Processing method of pre-stressed concrete reinforced pile

A technology of concrete reinforcement and processing methods, which is applied in the direction of sheet pile walls, manufacturing tools, and infrastructure engineering, etc., can solve the problems of shortening the service life of reinforced piles, cracks, etc., and achieve the effects of improving shear resistance, increasing strength, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

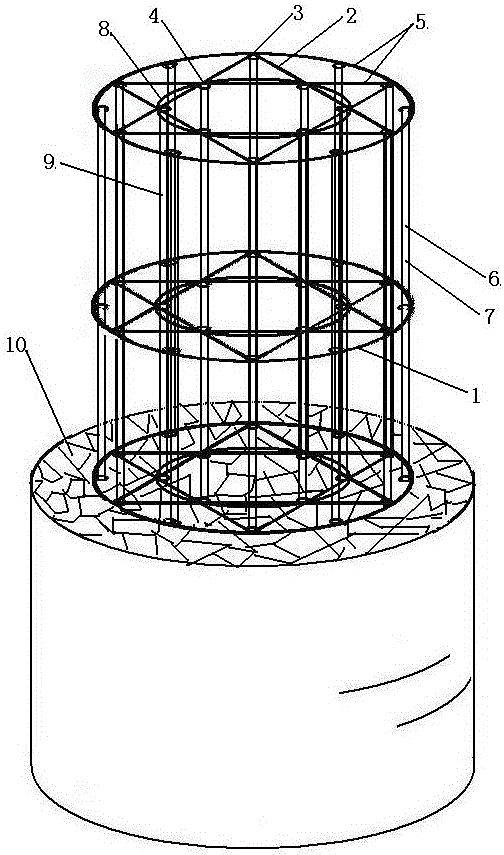

[0024] Prepare a prestressed high-strength concrete reinforcement cage, which is manufactured according to the following steps.

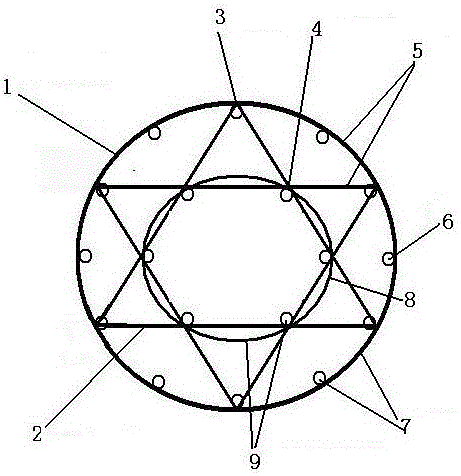

[0025] First prepare the reinforcement cage of the overall structure, that is, first make the outer ring stirrup 1 according to the set specifications, and install two reversely staggered regular triangle frames 2 in the outer ring stirrup 1; then connect the outer ring stirrup 1 and the regular triangle The top contact 3 of the frame 2 and the intersection point 4 of the side and the side of the equilateral triangle frame 2 are welded or bound, and the binding steel wire is reserved to make a high-strength stirrup 5; then a plurality of high-strength stirrups 5 are taken, and Bind the main reinforcement 6 on the reserved binding steel wire until each reserved binding steel wire is bound; layer reinforcement cage 7; then the inner ring stirrup 8 is installed on the main reinforcement 6 bound on the intersecting point 4 inside the outer layer reinfor...

Embodiment 2

[0030] Preparation of steel rods for prestressed concrete.

[0031] The weight percentage of the chemical composition used is: carbon 0.38%, silicon 0.45%, manganese 0.72%, chromium 0.75%, molybdenum 0.32%, tungsten 0.45%, copper 0.15%, phosphorus 0.015%, sulfur 0.013%, lanthanide rare earth 0.12% , Residual elements 0-0.05%, the balance is iron; the mass percentage of lanthanide rare earth components is lanthanum 17%, cerium 23.5%, praseodymium 24.5%, neodymium 18%, dysprosium 13.5%, and the remaining lanthanide elements 3.5%.

[0032] Its preparation method is.

[0033] ① Smelt and roll into steel rods in steel mills according to weight percentage.

[0034] ② Send the rolled steel bar into the induction heating furnace to heat to 976°C, and keep the heating temperature for 5 minutes.

[0035] ③The steel bar after induction heating is directly quenched with quenching liquid, the quenching cooling rate is controlled at 209°C / s, and the quenching cooling time is 17s, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com