads can be effectively prevented, and the problem that in the prior art, the working life of a packing bag is short is solved.

Owner:JIESHOU SHENGCHANG PLASTIC

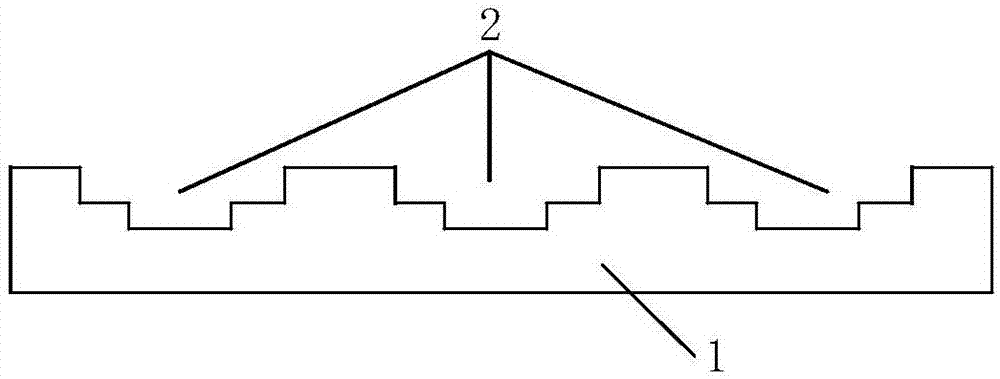

Color film substrate, liquid crystal display panel, and liquid crystal display

The invention relates to the technical field of display, and discloses a color film substrate, a liquid crystal display panel, and a liquid crystal display. The color film substrate comprises a substrate baseplate and a color filter layer formed on the substrate baseplate. The color filter layer is provided with a plurality of sunken portions whose openings are opposite to a substrate baseplate direction. The edge of each sunken portion forms a step shape structure, and the dimension of the opening of the sunken portion is larger than the dimension of a bottom of the sunken portion. The color film substrate is provided with the sunken portions whose edges are step shape structures on the color filter layer. The sunken portions are used to change force condition of the whole color filter layer in a bended state, color resistance stress on the color filter layer is reduced when a display screen bends, and a technical process of adding a fracture prevention protection layer on the color filter layer is simplified, manufacturing time is shortened, and production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

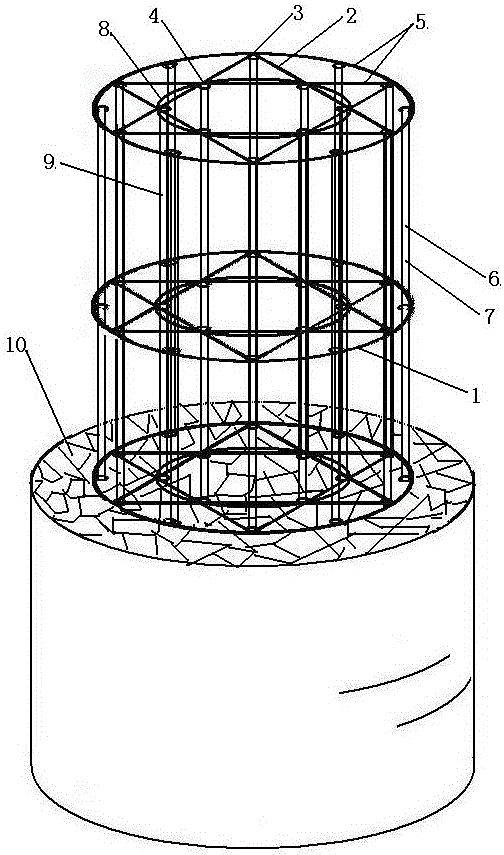

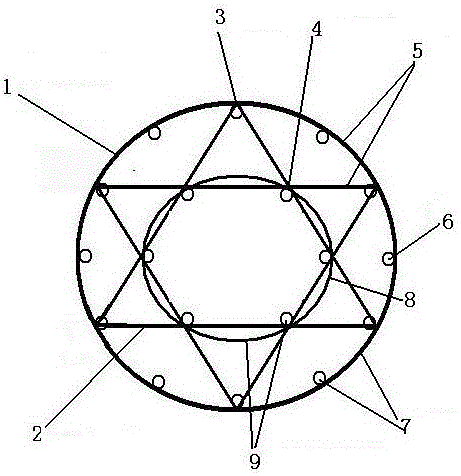

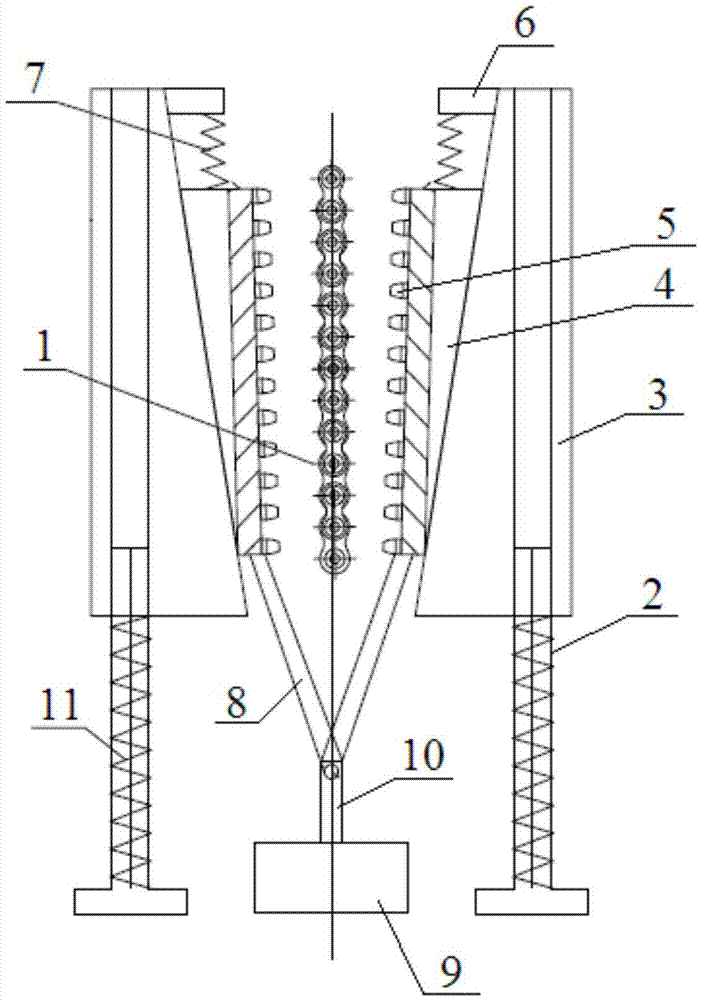

Processing method of pre-stressed concrete reinforced pile

InactiveCN106272953AHigh strengthImprove ductilityCeramic shaping apparatusFurnace typesHigh strength concreteCrack resistance

A processing method of a pre-stressed concrete reinforced pile comprises the following steps: firstly, preparing a reinforcement cage which adopts an integral structure with both an inner-layer reinforcement cage and an outer-side reinforcement cage, wherein the reinforcement cage takes high-strength stirrups as the basis and is supported by mutually staggered regularly triangular racks; a steel mould of a reinforced pile is filled with high-strength concrete, the high-strength concrete is subjected to curing molding to obtain the end product of the pre-stressed concrete reinforced pile. The processing method has the following beneficial effects: the stability of the triangles enhances the strength of the reinforcement cage; the regular triangles can guarantee uniform space between main ribs; the strength of the processed and manufactured reinforcement cage can be structurally improved greatly; in addition, pre-stressed concrete steel bars which are manufactured through special formulas and machining process have the strength exceeding 2,000 MPa and the ductility higher than 7%, and also have good drawability and delayed fracture prevention characteristic, and therefore, the shearing, bending and cracking resistance are greatly improved; the preparation cost is only that of the 1,420 MPa pre-stressed concrete steel bars, so that the cost is greatly lowered.

Owner:重庆市晟庄建材有限责任公司

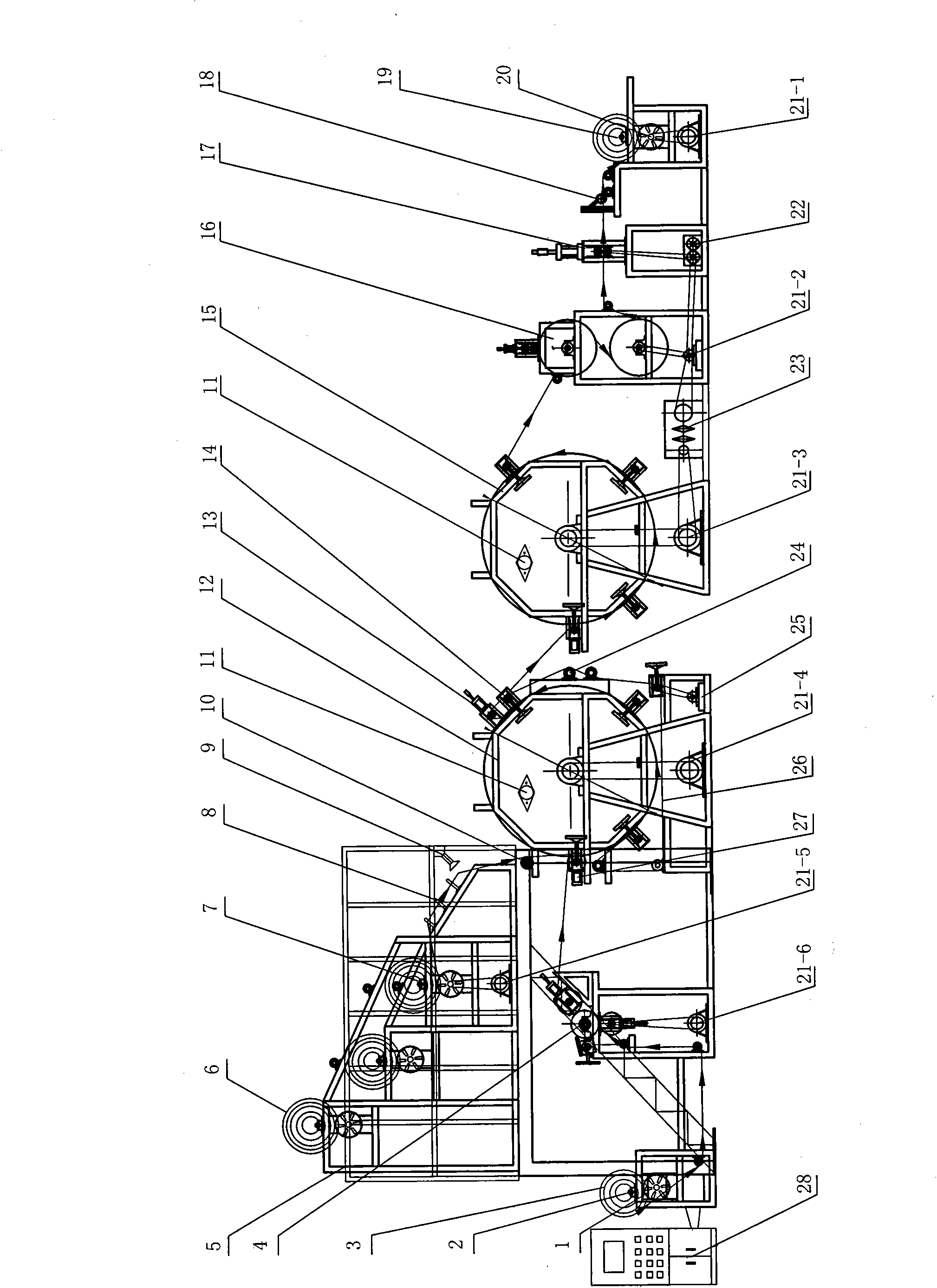

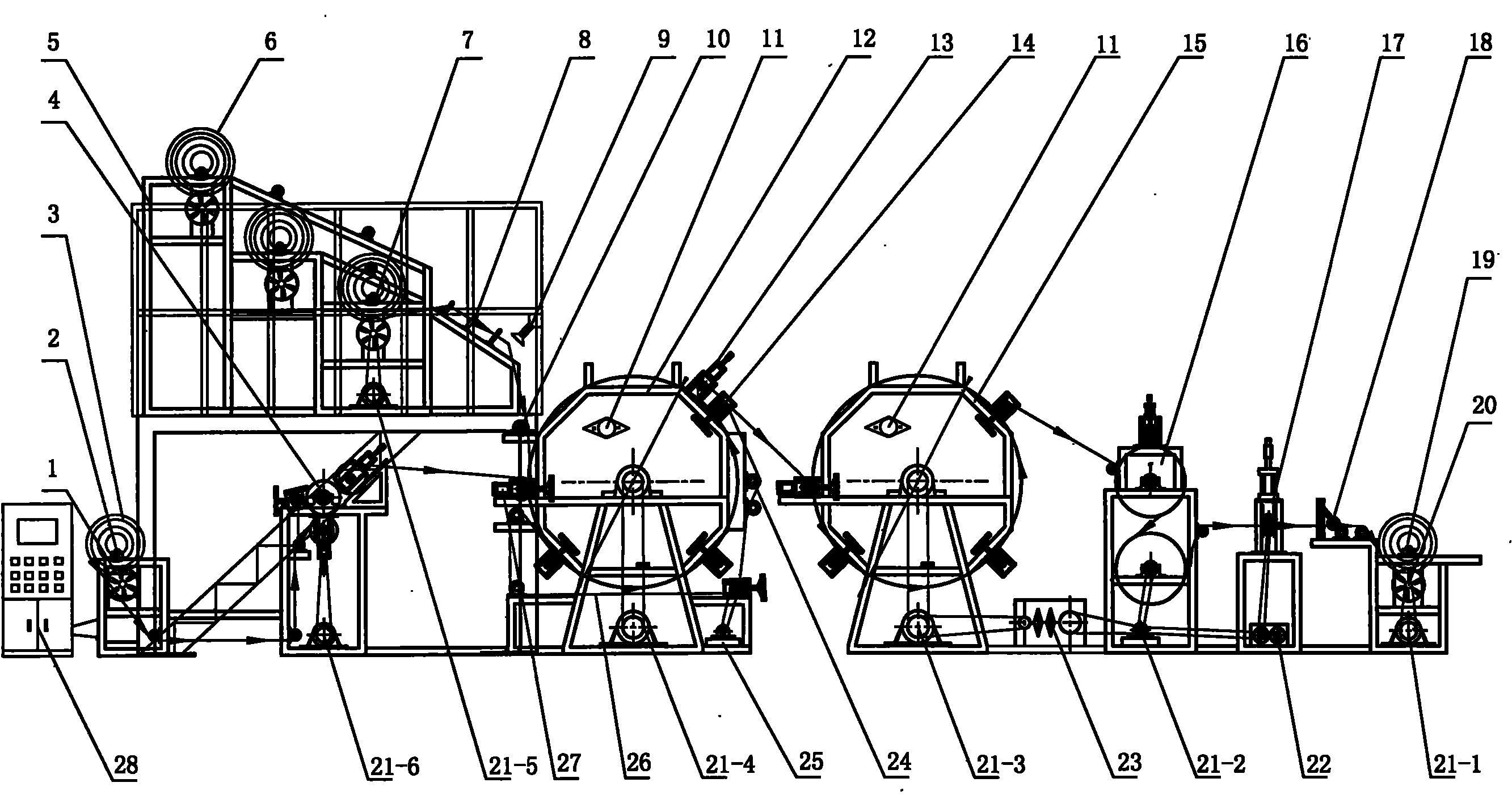

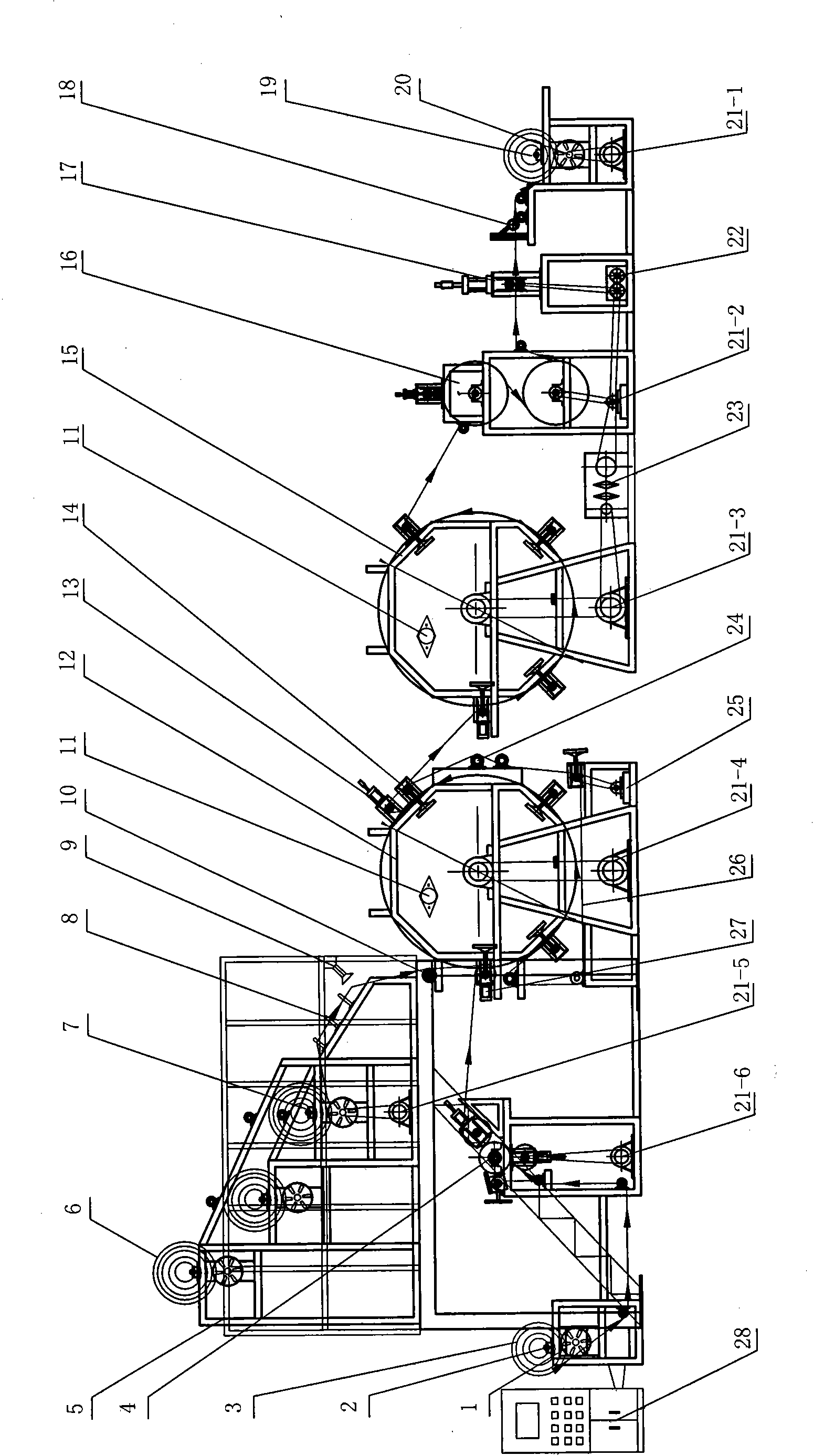

Multifunctional paper yarn wall paper compounding machine

InactiveCN102381001AImprove flexural tensile strengthQuality improvementLamination ancillary operationsLaminationThermal engineeringYarn

The invention relates to a multifunctional paper yarn wall paper compounding machine, which belongs to paper and yarn compounding machinery and comprises a magnetic powder brake, a constant tension uncoiling device, a paper coil, a gluing device, a support frame body, a yarn coil, a constant tension multi-layer yarn uncoiling device, a steel buckle, an optical yarn fracture prevention sensor, an expansion roller, a temperature sensor, a front braking tube device, an air cylinder, a steel roller, a back baking tube device, a cooling device, a traction device, a counter, a constant tension center coiling device, a magnetic powder clutch, a servo motor, a combined gearbox, a stepless speed changer, a deflection correcting roller, a clutch gearbox, a net belt, a main silicon gel roller and a computer control cabinet, wherein the multifunctional paper yarn wall paper compounding machine is designed by adopting and combining a computer closed loop technology and mechanical and thermal engineering principles. The machine has the advantages that the automation degree is high, the production efficiency is high, the production cost is reduced, the operation is safe and convenient, the produced paper and yarn compounding material is a novel environment-protection compounding material, the quality is good, the energy is saved, the environment is protected, the folding resistance and tensioning resistance intensity is high, the colors are rich, the use is convenient, and the pasting is firm.

Owner:JIANGSU KUNTAI MACHINERY

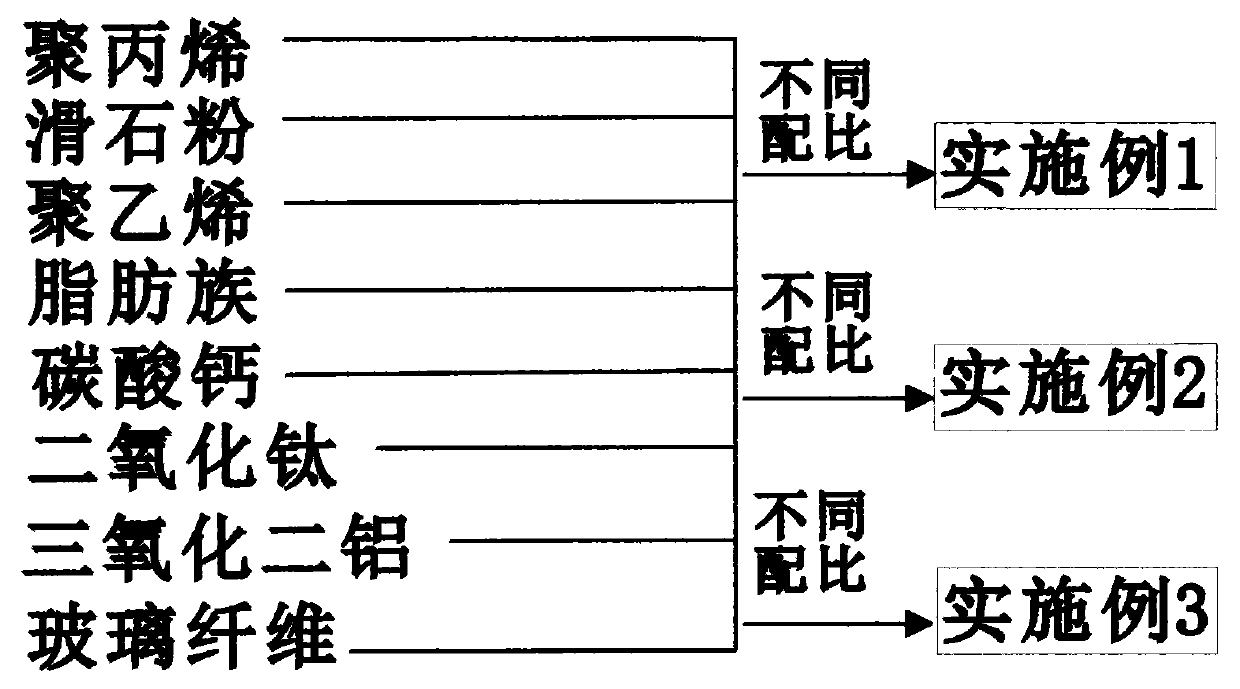

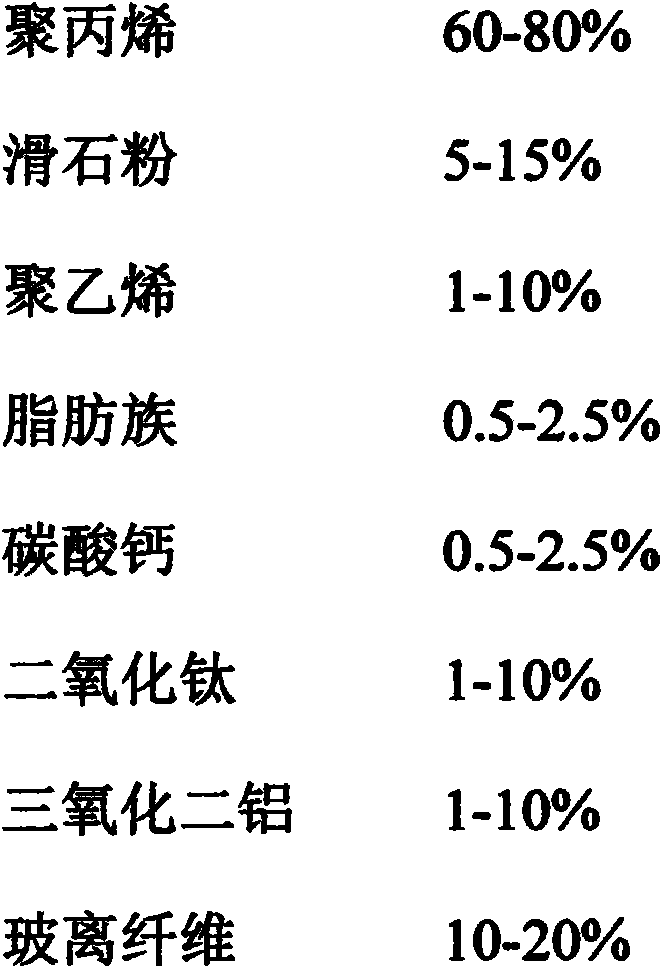

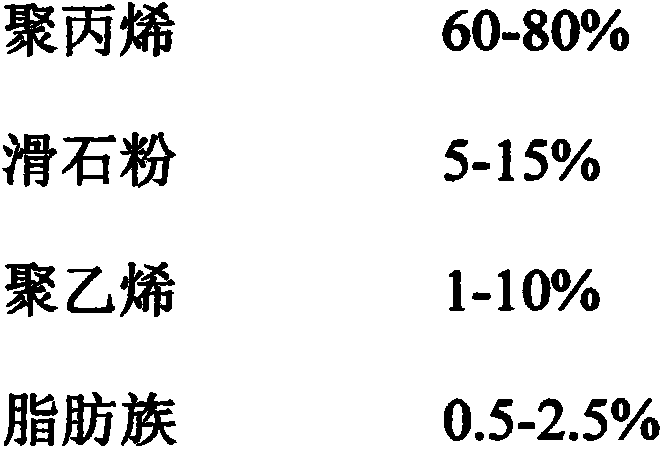

Polypropylene honeycomb hollow plate material

The invention discloses a polypropylene honeycomb hollow plate material, belonging to the field of multi-layer co-extrusion molded hollow plate materials. The polypropylene honeycomb hollow plate material is characterized in that an internal structure comprises the following components in percentage by weight: 60-80% of polypropylene, 5-15% of talcum powder, 1-10% of polyethylene, 0.5-2.5% of aliphatic series, 0.5-2.5% of calcium carbonate, 1-10% of titanium dioxide, 1-10% of aluminum oxide and 10-20% of glass fiber. The polypropylene honeycomb hollow plate material disclosed by the invention solves the defects that a conventional plastic hollow plate is poor in impact resistance, can be deformed when being compressed and is not solid, has the excellent properties of high strength, pressure resistance, abrasion resistance, thermal insulation, impact resistance, fracture prevention and the like, and is wide in application range and good in use effect.

Owner:NINGBO TIANQI HONEYCOMB MATERIALS

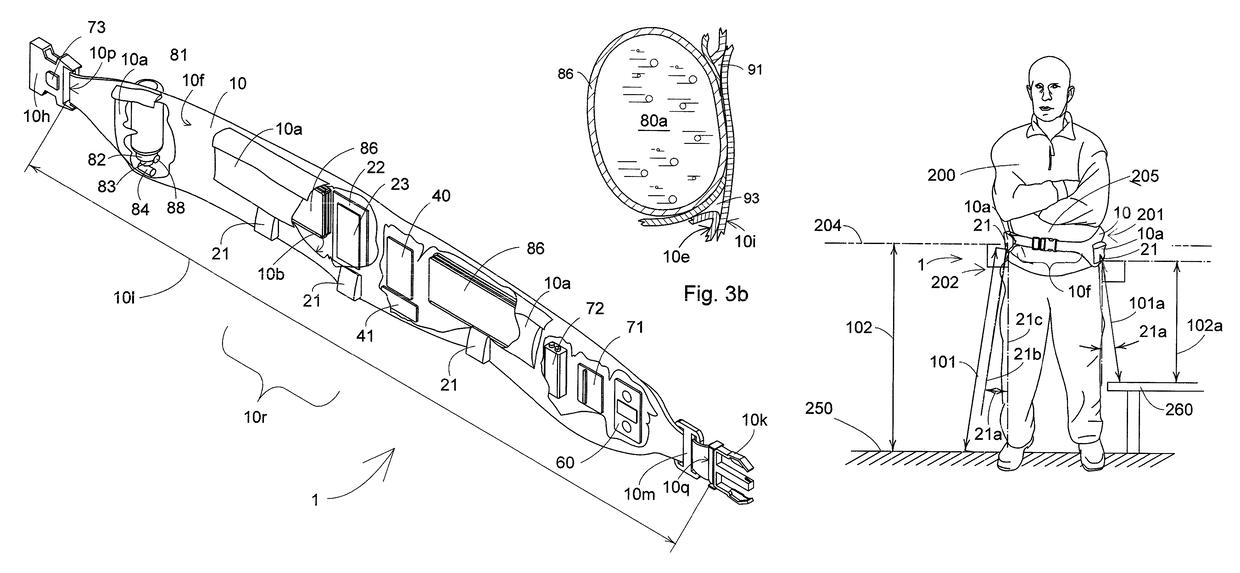

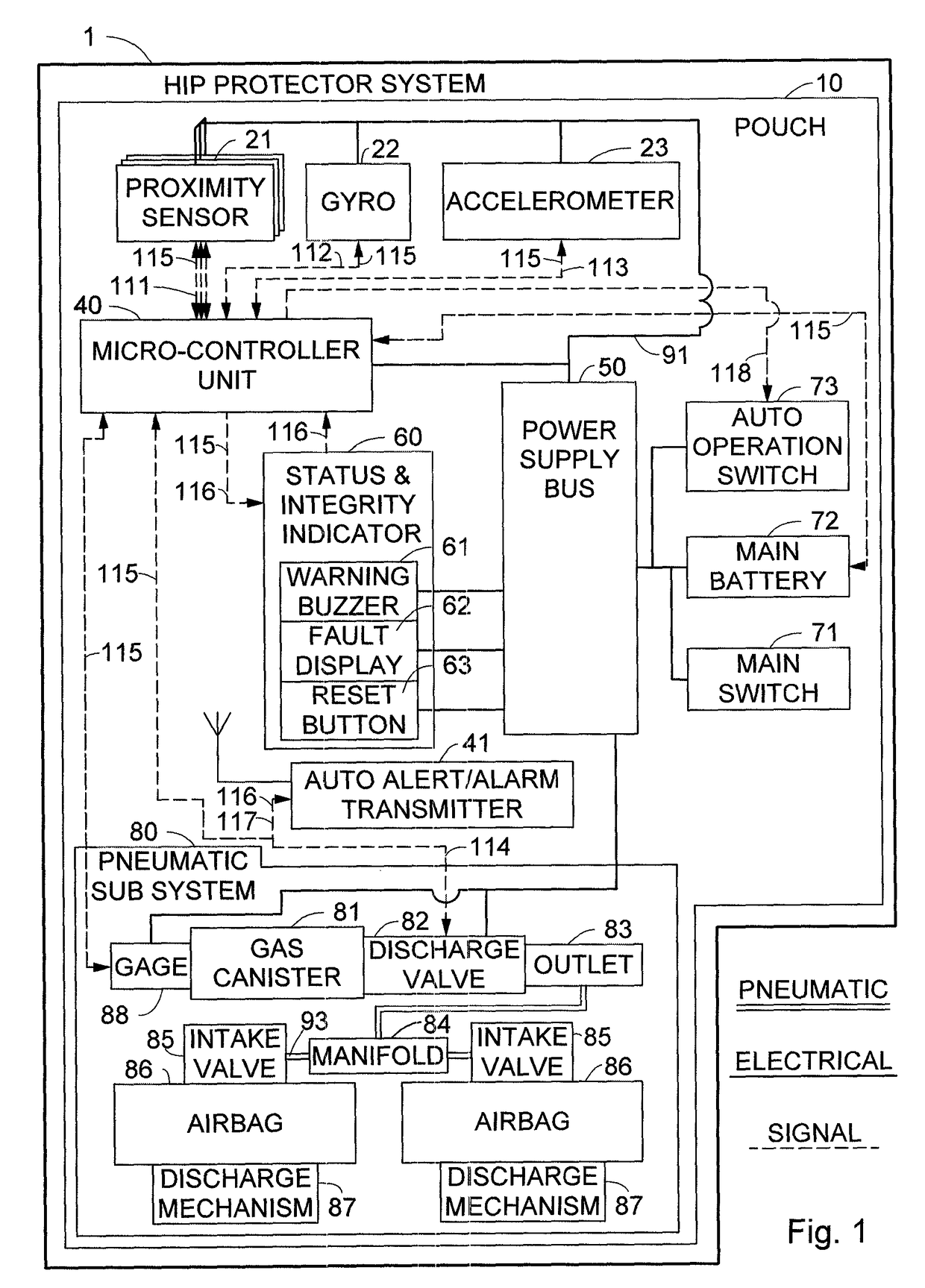

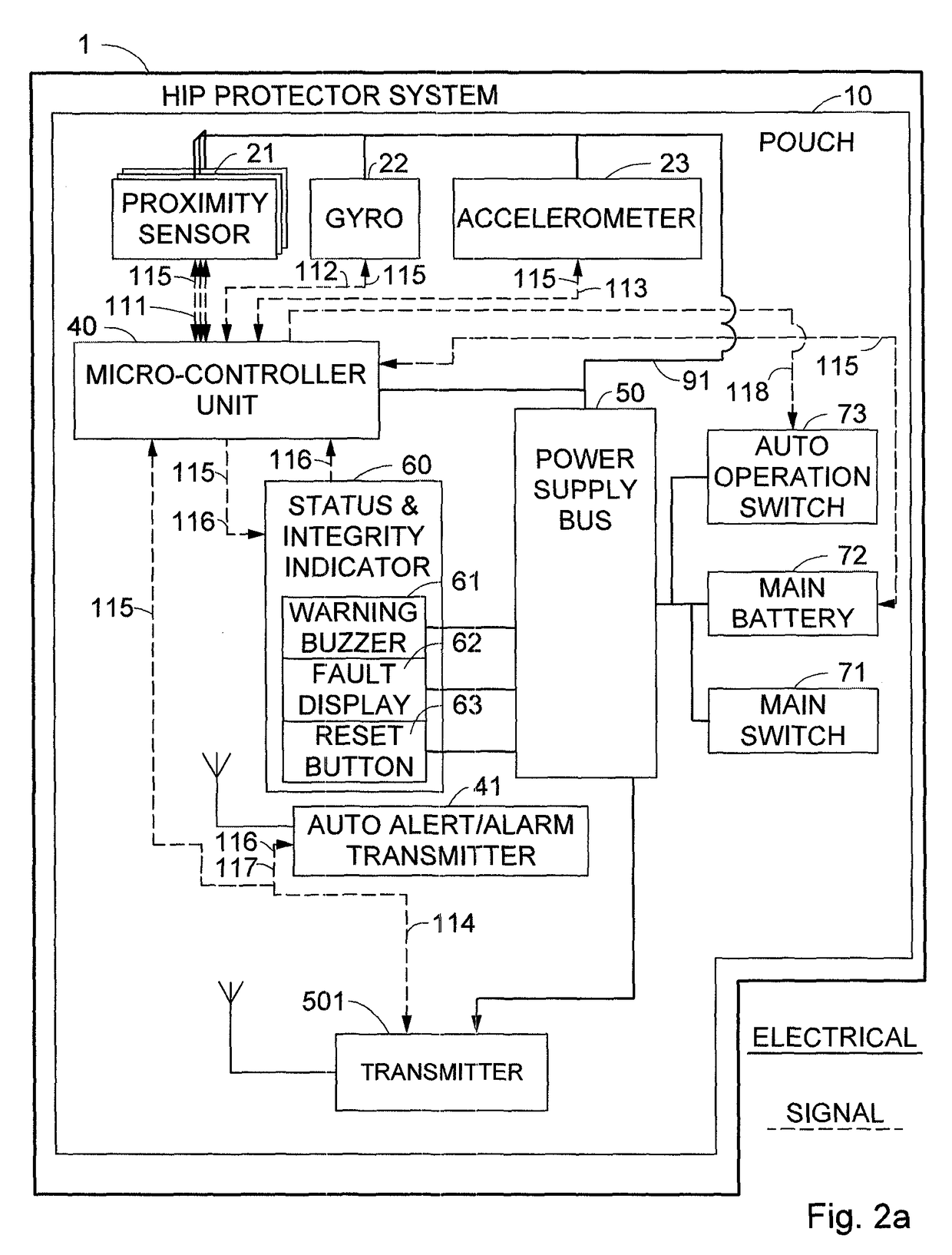

Hip protector system and method for hip fracture prevention

ActiveUS9629399B2Effective protectionComputer controlInertial sensorsSpatial OrientationsHip protector

Owner:HIP HOPE TECH

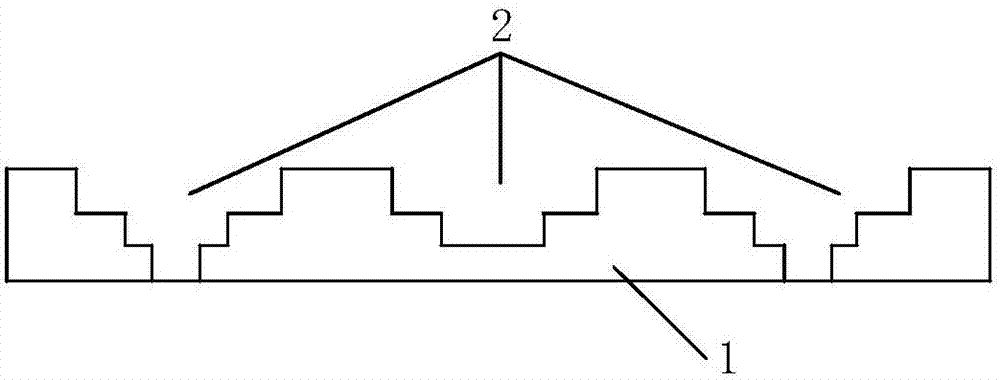

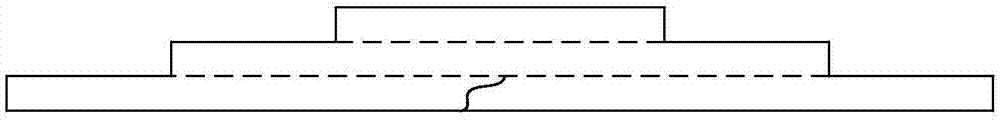

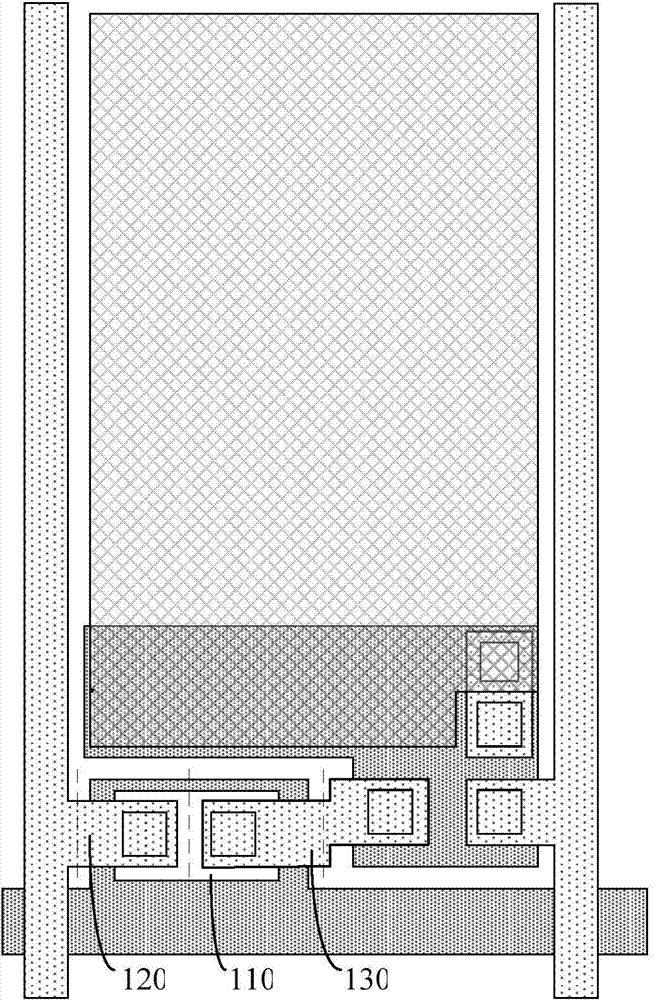

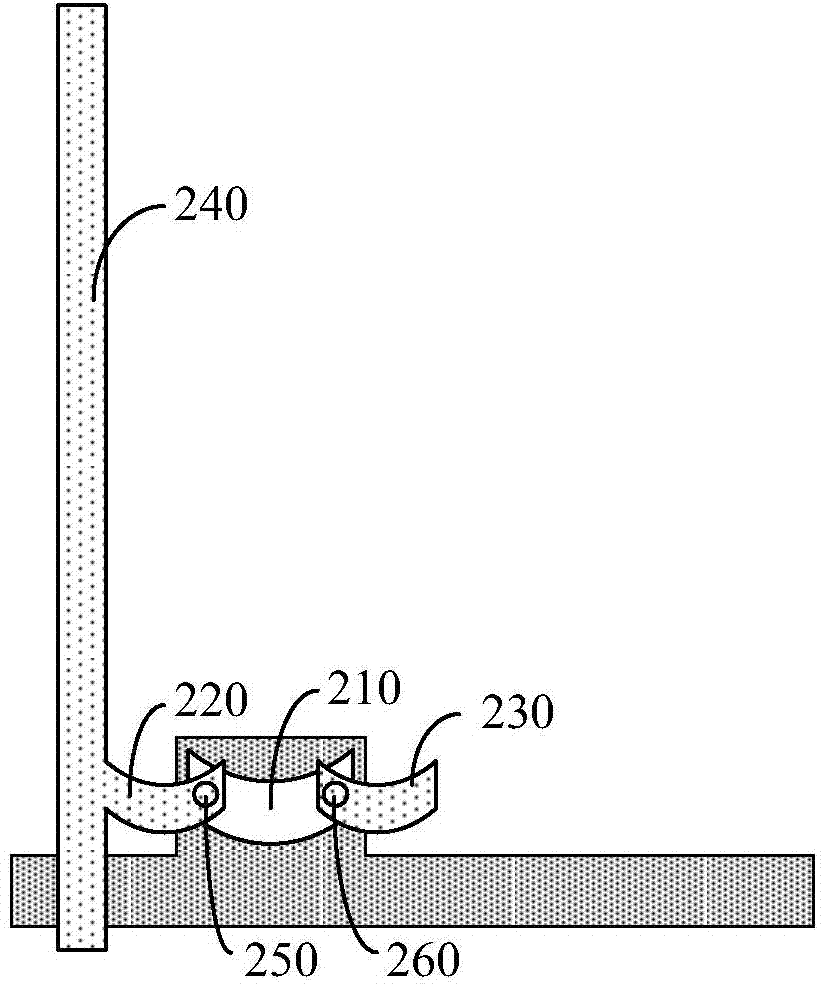

Array substrate and display device

ActiveCN103680327AReduce the chance of breakageGuaranteed display effectIdentification meansDisplay deviceFlexible display

The invention relates to the technical field of display, and discloses an array substrate. The array substrate comprises grid lines, data lines and a plurality of pixel units defined by intersecting the grid lines and the data lines. Each pixel unit comprises at least one TFT, and a graph of at least one of an active layer and a drain electrode of each TFT is of a fracture-prevention structure. According to the array substrate, as the graphs of the active layers or the drain electrodes and the like of the TFTs are manufactured to be of the fracture-prevention structures, when a flexible display device is bent, part of tension can be dispersed, the fracture probability of the TFTs when the flexible display device is bent is lowered, and it is guaranteed that the flexible display device can normally carry out display.

Owner:BOE TECH GRP CO LTD

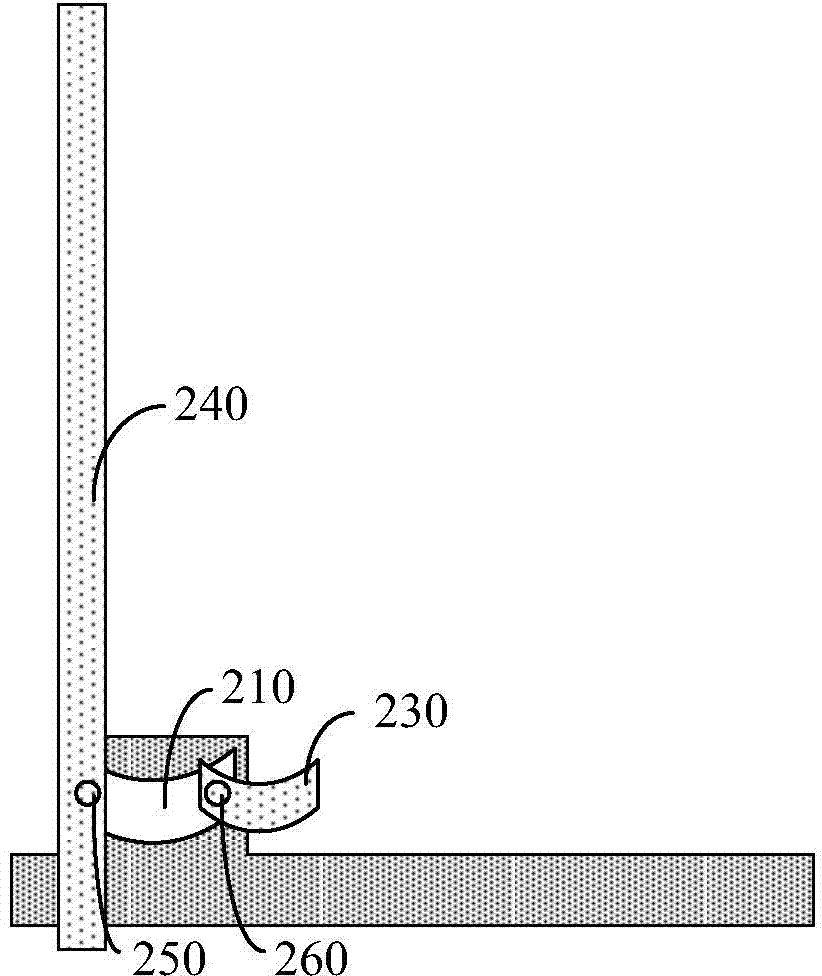

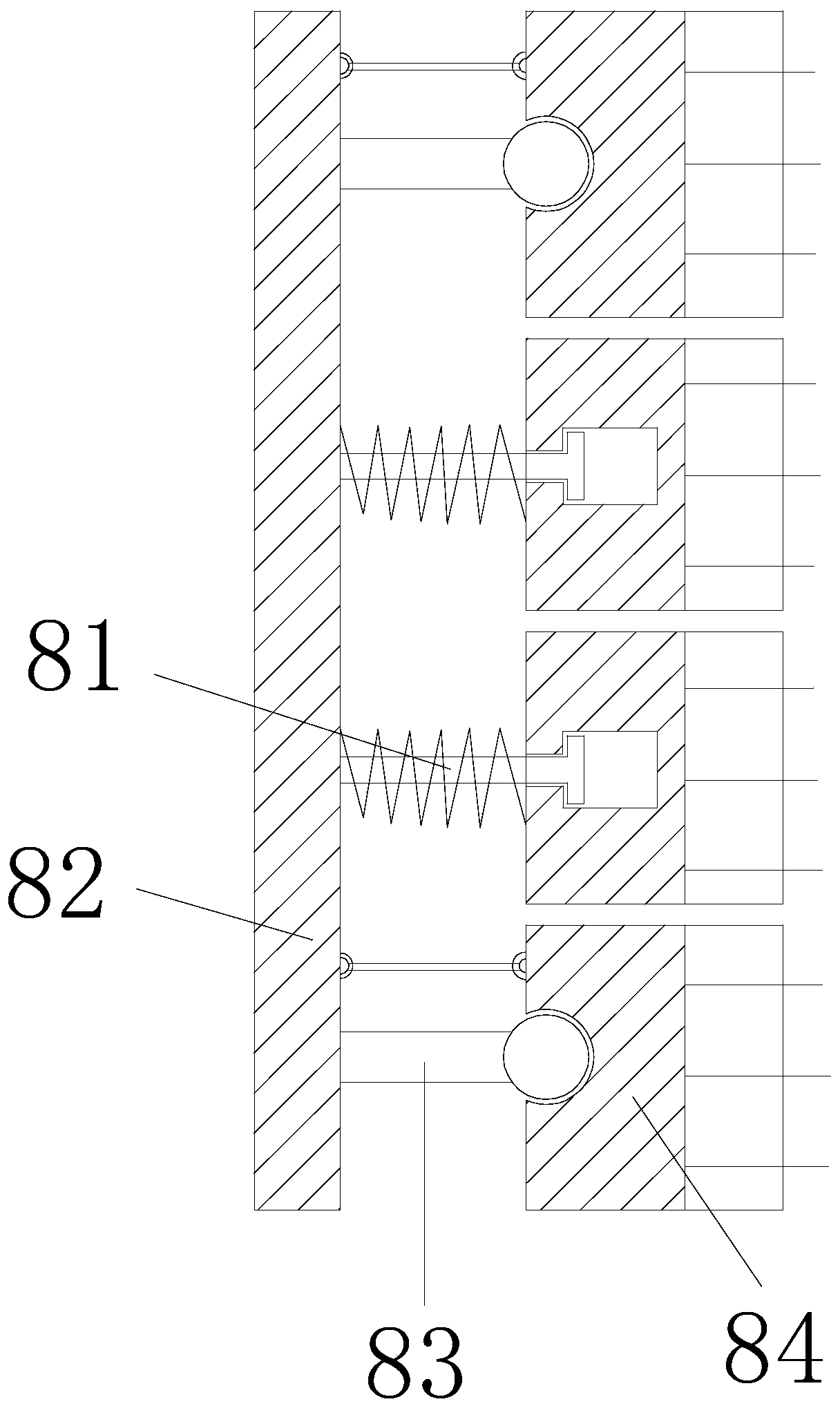

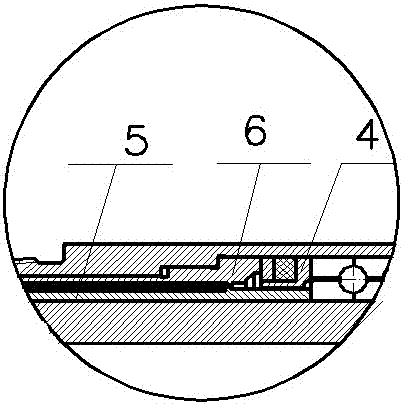

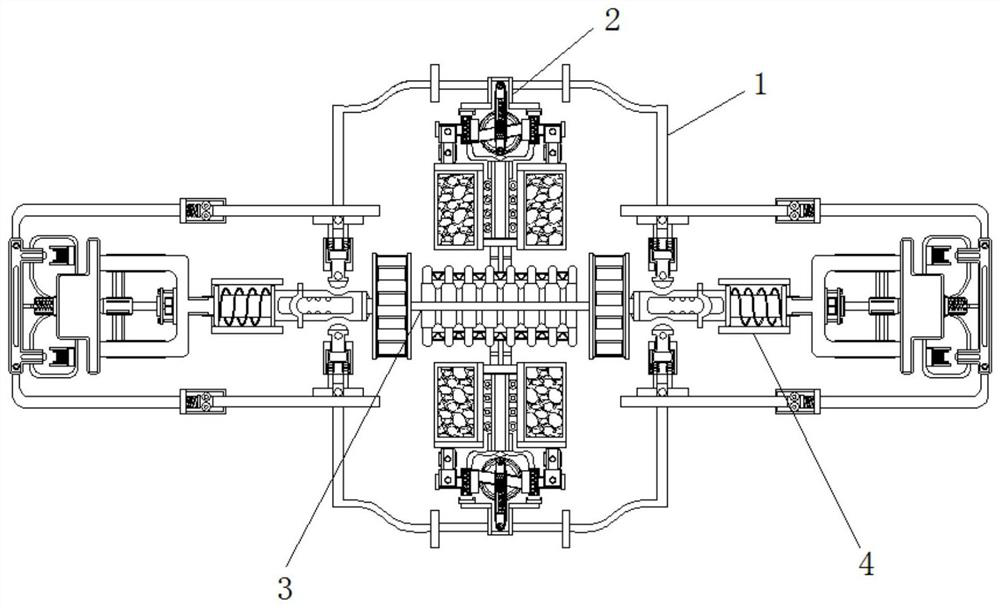

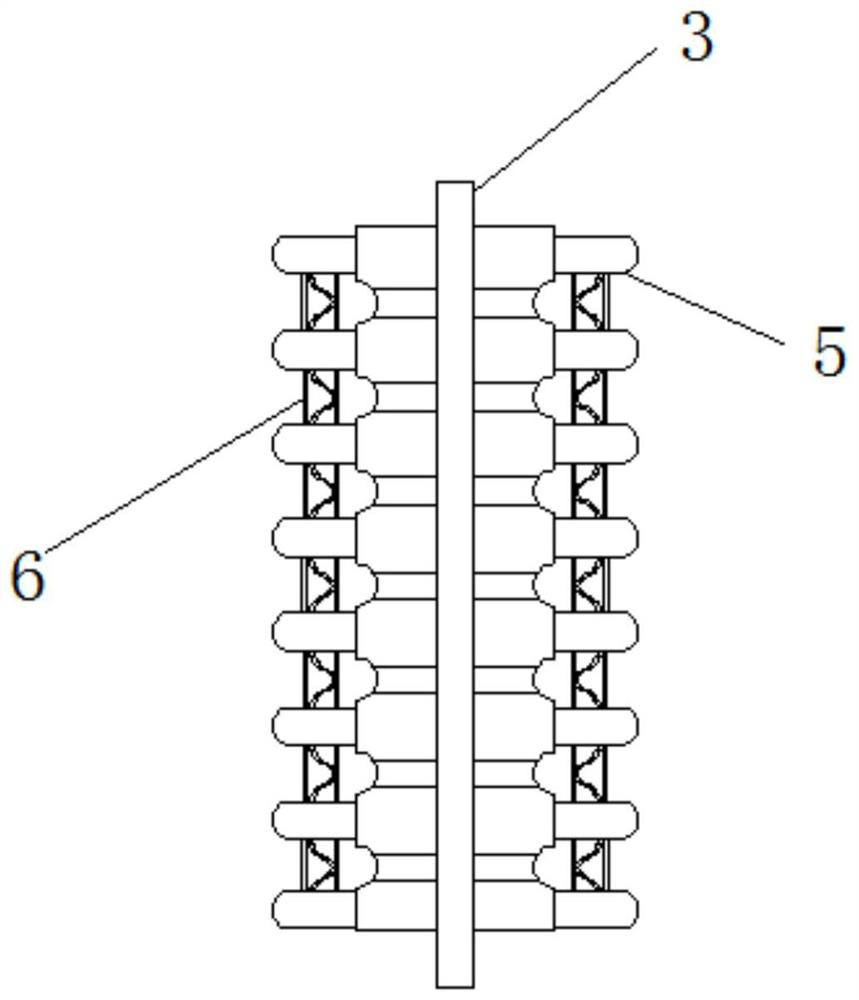

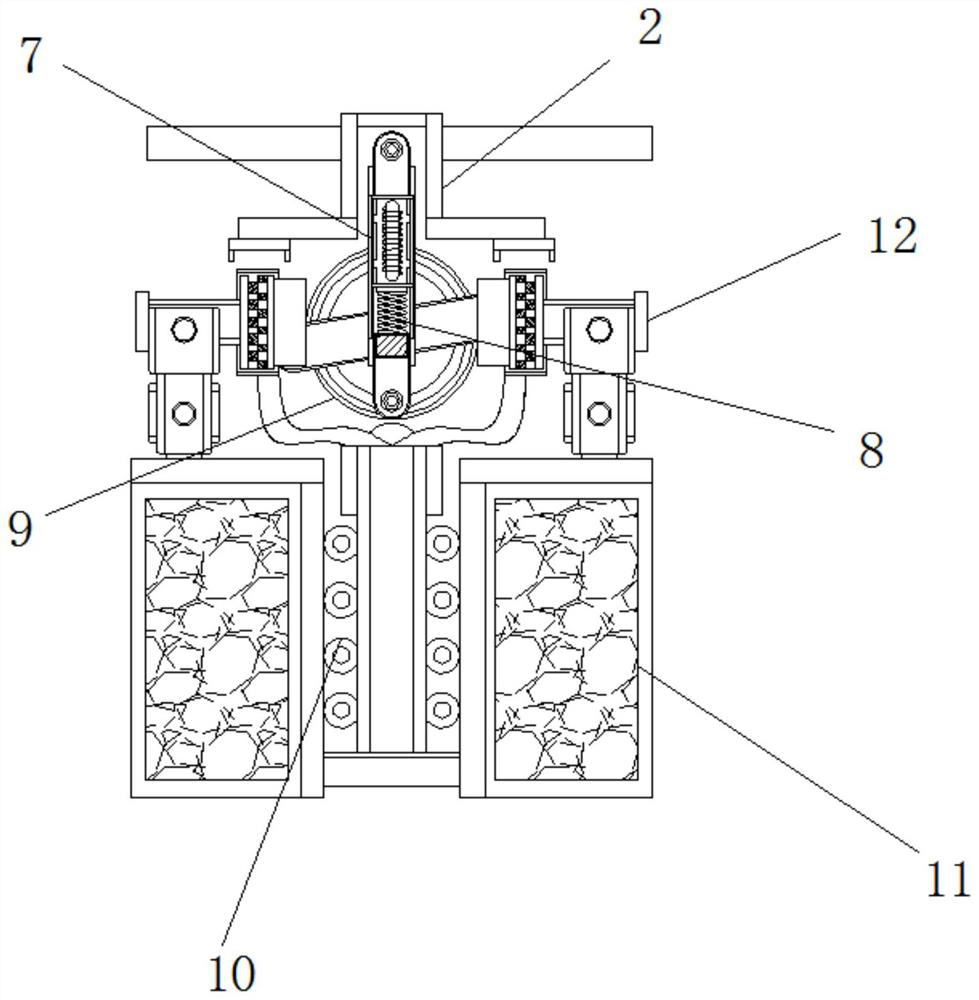

Real-time chain fracture prevention safety lock

The invention discloses a real-time chain fracture prevention safety lock which comprises a lifting chain, a chain fracture detection switch, a left upright column and a right upright column, wherein a left guide block and a right guide block are mounted on the left upright column and the right upright column respectively; a left oblique groove and a right oblique groove are formed in one side of the left guide block and one side of the right guide block respectively; a left sliding block and a right sliding block are mounted in the left oblique groove and right oblique groove in a sliding fit manner respectively; a row of toothed bars is mounted at one side of the left sliding block; a row of toothed bars is mounted at one side of the right sliding block; a left spring seat and a right spring seat are fixedly arranged at the tops of the left guide block and the right guide block respectively; springs are correspondingly connected between the left spring seat and the top end of the left sliding block and between the right spring seat and the top end of the right sliding block respectively; a left connecting rod and a right connecting rod are hinged to the bottom ends of the left sliding block and the right sliding block respectively; an electromagnet is arranged between the bottoms of the left upright column and the right upright column; the chain fracture detection switch is electrically connected with the electromagnet through a controller; a pull rod is hinged to the bottom ends of the left connecting rod and the right connecting rod; the bottom end of the pull rod extends to a place above an iron core of the electromagnet; and the pull rod is in clearance fit with the iron core. With the adoption of the structure, a comb-shaped rack and a vehicle on the comb-shaped rack can be protected effectively, and unnecessary accidents are precluded.

Owner:ANHUI HUAXING INTELLIGENT PARKING EQUIP

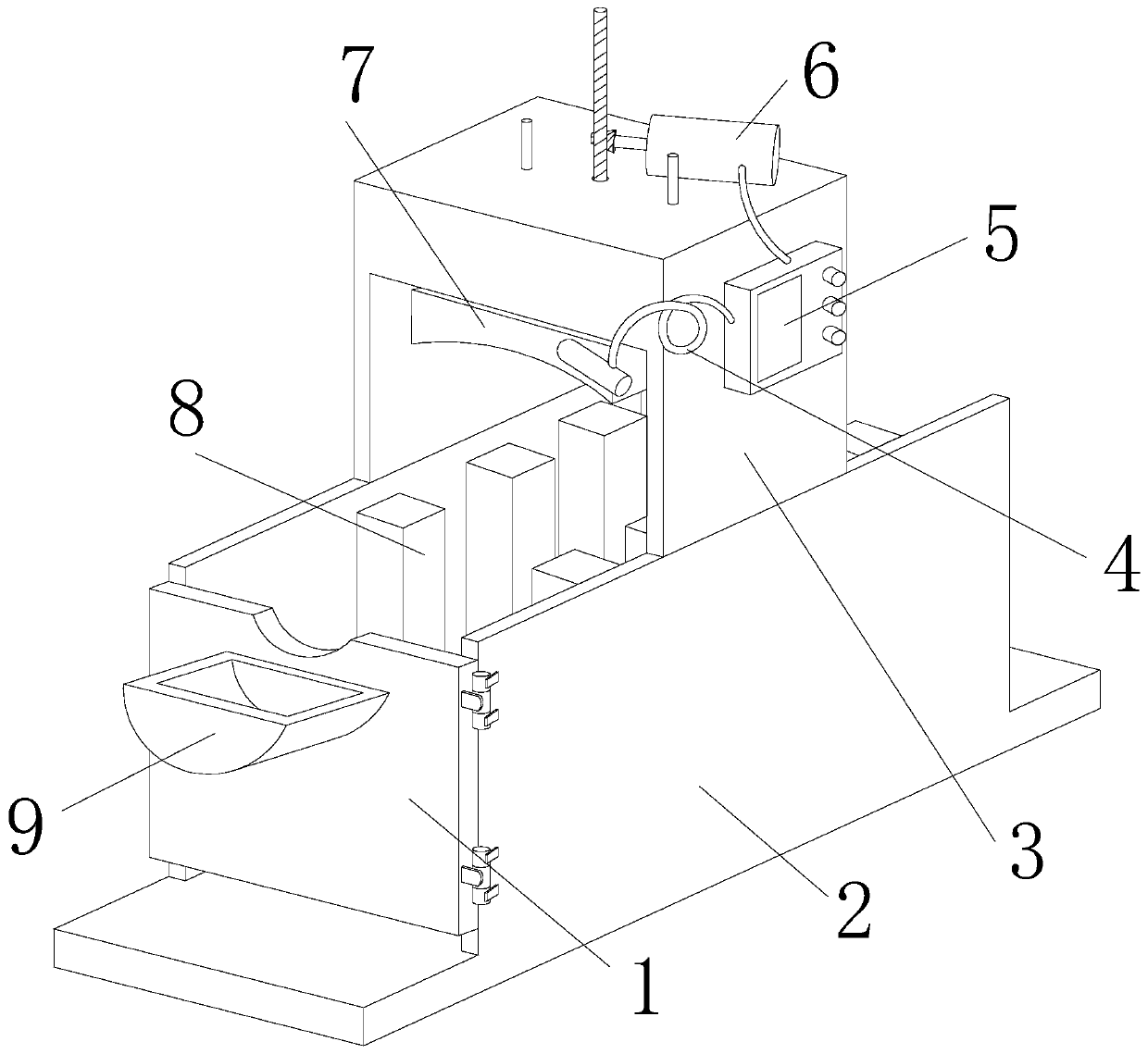

Automatic combing device for fine-wool sheep breeding according to wool thickness

The invention discloses an automatic combing device for fine-wool sheep breeding according to the wool thickness. The automatic combing device structurally comprises an opening and closing door, an underframe, an upper working platform, a transmission wire, a control panel, a driving motor, a sheep back spraying and carding mechanism, a form and position transformation combing mechanism and a trough. The automatic combing device for fine-wool sheep breeding according to the wool thickness has the advantages that the form and position transformation combing mechanism is arranged, and a spring rod, a supporting column and a carding transformation mechanism are combined with one another so that the form and position transformation combing mechanism can self-adjust the carding position according to the body form and wool thickness of the sheep, wool at the side of the sheep abdomen is comprehensively carded, and the skin at the side of the sheep abdomen is not damaged; the sheep back spraying and carding mechanism is arranged, and a liquid spray port cooperates with a driven rotating rod to spray a drug liquid in a drug liquid tank onto the wool, thereby preventing and controlling diseases and pests, improving the flexibility of the wool, and facilitating carding of the subsequent wool; a wool fracture prevention structure cooperates with a massage rod to card the wool while massaging the sheep back.

Owner:临沂市德厚饲料有限公司

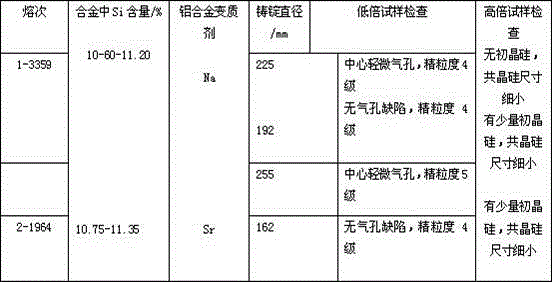

High-strength fracture prevention air conditioner radiator aluminum alloy sheet and molding technique thereof

InactiveCN106086554AHigh strengthImprove impact toughnessCorrosion preventionLaminated elementsSlagHigh intensity

The invention discloses a high-strength fracture prevention air conditioner radiator aluminum alloy sheet. The high-strength fracture prevention air conditioner radiator aluminum alloy sheet comprises the chemical elements of, by mass, 0.12-0.36 part of Cr, 0.15-0.30 part of Mg, 0.21-0.55 part of Cu, 1.22-1.77 parts of Zn, 0.11-0.18 part of Hg, 0.07-0.15 part of V, 0.15-0.28 part of Zr, 0.02-0.06 part of Nb, 0.01-0.03 part of Fe, 0.1-0.5 part of an aluminum alloy leavening agent, and the balance Al. Through addition of Nb and other elements, smell and impurities in alloy are reduced, mobility is improved, ingot formation through pouring is facilitated, and the technical performance is remarkably influenced. Grains of the aluminum alloy sheet are refined, high strength and impact toughness are achieved, the probability of cracks can be reduced through addition of Hg, and the aluminum alloy sheet has good corrosion resistance. By means of a production method, the phenomena of layering, peeling, bubbling and cracking of aluminum alloy are reduced, and the rate of finished products is increased. A refining agent is good in refining effect, so that the phenomena of pores and slag inclusion are reduced remarkably.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

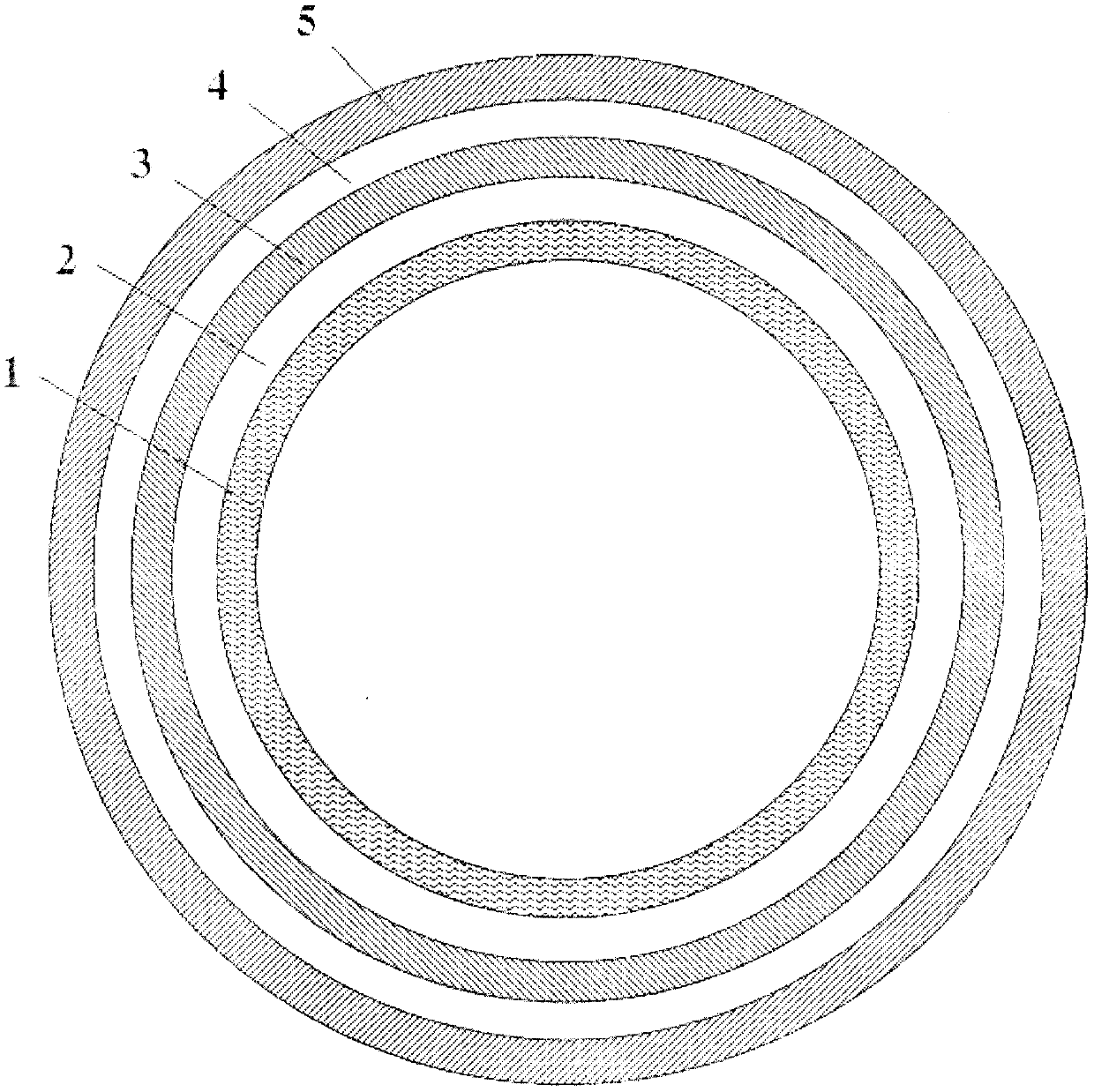

Special conduction oil resistant high pressure conveying pipe

The invention discloses a special conduction oil resistant high pressure conveying pipe. The special conduction oil resistant high pressure conveying pipe sequentially comprises an inner rubber layer,an inner skeleton layer, an inner rubber layer, an outer skeleton layer and an outer rubber layer from interior to exterior. The inner rubber layer is composed of, by weight part, 80-100 parts of inner rubber, 4-6 parts of a plastifying softener, 6-10 parts of cyclohexyl sulfo-phthalimide, 7-12 parts of raw methyl vinyl silicone rubber, 12-18 parts of butadiene-acrylonitrile rubber, 1-5 parts ofcalcium carbonate, 2-4 parts of diethylene glycol, 3-5 parts of carbon black, 2-4 parts of 1,2-ethylene thiourea, 4-8 parts of white oil, 3-7 parts of a fracturing prevention agent, 2-6 parts of fiber, 3-10 parts of lead tetroxide, 2-5 parts of dibutyl phthalate and 1-3 parts of Rhine wax. The special conduction oil resistant high pressure conveying pipe is reasonable in design, simple in structure and long in service and has the advantages of being resistant to oil, high temperature and abrasion, high in tenacity and fracture resistance and resistant to corrosion and aging, and has popularization significance.

Owner:DONGJIN CO LTD

Fracture-prevention protecting sleeve material for cables and preparation method of fracture-prevention protecting sleeve material

InactiveCN107325449AExtended service lifeHigh strengthPlastic/resin/waxes insulatorsPolyolefinEngineering

The invention discloses a fracture-prevention protecting sleeve material for cables. The fracture-prevention protecting sleeve material contains the following raw materials in parts by weight: 5-65 parts of PVC resin, 10-70 parts of three-form resin, 6-36 parts of chlorinated polyethylene, 4-24 parts of white carbon black, 5-35 parts of bentonite, 3-17 parts of polyolefin, 4-18 parts of stearic acid, 4-24 parts of chlorinated polyethylene, 3-13 parts of nylon, 0.5-2.5 parts of an impact modifier, 0.1-1.7 parts of an antioxidant and 0.3-1.3 parts of a flame retardant. The fracture-prevention protecting sleeve material has the advantages of fracture prevention, good safety performance, long service life and the like.

Owner:ANHUI YUANZHENG CABLE TECH

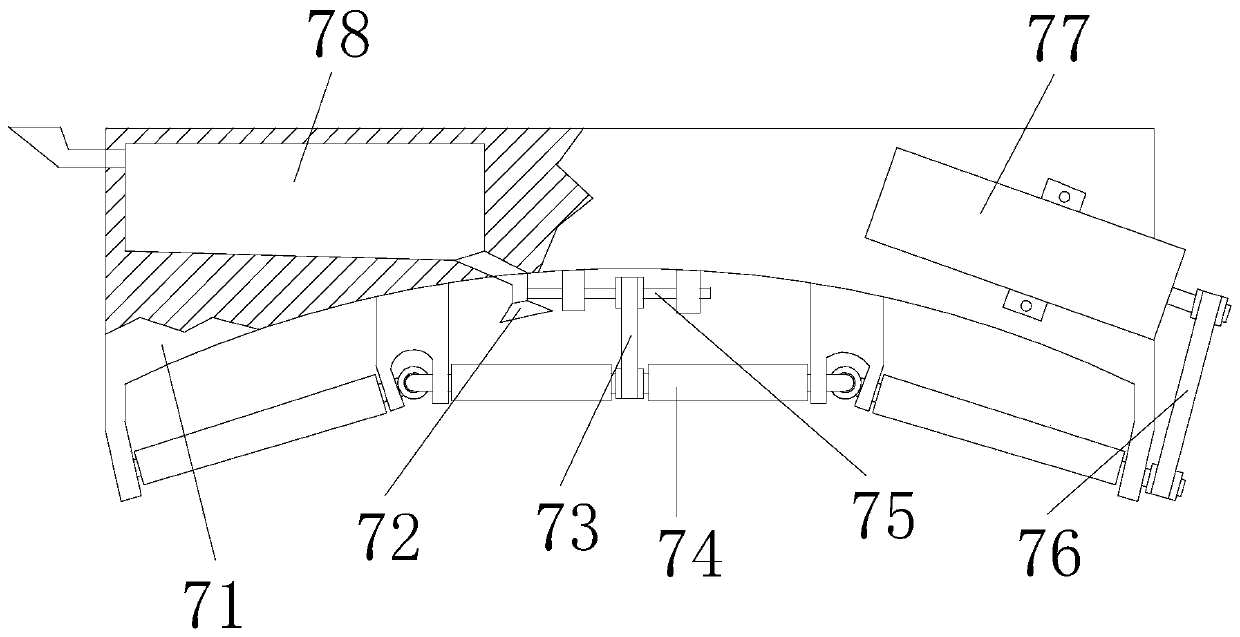

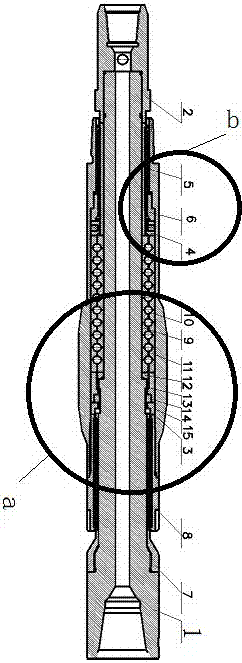

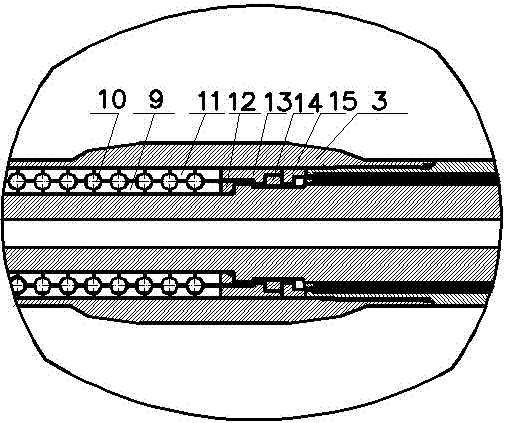

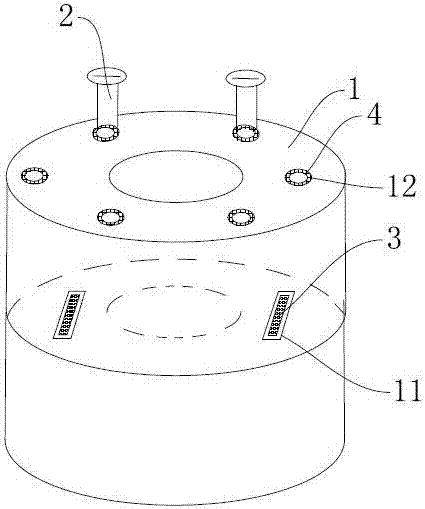

Fracture prevention transmission shaft assembly for petroleum mine drilling tool

The invention provides a fracture prevention transmission shaft assembly for a petroleum mine drilling tool. The fracture prevention transmission shaft assembly comprises a transmission shaft; the endof the transmission shaft is connected with a water passing connector; the outer surface of the transmission shaft is sleeved with a transmission shaft housing; an upper section part subassembly, a middle section part subassembly, a shock pad, a spacer bush subassembly and a lower section part subassembly are sequentially arranged on the transmission shaft; the upper section part subassembly is sequentially provided with an upper radial bearing inner ring and an upper radial bearing outer ring from the inside out; the lower section part subassembly is sequentially provided with a lower radialbearing inner ring and a lower radial bearing outer ring from the inside out; the middle section part subassembly is sequentially provided with a string bearing inner ring, steel balls and a string bearing outer ring from the inside out; the spacer bush subassembly is sequentially provided with a first spacer bush, an outer sleeve, a clamp sleeve and a second spacer bush from the top down; and the outer sleeve sleeves the excircle of the clamp sleeve. The fracture prevention transmission shaft assembly has the beneficial effects that the fracture prevention transmission shaft assembly is reasonable in design and stable in structure, the situation that the petroleum mine drilling tool is fractured and then falls into a well during operation can be avoided, the safety coefficient is increased and the service life is prolonged.

Owner:盐城华海石油机械有限公司

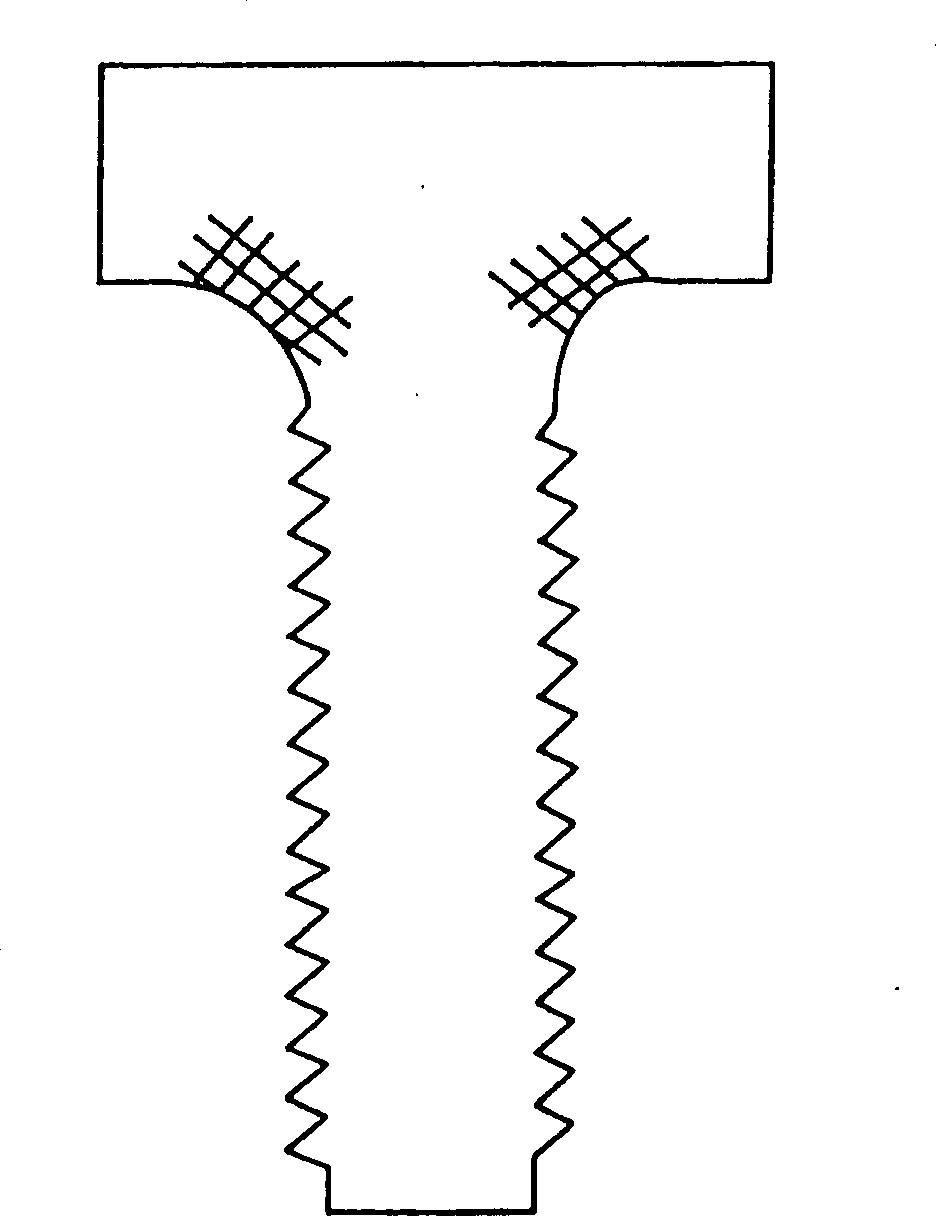

Delayed fracture prevention method for steel structure and steel structure manufacturing method

ActiveCN1711365ADelayed Corruption PreventionWelding apparatusStress concentrationFracture prevention

The present invention provides a method for preventing delayed failure of a steel structure and a method for manufacturing the steel structure. A method for preventing delayed failure of a steel structure. The steel structure includes steel with a tensile strength greater than or equal to 600N / mm2 and / or welded joints of the steel. Ultrasonic impact treatment is performed on the surface of the stress concentration part of the steel structure. The ultrasonic impact treatment is impacted with an ultrasonic vibration terminal having a diameter of 1 to 5 mm at the front end.

Owner:NIPPON STEEL CORP

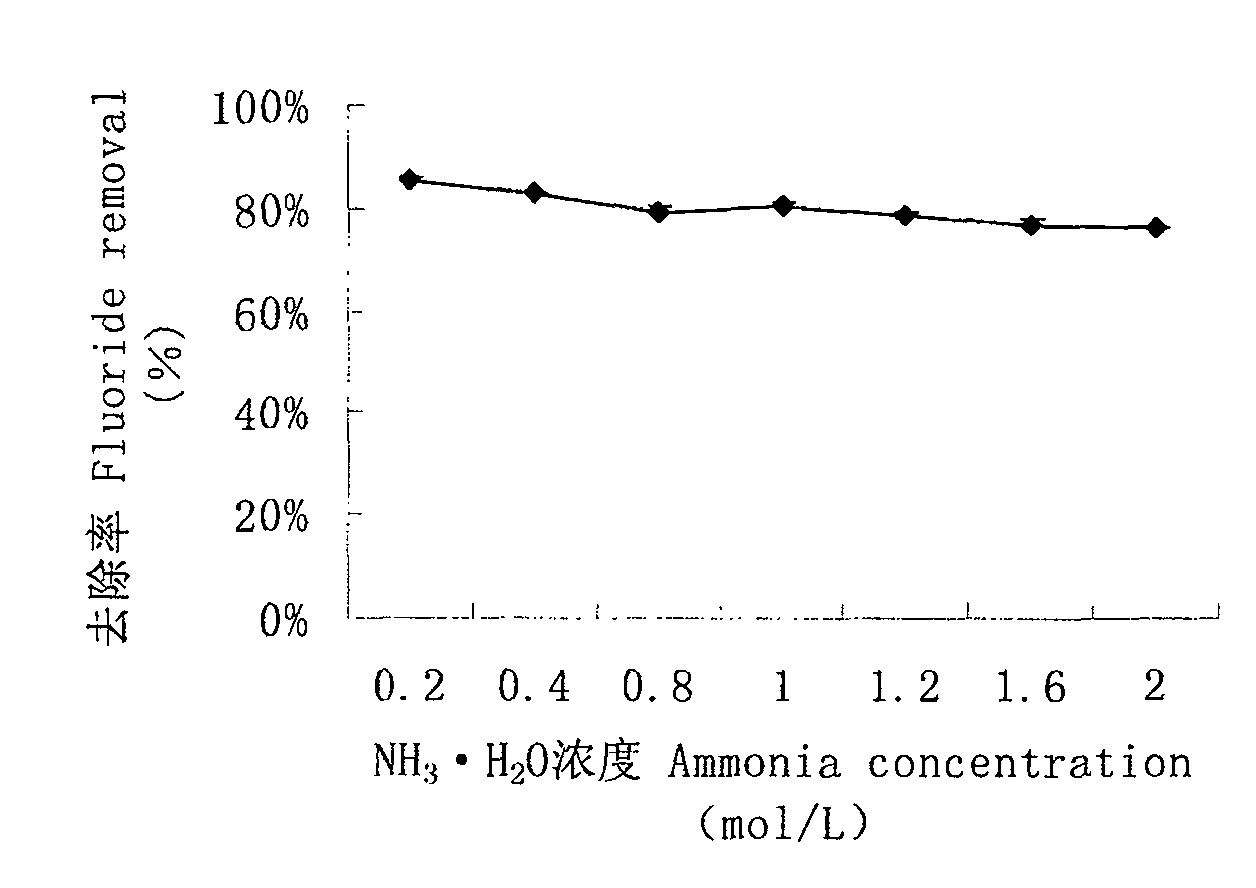

Modified chitosan crosslinked resin for defluorination in water and method of preparing the same

InactiveCN100566818CUnbreakableStable defluoridation effectOther chemical processesWater/sewage treatment by sorptionPolymer scienceIron chloride

A modified chitosan cross-linked resin for removing fluorine in the water is provided, in particular a ferric-modified chitosan cross-linked resin. The resin is prepared from chitosan with a high deacetylation degree higher than or equal to 95% as the raw material and ferric chloride as the modifier. The resin is used for removing the fluorine in the water with stable effect at a removal rate of more than 80%, and has the advantages of fracture prevention, simple regeneration and low cost. The resin can be used for treatment of industrial fluorine-containing water and high- fluorine drinking water as well.

Owner:SHANXI UNIV

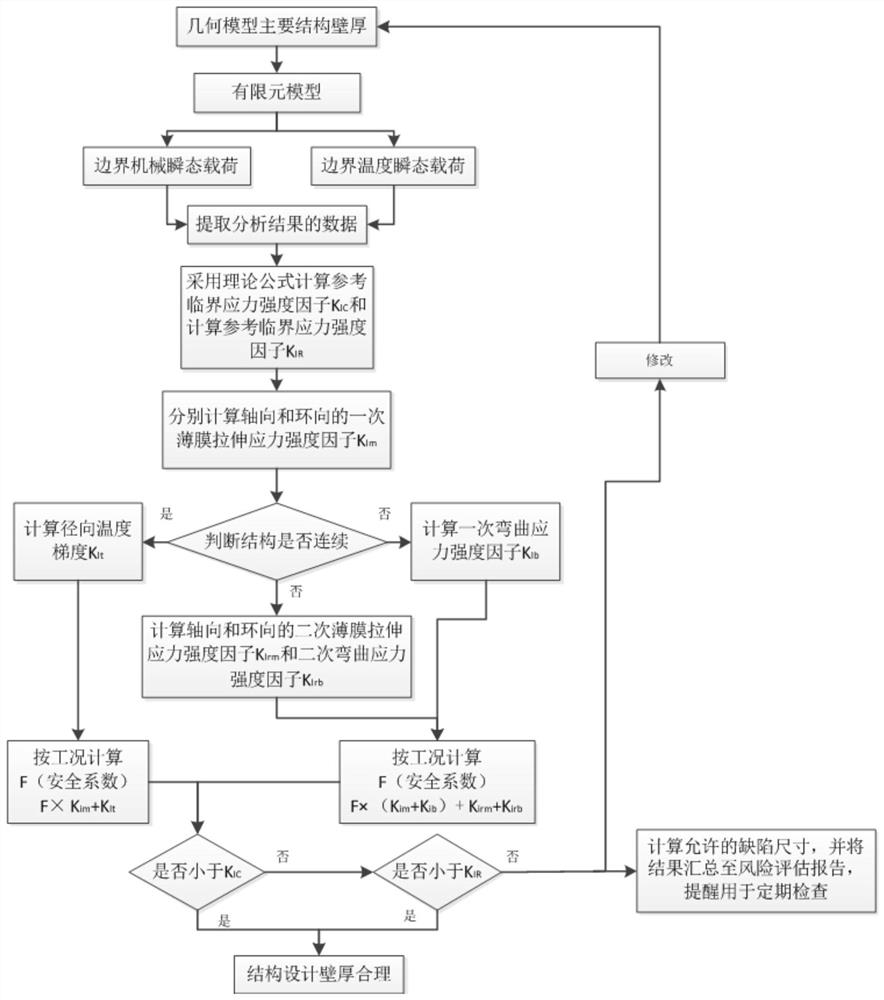

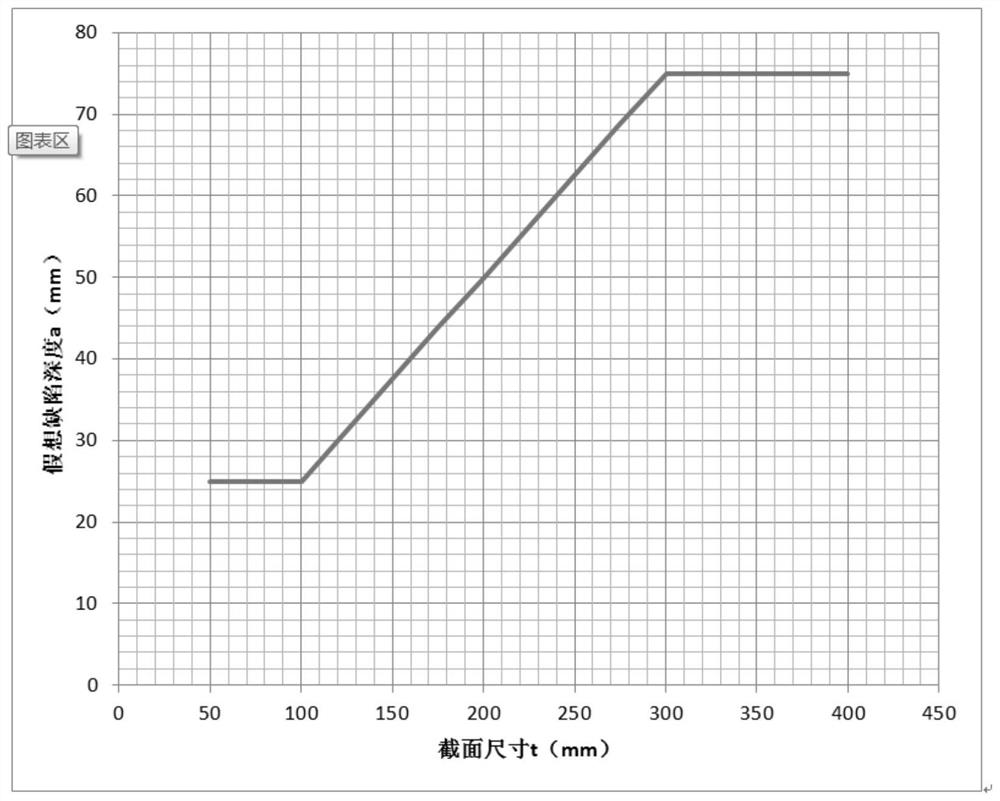

Fracture toughness analysis method for pressure-bearing main equipment and chemical machinery pressure-bearing equipment of nuclear power plant

PendingCN112730078AReduce wall thicknessReduce secondary stress componentsMaterial strength using tensile/compressive forcesDesign optimisation/simulationElastomerNuclear plant

The invention relates to a fracture toughness analysis method for pressure-bearing main equipment and chemical machinery pressure-bearing equipment of a nuclear power plant, in particular to a fracture toughness analysis method for the pressure-bearing equipment, belongs to the field of nuclear power and chemical machinery pressure bearing, and aims to solve the problem that no clear judgment and calculation method exists in an existing pressure vessel fracture prevention method. According to the method, a linear elastic fracture mechanics theory is adopted, that is, the numerical value and distribution of a stress field near the crack tip of a linear elastomer with cracks are associated with the crack size which may cause non-ductile failure; and the numerical relationship among the fracture toughness, the crack defect size and the stress level of the material during crack propagation is referred to. According to the method, the load at each moment can be analyzed and judged, the calculation accuracy is improved, corresponding calculation software is developed, and the economy and the calculation efficiency are improved.

Owner:HARBIN ELECTRIC POWER GENERATION EQUIP NAT ENG RES CENT CO LTD

Fish bone scale collagen peptide for preventing and curing egg and poultry fracture

InactiveCN101773664BPromote absorptionGood calcium supplementOrganic active ingredientsPeptide/protein ingredientsFracture preventionZoology

The invention relates to fish bone scale collagen peptide for preventing and curing egg and poultry fracture, which comprises the following components in parts by weight: 10 to 300 of fish bone scale collagen peptide, 300 to 1000 of ginseng polysaccharide, and 1.5 to 30 of silymarin. The fish bone scale collagen peptide for preventing and curing egg and poultry fracture has the advantages of easyabsorption, good calcium supplementation effect and egg and poultry fracture prevention and curing effect.

Owner:宋艳

A kind of inter-embedded slope protection block and its construction method

ActiveCN103774617BImprove frost resistanceGood weather resistanceCoastlines protectionExcavationsArchitectural engineeringHigh intensity

The invention discloses a mutually-embedded type slope protection building block. The mutually-embedded type slope protection building block comprises a building block body, an embedded groove is formed in one side of the building block body, an embedded tail is arranged on the other side of the building block body, the embedded tail is matched with the embedded groove, a barb groove is formed between the building block body and the embedded tail, an elastic barb is arranged on the building block body, the elastic barb is matched with the barb groove, and an ecological through hole is formed in an integrated structure of the building block body and the embedded tail. The invention further discloses a construction method for building a protection slope through building blocks. The construction method comprises the first step of surveying and setting out, the second step of construction preparing and digging, the third step of inverted filter paving, the fourth step of mutually-embedded type slope protection block paving, and the fifth step of grass planting. According to the mutually-embedded type slope protection building block and the construction method thereof, the building blocks are well buckled, a certain range of differential settlement or frost heaving thaw collapse deformation is allowed in a slope protection foundation, the advantage of high-strength fracture prevention is achieved, meanwhile, the whole building block set is paved during the construction process, pavement is easy and convenient, construction cost is saved, and the construction period is shortened.

Owner:浙江宇盛建设有限公司

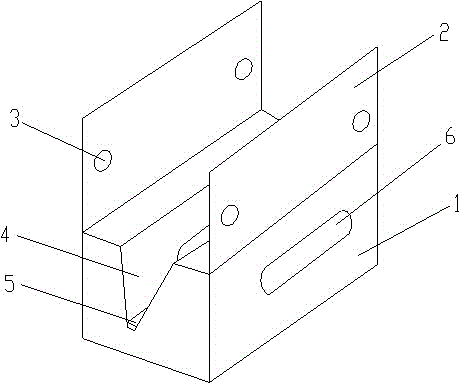

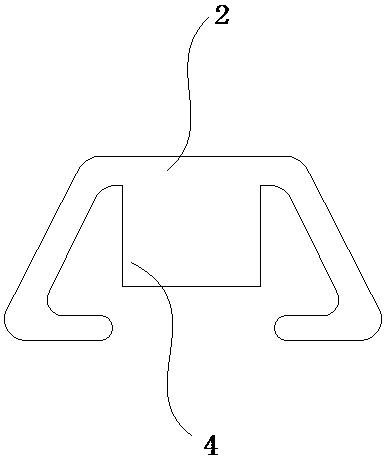

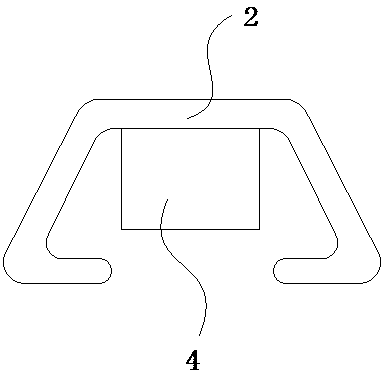

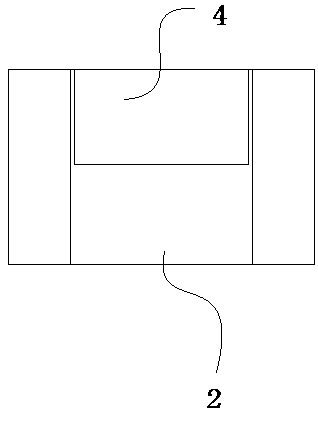

Steel beam fracture-prevention bracket

InactiveCN104670131ASafe and stable protectionMonitor usage in real timeUnderstructuresBumpersArchitectural engineeringFracture prevention

The invention discloses a steel beam fracture-prevention bracket, which comprises a bracket body, wherein the two sides of the bracket body are provided with installing protection plates, positioning installing holes are formed in the installing protection plates, the center of the bracket body is provided with a conical groove, the bottom of the conical groove is provided with a pressure triggering pad, weight reducing type observation open holes are also formed in the end surfaces of the two sides of the bracket body, and the weight-reducing type observation open holes are formed in a way of transversely penetrating through the bracket body. Through adopting the mode, the safe and stable protection can be provided for a steel beam, the alarm can be timely given out after the steel beam fractures and touches the pressure triggering pad, in addition, the observation hole holes are provided, the use condition of the steel beam can be conveniently observed in real time, and the potential safety hazards are eliminated.

Owner:王爱红

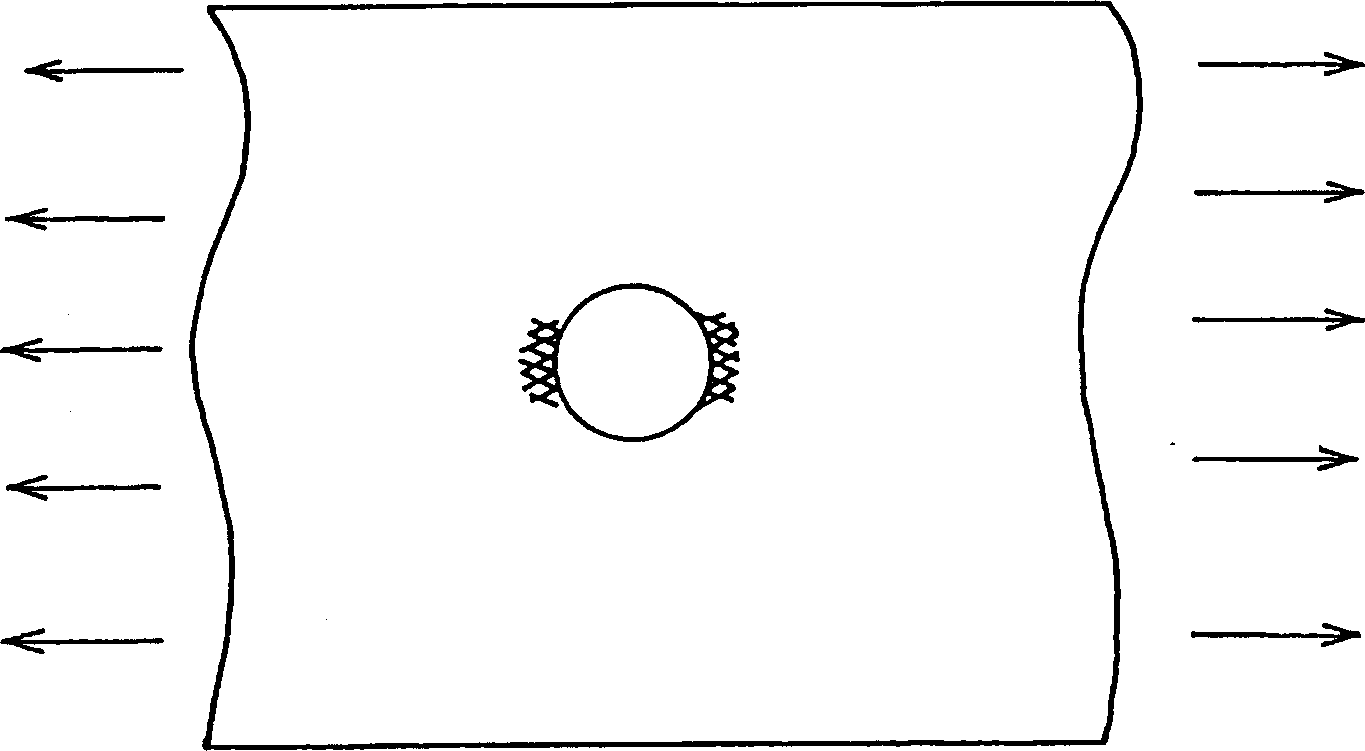

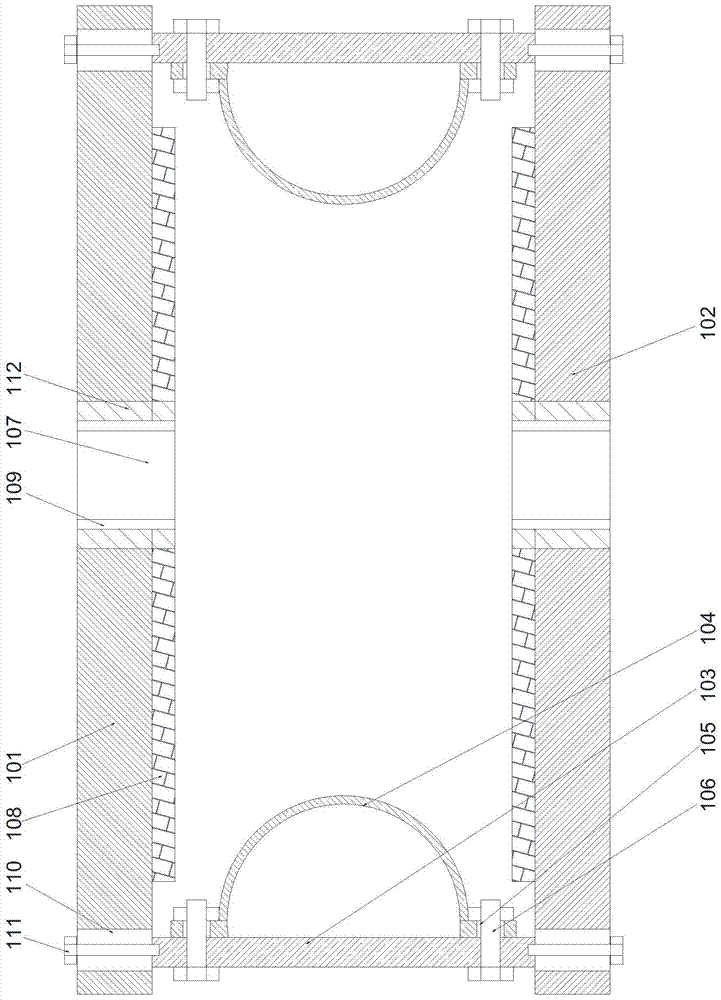

Lead plate fracture prevention separating block and fixed installation method thereof

InactiveCN109638364AOffset shear stressAvoid breakingFinal product manufactureLead-acid accumulators constructionShear stressEngineering

The invention discloses a lead plate fracture prevention separating block and a fixed installation method thereof and not only provides the separating block but also provides a connection method of the separating block in the using process. A battery produced according to the provided technical scheme can effectively inhibit the situation that a lead block fractures due to vibration inside a battery box. The separating block is simple in structure and reasonable in design, can effectively offset shear stress generated in the force bearing process of lead plates inside the battery and a batteryshell and can effectively avoid lead plate fracture. The provided method is simple, easy to understand and convenient to operate. The lead plate fracture prevention separating block and the fixed installation method thereof are widely applicable to the battery production and processing industry and relevant industries.

Owner:JIANGYAN LANTIAN PLASTIC PROD FACTORY

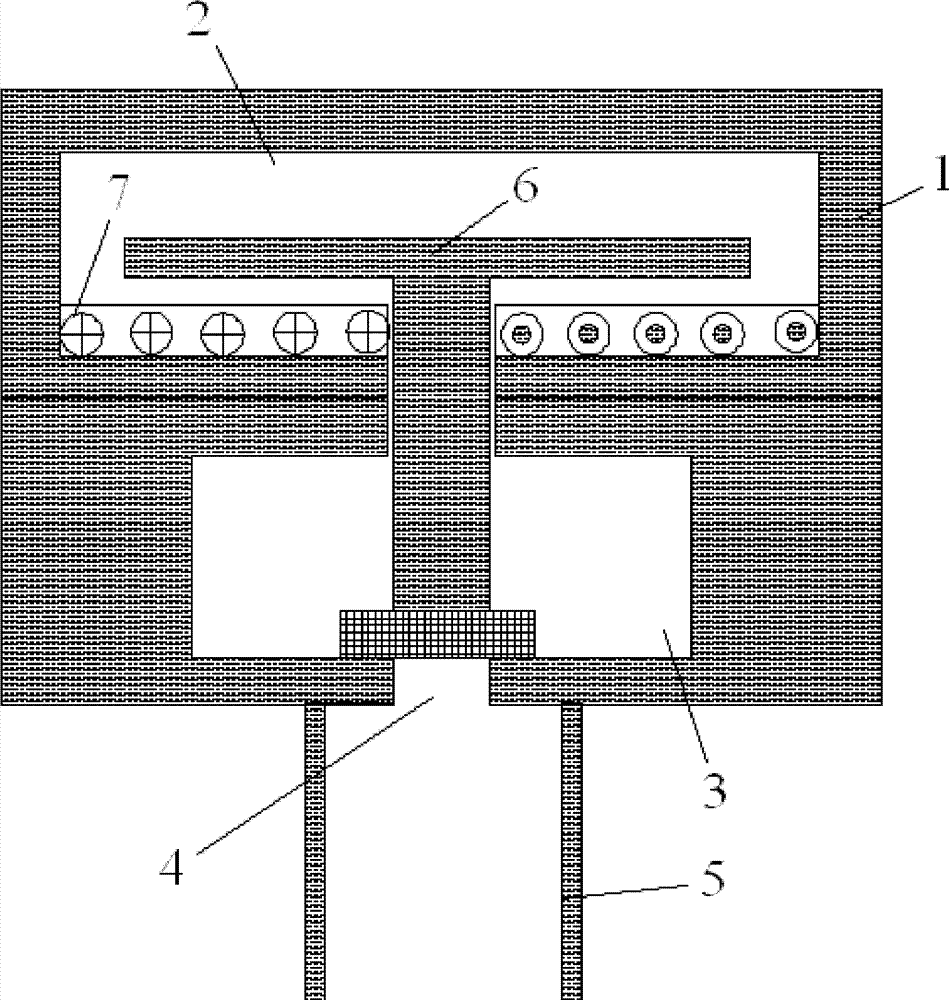

Bandage winding equipment capable of achieving fracture prevention through meshing teeth

InactiveCN112919180AAvoid misalignmentAchieve windingChemicalsWebs handlingEngineeringFracture prevention

The invention relates to the technical field of bandage manufacturing, and provides bandage winding equipment capable of achieving fracture prevention through meshing teeth. The bandage winding equipment comprises a bandage winding equipment body, regulation and control frameworks and an equidistant framework, a winding frame is movably connected to the center of the bandage winding equipment body, the regulation and control frameworks are movably connected to the upper side and the lower side of the bandage winding equipment body through the winding frame, the centers of the regulation and control frameworks are movably connected with rotating rods, the inner sides of the regulation and control frameworks are movably connected with torque spring rods through the rotating rods, and the inner sides of the regulation and control frameworks are movably connected with movable rotating wheels through the rotating rods. According to the bandage winding equipment capable of achieving fracture prevention through the meshing teeth, after an extrusion frame is connected with a connecting socket, a spring rod drives an extrusion wedging rod to be connected with the two sides of the equidistant framework, a circuit is in a closed state through a telegraph pole, the spring rods drive the rotating rods to move downwards, the rotating rods drive the movable rotating wheels to rotate through sliding friction force, and the torque spring rods limit the rotating angles of the rotating rods.

Owner:许继强

Fish bone scale collagen peptide for preventing and curing egg and poultry fracture

InactiveCN101773664APromote absorptionGood calcium supplementOrganic active ingredientsPeptide/protein ingredientsFracture preventionPolysaccharide

The invention relates to fish bone scale collagen peptide for preventing and curing egg and poultry fracture, which comprises the following components in parts by weight: 10 to 300 of fish bone scale collagen peptide, 300 to 1000 of ginseng polysaccharide, and 1.5 to 30 of silymarin. The fish bone scale collagen peptide for preventing and curing egg and poultry fracture has the advantages of easy absorption, good calcium supplementation effect and egg and poultry fracture prevention and curing effect.

Owner:宋艳

Special high-air-flow rapid inflation valve for plasma fracture prevention

InactiveCN102155569BAchieve automatic shutdownOperating means/releasing devices for valvesAerating valvesMedicineFracture prevention

The invention discloses an air-flow-adjustable rapid inflation valve which can be applied to plasma fracture remission. According to the requirement of EAST Tokamak plasma fracture remission, a great amount of inert gas is inflated within 10 milliseconds within very short time, thus the plasma fracture remission is realized so as to remit the damage to a Tokamak device caused by the plasma fracture. According to the invention, a great amount of inert gas is inflated in the Tokamak device within 5milliseconds to remit the damage caused by the plasma fracture. The inflation valve provided by the invention has another obvious advantage that the inflation valve can work close to a strong magnet field without being influenced by the magnetic field, which can play a role in remitting the fracture in terms of the use effect; and the successful research of the valve provides a solid and reliable experimental tool for fracture prevention physical research on EAST in the future.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Silicon steel sheet for transformer

InactiveCN107346703AReduce vibrationNot subject to wear and tearTransformers/inductances magnetic coresMetallurgyTransformer

The invention discloses a silicon steel sheet for a transformer, comprising a plurality of superimposed silicon steel sheet bodies and fixing bolts, and is characterized in that: the silicon steel sheet body is provided with a positioning groove and a plurality of fixing through holes, and the positioning groove There is a strip-shaped shock-absorbing pad, a ring-shaped shock pad is arranged on the side wall of the fixing through hole, and the fixing bolts connect the silicon steel sheet bodies together through the corresponding fixing through-holes. The invention has novel structure, shock absorption design, good anti-break effect and strong practicability.

Owner:JIANGYIN HENGTONG ELECTRICAL EQUIP CO LTD

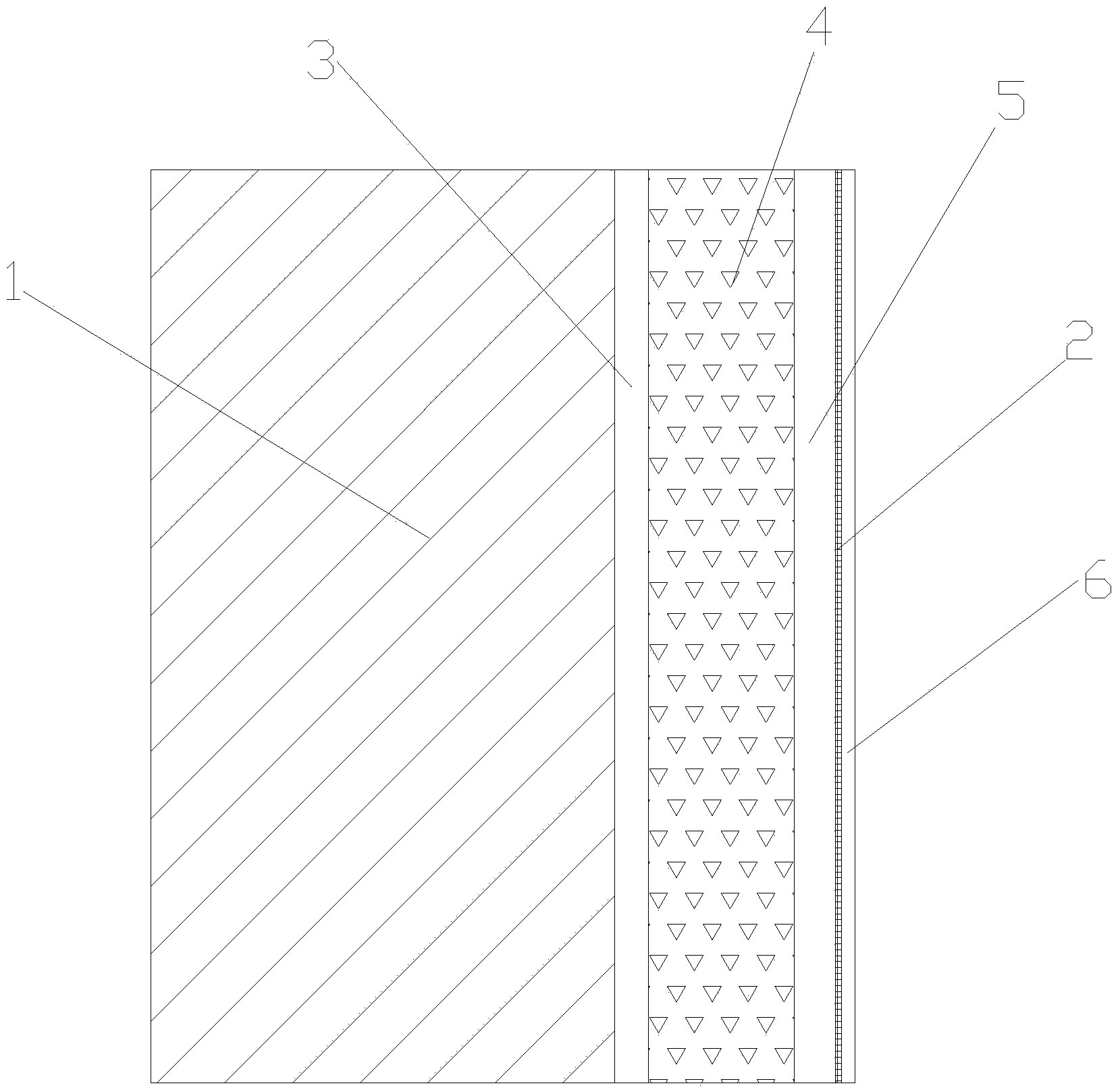

Fracture prevention and heat preservation wall structure

InactiveCN103669643AImprove crack resistanceImprove adhesionWallsHeat proofingFracture preventionMaterials science

The invention discloses a fracture prevention and heat preservation wall structure. The fracture prevention and heat preservation wall structure comprises a base wall and further comprises gridding cloth, an interface mortar layer, a heat preservation mortar layer and a fracture prevention mortar layer are arranged between one face of the gridding cloth and the base wall in sequence, and the other face of the gridding cloth is provided with an inorganic outer wall coating. Due to the fact that the interface mortar layer, the heat preservation mortar layer and the fracture prevention mortar layer are arranged between the base wall and the gridding cloth in sequence, and the other face of the gridding cloth is provided with the inorganic outer wall coating, the fracture prevention capability of the overall wall is greatly improved, and the wall structure has the effects that the fracture is prevented, adhering is firm, the structure is durable, the temperature is preserved, and energy is saved.

Owner:苏州天顺建筑科技有限公司

An anti-fracture device for drilling holes in building materials

InactiveCN105382304BAvoid vertical movementNot easy to damageMetal working apparatusDrill jigsMetal stripsArchitectural engineering

The invention discloses a drilled building material fracture prevention device which comprises an upper fixing plate and a lower fixing plate that are parallel to each other, wherein the two ends of the upper fixing plate are connected with the two ends of the lower fixing plate through support plates; two elastic metal strips are respectively arranged on the sides of the end faces, which are opposite to each other, of the support plates; the middles of the elastic metal strips are arched towards the sides far away from the support plates respectively; strip-shaped holes are respectively formed in the two ends of the elastic metal strips; threaded holes corresponding to the strip-shaped holes in position are formed in the support plates; and fixing bolts are arranged in the threaded holes. With the adoption of the elastic metal strips and the two fixing plates to fix a to-be-drilled building material from the upper side and the lower side, the fixing of the to-be-drilled building material is realized, and an acting force received by the to-be-drilled building material is buffered in the vertical direction through a rubber gasket layer, so that the building material can be prevented from fracturing and being damaged in a drilling process, and the drilling quality is improved.

Owner:CHONGQING HECHUAN YANJING CONSTR ENG CO LTD

Multifunctional paper yarn wall paper compounding machine

InactiveCN102381001BImprove flexural tensile strengthQuality improvementLamination ancillary operationsLaminationThermal engineeringYarn

The invention relates to a multifunctional paper yarn wall paper compounding machine, which belongs to paper and yarn compounding machinery and comprises a magnetic powder brake, a constant tension uncoiling device, a paper coil, a gluing device, a support frame body, a yarn coil, a constant tension multi-layer yarn uncoiling device, a steel buckle, an optical yarn fracture prevention sensor, an expansion roller, a temperature sensor, a front braking tube device, an air cylinder, a steel roller, a back baking tube device, a cooling device, a traction device, a counter, a constant tension center coiling device, a magnetic powder clutch, a servo motor, a combined gearbox, a stepless speed changer, a deflection correcting roller, a clutch gearbox, a net belt, a main silicon gel roller and a computer control cabinet, wherein the multifunctional paper yarn wall paper compounding machine is designed by adopting and combining a computer closed loop technology and mechanical and thermal engineering principles. The machine has the advantages that the automation degree is high, the production efficiency is high, the production cost is reduced, the operation is safe and convenient, the produced paper and yarn compounding material is a novel environment-protection compounding material, the quality is good, the energy is saved, the environment is protected, the folding resistance and tensioning resistance intensity is high, the colors are rich, the use is convenient, and the pasting is firm.

Owner:JIANGSU KUNTAI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com