An anti-fracture device for drilling holes in building materials

A technology of anti-fracture and building materials, applied in drilling dies, metal processing, metal processing equipment and other directions for workpieces, it can solve the problems of cracks in drilling parts, affecting the quality of drilling holes, fractures in drilling parts, etc., and achieves multi-deformation space. , not easy to damage or break, not easy to shift the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

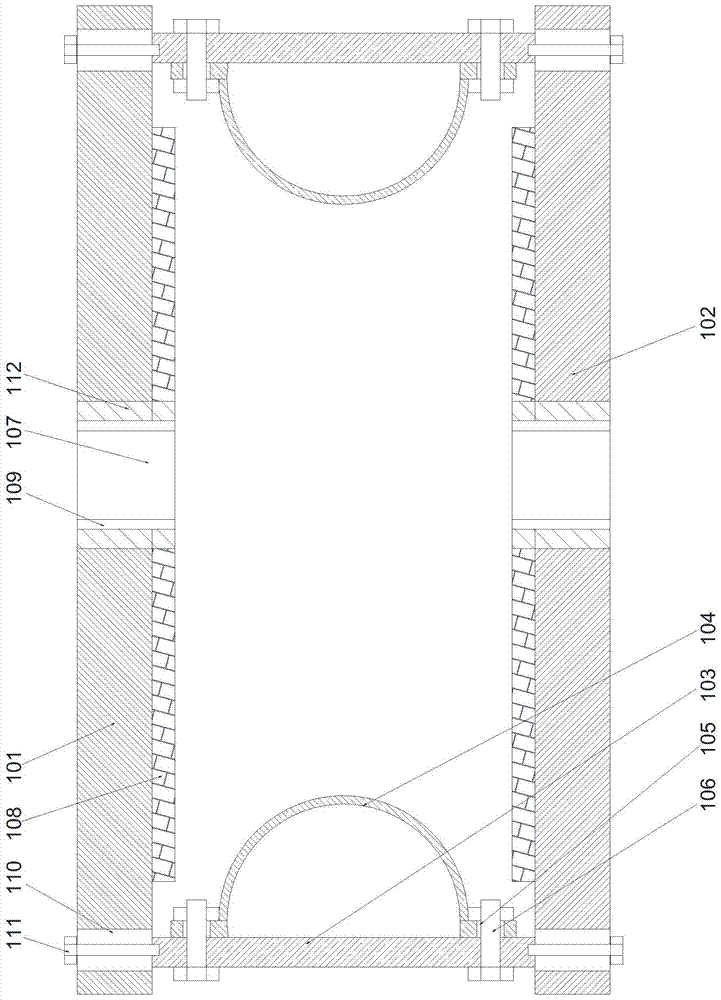

[0020] Such as figure 1 As shown, a building material drilling anti-fracture device includes an upper fixing plate 101 and a lower fixing plate 102 arranged parallel to each other, and the two ends of the upper fixing plate 101 and the lower fixing plate 102 are connected by a supporting plate 103 Elastic metal strips 104 are respectively arranged on the opposite end faces of the two support plates 103, and the middle parts of the elastic metal strips 104 are respectively arched toward the side away from the support plates 103, and the elastic metal strips 104 are Strip holes 105 are respectively provided at both ends of the strip 104, threaded holes corresponding to the positions of the strip holes 105 are provided on the support plate 103, and fixing bolts 106 are arranged in the threaded holes. The fixing bolts 106 pass through the threaded holes and the strip holes 105 in turn, and nuts are arranged at the end of the fixing bolts 106 away from the support plate 103, and on...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to avoid damage to the through hole due to mutual friction between the drill bit and the inner wall of the through hole during the drilling process, in this embodiment, preferably, on the inner wall of the through hole 107, A wear-resistant sleeve 112 is sleeved, and the wear-resistant sleeve 112 is a hollow cylindrical structure, and the wear-resistant sleeve 112 is made of stainless steel.

[0025] In order to facilitate the timely removal of powder and debris generated during the drilling process, in this embodiment, preferably, at least one through groove 109 is provided on the inner wall of the wear-resistant sleeve 112, and the through groove 109 The length direction is parallel to the axial direction of the wear-resistant sleeve 112 . By setting the through-groove structure, during the drilling process, the debris generated by the building materials can be discharged along the through-hole, which is helpf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com